Walchem WDS600, WDS410, WDS900, WDS100 Instruction Manual

Five Boynton Road Hopping Brook Park Holliston, MA 01746 USA

Disinfection Sensors

W A L C H E M

IWA KI Am eri ca Inc .

Non-Membrane Disinfection Sensors

Instruction Manual

TEL: 508-429-1110 WEB: www.walchem.com

Notice

© 2019 WALCHEM, Iwaki America Inc. (hereinafter “Walchem”) Five Boynton Road, Holliston, MA 01746 USA (508) 429-1110 All Rights Reserved Printed in USA

Proprietary Material

The information and descriptions contained herein are the property of

WALCHEM. Such information and descriptions may not be copied or

reproduced by any means, or disseminated or distributed without the

express prior written permission of WALCHEM, Five Boynton Road,

Holliston, MA 01746.

Statement of Limited Warranty

WALCHEM warrants equipment of its manufacture, and bearing its identification

to be free from defects in workmanship and material for a period of 24 months

for electronics and 12 months for mechanical parts and electrodes from date of

delivery from the factory or authorized distributor under normal use and service

and otherwise when such equipment is used in accordance with instructions

furnished by WALCHEM and for the purposes disclosed in writing at the time of

purchase, if any. WALCHEM’s liability under this warranty shall be limited to

replacement or repair, F.O.B. Holliston, MA U.S.A. of any defective equipment

or part which, having been returned to WALCHEM, transportation charges

prepaid, has been inspected and determined by WALCHEM to be defective.

Replacement elastomeric parts and glass components are expendable and are not

covered by any warranty.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EITHER

EXPRESS OR IMPLIED, AS TO DESCRIPTION, QUALITY,

MERCHANTABILITY, and FITNESS FOR ANY PARTICULAR PURPOSE OR

USE, OR ANY OTHER MATTER.

P/N 180560.G

June 2019

Table of Contents

1.0

Introduction ....................................................... 1

Sensor 1

Flow Cell 1

2.0 Installation ......................................................... 2

Assembling the Sensor 2

Flow Cell Placement 4

Installing Sensor into Flow Cell 4

Sensor Parts 5

Typical Installation 5

Optional Flow Switch Installation 7

Wiring Instructions 7

3.0 Operation ......................................................... 14

Conditioning 14

Calibration 14

4.0 Troubleshooting ............................................. 16

The disinfectant reading is much lower than the manual

analysis 16

The disinfectant reading is much higher than the manual

analysis 16

Sensor Error 17

Disinfectant Reading is Unstable 17

Calibration Failure 18

5.0 Maintenance .................................................... 19

Cleaning the Electrodes 19

Sensor Storage 19

6.0 Specifications ................................................. 21

7.0 Sensor Part Numbers ..................................... 22

1.0 Introduction

The Walchem non-membrane chlorine and chlorine dioxide sensors

consist of an amperometric sensor assembly, cable and a flow cell.

Assembly of these parts is required, so please read these instructions

carefully. The sensor is capable of measuring the disinfectant in drinking

water or drinking water quality water.

Sensor

The sensor assembly includes the sensor body, a 50-ml bottle of electrolyte

fill solution, and special abrasive emery paper. Make sure that all parts are

included.

The sensors are open (not-membrane covered) amperometric 3-electrode

types. The measuring and counter electrode are in direct contact with the

measuring water. The reference electrode is separated from the measuring

water by a housing which contains an electrolyte. Together with the

electrolyte, an electrical signal is generated at the measuring electrode

which is proportional to the concentration of the disinfectant, and

amplified by the electronics of the sensor. The measuring signal is

temperature compensated.

Flow Cell

The flow cell consists of a translucent flow cell body, mounting nut and oring, washer set and o-ring. Make sure that all parts are included.

The flow cell is required. The sensor will not read accurately if it is not

installed in the flow cell, with a steady flow rate between 20 and 100 liters

per hour, at an operating pressure of 8 atmospheres or less.

1

2.0 Installation

Assembling the Sensor

CAUTION: Wear gloves and safety glasses during assembly of

the sensor since the electrolyte is a diluted acid. It is recommended

to perform this operation over a sink with running water available.

Please heed the warnings on the electrolyte bottle. Do not swallow

the electrolyte. Avoid contact of the electrolyte with skin and eyes.

Otherwise wash with a lot of water. In case of eye inflammation,

contact a doctor.

After using, re-cap any remaining electrolyte and store the bottle

upside-down until the next use.

Never shake the electrolyte bottle, as this will introduce air bubbles

that will negatively impact performance!

Do not touch or otherwise contaminate the electrodes!

For PEEK sensors, never remove the reservoir cartridge

attached to the reference electrode!

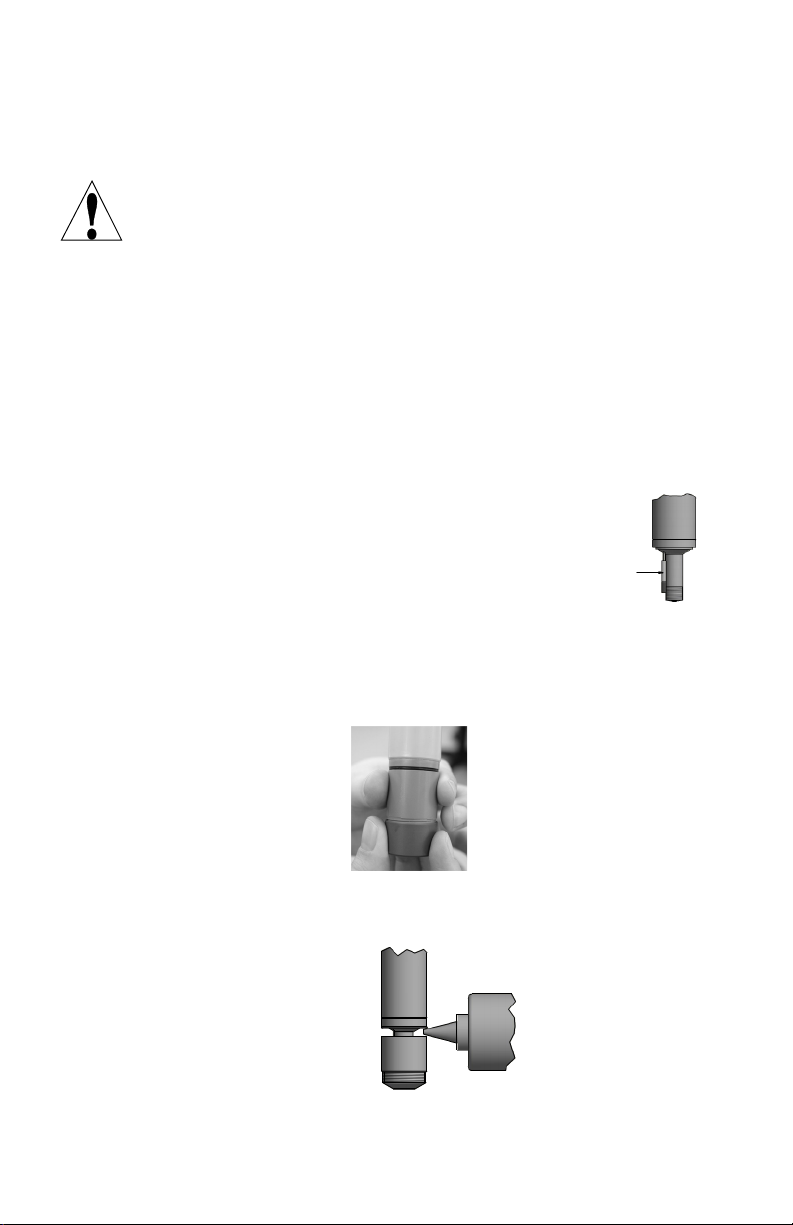

Sensors without optional cleaning attachment

1. Holding the sensor at the housing as shown, unscrew the dark grey

protective cap. The cap contains liquid. Save the protective cap in

case the electrode will need to be stored for more than a month of

downtime.

2. Unscrew the housing until there is a gap, then fill it to the top with

the electrolyte until it overflows. Never shake the electrolyte

bottle, it must stay free of bubbles!

2

3. SLOWLY screw on the housing until it is hand tight. Be prepared

for some electrolyte solution to squeeze out.

4. Rinse your hands, the sensor, and all surfaces contaminated with

electrolyte solution with running water. Check the sensor for leaks.

5. Push the cable onto the end of the sensor, aligning the pins with the

holes. Turn the connector until hand tight to seal the cable

connection.

Sensors with optional cleaning attachment

The cleaning attachment consists of a cleaning chamber and two

bags of glass balls. When using the cleaning attachment, the

minimum sample flow rate is 45 l/hour! The cleaning attachment

is only effective in removing thin deposits.

1. Complete the steps above for sensors without cleaning attachment.

2. Remove the o-ring holder from the acrylic flow cell and slide it up

onto the sensor to sit below the o-ring.

3. Place three of the glass balls into the cleaning chamber and screw

it onto the electrolyte housing.

3

Flow Cell Placement

Instructions for mounting the sensor into the process can vary greatly with

the circumstances that are encountered in your application. Here are some

general guidelines to assist you. Refer also to the typical installation

drawings.

The flow cell should be placed on the discharge side of a circulation pump

or downhill from a gravity feed. Flow into the cell must come from the

bottom side that has the 8 mm OD tubing x ¼” straight thread fitting

installed.

The outlet of the flow cell must be plumbed to open atmosphere unless the

system pressure is at or below 8 atmospheres. If the flow through the line

cannot be stopped to allow for cleaning and calibration of the sensor, then it

should be placed in a by-pass line with isolation valves to allow for sensor

removal. Install the sensor vertically, with the measuring surface pointing

down, at least 5 degrees above horizontal. (Refer to Installation drawing)

Flow rate regulation must be done upstream from the sensor, because any

flow restriction downstream can increase the pressure above the rated value.

The acrylic flow cell has a flow regulator knob on the lower left hand side.

The sensor should be installed in an area where there is good solution

movement and where it will respond rapidly to chemical additions. The

placement of the sensor relative to the placement of chemical

replenishment, along with the quality of the mixing, and the replenishment

chemical flow rate are critical to accurate process control.

To avoid biological growth on the electrodes, which can block

measurement, never leave the sensor in water without oxidant for longer

than 24 hours, unless using the optional cleaning attachment.

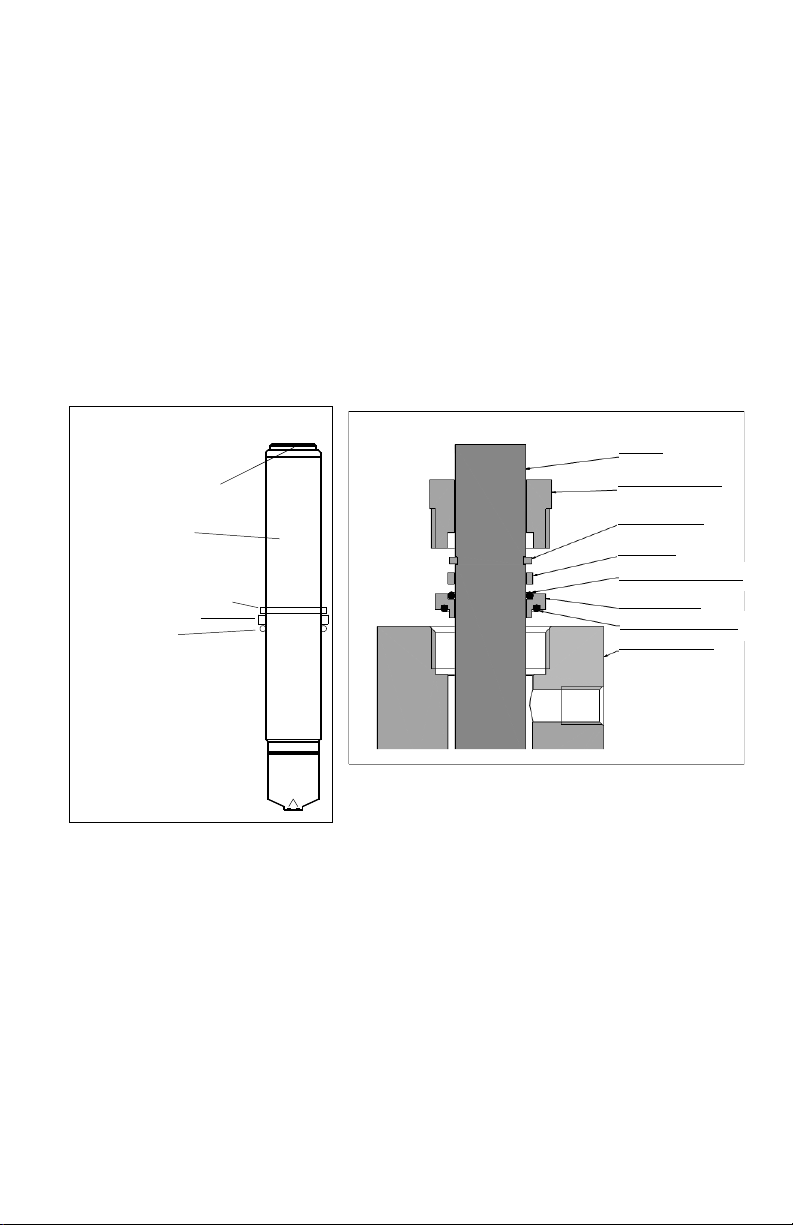

Installing Sensor into Flow Cell

1. For sensors without the cleaning attachment, unscrew the 1 ¼” fitting

from the acrylic flow cell. Insert the sensor as shown below.

Push the 1 ¼” fitting over the sensor and fasten it tightly. Make sure that

the sensor is tightly fastened in place, otherwise it may be pushed out of

the flow cell when it is under pressure, or leaks can occur.

2. For sensors with the cleaning attachment, unscrew the 1 ¼” fitting from

the acrylic flow cell. Insert the sensor with mounted cleaning attachment

and o-ring holder into the flow cell by turning it CLOCKWISE until the

o-ring holder is snug (turning CCW can loosen the electrolyte housing

4

and/or cleaning attachment). Make sure that the large black o-ring is

O ring

connector

electrode

shaft with

amplifier

retaining ring

slide ring

Sensor

Screw fitting 1¼”

Retaining ring

Slide ring

O-ring holder

O-ring 20 x 2.6 (Viton)

Acrylic flow cell

O-ring 25 x 2.5 (silicon)

located between the o-ring holder and the flow cell, as shown below.

Push the 1 ¼” fitting over the sensor and fasten it tightly. Make sure that

the sensor is tightly fastened in place, otherwise it may be pushed out of

the flow cell when it is under pressure, or leaks can occur.

3. To supply a sample, first open the water outlet valve. Then open slowly

the measuring water supply valve. The minimum flow rate is 45

liters/hour when using the cleaning attachment, 20 liters/hour without.

The acrylic flow cell has a flow regulator knob on the lower left hand

side. Avoid installations that allow air bubbles to enter the measuring

water.

Sensor Parts

5

Loading...

Loading...