Walchem WDP420, WPH420, WPH410, WDP340, WDP410 Instruction Manual

W A L C H E M

W

PH/WDP Controllers

WPH/WDP Series

pH & ORP Controllers

Instruction Manual

Walchem Corporation Five Boynton Road Hopping Brook Park Holliston, MA 01746 USA

TEL: 508-429-1110 FAX: 508-429-7433 WEB: www.walchem.com

Notice

© 2008 WALCHEM Corporation

5 Boynton Road, Holliston, MA 01746 USA

(508) 429-1110

All Rights Reserved

Printed in USA

Proprietary Material

The information and descriptions contained herein are the property of WALCHEM Corporation. Such

information and descriptions may not be copied or reproduced by any means, or disseminated or

distributed without the express prior written permission of WALCHEM Corporation, 5 Boynton Road,

Holliston, MA 01746.

This document is for information purposes only and is subject to change without notice.

Statement of Limited Warranty

WALCHEM Corporation warrants equipment of its manufacture, and bearing its identification to be

free from defects in workmanship and material for a period of 24 months for electronics and 12 months

for mechanical parts and electrodes from date of delivery from the factory or authorized distributor

under normal use and service and otherwise when such equipment is used in accordance with

instructions furnished by WALCHEM Corporation and for the purposes disclosed in writing at the time

of purchase, if any. WALCHEM Corporation's liability under this warranty shall be limited to

replacement or repair, F.O.B. Holliston, MA U.S.A. of any defective equipment or part which, having

been returned to WALCHEM Corporation, transportation charges prepaid, has been inspected and

determined by WALCHEM Corporation to be defective. Replaceable elastomeric parts and glass

components are expendable and are not covered by any warranty.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EITHER EXPRESS OR IMPLIED, AS

TO DESCRIPTION, QUALITY, MERCHANTABILITY, FITNESS FOR ANY PARTICULAR PURPOSE

OR USE, OR ANY OTHER MATTER.

180362.A

August 2008

TABLE OF CONTENTS

1.0 INTRODUCTION........................................................................................................................1

2.0 SPECIFICATIONS..................................................................................................................... 2

2.1 Measurement Performance...................................................................................................................2

2.2 Electrical: Input/Output ..........................................................................................................................2

2.3 Mechanical.............................................................................................................................................3

2.4 WPH/WDP Variables and their Limits....................................................................................................3

3.0 UNPACKING & INSTALLATION ..............................................................................................4

3.1 Unpacking the unit.................................................................................................................................4

3.2 Mounting the electronic enclosure.........................................................................................................4

3.3 Installation..............................................................................................................................................4

3.4 Icon Definitions ......................................................................................................................................5

3.5 Electrical installation ..............................................................................................................................7

4.0 FUNCTION OVERVIEW.......................................................................................................... 18

4.1 Front Panel ..........................................................................................................................................18

4.2 Display.................................................................................................................................................18

4.3 Keypad.................................................................................................................................................19

4.4 Access Code........................................................................................................................................19

4.5 Startup .................................................................................................................................................19

4.6 Shut Down ...........................................................................................................................................20

5.0 OPERATION............................................................................................................................20

5.1 Main Menu...........................................................................................................................................20

5.2 Sensor Menu........................................................................................................................................22

5.3 Temperature Menu (this menu does not appear if an ORP sensor has been selected).....................28

5.4 Control 1 - 4 Menus (FOR ON/OFF CONTROLLERS) .......................................................................29

5.5 Control 1-4 Menu (FOR PROPORTIONAL CONTROLLERS)............................................................34

5.6 Interlock A Menu..................................................................................................................................36

5.7 4-20 mA 1 and 2 Menus (Optional)......................................................................................................37

5.8 Time Menu...........................................................................................................................................38

5.9 Access Code Menu..............................................................................................................................39

5.10 Datalog Menu.......................................................................................................................................40

5.11 Config Menu.........................................................................................................................................42

5.12 Upgrade Menu.....................................................................................................................................44

6.0 MAINTENANCE.......................................................................................................................45

6.1 Electrode Maintenance........................................................................................................................45

6.2 Replacing the Fuses............................................................................................................................46

7.0 TROUBLESHOOTING............................................................................................................. 46

7.1 Error Messages....................................................................................................................................46

8.0 SERVICE POLICY...................................................................................................................48

1.0 INTRODUCTION

The Walchem WPH Series single sensor input and WDP Series dual sensor input controllers are wall

mount pH/ORP controllers that are available in on/off or modulated pulse proportional versions. They

are available with four on/off control relays (WPH410 or WDP410) with two modulated pulse

proportional output and two dry contact relays (WPH420 or WDP420) or four modulated pulse

proportional outputs (WDP340). A fifth output is used as a diagnostic alarm. One or two isolated 4-20

mA outputs are optional.

They are compatible with any amplified electrode. The choice of pH or ORP operation is selected

through the keypad. Use of Antimony pH electrodes is acceptable. Automatic temperature

compensation may be used via a Pt1000 or Pt100 input if pH operation is selected. The controller will

prompt you to calibrate the electrode at the desired frequency. Automatic buffer recognition may be

used in the calibration routine.

Our unique USB feature provides the ability to upgrade the software in the controller to the latest

version.

An advanced USB capability option is available. The Configuration file feature allows you to save all

the set points from a controller onto a USB flash disk, and then import them into another controller,

making the programming of multiple controllers fast and easy. The data logging feature allows you to

save the last 2 month’s readings and events to a USB flash disk.

1

2.0 SPECIFICATIONS

2.1 Measurement Performance

pH Range -2 to 16 pH units

pH Resolution 0.0015 pH units (0.01 pH displayed)

pH Accuracy (Calibrated): ± .01 pH

ORP Range -1500 to 1500 mV

ORP Resolution 92 µV (1mV displayed)

ORP Accuracy ±1 mV

Temp Comp (optional): 100 or 1000 ohm platinum RTD

Temperature Range 32-212°F (0-100°C)

Temperature Resolution ±0.09°F (0.05°C)

Temperature Accuracy ± 0.9°F (± 0.5°C)

2.2 Electrical: Input/Output

Input Power

Input Signals

pH/ORP ±1500 mV

Temp Comp (optional) Pt100 or Pt1000

Interlock (optional) Isolated, dry contact closure required (i.e., flow, level, etc.)

Outputs

Powered Relays Internally powered relays switching line voltage

Pulse Outputs Opto-isolated, Solid State Relay

Dry contact relays 6 A (resistive), 1/8 HP

Dry contact relays are not fuse protected

100-240 VAC, 50/60 Hz, 8A

Fuse: 1.0 ampere, 5 x 20 mm

6 A (resistive), 1/8 HP

All relays are fused together as one group, total current for this

group must not exceed 6A

150mA, 40 VDC Max.

VLOWMAX = .13V @ 18 mA

CTRL 1 CTRL2 CTRL 3 CTRL 4 ALARM

WPH410 Powered Powered Dry Dry Dry

WPH420 Pulse Pulse Dry Dry Dry

WDP410 Powered Powered Powered Powered Powered

WDP420 Pulse Pulse Dry Dry Dry

WDP440 Pulse Pulse Pulse Pulse Dry

Note: The Alarm relay is non-programmable. Refer to the Main Menu diagram for the list of error

conditions that trigger the alarm relay.

4 - 20 mA 1 or 2 (optional) Internally powered

pH/ORP Preamp Power ±5 VDC, 5 mA

Agency Approvals

CAN/CSA C22,2 No.61010-1:2004 2

CE Safety EN 61010-1 2

CE EMC EN 61326 :1998 Annex A*

Note: For EN61000-4-6,-3 the controller met performance criteria B.

*Class A equipment: Equipment suitable for use in establishments other than domestic, and those directly

connected to a low voltage (100-240 VAC) power supply network which supplies buildings used for

domestic purposes.

Fully isolated

600 Ohm max resistive load

Resolution .001% of span

Accuracy ± 1% of reading

UL ANSI/UL 61010-1:2004, 2

nd

Edition (2001)*

nd

Edition*

nd

Edition*

2

2.3 Mechanical

Enclosure Material Polycarbonate

NEMA Rating NEMA 4X

Dimensions 8.5" x 6.5" x 5.5"

Display 2 x 16 character backlit liquid crystal

Operating Ambient Temp 32 – 122°F (0 – 50°C)

Storage Temperature -20 – 180°F (-29 – 80°C)

Flow switch manifold temperature rating 140°F (60°C) max

Flow switch manifold pressure rating 150 psi

Flow switch manifold connections ¾" NPTF

2.4 WPH/WDP Variables and their Limits

Low Limit High Limit

Sensor menu

Temperature Menu

Control 1 -4 Menus

High or Low Set Point -2 pH, -1500 mV 16 pH, 1500 mV

High or Low Alarm Point -2 pH, -1500 mV 16 pH, 1500 mV

Dead Band (Relay Outputs only) 0 pH, 0 mV 1.99 pH, 199 mV

Proportional Band 0 pH, 0 mV 6.99 pH, 999 mV

Minimum SPM Rate (Pulse Outputs only) 0 strokes/minute 360 strokes/min

Maximum SPM Rate (Pulse Outputs only) 0 strokes/minute 360 strokes/min

Sample Period (Relay Outputs only) 0:01 min:sec 30:00 min:sec

Time Limit (Relay Outputs only) 0:01 min:sec 59:59 min:sec (enabled)

Hold Time (Probe Wash) 0 seconds 99 seconds

On Time (Probe Wash) 1 second 99 seconds

4-20 mA 1 and 2 Menus 4 & 20 mA Settings -2 pH, -1500 mV 16 pH, 1500 mV

Access Code Menu New Value 0 9999

Datalog Menu (Optional)

Config Menu (Optional)

Upgrade Menu

*Note: The Alarm relay is non-programmable. Refer to the Main Menu diagram for the list of error conditions

that trigger the alarm relay.

Days Between Calibration 0 days (no reminder) 59 days

No variables

0=unlimited (disabled)

No variables

No variables

No variables

3

3.0 UNPACKING & INSTALLATION

3.1 Unpacking the unit

Inspect the contents of the carton. Please notify the carrier immediately if there are any signs of damage

to the controller or its parts. Contact your distributor if any of the parts are missing. The carton should

contain: a WPH/WDP series controller and instruction manual. Any options or accessories will be

incorporated as ordered.

3.2 Mounting the electronic enclosure

The WPH/WDP series controller is supplied with mounting holes on the enclosure. It should be wall

mounted with the display at eye level, on a vibration-free surface, utilizing all four mounting holes for

maximum stability. Use M6 (1/4" diameter) fasteners that are appropriate for the substrate material of

the wall. The enclosure is NEMA 4X rated. The maximum operating ambient temperature is 122°F

(50°C); this should be considered if installation is in a high temperature location. The enclosure requires

the following clearances:

Top: 2" (50 mm)

Left: 8" (203 mm)

Right: 4" (102 mm)

Bottom: 7" (178 mm)

3.3 Installation

Once the enclosure is mounted, the metering pumps or other control devices may be located at any

distance from the controller. The electrode, once amplified, may be placed up to 1000 feet from the

controller. Shielded cable with twisted pairs is required. Always route AC voltage wiring in conduit that

is separated by 6 inches from low voltage DC signal lines (such as the electrode signal).

Electrode Installation

The WPH/WDP controllers are designed to work with most AMPLIFIED pH, ORP or ISE electrodes.

When in doubt, follow the electrode manufacturer's instructions for installation.

If you have ordered your controller with an external preamplifier pre-wired to the controller, simply

attach the electrode to the BNC connector on the preamplifier. If you are using automatic temperature

compensation, wire the ATC element to the preamplifier as shown in figure 3.

If you have ordered the external preamplifier separately, see figure 3 for wiring instructions.

NOTE: The cable between the electrode and the preamplifier is carrying an extremely sensitive high

impedance voltage signal. Never cut, splice or otherwise destroy the integrity of the cable or unstable

readings and susceptibility to electrical noise will result.

Instructions for physically mounting the electrode into the process solution will vary greatly with the

type of electrode and circumstances involved in your application. Here are some general guidelines to

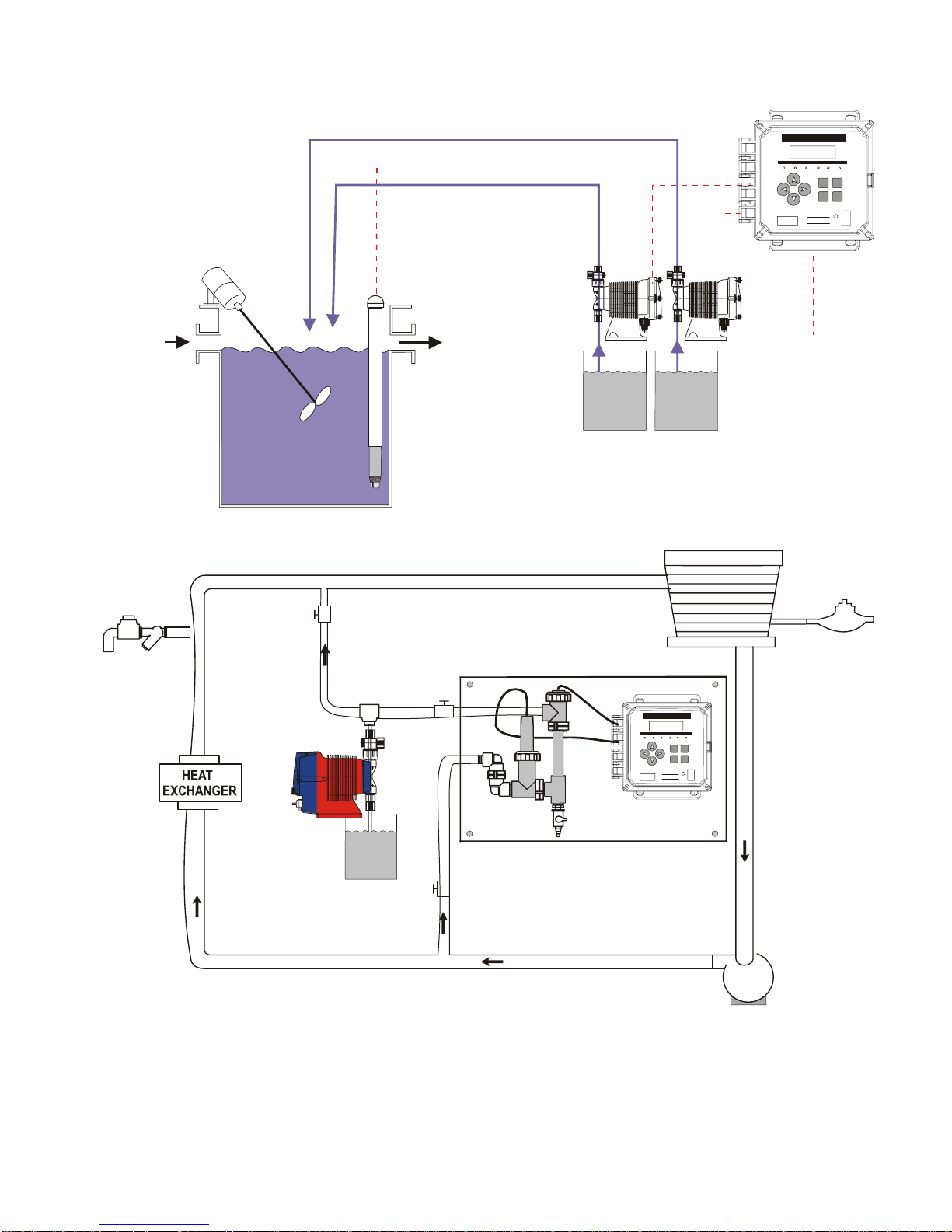

assist you. Refer to figure 1, Typical Installation.

The electrode should be installed such that the measuring surfaces will always stay wet. Many

electrodes have to be installed vertically, with the measuring surfaces pointing down. Follow the

manufacturer's recommendations if this is the case. If the electrode dries out, a slow response and short

life will result.

4

For submersion applications, mount the electrode below the minimum solution level. If the tank will be

completely emptied, plan on removing the electrode and storing it in tap water (NOT DI water) or pH 4

buffer solution while the tank is empty. If this is not desirable, a recirculation loop may be installed

with the electrode mounted in-line. The WEL electrode cable is not waterproof and must be protected

from moisture by connecting a pipe to the top of the electrode housing. The opposite end of the pipe

should also be protected from moisture using a cable gland. When submerging the electrode, make sure

the cable is protected by a length of pipe, sealed at the top using a cable gland.

For in-line applications, where the electrode is installed in a pipe, the electrode should be placed on the

discharge side of the pump (under positive pressure). A "U" trap should be included so that if flow

stops, the electrode is still immersed in the solution. If the flow through the pipe can not be shut down

for cleaning and calibrating the electrode, install the electrode in a by-pass line with isolation valves to

allow for electrode removal. The electrode should be installed in an area where there is good solution

movement and where it will respond rapidly to chemical additions. The placement of the electrode

relative to the placement of chemical replenishment, along with the quality of the mixing and

replenishment flow rate, is critical to accurate control.

IMPORTANT: To avoid cracking the female pipe threads on the supplied plumbing parts, use no more

than 3 wraps of Teflon tape and thread in the pipe FINGER tight plus 1/2 turn! Do not use pipe dope to

seal the threads of the flow switch because the clear plastic will crack!

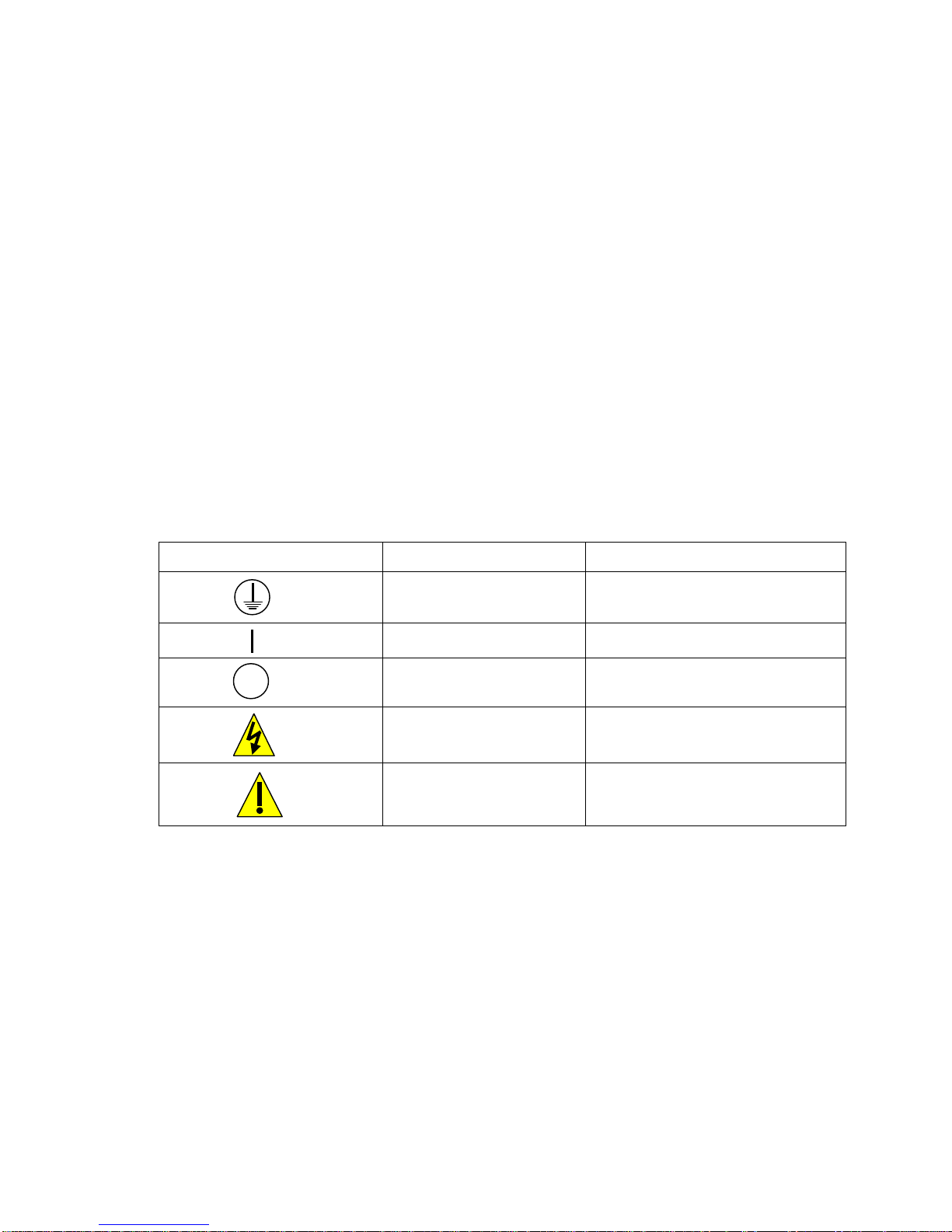

3.4 Icon Definitions

Symbol Publication Description

IEC 417, No.5019 Protective Conductor Terminal

IEC 417, No. 5007 On (Supply)

IEC 417, No. 5008 Off (Supply)

ISO 3864, No. B.3.6 Caution, risk of electric shock

ISO 3864, No. B.3.1 Caution

5

pH/ORP Controller

W A L C H E M

SOLENOID

VALVE

SUBMERSION

ELECTRODE

pH

PROBE

FLOW OUTFLOW IN

ACID

BASE

AC POWER

COOLING TOWER

WATER

METER

Flow

switch

Flow Switch

pH/ORP Controller

W A L C H E M

Installation with In-line electrode

pH

pH

Electrode

Electrode

Figure 1 Typical Installation

6

CIRCULATING

PUMP

3.5 Electrical installation

C

)

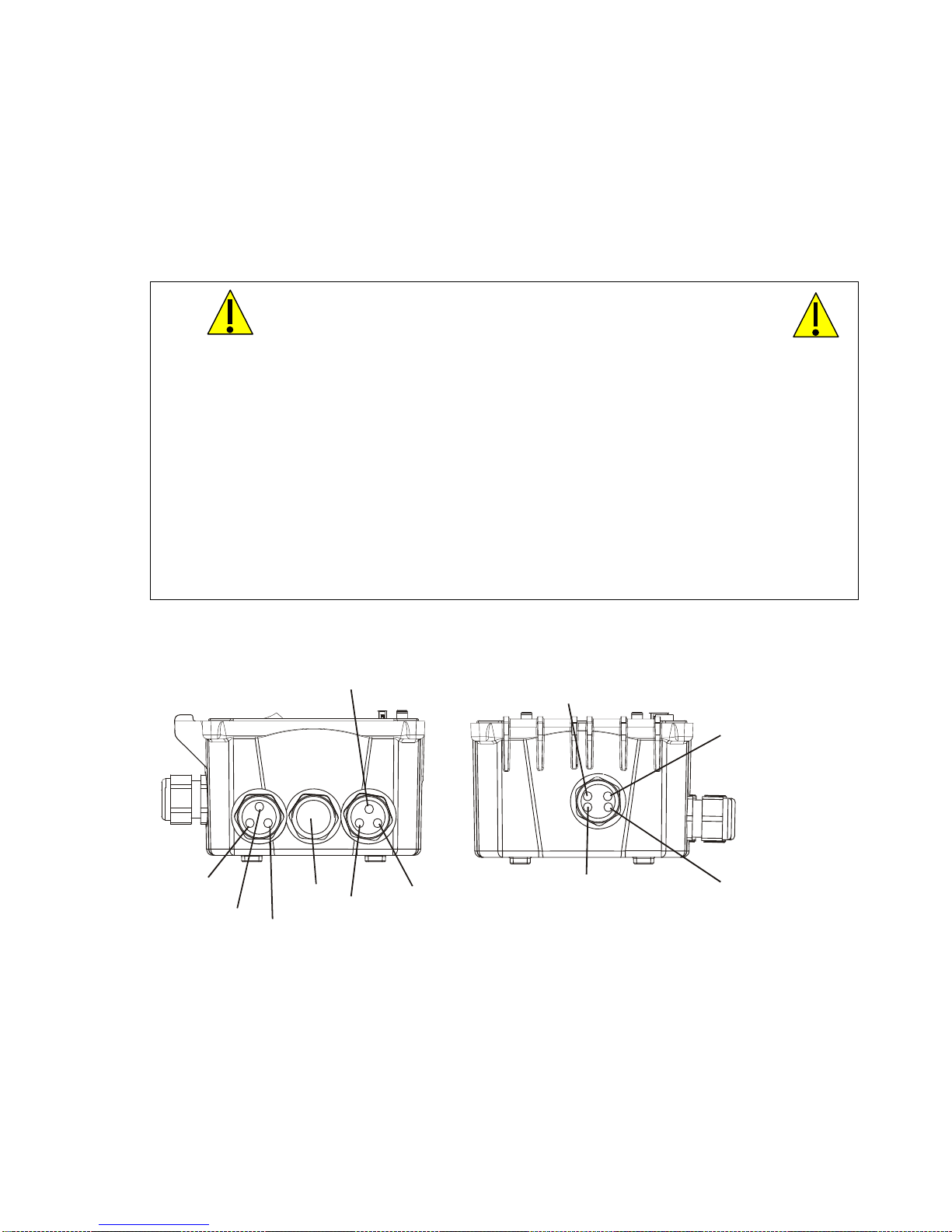

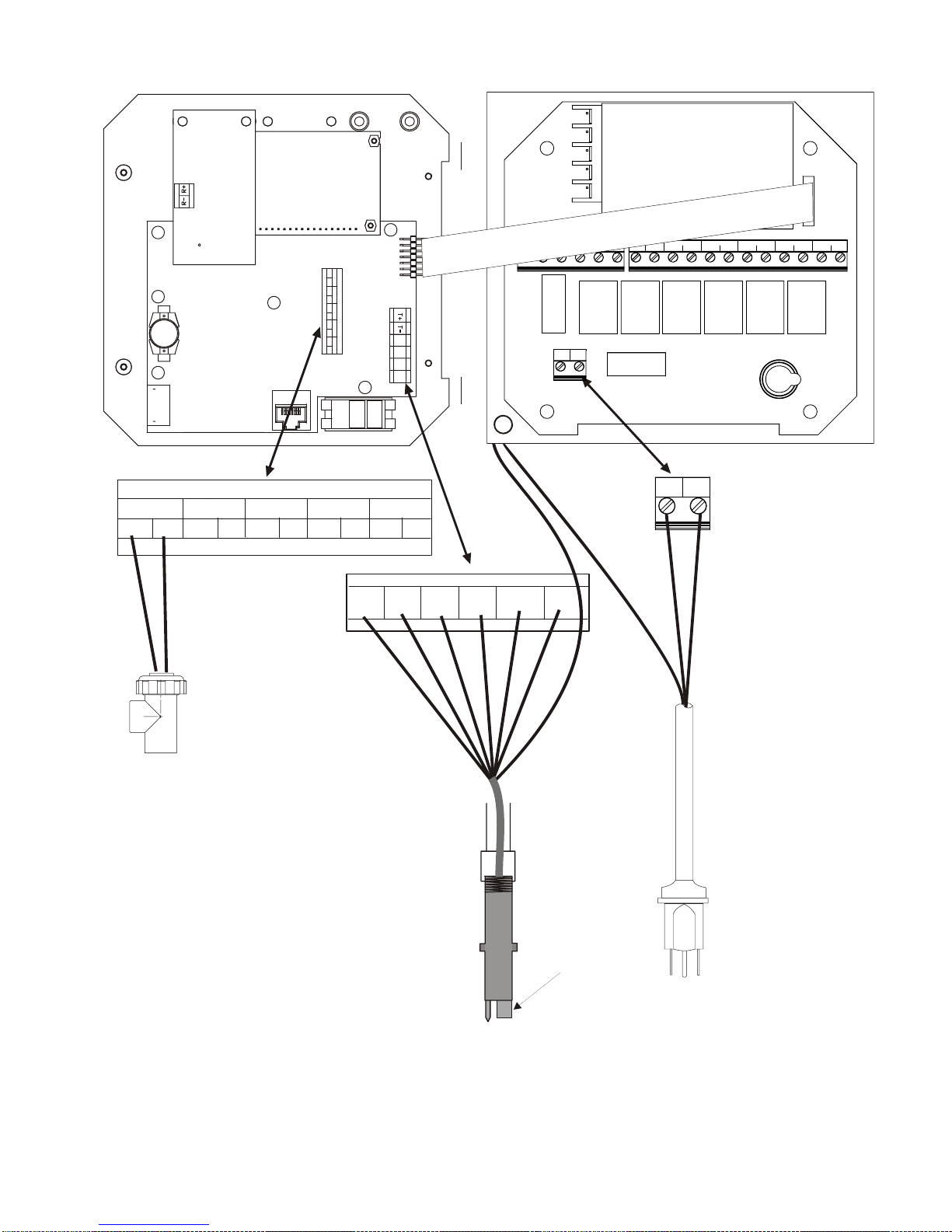

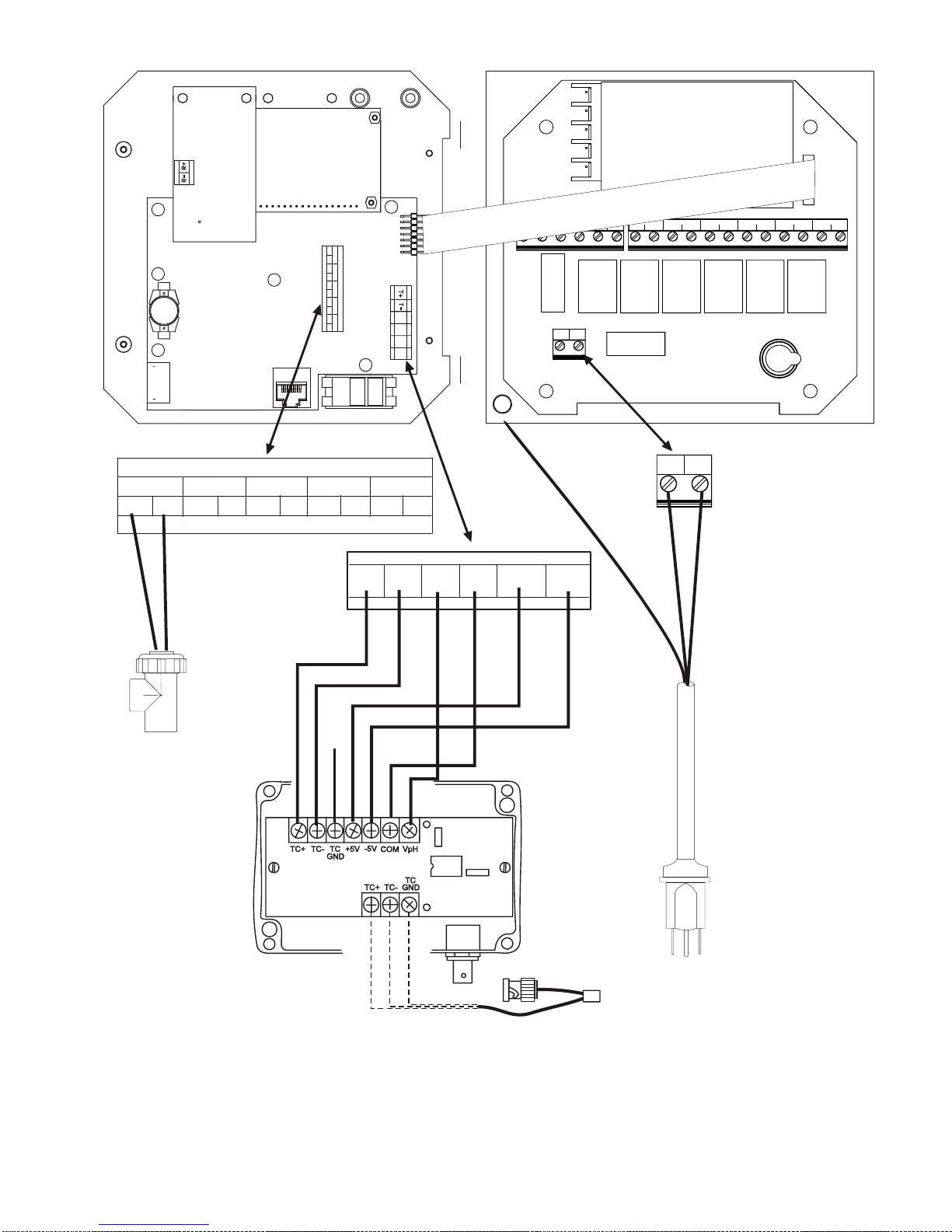

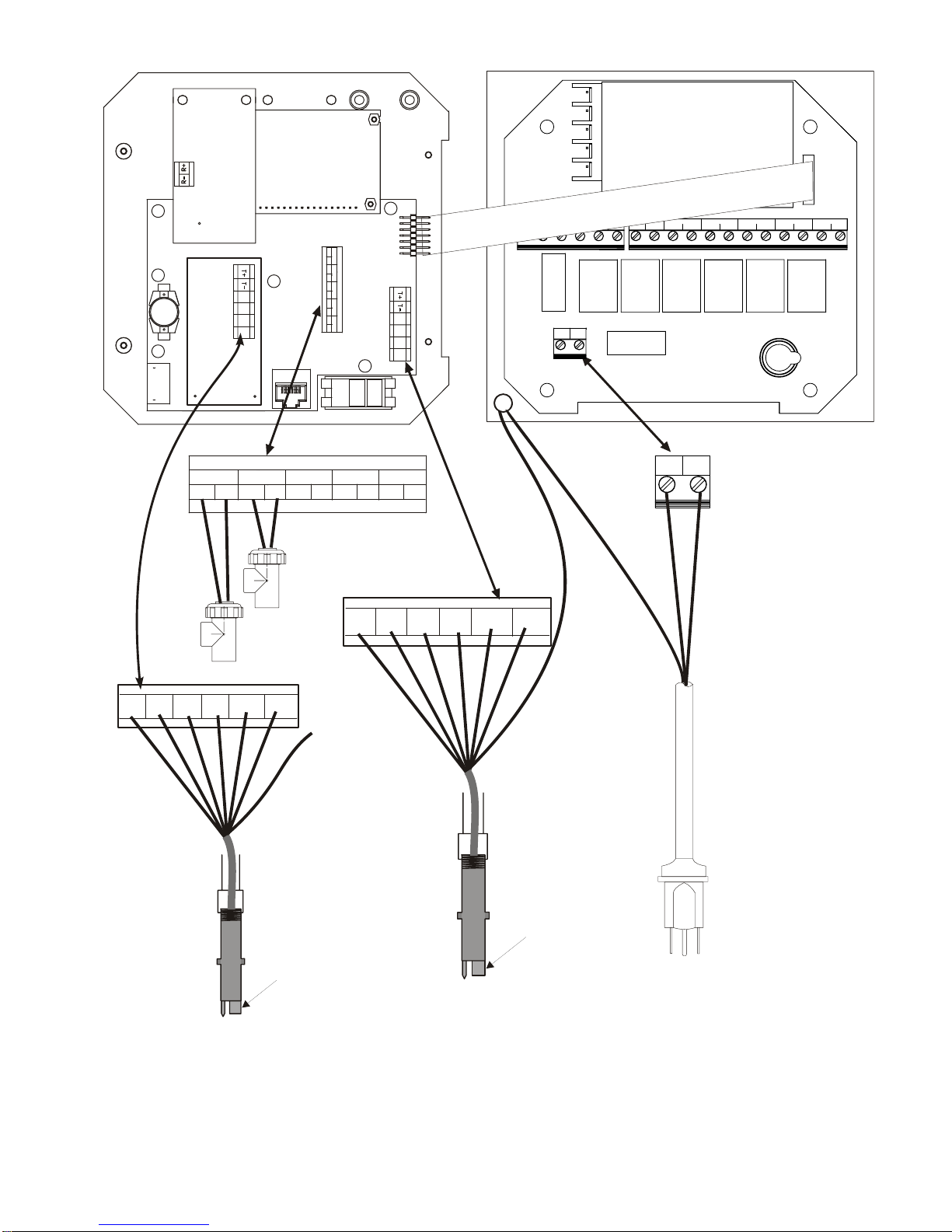

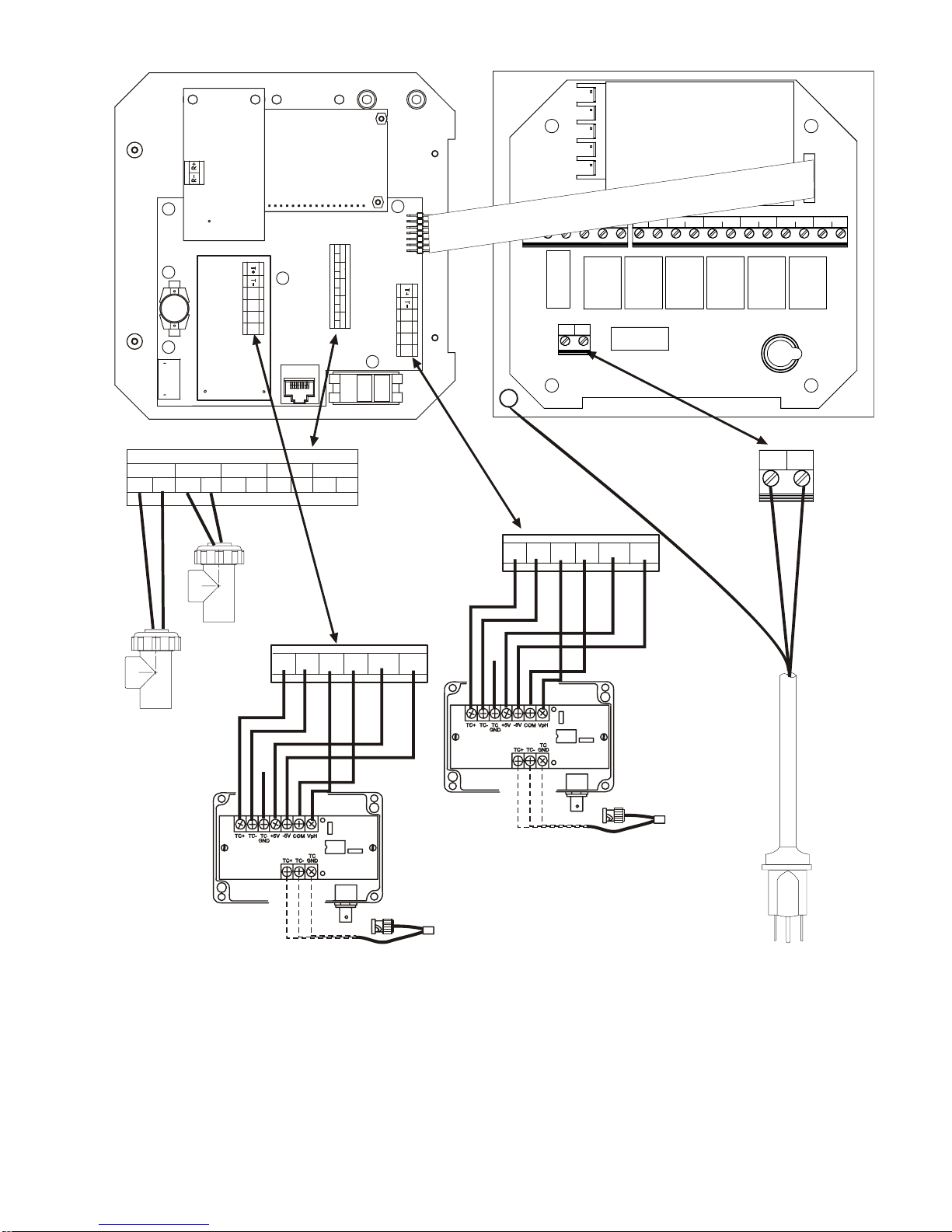

The various standard wiring options are shown in figure 2. Your WPH series controller will arrive from

the factory prewired or ready for hardwiring. Depending on your configuration of controller options,

you may be required to hardwire some or all of the input/output devices. Refer to figures 3 and 4 for

circuit board layout and wiring.

Note: when wiring the optional 4-20 mA output or a remote interlock switch, it is advisable to use

stranded, twisted, shield pair wire between 22-26 AWG. Shield should be terminated at the controller

ground stud (see figures 3 and 4).

1. There are live circuits inside the controller even when the power switch on the front panel is in

the OFF position! The front panel must never be opened before power to the controller is

REMOVED!

If your controller is prewired, it is supplied with a 8 foot, 18 AWG power cord with USA

style plug. A tool (#1 Phillips driver) is required to open the front panel.

2. When mounting the controller, make sure there is clear access to the disconnecting device!

3. The electrical installation of the controller must be done by trained personnel only and

conform to all applicable National, State and Local codes!

4. Proper grounding of this product is required. Any attempt to bypass the grounding will

compromise the safety of persons and property.

5. Operating this product in a manner not specified by Walchem may impair the protection

provided by the equipment.

CAUTION

POWER

CTRL 1

TRL 2

ALARM

PLUG

CTRL 3

CTRL 4

Figure 2a WPH410 Conduit Wiring

4-20mA #2

(OPTIONAL)

pH/ORP

SENSOR

4-20mA #1

(OPTIONAL

FLOW SWITCH

(OPTIONAL)

7

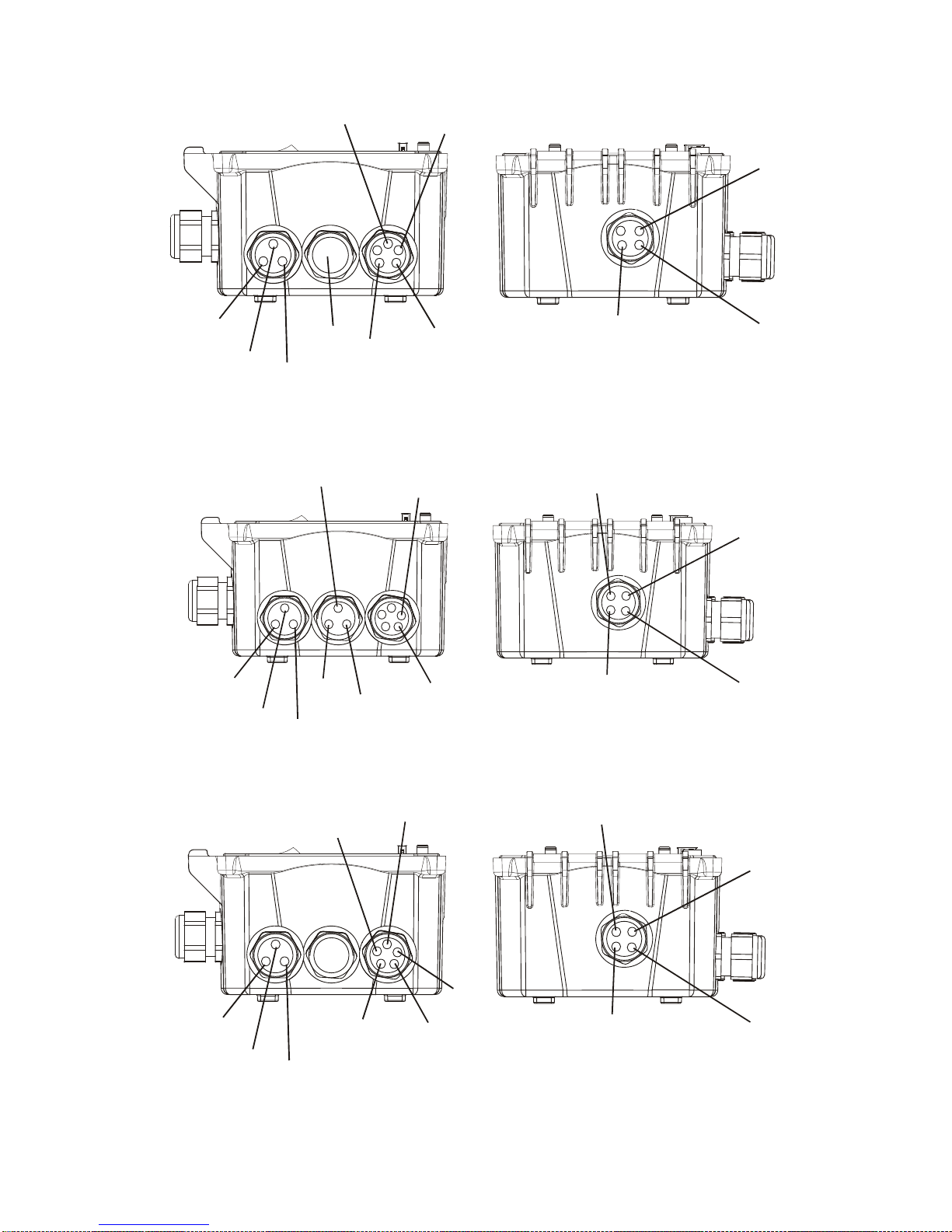

1

1

4-20mA #1

(OPTIONAL)

4-20mA #2

(OPTIONAL)

pH/ORP

SENSOR

POWER

CTRL 3

CTRL 4

PLUG

CTRL 2

CTRL 1

ALARM

FLOW SWITCH

(OPTIONAL)

Figure 2b WPH420 Conduit Wiring

CTRL 4

4-20mA 1

FLOW SWITCH 2

pH/ORP

POWER

POWER

CTRL 3

CTRL 1

CTRL 2

CTRL 4

CTRL 3

ALARM

PLUG

FLOW

ALARM

4-20mA 2

SWITCH 1

Figure 2c WDP410 Conduit Wiring

FLOW SWITCH 2

FLOW

SWITCH 1

CTRL 2

4-20mA 1

4-20mA 2

CTRL 1

Figure 2d WDP420 Conduit Wiring

pH/ORP 2

pH/ORP

pH/ORP 2

8

POWER

ALARM

PLUG

CTRL 2

4-20mA 1

CTRL 1

4-20mA 2

FLOW SWITCH 2

pH/ORP 1

FLOW

SWITCH 1

pH/ORP 2

CTRL 3

CTRL 4

Figure 2e WDP440 Conduit Wiring

9

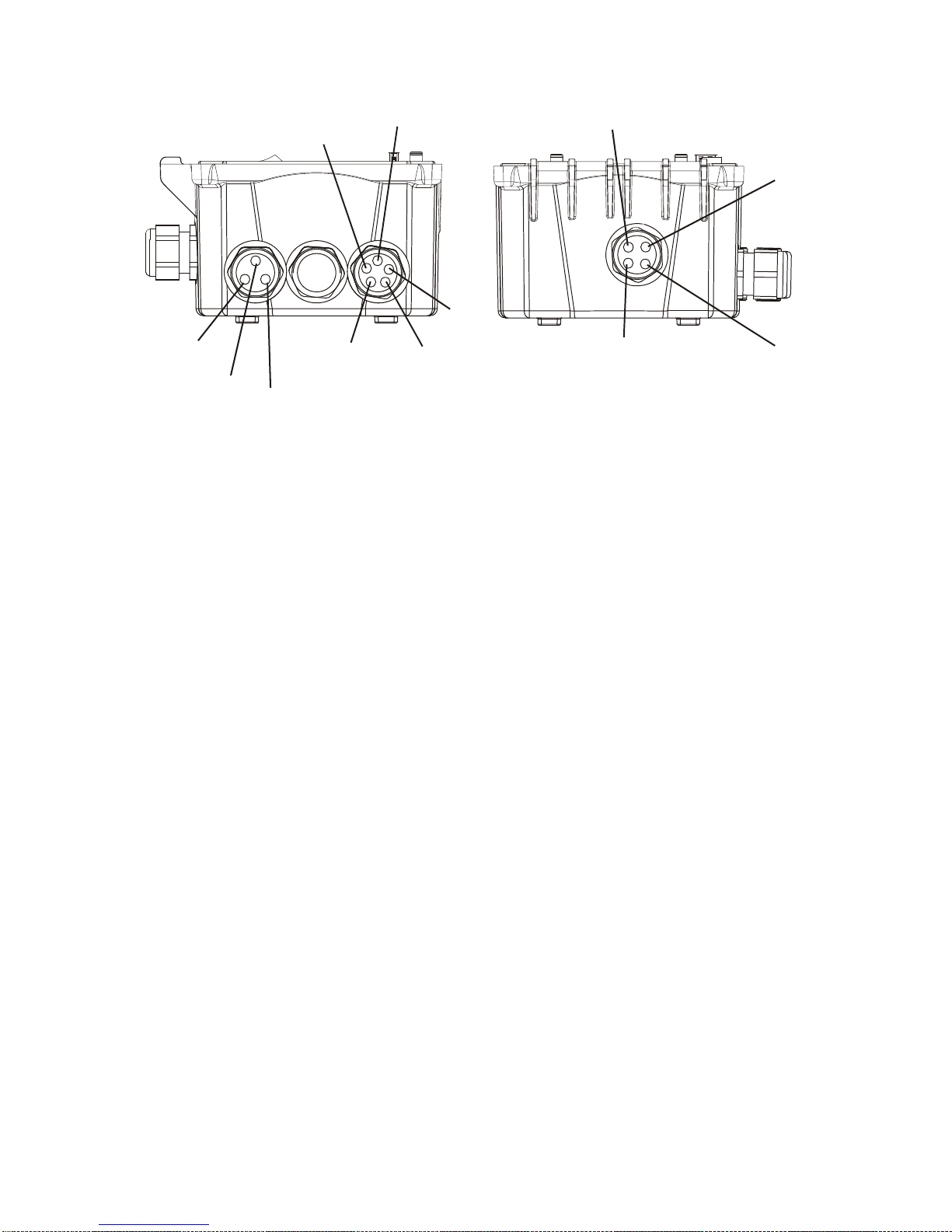

DIG IN 1

IN-

IN+

DIG IN 2

IN-

IN+

DIG IN 3

IN+ IN-

IN+

DIG IN 1

IN-

DIG IN 2

IN+

ININ+ IN-

DIG IN 3

IN+ IN-

DIG IN 4

IN+ IN -

DIG IN 5

DIG IN 4

IN+ IN-

IN+ IN-

+5V

-5V

DIG IN 5

IN+ IN-

T-T+

G

R

E

E

N

W

H

I

T

E

/

GROUND

STUD

O

R

N

G

R

N

L2 L2 L2 L2 L2 L2

+5V

W

B

H

L

I

U

T

E

/

O

R

N

E

/

B

L

U

FEED

N.O.N.C.

L2/N

BOI 1

N.C.

N.O. N.C. N.O.

WHT 120V

BLU 240V

BIO 2

ALARM

N.O.

N.O.

N.C.

BLEED

N.O. N.C.

N.C.

L1 L2/N

G

R

G

N

R

N

1

2

/

Y

0

E

V

L

2

4

0

V

-5VIN+ IN-

W

H

I

T

L1

B

B

L

R

K

N

1

2

2

4

0

0

V

V

Contact Closure:

Polarity not critical

Interlock Function

Figure 3a WPH Inputs using WEL pH/ORP Electrode Housings

WEL Electrode

Diffamp Housing

(102581, 102606,

102582,102607,

102758, 102759)

10

SHIELD

pH/ORP electrode

cartridge

Power Supply

(115 VAC or 230 VAC)

L2 L2 L2 L2 L2 L2

IN+

DIG IN 1

IN-

DIG IN 2

IN+

IN-

IN+ IN-

DIG IN 3

IN+ IN-

DIG IN 4

IN+ IN-

DIG IN 5

IN+

IN+5V

-5V

L1 L2/N

BLEED

N.O. N.C.

N.C.

BOI 1

FEED

N.O.N.C.

N.C.

BIO 2

N.O. N.C. N.O.

ALARM

N.O.

N.O.

N.C.

GROUND

STUD

IN-

DIG IN 2

IN+

DIG IN 1

IN+

Contact Closure:

Polarity not critical

Interlock Function

IN-

DIG IN 3

IN+ IN-

DIG IN 4

IN+ IN-

to ground

DIG IN 5

IN+ IN-

T-T+

+5V

G

R

G

N

R

N

1

/

2

Y

0

E

V

L

2

4

0

V

-5VIN+ IN-

B

R

N

2

4

0

V

L1 L2/N

B

L

K

1

2

0

V

WHT 120V

BLU 240V

EXTERNAL

PREAMPLIFIER

(190783)

Figure 3b WPH Inputs using pH/ORP Electrode/External Preamplifiers

GROUND

OPTIONAL TEMPERATURE

COMPENSATION (pH ONLY)

Power Supply

(115 VAC or 230 VAC)

11

L2 L2 L2 L2 L2 L2

IN+

DIG IN 1

IN-

DIG IN 2

IN+

ININ+ IN-

IN+

IN+5V

-5V

DIG IN 3

IN+ IN-

DIG IN 4

IN+ IN-

DIG IN 5

IN+

IN+5V

-5V

L2/N

L1

BLEED

N.O. N.C.

N.C.

BOI 1

FEED

N.O.N.C.

N.C.

BIO 2

N.O. N.C. N.O .

ALARM

N.O.

N.O.

N.C.

GROUND

STUD

SYSTEM A

SYSTEM B

T-T+

G

W

R

H

E

I

E

T

N

E

/

G

R

WEL Electrode

Diffamp Housing

(102581, 102606,

102582,102607,

102758, 102759)

DIG IN 1

IN+

O

R

N

N

DIG IN 2

IN-

IN-

IN+

Contact Closure:

Polarity not critical

Interlock Function

+5V

W

B

H

L

H

I

U

T

I

T

E

E

/

O

/

B

R

L

N

U

SHIELD

pH/ORP electrode

cartridge

DIG IN 3

IN+ IN-

SYSTEM B

-5VIN+ IN-

W

DIG IN 4

IN+ IN-

TO GRND

DIG IN 5

IN+ IN-

SYSTEM A

T-T+

G

W

R

H

E

I

E

T

N

E

/

G

R

WEL Electrode

Diffamp Housing

(102581, 102606,

102582,102607,

102758, 102759)

G

R

G

N

R

N

1

2

/

Y

0

E

V

L

2

4

0

V

+5V

-5VIN+ IN-

W

O

R

N

N

B

H

I

T

E

/

O

R

N

W

L

H

U

I

T

E

/

B

L

U

L2/N

L1

B

B

L

R

N

2

4

0

V

K

1

2

0

WHT 120V

BLU 240V

V

SHIELD

pH/ORP electrode

cartridge

Power Supply

(115 VAC or 230 VAC)

Figure 3c WDP Inputs using WEL pH/ORP Electrode Housings

12

DIG IN 1

IN-

IN+

DIG IN 2

IN-

IN+

SYSTEM B

IN+

IN+5V

-5V

DIG IN 3

DIG IN 4

IN+ IN-

IN+ IN-

Contact Closure:

Polarity not critical

Interlock Function

IN+ IN-

T-T+

IN+

DIG IN 1

IN-

DIG IN 2

IN+

ININ+ IN-

DIG IN 3

IN+ IN-

DIG IN 4

IN+ IN-

DIG IN 5

DIG IN 5

SYSTEM B

+5V

BLEED

L2 L2 L2 L2 L2 L2

IN+

IN+5V

-5V

L1 L2/N

FEED

N.C.

N.O. N.C.

N.O.N.C.

BOI 1

N.C.

BIO 2

N.O. N.C. N.O.

ALARM

N.C.

N.O.

N.O.

GROUND

STUD

G

R

G

N

R

1

N

2

/

0

Y

V

E

L

2

4

0

V

SYSTEM A

+5V

T-T+

to ground

-5VIN+ IN-

B

R

N

2

4

0

V

L1 L2/N

B

L

K

1

2

0

V

WHT 120V

BLU 240V

-5VIN+ IN-

Contact Closure:

Polarity not critical

Interlock Function

SYSTEM A

to ground

EXTERNAL

PREAMPLIFIER

(190783)

GROUND

OPTIONAL TEMPERATURE

COMPENSATION (pH ONLY)

EXTERNAL

PREAMPLIFIER

(190783)

GROUND

OPTIONAL TEMPERATURE

COMPENSATION (pH ONLY)

Power Supply

(115 VAC or 230 VAC)

Figure 3d WDP Inputs using pH/ORP Electrode/External Preamplifiers

13

Loading...

Loading...