Page 1

W

W A L C H E M

IWAKI America Inc.

ebMaster®ONE Controllers

Web

Master®ONE

Water Treatment Controller

Instruction Manual

Five Boynton Road Hopping Brook Park Holliston, MA 01746 USA

TEL: 508-429-1110 FAX: 508-429-7433 WEB: www.walchem.com

Page 2

Notice

© 2014 WALCHEM, Iwaki America Inc. (hereinafter “Walchem”)

Five Boynton Road, Holliston, MA 01746 USA

(508) 429-1110

All Rights Reserved

Printed in USA

Proprietary Material

The information and descriptions contained herein are the property of WALCHEM. Such

information and descriptions may not be copied or reproduced by any means, or

disseminated or distributed without the express prior written permission of WALCHEM,

Five Boynton Road, Holliston, MA 01746.

Statement of Limited Warranty

WALCHEM warrants equipment of its manufacture, and bearing its identification to be

free from defects in workmanship and material for a period of 24 months for electronics

and 12 months for mechanical parts and electrodes from date of delivery from the factory

or authorized distributor under normal use and service and otherwise when such

equipment is used in accordance with instructions furnished by WALCHEM and for the

purposes disclosed in writing a the time of purchase, if any. WALCHEM’s liability under

this warranty shall be limited to replacement or repair, F.O.B. Holliston, MA U.S.A. of

any defective equipment or part which, having been returned to WALCHEM,

transportation charges prepaid, has been inspected and determined by WALCHEM to be

defective. Replacement elastomeric parts and glass components are expendable and are

not covered by any warranty.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EITHER EXPRESS OR

IMPLIED, AS TO DESCRIPTION, QUALITY, MERCHANTABILITY, and FITNESS FOR

ANY PARTICULAR PURPOSE OR USE, OR ANY OTHER MATTER.

180272 Rev AC

Jan 2014

Page 3

TABLE OF CONTENTS

INTRODUCTION ........................................................................................................................................... 1

1.0

2.0 SPECIFICATIONS ......................................................................................................................................... 1

2.1 .....MEASUREMENT PERFORMANCE ..................................................................................................................... 1

2.2.....ELECTRICAL ................................................................................................................................................... 2

2.3.....MECHANICAL ................................................................................................................................................. 3

2.4.....VARIABLES AND THEIR LIMITS ....................................................................................................................... 5

3.0 UNPACKING & INSTALLATION ............................................................................................................. 10

3.1 .....UNPACKING THE UNIT .................................................................................................................................. 10

3.2 .....MOUNTING THE ELECTRONIC ENCLOSURE ................................................................................................... 10

3.3.....INSTALLATION.............................................................................................................................................. 10

3.4.....ICON DEFINITIONS ........................................................................................................................................ 14

3.5 .....ELECTRICAL INSTALLATION ......................................................................................................................... 18

4.0 FUNCTION OVERVIEW ............................................................................................................................ 27

4.1 .....FRONT PANEL ............................................................................................................................................... 27

4.2.....DISPLAY ....................................................................................................................................................... 27

4.3..... KEYPAD ....................................................................................................................................................... 28

4.4 .....ACCESS CODES ............................................................................................................................................. 28

4.5.....INITIAL STARTUP .......................................................................................................................................... 28

4.6 .....COMMUNICATING WITH THE WEBMASTERONE .......................................................................................... 30

4.7.....STARTUP ...................................................................................................................................................... 36

4.8 .....SHUT DOWN ................................................................................................................................................. 36

5.0 OPERATION – USING LOCAL DISPLAY AND KEYPAD .................................................................... 36

5.1 .....INPUT SUMMARY .......................................................................................................................................... 36

5.2 .....INDICES ........................................................................................................................................................ 37

5.3 .....OUTPUT SUMMARY ...................................................................................................................................... 37

5.4.....ALARMS ....................................................................................................................................................... 37

5.5 .....CALIBRATION ............................................................................................................................................... 37

5.7 .....SET POINTS .................................................................................................................................................. 44

5.8 .....COMMUNICATION ......................................................................................................................................... 48

5.9 .....ACCESS CODES ............................................................................................................................................. 50

5.10...SOFTWARE UPGRADE ................................................................................................................................... 50

5.11...COPY TO USB DISK ...................................................................................................................................... 50

5.12...FEATURE ACTIVATIONS ............................................................................................................................... 51

5.13...CONTROLLER RESTART ................................................................................................................................ 51

6.0 OPERATION – USING PC .......................................................................................................................... 51

6.1.....MENU SELECTION LINKS .............................................................................................................................. 52

6.2.....START UP MENU ........................................................................................................................................... 52

6.3 .....SYSTEM SUMMARY MENU ........................................................................................................................... 57

6.4 .....SENSOR MENU - CONDUCTIVITY INPUT ........................................................................................................ 58

6.5 .....SENSOR MENU - PH INPUT ........................................................................................................................... 61

6.6.....SENSOR MENU - ORP INPUT ........................................................................................................................ 65

6.7.....SENSOR MENU – CHLORINE, CHLORINE DIOXIDE INPUTS ............................................................................ 68

6.8 .....LEVEL (4-20 MA) INPUT MENU .................................................................................................................... 72

6.9.....FLOW METER (4-20 MA) INPUT MENU ......................................................................................................... 74

6.10...GENERIC (4-20 MA) INPUT MENU ................................................................................................................ 75

6.11...4-20 MA INPUT MENU .................................................................................................................................. 77

6.12...FLOW METER (DIGITAL) INPUT MENU ......................................................................................................... 79

6.13...INTERLOCK MENU ........................................................................................................................................ 81

Page 4

6.14...FEED VERIFICATION INPUT MENU ................................................................................................................ 81

6.15...LEVEL SWITCHES (DIGITAL) INPUT MENU ................................................................................................... 82

6.16...GENERIC (DIGITAL) INPUTS MENU ............................................................................................................... 82

6.17...COUNTER INPUTS MENU .............................................................................................................................. 83

6.18... DIGITAL INPUTS MENU ................................................................................................................................ 84

6.19... RELAY (1 – 8) OUTPUT MENUS – ON/OFF SET POINT TYPES ....................................................................... 84

6.20...RELAY (1-8) OUTPUT MENUS – TIME PROPORTIONAL TYPES ...................................................................... 87

6.21...RELAY (1 – 8) OUTPUT MENUS – CYCLES OF CONCENTRATION TYPES ........................................................ 89

6.22...RELAY (1 – 8) OUTPUT MENUS – INTERMITTENT (FIXED BLOWDOWN TIME) TYPES ................................... 92

6.23...RELAY (1 – 8) OUTPUT MENUS – INTERMITTENT (PROPORTIONAL BLOWDOWN TIME) TYPES ..................... 94

6.24...RELAY (1 - 8) OUTPUT MENUS – FLOW BASED FEED TYPE .......................................................................... 96

6.25...RELAY (1-8) OUTPUT MENUS – FEED WITH ANOTHER RELAY TYPES ......................................................... 99

6.26...RELAY (1 – 8) OUTPUT MENUS – FEED AFTER ANOTHER RELAY (%) TYPES ............................................. 101

6.27...RELAY (1-8) OUTPUT MENUS – FEED AFTER ANOTHER RELAY (FIXED TIME) .......................................... 103

6.28...RELAY (1 – 8) OUTPUT MENUS – FEED AS % OF TIME TYPES ..................................................................... 105

6.29...RELAY (1 – 8) OUTPUT MENUS – BIOCIDE TIMER BASED TYPES ............................................................... 107

6.30...RELAY (1 – 8) OUTPUT MENUS – SPIKE SET POINT TYPES ......................................................................... 110

6.31...RELAY (1 – 8) OUTPUT MENUS – DISPERSANT TYPES ................................................................................ 112

6.32...RELAY (1-8) OUTPUT MENUS - BLEED VOLUME BASED ON MAKEUP VOLUME ......................................... 115

6.33...RELAY (1- 8) OUTPUT MENU – ALARM TYPE ............................................................................................. 117

6.34...RELAY (1-8) OUTPUT MENUS – ACTIVATE ON A DI ................................................................................... 119

6.35...RELAY (1 - 8) OUTPUT MENUS – TARGET PPM FEED TYPE ....................................................................... 121

6.36...RELAY (1 - 8) OUTPUT MENUS – TARGET PPM FEED WITH FEED VERIFICATION TYPE ............................. 124

6.37...ANALOG OUTPUT (1-4) MENU – RETRANSMIT MODE ................................................................................ 127

6.38...ANALOG OUTPUT MENUS (1-4) - PROPORTIONAL FEED MODE .................................................................. 128

6.39...REMOTE ALARMING ................................................................................................................................... 131

6.40...LSI/RSI ...................................................................................................................................................... 132

6.41...VTOUCH CONFIG ....................................................................................................................................... 133

6.42...SYSTEM STATUS AUTO-REPORTING ........................................................................................................... 134

6.43...DATALOG AUTO REPORT ........................................................................................................................... 135

6.44...MANUAL DATALOG .................................................................................................................................... 137

6.45...GRAPHING/TRENDING ................................................................................................................................ 140

6.46...COMMUNICATIONS MENU .......................................................................................................................... 140

6.47...ADVANCED COMMS ................................................................................................................................... 145

6.48... CONFIGURATION FILE MENU ..................................................................................................................... 146

6.49...NOTEPAD ................................................................................................................................................... 147

6.50...ACCESS CODES ........................................................................................................................................... 147

6.51...SOFTWARE UPGRADES (ONLY APPEARS IF A NEWER REVISION OF SOFTWARE IS AVAILABLE) .................... 147

6.52...SUB-NETWORK .......................................................................................................................................... 148

7.0 MAINTENANCE ........................................................................................................................................ 149

7.1.....FLOW SWITCH CLEANING .......................................................................................................................... 149

7.2.....CONDUCTIVITY SENSOR CLEANING AND CALIBRATION ............................................................................. 151

7.3.....PH ELECTRODE CLEANING AND CALIBRATION .......................................................................................... 152

7.4.....ORP ELECTRODE CLEANING AND CALIBRATION ....................................................................................... 152

7.5.....DISINFECTION SENSOR CLEANING AND CALIBRATION ............................................................................... 153

7.6.....REPLACING THE FUSES ............................................................................................................................... 153

8.0 TROUBLESHOOTING .............................................................................................................................. 154

8.1.....ERROR MESSAGES ................................................................................................................................ 154

8.2.....PROBLEMS THAT DON’T GENERATE AN ERROR MESSAGE ........................................................ 171

8.3 .....CONNECTION PROBLEMS ................................................................................................................... 173

9.0 SERVICE POLICY ..................................................................................................................................... 174

Page 5

1.0 INTRODUCTION

The WebMasterONE series controller is multi-functional, but not all of the features mentioned are

necessarily present in the controller you have received. All features can be added in the field. The

controller may be configured to control a cooling tower, or a boiler, or both.

Standard features include a direct sensor measurement of either conductivity, pH, or ORP; six

digital inputs (for flow switch, metering pump flow feedback, counter, or other use), eight relay

outputs, and both Ethernet and USB connections to a computer.

Optional features include:

Up to three additional pH, ORP, chlorine, chlorine dioxide and/or conductivity measurements.

Up to six digital inputs (for level switch, metering pump flow feedback, counter, or other use).

Up to eight 4-20 mA inputs (for drum level, flow meters, or practically any other parameter).

Up to four 4-20 mA outputs (for retransmission of the conductivity, pH, ORP, Cl

temperature or any 4-20 mA input signals).

A modem card (for remote communications)

The controller can log data and events, automatically generate reports on a periodic basis at a

programmable frequency, and if equipped with a modem card, dial out in the event of an alarm

condition. The alarm notification may be via phone to a pager, or email.

Our revolutionary digital communications package allows you to change set points, manually

activate or deactivate pumps and valves, upgrade software, receive reports and alarms, from any

PC that has Internet access. No proprietary software needs to be installed on the PC, only a web

browser.

, ClO2,

2

2.0 SPECIFICATIONS

2.1 Measurement Performance

Contacting Conductivity pH

Range 0-10,000 µS/cm Range -2 to 16 pH units

Resolution 1 µS/cm Resolution 0.01 pH units

Calibration ± 50% of raw reading; Calibration single or dual point

scalable to read in ppm

mV Temperature

Range ± 1400 mV Range 32 to 392°F (0 to 200°C)

Resolution 1 mV Resolution 1°F (1°C)

Calibration single or dual point Calibration single point; degrees C or F

Chlorine Chlorine Dioxide

Range 0 to 8 mg/l Range 0 to 10 mg/l

Resolution 0.01 mg/l Resolution 0.01 mg/l

Calibration single or dual point Calibration single or dual point

Electrodeless Conductivity

Ranges 50 to 1000 µS/cm, 1-10 mS/cm, 10-100 mS/cm, or 100-1000 mS/cm

Resolution 1 µS/cm or 1 mS/cm (range dependent)

Calibration single or dual point; scalable to read in ppm or % concentration

1

Page 6

2.2 Electrical

Inputs

Input power 100 – 120/220-240 VAC ±10%, 12A, 50/60 Hz Fuse 1.6A, 5 x 20mm

Input signals

State-Type Digital Inputs Electrical: Non-isolated 5 VDC with 301K ohm pull-up

Low Speed Counter-Type

Digial Inputs

High Speed Counter-Type

Digial Inputs

Analog Inputs (1-8)

(Optional)

Sensor STANDARD (1)

Signal (isolated) ±1.5V Signal (isolated) ±1.5V

Temp (isolated) 1K or 10K or 100K ohm Temp (isolated) 1K or 10K or 100K ohm

Outputs

Typical response time: <10 seconds

Devices supported: Any isolated dry contact (i.e. relay, reed switch)

Types: Interlock, Level switch, Generic input

Electrical: Non-isolated 5 VDC with 301K ohm pull-up, 0-10 Hz, 50 msec minimum

width

Devices supported: Any device with isolated open drain, open collector, transistor or

reed switch

Supported on inputs: Standard inputs A-D, Optional inputs 1-6

Types: Contacting Flowmeter, Feed Verification, Generic Counter

Electrical: Non-isolated 5 VDC with 301K ohm pull-up, 0-400 Hz, 1.25 msec

minimum width

Devices supported: Any device with isolated open drain, open collector, transistor or

reed switch

Supported on inputs: Standard inputs A-D, Optional inputs 5-6

Types: Paddlewheel Flowmeter, Generic Counter

4-20 mA, 2-wire or 3 -wire, internally powered by 24 VDC, 25 ohm input resistance,

1000 ohm maximum load. Typical response time <10 seconds

Sensor OPTIONAL (3)

STANDARD

Mechanical relays:

R1, R2, R3, and R4 relays are fused together as one group, total current for this group must not exceed 5.5A

R5, R6, R7 and R8 relays are fused together as one group, total current for this group must not exceed 5.5A.

Relays 1-8 may be dry contact or may switch line (mains) voltage, depending upon model code; refer to Figure 4. Powered

relays have both NO and NC terminals available. Only powered relays are fused.

Digital: USB

Ethernet, 10 Base T

At 115 VAC, 10 amp (resistive), 1/8 HP

At 230 VAC, 6 amp (resistive), 1/8 HP

OPTIONAL

4-20 mA (1-4): Isolated, 500 ohm max. resistive load, internally powered

Agency Approvals

Safety ANSI/UL 61010-1:2012 3rd Ed.

C22.2 No. 61010-1:2012 3rd Ed.

IEC 61010-1:2010 3rd Ed.

EN 61010-1:2010 3rd Ed.

EMC IEC 61326-1:2005

EN 61326-1:2006

Note: For EN61000-4-6, and EN 61000-4-3, the controller meets performance criteria B.

*Class A equipment: Equipment suitable for use in establishments other than domestic, and those directly connected

to a low voltage (100-240 VAC) power supply network which supplies buildings used for domestic purposes.

2

Page 7

2.3 Mechanical

Enclosure

Material: Polycarbonate

NEMA Rating: NEMA 4X

Dimensions: 10” x 12” x 5-5/8” (25.4cm x 30.5cm x 14.5cm)

Display: 64 x 128 Pixel Backlit LCD Graphics Module

Operating Ambient Temp: 32-120°F (0 to 49°C)

Storage Temp: -20 to 176°F (-29 to 80°C)

Weight 11.5lb (5.2kg)

Flow switch manifold

Pressure: 150 psi up to 100° F, 50 psi @140° F

Temperature: 32 to 140°F (0 to 60°C)

Process connections: ¾” NPTF

Wetted Materials of construction: Glass-Filled Polypropylene, PVC, FKM, Isoplast

pH Electrode

Pressure: 0 to100 psi

Temperature: 50 to158°F (10 to 70°C)

Process connections: ¾” NPTF

Wetted Materials of Construction: Glass-Filled Polypropylene, CPVC, HDPE,

FKM, Glass

ORP electrode

Pressure: 0 to100 psi

Temperature: 32 to 158°F (0 to 70°C)

Process connections: ¾” NPTF

Wetted Materials of Construction: Glass-Filled Polypropylene, CPVC, HDPE,

FKM, Platinum, Glass

Contacting conductivity electrode

Pressure: 0 to150 psi

Temperature: 32 to158°F (0 to 70°C)

Process connections: ¾” NPTF

Wetted Materials of Construction: Glass-Filled Polypropylene, Graphite, FKM

Electrodeless conductivity sensor

Pressure: 0 to150 psi

Temperature: 32 to158°F (0 to 70°C)

Process connections: ¾” NPTF

Wetted Materials of Construction: Glass-Filled Polypropylene, CPVC, FKM

Stainless steel contacting conductivity electrode

Pressure: 0-150 psi

Temperature: 32-158°F (0 to 70°C)

Process connections: ¾” NPTF

Wetted Materials of Construction: Glass-Filled Polypropylene, 316 SS, FKM

3

Page 8

Chlorine, Chlorine Dioxide sensors

Pressure: 0 to 1 atm (0 to 14.7 psi)

Temperature

Chlorine Dioxide sensors: 41 to 122°F (5 to 50°C)

Chlorine: 41 to 113°F (5 to 45°C)

Flow Cell Inlet: ¼” NPTF

Flow Cell Outlet: ¾” NPTF

Wetted Materials of Construction: PVC, Silicone or PTFE, Nylon, Isoplast, FKM

High pressure tower contacting conductivity electrode

Pressure: 0-300 psi

Temperature: 32-158°F (0 to 70°C)

Process connections: ¾” NPTM

Wetted Materials of Construction: 316 SS, PEEK

High pressure boiler contacting conductivity electrode

Pressure: 0-250 psi

Temperature: 32-401°F (0 to 205°C)

Process connections: ¾” NPTM

Wetted Materials of Construction: 316 SS, PEEK

High pressure pH electrode

Pressure: 0-300 psi

Temperature: 32-275°F (0 to 135°C)

Process connections: ¾” NPTM

Wetted Materials of Construction: Glass, Polymer, PTFE, 316 SS, FKM

High Pressure ORP electrode

Pressure: 0-300 psi

Temperature: 32-275°F (0 to 135°C)

Process connections: ¾” NPTM

Wetted Materials of Construction: Platinum, Polymer, PTFE, 316 SS, FKM

High Pressure flow switch

Pressure: 0-300 psi

Temperature: 32-158°F (0 to 70°C)

Process connections: ¾” NPTF

Wetted Materials of Construction: Carbon steel, Brass, 316SS, FKM”

4

Page 9

2.4 Variables and their Limits

All menus shown may not be available. The menus that appear on your controller will vary with

options installed and programmed.

Sensor Input Menu – if pH

Calibration Reminder 0-365 days

Alarm Limits -2 to 16

Alarm Dead Band -2 to 16

Deviation from Primary Sensor 0.01 to 18

Damping 0 to 60 seconds

Temperature Alarm Limits 23 to 302°F (-5 to 150 °C)

Sensor Input Menu – if ORP

Calibration Reminder 0-365 days

Alarm Limits -1400 to 1400 mV

Alarm Dead Band -1400 to 1400 mV

Deviation from Primary Sensor 0.01 to 2800 mV

Damping 0 to 60 seconds

Temperature Alarm Limits 23 to 190°F (-5 to 88 °C)

Sensor Input Menu – if Contacting Conductivity

Calibration Reminder 0 – 365 days

ppm Conversion Factor 0.5 – 1.0

Alarm Limits 0 to 10,000 (units defined by user)

Alarm Dead Band 0 to 30,000 (units defined by user)

Deviation from Primary Sensor 0.01 to 30,000 (units defined by user)

Damping 0 to 60 seconds

Temperature Alarm Limits 23 to 190°F (-5 to 88 °C)

Sensor Input Menu – if High Temp Contacting Conductivity

Calibration Reminder 0 – 365 days

ppm Conversion Factor 0.5 – 1.0

Alarm Limits 0 to 10,000 (units defined by user)

Alarm Dead Band 0 to 30,000 (units defined by user)

Deviation from Primary Sensor 0.01 to 30,000 (units defined by user)

Damping 0 to 60 seconds

Temperature Alarm Limits 32 – 392°F (0 to 200°C)

Sensor Input Menu – if Electrodeless Conductivity

Calibration Reminder 0 – 365 days

ppm Conversion Factor 0.5 – 1.0

Alarm Limits 0 to full scale of range

Alarm Dead Band 0 to full scale of range

Deviation from Primary Sensor 0.01 to full scale of range

Temperature Alarm Limits 23 to 190°F (-5 to 88 °C)

5

Page 10

Sensor Input Menu – if Chlorine or Chlorine Dioxide

Calibration Reminder 0-365 days

Alarm Limits 0 to 10 mg/l

Alarm Dead Band 0 to 10 mg/l

Deviation from Primary Sensor 0.01 to 10 mg/l

Damping 0 to 60 seconds

Flowmeter Input Menu – Analog Input Type

Flow Rate at 4 mA 0 to 1000 (units of measure defined by user)

Flow Rate at 20 mA 0 to 1000 (units of measure defined by user)

Level Input Menu – Analog Input Type

Empty mA 0 to 20 mA

Full mA 0 to 20 mA

Full volume 0 to 10,000 (units defined by user)

Low Level Alarm Limit 0.001 to 10,000 (units defined by user)

Generic 4-20 mA Input Menu

Parameter = 4 mA -10,000 to 10,000 (units defined by user)

Parameter = 20 mA -10,000 to 10,000 (units defined by user)

Low Alarm Limit -100,000,000 to 100,000,000 (units defined by user)

High Alarm Limit -100,000,000 to 100,000,000 (units defined by user)

Flowmeter Input Menu – Digital Input Type

Volume per Contact 0 to 1000 (units of measure defined by user)

K Factor 0.001 to 20,000 (Pulses per Gallon or Liter)

Total Alarm Limit 0 = no limit, otherwise >0

Rate High Alarm >0

Rate Low Alarm >0

Feed Verification Input Menu

Alarm Time 0.1 to 10 minutes

Pump Volume per Stroke 0.000 to 100 (units of measure defined by user)

Counter Input Menu

One Count = >0

Total Alarm Limit 0 =no limit, otherwise >0

Rate High Alarm >0

Rate Low Alarm >0

Relay Output Menu – On/Off Set Point

Set Point Full scale range of the input parameter

Dead Band Full scale range of the input parameter

Output Time Limit 0 = , 1 to 1440 minutes

Hand Time Limit 1 to 1440 minutes

6

Page 11

Relay Output Menu – Time Proportional

Set Point Full scale range of the input parameter

Sample Period 1 to 1440 minutes

Proportional Band Full scale range of the input parameter

Output Time Limit 0 = , 1 to 1440 minutes

Hand Time Limit 1 to 1440 minutes

Relay Output Menu – Feed with Another Relay

Output Time Limit 0 = , 1 to 1440 minutes

Hand Time Limit 1 to 1440 minutes

Relay Output Menu – Feed after Another Relay (Fixed Time)

Fixed Time to Feed 0 to 1440 minutes

Hand Time Limit 1 to 1440 minutes

Relay Output Menu – Flow Based Feed

Volume to trigger Feed 1 to 99,999 (units defined by user)

Feed Time per unit Volume 1 second to 1440 minutes

Output Time Limit 0 = , 1 to 1440 minutes

Hand Time Limit 1 to 1440 minutes

Relay Output Menu – Biocide Timer Based

Output On-Time 0 = , 1 to 1440 min

Hand Time Limit 1 to 1440 minutes

Relay Output Menu – Feed After Another Relay (%)

% of Relay to Feed 0 to 100%

Output Time Limit 0 = , 1 to 1440 minutes

Hand Time Limit 1 to 1440 minutes

Relay Output Menu – Feed as % Time

Time Period 1 – 1440 minutes

% of Period to Feed 0.1 to 100%

Output Time Limit 0 = , 1 to 1440 minutes

Hand Time Limit 1 to 1440 minutes

Relay Output Menu – Cycles of Concentration

Cycles Set Point 1 – 50 cycles

Cycles Dead band 0.01 – 20 cycles

Cycles Low Alarm 0 – 50 cycles

Cycles High Alarm 0 – 50 cycles

Output Time Limit 0 = , 1 to 1440 minutes

Hand Time Limit 1 to 1440 minutes

7

Page 12

Relay Output Menu – Spike

Set Point Full scale range of the parameter

Dead Band Full scale range of the parameter

Relay On-Time 1 sec to 1440 minutes

Hand Time Limit 1 to 1440 minutes

Relay Output Menu – Intermittent, Fixed Blowdown Time

Set Point Full scale range of the parameter

Interval Time 5 to 1440 minutes

Duration of Sample 10 seconds to 60 minutes

Hold Time 30 seconds to 10 minutes

Blowdown Time 1 to 1440 minutes

Hand Time Limit 1 to 1440 minutes

Relay Output Menu – Intermittent, Proportional Blowdown Time

Set Point Full scale range of the parameter

Interval Time 5 to 1440 minutes

Duration of Sample 10 seconds to 60 minutes

Hold Time 30 seconds to 10 minutes

Blowdown Time 1 to 1440 minutes

Hand Time Limit 1 to 1440 minutes

Relay Output Menu - Alarm

On Delay Time 0 to 1440 minutes

Power Up On Delay Time 0 to 1440 minutes

Output Time Limit 0 = , 1 to 1440 minutes

Hand Time Limit 1 to 1440 minutes

Relay Output Menu – Activate on a DI

On Delay Time 10 seconds to 1440 minutes

Off Delay Time 10 seconds to 1440 minutes

Output Time Limit 0 = , 1 to 1440 minutes

Hand Time Limit 1 to 1440 minutes

Relay Output Menu – Target PPM Feed

Makeup Conductivity Full scale range of the parameter

Unit Volume to Trigger Output 1 to 999,999,999 (units defined by user)

Target PPM Set Point 0 to 100,000 ppm

Specific Gravity of Chemical Fed 0 to 10.000 g/ml

Pump Flow Rate 0 to 1,000 (units defined by user)

Output Time Limit 0 = , 1 to 1440 minutes

Hand Time Limit 1 to 1440 minutes

8

Page 13

Relay Output Menu – Target PPM Feed with Feed Verification

Makeup Conductivity Full scale range of the parameter

Unit Volume to Trigger Output 1 to 999,999,999 (units defined by user)

Target PPM Set Point 0 to 100,000 ppm

Specific Gravity of Chemical Fed 0 to 10.000 g/ml

Output Time Limit 0 = , 1 to 1440 minutes

Hand Time Limit 1 to 1440 minutes

4-20 mA Output Menu - Retransmit

(parameter selected) = 4 mA Full scale range of the parameter

(parameter selected) = 20 mA Full scale range of the parameter

Full Scale Ranges are:

Contacting Conductivity: 0 to 10,000 μS/cm

Electrodeless Conductivity: 50 to 10,000 μS/cm

Or 10 mS/cm to 100 mS/cm

Or 100 mS/cm to 1000 mS/cm

Temperature: 32 to 392°F (-18 to 200° C)

pH: -2 to 16 standard units

ORP: -1400 to 1400 mV

Chlorine, Chlorine Dioxide 0 to 10 mg/l

4-20 mA Output Menu – Proportional Feed

Set Point Full scale range of the parameter

Minimum Output Allowed 0 – 100%

Input Value when Output is Max Full scale range of the parameter

Damping 0 – 60 seconds

Interlock Value 0 – 100%

Input Fault Value 0 – 100%

Input Cal Set Value 0 – 100%

Output Time Limit 0 = , 1 to 1440 minutes

Hand Time Limit 1 to 1440 minutes

Hand Value 0 – 100%

Full Scale Ranges are:

Contacting Conductivity: 0 to 10,000 μS/cm

Electrodeless Conductivity: 50 to 10,000 μS/cm

Or 10 mS/cm to 100 mS/cm

Or 100 mS/cm to 1000 mS/cm

Temperature: 32 to 392°F (-18 to 200° C)

pH: -2 to 16 standard units

ORP: -1400 to 1400 mV

Chlorine, Chlorine Dioxide 0 to 10 mg/l

Data Logging Menu

Logging Interval 10 to 1440 minutes

9

Page 14

3.0 UNPACKING & INSTALLATION

3.1 Unpacking the Unit

Inspect the contents of the carton. Please notify the carrier immediately if there are any signs of

damage to the controller or its parts. Contact your distributor if any of the parts are missing. The

carton should contain a WebMasterONE and technical support package (contains instruction

manual, Quick Start Guide, CD and USB cable). Any options or accessories will be incorporated

as ordered.

3.2 Mounting the Electronic Enclosure

The WebMasterONE is supplied with mounting holes on the enclosure. It should be wall mounted

with the display at eye level on a vibration-free surface, utilizing all mounting holes for maximum

stability.

The enclosure is NEMA 4X rated, suitable for outdoor installation. The maximum ambient

operating temperature is 120° F (49° C); this should be considered if installation is in a high

temperature location.

The installation site should be in close proximity to grounded AC power, the chemistry to be

controlled, and phone line or Ethernet hub (if applicable).

Avoid locations that are in close proximity to sources of electrical noise (motor starters, power

transformers, variable speed motor drives, radio transmitters, etc.), corrosive fumes or excessive

moisture.

The enclosure requires the following clearances:

Top: 2”

Left: 10”

Right: 4”

Bottom: 8”

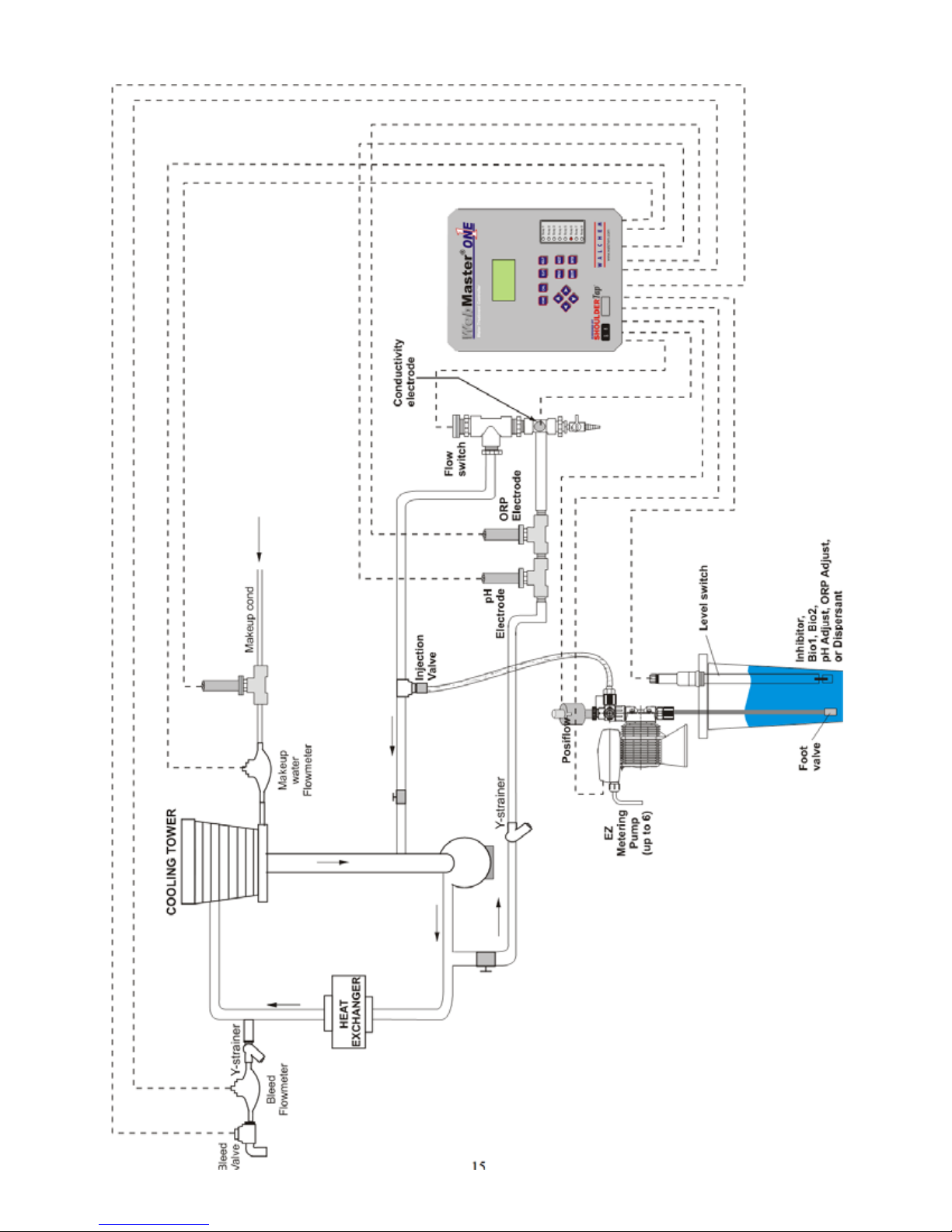

3.3 Installation

Plumbing

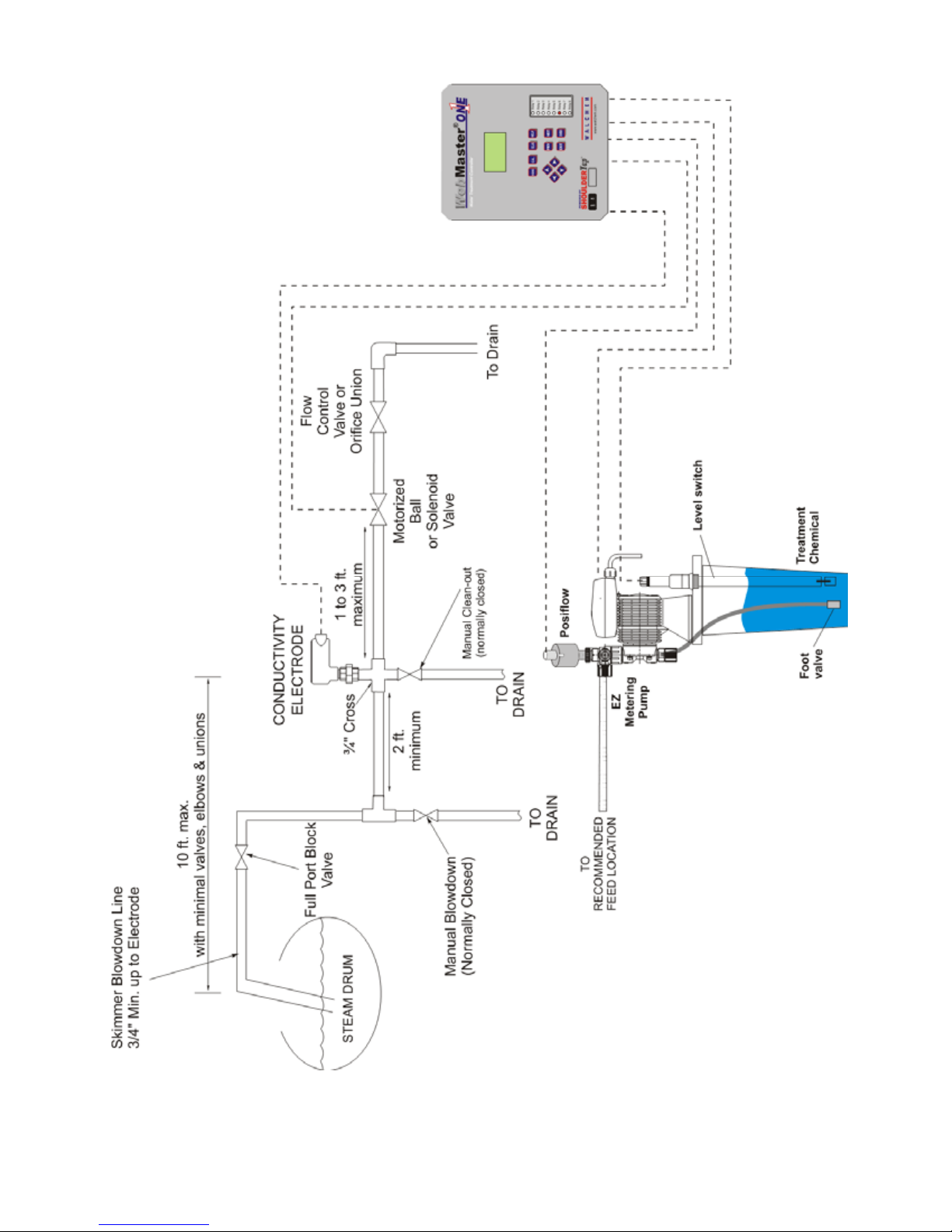

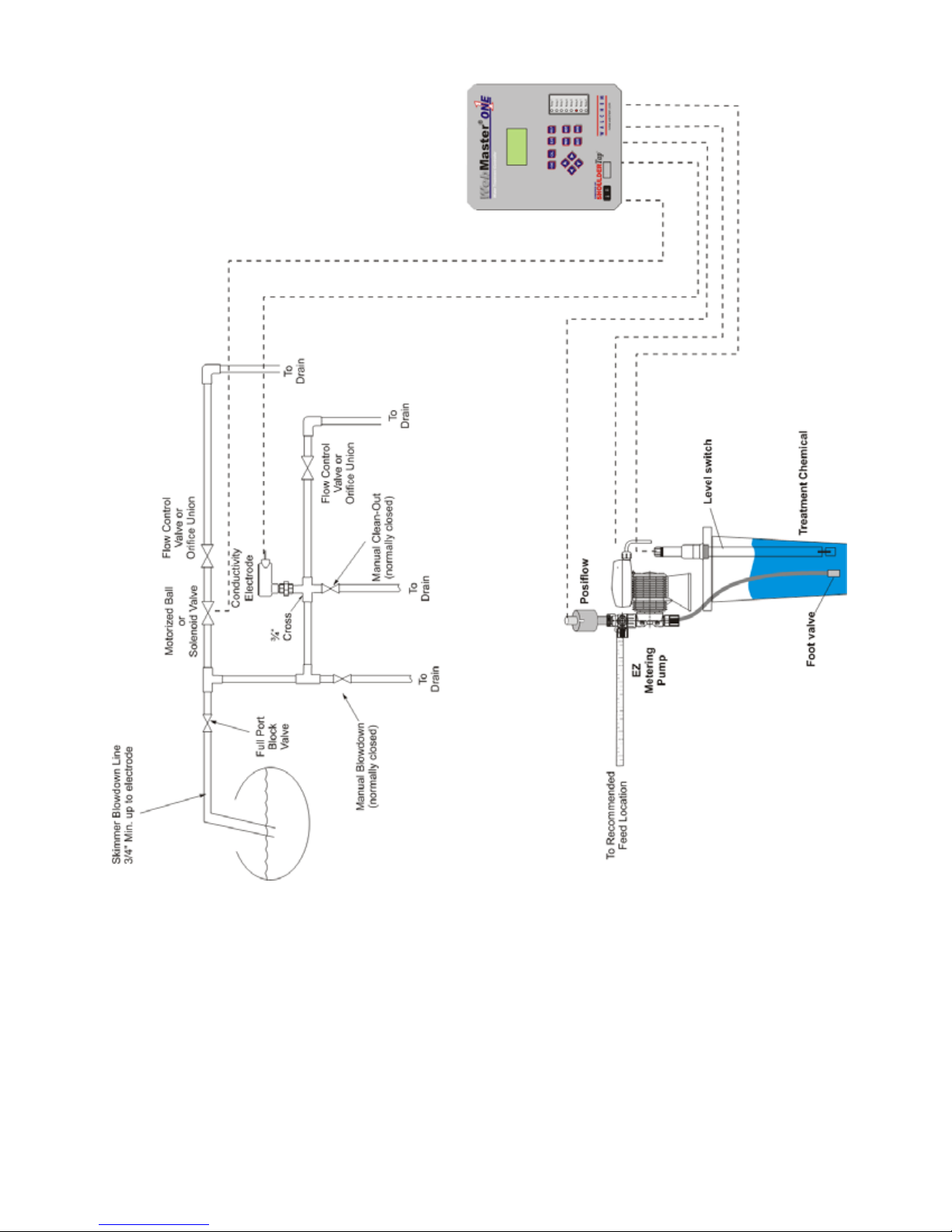

The WebMasterONE series controllers are supplied with a flow switch manifold designed to

provide a continuously flowing sample of cooling water to the sensors. Please refer to Figures 1

(a-d) below for some typical installation drawings.

Cooling Towers:

Tap off the discharge side of the recirculation pump to provide a minimum flow of 1 gallon per

minute through the flow switch manifold. The sample must flow into the bottom of the manifold in

order to close the flow switch, and return to a point of lower pressure in order to ensure flow.

Install an isolation valve on both sides of the manifold to stop flow for sensor maintenance.

IMPORTANT: To avoid damaging the female pipe threads on the supplied plumbing parts, use no

more than 3 wraps of PTFE tape and thread into the pipe FINGER tight only! DO NOT use any

pipe dope, plumber’s putty or other sealing products that contain diacetone alcohol, as these attack

the flow switch plastic! Use PTFE tape ONLY!

10

Page 15

Boilers:

The conductivity probe should be placed as close to the controller as possible, to a maximum

distance of 250 ft. The cable MUST be shielded from background electrical noise. Use 24 AWG,

3 twisted pair, shielded, low capacitance (15 pF/ft) cable such as Walchem P/N 102535 (Belden

9680) or equivalent.

Important Boiler Installation Notes: (see figure 1b and c)

1. Make sure the minimum water level in the boiler is at least 4-6 inches above the skimmer

blowdown line. If the skimmer line is closer to the surface, it is likely that steam will be drawn

into the line instead of boiler water. The skimmer line must also be installed above the highest

tube.

2. Maintain a 3/4 inch minimum pipe ID with no flow restrictions from the tap for the boiler

skimmer blowdown line to the electrode. If the ID is reduced below 3/4 inch, then flashing will

occur beyond that point and the conductivity reading will be low and erratic. Minimize the usage

of tees, valves, elbows or unions between the boiler and the electrode.

3. A manual shut off valve should be installed so that the electrode can be removed and cleaned.

This valve must be a full port valve in order to avoid a flow restriction. Keep the distance

between the tap for the boiler skimmer line to the electrode as short as possible, to a maximum

of 10 feet.

4. Mount the electrode in the side branch of a tee in a horizontal run of pipe. This will minimize

entrapment of steam around the electrode and will allow any solids to pass through.

5. There MUST be a flow restriction after the electrode and/or control valve in order to provide

back pressure. This flow restriction will be either a flow control valve or an orifice union. The

amount of the flow restriction will affect the blowdown rate as well, and should be sized

accordingly.

6. Install the motorized ball valve or solenoid valve per the manufacturer’s instructions.

7. For best results, align the hole in the conductivity electrode such that the direction of water flow

is through the hole.

Guide to Sizing Blowdown Valves and Orifice Plates

1. Determine the Rate of Steam Production in Pounds per Hour:

Either read off the boiler name plate (water-tube boilers) or Calculate from horsepower rating (fire-tube

boilers):

HP x 34.5 = lbs/hr. Example: 100 HP = 3450 lbs/hr.

2. Determine the Concentration Ratio (BASED ON FEEDWATER)

A water treatment chemical specialist should determine the desired number of cycles of concentration.

This is the ratio of TDS in the boiler water to TDS in the feedwater. Note that feedwater means the water

that is fed to the boiler from the deaerator and includes makeup water plus condensate return.

Example: 10 cycles of concentration has been recommended

11

Page 16

3. Determine the Required Blowdown Rate in Pounds Per Hour

Blowdown Rate = Steam Production / (Concentration Ratio –1)

Example: 3450/(10-1) = 383.33 lbs./hr

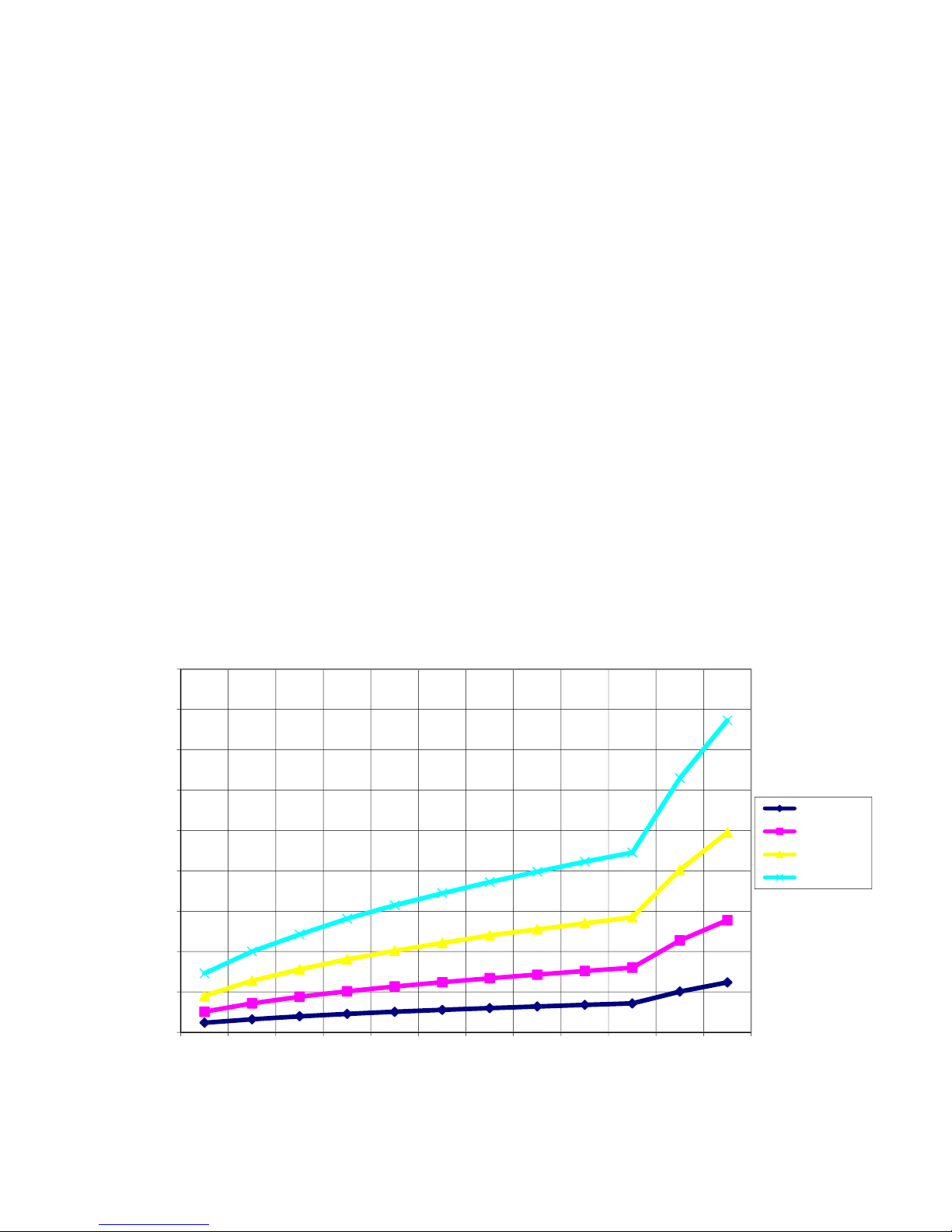

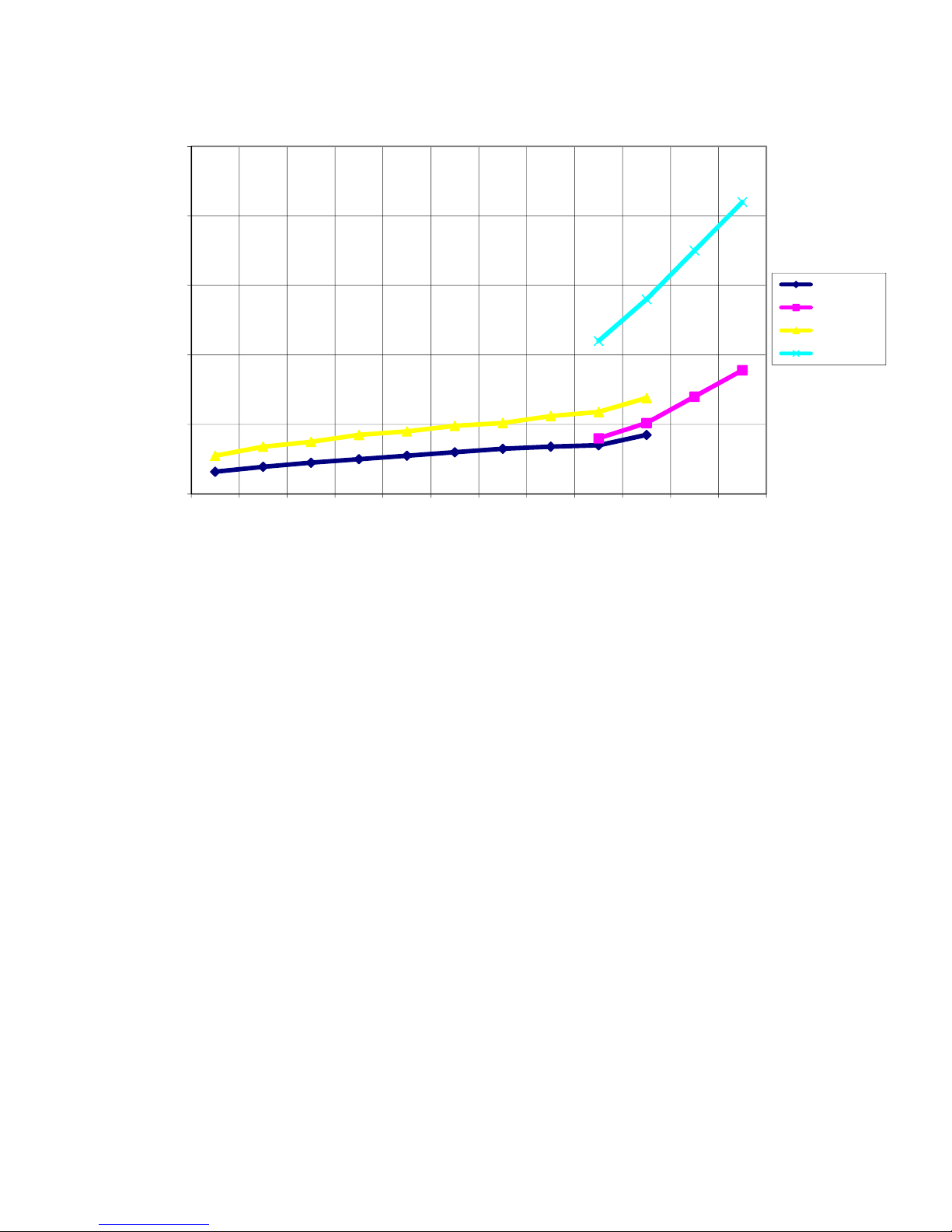

4. Determine if Continuous or Intermittent Sampling is Required

Use intermittent sampling when the boiler operation or loading is intermittent, or on boilers where the

required blowdown rate is less than 25% of the smallest available flow control valve or less than the flow

through the smallest orifice. See the graphs on the next page.

Use continuous sampling when the boiler is operating 24 hours per day and the required blowdown rate is

more than 25% of the smallest applicable flow control valve or orifice. See the graphs on the next page.

Use of a flow control valve will give you the best control of the process, since the flow rate can be easily

adjusted. The dial on the valve also gives you a visual indication if the flow rate has been changed. If the

valve clogs, it can be opened to clear the obstruction, and closed to the previous position.

If an orifice plate is used, you must install a valve downstream from the orifice in order to fine tune the

flow rate and provide additional back pressure in many applications.

Example: An 80 psi boiler has a Required Blowdown Rate of 383.33 lbs./hr. The maximum flow rate of

the smallest flow control valve is 3250 lbs./hr. 3250 x 0.25= 812.5 which is too high for continuous

sampling. Using an orifice, the flow rate through the smallest diameter plate is 1275 lbs./hr. This is too

high for continuous sampling.

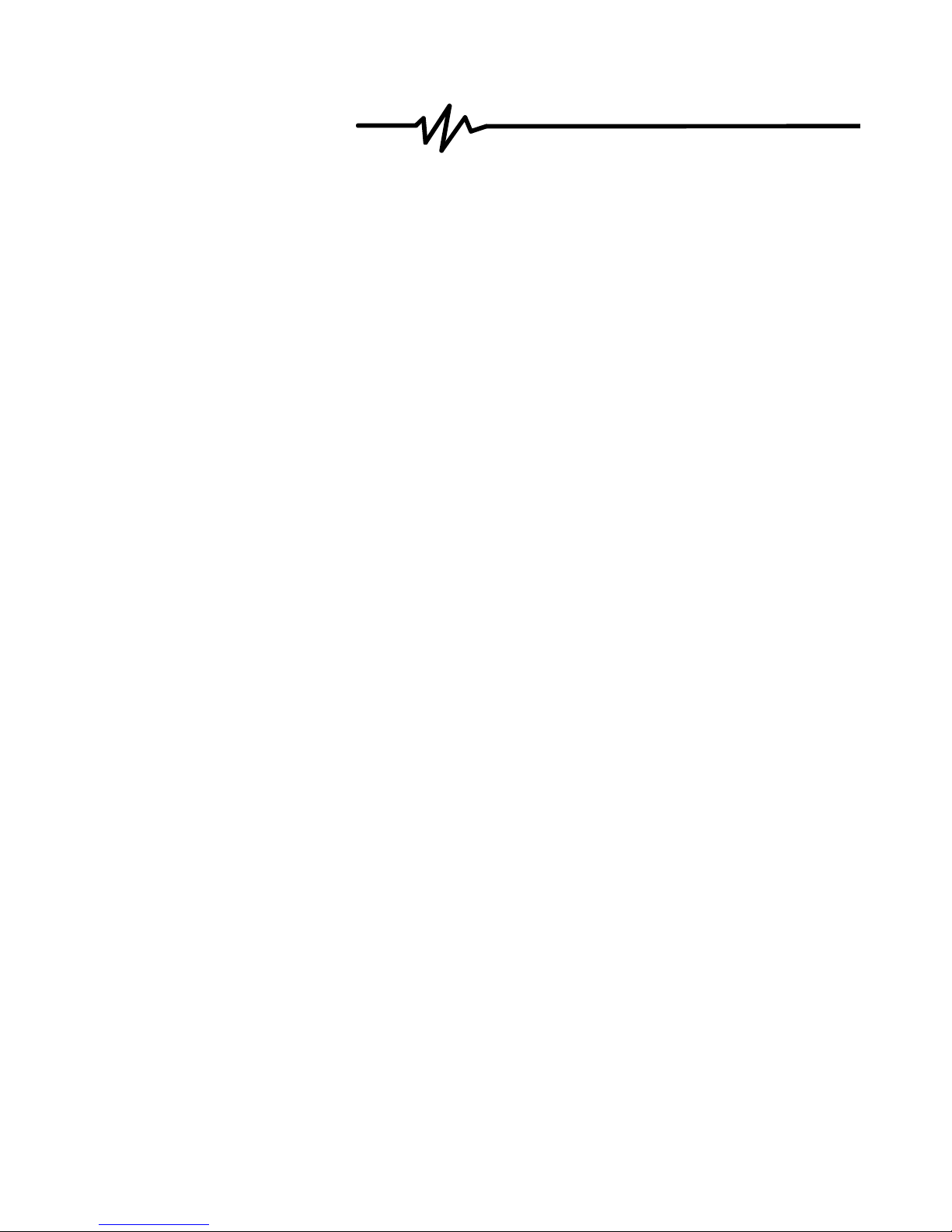

5. Determine the Orifice or Flow Control Valve Size for this Blowdown Rate

Use the following graphs to select a flow control device:

Flow Rate in Lbs/hr for Various Orifices

18000

16000

14000

12000

10000

Lbs/hr

8000

6000

4000

2000

0

10 20 30 40 50 60 70 80 90 100 200 300

Pressure PSI

1/8 inch dia

3/16 inch dia

1/4 inch dia

5/16 inch dia

12

Page 17

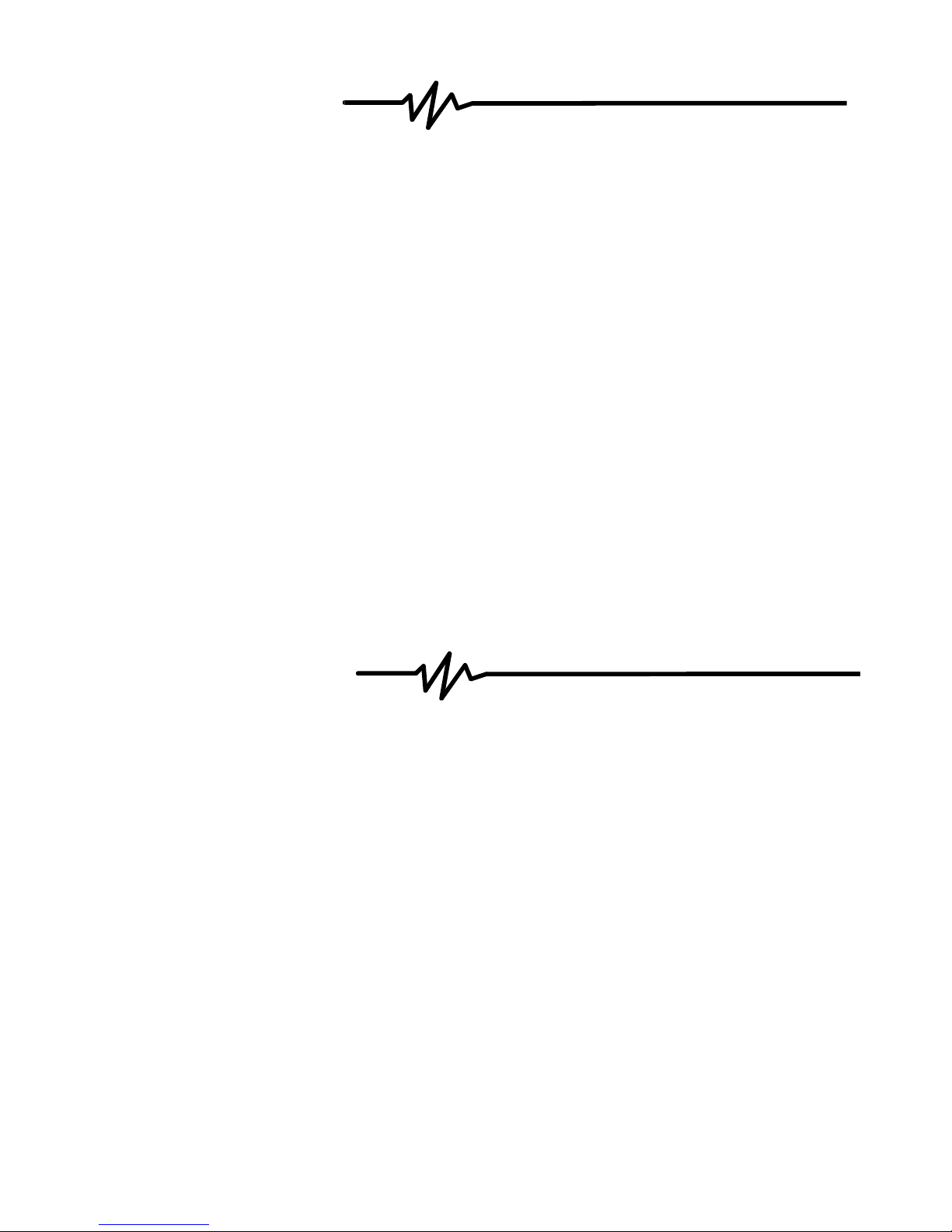

Flow Control Valve

25000

Maximum Flow Rates in Lbs/hr

20000

15000

Lbs/hr

10000

5000

0

20 30 40 50 60 70 80 90 100 150 200 300

Sensor Installation

All sensors for the WebMasterONE series are provided with signal conditioning electronics, and

conductivity sensors may be located up to 250 feet (75 meters) from the controller, and pH/ORP

sensors may be located up to 1000 feet (303 meters) from the controller. It is highly recommended

that the sensors be installed within 20 feet of the controller in order to make periodic calibration

more convenient.

Sensors should be located such that they respond rapidly to a well-mixed sample of the process

water and the treatment chemicals. If they are too close to the chemical injection point, they will

see spikes in concentration and cycle on and off too frequently. If they are too far away from the

chemical injection point, they will respond too slowly to the concentration changes, and you will

overshoot the set point.

If the sensor cables need to be extended, then 24 AWG shielded low capacitance (15 pF/ft) twisted

pair cable such as Walchem P/N 102535 (Belden 9680) or equivalent should be used. Pay attention

to the integrity of the cable shield. Always route sensor cables (or any other low voltage wiring) in

conduit that is separated from any AC voltage wiring by at least 6 inches.

pH and ORP electrodes must be installed such that the measuring surfaces will always remain wet.

A U-trap provided in the manifold design should achieve this, even if the sample flow stops. These

electrodes also must be installed with the measuring surfaces pointing down; that is 5 degrees

above the horizontal, at a minimum.

If the sensors are to be submersed in the process, mount them firmly to the tank, and protect the

cable with plastic pipe, sealed at the top with a cable gland, to prevent premature failure. Place the

sensors in an area of good solution movement.

1/2" 150 PSI

1/2" 300 PSI

3/4" 150 PSI

3/4" 300 PSI

Pressure PSI

13

Page 18

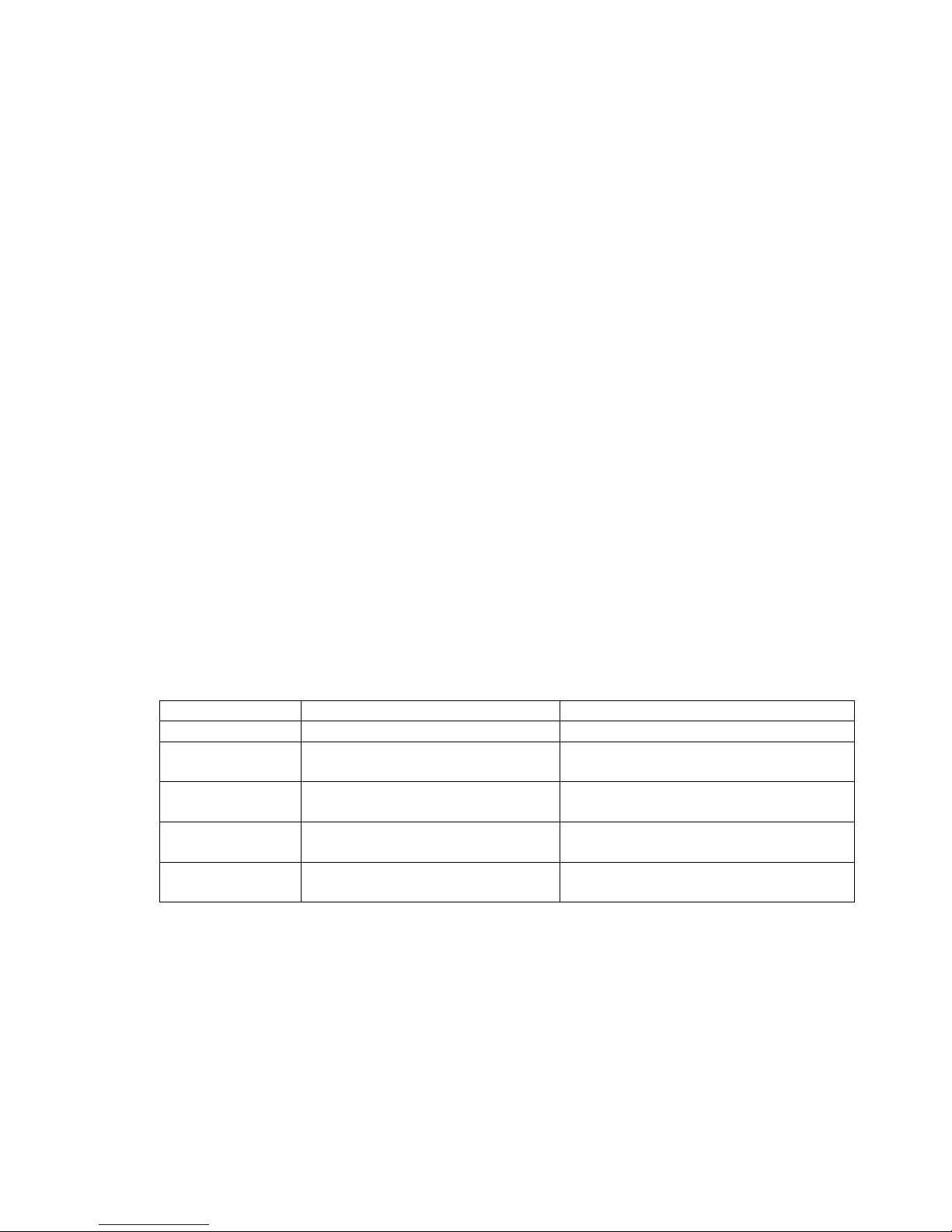

3.4 Icon Definitions

Symbol Publication Description

IEC 417, No.5019 Protective Conductor Terminal

IEC 417, No. 5007 On (Supply)

IEC 417, No. 5008 Off (Supply)

ISO 3864, No. B.3.6 Caution, risk of electric shock

Pending

Caution, High temperature, risk of

burn

ISO 3864, No. B.3.1 Caution

14

Page 19

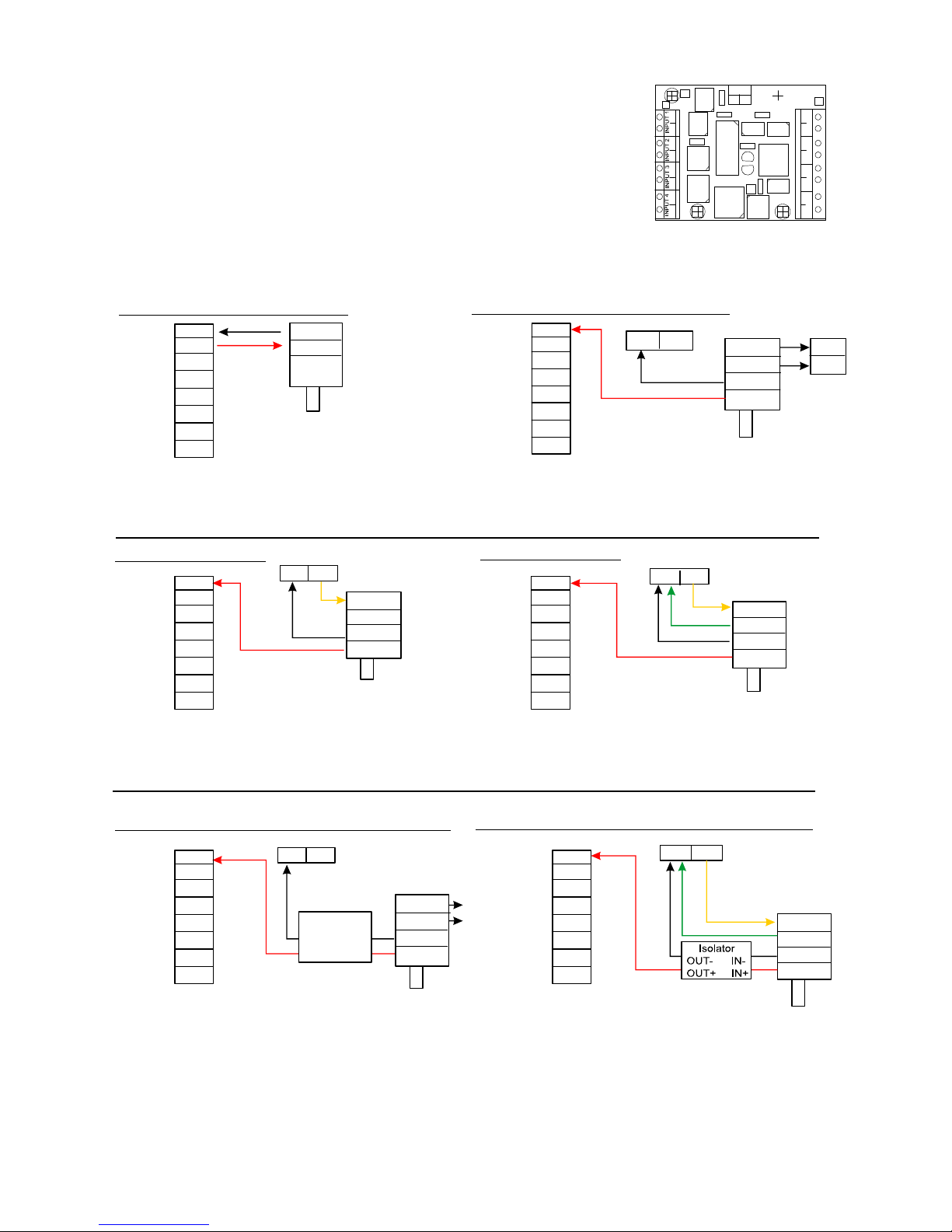

Figure 1a: Typical Installation, Cooling Tower

15

Page 20

Figure 1b Typical Installation, Boiler

p

g

Intermittent Sam

16

lin

Page 21

Figure 1c: Typical Installation, Boiler

p

g

Continuous Sam

lin

17

Page 22

3.5 Electrical Installation

The WebMasterONE series controllers require the following voltages:

100 –120/200-240 VAC± 10%, 50/60 Hz, 12 amperes maximum

The controller must be connected to its own 15 ampere breaker, close by, to act as an alternate

power shutdown.

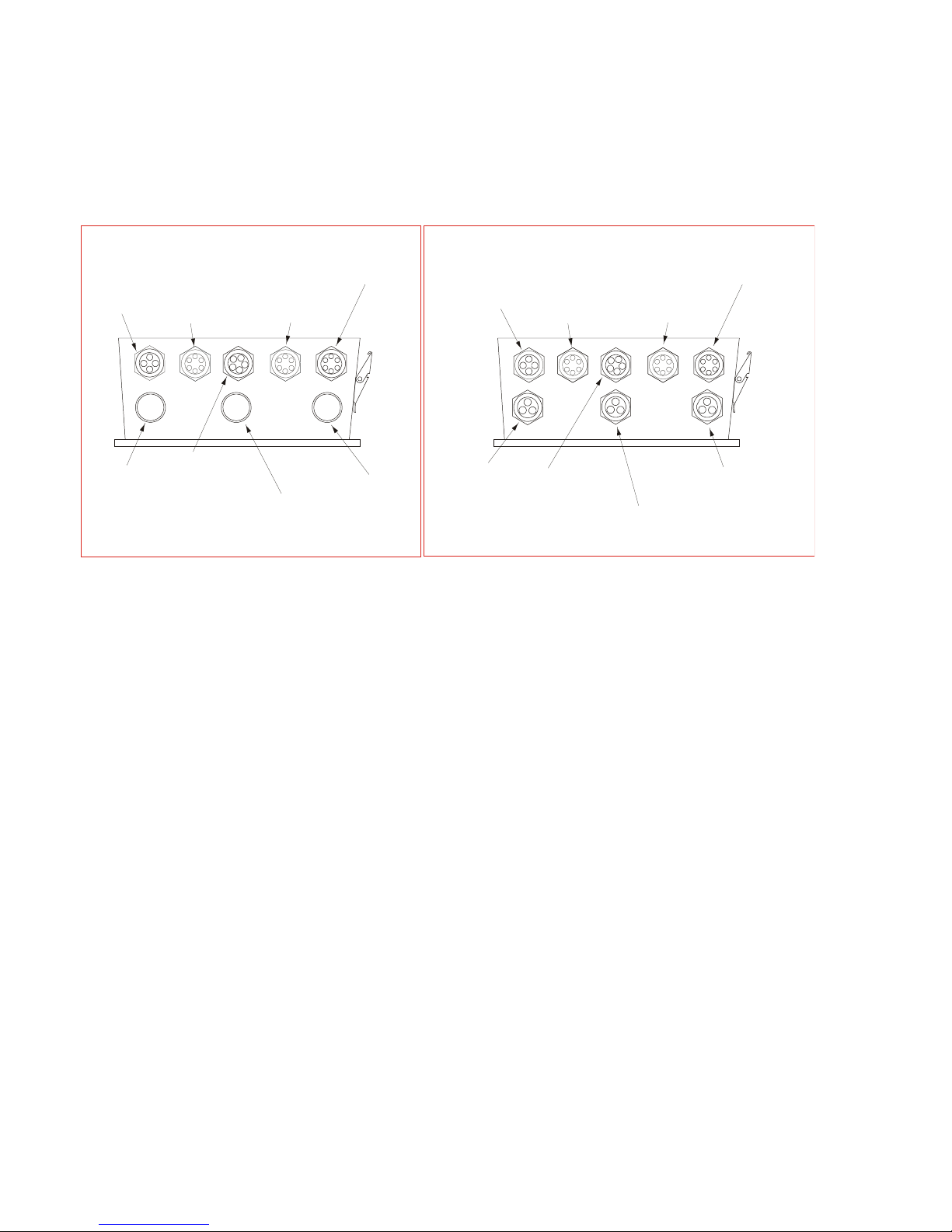

Your controller is supplied either factory prewired or ready to be hardwired. Depending upon your

choice of options, you may be required to hardwire some or all of the input/output devices. Please

refer to Figures 4 through 8 for wiring diagrams.

The output loads may be connected to pigtail

(125V prewired) connections or terminal block

(hardwired) connections. The total output current

must not exceed 11 amps. The output relays are

connected in two relay banks each fused at 6.3 amps.

See figure on the right. Assess the steady state amps

of all loads before connecting to controller. Depending

upon your model code, some relays may be dry contact

and not fused.

CAUTION! There are live circuits inside the controller even when the power switch on the front

panel is in the OFF position! The front panel must never be opened before power to the controller

is REMOVED!

If your controller is prewired, it is supplied with a 10 foot, 14 AWG power cord with USA style

plug and 8 inch, 18 AWG USA style receptacle cords for the powered relay outputs. A tool (#1

Phillips driver) is required to open the front panel.

CAUTION! The electrical installation of the controller must be done by trained personnel only

and conform to all applicable National, State and Local codes!

MAINS VOLTAGE

6.3A

F3

R1

R2

R3

R4

6.3A

F2

R5

R6

R7

R8

18

Page 23

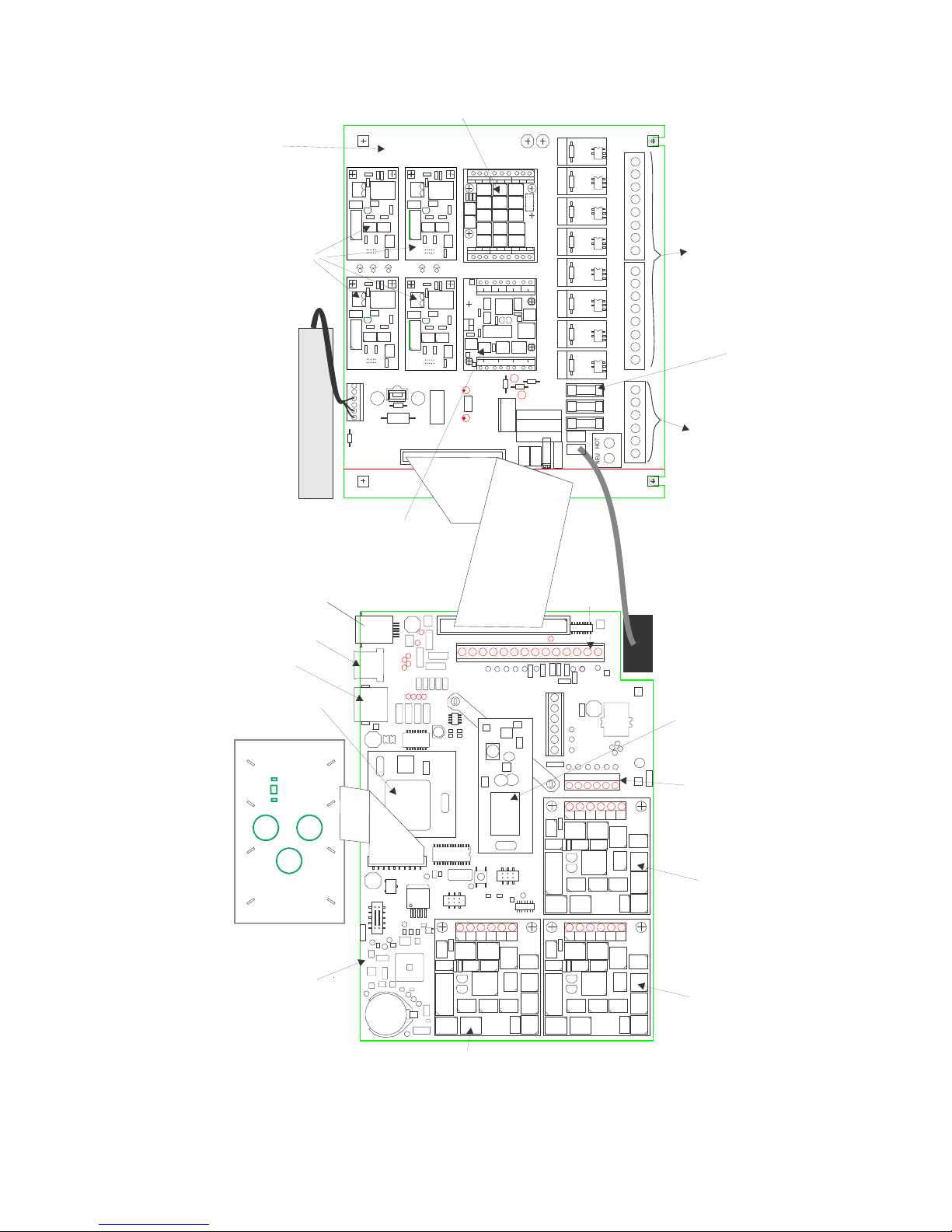

A

Sensor Inputs

A

A

A

(up to 4)

(Recommended)

R4

C Power

R7

Note: Many of the inputs and outputs listed are optional

and may not be present in your controller.

Hardwired Options

Bottom View

Strain relief

installed with

analog card option

nalog Inputs

Digital Input A

Digital Input B

Digital Input C

digital card option

Digital Inputs

(Recommended)

Strain relief

installed with

R5

R6

R8

Misc. Inputs/

Outputs

(Recommended)

R1

R2

R3

Sensor Inputs

(up to 4)

R4

C power

R7

analog card option

nalog Inputs Digital Inputs

Digital Input A

Digital Input B

Digital Input C

Figure 2: Conduit/Wiring Configuration

Prewired Option

Bottom View

Strain relief

installed with

Strain relief

installed with

digital card option

R5

R6

R8

Misc. Inputs/

Outputs

R1

R2

R3

19

Page 24

D

i

l

Power

use

s

Relay

Digital

Input

Option

Card

Board

DIG INPUT 6 DIG INPUT 5 DIG INPUT 4

IN-

IN+ +v IN- IN+ IN+IN-+v +v

REV 3

-

+-+-+

INPUT 3 INPUT 2 INPUT 1

102847

+-+-+-+

INPUT 4

+v+v +v

IN-IN-IN-

IN+IN+IN+

DIG INPUT 3DIG INPUT 2DIG INPUT 1

4-20 mA Output

Option Cards

INPUT 5

INPUT 5 INPUT 6 I NPUT 7

-

102815 RV2

+24V

TB1

GN+24

-

+

RELAY1NC NO

RELAY2NC NO

3

RELAY

NC NO

RELAY4NC NO

5

RELAY

NC NO

6

RELAY

NC NO

RELAY7NC NO

8

RELAY

NC COM

Hot

Relay Outputs

F

ay

sp

Ethernet

USB

RJ45

Power Supply

Modem

Host

Core

Neutral

Relay outputs

Card

4-20mA

Input Option

RJ11

Digital

Inputs

A, B, C, D, E & F

Modem

Option

Card

t- t+ IN- IN+ +5V -5V

Sensor 1

t- t+ IN- IN++5V -5V

Core

Interface

Board

t- t+ IN- IN++5V -5V

B1

REV 2

102839

t- t+ IN- IN++5V -5V

(Observe

markings on

circuit board)

Sensor 4 or 2

Figure 3 Identification of Parts

20

REV 2

102839

REV 2

102839

Sensor 2 or 4

(Observe markings

on circuit board)

Sensor 3

Page 25

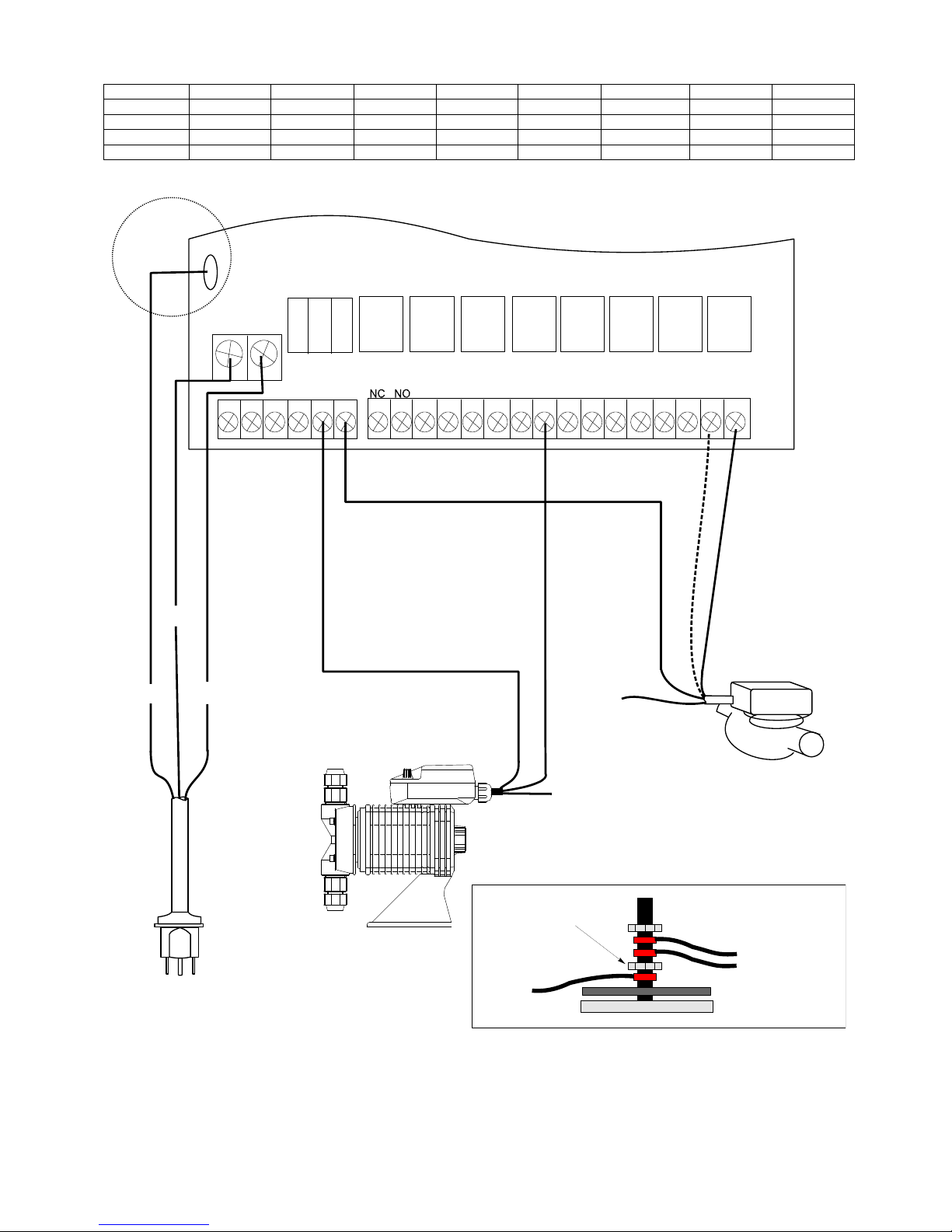

VoltageCode

S

0 or 4 DRY DRY DRY DRY DRY DRY DRY DRY

1 or 6 POWERED POWERED POWERED POWERED POWERED POWERED POWERED DRY

2 or 5 POWERED POWERED POWERED POWERED POWERED POWERED POWERED POWERED

3 or 7 DRY POWERED DRY POWERED DRY POWERED DRY POWERED

R1 R2 R3 R4 R5 R6 R7 R8

DRY CONTACTS WILL BE LABELED COM INSTEAD OF NC.

EE

DETAIL “A”

GROUND

STUD

WHT

GND

GRN

NEU

HOT

BLK

NEU HOT

NEUTRAL

Important: The mains power supply earth ground connection

must be retained by separate nut.

RELAY8 RELAY7 RELAY6 RELAY5 RELAY4 RELAY3 RELAY2 RELAY1

IF USING

A MOTORIZED

WHT

BLK

WHT

TO GND

STUD

BALL VALVE

GRN

NC NONC NONC NONC NONC NONC NONC NO

BLK

BLK

AC POWER

INPUT

Figure 4: Wiring Diagram for AC Power Input and Relay Outputs

GRN

METERING

PUMP

SEPARATE

PRIMARY EARTH

CONNECTION

21

TO GND

STUD

NUT

BRACKET

SOLENOID OR

MOTORIZED

BALL VALVE

OTHER EARTH

CONNECTIONS

PC

BOARD

“

”

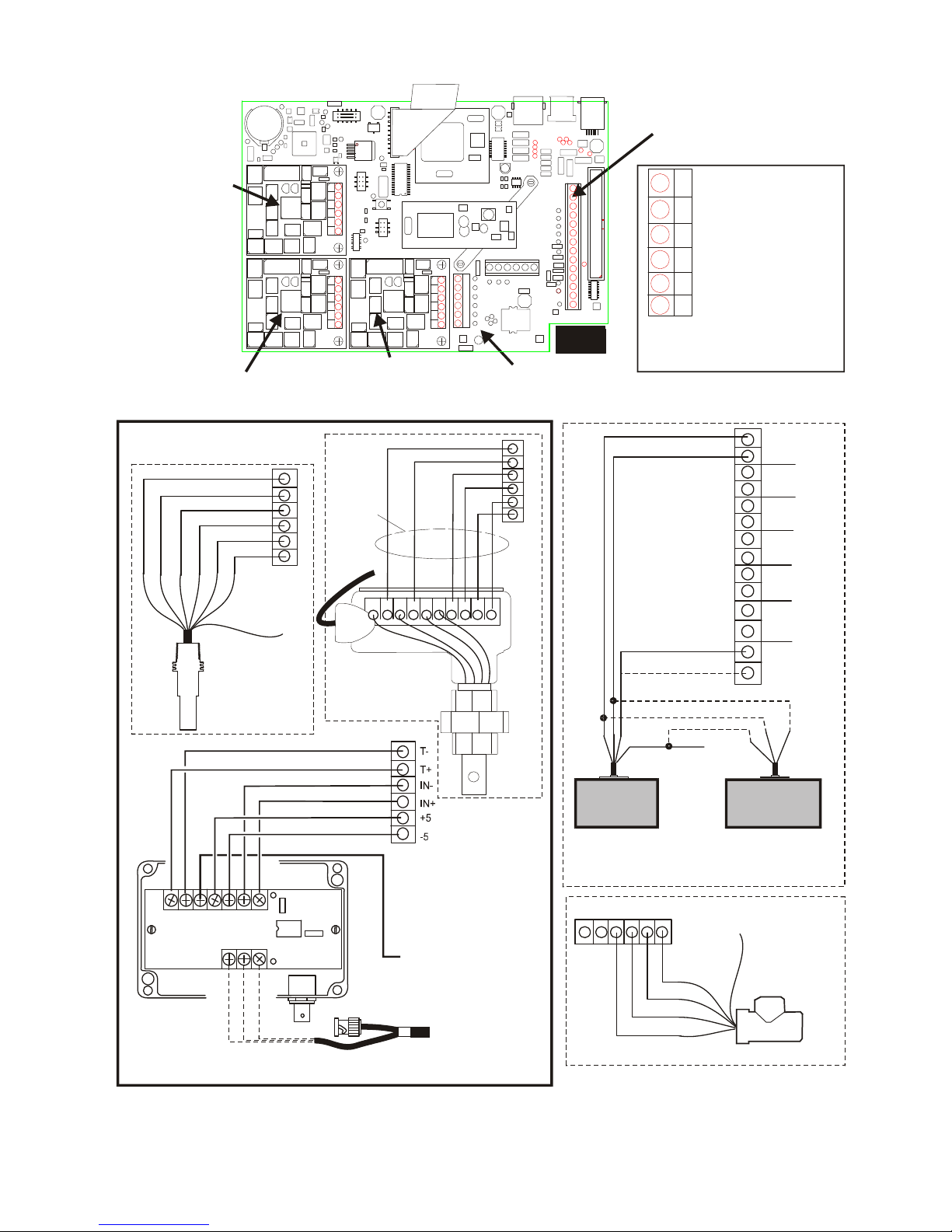

Page 26

B1

DIGITAL INPUTS

SEE DETAIL 'A'

SENSOR 4 or 2

(Observe markings

on circuit board)

SEE DETAIL 'C'

SENSOR 3

SEE DETAIL 'C'

SENSOR DETAIL "C"

Low Pressure

CONDUCTIVITY

102839

REV 2

102839

REV 2

WHT/GRN

GRN

WHT/ORN

ORN

BLU

WHT/BLU

SHIELD

TO GND STUD

pH/ORP OR

SENSOR

TT+ IN-

IN+

+5

-5

GROUND/SHIELD

t- t+ IN- IN++5V -5V

t- t+ IN- IN++5V -5V

102839

REV 2

SENSOR 2 or 4

(Observe markings

on circuit board)

SEE DETAIL 'C'

Shield

(Drain wire)

to GND

stud on

front

panel

-T -T

+T

W

H

High Pressure

Conductivity

Electrode

WHT/GRN

GRN

WHT/ORN

ORN

BLU

WHT/BLU

Sensor 1

Terminal

Block

t- t+ IN- IN++5V -5V

t- t+ IN- IN++5V -5V

SENSOR 1**

SEE DETAIL 'C'

* Either an unpowered or a powered device may be

connected to each digital input, one device per input.

WHT/GRN

GRN

WHT/ORN

WHT/BLU

-S

+

+S

-

+T

T

-5

G

B

R

L

N

K

RE

ORN

BLU

+5

D

TT+

ININ+

+5

-5

SIGNAL +

SIGNAL -

POWERED

DEVICES

HALL EFFECT

WATERMETER

OR

PADDLEWHEEL

t- t+ IN- IN+ +5V -5V

** Please note: Sensor 1 terminal

block is oriented OPPOSITE of

sensors 2-4.

OR

SHIELD

(TO GROUND

STUD)

UNPOWERED

OR*

WATERMETER-CONTACTOR

DEVICES

RELAY, REED SWITCH

DIGITAL

IN+

INPUT A

ININ+

DIGITAL

INPUT B

ININ+

DIGITAL

INPUT C

ININ+

DIGITAL

INPUT D

ININ+

DIGITAL

INPUT E

ININ+

DIGITAL

INPUT F

IN-

12V

12V

DETAIL "A"

GND

-5V

+5V

TC+ TC- GND

VpH

COM

TC

GROUND

OPTIONAL TEMPERATURE

COMPENSATION (pH ONLY)

TC+ TC- TC

Figure 5: Wiring Diagram for Sensor Inputs and Digital Inputs A-F

TO GROUND STUD

INSIDE ENCLOSURE

PREAMPLIFIER

High Pressure

pH/ORP Sensor

22

T-

T+ IN-

WHT

IN+

+5

-5

RED

GRN

BLACK

TO GND STUD

SHIELD

DISINFECTION

SENSOR

SENSOR

DETAIL "C"

Page 27

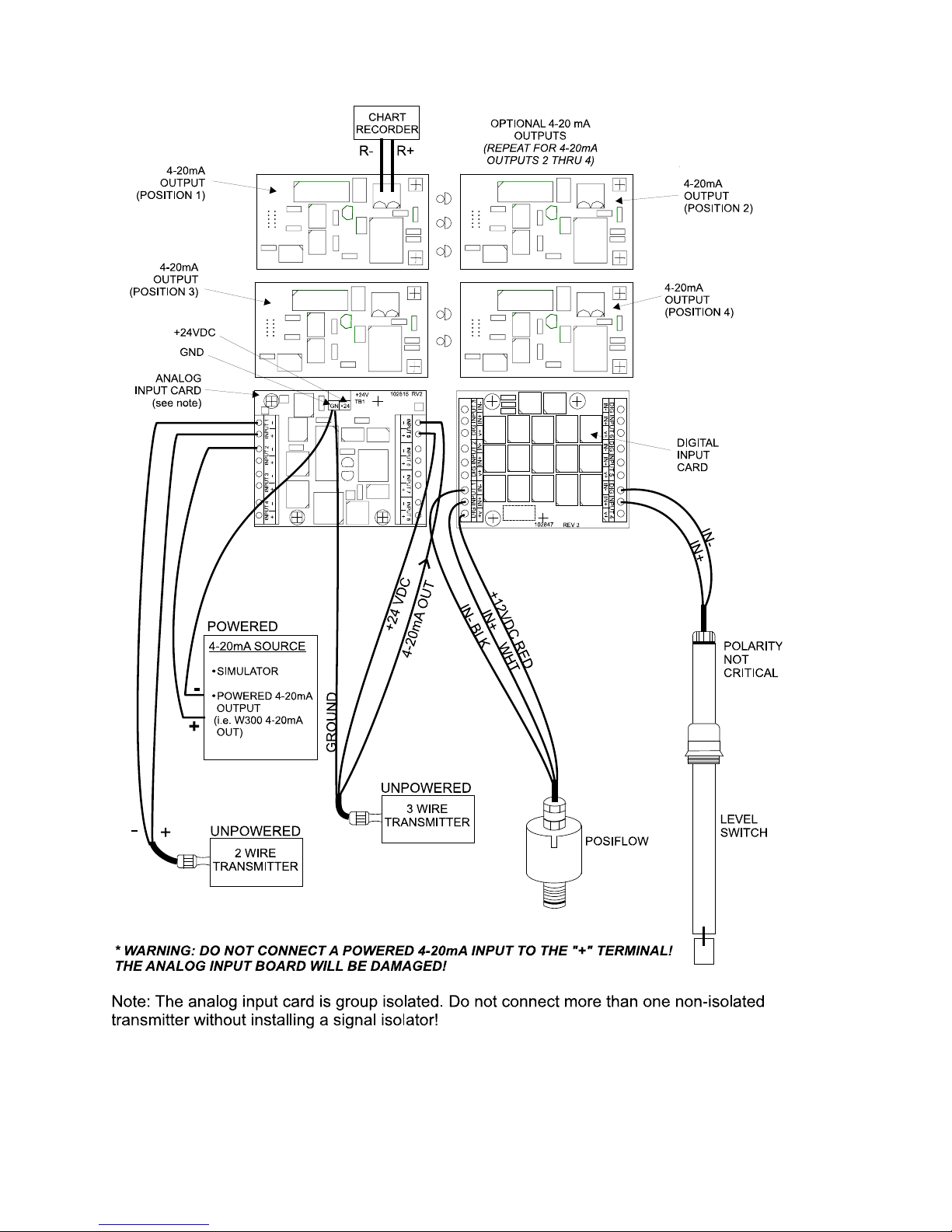

(See 4-20mA Wiring Guide on the following pages)

*Use shielded cable, grounded only at controller end, for ALL connections.

Figure 6: Wiring Diagram for Optional Digital Inputs, 4-20 mA Inputs and 4-20 mA Outputs

23

Page 28

+24V

C

y

D

TB1

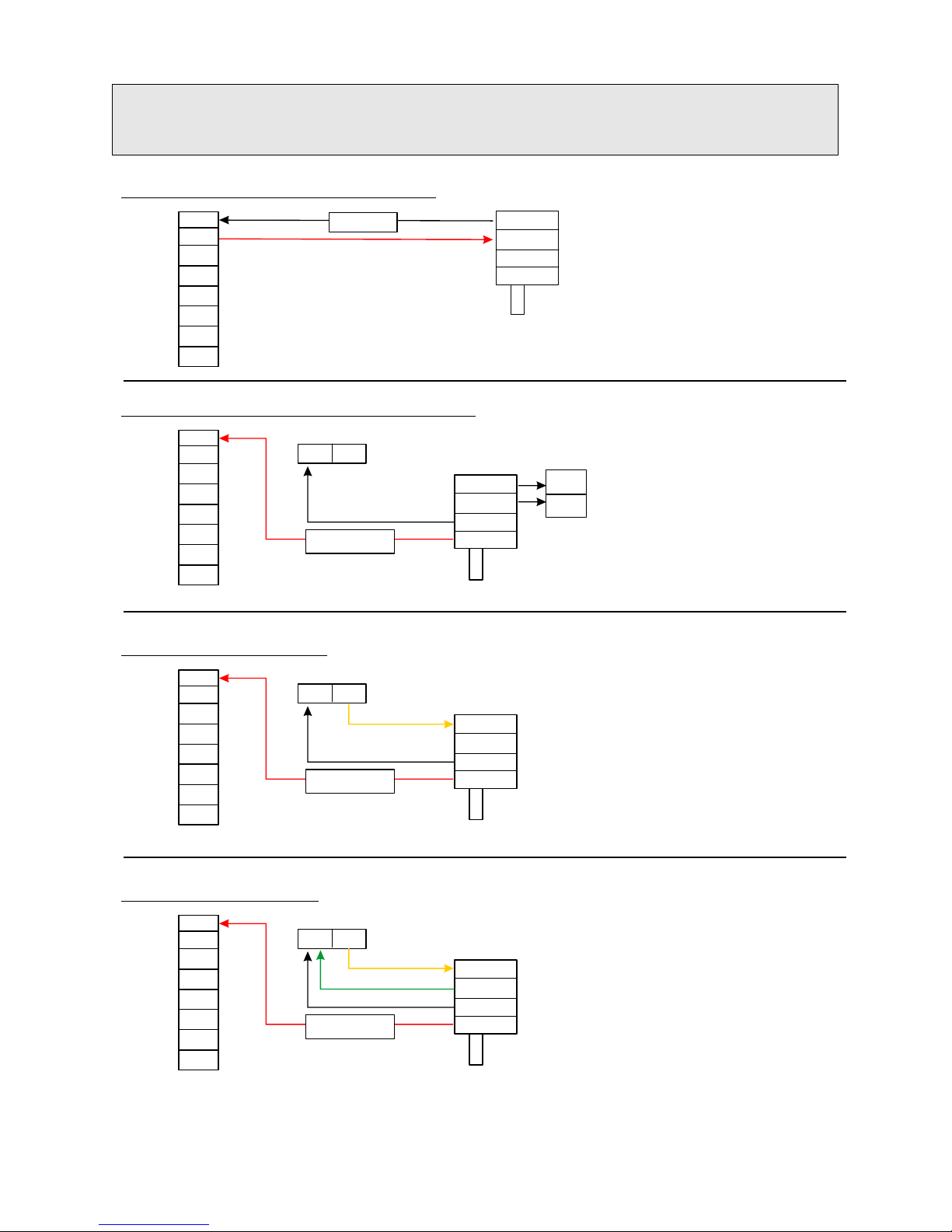

WebMaster 4-20 mA Input Wiring Guide

KEY:

(-) minus terminal is the signal input. The 4-20mA signal goes here.

A.

(+) plus terminal is a +24VDC power supply for the transmitters.

B.

GND terminal is the return for completing circuits, both signal and power.

C.

+24 terminal at the top middle of the board is the same supply as the (+) plus terminal.

D.

-

A

+

B

-

+

-

+

-

+

GN +24

Use shielded cable, grounded only at the controller end, for all connections.

INPUT 5

INPUT 5 INPUT 6 INPUT 7

-

+

-

+

-

+

-

+

A. Two-Wire Loop-Powered Transmitter

Input 1 Input 1 +

- SIGNAL

+ 24

Input 2 Input 2 +

Input 3 Input 3 +

Input 4 Input 4 +

C. Three-Wire Transmitter

Notes:

The (-) signal wire is the actual 4-20mA

signal and is also the GND return wire

to complete the circuit.

'Input -' is internally connected to GND

via 25 ohm resistor.

GND +24

Input 1 Input 1 +

Input 2 Input 2 +

Input 3 Input 3 +

Input 4 Input 4 +

+24

-SIGNAL

+SIGNAL

B. Two-Wire Externally-Powered Transmitter

Input 1 -

GND +24

Input 1 +

Input 2 Input 2 +

Input 3 Input 3 +

Input 4 Input 4 +

D. Four-WireTransmitter

Notes:

This transmitter gets its power from its own

dedicated power supply.

* Connecting a powered transmitter to the

'Input +' terminal of the WebMaster will

permanently damage the input!

GND +24

Input 1 Input 1 +

Input 2 Input 2 +

Input 3 Input 3 +

Input 4 Input 4 +

POWER+

POWER-

-SIGNAL

+SIGNAL

+24

GND

-SIGNAL

+SIGNAL

+24V

GND

E. Non-Isolated Two-Wire Externally-Powered Transmitter

GND +24

Input 1 Input 1 +

Input 2 Input 2 +

Input 3 Input 3 +

Input 4 -

Isolator

OUT- INOUT+ IN+

Input 4 +

Notes:

The analog inputs share their negative terminals.

They are all isolated from earth ground but not isolated from each other.

One non-isolated device may be connected without pr ob le ms.

If more than one non-isolated transmit ter is connected, the

F. Non-Isolated Four-Wire Externally-Powered Transmitter

GND +24

Input 1 Input 1 +

Input 2 -

POWER+

POWER-

-SIGNAL

+SIGNAL

must be installed with an isolator.

Input 2 +

Input 3 Input 3 +

Input 4 Input 4 +

+24

GND

-SIGNAL

+SIGNAL

24

Page 29

ADDING AN ISOLATED RECEIVER TO THE LOOP (PLC, CHART RECORDER, ETC)

The WebMaster GND must always be at the bottom of the loop.

Maximum total loop resistance 1000 ohms.

A. Two-Wire Loop-Powered Transmitter

Input 1 -

- PLC +

Input 1 +

Input 2 Input 2 +

Input 3 Input 3 +

Input 4 Input 4 +

B. Two-Wire Externally-Powered Transmitter

Input 1 Input 1 +

Input 2 Input 2 +

Input 3 Input 3 +

Input 4 Input 4 +

GND +24

- PLC +

C. Three-Wire Transmitter

Input 1 Input 1 +

Input 2 Input 2 +

Input 3 Input 3 +

Input 4 Input 4 +

GND +24

- PLC +

-SIGNAL

+24

POWER+

POWER-

-SIGNAL

+SIGNAL

+24

-SIGNAL

+SIGNAL

Notes:

The (-) signal is the actual 4-20mA signal

and is also the GND return wire to complete

the circuit.

'Input -' is internally connected to GND via

25 ohm resistor.

Notes:

This transmitter gets its power from its own

dedicated power supply.

+24V

* Connecting a powered transmitter to the

GND

'Input +' terminal of the WebMaster

will permanently damage the input!

D. Four-Wire T ran smitter

Input 1 Input 1 +

Input 2 Input 2 +

Input 3 Input 3 +

Input 4 Input 4 +

GND +24

- PLC +

+24

GND

-SIGNAL

+SIGNAL

25

Page 30

Figure 7: Wiring Diagram for Optional Digital Communications

26

Page 31

4.0 FUNCTION OVERVIEW

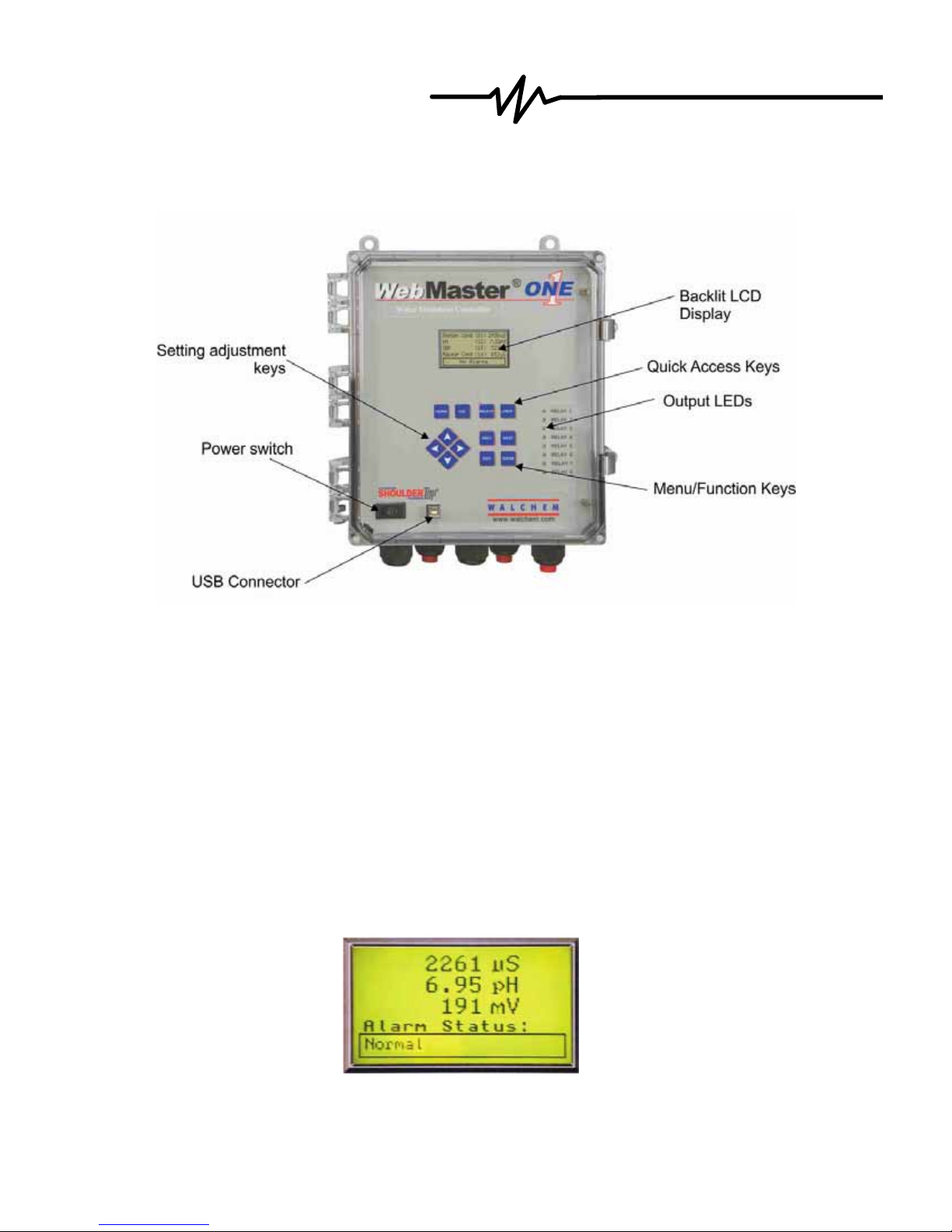

4.1 Front Panel

4.2 Display

Turn the power switch on. Be patient, the start up sequence will take about the same time as it

takes a computer to boot up, approximately 2 minutes. At first the display backlight will blink and

all output LEDS will light. Around 30 seconds later, the display backlight will come on, and the

LEDS will shut off. Then the display will come up, and show you the % complete status of the

start up process. After around 1 minute, the Summary Screen will appear. In 15 seconds, you will

hear 3 beeps, and the controller is ready to go.

The Summary Screen will display the sensor inputs, analog inputs, PPM, etc (up to 5 parameters

selected from the Startup web page) and the most significant active alarm. Any additional alarms

may be viewed by pressing the Down Arrow key.

Figure 8: Front Panel

Figure 9: Display

27

Page 32

4.3 Keypad

The keypad consists of 4 directional arrow keys (up, down, left and right), 4 menu/function keys

(previous, next, exit and enter), and 4 quick access keys (home, calibrate, relays, and help).

The arrow keys are used to change settings (up and down) and move the cursor to a different

location within that menu in order to change that setting (left and right).

The function keys are used to navigate through the different menu selections. The Next and Prev

keys move you from menu to menu. The Enter key is used to enter a submenu, and to accept a new

setting. The Exit key is used to back up one menu level. No matter where you are in the menus,

pressing Exit enough times will bring you to the Summary Screen (or press Home, see below).

To change a numeric value, move the cursor to the digit you want to change by pressing the left or

right arrow keys, then use the up or down arrow keys to change the value. Press the Enter key after

all digits have been changed to enter the new value into memory. Similarly, to change an

alphanumeric value, use the up or down arrow keys to change that character, and the left and right

arrow keys to move to the next character. Press the Enter key after all characters have been

changed.

The quick access keys bring you directly to frequently used or critical functions. The Home key

will bring you directly back to the Summary Screen. The CAL key will bring you directly to the

sensor calibration menus. The Relays key will bring you directly to menus that allow you to force

the relays off or on. The Help key is under construction. Refer to Section 5.0 for details on use of

the keypad for sensor calibration, relay control, setting communications parameters, etc.

4.4 Access Codes

The WebMasterONE series controller is shipped with the access codes at default values. In order

to prevent against unauthorized tampering, you will need to change the access codes to your own

values. See section 6.50 for details.

There are three levels of protection. If the Master password is used in the WebMasterONE

Authentication page, then any set point can be changed. The default Master password is 2001.

If the Calibration password is used in the Authentication page, then sensor calibrations will be

allowed, but other changes will not. The default Calibration password is 2002.

If the Read Only password is used the user will be able to look at any page, but will not be allowed

to make any changes. The default Read Only is 2003.

The default user name is "webmaster." This can and should be changed in the Access Code page.

See section 6.50 for details.

4.5 Initial Startup

Turn the power switch on. Be patient, the start up sequence will take about the same time as it

takes a computer to boot up, approximately 2 minutes. At first the display backlight will blink and

all output LEDS will light. Around 30 seconds later, the display backlight will come on, and the

LEDS will shut off. Then the display will come up, and show you the % complete status of the

start up process. After around 1 minute, the Summary Screen will appear. In 15 seconds, you will

hear 3 beeps, and the controller is ready to go.

The WebMasterONE Series controllers have a wide range of capabilities, so the steps required

preparing the site for installation would be different depending upon the capability you will be

using.

28

Page 33

Currently the WebMasterONE has only limited functionality for the local display and

keypad. ALL of the programming must be accomplished using a computer.

You will be able to calibrate all sensor inputs, change access codes, and enter the information

necessary to communicate with the WebMasterONE via an Ethernet connection or via the

modem over the Internet (if a modem card is installed in the controller). If neither of these

communications options are installed, you must use an USB connection to a PC for

programming. You may set most set points with the keypad, but you may not change

operating modes (for example, you may change the pump on time for a time-based add, but

not the time of day; nor can you change from a 1 week cycle to a 2 week cycle).

If you have a stand-alone controller with no communications, but you do have a computer to

connect to the USB port on the front panel of the controller for programming, go to the section

below called “Connection via the USB Port”.

If you have a controller that is equipped with a modem, then you can take full advantage of the

WebMasterONE. The controller is like a web server. Once you set up an Internet Service Provider

(ISP) account for the controller, you can “surf” to the controller from any web connected computer

to access data or reconfigure the controller. The controller can also contact you, by email or pager,

in case of trouble. In this case, a dedicated analog phone line that does not go through a company

switchboard for the controller must be provided. For details, go to the section below called

“Remote Modem Access: Shoulder Tap.” The ISP information must be entered into the controller

via the USB port, or via the local keypad before attempting a Shoulder Tap connection.

If you have not yet set up an ISP account and wish to program the WebMasterONE from a remote

location, or if you just prefer the “old fashioned method” of direct modem-to-modem

communication, go to the section below called “Direct Modem Access: Direct Tap.”

If you have the Ethernet connected, then the controller can become another PC on the network.

You can use your web browser software, enter the controller’s address (assigned by your network

administrator) and access data or reconfigure the controller. You will need to have a network node

nearby to connect your WebMasterONE. See the section below called “Ethernet Connection to

LAN”.

You may also use the Ethernet card in your laptop to communicate with the Ethernet card in the

WebMasterONE. This requires a special null (crossover) cable and the Ethernet parameters must

be programmed into the WebMasterONE using either USB or the local keypad. Refer to the

section below called “Direct Ethernet (for an WebMasterONE not connected to the LAN).”

Uploading Configuration Files

You can save all of the set points from a previously programmed controller, and then upload the

same set points into another controller. If you have already downloaded a configuration file from a

previously programmed controller, you can upload that file to this controller in order to make all

the set points the same. If you want to save the set points of this controller for use in future

controllers, or want to program this controller using a stored configuration file, refer to section

6.48 for specific instructions.

See the appropriate section above, depending upon how you plan on uploading the configuration

file; via a laptop connected to the front panel, via modem, via Ethernet connection, or via local PC

connected to the USB port.

29

Page 34

4.6 Communicating with the WebMasterONE

4.6.1 Connection via the USB Port

Web Browser

(Client)

USB

A USB connection to the WebMasterONE can be made via a temporary cable between a laptop

and the front panel of the controller.

Equipment Required

An USB cable with the appropriate connectors to connect your computer to the

WebMasterONE.

Features Required in the WebMasterONE

Any WebMasterONE controller is capable of an USB connection.

Utilities you need to set up on your computer

You will need the USB driver, which comes with the WebMasterONE. It’s also available on

our Web site under Tech Support > WebMaster/WIND > Downloads and Upgrades. You will

also need the Quick Start Guide which comes with the WebMasterONE, or you can download

it from our Web site under Literature > WebMaster.

Parameters that need to programmed into the WebMasterONE

The WebMasterONE is capable of this type of communication without any programming by

the user prior to attempting the communication.

Steps Required to Establish a Connection

Connect the supplied USB cable between the WebMasterONE and your computer.

Install the driver on your PC by inserting the disc supplied and following the instructions in

the Quick Start Guide. This needs to done only once for each PC that will be used to

communicate with a WebMasterONE controller.

Go to Control Panel, Network Connections, and locate the new Local Area Connection 2 that

has been created. Click on the Properties button. Highlight Internet Protocol (TCP/IP) then

click Properties. Click Use the following IP address and enter 199.199.199.1. Click OK to

exit. This needs to done only once for each PC that will be used to communicate with a

WebMasterONE controller.

Open Internet Explorer and type in the address 199.199.199.2. The sign-on screen for the

WebMasterONE will come up.

The sign-on screen of the WebMasterONE will come up. Type the User Name and Password

(Access Code) in the text boxes and click the Submit button. The default user name is

"webmaster" and the default passwords are "2001" for full access, "2002" for calibration only,

and "2003" for read only. These defaults can and should be changed in the Access Code page.

Hard coded Fixed

IP Address:

199.199.199.2

30

Page 35

4.6.2 Remote Modem Access: Shoulder Tap

Equipment Required

An Internet-ready computer.

An active analog phone line, direct to the controller (without a PBX system in between) must

be connected to the modem of the WebMasterONE.

A dialup account must be established for the WebMasterONE with an Internet Service

Provider (ISP). The connection will only be as reliable as the ISP. ISPs that require the

installation of a CD cannot be used. Contact the factory for recommendations.

Features Required in the WebMasterONE

The WebMasterONE must have the modem option installed in order to communicate via Shoulder Tap.

Utilities you need to set up on your computer

There are no special drivers, adapters or other software components required on the PC.

Parameters that need to be programmed into the WebMasterONE

Prior to attempting a Shoulder Tap connection, the following information needs to be entered

into the Communications page of the WebMasterONE, either via an USB connection, direct

modem connection (Direct Tap) or via the local keypad. Some of this information needs to be

provided to you by the Internet Service Provider (ISP) that the WebMasterONE will use to

access the Internet.

The controller’s phone number.

The local access phone number for the ISP. More than one access number may be entered.

The ISP Username that the controller will use to connect to the ISP.

The ISP Password that the controller will use to connect to the ISP.

Steps Required to Establish a Connection

Connect your PC to the Internet.

Enter the address htttp://w700.walchem.com/walchem/frontdoor.asp.

Click the link “Log onto WebMasterONE”, which will bring you to the WebMasterONE

Connection Utility Authentication Page.

Enter the Connection Utility Username (WebMaster) and Password (2001) and click the

Submit button.

Enter the phone number of the controller and click the Connect button. After a few minutes,

the sign-on screen for the WebMasterONE will come up.

The sign-on screen of the WebMasterONE will come up. Type the User Name and Password

(Access Code) in the text boxes and click the Submit button. The default user name is

"webmaster" and the default passwords are "2001" for full access, "2002" for calibration only,

and "2003" for read only. These defaults can and should be changed in the Access Code page.

31

Page 36

4.6.3 Ethernet Connection to LAN

Equipment Required

An Internet-ready computer.

A connection between the PC and the local area network (LAN).

An Ethernet connection between the WebMasterONE and the LAN.

Utilities you need to set up on your computer

There are no special drivers, adapters or other software components required on the PC.

Parameters that need to be programmed into the WebMasterONE

Prior to attempting an Ethernet connection, the following information needs to be entered into

the Communication page of the WebMasterONE, either via an USB connection or via the

local keypad. This information must be provided by the IT Administrator of the LAN.

The Ethernet IP address of the WebMasterONE. If the controller will only be accessed by

computers on the LAN then this may be a local IP address. If the controller needs to be

accessible by computers not on the LAN then this must be an Internet accessible IP address.

The Subnet Mask.

The Gateway IP address.

Steps Required to Establish a Connection

Open Internet Explorer.

Type in the Ethernet IP address that has been assigned by the IT Administrator.

The sign-on screen of the WebMasterONE will come up. Type the User Name and Password

(Access Code) in the text boxes and click the Submit button. The default user name is

"webmaster" and the default passwords are "2001" for full access, "2002" for calibration only,

and "2003" for read only. These defaults can and should be changed in the Access Code page.

32

Page 37

4.6.4 Direct Modem Access: Direct Tap

Web Browser

(Client)

Equipment Required

An Internet-ready computer.

An active analog phone line, direct to the controller (without a PBX system in between) must

Features Required in the WebMasterONE

The WebMasterONE must have the modem option installed in order to communicate via

Utilities you need to set up on your computer

A Windows dialup networking adapter must be created. Refer to the Quick Start Guide

Parameters that need to be programmed into the WebMasterONE

The WebMasterONE is capable of this type of communication without any programming by

Steps Required to Establish a Connection

Create the dialup networking adapter on your PC. This needs to done only once for each PC

Use the dialup networking adapter to connect the PC to the WebMasterONE.

Open Internet Explorer.

Type in the address 199.199.199.3. The sign-on screen for the WebMasterONE will come up.

The sign-on screen of the WebMasterONE will come up. Type the User Name and Password

modem

be connected to the modem of the WebMasterONE.

Direct Tap.

instructions for this procedure.

the user prior to attempting the communication.

that will be used to communicate with a WebMasterONE controller.

(Access Code) in the text boxes and click the Submit button. The default user name is

"webmaster" and the default passwords are "2001" for full access, "2002" for calibration only,

and "2003" for read only. These defaults can and should be changed in the Access Code page.

TELCO

modem

Embedded

Web Server

Hard coded

Fixed IP Address:

199.199.199.3

33

Page 38

4.6.5 Direct Ethernet (for a WebMasterONE not connected to a LAN)

Web Browser

(Client)

Fixed IP

Address User

Assigned

Ethernet Cable

Equipment Required

An Internet-ready computer.

An Ethernet cable connection between the PC and WebMasterONE.

Note: Ethernet cross-over cable is required if your PC is using Windows XP. For Vista,

Windows 7 or Mac OS, a standard Ethernet cable will work.

Setting up your computer:

Go to LAN connections

For Windows XP: Control Panel > Network and Internet Connections > Network

Connections > Local Area Network

For Windows Vista: Control Panel > Network and Sharing Center > Manage Network

Connections

For Windows 7: Control Panel > View Network Status and Tasks

For Mac OSX: System Preferences > Ethernet

Right-click on the LAN connection, and choose Properties.

For Windows XP: Highlight Internet Protocol (TCP-IP)

For Vista and Windows 7: Highlight Internet Protocol Version 4 (TCP/IPv4)

For Mac OSX: Set Configure IPv4 to Manually

Select Use the following IP address

Change the IP address to 10.0.100.30. Subnet mask should be 255.255.254.0.

Parameters that need to be programmed into the WebMasterONE

The default settings will work with the LAN settings shown above. The default IP address for

the controller is 10.0.100.29. The default subnet mask is 255.255.254.0.

Steps Required to Establish a Connection

Open Internet Explorer.

Type in the Ethernet IP address that has been assigned to the WebMasterONE (10.0.100.29).

The sign-on screen of the WebMasterONE will come up. Type the User Name and Password

(Access Code) in the text boxes and click the Submit button. The default user name is

"webmaster" and the default passwords are "2001" for full access, "2002" for calibration only,

and "2003" for read only. These defaults can and should be changed in the Access Code page.

User Assigned

Fixed IP Address

Gateway + Subnet Mask

34

Page 39

4.6.6 Networking WebMasterONE Controllers via Ethernet

Web Browser connected

using any of the

previous methods

Equipment Required

An Internet-ready computer.

An Ethernet cable connection between each WebMasterONE using a hub or connection to

LAN.

Utilities you need to set up on your computer

There are no special drivers, adapters or other software components required on the PC to

support networking. Refer to the previous sections for connecting to the master controller via

USB, Ethernet, or modem.

Parameters that need to be programmed into the WebMasterONE

Prior to attempting an Ethernet connection, the following information needs to be entered into

the Communication page of each WebMasterONE on the network, either via an USB

connection or via the local keypad.

The Ethernet IP address of the WebMasterONE.

The Subnet Mask.

The Gateway IP address.

The master must be selected as the master, and the slaves selected as slaves.

Steps Required to Establish a Connection

Connect to the master controller using one of the methods described in sections 4.6.1

through 4.6.5.

The sign-on screen of the WebMasterONE will come up. Type the User Name and

Password (Access Code) in the text boxes and click the Submit button. The default user

name is "webmaster" and the default passwords are "2001" for full access, "2002" for

calibration only, and "2003" for read only. These defaults can and should be changed in

the Access Code page.

Once connected to the master, you may connect to the slaves by clicking on the link under

the heading of “Sub-Network”.