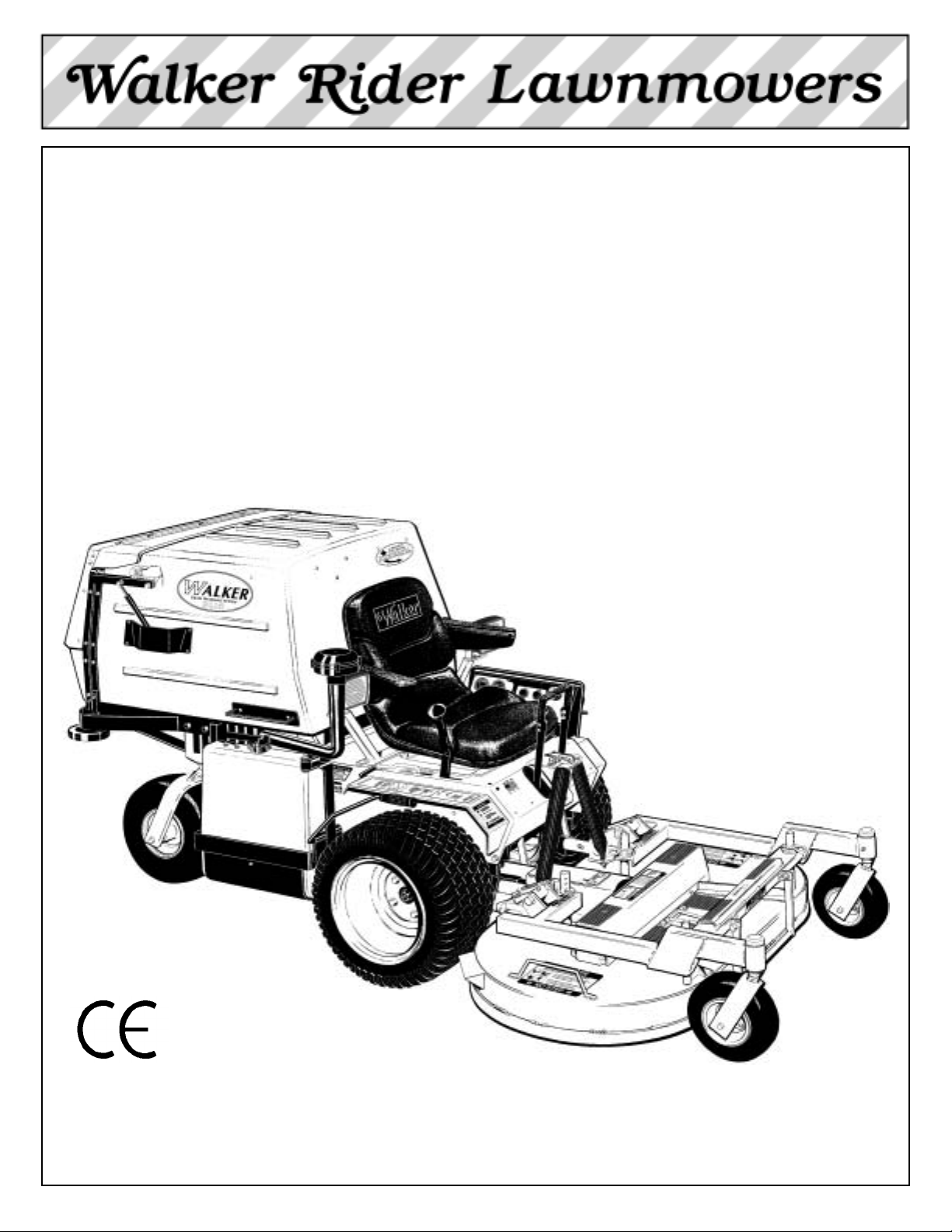

Page 1

OWNER’S MANUAL

Safety, Assembly, Operating, and Maintenance Instructions

Model MDD (20.9 HP Diesel)

™

Please Read and Save These Instructions Effective Date: 02-15-05

For Safety, Read All Safety and Operation P/N 7000-8

Instructions Prior to Operating Machine

Page 2

Foreword

Thank you. . .for purchasing a Walker mower. Every effort has been made to provide you with the

most reliable mower on the market, and we are sure you will be among our many satisfied customers. If for any reason this product does not perform to your expectations, please contact us at (970)

221-5614. Every customer is important to us. Your satisfaction is our goal.

Please. . .rea d this manual thoroughl y! This manual is to be used in conjuncti on with the engine

manufacturer’s manual for the specific engine on the mower model you have purchased. Before you

operate your new mower, please read this entire manual. Some of the information is crucial for proper operation and maintenance of this mower - it will help protect your investment and ensure that the

mower performs to your satisfaction. Some of the information is important to your safety and must

be read and understood to help prevent possible injury to the operator or others. If anything in this

manual is confusing or hard to understand, please call our service department, at (970) 221-5614,

for clarification before operating or servicing this mower.

This manual covers Model MDD with the Kubota D722 20.9 HP diesel engine (liquid cooled).

All shields and guards must be in place for the proper and safe operation of this machine.

Where they are shown removed in this manual, it is for illustration purposes only. Do not operate

this machine unless all shields and guards are in place.

Specifications given are based on the latest in format ion available at the time this m anu al wa s produced.

Walker Mfg. Co. is continually s tr iv ing to improve the desi gn and per for ma nc e of its products. We

reserve the righ t to m ake c hanges i n sp ecifi catio ns and de sign wi thout th ereby incu rring any obligation relative to previously manufactured products.

Sincerely,

WALKER MANUFACTURING COMPANY

Bob Walker, President

Page 3

Table of Contents

General Information________________ 1

HIGHLIGHTED INFORMATION _____________ 1

GLOSSARY ____________________________ 1

IDENTIFYING NUMBER LOCATIONS________ 1

ENGINE SERIAL NUMBER LOCATION ______ 2

SERVICING OF ENGINE AND

DRIVETRAIN COMPONENTS ______________ 2

Specifications________________________ 3

ENGINE________________________________ 3

ELECTRICAL SYSTEM ___________________ 3

TRANSMISSION_________________________ 3

BLADE DRIVE __________________________ 4

TIRE SIZE______________________________ 4

TIRE PRESSURE ________________________ 4

DIMENSIONS (Tractor and Mower) _________ 5

MOWER DECK__________________________ 5

CURB WEIGHT (Approximate) _____________ 5

DRIVE BELTS___________________________ 6

GHS SYSTEM (Optional)__________________ 6

SEAT__________________________________ 6

FRAME/BODY CONSTRUCTION ___________ 6

Component Identification___________ 7 Safety Instructions _________________ 11

BEFORE OPERATING___________________ 11

OPERATING___________________________ 12

MAINTENANCE ________________________ 14

SAFETY, CONTROL, AND

INSTRUCTION DECALS _________________ 15

Assembly Instructions _____________ 17

SETUP INSTRUCTIONS _________________ 17

Tire Installation (Tractor)_______________ 17

Battery Service_______________________ 17

Wet Battery Service __________________ 17

Dry Battery Service __________________ 17

Battery Charging ____________________ 18

Battery Installation ___________________ 18

Mower Deck Assembly ________________ 18

Deck Caster Wheels Installation ________ 18

Deck Discharge Chute Installation ______ 19

Deck Discharge Shield Installation ______ 19

PTO Shaft Guard Installation __________ 19

Tilt-Up Roller Wheel Installation ________ 19

Mower Deck Installation on Tractor ______ 20

Deck Installation ____________________ 20

Deck Leveling ______________________ 22

PREOPERATING CHECKLIST ____________ 23

Operating Instructions_____________ 25

CONTROL IDENTIFICATION,

LOCATION, AND FUNCTION _____________ 25

Operating Controls ___________________ 25

Engine Throttle ______________________ 25

Forward Speed Control (FSC) __________ 26

Steering Levers ______________________ 26

Blade Clutch (PTO) ___________________ 26

Parking Brake _______________________ 26

Front Body Latch Release _____________ 26

Transmission Lockout Levers __________ 27

Cold Start Lever

(Jackshaft Drive Belt Release) _________ 27

Instrument Panel _____________________ 29

Voltmeter ___________________________ 30

Water Temperature Gauge _____________ 30

Oil Pressure Warning Light ____________ 30

Water Temperature Warning Light_______ 30

Ignition Switch_______________________ 30

Light Switch (For Optional Lights)_______ 31

Hourmeter __________________________ 31

Circuit Breakers______________________ 31

Warning Horn________________________ 31

STARTING THE ENGINE_________________ 31

ADJUSTING GROUND

SPEED AND STEERING _________________ 33

ENGAGING THE MOWER________________ 34

STOPPING THE MACHINE _______________ 35

ADJUSTING CUTTING HEIGHT ___________ 35

TRANSMISSION LOCKOUT ______________ 36

RECOMMENDATIONS FOR MOWING ______ 37

RECOMMENDATIONS FOR TILT-UP DECK

OPERATION/TRANSPORT_______________ 38

GRASS HANDLING SYSTEM (GHS) _______ 39

General Information __________________ 40

Clogging Checklist ___________________ 41

Using the Tilt-Up Deck ________________ 42

Using the GHS Catcher________________ 42

Powerfil

“Full” Signal Horn ___________________ 42

Cleaning the GHS Exhaust Screen ______ 42

Dumping the Catcher _________________ 43

Tailgate Dumping ___________________ 43

Using the Dump Bag _________________ 43

Power Dump Option _________________ 44

®

_________________________ 42

Page 4

Table of Contents

Maintenance Instructions__________ 46

MAINTENANCE SCHEDULE CHART _______ 46

IMPORTANT TIPS FOR CARE

OF THE KUBOTA ENGINE _______________ 47

Fuel System _________________________ 47

Starting/Stopping_____________________ 47

Cooling System ______________________ 47

Air Cleaner System ___________________ 47

Oil _________________________________ 47

LUBRICATION _________________________ 48

Engine Oil ___________________________ 48

Engine Break-In Oil __________________ 48

Checking Engine Crankcase Oil Level ___ 48

Changing Engine Crankcase Oil/Oil Filter _48

Grease Fitting and Oil Point Lubrication__ 49

Mower Deck Gearbox Lubrication _______ 52

DSD52 or DSD62

Mower Deck Lubrication _______________ 52

Tractor PTO Gearbox Lubrication _______ 53

Checking Gearbox Oil Level ___________ 53

Changing Gearbox Oil ________________ 53

Gear Axle Lubrication _________________ 53

Hydrostatic Transmission Fluid_________ 54

Checking Hydrostatic

Transmission Fluid Level ______________ 54

CLEANING ____________________________ 55

Engine Air Cleaner System_____________ 55

Turbine Precleaner __________________ 55

Donaldson Radialseal™ Air Cleaner _____ 56

Engine Cooling System________________ 57

Radiator Screen and Cooling Fins ______ 57

Flushing Radiator and Changing Coolant _58

Grass Buildup in Mower Housing________ 58

GHS Blower _________________________ 59

GHS Exhaust Screen__________________ 59

Hydrostatic Transmission Cooling Fins __ 59

CHECKING/SERVICING _________________ 60

Engine Cooling System________________ 60

Coolant Level ______________________ 60

Fan Belt Tension ____________________ 60

Security of Air Filtration Components____ 61

Battery______________________________ 61

Electrolyte Level ____________________ 61

Cleaning the Terminals _______________ 61

Chargin g the Battery _________________ 61

Tire Pressure ________________________ 61

Sharpen Mower Blades ________________ 62

Drive Belts __________________________ 63

Mower Deck Gearbox Oil Seals _________ 63

Fuel Lines and Clamps ________________ 63

Radiator Hoses and Clamps ____________ 63

Blade Brake Action ___________________ 63

REPLACING/REPAIRING ________________ 64

Drive Belts __________________________ 64

Engine PTO Drive Belt _______________ 65

Jackshaft Drive Belt _________________ 66

GHS Blower Drive Belt _______________ 67

Hydrostatic Ground Drive Belt _________ 68

Engine Fan Belt ____________________ 69

Fuel Filter ___________________________ 70

Blade Overload Shear Bolts ____________ 70

PTO Shear Pin _______________________ 71

Mower Blades _______________________ 71

ADJUSTMENTS________________________ 72

Steering Levers ______________________ 72

Tilt-Up Deck Adjustable Stop ___________ 72

GHS Signal Horn Adjustment

(When Horn Sounds at Wrong Time)_____ 72

Maintenance And Service Record Sheet

_______________________ 74

Warranty___________________________ 75

Page 5

General Information

HIGHLIGHTED INFORMATION

Walker Manufacturing recommends that any service requiring special training or tools be performed

by an authorized Walker Mower Dealer. There are

several general practices to be aware of in the area

of safety. Most accidents associated with the operation or maintenance of a Walker Mower are

caused by disregardi ng bas ic saf ety pr ecau tions or

specific warnings. Such accidents, in most cases,

can be prevented by being aware of the dangers

present.

Information of special importance has been highlighted in bold type in this man ual. Refer to Safety

Instructions for the mean ing s of DANGE R, WARNING, CAUTION, IMPORTANT, and NOTE.

GLOSSARY

There are many ter ms th at are either unique to this

equipment or that ar e used as acronyms . The following terms and their definitions will help while

using this manual:

• DECK is the mowing attachment mounted on

the front of the tractor which includes the carrier

frame, deck housing, blade drive gearboxes,

and cutter blades.

• FORW ARD SPEED CONTROL (FSC) cont r ol s

the maximum forward speed of the tractor;

functioning as a cruise control.

• GRASS HANDLING SYSTEM (GHS

mowed material and deposits it in the catcher.

) collects

• POWER TAKE-OFF (PTO) transmits engine

power to run the cutter blades and GHS blower.

• POWERFIL

throughout the interior of the gr ass catcher by

an oscillating delivery spo ut.

spreads the mowed material

• RIGHT HAND (RH) refers to the right-hand side

of the tractor when the operator is seated facing

forward in the tractor seat.

• SIDE DISCHARGE (SD) mows but does not

collect the mowed material.

• STEERING LEVERS steer the tractor by con-

trolling the dual hydrostatic transmissions.

• TRACTOR is the prime mo ver, including t he en-

gine, drive train, operator seat, and contr ols to

operate the mower.

• TRANSMISSION LOCKOUT releases the hy-

drostatic transmissions to permit freewheeling

the tractor.

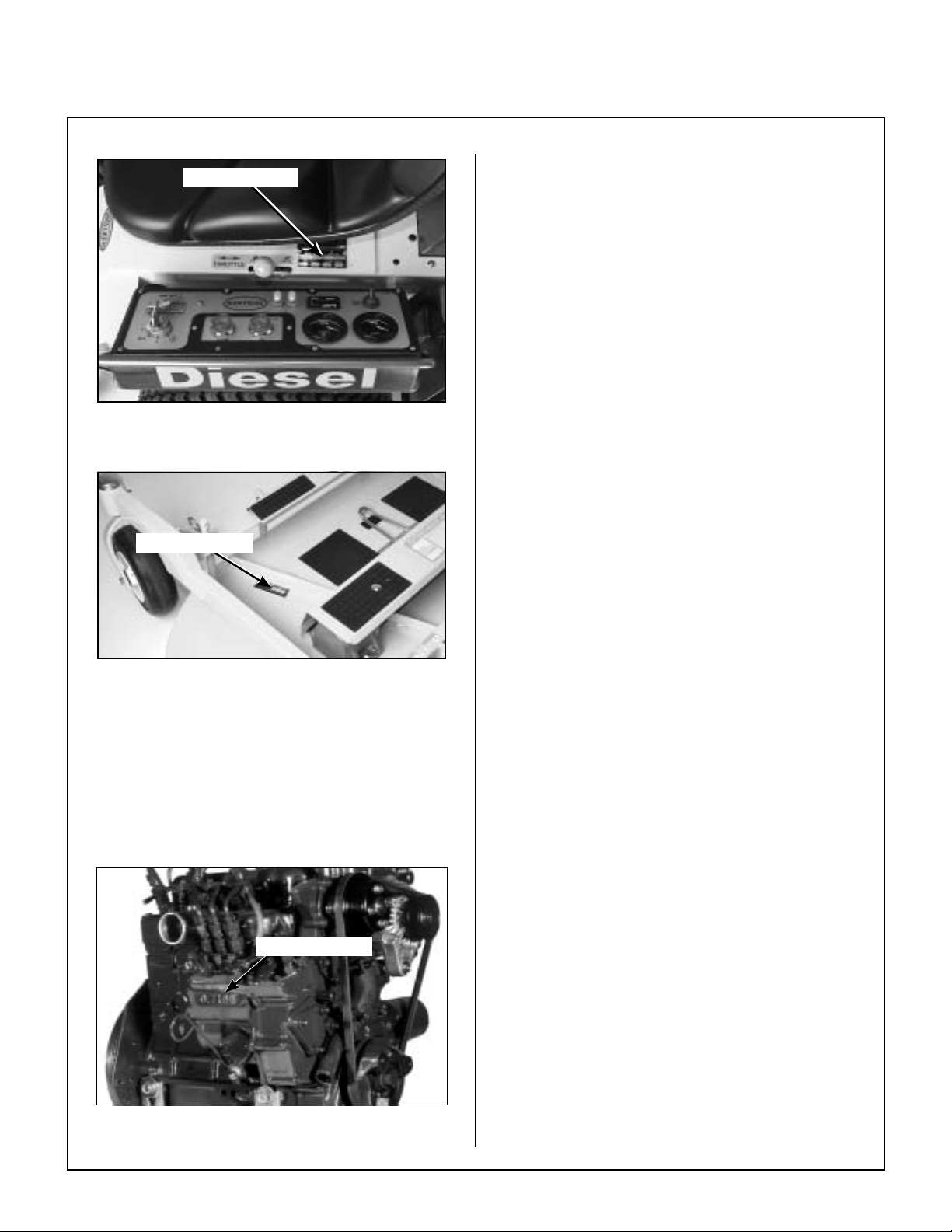

IDENTIFYING NUMBER LOCATIONS

The tractor serial number plate is affixed to the tractor body just below the left rear corner of the seat.

The mower deck serial number plate is affixed

alongside the angle iron framing on the LH side of

the LH mower blade d rive. Model and serial numbers are helpful when obtaining repl acement parts

and maintenance assistance. For ready refer ence,

please record these numbers in the space provided.

• GRASS-PAK

grass delivery s pout (in the catcher) and act ivates the “full” signal horn when the grass

catcher is full.

SWITCH is mounted on the

• GROUND DRIVE refers to the dual h yd rostatic

transmissions which drive the main wheels.

• HYDROSTATIC TRANSMISSION transmits

and controls power from the ground drive belt to

the main drive wheel.

• LEFT HAND (LH) refers to the left-hand side of

the tractor when the opera tor is seated facing

forward in the tractor seat.

Tractor Model No. _______________________

Tractor Serial No. _______________________

Deck Serial No. _______________________

Engine Model No. _______________________

Engine Serial No. _______________________

Date of Purchase _______________________

Fill In By Purchaser

1

Page 6

General Information

Serial Number

Tractor Serial Number Location

Serial Number

SERVICING OF ENGINE AND DRIVETRAIN COMPONENTS

The detailed servicing and repair of the engine,

hydrostatic transmission, and gearboxes are not

covered in this m anual. Only ro utine maintenanc e

and general service i nstructions are p rovided. For

the service of these compo nents during the limited

warranty period, it is important to find a local,

authorized servicing agent of the component manufacturer. Any unauthorized work done on these

components during the wa rranty period may void

the warranty. If you ha ve any difficulty finding an

authorized outlet or obtaining warranty service,

please contact our Service Department for assistance:

Walker Manufacturing Company

5925 E. Harmony Road

Fort Collins, CO 80528

1-970-221-5614

Service manuals are available for each of these

components from their respective manufacturers as

follows:

Mower Deck Serial Number Location

ENGINE SERIAL NUMBER LOCATION

Refer to the engine manu al that accompanies this

manual for the location of the engine serial number.

For the mower model covered by this manual, an engine manual is ava ilable cov ering the Ku bota D722

diesel engine (liquid cooled).

Serial Number

Kubota Engines Kubota Tractor Corp.

1300 Remington Road

Schaumburg, IL 60173

Hydrostatic Eaton Corporation

Transmissions 15151 Highway 5

Eden Prairie, MN 55344

Gearboxes (Deck) Tecumseh Products Co.

900 North Street

Grafton, Wl 53024

Engine Serial Number Location

2

Page 7

Specifications

MODEL

ENGINE

Manufacturer/Model Kubota D722, 3 Cyl., Diesel (Liquid Cooled)

Displacement 44.0 cu. in. (722 cc)

HP (@ 3600 RPM) 20.9

Max. RPM (No Load) 3800

Governed RPM 3600

Max. Torque [ft-lb (N·m) @ RPM] 34 (46.1) @ 2600

Idle RPM 1000

Spark Plug Type N/A

Spark Plug Gap N/A

Crankcase Capacity 3.1 qts (2.9 liters)

Crankcase Lubricant API CC/CD/CE Grade Oil Only with 10W-30 Viscosity or 30W

Fuel Tank Capacity 5 Gallons (19 liters)

Fuel Diesel Fuel 2-D

Cooling System Capacity

(Approx.)

Cooling Fan Electric radiator cooling fan with reversible self-cleaning action

Coolant 50/50 Pre-Mix Antifreeze/Water

MDD

± 50

above 77° F (25° C) Only

1.25 Gallon (4.74 liters)

ELECTRICAL SYSTEM

Battery 12 Volt, 41AH, 340 CCA

(Interstate U1-SP40)

Charging System Automotive Type Alternator

Charging Output 12.5 Amp DC (Regulated)

System Polarity Negative Ground

Ignition Diesel with Glow Plugs

Starter 12 Volt Electric Ring-Gear Type, Solenoid Shift

Interlock Switch Ignition Lockout by Seat Switch, Transmission Neutral and Blade

Clutch

Circuit Breaker Manual Reset (40A)

TRANSMISSION

Manufacturer/Model Dual Hydrostatic, Eaton Model 7, Each Wheel Independently

Driven

Steering Hand Lever Control / Individual Wheel

Forward Speed Control Precision Friction Lock Lever, Cruise Control, with Neutral-Park

Position

3

Page 8

Specifications

MODEL

TRANSMISSION (continued)

Service Brake Dynamic Braking through Hydrostatic Transmission

Parking Brake Mechanical Pin Lock in Transmission Gear

Neutral Transmission Release by Manual Dump Valve

Final Drive Gear Drive Axle

Transmission Fluid

Factory Service Mobil 1 Synthetic Motor Oil (15W50)

Alternate Transmission Fluid SAE 30W Straight Viscosity Motor Oil

Transmission Fluid Capacity 1 qt (1 liter)

Transmission Cooling Cooling Fan Mounted on Drive Pulley

Ground Travel Speed

Forward m.p.h. (km/h)

Reverse m.p.h. (km/h)

BLADE DRIVE

PTO Shaft Quick Disconnect Spline Shaft with Two High-Speed

Blade Spindle Each Blade (2) Mounts Direct on Peerless Right Angle Gearbox

Blade Drive Clutch and Brake Manual Belt Tightener Clutch and Band Brake (Stops Blades

Max. Blade Speed

[25 in. (64 cm) Blade]

@ 3600 RPM Engine

MDD

0-5 (0-8) Infinitely Variable

0-5 (0-8) Infinitely Variable

U-Joints

with Tee Gearbox in Center Connected to PTO Shaft (Complete

Geared Drive, Peerless Model 1000 Gearboxe s)

within Five (5) Seconds of Disengagement)

2900 RPM [16700 FPM (5090 m/min)]

TIRE SIZE

Deck Caster Wheel 2.80/2.50-4 Pneumatic (4-Ply)

Deck Caster Wheel (Optional) 8.25 x 2.75 Semi-Pneumatic

Drive 18 x 9.50-8 (4-Ply)

Rear (Dual) 13 x 5.00-6 (4-Ply)

TIRE PRESSURE

Deck Caster Wheel 20 PSI (137 kPa)

Drive 15 PSI (103 kPa)

Rear 20 PSI (137 kPa)

4

Page 9

Specifications

MODEL

DIMENSIONS (Tractor and Mower)*

Length 91 in. (231 cm)

Width 49 in. (124 cm)

Height 44 in. (112 cm)

Wheel Base (Tractor) 42-1/4 in. (107 cm)

Tread Width (Tractor) 29-3/4 in. (76 cm)

MOWER DECK

Width of Cut SD/GHS 42 or 48 in. (107 or 122 cm)

Cutting Height 1 to 4 in. (3 to 10 cm)

Height Adjustment 7 Positions - 1/2 in. (1 cm) Increment Hitch Pins Installed in

Blade Size (Typical)

42 in. (107 cm) SD 22 in. (56 cm)

48 in. (122 cm) GHS 25 in. (64 cm)

Deck Suspension Torsion-Flex Frame with Caster Wheels and Counterweight

MDD

Multi-Position Deck Support

2 in. (5 cm) Center Overlap

(Two Blades, CW Rotation)

2 in. (5 cm) Center Overlap

(Two Blades, Counter Rotate)

Springs

CURB WEIGHT (Approximate)

SD Tractor Only 760 lb (345 kg)

GHS Tractor Only 850 lb (386 kg)

Tractor and Mower* 1020 lb (463 kg)

*Dimensions and weight shown are for 48 in. (122 cm) GHS Model (typical).

Dimensions for Tractor and Mower with 42 in. (107 cm) deck are:

Length = 88 in. (224 cm)

Width = 43 in. (110 cm)

For SD Models, subtract 7 in. (18 cm) from the height.

Deck weight for 48 in. (122 cm) Tilt-Up deck = 205 lb (93 kg). Deck sizes range from 42 to 72 in.

(107 to 183 cm), with corresponding deck weights ranging from 170 to 400 lb (77 to 181 kg).

Optional (9.5 Bushel) Grass Catcher adds approx. 5 lb (2 kg) and 5 in. (13 cm) in Height

5

Page 10

Specifications

MODEL

DRIVE BELTS

Engine PTO Walker P/N 7230

Jackshaft Drive Gates 3VX355 (P/N 6231)

Ground Drive Walker P/N 7248

Blower (GHS Model) Gates 3VX280 (P/N 7234-1)

GHS SYSTEM (Optional)

Blower 4 x 10 x 1/4 in. (10 x 25 x 1 cm) Three-Blade Paddle Wheel (Driven

Blower Brake Band Brake (Works in Combination with PTO Clutch, Stops Blower

Max. Blower Speed 3600 RPM

Grass Catcher Capacity 65 Gallons (246 liters)/7.0 Bushels

Optional Grass Catcher Capacity 89 Gallons (335 liters)/9.5 Bushels

Full Signal Oscillating Vane Switch Mounted on Grass Delivery Spout

Powerfil

SEAT

®

MDD

by Mower Engine)

within Five (5) Seconds of PTO Disengagement)

Triggers Horn Signal

Oscillating Delivery Spout Driven by 12 Volt Electric Gearmotor

Spreads Material throughout Interior of Catcher @ 25 Cycles/

Minute

Contour-Molded, with Nylon Backed Vinyl Cover and Integral

Foam Cushion

FRAME/BODY CONSTRUCTION

Frame All Welded Unitized Steel Chassis

Body 14 Gauge Steel

Deck 11 Gauge Steel

GHS Catcher and Chutes Molded Cross-Linked Polyethylene (UV Stabilized)

NOTE: The manufacturer reserves the right to make changes in specifications shown herein at any time

without notice or obligation.

6

Page 11

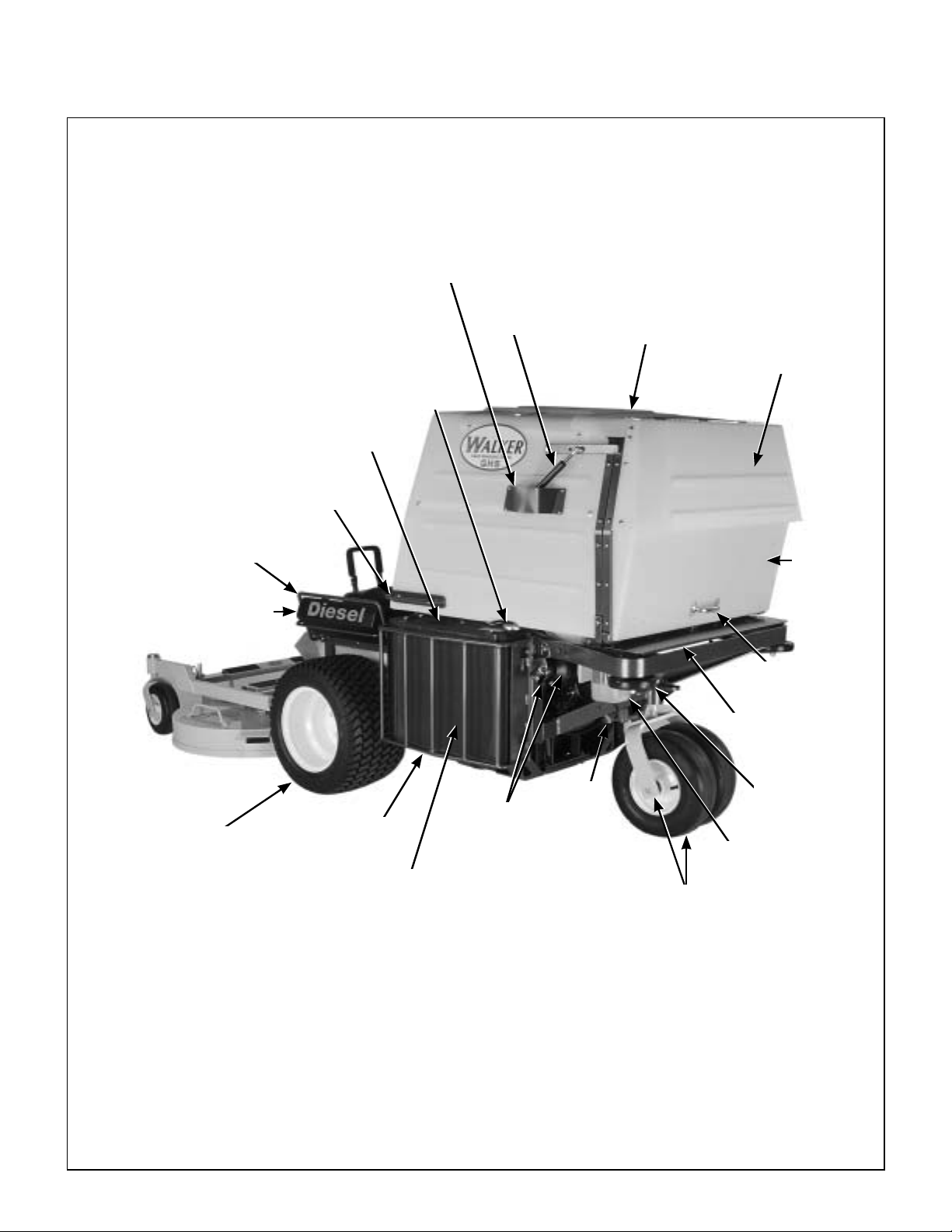

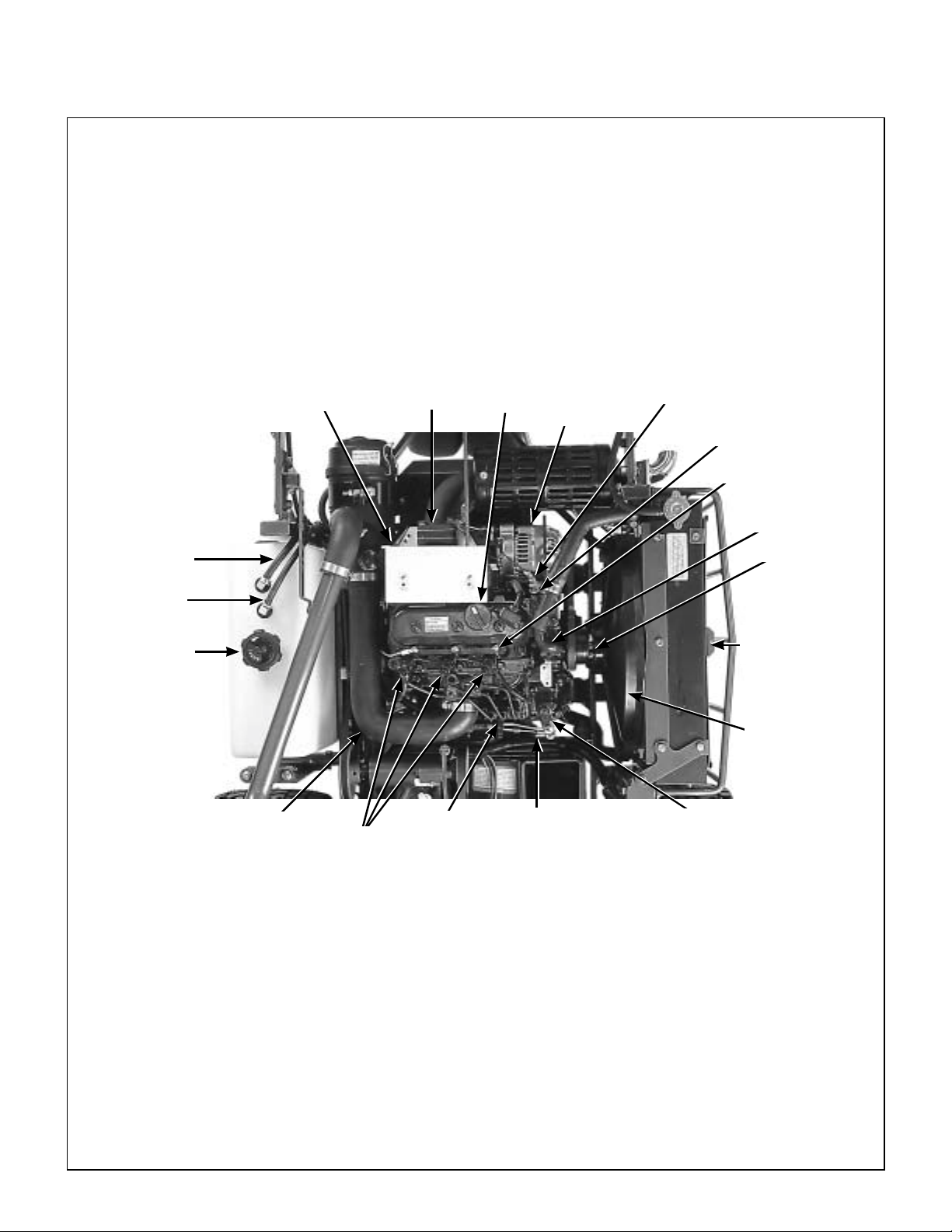

Component Identification

NOTE: Control Identification

shown in Operating

Instructions section.

Catcher Door

Safety Latch

Anti-Scuff

Roller

Catcher Lift /

Dump Handle

Fuel Tank and Cap

Turbine

Precleaner

Grass Handling System

9.5 Bushel Catcher

Tilt-Up

Latch

Spring Clip

Counterweight Spring

Counterweight Spring

and Protective Cover

and Protective Cover

Transmission Control Rod

Adjustment Nut (LH)

Deck Support Pins

and Height Adjustment

Hitch Pins

Tilt-Up

Deck Handle

Tran smission Control Rod

Adjustment Nut (RH)

Deck Support Arms

(Cutting Height Adjustment)

Deck Lift Handle

Front View and Right Side View

Footrests

Til t -U p H o ok

Deck Caster Wheels

7

Page 12

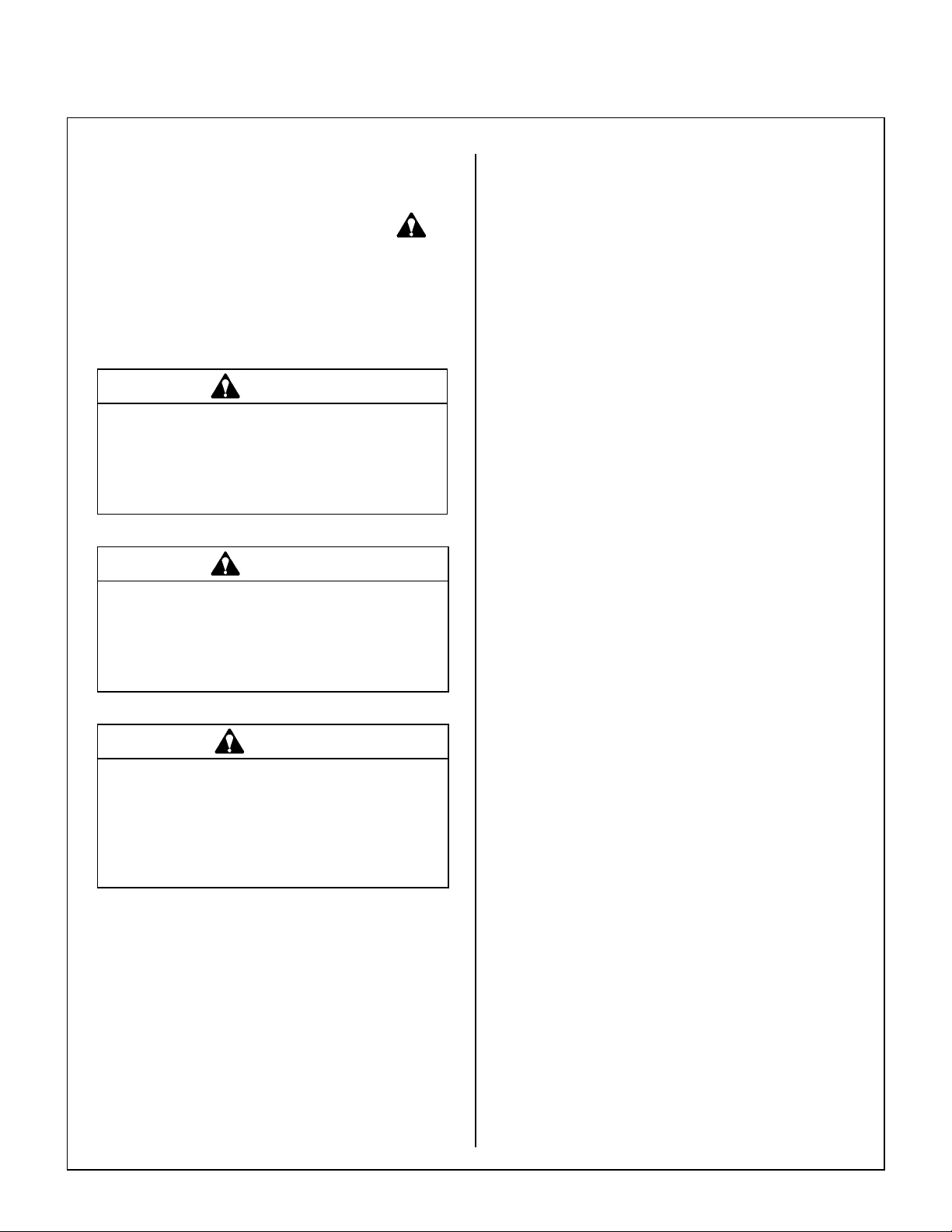

Component Identification

Spring Protective Cover

Catcher Door Gas

Catcher Lift /

Dump Handle

Instrument Panel

Guard

Instrument Panel Box

(Shock Mounted)

Radiator Cap

Radiator

Catcher Door

Gas Spring

Removable Grass

Catcher Screen

(Not Visible)

Catcher Exhaust

Deflector

Catcher

Door

Catcher

Door Handle

Dump Plate

Fuel

Left Hand

Drive Wheel

8

Radiator

Guard

Radiator

Screen

Rear View and Left Side View

Muffler and

Tailpipe

Filter

Recovery Tank

Tailwheel Fork

and Wheel

Anti-Scuff

Roller

Coolant

Page 13

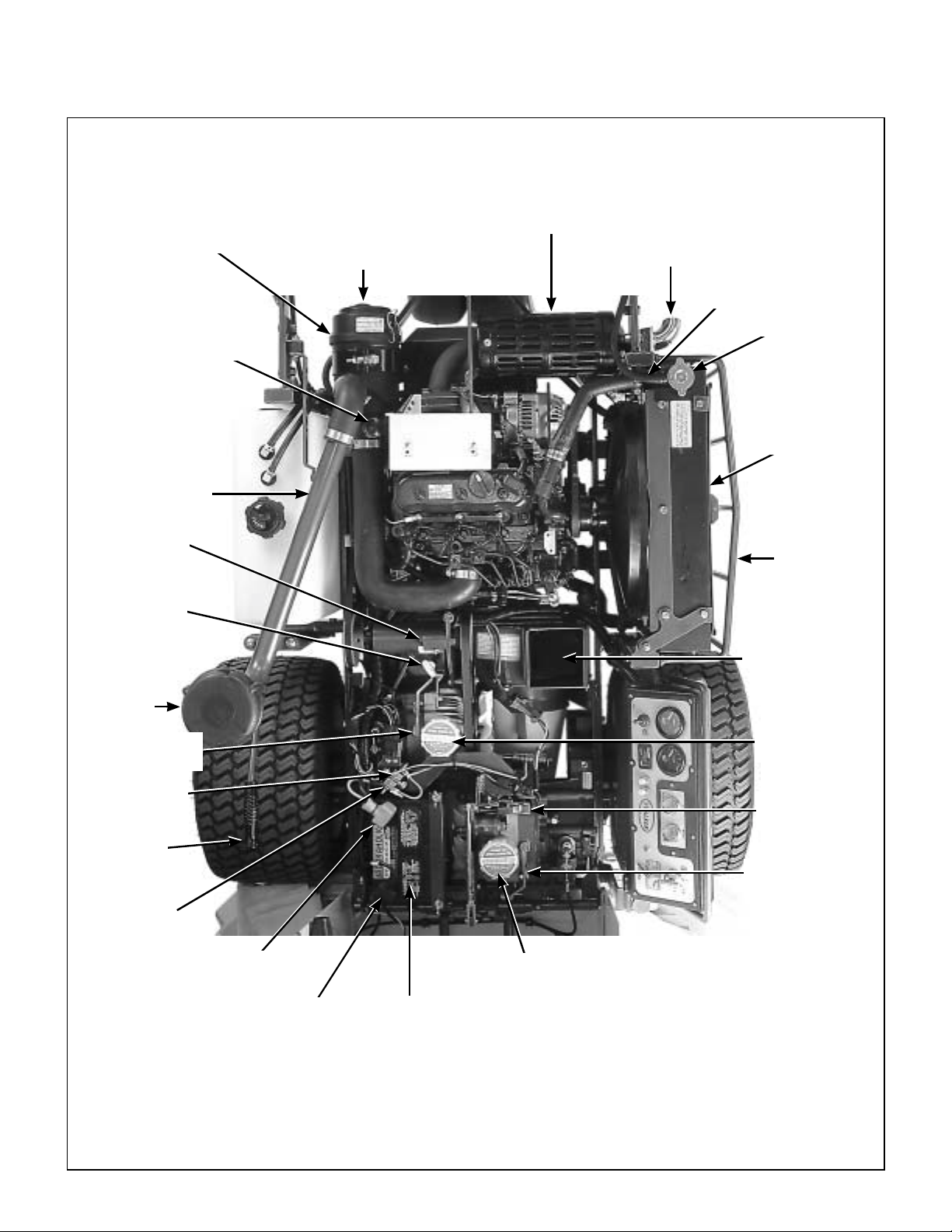

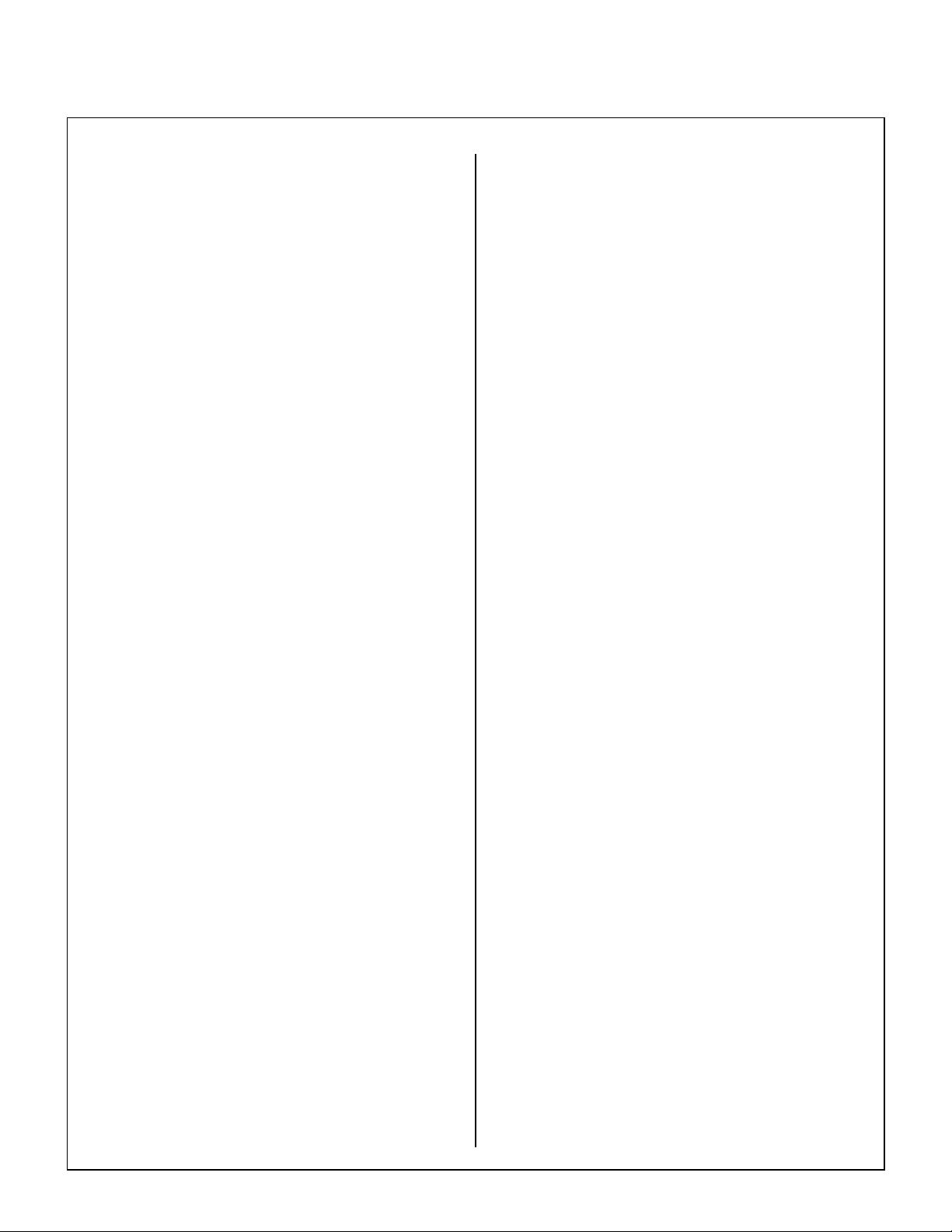

Component Identification

Donaldson

Air Cleaner

Air Restriction Indicator

Precleaner Tube

Jackshaft

PTO Gearbox

Dipstick

Air Cleaner

Cover

Muffler

Tailpipe

Overflow Hose

Radiator Cap

Radiator

Radiator

Guard

GHS Blower

Turbine

Precleaner

RH Transmission

Lockout Lever

40 Amp

Circuit Breaker

PTO

Clutch Lever

30 Amp

Circuit Breaker

Positive (+)

Battery Cable

Negative (-)

Battery Cable

RH Hydrostatic

Transmission

Neutral Safety

Switch

LH Transmission

Lockout Lever

LH Hydrostatic

Transmission

Battery

Top View (Engine Compartment)

9

Page 14

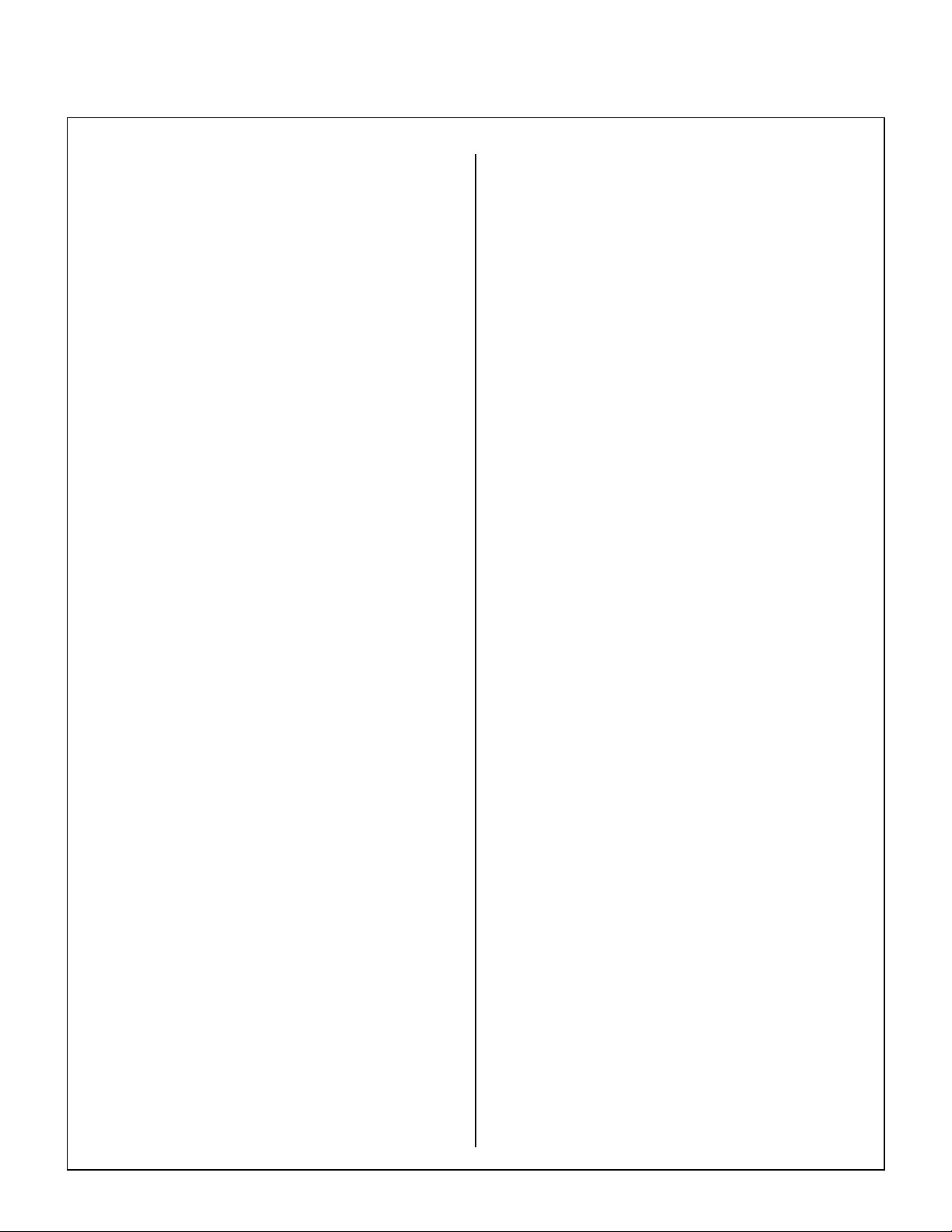

Component Identification

Fuel Pickup

Line

Fuel Return

Line

Fuel Tank

Cap

Starter Motor Below

(Not Visible)

Air Intake

Hose

Injectors

Exhaust

Manifold

Injection

Pump

Oil Fill

Cap

Alternator

Throttle Control

Linkage Lever

Water Temperature

Gauge Sender

Thermostat Housing

and Thermostat

Glow Plug(s)

Water Pump

Fan Motor

Radiator Screen

(Removable)

Radiator Fan

and Shield

Engine Stop Lever Linkage

(Fuel Shut-Off Valve)

10

Top View (Engine Compartment)

Page 15

Safety Instructions

Pay particular attentio n to any information labeled

DANGER, WARNING, CAUTION, IMPORTANT,

and NOTE in this manual.

When you see the Safety Alert Symbol ( ),

read, understand, and follow the instr uctions. Failure to comply with safety instructions may result in

personal injury.

The seriousness or degree of imp ortance of each

type of information is defined as follows:

DANGER

An IMMEDIATE hazard that WILL result in

severe personal injury or DEATH, if warning is ignored and proper safety precautions are not taken.

WARNING

A POTENTIAL hazard that COULD result in

severe personal injury or DEATH, if warning is ignored and proper safety precautions are not taken.

Walker Manufacturing cannot predict every potentially dangerous situation. Therefore, items labeled

as such in this manual do not cover all conceivable

situations. Any person using procedur es, tools, or

control techniques not recommended by Walker

Manufacturing must take full responsibility for safety.

The Walker Rider Lawnmower has been designed

with many safety features to protect the operator

from personal harm or in jury. However, it is necessary for the operator to use safe o perating procedures at all times. Failure to follow safety

instructions contained in this manual may result in personal injury or damage to equipment

or property.

If you have any questions concerning setup, operation, maintenance, or safety, please contact your

authorized Walker Mower Dealer or call Walker

Manufacturing Company at (970) 221-5614.

BEFORE OPERATING

1. Read and understand the contents of this

Owner’s Manual before starting and operating the machine. Become thoroughly familiar

with all machine controls and how to stop the

machine and disengage the controls quickly.

Replacement Owner’s Manuals are available

by sending the Model and Serial Number to:

CAUTION

Possible hazards or unsafe practices that

MAY result in MODERATE personal injury

or property damage, or machine damage, if

warning is ignored and proper sa fety precautions are not taken.

IMPORTANT: Identifies mechanical information

demanding special a ttentio n, since i t deals with th e

possibility of damaging a part or parts of the machine.

NOTE: Identifi es information worthy of special attention.

Walker Manufacturing Company

5925 East Harmony Road

Fort Collins, CO 80528

2. Never al low chi ldre n to op erate rider mower.

Do not allow adults to operate without proper

instruction.

3. Clear the area to be mowed of any fo reign

objects which may be picked up and thrown by

cutter blades. Pick up all sticks, stones, wire,

and any other debris.

4. Ke ep e very on e, es peci all y child re n an d pets, a

safe distance away from the area being mowed.

Do not mow with bystanders in the area.

5. Do not operate the machine barefoot or wearing

sandals, sneakers, tennis shoes, or similar lightweight footwear. Wear substantial protective

footwear.

11

Page 16

Safety Instructions

6. Do not wear loose fitting clothing that could get

caught in moving parts. Do not operate this

machine while wearing shorts; always wear

adequate protective clothing, including long

pants. Wearing safety glasses, safety shoes,

and a helmet is advisable and required by some

local ordinances and insurance regulations.

7. Prolonged exposure to loud noise can cause impairment or loss of hearing. Operator hearing

protection is recommended; particularly for

continuous operati on of the GH S Mode l due to

blower noise level. Wear a suitable hearing protective device, such as earmuffs or earplugs.

8. Keep all protective shields and safety de-

vices in place. If a protective shield, safety

device, or decal is damaged, unusable, or missing, repair or replace it before operating the machine.

9. Be sure interlock switches are functioning

correctly, so th e engine cannot be starte d unless the Forward Speed Control lever is in the

NEUTRAL-PARK position, and the PTO clutch

is in the DISENGAGED position. Also, the engine should stop if the operator li fts off the seat

with the PTO clutch in the ENGAGED position.

10. Handle diesel fuel with care:

a. Use an approved fuel container.

b. Never add fuel to a running engine or hot

engine (allow hot engine to cool several

minutes).

12. The elec trical system battery contains sulfuric

acid. Avoid any contact with skin, eyes, and

clothing. Keep the battery and acid out of reach

of children.

OPERATING

1. Operate the mower only in daylight or in

good artificial light with good visibility of the area

being mowed.

2. Sit on the seat when starting the engine and

operating the machine. Keep feet on the deck

footrests at all times when the tractor is moving

and/or mower blades are operating.

3. For a beginning operator, learn to steer (ma-

neuver) the tractor with a slow engine speed

before attempting any mowing operation.

Be aware that, with the front mou nted mower

configuration, the bac k of the tractor swings to

the outside during turns.

4. Remember, for an emergency stop, the forward

motion of th e tractor can always be stopped by

pulling the Forwar d Speed Control (F SC) into

the NEUTRAL-PARK position.

5. In case either of the transmission drive belts

break during operation, and if the machine is on

a slope, the machine will f reewheel down the

slope. To maintain control, immediately (1)

Release the steering levers and simultaneously

(2) Move the FSC to the NEUTRAL-PARK position. When the machine is sto pped or moving

slowly, engage the parking brake.

12

c. Keep matches, cigarettes, cigars, pipes,

open flames, or sparks away from the fuel

tank and fuel container.

d. Always fill the fuel tank outdoors using care.

Fill to about one inch from the top of the tank.

Use a funnel or spout to prevent spilling.

e. Replace the machine fuel cap and container

cap securely a nd clean up any s pilled fuel

before starting the engine.

11. Never attempt to make any adjustments

while the engine is running, except where

specifically instructed to do so.

NOTE: This is exactly the same procedure used

to normally stop and park the machine.

6. Disengage the blade clutch and put the FSC in

the NEUTRAL-PARK position before starting

the engine (an ignition interlock switch normally

prevents starting of th e machine if these controls ar e in the OPERATING position).

7. Do not run the engine in a confined area

without adequate ventilation. Exhaust fumes

are hazardous and can be deadly.

8. Do not carry passengers - max imum seating

capacity is one (1) person.

Page 17

Safety Instructions

9. Watch for holes, rocks, and roots in the terrai n

and for other hidde n hazards. When mowing

tall grass, mow hig her than desired to e xpose

any hidden obstacles. Then, clean the area

and mow to the desired height.

10. Avoid sudden start s or stops. Bef ore backing

the machine up, look to th e rear to b e sure n o

one is behind the machine. Watch carefully for

traffic when crossing or working near roadways.

11. Disengage the blade drive when transporting

the machine across drives, si de wa lks , e tc. Ne-

ver raise the mower deck while blades are

rotating.

12. The maximum recommended side slope operating angle is 20 degrees or 33% grade.

When operating the machine on a slope, reduce

speed and use ca ution to start, stop, and m aneuver. To prevent tippin g or loss of control of

the machine, avoid sharp turns or sudden

changes in direction.

13. Never adjust cutti ng height with the engine

running. Before adjusting cutting height or

servicing, disengage the blade clutch (PTO),

stop the engine, and remov e the ignition key.

Wait for all movement to stop before getting off

the seat.

NOTE: A blade/blower br ake should nor mally

stop drive line rotation within five (5) seconds of

disengaging the PTO clutch.

14. For side discharge mower decks, do not oper-

ate with the grass deflector chut e removed .

Keep the deflec tor in th e lowest possible position.

15. For tractors equipped with tilt-up deck, observe

the following recommendations:

a. Do not move tractor with dec k in tilt-up po-

sition.

17. For GHS equipped models, use care when

closing the grass catcher door . Keep fingers

and hands away from the hinge and pinch

points when the door is being closed. Also,

keep fingers and hands clear of the door frame.

The door is held closed with springs and the

door may slam shut with considerable force.

18. In case of a clogged or plugged mower deck

or GHS catching system:

a. Disengage the blade clutch (PTO) and turn

the engine off before leaving the seat.

b. LOOK to make sure blade drive shaft and

blower drive pulley movement has stopped

before trying to unclog the system.

c. Disconnect the electrical plug on the fuel

shut-off solenoid.

d. Never place hands under the deck or in the

GHS blower - us e a stick or similar tool to

remove clogged material.

19. If the cutting bl ades strike a solid object o r the

machine begins to vibrate abnormally, immedi-

ately disengage the blade clutch (PTO), stop

the engine, and wait for all moving parts to

stop. To prevent accidental starting, discon-

nect the electrical plug on the fuel shut-off solenoid. Thoroughly inspect the mower and repair

any damage before restartin g the engine and

operating the mower. Make sure cutter bl ades

are in good condition and blade nuts are

torqued to 60 ft-lb (81.3 N·m).

20. Do not touch the engine or muffler while the

engine is running or immediately after stopping the engine. These areas may be hot

enough to cause serious burns.

21. Never remove the radiator pressure cap

when the engine is hot (hot water may spra y

and cause burns).

b. Ne ver tilt body forward with deck in tilt- up

position.

16. For GHS equipped models, do not operate the

machine with the grass catcher in the DUMP

position or with the back door OPEN. Dan-

gerous projectiles may be thrown out of the discharge chute or the back of the grass catcher.

22. Do not use ether or any starting fluid to assist

starting the engine in cold weather.

23. When leaving the machine unattended, dis-

enga ge t he b lade clu tch (PTO), stop t he e n gine, and remove the key.

13

Page 18

Safety Instructions

MAINTENANCE

1. To prevent accidental starting of the engine

when servicing or adjusting the machine, remove the key from the ignition s witch and disconnect the electrical plu g on the fuel shut-off

solenoid.

2. To reduc e fire hazards, keep the engine free of

grass, leaves, excessive grease, and dirt.

3. K eep all nuts, bo lts, and sc rews tig ht to e n su re

the machine is in a safe, working condition.

Check the blade mounting nuts frequently , making sure they are tight.

4. Perform only maintenance instructions de-

scribed in this manual. Unauthorized maintenance operations or machine modifications

may result in unsafe operating conditions.

5. If the engine must be running to perform a maintenance adjustment, keep hands, feet, and

clothing away from moving parts. Do not wear

jewelry or loose clothing.

6. Always use the proper engine service manual when working on the engine. Unautho-

rized maintenance o perations or modifications

to the engine may result in unsafe operating

conditions.

11. Use genuine factory replacement parts.

Substitute parts may result in produc t malfu nction and possible injury to the operator and/or

others.

12. Use care when charging the battery or performing maintenance on the battery and electrical system:

a. Make sure the battery charger is unplugged

before connecting or disco nnecti ng ca ble s

to the battery.

b. Charge the battery in a well-ventilated

space, so gases produced whi le charging

can dissipate. Make sure the battery vents

in the caps are open.

c. Ke ep sparks, fla mes, a nd smo king mater i-

als away from the ba ttery at all times. To

avoid sparks, use care when removing battery cables from posts.

d. Disconnect both battery cables before

unplugging any wiri ng connectors or mak ing repairs on the electrical system.

IMPORTANT: Keep all applicable manuals

immediately accessible to anyone who may

operate or service this machine.

7. The fuel oil injection system operates under

high pressure and can penetrate the skin and

result in serious injury. Unqualified persons

should not remove or attempt to adj us t a pum p

injector, nozzle, or any part of the fuel injec tion

system.

8. Altering the equipment or engine in any manner

which adversely affects its operation, performance, durability, or use will VOID the warran-

ty and may cause hazardous conditions.

9. Never attempt to di sconnec t any safety devi ces

or defeat the purpose of these safety devices.

10. Do not cha nge the e ngine g over nor setti ngs or

overspeed the engine. The governor has been

factory-set for m axim um- s afe engi ne ope rating

speed.

14

Page 19

Safety Instructions

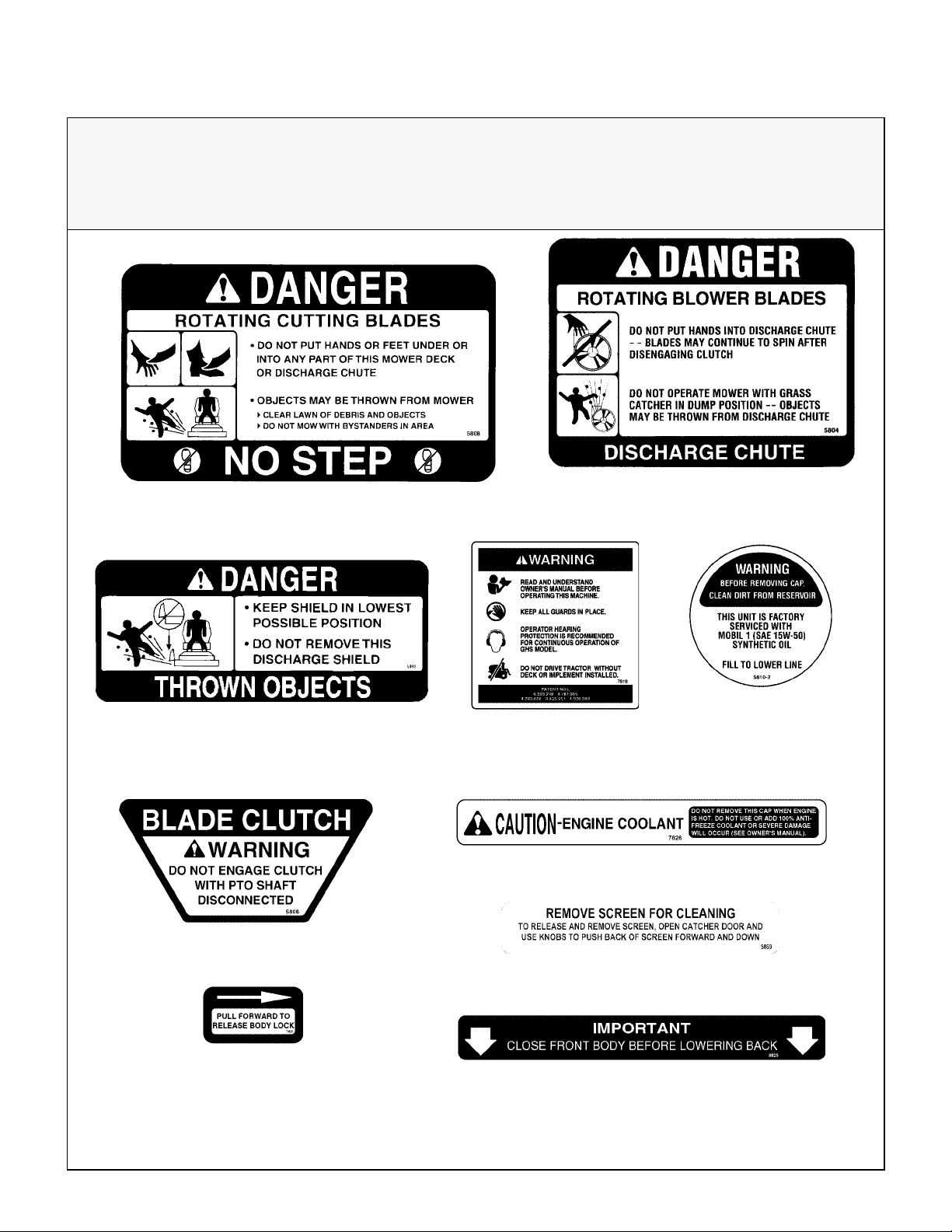

SAFETY, CONTROL, AND INSTRUCTION DECALS

Safety, Control, and Instruction Decals are installed on the machine;

if any are missing, illegible, or damaged, a replacement should be ordered and installed before

putting the machine into operation. The Decal Part Number is listed below and in the Parts Manual.

Each End of Mower Deck (5808)

SD Deck Discharge Shield (5848)

Adjacent to Blower Discharge Chute

through Body (5804)

Hydrostat Oil

Front Body Adjacent to

RH Steering Lever (7818)

Radiator Screen Frame Near Radiator Fill Cap (7826)

Reservoir (5810-2)

On Body Adjacent to Clutch

Control Lever (5806)

Right Side of Front Body, Below

Front Body Latch Release (7820)

Rear of Grass Catcher Exhaust Screen (5869)

Rear Cross Member of Front Body (8825)

15

Page 20

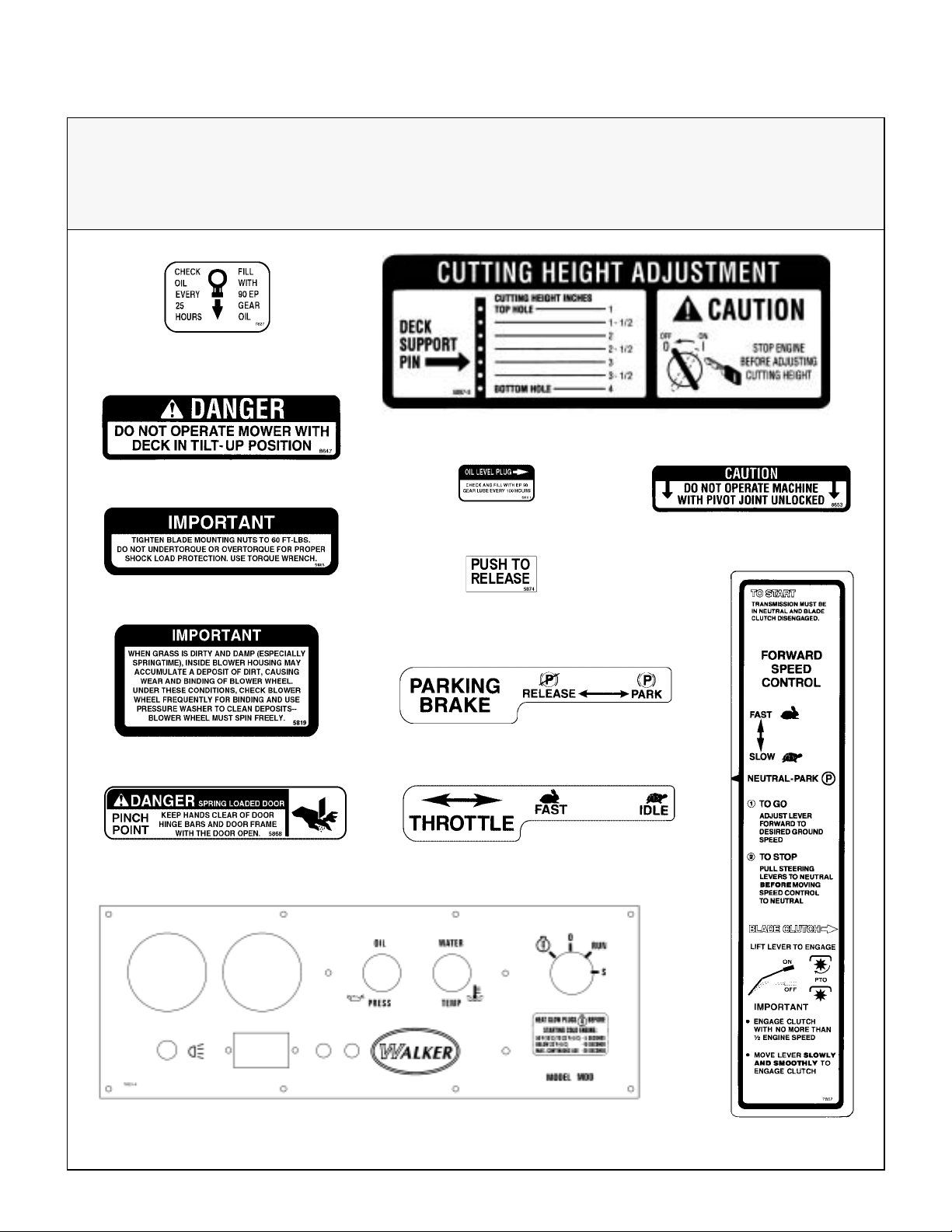

Safety Instructions

SAFETY, CONTROL, AND INSTRUCTION DECALS

Safety, Control, and Instruction Decals are installed on the machine;

if any are missing, illegible, or damaged, a replacement should be ordered and installed before

putting the machine into operation. The Decal Part Number is list ed below and in the Parts Manual.

Jackshaft Support Adjacent

to Dipstick (7827)

Deck Carrier Frame (8647)

Deck Gearbox Cover (5807-3)

Deck Carrier Frame (5865)

Top of Blower Housing (5819)

Catcher Door Hinge Bar,

LH and RH Sides (5868)

Gear Axle (5810-1)

Catcher Safety Latch,

RH Side (5874)

Right Side, Below Operator Seat (7809)

Left Side of Operator Seat (7819)

Deck Carrier Frame (8653)

16

Instrument Panel (7823-4)

Fender, RH Side (7802)

Page 21

Assembly Instructions

SETUP INSTRUCTIONS

Walker Mowers are shipped partially assembled.

After uncrating the tractor and mower deck, initial

setup is required.

NOTE: During the process of unpacking, any damaged or missing parts should be noted and reported

to the delivering ca rrier immediately (put in wri ting

within 15 days). The carr ier will provide directions

for proceeding with a claim to receive compensation

for damage.

Tire Installation (Tractor)

• Install the drive ti res usin g the eig ht (8) lug bo lts

that are supplied with the o wner’s packet of materials. Drive tires are 18 x 9.50-8, 4-ply; rear tires are

13 x 5.00-6, 4-ply.

• Check and adjust the inflation of the tires. The

tire inflation recommendations are:

Drive = 15 PSI (103 kPa)

Rear = 20 PSI (137 kPa)

Battery Service

Raise front mower body up for battery access (refer

to Front Body Latch Release in Operating Instruc-

tions). Check the battery for electrolyte level and

charge. The electrolyte lev el should be at the bottom of the vent wells [1/4 to 1 /2 in. (6 to 13 mm)

above plates]. If the specific gravity is less than

1.225, the battery needs charging. If the battery has

been shipped dry, or is wet but needs service, refer

to the following instructions.

Dry Battery Servic e

DANGER

Activating a battery can be dangerous.

The battery should be taken to a reliable

service station, battery store, or power

equipment dealer where a trained technician can activate the b attery safely. DO

NOT attempt to activate the battery unless

you are experienced in battery service

work. The following activation and charging instructions are provided for use by a

trained battery technician.

DANGER

Battery electrolyte is a poisonous and corrosive sulfuric acid solution.

• Avoid spillage and contact with skin,

eyes, and clothing - causes severe burns.

• To prevent accidents, wear safety gog-

gles and rubber gloves when working with

electrolyte.

• Neutralize acid spills with baking soda

and water solution.

T o fill (activate) battery with electrolyte (if battery has

been shipped dry):

IMPORTANT: Make sure battery is securely

mounted in the frame. A loose battery may cause

damage to the case resulting in acid leakage and severe damage to the machine. A hazard may be created by damage to cr itical work ing parts and sa fety

systems.

Wet Battery Service

If the battery has been shipped wet, but the electrolyte

level is low or the battery needs to be charged then:

1. Fill each battery cell with drin king water to the

bottom of the vent wells.

2. Charge battery. Refer to Battery Charging in

this section.

1. Remove the battery ho ld dow n bar, disconnect

the battery cables and li ft the battery ou t of the

tray.

IMPORTANT: Battery must be removed from

the mower before filling with electrolyte.

IMPORTANT: Obtain and use only battery

grade sulfuric acid electrolyte with a 1.265 specific gravity to activate the battery. DO NOT use

water or any other liquid during initial activation.

2. Remove the filler caps and carefully fill each cell

until the electrolyte is just above the plates.

3. After the battery is filled with electrolyte, replace

the filler caps and cha rge the batt ery. Refer to

Battery Charging.

17

Page 22

Assembly Instructions

Battery Charging

DANGER

BATTERIES PRODUCE EXPLOSIVE GASES

• Charge the battery in a well-ventilated

area, so that gases produced while charging can dissipate.

• Keep sparks, flames, and smoking mate-

rials away from the battery at all times.

• Make sure the battery cap vents are open

after the battery is filled with acid (check

manifold vent on each cap).

• Make sure the battery charger is unplug-

ged before connecting or disconnecting

cables to the battery.

1. Charge the battery at 15 amps for 10 minutes .

DO NOT exceed 20 amps maximum recommended charging rate. Charge until specific

gravity is at least 1.250. Total charging time

should not exceed one (1) hour.

2. After charging the battery, adjust the electrolyte

level to the bottom of the vent wells [1/4 to 1/2 in.

(6 to 13 mm) above the plates].

IMPORTANT: DO NOT overfill the battery.

Electrolyte will overflow through the vented caps

onto parts of the machine and WILL result in

severe corrosion.

3. Install battery.

WARNING

Make sure the battery cap vents are open.

Improper venting of the battery COULD

cause a battery explosion.

Battery Clamp Secured

by Wing Nut(s)

Battery Installation

Mower Deck Assembly

Deck Caster Wheels Installation

1. Remove the bolt, nut, axle spacer tube, and

spacer washers from each deck caster wheel

fork.

NOTE: Spacer washers are used only when

the optional semi-pneumatic deck wheels (8.25

x 2.75) are installed.

2. Fit the axle spacer tube through the wheel hub,

position the spacer wa sh er on ea ch si de of the

hub (if used), and fit the assembly into the wheel

fork.

(+) Battery Cable

Connection

18

Battery Installation

IMPORTANT: Make sure battery is securely

mounted in the frame. A loose battery may cause

damage to the case resulting in acid leakage and severe damage to the machine. A hazard may be created by damage to cr itical work ing parts and sa fety

systems.

Install the battery in the mower as shown in Battery

Installation photo. Connect the positive and negative cables to the proper battery terminal [red cable

and boot connects to the Positive (+) terminal].

Slide the rubber boot up and over the ba ttery post,

making sure it covers the post completely to pre-

vent an electrical short.

3. Insert the 3/8-16 x 4-1/2 in. bolt through the

wheel fork with the bolt head to the outside and

install the 3/8-16 in. Keps nut.

4. Tighten the bolt and nut until the axle spacer

tube bottoms against the inside of the wheel

fork (will not turn) while the wheel and spacer

washers (if used) spin freely without binding.

Page 23

Assembly Instructions

Grease Fitting

Locations

Spacer Washer

Axle Spacer Tube

Deck Caster Wheel Installation

NOTE: If semi-pneumatic wheels are installe d,

make sure the spacer washers fit over the

spacer tube and are not caught between the fork

and the end of the tube. The washers should

move freely on the axle spacer tube.

5. Grease the caster wheel bearings and caster

pivot bearings - one grease fitting for each

wheel and each pivot.

Deck Discharge Shield Installation (Side Discharge Models Only)

Attach the deck side discharge shield by positioning

the shield hinge lug i n fr ont of the deck mou nt and

fastening with two 3/8-16 x 1-1/4 in. bolts, 3/8-16

ESNA nuts, and 3/8 in. wave sp ring washers. Th e

wave washers fit between the two hinging surfaces.

Tighten the nuts until the shield moves freel y but is

not loose.

WARNING

DO NOT operate the machine without the

grass deflector chute a ttached and in the

lowest possible position.

Attach Shield

Deck Discharge Chute Installation (GHS Rear Discharge Models Only)

Mount the discharge chute hinge on top of the deck

discharge openin g using the 1/4-20 x 1/2 i n. s oc ket

button head bolt and 1/4-20 ESNA nut. Position the

bolt with the head inside of the chute and the nut on

the outside. Attach spring for tilt-up action from

chute to bracket on deck.

Carrier Frame

Tube Sockets

Attach Guard

Nut on Top

Discharge Chute and PTO Shaft Guard

Installation on Rear Discharge Deck

Attach

Chute

Discharge Shield Installation

on Side Discharge Deck

PTO Shaft Guard Installation

Position the shaft guard as shown and moun t with

two 1/4-20 x 1/2 in. bolts.

Tilt-Up Roller Wheel Installation

Mount the two (2) tilt-up roller whee ls on the brac kets on the rear skirt o f the deck housing using the

P/N 8490 axle b olt , 3 /8 in. wa ve s pr in g washer and

3/8-16 in. Whiz loc knut. Tighten the axle bolt until

the wheel rolls freely, but is not loose.

19

Page 24

Assembly Instructions

Attach Spring

Tilt-Up Spring and Roller Wheel

Installation on Rear Discharge Deck

Mower Deck Installation on Tractor

Roller Wheels

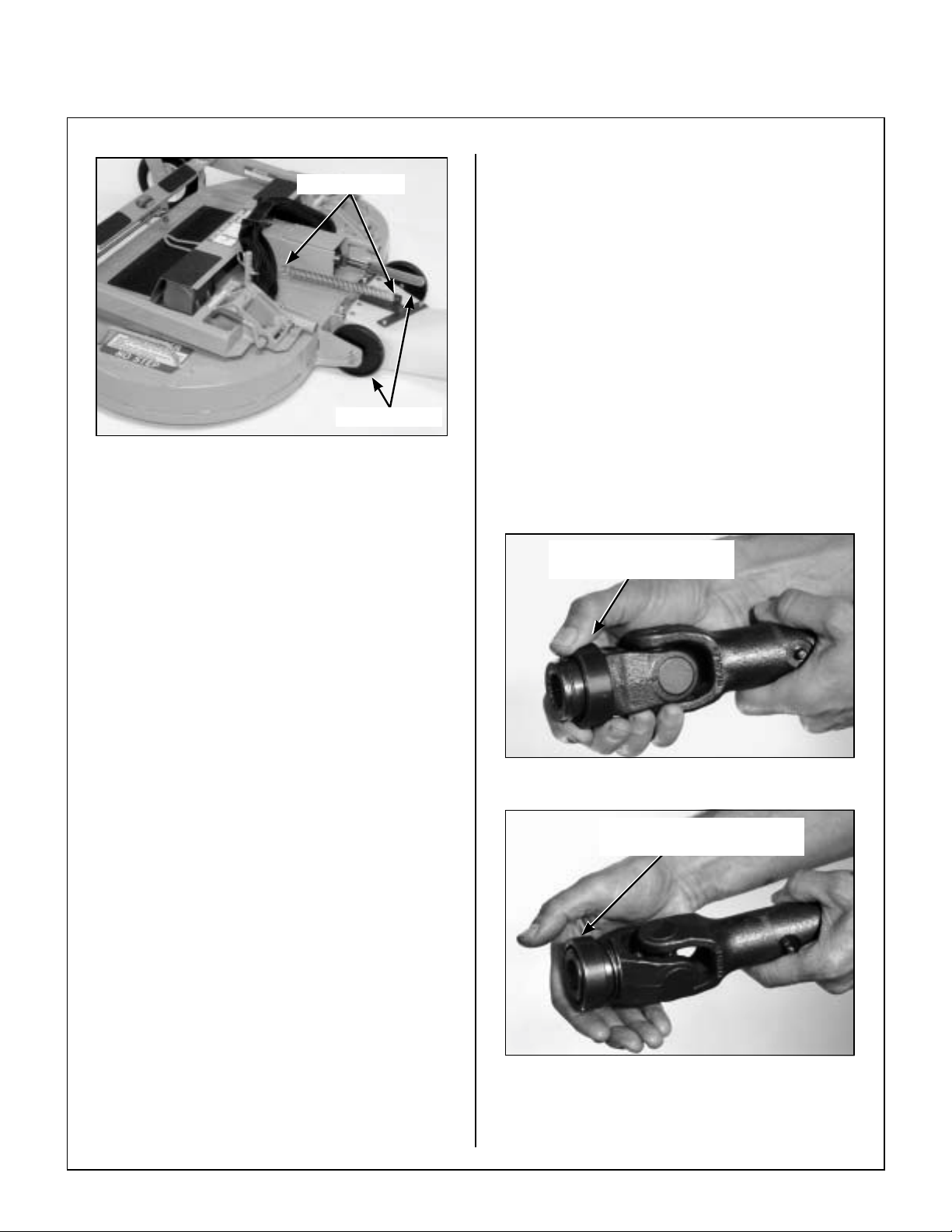

5. Connect the mower deck PTO drive shaft

assembly to the tractor with the splined quick

disconnect coupler. This coupler simplifies

shaft alignment and installation.

a. Use the arrows on the shaft and tube to

align and slide the PTO quick coupler onto

the deck splined shaft.

b. Reaching under the tractor, pull the ring

back on the coupler, slide onto the spline

shaft on the tractor, and release the ring.

IMPORTANT: To prevent damage to the

mower, make sure the PTO shaft assembly is

securely locked on the tractor, with the locking

balls fully seated in the groove and th e ring in the

full forward position (refer to the Coupler Ring

“Locked” Position photo). After installation,

pull on the shaft to check for security.

Deck Installation

1. Lightly grease each deck support arm (2) on the

tractor. Refer to Mower Deck Installation photo

on next page for location of deck support arm.

2. Engage the deck carrier frame tube sockets on

the tractor support arms (refer to Discharge

Chute and PTO Shaft Guard Installation

photo for socket locat ion). Slide the deck ont o

the support arms: all the way if SD equipped

model, approximately 3 in. (76 mm) if GHS

equipped model.

NOTE: When installing the DSD52 or DSD62

Mower deck, make sure to retract the dolly

wheel after mounting the deck on the tractor.

3. If the deck is rear discharge (GHS equipped

model), the rear discharge chute will need to be

aligned and connected to th e blower inlet during the last 2 in. ( 51 mm) of sl ide acti on on th e

support arms.

NOTE: Raising the mower body may be helpful

in fitting and guiding the deck chute into the

blower.

Pull Back Spring-Loaded

Coupler Ring

Installing PTO Quick Coupler

Spring-Loaded Coupler Ring

In Fully Forward Position

20

4. Install the hitch pin through the hole on the end

of each suppo rt arm to lock the deck in place

(refer to Deck Counterweight Spring Installa-

tion p hoto). Two (2) hitch pins are inc luded in

the owner’s packet of materials.

Coupler Ring “Locked” Position

Page 25

Assembly Instructions

6. Raise the front mower body (instead of lifting

the front of deck) and clip the counterweight

springs to the receptacle on front of body.

Lower the front body to tension the springs.

(Refer to Deck Counterw eight Spring Instal-

lation photo.)

Grease Deck

Support Arms

PTO Connection

Arrows on Shaft and Tube

(used to align when slidin g together)

Mower Deck Installation (PTO Shaft Connection)

7. With the counterwe ight springs co nnected, the

weight on the deck caster wheels should be

15 to 25 Ib (7 to 1 1 kg). Check this weight by lifting on the front of the deck carrier frame. If

required, the spring tension can be adjusted by

tightening or loosening the elastic stop nuts

located underneath the lower spring hook.

Refer to Deck Counterweight Spring Installa-

tion photo.

Spring Tension Adjus tm ent

Nut Located Under Lower

Spring Hook (Not Visible)

Counterweight Springs Clip

Onto Body With Forward

Body Tilted Up

Hitch Pins

Lock Deck On

Support Arms

Deck Counterweight Spring Installation

21

Page 26

Assembly Instructions

Deck Leveling

1. Position mower on a smooth , level sur face. S et

the cutting height to th e highest position - 4 in.

(102 mm) - for easy acce ss under the deck to

measure blade hei ght. Refer to ADJUSTING

CUTTING HEIGHT in Operating Instructions.

NOTE: A block of wood cut 4 in. (102 mm) high

is a convenient gauge to measure blade height

above ground during the leveling process.

WARNING

The machine must be shut off during this

procedure.

2. Check the side-to-side level. Rotate each blade

sideways and measure the distance from blade

tip to ground on each side. If measurements

vary more than 1/8 in. (3 mm), ad d a washer

shim under the deck support pins on the low side

to level the deck.

3. Check the front-to-rear level. Rot ate the blades

to point forward. Me asure the distance from

blade tip to ground on t he front and rear. The

rear of the blade should be 1/8 to 1/4 in. (3 to 6

mm) higher than the front of the blade; shim the

rear (or front) deck support pins equally to

achieve at least 1/8 in. (3 mm) difference.

NOTE: The mower deck and support frame are

jig welded; within normal tolerances, very little, if

any, shimming should be required to level the

deck. Tire pressure will influence the levelness

of the deck. Check the tire pressure as a possible cause of the deck not being level.

4 in. (102 mm)

Wood Block

Should not vary more

than 1/8 in. (3 mm)

side-to-side

Should be 1/8 in. (3 mm)

to 1/4 in. (6 mm) higher

at the rear of the blade

4 in. (102 mm)

Wood Block

Deck Leveling

22

Page 27

Assembly Instructions

PREOPERATING CHECKLIST

Before operating the mower for the first time, and as

a routine before da ily operations, it is important to

make sure the mower is properly prepared and

ready for operation. The following is a list of items to

be checked. (For a mower with frequent operation,

some of these items will not need to be checked every day, but the operator should be aware of the condition of each.)

For proper fuels and lubricants refer to Specifica-

tions.

FILL FUEL TANK

Fill the fuel tank with clean, fresh fuel. Clean diesel

fuel is particularly important since contaminated fuel

will damage the fuel injectors and injection pump.

NOTE: An electric fuel pump makes it unnecessary to bleed (p urge out air bubbles ) th e d ie se l fuel

injection system when ini tiall y fueling an e mpty fuel

tank.

DANGER

CHECK ENGINE CRANKCASE OIL LEVEL

Check the en gine cran kcase oi l level bef ore use an d

after each 5 hours of continuous operation. Refe r

to LUBRICATION for Checki ng Engine Cra nkcase

Oil Level in Maintenance Instructions.

CHECK AND SERVICE ENGINE AIR CLEAN-

ER SYSTEM

• Check a ir restriction gauge to mak e sure there

is no red indication showing.

• Check condition, cleanliness, and security of

the complete air c leane r sys tem (cl ean ai r filte r

every 100 hours). For detailed procedures,

refer to CLEANING the Engine Air Cleaner

System in Maintenance Instructions.

CHECK ENGINE COOLING SYSTEM

• Check the radiator air intake screen to make

sure the screen is clean and free of obstruction.

Also, the radiator cooling fins should be

inspected and cleaned if there is any buildup of

dirt or debris. (Remove the intake screen

assembly to inspect and clean.)

Handle diesel fuel with care. Use safe refueling procedures:

• DO NOT fill fuel tank with the engine run-

ning.

• If the engine is hot, allow to cool before

refueling.

• Use an approved fuel container.

• Fuel the mower outdoors.

• DO NOT smoke while refueling.

• Avoid spilling fuel; use a funnel or spout.

• DO NOT overfill the fuel tank; fill up to

about 1 in. (25 mm) below the top of tank.

IMPORTANT: DO NOT permit dirt or other foreign

matter to enter the fuel tank. Wipe dirt from around

the filler cap before removing. Use a clean fuel storage container and funnel.

• Check the coolant levels in the radiator and

overflow tank. If additional cool ant is needed,

refer to CHECKING/SERVICING the Engine

Cooling System in

Maintenance Instructions.

WARNING

DO NOT remove the radiator pressure cap

when engine is hot.

• Check engine fan belt.

CHECK GEAR AXLE OIL LEVEL

Refer to LUBRICATION for Gear Axle Lubrication

in Maintenance Instructions.

INSPECT FIVE (5) BELTS

Engine PTO Drive, Jackshaft Drive, Hydrostatic

Ground Drive, Engine Fan Belt, and GHS Blower

Drive (if equipped).

23

Page 28

Assembly Instructions

CHECK HYDROSTATIC TRANSMISSION OIL

LEVEL

Refer to LUBRICATION for Checking Hydrostatic

Transmission Fluid Level in Maintenance Instructions.

CHECK BATTERY ELECTROLYTE LEVEL

Refer to CHECKING/SERVICING the Battery in

Maintenance Instructions.

C HECK FUNCTIONS OF INSTRUMENT PANEL

AND WARNING HORN

Tilt-Up Lift Handle

Tilt-Up

Latch

Tilt-Up Latch

Tilt-Up Hook

on Deck

Deck Lock Lever

Turn the ignition key to the RUN position. Voltmeter,

Oil Pressure Warning Light, and Warning Horn

should all operate, indicating normal function.

CHECK TIRE PRESSURE

Deck Caster Wheel = 20 PSI (137 kPa)

Drive = 15 PSI (103 kPa)

Rear = 20 PSI (137 kPa)

CHECK AND CLEAN GRASS BUILDUP

UNDERNEATH MOWER DECK (and inside

GHS blower, if equipped)

Refer to CLEANING the GHS Blower in Mainte-

nance Instructions for blower cleaning information.

DANGER

Never operate cutter b lades with deck in

raised position because it is hazardous.

The tilt-up deck can be secured in the raised position

by unlocking the deck lock levers on each side of the

carrier frame and inserting the deck hook into the tiltup latch on the tractor body. Before operating th e

tractor, make sure to re-engage the deck lock levers

after lowering the deck to the normal operating position.

Deck Secured in TILT-UP Position

CAUTION

Do not operate machine with deck tilt-up

pivot joint unlocked.

DANGER

Do not operate the mower with deck in tiltup position. Do not move t he tra ctor with

the deck in the tilt-up position.

CHECK MOWER BLADE CONDITION, SHARP-

NESS, AND SECURITY OF MOUNTING

The blade mounting nut should be tightened to

60 ft-lb (81.3 N·m). If blade sharpening is required,

refer to CHECKING/SERVICING for Sharpen

Mower Blades in Maintenance Instructions.

CHECK DRIVE WHEEL BOLT TORQUE

The lug bolts mounting the drive tires should be

tightened to 75 to 85 ft-lbs. (101.7-115.2 N

ADJUST MOWER CUTTING HEIGHT, IF RE-

QUIRED

⋅m).

24

Position the hitch pins in the four deck support pins.

Refer to the “Cutting Heigh t Adjustment” decal on

the deck gearbox cover.

PERFORM ANY ADDITIONAL PROCEDURES

called for on the MAINTENANCE SCHEDULE

CHART in Maintenance Instructions.

Page 29

Operating Instructions

CONTROL IDENTIFICATION, LOCATION, AND FUNCTION

Operating Controls

CAUTION

Before operating the mower, become familiar with the location and function of all

operator controls. Knowing the location,

function, and operation of these controls

is important for safe and efficient operation of the mower.

Engine Throttle

The throttle control lever (red knob) is located on the

left side of the seat and is used to control engine

speed. Moving the lever forward toward the FAST

position increases engine s peed; moving it back-

ward toward the IDLE position decreases e ngine

speed.

Throttle

Throttle Location

Parking Brake

Front Body

Latch Release

Blade Clutch

(PTO)

Steering Levers

Forward Speed Control

(FSC)

Operating Controls

25

Page 30

Operating Instructions

Forward Speed Control (FSC)

Forward Speed Control (FSC) has two functions:

One is to set forward travel speed, and the othe r is

to establish the NEUTRAL-PARK position. When

the FSC lever is move d into the FORWARD posi-

tion, a friction lo ck holds an y forwa rd speed setting

from 0 to 5 mph (0 to 8 km/h). The ground speed is

proportional to the le ver positi on; the furth er the lever is advanced forward, the faster the tractor

moves. It is not necessary to hold the FSC in position since the friction lock maintains the selected lever position. Pulling back on the steering levers

overrides the FSC setting and slows or stops forward travel. Releasing the steering levers allows

the tractor to resume forward travel at the speed set

by the FSC lever. T o stop and park the machine, the

FSC lever is moved backward to the NEUTRAL-

PARK position. Steering Levers

Each drive wheel is controlled by its own in dependent steering lever, for both steering function and

FORWARD/REVERSE motion. The FSC lever sets

the maximum forward s peed, a nd also se ts the forward position of the steering levers. The steering levers operate only with a backward pulling

movement of the lever, which causes the drive

wheel for that lever to first slow down, stop, and then

reverse with a full backw ard lever stroke. The levers

are released to the FORWARD position for “straight-

ahead” ground travel.

Parking Brake

The parki ng brake f unction s by locki ng a pin into the

hydrostatic transmission pi nion gear teeth. Movi ng

the lever FORWARD engages the parking brake;

moving the lever BACKWARD releases the brake.

IMPORTANT: Stop the tractor completely before

engaging the parking brake. The parking brake

uses a positive mechanical lock similar to the PARK

position on an automo tive automatic transmissi on.

If the tractor is moving when the brake is engaged, it

will result in sud den s toppage an d p os si ble i nte rn al

damage to the axle drive.

NOTE: I f pressure on the parking brake pin (e.g.

parked on a hill) makes it i mposs ible to releas e the

parking brake with the parking brake lever, move the

mower gently forward or backward to release the

pin.

Front Body Latch Release

The front portion of the tract or body hin ges forwar d

for maintenance ac cess and is latched do wn in the

OPERATING position. To raise the body, move the

latch release forward.

26

NOTE: Pushing forward on the steering levers will

not cause any change in tr actor motion - there will

be no steering lev er reaction and there will be n o

machine damage.

Blade Clutch (PTO)

The blade clutch lever has two positions. Pulling the

lever UP engages the PTO that drives the mower

blades. Pushing the lever DOWN disengages the

PTO and engages the blade brake.

NOTE: O n GHS equipped models, the Powerfil

motor and Grass-Pak® full signal swit ch are activa ted by engaging the blade clutch. Refer to Using the

GHS Catcher in this section for a complete description of GHS operation.

Front Body

Latch Release

Front Body Latch Release

®

Page 31

Operating Instructions

Transmission Lockout Levers

The transmission loc kout levers disengag e the hydrostatic transmissons. By lifting the lever on top of

the transmission a nd locking it into place with th e

lockout cam, the hydrostatic tr ansmissions are released to permit freewheeling. By releasing the cam

and lowering the lever, the transmissions are en-

gaged for normal operation. The transmission lever

in the LOCKOUT position is used to enable moving

the machine without the engine running (e.g., for

service). Refer to TRANSMISSION LOCKOUT in

this section for operating instructions.

Lockout

Levers

Transmission

Plunger

Cold Start Lever (Jackshaft Drive Belt Release)

The cold start lever is used for starting the mach in e

in cold weather [below 40° F (4° C)]. Pulling the lever DOWN disengages the jackshaft drive belt.

When the jackshaft drive belt is released, the hydrostatic transmissions are removed from the engine

starter cranking load.

Jackshaft Drive

Engaged

Cold Start Lever - Normal Operating Position

Lockout Lever Location

NOTE: The transmission plunger on the side of the

transmission case (a ct i vated by the LOCKOUT LEVER) must be completely released during operation

of the mower, otherwise operation of the t ransmission will be erratic.

Jackshaft Drive

Disengaged

Cold Start Lever - Cold Start Position

27

Page 32

Operating Instructions

The Forward Speed Control also Establishes the Neutral-Park Position of the Steering Levers

LEFT WHEEL

STEERING LEVER

Forward Position

(No Control Change)

RIGHT WHEEL

STEERING LEVER

FORWARD SPEED

CONTROL LEVER (FSC)

Full Forward

Ground Speed

Position

Neutral-Park

Position

Reverse Drive

Wheel Motion

Position

PARKING

BRAKE

Disengaged

Position

Intermediate

Ground Speed

Position

Neutral-Park

Position

Engaged

Position

Disengaged

Position

28

Fast

Throttle

Position

Idle

Position

THROTTLE

Engaged

Position

BLADE CLUTCH (PTO)

Pull Up to Engage

Operating Controls (Top View from Drivers Point of View)

Page 33

Operating Instructions

Instrument Panel

This illustration shows the configuration of the

switches and ind ic ato rs lo cated on the ins trument

panel.

Voltmeter

Light Switch

(Optional)

Water

Temperature

Gauge

Hourmeter

Oil Pressure

Warning Light

Circuit Breaker - 7 Amp

(Instrument Panel)

Water Temperature

Warning Light

Ignition

Switch

Warning Horn

Powerfil

Circuit Breaker - 10 Amp (Headlights, Safety

Interlock Switch System, Fuel Solenoid Hold,

®

Motor - GHS Only, “Full” Signal Horn - GHS Only)

Instrument Panel

29

Page 34

Operating Instructions

Voltmeter

The voltmeter displays battery and charging system

voltage. An indication of low or high voltage (the red

area) indicates an electrical system f ailure. The

cause of the failure sh ould be deter mined and corrected.

Water Temperature Gauge

The water temperature gauge monitors engine

cooling system temperature. If engine coolant

temperature excee ds 230° F (110° C), an overheat

condition exists; the water temperature light will

come on and the warning horn will sound.

WARNING

If engine cooling system overheating is

indicated, continued operation of the engine, even for a short time, COULD result

in fire, risk of personal injury, and severe

damage to equipment.

Oil Pressure Warning Light

• Engine fan belt

• Thermostat function

Stop the engine and correct the problem before further operation.

IMPORTANT: Continued operation of the engine

with an illuminated water temperature warning light

MAY result in severe engine damage. Ignition Switch

The ignition switch is used to s tart and stop the engine (and preheat the di esel engine). The switch

has four positions: is the glow plug preheat position; “O” is the OFF posi tion; RUN is the pos ition

the key returns to after starting; “S” is the START position. When starting the engine, turn the key clockwise to the “S” position . Do not hold the ke y in the

“S” position longer than 10 sec onds. If the engine

does not start, return the key to the “O” position for at

least 60 seconds befor e making a restart attempt.

Prolonged cranking can damage the starter motor

and shorten batter y life. Relea se the ke y when the

engine starts, and it will return to the RUN position.

To stop the engine, rotate the key counterclockwise

to the “O” position.

The oil pressure warn ing li ght indi cates tha t eng ine

oil pressure is below the safe operating level [below

7 PSI (48 kPa)]. This light (and warning horn) will

come on when the ignition is turned ON, but should

go off after the engine is s tarted. If the ligh t fails to

come on when the ignition s witch is turned ON, it

could indicate a burned out b ul b. If th e li ght co mes

on during engine oper ation, stop the engine immediately and correct the source of the problem before

further engine operation.

IMPORTANT: Continued operation of the engine

with an illumina ted oil pressure warning l ight MAY

cause severe eng ine damage (i f a low oil pres sure

condition exists).

Water Temperature Warning Light

The water temperature wa rning light indicates that

engine coolant tempera ture is abov e the safe oper ating limit and the engine is overheating. If this

light comes on, there may be a problem with:

• Radiator cooling air flow (material packed into

radiator cooling fins, clogged air intake screen)

NOTE: When starting the engine, turn and hold the

ignition key in t he glow plug preheat pos ition. The

time required is approximately 10 to 30 seconds, depending on engine tem perature. Refer to START-

ING THE ENGINE in this section.

Glow Plug Preheat

Ignition Switch

OFF

ON

START

30

• Low coolant quantity in cooling system

Page 35

Operating Instructions

Light Switch (For Optional Lights)

Operates headlights (when ins talle d) .

Hourmeter

The hourmeter displays operating time accumulated while the ignition switch is in the ON position.

The hourmeter provides maintenance reminders

after certain hours of operation. The hourmeter

screen will start flashing the reminder one hour prior

to the recommended in terval and w ill conti nue until

one hour after the recommended interval (two

hours). The hourmeter does not have a manual

reset function.

Procedure Interval* Reminder

Oil Change

(Break-In)**

Lubricate

and Check

Levels

Oil Change

4-6 Hours

24-26 Hours LUBE

49-51 Hours***

* These intervals refl ect the actual time that the

reminder will flash ( one hour prior to and one

hour after the recommended interval).

** This reminder is only used one time.

*** In normal ope rating conditions, oil changes in

100-hour intervals are ac c eptable . Walker and

the engine manufa cturers recommend engine

oil changes ever y 50 hours in extremely dirty

or dusty conditions or for units with less than

100 hours annual use.

NOTE: The blinking hour glass on the display

means that the meter is operating properly.

C

H

G

C

H

G

OIL

OIL

Hourmeter

Circuit Breakers

Two manual reset circuit breakers are located on the

instrument panel. Each has a button that pops out if

the circuit breaker trips. The 10 amp circuit breaker

protects the circuits to the headlights, fuel valve solenoid, safety swi tch r elays and tim e de lay m odule,

and GHS. The 7 amp circuit breaker protects the instrument panel circuits to the meters, warning lights,

and warning horn.

Warning Horn

The warning horn sounds to alert the operator that

an unsafe engine condition is being indicated when engine coolant temperature is too high or

engine oil pressure is too low. If the horn sounds,

check the indicator lights and water temperature

gauge and correct the problem before further

operation.

STARTING THE ENGINE

CAUTION

Before operating the mower , r ead and understand all Safety Instructions and Operat-

ing Instructions.

WARNING

NEVER run the engine in an enclosed or

poorly ventilated area. Engine exhaust

contains carbon monoxide, an odorless

and deadly gas.

31

Page 36

Operating Instructions

1. Before attempting to start the engine, make

sure the operator is in the seat, the Forward

Speed Control is in NEUTRAL-PARK position,

and the blade clutch and parking brake are

DISENGAGED.

NOTE: Release parking brake to prevent extra

load on the starter if the transmission neutral is

slightly out of adjustment.

CAUTION

A safety interlock switch system PRE-

VENTS CRANKING the engine with either

the Forward Speed Control or the blade

clutch (PTO) out of neutral. If the engine

cranks otherwise, the safety system is not

working and should be repaired or ad-

justed before operating the mower. DO

NOT disconnect safety switches; they are

for the operator’s protection.

NOTE: For starting in cold weather [below 40° F

(4° C)], use the cold start lever to release the

jackshaft drive belt and remove the hydrostatic

transmission from the starter cranking load.

After the engine has been started and warmed

up, raise the lever to re-engage the jackshaft

drive belt.

3. Move the throttle 1/4 to 1/2 open (toward

FAST) and turn the ignition switch to the

START position to start the engine. Release

the key to the RUN position as soon as the

engine starts.

IMPORTANT: If the engine fails to start after

approximately 10 seconds of cranking, the

engine should be checked before further cranking. Turn the key to the OFF position and allow

a 60 second cool-down period between starting

attempts. Failure to fo llow the se guideline s can

damage the starter motor and shorten battery

life.

TROUBLESHOOTING NOTE: If the engine

cranks but does not start, check the following:

• The fuel valve solenoid is operating. Look at

the exhaust pipe when cranking the engine - no

smoke indicates no fuel is reaching the cylinder.

If the solenoid is not operating, contact your

Walker Dealer.

• The glow plugs are operating. Look at the

exhaust pipe when cranking the engine - white

smoke indicates improper glow plug operation

and inadequate preheat. Consult the Kubota

Workshop Manual to check glow plug function.

4. After the engine starts, make sure the oil

pressure light goes off. If n ot, stop the e ngine

immediately and find the cause of the problem.

Make sure the oil pressure light is off prior to

engaging the mower blades and beginning

operation.

32

Cold Start

Lever Engaged

Jackshaft Drive Belt Release

2. Turn and hold the ignition key in the PREHEAT

position to prehea t the en gine glo w plug s. For

temperatures below 35° F (2° C), the time

required is approximately 25 to 30 seconds. For

temperatures 35° F (2° C) or higher, the time

required is approximately 10 to 15 seconds.

Page 37

Operating Instructions

ADJUSTING GROUND SPEED AND STEERING

IMPORTANT: If the DSD52 or DSD62 Mower

deck is installed on the tractor, make sure the

dolly wheel is retracted BEFORE moving.

CAUTION

Learn to START, STOP, and MANEUVER

the mower in a large, open area.

If the operator has not operated a machine with LEVER STEERING OR DUAL

HYDROSTATIC TRANSMISSIONS, steering and ground operation should be

learned and practiced until the operator is

completely comfortable handling the machine BEFORE ATTEMPTING TO MOW.

DANGER

Keep feet on footrests at all times when

the machine is moving.

1. Move the FSC out of NEUTRAL-PARK

position to the desired forward speed. DO

NOT hold forward on steering levers. It is not

necessary to hold the FSC lever in position

since a friction lock maintains the selected

lever position (and forward travel speed).

WARNING

In case either of the transmission drive

belts break during operation, and if the

machine is on a slope, the machine will

freewheel down the slope. To maintain

control, immediately (1) Release the

steering levers and simultaneously (2)

Move the FSC to the NEUTRAL-PARK

position. When the machine is stopped

or moving slowly, engage the parking

brake.

NOTE: If the FSC lever will not stay in the

selected position, the friction lock needs to be

adjusted. Contact your Walker Dealer.

2. Steer by pulling the lever on the side of desired

direction of turn, e.g., p ull the LH lever to turn

left. To minimize the possibility of overcontrol,

use only one hand on both steering levers.

Beginning Recommendations are: