Walchem WDT400 Series Instruction Manual

W

W A L C H E M

IW AKI America Inc.

DT400 Controllers

WDT400 Series

Dual Cooling Tower

Conductivity Controller

Instruction Manual

Five Boynton Road Hopping Brook Park Holliston, MA 01746 USA

TEL: 508-429-1110 FAX: 508-429-7433 WEB: www.walchem.com

Notice

© 2014 WALCHEM, Iwaki America Inc.(hereinafter “Walchem”)

Five Boynton Road, Holliston, MA 01746 USA

(508) 429-1110

All Rights Reserved

Printed in USA

Proprietary Material

The information and descriptions contained herein are the property of WALCHEM. Such information and

descriptions may not be copied or reproduced by any means, or disseminated or distributed without the

express prior written permission of WALCHEM, Five Boynton Road, Holliston, MA 01746.

Statement of Limited Warranty

WALCHEM warrants equipment of its manufacture, and bearing its identification to be free from

defects in workmanship and material for a period of 24 months for electronics and 12 months for

mechanical parts and electrodes from date of delivery from the factory or authorized distributor

under normal use and service and otherwise when such equipment is used in accordance with

instructions furnished by WALCHEM and for the purposes disclosed in writing a the time of

purchase, if any. WALCHEM’s liability under this warranty shall be limited to replacement or

repair, F.O.B. Holliston, MA U.S.A. of any defective equipment or part which, having been

returned to WALCHEM, transportation charges prepaid, has been inspected and determined by

WALCHEM to be defective. Replacement elastomeric parts and glass components are expendable

and are not covered by any warranty.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EITHER EXPRESS OR IMPLIED,

AS TO DESCRIPTION, QUALITY, MERCHANTABILITY, and FITNESS FOR ANY

PARTICULAR PURPOSE OR USE, OR ANY OTHER MATTER.

180331 Rev. L

April 2014

Table of Contents

1.0 INTRODUCTION..................................................................................................................... 1

2.0 SPECIFICATIONS .................................................................................................................. 2

2.1 Measurement Performance ................................................................................................. 2

2.2 Electrical: Input/Output ........................................................................................................ 2

2.3 Mechanical .......................................................................................................................... 2

2.4 WDT Variables and their Limits ........................................................................................... 3

3.0 UNPACKING & INSTALLATION ............................................................................................. 4

3.1 Unpacking the unit............................................................................................................... 4

3.2 Mounting the electronic enclosure....................................................................................... 4

3.3 Installation ........................................................................................................................... 4

3.4 Icon Definitions.................................................................................................................... 6

3.5 Electrical installation............................................................................................................ 6

4.0 FUNCTION OVERVIEW ....................................................................................................... 10

4.1 Front Panel........................................................................................................................ 10

4.2 Display .............................................................................................................................. 10

4.3 Keypad .............................................................................................................................. 11

4.4 Access Code ..................................................................................................................... 11

4.5 Startup............................................................................................................................... 11

4.6 Shut Down......................................................................................................................... 11

5.0 OPERATION ......................................................................................................................... 12

5.1 Main Menu ........................................................................................................................ 12

5.2 Conductivity (A or B) Menu ............................................................................................... 14

5.3 Temperature (A or B) Menu .............................................................................................. 16

5.4 Bleed (A or B) Menu .......................................................................................................... 17

5.5 Feed (A or B) Menu ........................................................................................................... 18

5.6 WM1 and WM2 Menu........................................................................................................ 20

5.7 Alarm (A or B) Menu.......................................................................................................... 21

5.8 Time Menu ........................................................................................................................ 22

5.9 4-20mA (A or B) Menu ...................................................................................................... 23

5.10 Access Code Menu ........................................................................................................... 24

5.11 Datalog Menu.................................................................................................................... 25

5.12 Config Menu...................................................................................................................... 26

5.13 Upgrade Menu .................................................................................................................. 27

6.0 MAINTENANCE .................................................................................................................... 28

6.1 Electrode Cleaning............................................................................................................ 28

6.2 Replacing the Fuses.......................................................................................................... 29

7.0 TROUBLESHOOTING .......................................................................................................... 29

7.1 Error Messages................................................................................................................. 29

7.2 Conductivity Readout Does Not Change........................................................................... 31

7.3 Procedure for evaluation of the conductivity electrode ..................................................... 31

7.4 Procedure for checking relay outputs ................................................................................ 32

8.0 SERVICE POLICY ................................................................................................................ 32

1.0 INTRODUCTION

The Walchem WDT400 Series controllers offer conductivity control of cooling tower water and control

of corrosion/scale inhibitor feed. The inhibitor pump may be selected to operate in one of the following

modes:

The WDT series cooling tower controllers are supplied with temperature compensated electrodes with a

cell constant of 1.0. The controllers are microprocessor driven industrial type with on/off control

outputs. A timed sample mode may be selected, and on small towers can reduce installation costs by

eliminating the need for a sampling bypass line. One or two optional isolated 4-20 mA outputs that are

proportional to the conductivity reading are available for all models.

Any set point may be viewed without interrupting control. Each set point change will take effect as soon

as it is entered. An access code is available to protect set point parameters, while still allowing settings

to be viewed.

All outputs are interlocked with a flow switch input.

An alarm relay is provided with WDT400 models. It is triggered by:

Our unique USB feature provides the ability to upgrade the software in the controller to the latest

version.

An advanced USB capability option is available. The Config file feature allows you to save all the set

points from a controller onto a USB flash disk, and then import them into another controller, making the

programming of multiple controllers fast and easy. The data logging feature allows you to save the last

2 month’s readings and events to a USB flash disk.

Feed and Bleed

Feed and Bleed with Lockout

Feed as a percent of Bleed

Feed as a percent of Time

Feed based on a Water Contactor input

Feed based on a Paddlewheel input

Temp A or B Error

Cond A or B Error

No Flow Tower A or B

Bleed A or B Timeout

Feed A or B Timeout

Tower A or B Hi Alarm

Tower A or B Lo Alarm

1

2.0 SPECIFICATIONS

2.1 Measurement Performance

Conductivity Range 0 - 10,000 µS/cm (microSiemens/centimeter)

Conductivity Resolution 1 µS/cm

Conductivity Accuracy 10 - 10,000 µS/cm ± 1% of reading

Temperature Range 32 – 158°F (0 – 70°C)

Temperature Resolution 0.1°C

Temperature Accuracy ± 1% of reading

2.2 Electrical: Input/Output

Input Power

Input Signals

Conductivity Electrode 1.0 cell factor, 10K thermistor

Flow Meter (0, 1 or 2 optional) Isolated, dry contact closure required (i.e. relay, reed switch)

Flow Switch (0, 1 or 2 optional) Isolated, dry contact closure required (i.e. reed switch)

Outputs

Mechanical Relays (5) Pre-powered on circuit board switching line voltage

0 - 10 µS/cm ± 20% of reading

100-240 VAC, 50/60 Hz, 8A

Fuse: 1.0 ampere, 5 x 20 mm

6 A (resistive), 1/8 HP

All relays are fused together as one group, total current for this

group must not exceed 6A

4 - 20 mA (0,1, or 2 optional) Fully isolated

Agency Approvals

Safety UL 61010-1:2012 3rd Ed.

Note: For EN61000-4-6, EN61000-4-3 the controller met performance criteria B.

*Class A equipment: Equipment suitable for use in establishments other than domestic, and those directly

connected to a low voltage (100-240 VAC) power supply network which supplies buildings used for

domestic purposes.

600 Ohm max resistive load

Resolution .001% of span

Accuracy ± 1% of reading

CSA C22.2 No. 61010-1:2012 3rd Ed.

IEC 61010-1:2010 3rd Ed.

EN 61010-1:2010 3rd Ed.

EMC IEC 61326-1:2005

EN 61326-1:2006

2.3 Mechanical

Enclosure Material Polycarbonate

NEMA Rating NEMA 4X

Dimensions 8.5" x 6.5" x 5.5"

Display 2 x 16 character backlit liquid crystal

Operating Ambient Temp 32 – 122°F (0 – 50°C)

Storage Temperature -20 – 180°F (-29 – 80°C)

Graphite electrode pressure rating 150 psi

Flow switch manifold pressure rating 150 psi

Flow switch manifold connections ¾" NPTF

2

2.4 WDT Variables and their Limits

Low Limit High Limit

Conductivity menu

Temperature Menu

Bleed Menu

Feed Menu

WM1 and WM2 Menus

K Factor (Paddlewheel) 0.01 pulse/vol 999.99 pulses/vol

4-20 mA Menus 4 & 20 mA Settings 0 µS/cm 10,000 µS/cm

Access Code New Value 0 9999

Alarms Menu* High & Low (set to zero to disable) 1% 50%

Datalog Menu (Optional)

Config Menu (Optional)

Upgrade Menu

*Note: The Alarm relay is non-programmable. Refer to the Main Menu diagram on page 16 for the list of error

conditions that trigger the alarm relay.

Bleed Limit Time (set in hours/minutes) 1 minute 8 hrs: 20 min

PPM Conversion Factor 0.200 ppm/µS/cm 1.000 ppm/µS/cm

Interval Time (sampling) 5 minutes 24:00 hours

Duration Time (sampling) 1 minute 59 min: 59 sec

% Calibration Range -50 +50

Set Point 0 µS/cm 10,000 µS/cm

Dead Band 5 µS/cm 500 µS/cm

Feed Lockout Timer (Mode A) 1 second 99 min: 59 sec

Percent of Bleed (Mode B) 5 % 99 %

Feed Time Limit (Mode B) 1 minute 99 min: 59 sec

Percent of Time (Mode C) 5 % 99 %

Feed Cycle Time (Mode C) 10 minutes 59 min: 59 sec

Time per Contact (Mode D) 1 second 59 min: 59 sec

÷ Contacts by (Mode D) 1 contact 100 contacts

Time Limit (Mode D & E) 1 minute 99 min: 59 sec

Time/Vol (Mode E) 1 second 59 min: 59 sec

Vol to Initiate Feed (Mode E) 1 9,999

Gallons per Contact 1 gal/contact 500 gal/contact

Liters per Contact 1 L/contact 500 L/contact

No variables

No variables

No variables

No variables

(enabled)

0=unlimited (disabled)

3

3.0 UNPACKING & INSTALLATION

3.1 Unpacking the unit

Inspect the contents of the carton. Please notify the carrier immediately if there are any signs of damage

to the controller or its parts. Contact your distributor if any of the parts are missing. The carton should

contain: a WDT400 series controller and instruction manual. Any options or accessories will be

incorporated as ordered.

3.2 Mounting the electronic enclosure

The WDT series controller is supplied with mounting holes on the enclosure. It should be wall mounted

with the display at eye level, on a vibration-free surface, utilizing all four mounting holes for maximum

stability. Use M6 (1/4" diameter) fasteners that are appropriate for the substrate material of the wall.

The enclosure is NEMA 4X rated. The maximum operating ambient temperature is 122°F (50°C); this

should be considered if installation is in a high temperature location. The enclosure requires the

following clearances:

Top: 2" (50 mm)

Left: 8" (203 mm)

Right: 4" (102 mm)

Bottom: 7" (178 mm)

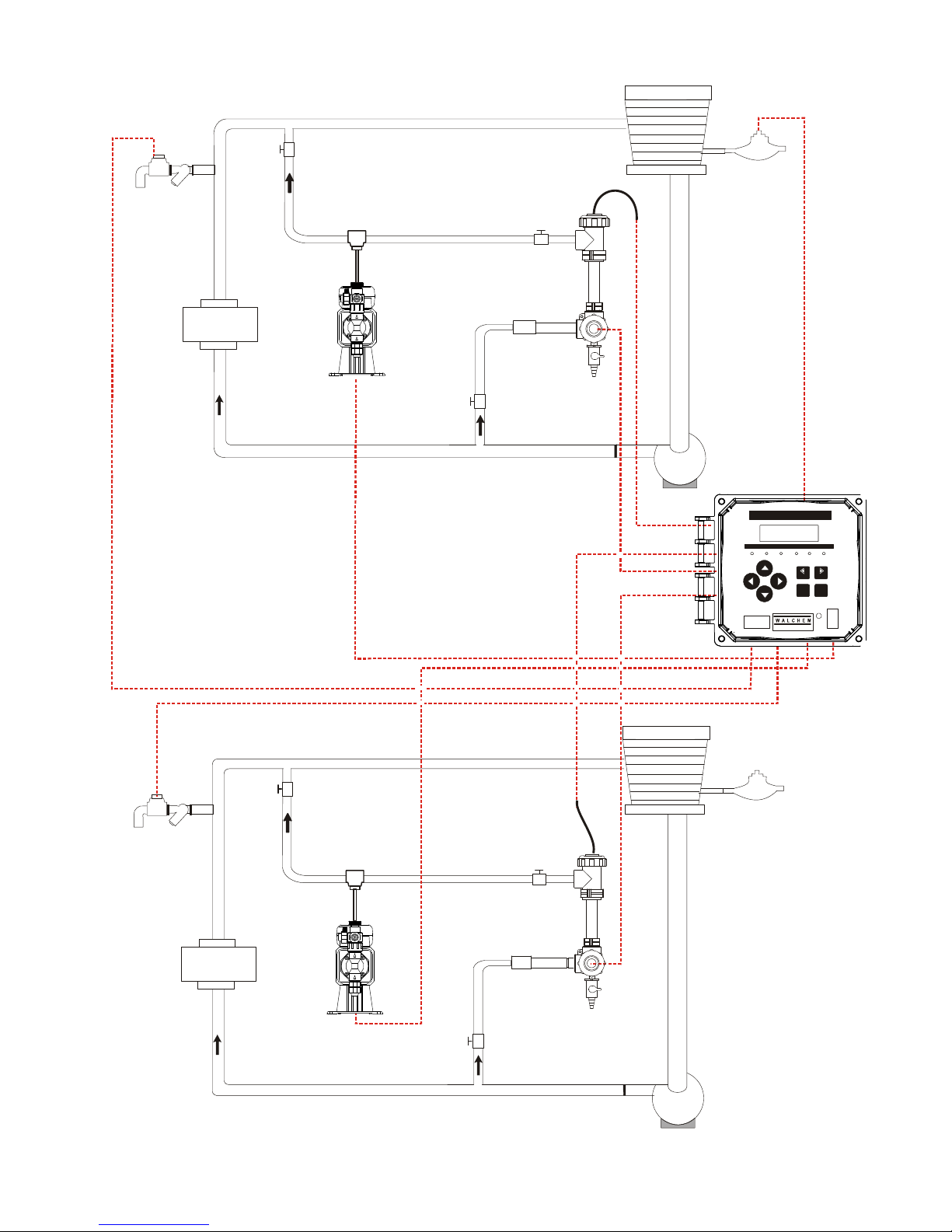

3.3 Installation

Once the WDT series controller is mounted, the metering pumps may be located at any distance from

the controller. The conductivity electrodes should be placed as close to the controller as possible, to a

maximum distance of 250 ft. Under 25 ft is recommended. The cable must be shielded from background

electrical noise. Always route low voltage (sensor) signals with at least a 6” separation from AC voltage

wiring.

Locate the electrode tees where an active sample of cooling tower water is available and where the

electrode can easily be removed for cleaning. They must be situated so that the tee is always full and the

electrode is never subjected to a drop in water level resulting in dryness. Refer to Figure 1 for typical

installation.

IMPORTANT: To avoid cracking the female pipe threads on the supplied plumbing parts, use no more

than 3 wraps of Teflon® tape and thread in the pipe FINGER tight plus ½ turn! Do not use pipe dope to

seal the threads of the flow switch because the clear plastic will crack!

4

COO

LING TOWER

BLEED

VALVE

EXCHANGER

HEAT

System A

METERING

PUMP

Cooling Tower Controller

PRE V N EXT

ENTER

www.wal chem.com

I

EX T

COOLING TOWER

BLEED

VALVE

EXCHANGER

HEAT

METERING

PUMP

System B

Figure 1 Typical Installation

5

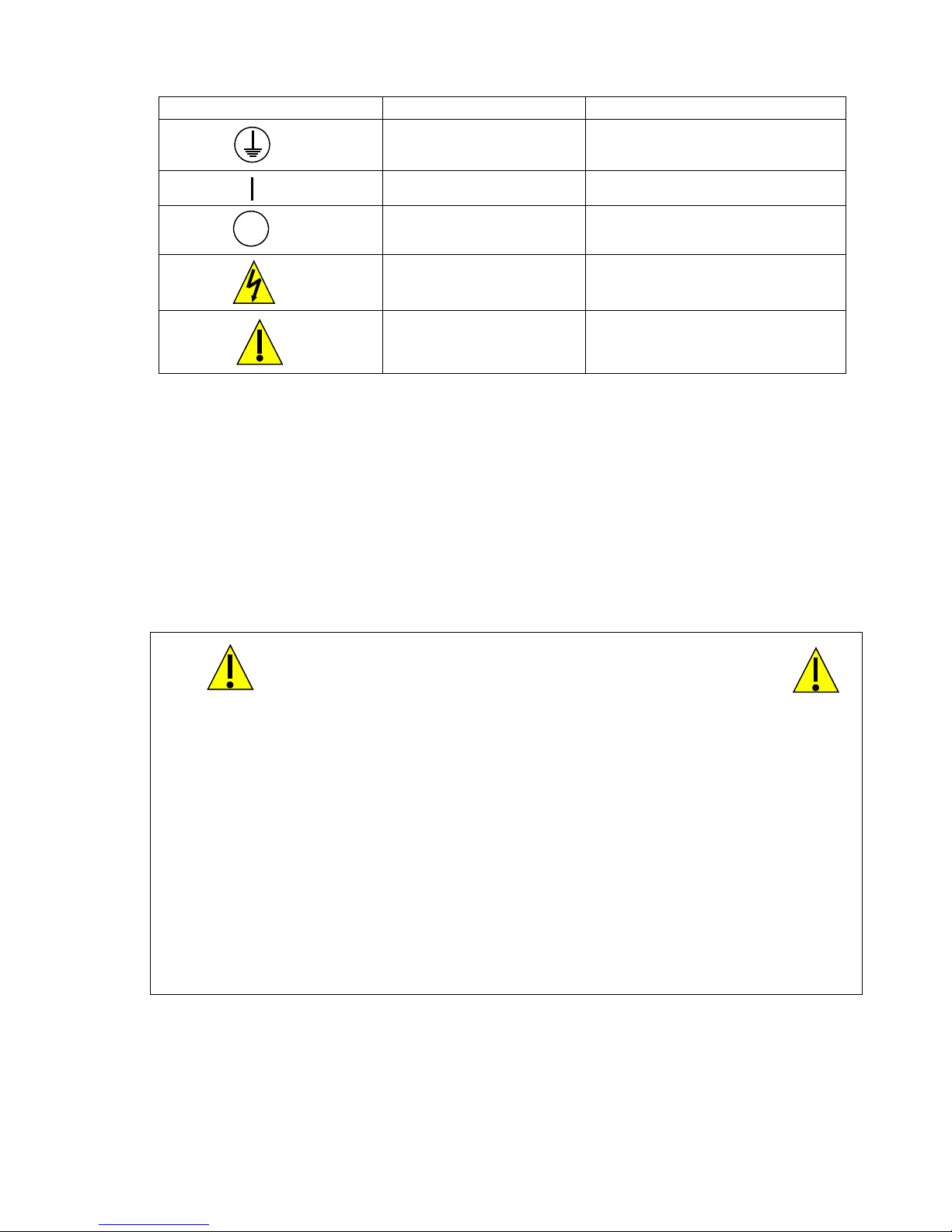

3.4 Icon Definitions

Symbol Publication Description

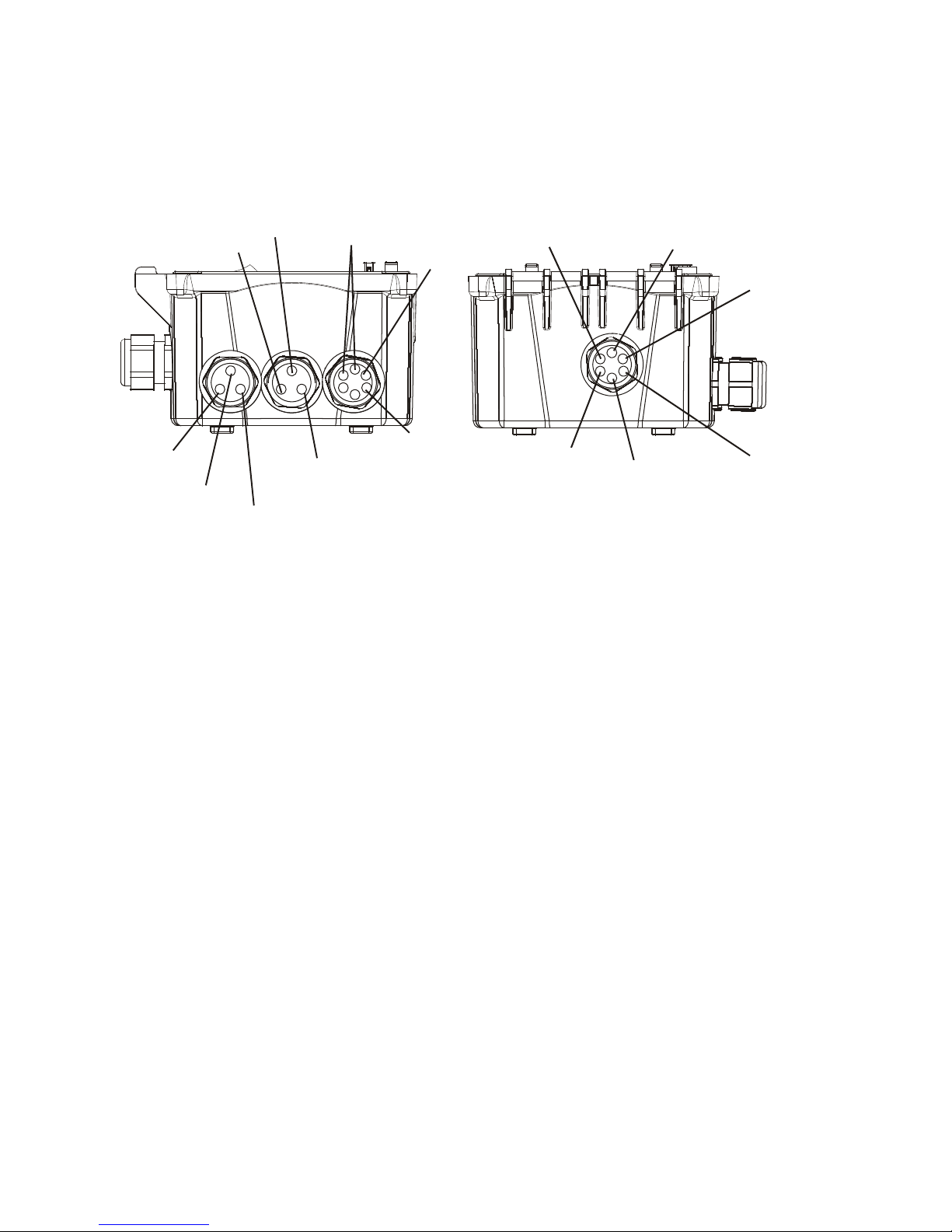

3.5 Electrical installation

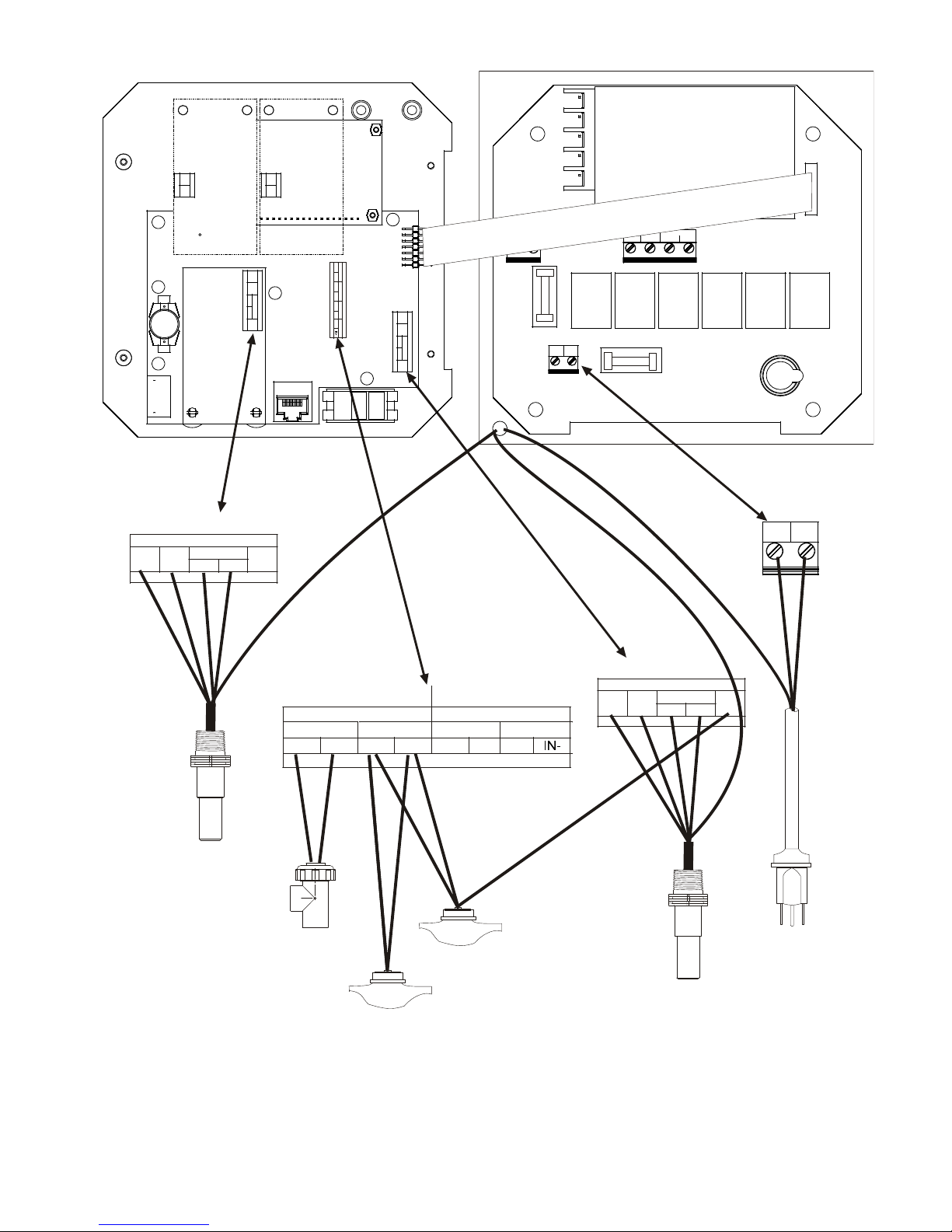

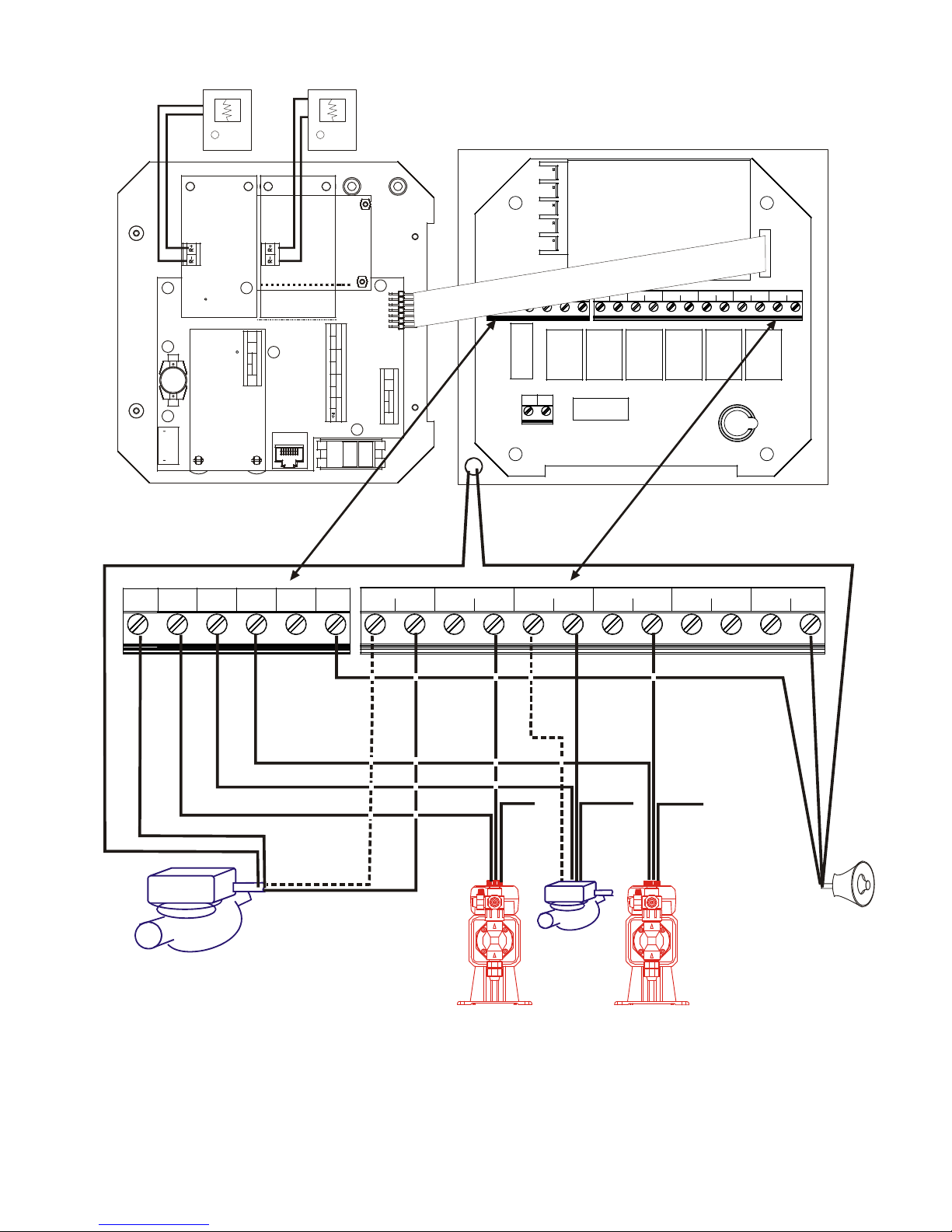

The various standard wiring options are shown in figure 2, below. Your WDT series controller will

arrive from the factory prewired or ready for hardwiring. Depending on your configuration of controller

options, you may be required to hardwire some or all of the input/output devices. Refer to figures 3 and

4 for circuit board layout and wiring.

Note: when wiring the optional flow meter contactor input, the 4-20 mA output or a remote flow switch,

it is advisable to use stranded, twisted, shield pair wire between 22-26 AWG. Shield should be

terminated at the controller ground stud (see figures 3 and 4).

IEC 417, No.5019 Protective Conductor Terminal

IEC 417, No. 5007 On (Supply)

IEC 417, No. 5008 Off (Supply)

ISO 3864, No. B.3.6 Caution, risk of electric shock

ISO 3864, No. B.3.1 Caution

CAUTION

1. There are live circuits inside the controller even when the power switch on the front panel is in

the OFF position! The front panel must never be opened before power to the controller is

REMOVED!

If your controller is prewired, it is supplied with a 8 foot, 18 AWG power cord with USA style

plug. A tool (#1 Phillips driver) is required to open the front panel.

2. When mounting the controller, make sure there is clear access to the disconnecting device!

3. The electrical installation of the controller must be done by trained personnel only and

conform to all applicable National, State and Local codes!

4. Proper grounding of this product is required. Any attempt to bypass the grounding will

compromise the safety of persons and property.

5. Operating this product in a manner not specified by Walchem may impair the protection

provided by the equipment.

6

BLEED B

Y

CO

FEED B

SPARES

4-20 mA (2)

(optional)

CONDUCTIVIT

ELECTRODE B

NDUCTIVITY

ELECTRODE A

FLOW SWITCH A

(OPTIONAL)

POWER

BLEED A

FEED A

ALARM

4-20 mA (1)

(optional)

FLOW METER B

(OPTIONAL)

Figure 2 Conduit/Wiring Configuration

FLOW SWITCH B

(OPTIONAL)

FLOW METER A

(OPTIONAL)

7

T+ T-

G

R

E

E

N

R- R+

SYSTEM B

COND

RED BLK

W

H

I

T

E

T+ T-

RED BLK

+5V

+5V

COND

R- R+

BLEED

L2 L2

IN+ IN-

FLOW SW 1 FLOW SW 2

FLOW M TR 1

IN+ IN-

IN+ IN- IN+

FL O W M TR 2

T+ T-

RED BLK

COND

+5V

F1

L1 L2/N

N.C. N.O.

FEED

N.C. N.O.

F2

GROUND

STUD

GR

GR

N

1

N

2

/

Y

0

V

E

L

2

4

0

V

L1 L2/N

B

B

LK

R

N

120V

2

40V

WHT 120V

BLU 240V

SHIELD

FLOW SW 1 FLOW SW 2

IN+ IN- IN+ IN- IN+

Conductivity

Electrode

Contact Closure:

Polarity not critical

SYSTEM A

FLOW MTR 1

IN+ IN-

Flow Meter

Reed Switch

Flow Meter

Polarity not Critical

Figure 3 Inputs

SYSTEM B

Hall Effect

FLOW MTR 2

T+ T-

G

R

E

E

N

SYSTEM A

COND

RED BLK

W

H

I

T

E

Conductivity

Electrode

+5V

SHIELD

Power Supply

(115 VAC or 230 VAC)

8

System

A

A

p

p

Chart Chart

Recorder Recorder

System B

T+ T-

RED BLK

COND

+5V

IN+ IN- IN+ IN- IN +

IN+ IN-

GRN 120V

GRN/YEL 240V

L2/N L2/N L2/N L2/N L2/N L2/N

WHT 120V

BLU 240V

WHT 120V

BLU 240V

WHT 120V

WHT 120V

BLU 240V

BLU 240V

L2 L2 L2 L2 L2 L2

FLOW SW 1 FLOW SW 2

FLOW MTR 1 FLOW MTR 2

T+ T-

RED BLK

COND

+5V

L1 L2/N

BLEED FEE D BOI 1 BIO 2 ALARM

N.C. N.O. N.C. N.O. N.C. N.O. N.C. N.O. N.C. N.O. N.C. N.O.

GROUND

STUD

BLK 120V

BLEED B

BRN 240V

IF MOTORIZED

WHT 120V

BLU 240V

BLK 120V

BALL VALVE

BRN 240V

BLK 120V

BRN 240V

BLEED A FEED A FEED B ALARM

N.C. N.O. N.C. N.O. N.C. N.O. N.C. N.O. N.C. N.O.

BLK 120V

BRN 240V

GRN 120V

GRN/YEL 240V

BLK 120V

BRN 240V

IF MOTORIZED

BALL VALVE

NOTE: When connecting a

motorized ball valve, the pre-wired

pigtail must be removed and the

valve requires two wires, one to

N.O. to open the valve and one to

Bleed Solenoid/

N.C. to close the valve.

Motorized Ball Valve

GRN 120V

GRN/YEL 24 0V

TO GROUND

STUD

Solenoid/

Motorized

Ball Valve

Pum

Figure 4 Outputs

9

Bleed

GRN 120V

GRN/YEL 240V

TO GROUND

STUD

Pum

GRN 120V

GRN/YEL 240V

TO GROUND

STUD

larm

Loading...

Loading...