Page 1

WCU Series

Electroless Copper Controller

Instruction Manual

Page 2

Notice

©2006 WALCHEM Corporation

5 Boynton Road, Holliston, MA 01746 USA

(508) 429-1110

All Rights Reserved

Printed in USA

Proprietary Material

The information and descriptions contained herein are the property of WALCHEM

Corporation. Such information and descriptions may not be copied or reproduced by any

means, or disseminated or distributed without the express prior written permission of

WALCHEM Corporation, 5 Boynton Road, Holliston, MA 01746.

This document is for information purposes only and is subject to change without notice.

Statement of Limited Warranty

WALCHEM Corporation warrants equipment of its manufacture, and bearing its

identification to be free from defects in workmanship and material for a period of 24

months for electronics and 12 months for mechanical parts from date of delivery from the

factory or authorized distributor under normal use and service and otherwise when such

equipment is used in accordance with instructions furnished by WALCHEM Corporation

and for the purposes disclosed in writing at the time of purchase, if any. WALCHEM

Corporation's liability under this warranty shall be limited to replacement or repair, F.O.B.

Holliston, MA U.S.A. of any defective equipment or part which, having been returned to

WALCHEM Corporation, transportation charges prepaid, has been inspected and

determined by WALCHEM Corporation to be defective. Replaceable elastomeric parts and

glass components are expendable and are not covered by any warranty.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EITHER EXPRESS OR

IMPLIED, AS TO DESCRIPTION, QUALITY, MERCHANTABILITY, FITNESS FOR ANY

PARTICULAR PURPOSE OR USE, OR ANY OTHER MATTER.

P/N 180099.J1

Feb 2006

Page 3

TABLE OF CONTENTS

1.0 Introduction.............................................................................................................1

2.0 Specifications .........................................................................................................1

2.2 Electrical: Input/Output..........................................................................................1

2.3 Mechanical............................................................................................................2

3.0 Unpacking and Installation....................................................................................2

3.1 Unpacking the unit ................................................................................................2

3.2 Mounting the electronic enclosure ........................................................................3

3.3 Immersible Copper Sensor Installation .................................................................3

3.4 Flow Through Copper Sensor/Sample Loop Installation.......................................4

3.5 Control Module Installation....................................................................................8

3.6 Icon Definitions .....................................................................................................9

3.7 Electrical Installation .............................................................................................9

4.0 Function Overview ...............................................................................................14

4.1 Front Panel .........................................................................................................15

4.2 Display ................................................................................................................15

4.3 Keypad................................................................................................................16

4.4 Access Code.......................................................................................................16

4.5 Startup ................................................................................................................16

4.6 Shutdown............................................................................................................17

5.0 Operation...............................................................................................................17

5.1 Main Menu ..........................................................................................................17

5.2 Sensor Menu.......................................................................................................18

5.3 Output 1 Menu ...................................................................................................22

5.4 Output 2, 3, and 4 Menus....................................................................................26

5.5 Clock Menu .........................................................................................................27

5.6 Alarm Menu.........................................................................................................28

5.7 4-20 mA Menu (Optional)....................................................................................28

5.8 Access Code Menu.............................................................................................29

6.0 Maintenance..........................................................................................................31

6.1 Sensor Maintenance ...........................................................................................31

6.2 Replacing the Fuses ...........................................................................................31

7.0 Troubleshooting ...................................................................................................32

7.1 Error Messages...................................................................................................32

8.0 Service Policy .......................................................................................................35

Page 4

1.0 Introduction

The WCU310 series copper controllers are optoelectronic on-line analyzers that may

be used in variety of applications including electroless copper baths, microetch baths

and a number of other chemistries that contain more than 0.10 grams/liter (g/L) of

copper ions.

There are four relays that may be used as control outputs that are activated

simultaneously. The direction of control is selected via software. The outputs each

have timers associated with them, that may be used to track the volume of chemistry

added, or the time that the output has been on.

An optional 4-20 mA output that is proportional to the copper concentration is

available.

Either an immersible in-tank sensor or flow-through out-of-tank sensor may be

specified.

2.0 Specifications

2.1 Measurement Performance

Electroless Copper Concentration Range: .01 - 5.5 g/L (.001 - 0.73 oz/gal)

Microetch Copper Concentration Range: .01 - 99 g/L (.001 – 13.2 oz/gal)

Concentration Resolution: .001 g/L (.0001 oz/gal)

Concentration Accuracy: .01 g/L (.001 oz/gal)

2.2 Electrical: Input/Output

Input Power

110-120 VAC or 220-240 VAC

50/60 Hz, 10A 50/60 Hz, 5A

Input Signals

Sensor Power: + 5VDC, 150 mA

Signals: 0 to 2VDC

Interlock (optional) Isolated dry contact closure required (i.e., flow,

level, etc.)

Output

Mechanical Relays (5) @ 120 VAC, 10A resistive, 1/8 HP

@ 240 VAC, 5A resistive, 1/8 HP

internally powered, switching line voltage

4 - 20 mA (optional) Fully isolated, internally powered 600 Ω max.

resistive load. Resolution .001% of span, accuracy

± 1% of reading.

1

Page 5

Agency Approvals

UL UL 61010-1, 2

CSA C22,2 No.61010-1 2nd Edition

CE Safety EN 61010-1 2

CE EMC EN 61326 :1998 Annex A*

Note: For EN61000-4-6,3 the controller met performance criteria B.

*Class A equipment: Equipment suitable for use in establishments other than

domestic, and those directly connected to a low voltage (100-240 VAC) power

supply network which supplies buildings used for domestic purposes.

2.3 Mechanical

Controller

Enclosure: Fiberglass

NEMA Rating: NEMA 4X

Dimensions: 8.5" x 6.5" x 5.5"

Display: 2 x 16 character backlit liquid crystal

Operating Ambient Temp: 32 - 122°F (0 - 50°C)

Storage Temperature: -20 to 180°F (-29 to 80°C)

Shipping Weight: 7 lbs (3kg) (approximately)

Sensor

Immersible Flow Through

Enclosure: Polycarbonate/Polypro ABS

NEMA Rating: NEMA 4X NEMA 4X

Dimensions: 5.25" x 4.0" x 20.25" 6.75" x 4.75" x 2.25"

Operating Ambient Temp: 32 - 122°F (0 - 50°C) 32 - 122°F (0 - 50°C)

Storage Temperature: -40 to 185°F (-40 to 85°C) -40 to 185°F (-40 to 85°C)

Solution Temperature: 200°F (93°C) max. 200°F (93°C) max.

Maximum cable length: 80 ft . 80 ft.

nd

Edition

nd

Edition

3.0 Unpacking and Installation

3.1 Unpacking the unit

Inspect the contents of the carton. Please notify the carrier immediately if there are

any signs of damage to the controller or its parts. Contact your distributor if any of

the parts are missing. The carton should contain a WCU310 controller and

instruction manual. Any options or accessories will be incorporated as ordered.

2

Page 6

3.2 Mounting the electronic enclosure

The WCU series controller is supplied with mounting holes on the enclosure. It

should be wall mounted with the display at eye level, on a vibration-free surface,

utilizing all 4 mounting holes for maximum stability. Use M6 (1/4" diameter)

fasteners that are appropriate for the substrate material of the wall. The enclosure is

NEMA 4X rated. The maximum operating ambient temperature is 122° F (50° C).

The enclosure requires the following clearances:

Top: 2"

Left: 8"

Right: 4"

Bottom: 7"

3.3 Immersible Copper Sensor Installation

The immersible copper sensor is designed for direct in-tank monitoring of

electroless copper and microetch solutions. By monitoring the copper content

directly in the solution, control lag and hydraulic problems are eliminated.

The sensor is constructed such that a constant path length exists between the fiber

optic light guides. The solution between the light guides absorbs light at specific

wavelengths in proportion to the copper concentration. The lamp and electronics are

located under the cover of the sensor. In order to avoid a shift in calibration due to

condensation, the sensor's cover should NEVER be opened.

The immersible sensor is provided with a mounting plate and 20 feet of cable.

Extension cable is available if the sensor can not be mounted within 20 feet of the

controller. The maximum cable length is 80 feet.

While the positioning of the sensor is not particularly sensitive to the tank layout,

the following suggestions are given to aid installation:

Do not place the sensor beside heaters; if solution flow stops, the polypropylene

guard may melt.

Do not immerse the entire sensor, or the cable.

Place the sensor where the loads of parts will not strike it.

Place the sensor in an area of good solution movement, but not directly in the

path of any air agitation.

Mount the sensor securely to the rim of the tank using the holes provided. If the

tank is rimless, use a block to provide the support for the mounting plate.

Attach the cable's connector to the WCU controller. The connector is keyed, do not

force! The sensor you receive with the controller has already been calibrated.

3

Page 7

3.4 Flow Through Copper Sensor/Sample Loop Installation

The copper flow through sensor is designed for out-of-tank monitoring of electroless

copper and microetch solutions.

The sensor is designed with a glass tube that contains the copper solution that forms

a fixed path length between the lamp and receptor module. The solution absorbs

light at specific wavelengths in proportion to the copper concentration. In order to

avoid a shift in calibration caused by condensation, the sensor cover should NEVER

be removed!

The flow through sensor is provided with a mounting plate and 20 feet of cable.

Extension cable is available if the sensor can not be placed within 20 feet of the

controller. The maximum cable length is 80 feet.

The sample loop consists of a shut off valve, a cooling coil or plate, a sensor and a

pump or any combination thereof. The shut off valve is to quickly isolate the system

if necessary. A cooling coil or plate is necessary to cool the copper solution down to

a temperature acceptable to a sample pump. Cooling the solution is also

recommended to help reduce the amount of plate out which may form in the sample

loop. The pump may be either a stand alone sample pump (which typically have

temperature restriction) or a high temperature pump (which is usually just a branch

off the recirculation pump).

4

Page 8

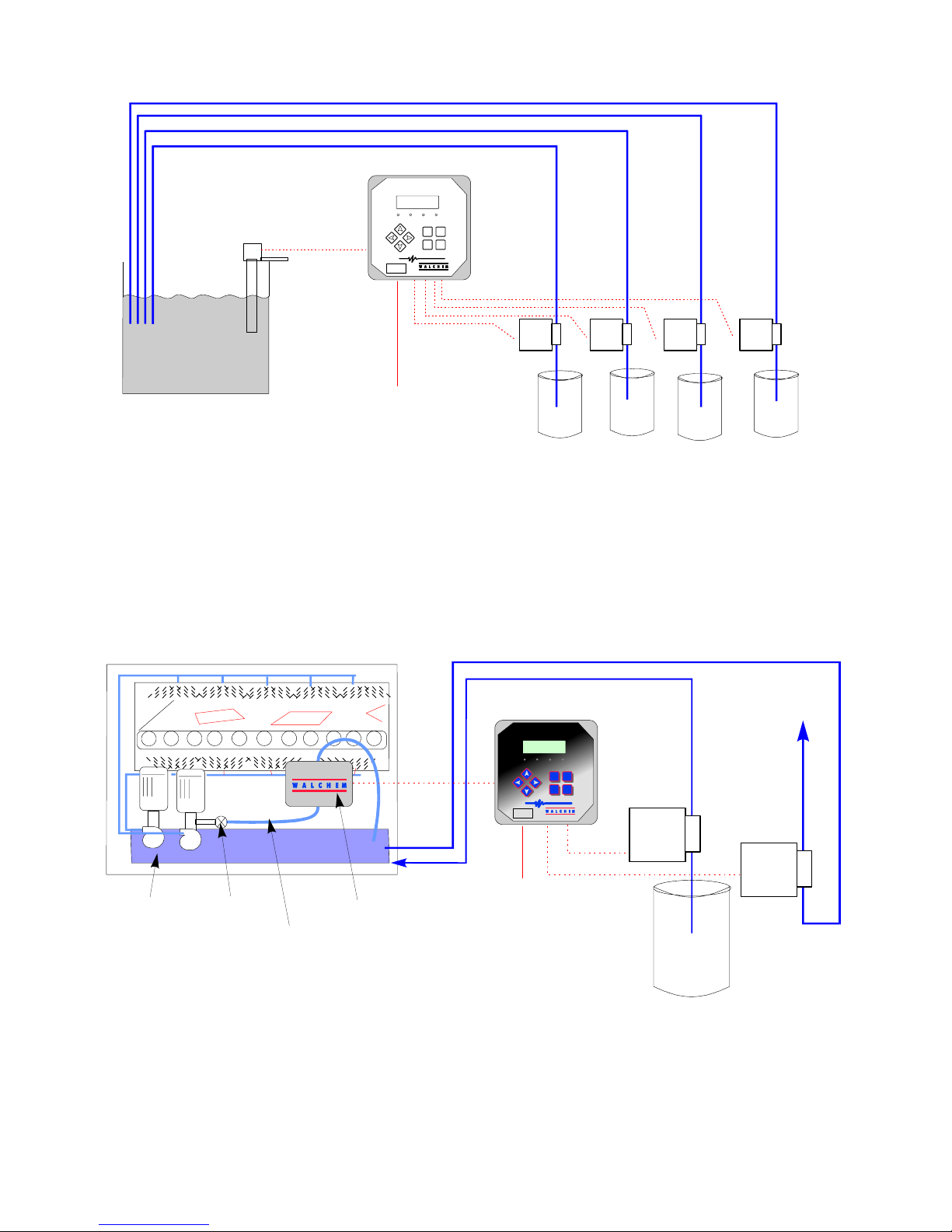

IMMERSIBLE

SENSOR

PLATING BATH

(TYPICAL ELECTROLESS COPPER APPLICATION)

CONVEYORIZED SPRAY EQUIPMENT

CIRCULATING

PUMPS

MANUAL

VALV E

3/8" TUBING

(< 20' PERFERRABLE)

WCU with Immersible Sensor

COPPER CONTR OLLER

CU

OUT 3OUT 2 OUT 4

20 FT

(80 FT MAX.)

POWER

WCU WITH IMMERSIBLE SENSOR

NEXTPREV.

EXIT ENTER

WCU MICROETCH CONTROLLER

COPPER CONTROLLER

CU

80 FT. MAX.

POWER

FLOW

THROUGH

SENSOR

WCU WITH FLOW-THROUGH SENSOR

(TYPICAL MICROETCH APPLICATION)

WCU310 Series Copper Controller

Figure 1 Typical Installation

COPPER

OUT 3OUT 2 O UT 4

NEXTPREV.

EXIT ENTER

CAUSTIC

FORMALDEHYDE

METERING PUMPS

SODIUM

PERSULFATE

STABILIZER

TO

WASTE

TREATMENT

"BLEED"

5

Page 9

The flow through sensor/sample loop must be installed according to the following

guidelines:

Mount the sensor on a vibration-free, vertical surface so that the sensor tubing

inlet connection is at the bottom and the outlet is at the top. The vertical

orientation will prevent air bubbles from being trapped in the sensor.

Install a shut-off valve at the beginning of the sample loop so that the system

may be shut off quickly if necessary.

If a sample pump is to be used, it must be installed last, after the flow through

sensor and the cooling coil or plate, if applicable.

Other installation guidelines which may be helpful in the overall system:

Mount the sensor as close to solution as possible. Keep tubing distances to the

sensor inlet as short as possible to avoid hydraulic lag time. Maximum

recommended length of tubing from solution to sensor is 25 feet. If this is not

possible, see Application Notes below.

The solution inlet should draw sample from an area of good solution movement

in order to respond quickly to chemical additions. However, the solution inlet

should not draw too near to where the chemistry is added to avoid artificial

'spikes' in concentration.

The solution discharge should be open to atmospheric pressure in order to ensure

proper flow.

The cable connector to the controller is keyed, do not force!

6

Page 10

Application Notes

If the distance from the solution to the sensor is further than the recommended

length of 25 feet, the maximum lagtime must be calculated from the desired control

band to determine a pump flow rate based on a given distance of standard, uniform

tubing. The maximum lagtime is the maximum allowable time for the solution to

continuously get to the sensor in order to achieve the desired control band.

To calculate maximum lagtime:

Max. Lagtime = Desired Control Band*

4 x Depletion Rate

For Example: The set point is 4.00 g/L.

then Max. Lagtime = 0.20 g/L

4 x (0.08333 g/L /min)

So, 0.60 minutes is the maximum time it should take for the solution to reach the

sensor.

To calculate pump flow rate:

Minimum Pump Flow Rate = Volume of System*

Maximum Lagtime

where Volume of system = ( Tubing I.D.)2 x Length of tubing

2

Maximum lagtime = Previously calculated time to get solution to

sensor.

* Volume is based on length from solution to sensor, not the return.

For Example: If the system parameters are: Tubing is 3/8" O.D. x 1/4" I.D.

Length is 30 feet (360 inches)

then the volume of the system = ( 0.25 in )2 x (360 in) = 17.7 in3

2

where Control band = Maximum deviation of concentration

Depletion rate = Rate at which the bath will deplete per unit

of time

* The deadband should be adjusted so that it is 1/4 the desired control

band.

If the desired control band is 0.20 g/L (± 0.10 g/L or 2.5%) and the bath is

depleting at a rate of 1.25 g/L every 15 minutes (0.08333 g/L every minute),

= 0.60 minutes

7

Page 11

Note: 1 U.S. Gallon = 231 U.S cubic

inches

1 Liter = 61.03 U.S. cubic inches

Volume of Cooling Coil: 0.018 Gallons

0.068 Liters

Volume of Cooling Plate: 0.023 Gallons

0.088 Liters

Volume of 3/8" O.D. x 1/4" I.D. (0.59 in3/ft): 0.00255 Gallons/linear ft

0.00965 Liters/linear ft

Volume of the system = 17.7 in3 = 0.0765 gallons

231 in3 / gallon

Maximum lagtime = 0.60 minutes (previously calculated)

So, the minimum pump flow rate

= 0.0765 gallons

0.60 minutes

= 0.127 gal/min (483 mL/min)

Caution: The calculated pump flow rate is the minimum required to obtain the

desired control band, however, if the flow rate increases over the recommended rate

of 500 mL/min (approx. 0.13 gal/min) the rate of cooling will decrease. This may be

compensated for by re-evaluating the system criteria: length / desired control band

or to double up on the cooling plate/coil.

Consult factory with any further installation questions.

3.5 Control Module Installation

Once the enclosure is mounted, the output pumps may be located at any distance

from the controller. The sensor may be placed up to 80 feet from the controller.

Shielded cable is preferable. Always route AC voltage wiring in conduit that is

separated a minimum of 6 inches away from low voltage DC signal lines (such as

the sensor signal).

8

Page 12

3.6 Icon Definitions

Symbol Publication Description

IEC 417, No. 5008 Off (Supply)

3.7 Electrical Installation

Based on the model number, the following voltages are required:

WCU310-1xx 120 VAC, 50/60 Hz

WCU310-4xx 120 VAC, 50/60 Hz

WCU310-5xx 240 VAC, 50/60 Hz

The various standard wiring options are shown below. Your WCU series controller

will arrive from the factory prewired or ready for hardwiring. Depending on your

configuration of controller options, you may be required to hardwire some or all of

the input/output devices. Refer to figures 3 and 4 for circuit board layout and wiring.

Note: When wiring the optional 4-20 mA output or a remote flow switch, it is

advisable to use stranded, shielded, twisted pair wire between 22-26 AWG. Shield

should be terminated at the controller ground stud (see figure 4).

IEC 417, No.5019

Protective Conductor

Terminal

IEC 417, No. 5007 On (Supply)

ISO 3864, No. B.3.6 Caution, risk of electric shock

ISO 3864, No. B.3.1 Caution

9

Page 13

CAUTION! There are live circuits inside the controller even when the power

switch on the front panel is in the OFF position! The front panel must never be

opened before power to the controller is REMOVED!

If your controller is prewired, it is supplied with a 8 foot, 18 AWG power cord with

USA style plug. A tool (#1 phillips driver) is required to open the front panel.

CAUTION! When mounting the controller, make sure there is clear access to the

disconnecting device!

CAUTION! The electrical installation of the controller must be done by trained

personnel only and conform to all applicable National, State and Local codes!

CAUTION! Proper grounding of this product is required. Any attempt to bypass

the grounding will compromise the safety of persons and property.

CAUTION! Operating this product in a manner not specified by Walchem may

impair the protection provided by the equipment.

Optional Input

Hardwired Option WCU310

4-20 mA Output Optional Optional Sensor

(optional) Input Input Connector

Strain reliefs (230 VAC) or Holes for

Hardwiring of Input Power and Control Outputs

Side View

Optional

Input

WCU310 Prewired Option

4-20 mA (optional)

Sensor

Connector

Bottom View

Outputs

Inputs

Bottom View

Alarm Output 3 Output 4

Power Output 2 Cu

Supply Output

Figure 2 Conduit/Wiring Configuration

10

Page 14

Figure 3 Inputs (for power relay board #191236)

11

Page 15

4-20mA

_

+

(Optional 4-20 mA Board)

F1

F2

To Grounding

Stud

White

w/Green Stripe

Green

(INPUTS - ALL MODELS)

COM

White

w/Blue

Stripe

Blue

Orange

(Grounding

Stud)

FLOW

VM

SWITCH

NEU

GRN (115V)

GRN/YEL (230 V)

WHT (115V) BLU (230V)

FM

(Polarity

not

critical)

HOT

190873

BLK (115V)

BRN (230V)

TB2

TB3

NEUTRAL

Panel Mount

Connector

Figure 3a Inputs (for power relay board #190873)

Flow or Level

Switch

12

Power Supply

(115 VAC or 230 VAC)

Page 16

Note: The Alarm Rel ay is non-programmable.

Refer to the Main Menu diagram on page 16

for the list of error conditions that trigger the

alarm relay.

Figure 4 Outputs (for power relay board #191236)

Note: All relay outputs are

internally powered switching

line voltage.

13

Page 17

A

Chart

Recorder

4-20mA

_

+

(Optional 4-20 mA Board)

F1

F2

TB2

TB3

(Grounding

Stud)

OUTPUTS

OUT3

OUT4

LRM

N.O.

K

L

GRN

GRN

GRN

B

N.O.

N.O.

OUT2

N.O.

BLK

NEU

HOT

OUT1

N.C. N .O.

190873

BLK

NEUTRAL

WHT

WHT

WHT

WHT

Alarm

GRN

Pump(s)

GRN

Figure 4a Outputs (for power relay board #190873)

14

WHT

Page 18

4.0 Function Overview

4.1 Front Panel

Backlit LCD Display

Output LEDs

Setting Adjustment Keys

Menu/Function Keys

COP PER CO NTR OLLER

CU

OUT 3OUT 2 OUT 4

EXIT

NEXTPREV.

ENTER

On/Off Power Switch

4.2 Display

A summary screen is displayed while the WCU controller is on. This display shows

a bar graph of the copper concentration relative to the set point, a digital display of

the copper concentration, and the current operating conditions.

Towards the center of the bar graph is an (S), which represents the set point. For

each 1% rise above the set point a vertical line appears to the right of the (S). For

each 1% drop below the set point a vertical bar appears to the left of the (S). There

are small breaks in the bars at each 5%. If high or low alarm limits are reached, then

either an (H) or (L) will appear.

The operating conditions which may be displayed on the bottom line of the display

are: Control Delay 30* (number counts down), Sensor Error, Light Bulb Out, No

Sample, Plate Out, Manual Output* Interlock, Output Disabled*, Pump Overrun,

High/Low Alarm, Turnover Limit, Calibration Time, Outputs On* and Normal*

*These messages do not activate the diagnostic alarm relay.

Front Panel

Summary Display

15

Page 19

4.3 Keypad

The keypad consists of 4 directional arrows and 4 function keys. The arrow keys are

used to move the adjustment cursor and change settings, while the function keys are

used to enter values, and navigate the various menu screens. The function keys are

ENTER, EXIT, NEXT and PREV (previous). NEXT and PREV scroll through the

various menu choices. ENTER is used to enter a menu and to enter a value. EXIT is

used to back up one menu level. If you are at the main menu level, EXIT will return

you to the summary screen.

To change a value or option in a submenu, the left/right arrow keys move the cursor

left and right to each digit or option that can be changed. The up/down arrows will

change numeric values up or down, or scroll through option choices. Press ENTER

only when you have finished making ALL of the changes for that menu screen.

4.4 Access Code

The WCU series controller is shipped with the access code disabled. If you wish to

enable it, see Section 5.8 for operation. With the access code enabled, any user can

view parameter settings, but not change them. Note that this provides protection

only against casual tampering. Use a lock on the cover latch if you need more

protection.

4.5 Startup

Initial Startup

After having mounted the enclosure and wired the unit, the controller is ready to use.

CONTROL DELAY: The display will show the WCU series model number then

revert to the top level summary screen with "Control Delay" for a status message. This

message will be displayed for approximately 30 seconds. In some situations, the user

may not want the unit to be controlling and possibly turning on pumps when it is first

powered on. This allows you enough time to enter the Output menus and disable the

outputs. The only difference in the controller operation during these 30 seconds is that

it will not activate any outputs. All measurements are live and all menus are

accessible. Scroll through the menus, calibrate the sensor, and set the control

parameters as detailed in Section 5, Operation.

16

Page 20

To return to the summary screen, press the EXIT key until you return to this screen.

The controller will automatically return to this screen after 10 minutes.

Normal Startup

Startup is a simple process once your set points are in memory. Simply check your

supply of chemicals, turn on the controller, calibrate the sensor if necessary and it

will start controlling.

4.6 Shutdown

To shut the WCU controller down, simply turn off the power switch. Programming

remains in memory.

5.0 Operation

These units control continuously while power is applied. Programming is

accomplished via the local keypad and display.

To view the top level menu, press any key. The menu structure is grouped by inputs

and outputs. Each input has its own setup menu for calibration and unit of measure

selection as needed. Each output has its own setup menu including set points, timer

values, direction of control, etc as needed. After 10 minutes of inactivity in the

menu, the display will return to the summary screen. Keep in mind that even while

browsing through the menus, the unit is still controlling.

5.1 Main Menu

The exact configuration of your WCU controller determines which menus are

available as you scroll through the settings. Certain menus are only available if you

select certain options. All settings are grouped under the following main menu

items:

Sensor

Out 1

Out 2

Out 3

Out 4

Alarm

Time

4-20 mA (Only if 4-20 mA option circuit board is installed)

Access Code

The NEXT key travels forward through this list while the PREV key travels

backwards through the list. Pressing ENTER will enter the lower level menu that is

currently displayed.

17

Page 21

5.2 Sensor Menu

The sensor menu provides the following settings: Calibration history (informational

only), 1 point calibration, Days between Calibration, Units of measure, Control

mode, and New sensor set-up. Each is discussed in detail below. Refer to the Sensor

Menu Chart.

Note: If you are programming the unit for the first time, scroll to the Cu Mode menu

and set the "Cu Mode" option first, choosing either Electroless Copper or Microetch

mode. Then press PREV to choose units of measure. Then press NEXT to set the

rest of the menus.

Cal'd

Displays the date of the last sensor calibration.

1 Pt Calibration

Press ENTER to perform a 1 point calibration of the copper sensor. This calibration

is best performed at normal operating temperature.

Keep the immersible sensor in place or have solution flowing through the flow-

through sensor. Take a sample of the solution and note the concentration displayed

by the WCU controller. Carefully perform the normal laboratory analysis of the

copper concentration. Calculate the offset by subtracting the displayed value from

the lab results. If the lab analysis is significantly different, adjust the offset in the 1

point calibration menu, using the arrow keys to change the value and the +/- sign. If

the controller's display is higher than the lab analysis, the offset should be negative.

The maximum offset for a one point calibration is 7 g/l(0.7 oz/gal) from the last new

sensor setup value. If you have an offset larger than this, then perform a new sensor

setup (see next page).

Days Btwn Cal

Use the arrow keys to set the number of days that you would like to go by before

recalibrating the sensor. The controller will prompt you to recalibrate when that time

has expired. Setting this to zero days will disable the calibration reminder.

Conc. Units

Press ENTER to change the units of measure. Use the Up and Down arrows to

toggle between grams per liter and ounces per gallon, then press ENTER to make

your selection. The controller will warn you to check your set points, since all set

point values will stay the same even though the units of measure may have changed.

Cu Mode

Press ENTER to change the controller from Electroless copper mode to Microetch

mode by toggling between the two choices using the Up and Down arrow keys. The

controller will warn you to check your set points, since these do not change when

the Cu Mode is changed.

18

Page 22

S

S

Main Menu

OperationLegend

Press Enter key to enter menu or submenu.

Press Exit key to exit menu.

After 10 minutes of inactivity the controller will

Copper 1.98 g/L

Out 4 A 11:40

Copper 1.98 g/L

Access Code DIS

automatically return to the summary screen.

creens

tatus

Possible

* Control Delay 30

Sensor Error

Light Bulb Out

No Sample

Plate Out

* Manual Input

Interlock

* Output Disabled

Pump Overrun

1.98 g/L

S

NEXTPREV.

* These status screens DO NOT activate the diagnostic alarm relay

High/Low Alarm

Turnover Limit

Calibration Time

* Outputs On

* Normal

ENTEREXIT

NormalA

Copper 1.98 g/L

Out 3 A 11:40

Copper 1.98 g/L

4-20mA 12.4mA

Copper 1.98 g/L

Out 2 A 11:40

Copper 1.98 g/L

Time Thur 11:40

4-20mA menu is only present if

Copper 1.98 g/L

Out 1 A 11:40

Copper 1.98 g/L

Alarm

4-20mA option is installed.

Copper 1.98 g/L

Sensor

Main Menu

19

Page 23

Self Test

This feature is a diagnostic tool which can help isolate a problem between the sensor

and controller. Before initiating the self test, the sensor MUST be disconnected from

the controller in order to function properly. When ENTER is pressed the controller

disables the sensor inputs and injects 2 test signals, simulating a properly

functioning sensor. The controller will display "PASS" or "FAIL" along with a live

mV reading. If "PASS" is displayed then it indicates the controller is functioning

properly and the problem is likely to be with the sensor. See the troubleshooting

section for further details. If "FAIL" is indicated, the controller is defective. Consult

your factory representative for service options.

New Sensor Setup

Press ENTER to set up a new sensor. First you see a warning message:

"WARNING Chg sensor cal? N" This acts as a safety precaution for those who may

only be "browsing" through the menus. If you enter the New Sensor Setup menu,

you may easily, inadvertently, change the calibration of the sensor. If you continue

with the following procedures, you must recalibrate the new sensor.

Water....xxxx.x

Place the immersible sensor in clean tap or DI water, or circulate through the flow

through sensor. When the number on the display is constant, press ENTER.

Sample....xxxx.x

Place the sensor in the bath at a known concentration or restart pumping the bath

sample through the flow through sensor. No work should be going through the bath

so that the concentration remains constant. Ideally the bath should be at the typical

operating copper concentration. When the number on the display is constant, press

ENTER.

Smpl Conc

Use the arrow keys to change the displayed number to the actual concentration of

the bath in grams/liter or ounces/gallon, depending on the unit of measure you have

selected, then press ENTER.

mV in Display

This display is only for diagnostic purposes. The top line shows 2 live voltage

readings from the sensor in millivolts. The bottom line shows the stored values for

each sensor signal from the most recent new sensor set up calibration - specifically

the signal values measured with water.

20

Page 24

ENTER

EXIT

Sensor 1.98 g/L

mV in Display

ENTER

EXIT

Sensor 1.98 g/L

New Sensor Setup

m 300.4 r 232.1

*H 20 m 811.1 r234.6

New Sensor Setup

Water. . . 1230.8

New Sensor Setup

Sample. . . 30.2

New Sensor Setup

Chg Sensor Cal? N

. . . . WARNING . . . .

Smpl Conc 5.04

Sensor Menu

Operation

NEXTPREV.

Press Enter key to enter menu.

ENTER

Press Exit key to exit menu.

Blinking fields may be edited with the adjust arrows.

Press Enter when modification is complete to return

to Main Menu Level.

Sensor 1.98 g/L

Self Test

Sensor 1.98 g/L

Cu Mode E-Cu

Sensor 1.98 g/L

Days Btwn Cal 7

Sensor 1.98 g/L

Conc. Units g/L

ENTER

EXIT

Self Test PASS

m 611 r 202

ENTER

EXIT

Micro Etch

Cu Mode E-Cu

Electroless Cu

ENTER

EXIT

Conc. Units g/L

grams per Liter

Conc. Units g/L

ounces per Gal.

. . . . WARNING . . . .

. . . . WARNING . . . .

Check Set Points

Check Set Points

Sensor 1.98 g/L

1 Pt Calibration

ENTEREXIT

Copper 1.98 g/L

Sensor

Sensor 1.98 g/L

Cal'd Mar/10/96

EXIT

Adjust Offset

g/L + 0.10

Sensor Menu

21

Page 25

5.3 Output 1 Menu

The Out 1 menu is used to set the control set point, and to configure the

timer/totalizer to keep track of replenishment in the desired way. This menu

provides the following settings: Total 1, Set Point, Dead Band, Time Limit,

Interlock, and H O A.

The top level menu status line may display the following messages: Off, Intrlck,

Timeout, or a time. "Off" indicates that the output is off. "Intrlck" indicates that the

output would be on but is not because of a signal from a flow switch or level switch

is stopping control. "Overrun" indicates that the output has been on for longer than

the maximum time programmed by the user. The time shows how long the output

has been on.

Total 1

Press ENTER to program the timer/totalizer functions.

Reset Total Y/N

Use the arrow keys to toggle between Y(Yes) and N(No) to reset the totalizer.

Total As

Press ENTER, then use the Up and Down arrows to choose whether to totalize in

units of time, volume or copper metal turnovers.

Turnover Lim.

Only appears if you choose to totalize by metal turnovers. Use the arrow keys to

enter the maximum number of turnovers. The controller will prompt you when this

number has been exceeded.

Turn Vol(G or L)

Only appears if you choose to totalize by metal turnovers. Enter the number of

gallons (G) or liters (L) that equals one metal turnover. The unit of measure

displayed correlates with that of the rate units selected in the next menu.

Rate Units

Only appears if you choose to totalize by volume or metal turnovers. Press ENTER,

then use the arrow keys to toggle between Gallons per Hour, mL per minute or

Liters per hour. These units of measure will be used to enter the rate at which the

replenishment pump adds chemicals.

Pump Rate

Only appears if you choose to totalize by volume or metal turnovers. Use the arrow

keys to set the flow rate of the replenishment pump.

Set Point

Use the arrow keys to adjust the display to read the desired set point value of the

bath. Press ENTER to accept the change.

22

Page 26

S

S

HAND OFF >AUTO

Out 1 A 11:40

Total 1 0.0TURN

Out 1 A Overrun

Rest Timer N

Turn Vol (G) 200

Output 1 Menu

Total 1 0.0TURN

Out 1 A 11:40

Interlock N

Turnover Lim 5

Operation

creens

tatus

Possible

Press Enter key to enter menu.

Press Exit key to exit menu.

Blinking fields may be edited with the adjust arrows.

Press Enter when modification is complete to return

to Main Menu Level.

Total 1 0.5Gal

NEXT

Out 1 A 11:40

Time Limit 0:00

PREV.

Out 1 A 11:40

Dead Band 0.10

Out 1 H 9:59

Out 1 A Overrun

Out 1 A Intrlck

Out 1 A Off

* (If placed in Hand mode, a timer indicates

how much time is left before turning off

automatically.)

*

ENTEREXIT

Out 1 A 11:40

Set Point 2.10

NEXT

PREV.

ENTER

Pump Rate 1.00

ENTER

EXIT

Total 1 0.5Gal

Rate Units G/h

ENTER

EXIT

Total 1 0.5Gal

Total As Vol

ENTER

Rate Units G/h

Gal per hour

L per hour

mL per min

Legend

Total As Volume

Total As Vol

Total As Time

Cu Turnovers

Menu appears when a pump overrun condition occurs

Menu appears when Total As Volume or As Cu Turnovers

is selected

Menu appears when Total As Copper Turnovers

is selected

Copper 1.98 g/L

Out 1 A 11:40

Out 1 A 11:40

EXIT

Total 1 0.5Gal

Total 1 0.5 Gal

Reset Total Y

EXIT

Total 1 0.5Gal

Reset All? Y

Output 1 Menu

23

Page 27

Dead Band

Time Limit

Interlock

Reset Timer

H O A

Use the arrow keys to set the desired dead band, then press ENTER. If the set point

is 2.50 g/L, and the dead band is 0.05 g/L, then the relay will close at 2.50 g/L and

open 0.05 g/L away from 2.50 g/L (2.55 g/L if set for EC, 2.45 g/L if set for

microetch).

Use the arrow keys to set the time limit for the output to be active, then press

ENTER. Since all outputs are turned on at the same time for control purposes, the

time limit set applies to outputs 2, 3 and 4 also. If it is set for "0:00", no limit will be

imposed and the output could stay on forever.

Use the Up and Down arrows to toggle between Y(Yes) and N(No). Choosing Y

means that the output will deactivate depending on the state of the device attached to

the controller. If the device is open, the interlock condition exists and control is

stopped. For example, if the sensor is installed in a recirculating pipe line, a flow

switch that is closed if flow is sufficient and open if flow is insufficient may be

installed in the line, so that if flow past the sensor stops, the controller will not pump

in chemicals based on a stagnant sample.

An interlock condition disables all outputs.

This menu appears when the programmed time limit has elapsed, creating a pump

overrun condition. Use this menu to reset the timer. This applies to all outputs.

Use the Left and Right arrows to move between Hand, Off and Auto (H O A). In

Hand (Manual) mode, the output will be turned on immediately for a maximum of

10 minutes. In the Off mode, the output will be turned off indefinitely. In the Auto

mode, the output turns on and off in response to changes in the process value

relative to the set point. The letter inside the block on the status screen indicates

which mode the output is in.

24

Page 28

Output 2, 3 & 4 Menus

Operation

Press Enter key to enter menu.

Press Exit key to exit menu.

Blinking fields may be edited with the adjust arrows.

Press Enter when modification is complete to return

to Main Menu Level.

Possible Status Screens

Total 2 0.5Gal

Pump Rate 1.00

ENTER

HAND OFF >AUTO

Out 2 A 11:40

EXIT

L per hour

mL per min

Rate Units G/h

Total 2 0.5Gal

Rate Units G/h

NEXT

PREV.

Out 2 A Intrlck

Out 2 A Off

Out 2 A OVERRUN

NEXT

PREV.

Total 2 0.5Gal

Total As Vol

ENTER

EXIT

Gal per hour

Legend

Total As Volume

Total As Vol

Total As Time

Menu appears when Total As Volume is selected

ENTEREXIT

Copper 1.98 g/L

Out 2 11:40

Out 2 A 11:40

Total 2 0.5 Gal

ENTER

EXIT

Total 2 0.5Gal

Reset Total Y

Output 2,3,4 Menu

25

Page 29

5.4 Output 2, 3, and 4 Menus

The Out 2, 3 and 4 menus are separate from each other but operate in exactly the

same way. Each menu provides the Total and H O A settings. These additional

outputs are activated simultaneously with output 1 and are provided to be able to add

other bath components in proportion to the copper, and display independent

replenishment totals.

The top level menu status line may display the following messages: Off, Intrlck,

Timeout, or a time. "Off" indicates that the output is off. "Intrlck" indicates that the

output would be on but is not because of a signal from a flow switch or level switch

is stopping control. "Overrun" indicates that the output has been on for longer than

the maximum time programmed by the user. The time shows that the output is on,

and has been for that amount of time.

Total 2,3 or 4

This menu works the same as Total 1 described for Out 1 in Section 5.3.

H O A

Use the Left and Right arrows to move between Hand, Off and Auto (H O A). In

Hand (Manual) mode, the output will be turned on immediately for a maximum of

10 minutes. In the Off mode, the output will be turned off indefinitely. In the Auto

mode, the output turns on and off in response to changes in the process value

relative to the set point. The letter inside the block on the status screen indicates

which mode the output is in.

26

Page 30

5.5 Clock Menu

The clock menu is used to set the date and time that the controller uses to schedule

calibration prompts. There is only one menu selection: Set Clock.

Set Clock

Press ENTER to set the clock. Use the arrow keys to change the year, date, and

month, then press ENTER. Use the arrow keys again to set the day of the week and

the time. Use military time (for example, 1:00 PM is 13:00). Press ENTER to return

to the top level clock menu.

Copper 1.98 g/L

Time Thur 12:15

ENTEREXIT

Time 1Sat 12:15

Set Clock

Clock Menu

ENTEREXIT

Set Clock

Set Apr/04/96

ENTEREXIT

Set Clock

Set Thur 12:15

Clock Menu

27

Page 31

5.6 Alarm Menu

This menu is used to set the high and low copper concentration alarm points. Press

ENTER to adjust the alarm set points.

% Low Alarm

Use the arrow keys to change the % below the set point copper concentration that

will trigger a low alarm. Percentage range is 0-50%. Alarm can be disabled if zero is

entered.

% High Alarm

As above for the high alarm set point.

Possible Status Screens

Copper 1.98 g/L

Alarm

ENTEREXIT

Alarm

% Low Alarm 20

Alarm Low Alarm

Alarm High Alarm

NEXT

Adjust Value

then

ENTER

Alarm

% Hi Alarm 20

5.7 4-20 mA Menu (Optional)

This menu will only appear if the optional 4-20 mA output board is installed. It is

used to scale the 4-20 mA output to a corresponding copper range. It contains the

following menu selections: 4 mA Point, 20 mA Point, and Calibrate.

4 mA Pt

Use the arrow keys to enter the copper concentration that you want to correspond to

a 4 mA output from the controller.

20 mA Pt

Use the arrow keys to enter the copper concentration that you want to correspond to

a 20 mA output from the controller.

Alarm Menu

Alarm Menu

28

Page 32

Calibrate

This menu, in conjunction with an ammeter, is used to calibrate the mA output.

Press ENTER to start the calibration.

Fixed 4 mA Out

The controller will output 4.00 mA. Adjust the chart recorder or data logger per its

instruction so that the process value displayed is what is expected for a 4.00 mA

input.

Fixed 20 mA Out

As above, except that the controller will output 20.00 mA.

The design of the 4-20 mA output is such that it should never need calibration. If

the mA signal is not what it should be, call the factory for service.

Copper 1.98 g/L

4-20mA 12.4mA

ENTEREXIT

4-20mA 12.4mA

Set 4mA Pt 0

4-20mA menu is only present if

4-20mA hardware is installed.

5.8 Access Code Menu

This menu determines whether the access code feature of the controller is enabled or

disabled and allows you to customize the access code. The access code controls

whether or not you are allowed to change the parameters in the controller. With the

access code disabled, any user may change any parameter. With the access code

enabled, any user can view any parameter, but cannot change them.

Once an attempt is made to change a parameter, the display will prompt the user to

enter the access code. If the correct code is entered, the parameter can be changed.

(If the cursor is blinking, a change will be allowed; if the number or words are not

blinking, they can't be changed). Once the correct access code has been entered, it

will remain valid until there is a period of 5 minutes without a key being pressed.

NEXTPREV.

4-20mA 12.4mA

Set 20mA Pt 0

4-20 mA Menu

4-20mA Menu

4-20mA 12.4mA

Calibrate 4-20mA

ENTER

EXIT

Calibrate 4-20mA

Fixed 4mA Output

ENTER

EXIT

Calibrate 4-20mA

Fixed 20mA Output

29

Page 33

y

Enable Y/N

New Value

Any Top Display

Access Code 0000

Possible status screens are: Access Code REQ, Access Code OK, and Access Code

DIS.

The first indicates that the access code is required to alter settings. The second

indicates that the access code is required and has been entered correctly, and the last

indicates that the access code has been disabled.

Use the arrow keys to select Y(Yes) or N(No) and press ENTER to enable or disable

the access code. If the code was enabled, you must enter the access code in order to

disable it.

Press ENTER to display the current access code value and use the arrow keys to

change it to any value between 0 and 9999. If the access code has been enabled, you

will be prompted to enter the current access code before being allowed to change it.

The factory default access code is 1995.

If you change the access code and can't remember it, follow this procedure:

1. Turn off the power to the controller.

2. Wait 10 seconds.

3. Press and hold the Up and Down arrow keys while turning on the power.

4. Read the access code on the display.

5. Release the arrow keys and the code will disappear.

The Access Code prompt may appear at any screen in the entire menu

structure if the current access code has not been entered by the user.

Access code entries will be valid for 10 minutes from the most recent

key press.

Possible status screens

Copper 1.98 g/L

Access Code DIS

ENTEREX IT

Access Code DIS

Disable N

Access Code DIS

Disable Y

NEXTPR EV.

Access Code DIS

New Value 0

Access Code DIS

New Value 1234

Enter an

Access Code REQ

Access Code OK

four digit code

Access Code Menu

Access Code Menu

30

Page 34

6.0 Maintenance

The WCU control module itself needs very little maintenance. Clean the outside of

the controller enclosure with a damp cloth. Do not spray down the controller unless

the enclosure door is closed and latched. "Pigtails" should be protected from spray

or washdown. Check the cords and cables for damage.

6.1 Sensor Maintenance

The most important maintenance item for the sensor is to keep the optical paths

clean of plate-out or other coatings. In electroless copper applications, the sensor

should be etched when the tank is etched, or whenever plate-out is evident. If plate-

out does occur in the sample line or sensor, etch the system as you would the tank.

Avoid any mechanical cleaning of the optical surfaces to avoid scratching them.

Chemical cleaning is preferred over mechanical cleaning methods. Plate-out should

be removed using nitric acid or a persulfate or peroxide/sulfuric etch.

Field repairs should not be attempted. Call your factory representative in order to

arrange for factory service.

NOTE: TO PREVENT CALIBRATION SHIFTS DUE TO CONDENSATION

FORMING ON THE FIBER OPTIC LIGHT GUIDES INSIDE THE CAP OF THE

SENSOR, DO NOT REMOVE THE SENSOR CAP FOR ANY REASON!

6.2 Replacing the Fuses

CAUTION: Disconnect power to the controller before opening front panel!

Locate the fuses on the circuit board at the back of the controller enclosure. Gently

remove the old fuse from its retaining clip and discard. Press the new fuse into the

clip, secure the front panel of the controller and return power to the unit.

Warning: Use of non-approved fuses can affect product safety approvals. Fuse

ratings depend on controller power rating. Specifications are shown below. To

insure product safety certifications are maintained, it is recommended that a

Walchem fuse is used.

Controller

Rating F1 Walchem PN F2 Walchem PN

120 VAC 5 x 20 mm, 0.125A,250V 102369 5 x 20mm,10A,125V 102432

240 VAC 5 x 20 mm, 0.063A,250V 103363 5 x 20mm, 5A, 250V 102370

31

Page 35

7.0 Troubleshooting

CAUTION: Disconnect power to the controller before opening front panel!

Troubleshooting and repair of a malfunctioning controller should only be attempted

by qualified personnel using caution to ensure safety and limit unnecessary further

damage. Contact the factory.

7.1 Error Messages

HIGH ALARM

The summary screen will display an H at the right side of the bar graph if the copper

concentration rises above the high alarm set point.

Possible Cause Corrective Action

1. Overshooting set point Reduce replenishment pump rate.

Increase solution flow through sensor.

Immerse sensor in area of better solution

movement.

Place replenishment line closer to sensor.

2. Pump siphoning Check all valves.

Re-route tubing.

3. Output 1 in HAND mode Go to H O A menu and put in AUTO mode.

LOW ALARM

The summary screen will display an L at the left side of the bar graph if the copper

concentration drops below the low alarm set point.

Possible Cause Corrective Action

1. Pump not working Inspect and repair pump if necessary.

2. No replenishment Refill chemical supply. Check pump valves.

3. Output 1 in OFF mode Go to H O A menu and put in AUTO mode.

NO SAMPLE

No sample will be displayed if the measurement signals indicate excess air in the

sample. Perform a self test to verify that the control module passes, which indicates

that the problem is with the sensor (see section 5.2). If the control module fails the

self test, return it for repair.

32

Page 36

Possible Cause Corrective Action

1. Liquid level too low for Increase liquid level

immersible sensor.

2. Sample pump failure. Repair sample pump

3. Leak in or blockage of sample line. Repair sample line

4. Partial plate out of sensor. Etch sensor.

5. Excess air in line. Check vertical mounting of sensor

LIGHT BULB OUT

This message indicates that the measurement signals have disappeared. Perform a

self test to verify that the control module passes, which indicates that the problem is

with the sensor (see section 5.2). If the control module fails the self test, return it for

repair.

Possible Cause Corrective Action

1. Light bulb failure Return sensor for repair

2. Severe plate out Etch sensor

3. Sensor disconnected Reconnect sensor

PLATE OUT

This message is displayed when signals levels have been reduced considerably due

to plate out. Perform a self test to verify that the control module passes, which

indicates that the problem is with the sensor (see section 5.2). If the control module

fails the self test, return it for repair.

Possible Cause Corrective Action

1. Plate-out of sensor Etch sensor

SENSOR ERROR

Caused by the measurement signals being outside the normal range, such as a

negative concentration reading. perform a self test to verify that the control module

passes, which indicates that the problem is with the sensor (see section 5.2). If the

control module fails the self test, return it for repair.

33

Page 37

Possible Cause Corrective Action

1. Condensation inside sensor Allow to dry out thoroughly

2. Faulty new sensor set-up Repeat new sensor set-up with clean water

3. Sensor disconnected Reconnect sensor

CALIBRATION TIME

The controller will display this prompt based upon the setting of the "Days between

cal" menu in the Sensor menu group and the time of the last calibration. It may be

cleared by performing a 1 point calibration of the sensor. If this feature is not

desired, setting "Days between cal" to 0 will disable it.

TURNOVER LIMIT

This prompt is displayed if the output 1 totalizer has calculated a replenishment

volume that exceeds the number of turnovers set in the "turnover limit" menu.

PUMP OVERRUN

This display appears if the pump output has been on longer than the time limit set in

the "Time Limit" menu. It could be caused by a pump failure, lack of replenishment

chemical, the time limit being set too low, or a failure of the pump to respond.

INTERLOCK

This error message is displayed if the signal from a flow or level switch is open, and

the "Interlock Y/N" menu is set for "Y". Restore flow or level. The switch may be

tested by measuring ohms when the switch should be closed (it should be very low,

not infinite). The input may be tested by shorting the two terminals (interlock

message should disappear).

CHECK SET POINTS

This is a normal display if you have changed the units of measure of the copper

concentration. This serves as a reminder that the controller does not convert the

numerical value of the set points; for example, if the set point was 7.5 g/L, it will

become 7.5 oz/gal, not 1 oz/gal.

34

Page 38

PASS

This message is displayed after initiating the SELF TEST feature. This indicates the

controller is functioning properly and the problem is likely to be with the sensor.

However, the wiring between the controller front panel circuit board and the

external sensor connector should be checked for breakage or wear. See diagram in

figure 3.

FAIL

This message is displayed after initiating the SELF TEST feature. The controller is

probably defective. Make sure to disconnect the sensor prior to attempting the self

test. Consult your factory representative for service options.

8.0 Service Policy

The WCU Series Copper Controller has a 2-year warranty on electronic components

and a 1-year warranty on mechanical parts (keypad, terminal strip and relays).

We stock circuit boards for immediate exchange after we have isolated the cause of

the problem.

Factory authorized repairs that are received by next-day-air will be returned within

24 hours. Normal priority for returns is two weeks.

Out of warranty repairs or circuit board exchanges are done on a flat fee basis after

the warranty is expired.

5 BOYNTON ROAD HOPPING BROOK PARK HOLLISTON, MA 01746 USA

TEL: 508-429-1110 FAX: 508-429-7433 WWW.WALCHEM.COM

WALCHEM CORPORATION

35

Loading...

Loading...