Page 1

W

A L C H E

P

POSI

OSIFLOW

OSIOSI

PP

Sensor

M

Instruction Manual

Read this manual before using product.

PRODUCT DESCRIPTION

PPPPOSI

The

metering pump is truly moving liquid into the

system and has not lost prime. Utilizing

proprietary circuitry coupled with advanced

pressure sensing technology, the

Sensor provides the most accurate and non-

intrusive flow verification device to date.

Without any moving parts in the sensor, the

standard flow path of the pump is preserved

and the liquid does not move through any gears

or lift a magnet to actuate a pulse in the sensor.

This eliminates any concern of plugging,

leaking or jamming of the flow path or sensing

mechanism.

OSIFLOW

OSIOSI

Sensor will verify that your

PPPPOSI

OSIFLOW

OSIOSI

The output signal of the

an open-collector contact closure

corresponding with each flow pulse.

Additionally, a visual green LED is mounted

on the topside of the sensor. This is always

ON to indicate power and will briefly flash

OFF in sync with each output signal.

PPPPOSI

The

pressure. If the pump becomes either air-locked or in a dead head condition, the sensor will no longer

output a signal. And unlike the competition, if the discharge line breaks or becomes disconnected,

pressure will be lost and the

OSIFLOW will send out a signal with every stroke as long as there is liquid pumping against

OSIOSI

Five Boynton Road Hopping Brook Park Holliston, MA 01746 USA TEL 508-429-1110 FAX 508-429-7433

PPPPOSI

OSIFLOW Sensor is

OSIOSI

PPPPOSI

OSIFLOW sensor will stop signaling flow.

OSIOSI

Member of the Walchem Group

Page 2

W

A L C H E

SAFETY & CAUTION NOTES

Wear Protection

When working on or around a metering pump,

always wear proper protective clothing and

equipment as recommended by the supplier of the

chemical being pumped.

Remove Power

Disconnect the pump and sensor from their electrical

power sources before performing any maintenance.

If the pump starts operation during maintenance,

chemical may be sprayed & cause injury.

Application of Product

Use the PosiFlow within the specified range.

Using the PosiFlow in any other application than its

intended purpose may result in personal injury or

damage to the product.

Not observing precautions may cause injury or damage to the product.

SPECIFICATIONS

1. Identification:

Part Number Description Material

FCP-1VC PosiFlow Sensor, VC VC

FCP-1VE PosiFlow Sensor, VE VE

FCP-1PC PosiFlow Sensor, PC PC

FCP-1PE PosiFlow Sensor, PE PE

2. Applicable Models and Ordering Information:

PPPPOSI

OSIFLOW Sensor is available for the 10, 15 & 20 sizes of EH and EZ

The

OSIOSI

pumps with matching liquid end codes. It will mount into either the manual air

vent valve or the Multi

auto air vent valve (VCA or VCC codes).

3. Electrical

Power Source Voltage 12VDC +

Current 25mA max (@12VDC)

Output Type Non-Isol. Open Collector (NPN)

Rating 24VDC max (from source)

Wave Form 100mS +

Indicator LED (Green)

Cable

Length 9.75 Feet

Cross Section 3.1x10

Termination #6 Fork Terminal

4. Materials of Construction

Housing PVC or GFRPP

O-Rings FKM or EPDM

Sensor 96% Ceramic (Al2O3)

MultiFunction valve, but at this time it is not compatible with

MultiMulti

2VDC

15mS

-4 in2

Power Source

Use only stable DC voltage within the specified range.

Voltage outside the range may cause damage or fire.

Do Not Modify the Product

Never attempt to modify the PosiFlow. Alteration of

the product may produce a dangerous situation and

will void the warranty.

Location

Do not use the PosiFlow Sensor in an aggressive

environment. Exposure to liquid or excess humidity

may cause failure or electrical shock.

Do Not Use a Damaged Sensor

Using a damaged PosiFlow may cause chemical

leakage or electrical shock.

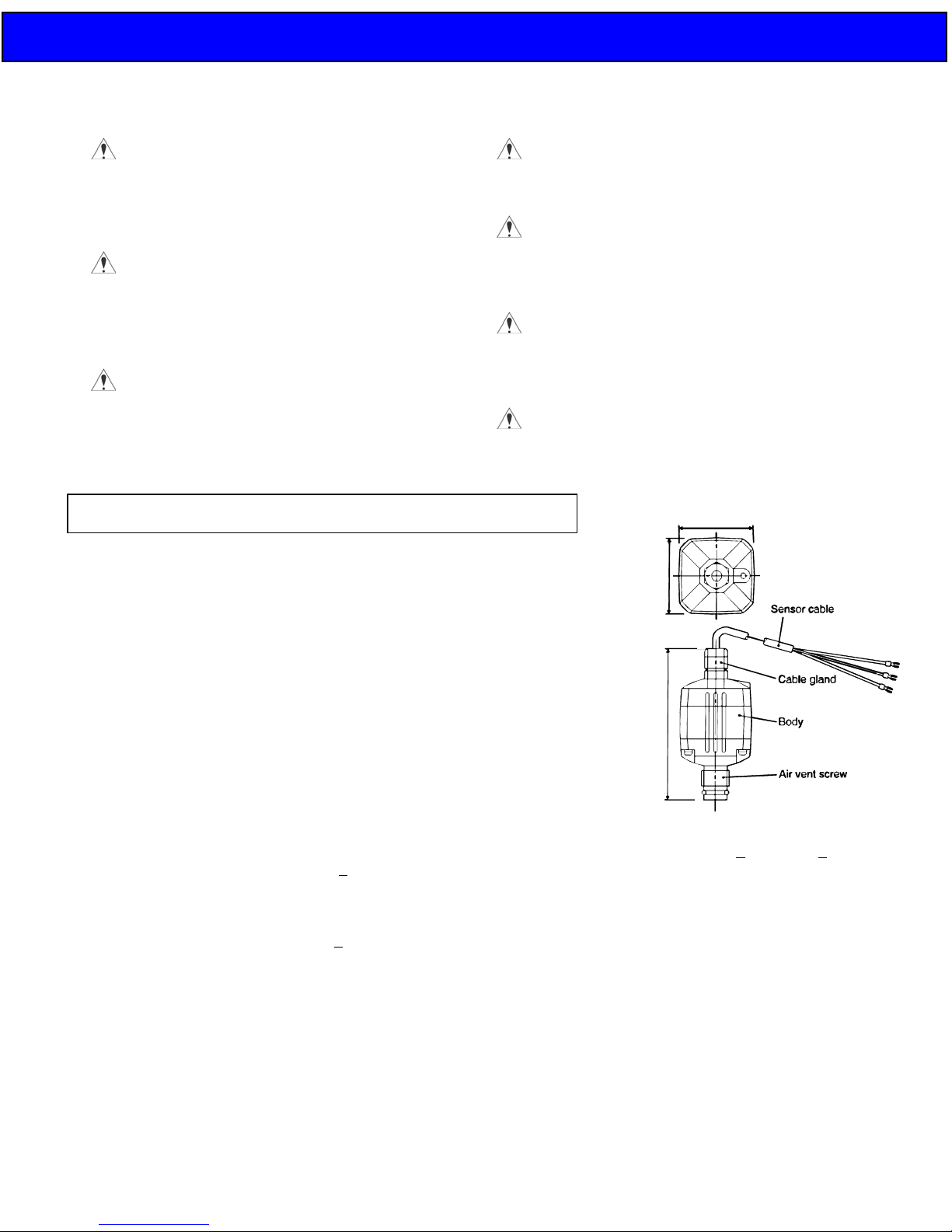

1.89”

3.82”

5. Output Pressure Range*: 30+

6. Environment:

Ambient Temperature 0-120°F

Ambient Humidity 35-90% RH

Storage Temperature 32-120°F

Liquid Temperature 32-105°F (PVC models)

32-140°F (GFRPP models)

PPPPOSI

*The

OSIFLOW Sensor requires a minimum of 30PSI

OSIOSI

total back pressure. If this is not available, the injection

valve supplied with the pump can be retrofitted with an

optional high-pressure spring, part number E90375.

This spring will increase the back pressure at the pump

approximately 50PSI.

M

1.89”

5PSI to 150+15PSI

Page 3

W

A L C H E

t

INSTALLATION

Disconnect the pump from the electrical power source before performing maintenance.

Release the pressure in the discharge tubing before disconnecting or performing any maintenance on the pump.

Plumbing

1. Unscrew and remove the air vent knob from the manual air vent valve (or Multi

clockwise.

2. Insert the PosiFlow Sensor directly where the air vent knob was located (turn clockwise to secure).

CAUTION: The wires on the sensor will want to twist as it is being screwed into the

valve. While installing the sensor, also turn the cable to avoid wire twisting and

damage. If this is not possible, pre-twist the wire in the opposite direction about 5

turns to relieve stress during sensor installation.

3. The function of the manual air vent is not lost when using the PosiFlow Sensor.

Simply use the sensor itself as the manual air vent valve when necessary, turning it

one-half to one turn counter clockwise to bleed out air, prime the pump or release the

discharge pressure.

Installing the PosiFlow Sensor into the manual air vent valve.

Electrical

Wiring

The PosiFlow Sensor requires 12VDC power to operate. Attach the RED wire to +12VC and the BLACK wire to GND

(common). The output signal is a closed contact between the WHITE and BLACK wires.

CAUTION: Do not run the PosiFlow cable near other power lines carrying high current or high power equipment as line

noise can cause sensor damage or abnormal operation.

Output Signal

The output signal (white wire) is normally high and drops to zero when the PosiFlow senses a pulse from the discharge of

the pump. The time of the closed contact is 100mS. See the output wave form below.

This type of signal acts similar to a contact closure from a reed switch device between the signal (white) and the common

(black) wires. The only difference is that the receiving device will see a trigger on the rise of the output instead of the fall

(reverse of typical).

MultiFunction Valve) by turning counter-

MultiMulti

Installing the PosiFlow

Sensor into the

Multi

MultiFunction Valve

MultiMulti

M

PosiFlow Outpu

Page 4

W

A L C H E

OPERATION

Back Pressure Requirement

In order for the PosiFlow Sensor to function, a minimum of 30PSI system pressure is required at the sensor. In cases

where there is little or no system pressure, the standard injection check valve supplied with each pump can be modified

with a high-pressure spring that adds approximately 50PSI. Contact your local distributor to order Part Number E90375.

Operation

Turn on the pump. The PosiFlow will not output a signal until the pump actually is moving liquid. For priming of the

pump, the PosiFlow sensor may have to be turned one-half or one full turn counter-clockwise to vent the air out the vent

connection.

CAUTION: Tubing should always be connected from the air vent back into the supply tank or suitable drain. Do not

submerge the air return tubing below the chemical surface level in the supply tank.

Once fully primed, close the air vent by tightening down the PosiFlow Sensor. The green LED on the PosiFlow should

now begin to flash OFF with each pump stroke and it will output a pulse simultaneously. The PosiFlow will continue to

output pulses as long as it senses pressure changes. If the pump loses prime or is air locked, the compression of air with

each pump stroke will not generate enough pressure for the PosiFlow to sense and it will not output pulses. Similarly,

excessive pressures will cause the pump to begin to stall and not generate enough pressure differential for the PosiFlow

to sense.

NOTE: If there is any trapped air, long lengths of flexible tubing, or any area of relief or expansion during a

deadhead situation, the PosiFlow may still keep sensing flow. This is more likely in C15/20 sized pumps.

Output Signal

The output signal from the PosiFlow simulates a contact closure. It can be used in any device that takes a non-powered

contact closure as a switch. It can also be used to drive another EH series pump.

The Walchem Web

The Web

WebMaster will alarm a no flow condition after a customer-set time limit and will also totalize pumped volume

WebWeb

once the pump is calibrated.

In a similar manner, a PLC or other device can be programmed to interpret the PosiFlow signal in any number of ways.

TROUBLESHOOTING & MAINTENANCE

CAUTION: Do NOT disassemble the PosiFlow Sensor! There are no user serviceable parts inside and the components

No output pulses from the

PosiFlow Sensor

(Output pulse is not synchronous

with the pump stroke)

Liquid Leakage from around the

PosiFlow Sensor

WebMaster is designed to accept the PosiFlow Sensor signal. It both powers and reads the signal.

WebWeb

can easily be damaged. Disassembly of the Sensor will void the manufacturer’s warranty.

Problem Possible Cause Corrective Action

o Incorrect or disconnected wiring

o Pump has lost prime (air-lock)

o Pump is drawing in air

o Disconnected or cut tubing

o Pinched or clogged tubing

o Foreign material lodged in pump

o PosiFlow Sensor not tightened

down (in the air vent condition)

o Not enough back pressure

o O-ring seals on PosiFlow missing,

dislocated, or worn

o Double check wire connections

o Unscrew PosiFlow one-half turn to

vent air

o Check the tubing and fitting

connections

o Correct/Replace the tubing

o Correct/Replace Tubing

o Disassemble/inspect/clean pump

head assembly

o Tighten the PosiFlow Sensor by

turning clockwise by hand.

o Check Injection Valve location and

system pressure. Install the High

Pressure Spring (E90375) if there

is little or no system pressure

o Re-install or replace the o-rings

M

Five Boynton Road Hopping Brook Park Holliston, MA 01746 USA TEL 508-429-1110 FAX 508-429-7433

E00098 PosiFlow Sensor

Instruction Manual

REVISION A 4/10/02

Member of the Walchem Group

Loading...

Loading...