Page 1

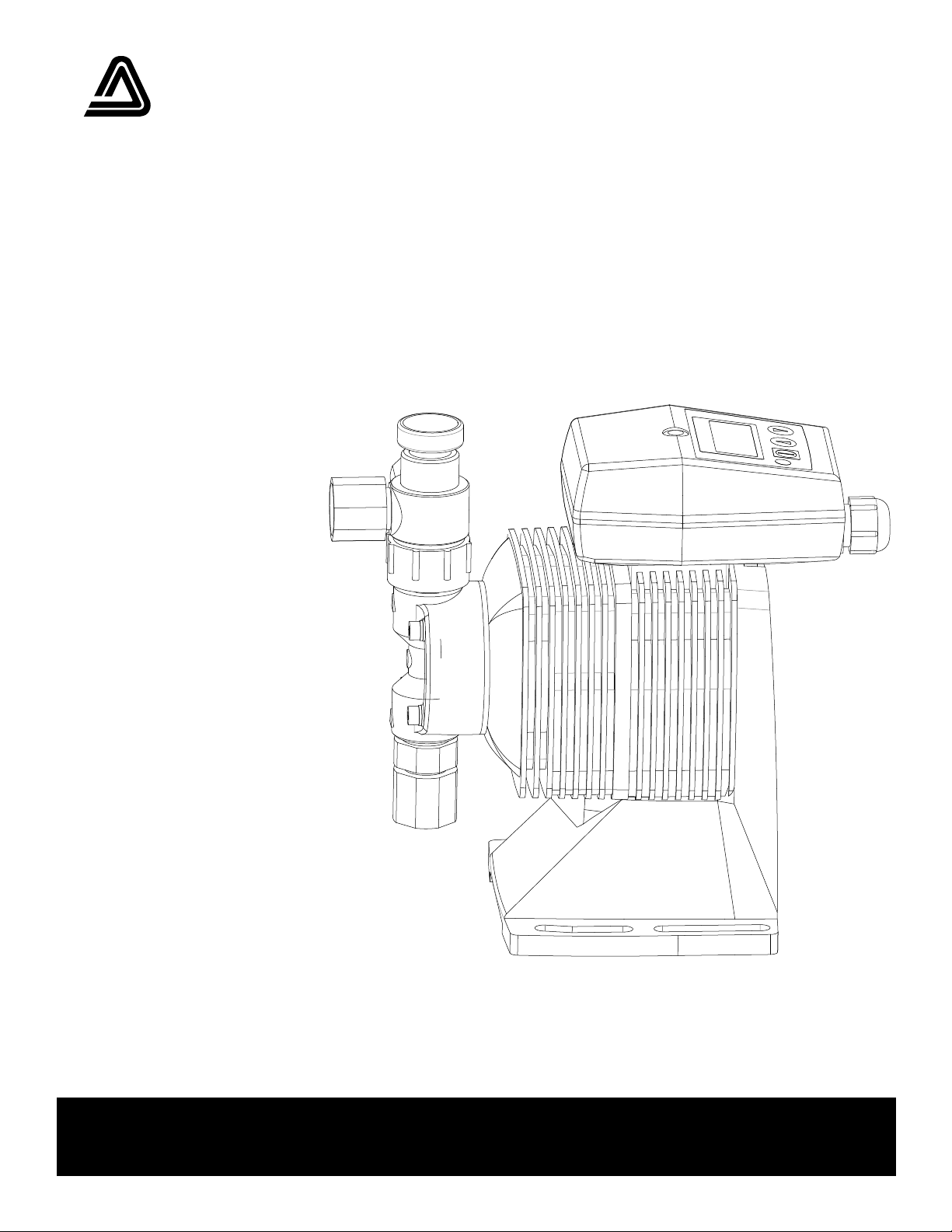

IWAKI PUMPS

EZ Series Electronic Metering Pump

Instruction Manual

Five Boynton Road Hopping Brook Park Holliston, MA 01746 USA

TEL: 508-429-1110 WEB: www.walchem.com

Page 2

Notice

© 2017

Five Boynton Road, Holliston, MA 01746 USA

tel (508) 429-1110 fax (508) 429-7433

All Rights Reserved

Printed in USA

WALCHEM, Iwaki America Inc. (hereinafter “Walchem”)

Proprietary Material

The information and descriptions contained herein are the property of WALCHEM. Such information and

descriptions may not be copied or reproduced by any means, or disseminated or distributed without the

express prior written permission of WALCHEM.

This document is for information purposes only and is subject to change without notice.

Statement of Limited Warranty

WALCHEM warrants equipment of its manufacture and bearing its identication to be free from defects in

workmanship and material for a period of two years from date of delivery from the factory or authorized

distributor under normal use and service and otherwise when such equipment is used in accordance with

instructions furnished by WALCHEM and for the purposes disclosed in writing at the time purchased, if

any. WALCHEM’s liability under this warranty shall be limited to replacement or repair, F.O.B. Holliston,

MA U.S.A. of any defective equipment or part which, having been returned to WALCHEM, transportation

charges prepaid, has been inspected and determined by WALCHEM to be defective.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EITHER EXPRESS OR IMPLIED, AS

TO DESCRIPTION, QUALITY, MERCHANT-ABILITY, FITNESS FOR ANY PARTICULAR PURPOSE

OR USE, OR ANY OTHER MATTER.

P/N E00159.N

January 2017

Page 3

TABLE OF CONTENTS

Thank you for choosing a Walchem EZ Series metering pump. This instruction manual deals with the correct installation, operation, maintenance and troubleshooting procedures for the EZ metering pumps. Please

read through it carefully to ensure the optimum performance, safety and service of your pump.

Contents

1.0 INTRODUCTION ..................................................................................... 1

1.1 Safety and Caution Notes ................................................................................................................. 1

1.2 Principle of Operation ........................................................................................................................ 1

1.3 Model Code ....................................................................................................................................... 2

1.4 Specications .................................................................................................................................... 2

1.4.1 Electrical

1.4.2 Operating Conditions .............................................................................................................. 2

1.4.3 Capacity/Pressure Rating ....................................................................................................... 3

1.4.4 Adjustment Range ................................................................................................................... 3

1.4.5 Materials of Construction ........................................................................................................ 3

1.5 Dimensions ........................................................................................................................................ 4

.............................................................................................................................................. 2

2.0 INSTALLATION ....................................................................................... 6

2.1 Unpacking ......................................................................................................................................... 6

2.2 Location ............................................................................................................................................. 6

2.3 Supply Tubing .................................................................................................................................... 7

2.4 Discharge Tubing .............................................................................................................................. 8

2.5 Installing Injection/BackPressure Valve ............................................................................................. 8

2.6 Interlocking Pump .............................................................................................................................. 9

2.7 Electrical ............................................................................................................................................ 9

3.0 OPERATION ............................................................................................ 9

3.1 Priming .............................................................................................................................................. 9

3.2 Adjustment and Control ..................................................................................................................... 10

3.3 Calibration ......................................................................................................................................... 13

3.4 STOP Function .................................................................................................................................. 13

3.5 AC Power Interruption ....................................................................................................................... 13

3.6 Auto Air Vent Valve Operation ........................................................................................................... 14

3.7 MultiFunction Valve Operation .......................................................................................................... 14

4.0 MAINTENANCE ..................................................................................... 16

4.1 Diaphragm Replacement ................................................................................................................... 16

4.2 Valve Replacement ........................................................................................................................... 16

4.3 Tubing ............................................................................................................................................... 16

5.0 EXPLODED VIEW & PARTS GUIDE ......................................................17

6.0 TROUBLESHOOTING ............................................................................27

7.0 SERVICE POLICY ...................................................................................27

Page 4

1.0 INTRODUCTION

1.1 Safety and Caution Notes

Always wear protective clothing, eye protection and gloves before working on or near a metering pump. Follow

all recommendations of the supplier of the solution being pumped. Refer to the MSDS from the solution supplier

for additional precautions.

Walchem EZ Series metering pumps should be installed where ambient temperatures do not exceed 122°F

(50°C) or do not fall below 32°F (0°C). Pumps should always be shielded from direct exposure to the elements.

Black UV resistant tubing should be used if the tubing is exposed to strong UV radiation (sunlight/lamps).

WARNING Risk of electrical shock! This pump is supplied with a grounding conductor and grounding-type

attachment plug. To reduce the risk of electrical shock, be certain that it is connected only to a properly

grounded, grounding type receptacle with ratings conforming to the data on the pump data plate. Prior to

performing any maintenance on a pump, disconnect the pump from the electrical power source.

Plumbing Precautions

All tubing must be securely attached to the ttings prior to starting the pump (see Section 2.3). Only use

Walchem tubing with your pump. Tubing should be shielded to prevent possible injury in case of rupture or

damage. UV resistant tubing should be used if the tubing is exposed to UV light. Always adhere to local

plumbing codes and requirements. Be sure that the installation does not constitute a cross connection. Walchem

is not responsible for improper installations. Prior to performing any maintenance on a pump, depressurize the

discharge tubing.

In ooded suction, pumping downhill, or pumping into little or no system pressure installations, a back

pressure/anti-syphon device must be installed to prevent over-pumping or siphoning. Contact your Walchem

distributor for additional information.

Solution Compatibility

CAUTION! This pump has been evaluated for use with water only. The suitability of this pump for use with

liquids other than water (such as acids or alkalines) is the responsibility of the user. For liquids other than

water, select the best-suited liquid end material combination using a chemical compatibility chart.

1.2 Principle of Operation

The EZ series electronic metering pumps consist of a pump unit, a drive unit, and a control unit. The drive unit is an

electromagnetic solenoid. When the solenoid coil is energized by the control unit the armature shaft moves forward

due to the magnetic force of the solenoid. The shaft is attached to a PTFE faced diaphragm which is part of the pump

unit. The diaphragm is forced into the pump head cavity decreasing volume and increasing pressure which forces liquid

in the pump head out through the discharge check valves. When the solenoid coil is de-energized, a spring returns the

armature to its starting position. This action pulls the diaphragm out of the head cavity increasing volume and decreasing

pressure. Atmospheric pressure then pushes liquid from the supply tank through the suction check valves to rell the

pump head.

1

Page 5

1.3 Model Code

EZ B16 D 1 - VC A

1 2 3 4 5 6

1 Pump Series

EZ: Electronic metering pump with manual speed control (adjustable to 360 strokes per minute)

2 Capacity/Pressure Rating (See Section 1.4 for detailed chart.)

3 Control Module

D: For use on all EZ models, features digitally adjustable speed and xed stroke length

T: Timer module allows daily, weekly, or 2 week operation with digitally adjustable speed and

external stop control. Available on 115V EZB models.

4 Voltage

1: 115 VAC, 50/60 Hz

2: 230 VAC, 50/60 Hz (not available on EZB pumps)

5 Liquid End (See Section 1.45 for detailed chart.)

6 Options

M: Multifunction Valve is supplied in place of the manual air vent valve. Available for the EZ

series pumps in all sizes and iquid ends except FC. Not available with the ADV feature.

A Auto Degassing Valve is supplied under the manual air vent valve. Available for the EZ Series

in B11/16/21 and C16/21 sizes with –VC/-VE liquid ends only.

1.4 Specications

1.4.1 Electrical

(50/60 Hz, single phase)

EZB 115 VAC±10% 0.9 Amp max. 16 watt avg.

EZC 115 VAC±10% 1.4 Amp max. 24 watt avg.

230 VAC±10% 0.6 Amp max. 24 watt avg.

1.4.2 Operating Conditions

Ambient temperature 32°F to 122°F (0°C to 50°C)

Relative humidity 30% to 90% non-condensing

Liquid temperature 32° to 104°F (0 to 40°C) for PVC based liquid ends

32° to 140°F (0 to 60°C) for PP, PVDF, SS based liquid ends

2

Page 6

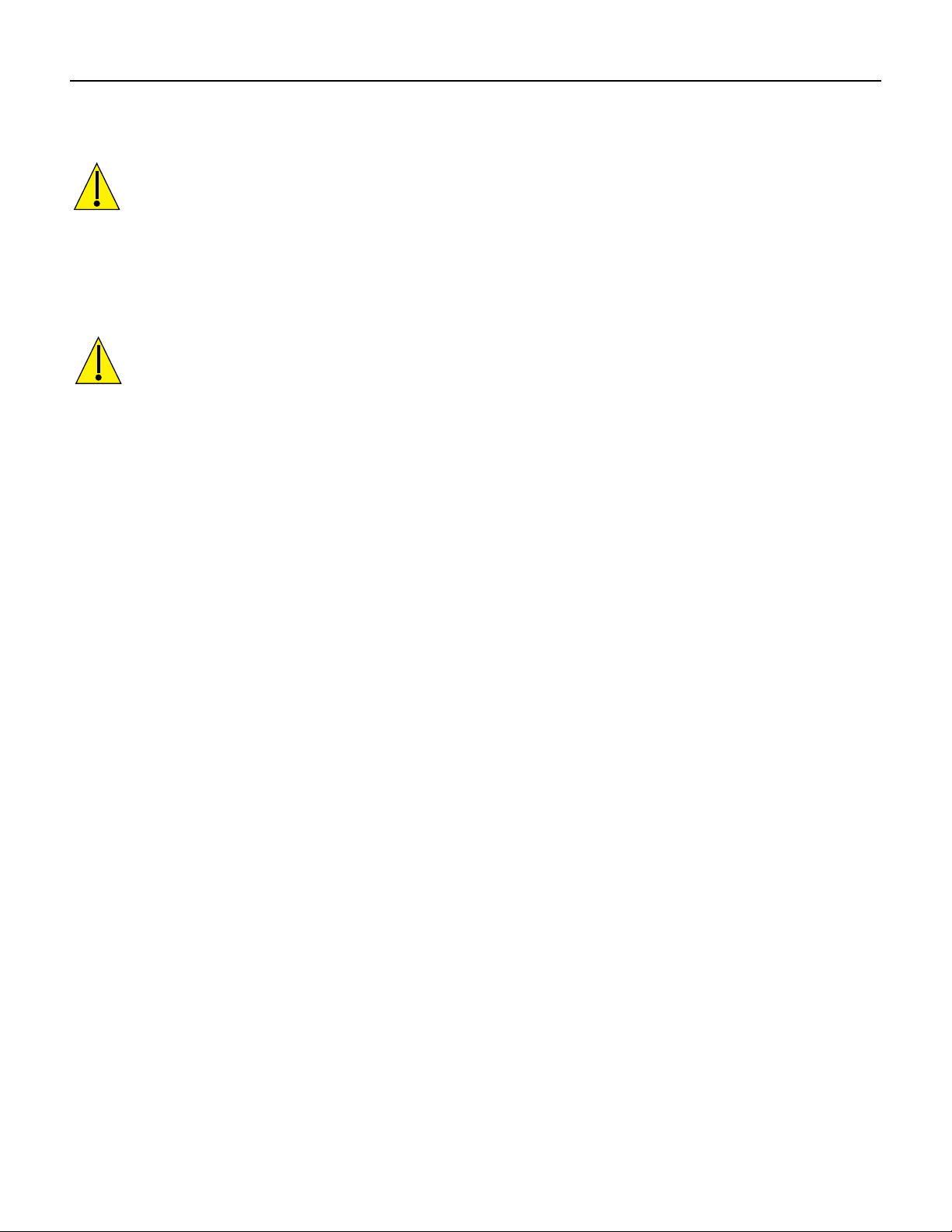

1.4.3 Capacity/Pressure Rating

Size Maximum

Output Capacity

(Gal/hr) (mL/min) PSI MPa

Max Output per

Stroke (mL)

Maximum

Pressure

B11 0.6 38 0.11 150 1.0 3/8

B16 1.0 65 0.18 105 0.7 3/8

B21 1.5 95 0.26 60 0.4 3/8

B31 3.2 200 0.56 30 0.2 1/2

C16 1.3 80 0.22 150 1.0 3/8

C21 2.0 130 0.36 105 0.7 3/8

C31 4.3 270 0.75 50 0.35 1/2

C36 6.3 400 1.17 30 0.2 1/2

1

Auto Degassing valve reduces output by approx. 20%

1.4.4 Adjustment Range

Frequency adjustment range: 0 to 360 strokes per minute

1.4.5 Materials of Construction

1

Size (in)

Tubing O.D

Connection

Liquid

End

Code

PA GFRPP

Pump

Head

& Fittings

Diaphragm

Valve

Balls

Valve

Seat

Valve

Seals

CE PCTFE AFLAS

Gasket Tubing

®

PC GFRPP CE FKM FKM

PE GFRPP CE EPDM EPDM

VC PVC CE FKM FKM

VE PVC CE EPDM EPDM

VF PVC PTFE EPDM EPDM

TA PVDF CE PCTFE AFLAS

PTFE

(bonded to

EPDM)

PTFE PE

®

TC PVDF CE FKM FKM

FC PVDF CE PCTFE PTFE

CE Alumina ceramic PE Polyethylene

EPDM Ethylene propylene diene monomer PTFE Polytetrauoroethylene

FKM Fluoroelastomer PVC Polyvinylchloride (translucent)

GFRPP Glass ber reinforced polypropylene PVDF Polyvinylideneuoride

PCTFE Polychlorotriuoroethylene

3

Page 7

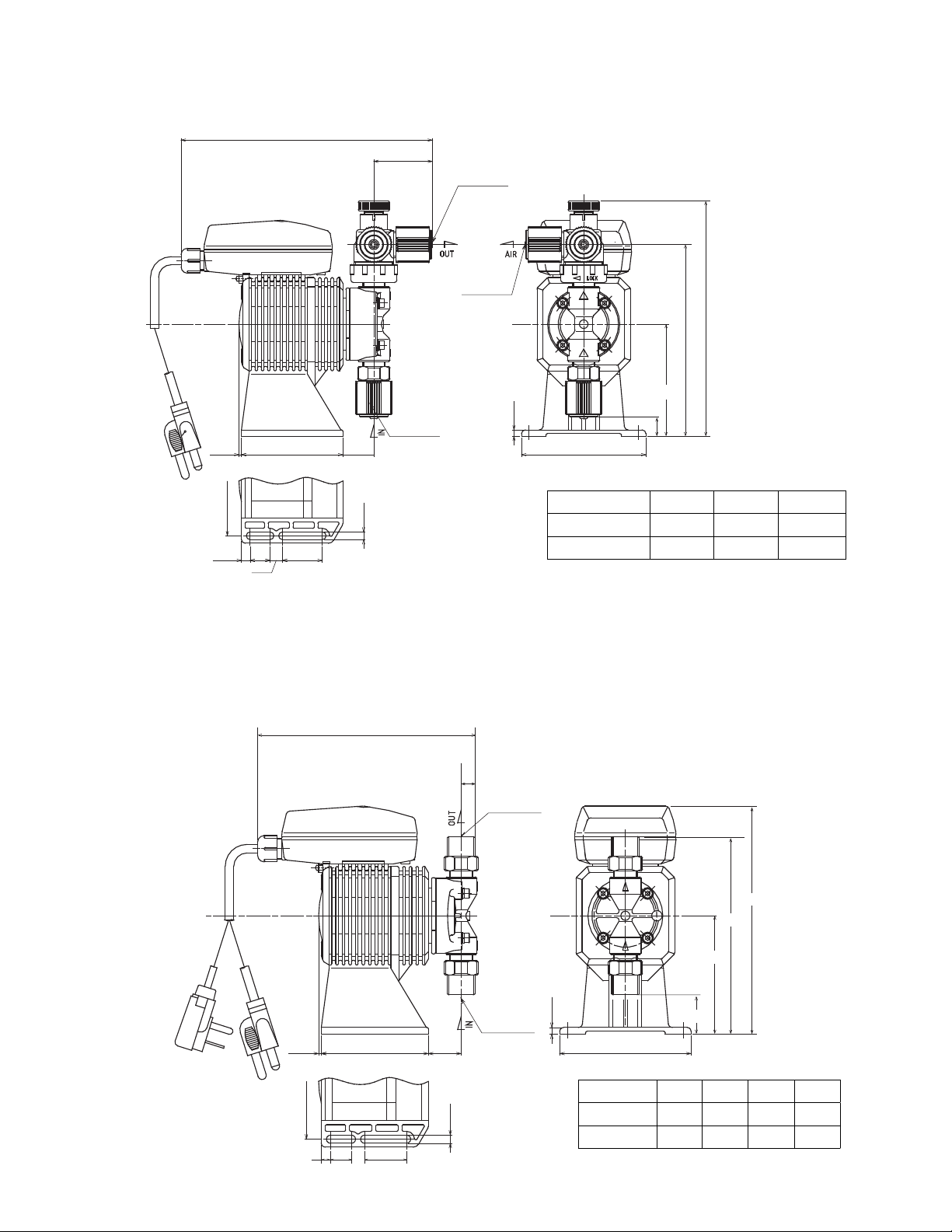

1.5 Dimensions

EZB Models with thermoplastic liquid end materials (except -FC)

7.95” (See Note 1)

1.85”

Tubing (ID x OD)

ø1/4” x ø3/8”

Tubing (ID x OD)

ø1/4” x ø3/8”

Z (See Note 3)

Y (See Note 2)

3.54”

Notes:

0.08”

0.28”

3.46”

0.63”

0.39”

3.21”

1.26”

(0.98”)

Tubing (ID x OD)

0.24”

ø1/4” x ø3/8”

0.20”

3.94”

Model Size X Y Z

11-21 0.54" 6.1" 7.47"

31 -0.15" 6.57" 7.91"

X

1. Addition of a Multifunction valve increases overall length by 0.10”.

2. Addition of a Multifunction Valve increases discharge height by 2.62”. The Auto Degassing Valve increases discharge height by 1.82”.

3. Addition of a Multifunction Valve increases overall liquid end height by 1.25”. The Auto Degassing Valve increases height by 1.82”

EZB Models with FC liquid end materials

L

E

1/4” FNPT

ø3/8 OD Fittings

supplied

0.08” (0.98”)

3.46”

0.28”

0.63”

3.21”

1.26”

1/4” FNPT

ø3/8 OD Fittings

supplied

0.24”

4

6.83”

Y

3.54”

0.20”

X

3.94”

Model Size X Y L E

11-21 1.20” 5.90” 6.57” 0.51”

31 0.55” 6.54” 6.81” 0.63”

Page 8

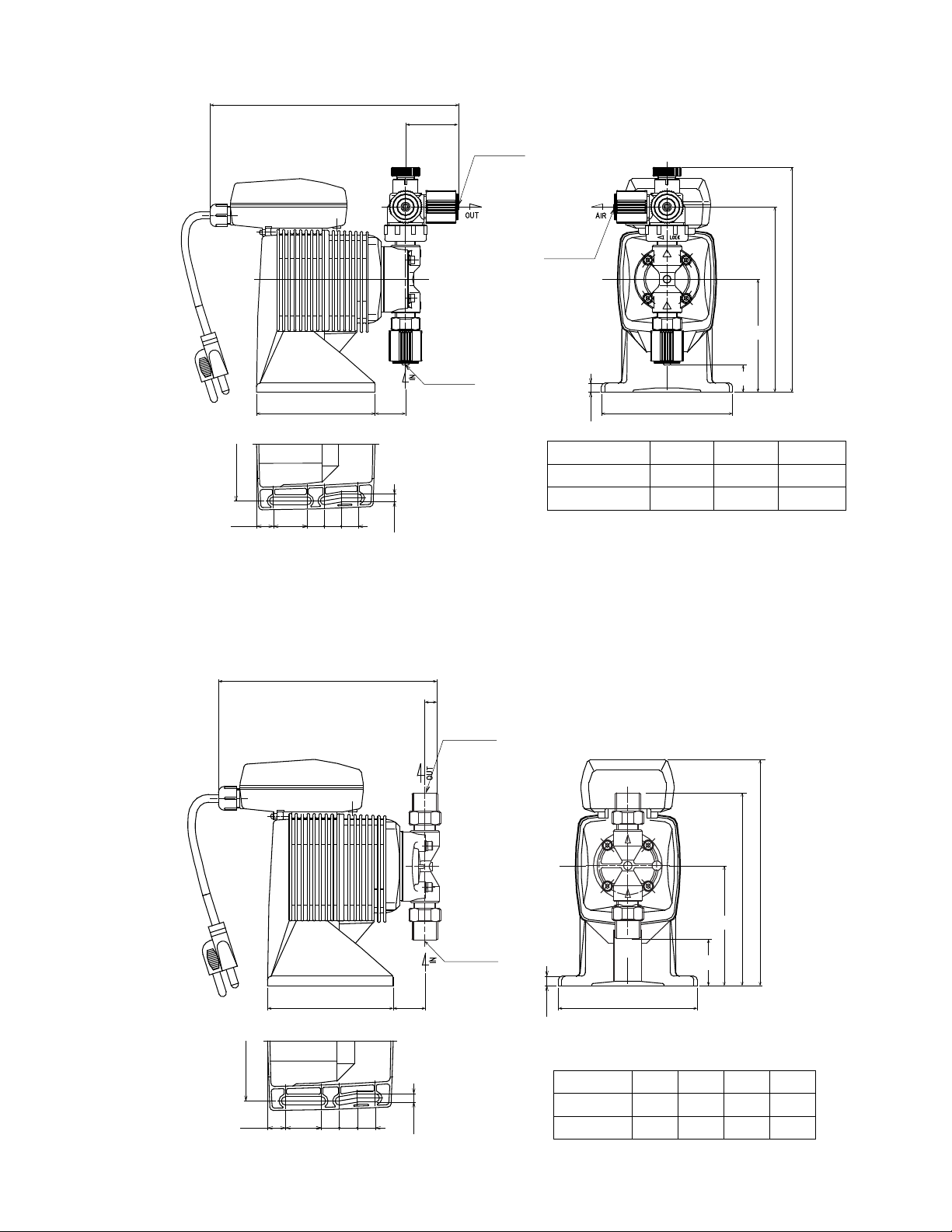

EZC Models with thermoplastic liquid end materials (except FC)

0.28”

0.28”

8.66” (See Note 1)

1.85”

Tubing (ID x OD)

ø1/4” x ø3/8”

Tubing (ID x OD)

ø1/4” x ø3/8”

3.94”

Y (See Note 2)

Z (See Note 3)

4.13”

(1.06”)

Tubing (ID x OD)

ø1/4” x ø3/8”

0.31”

4.57”

X

Model Size X Y Z

3.94”

16-21 0.94" 6.46" 7.83"

31-36 0.24" 6.95" 8.33"

0.59” 1.18”

0.59”

0.59”

0.59”

Notes:

1. Addition of a Multifunction valve increases overall length by 0.10”.

2. Addition of a Multifunction Valve increases discharge height by 2.62”. The Auto Degassing Valve increases discharge height by 1.82”.

3. Addition of a Multifunction Valve increases overall liquid end height by 1.25”. The Auto Degassing Valve increases height by 1.82”

EZC Models with FC liquid end materials

L

E

1/4” FNPT

ø3/8 OD Fittings

supplied

3.94”

0.59” 1.18”

4.13”

0.59”

0.59”

0.59”

(1.06”)

1/4” FNPT

ø3/8 OD Fittings

supplied

5

Y (See Note 2)

Z (See Note 3)

3.94”

X

0.31”

4.57”

Model Size X Y L E

16-21 1.57” 6.31” 7.32” 0.51”

31-36 0.91” 6.97” 7.44” 0.63”

Page 9

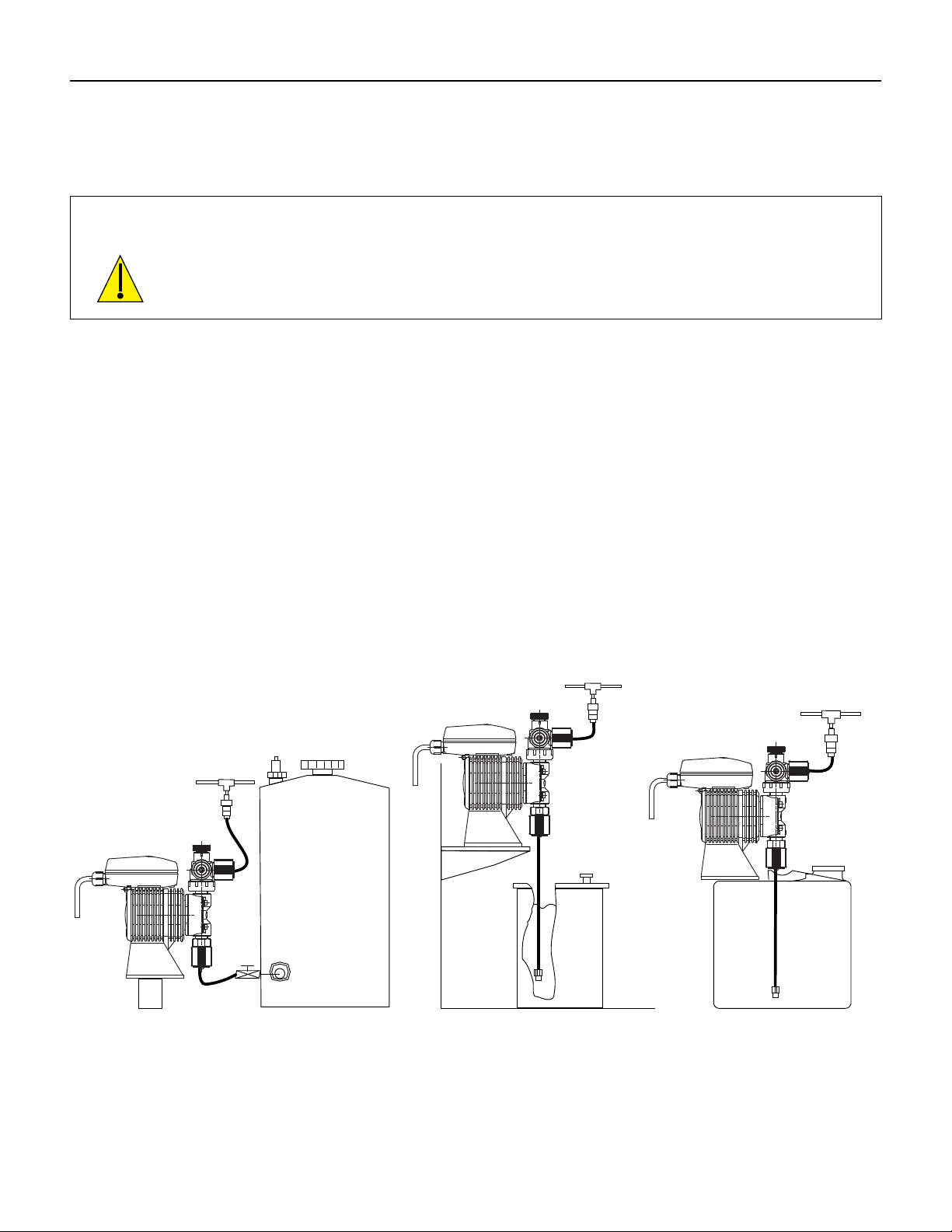

2.0 INSTALLATION

2.1 Unpacking

Open the shipping carton and inspect contents for damage. If any items are missing or damaged contact your local

distributor.

Pumps are pre-primed with water at the factory. If the application is not compatible with water, drain

and dry before use. Be sure to remove caps from ttings before attaching tubing.

CAUTION: Head bolts may have loosened during storage or shipment. Be sure to check and tighten

to 19 lb-in torque, if necessary.

Do not handle or move the pumps using the Control Module only. The pump should be supported by the base or drive

unit during handling

2.2 Location

Choose a location for the pump which is clean, dry, vibration-free, close to an electrical outlet, and allows convenient

access to stroke length control, frequency control, and tubing connections. Avoid areas where ambient temperature

exceeds 122°F (50°C) or falls below 32°F (0°C). Pumps should always be shielded from direct exposure to the elements. Black UV resistant tubing should be used if the tubing is exposed to strong UV radiation (sunlight/lamps).

This pump is cord connected and not intended for permanent mounting to a building structure. However, temporary

mounting to stabilize the pump during operation may be necessary as long as tools are not required for the installation

or removal of the pump.

Flooded suction (mounting the pump below the level of liquid in the supply tank) is strongly recommended, especially

when pumping liquids that readily generate gas bubbles. Sodium hypochlorite and hydrogen peroxide are common

examples of such liquids. (See Figure 1.)

Figure 1 Flooded suction

Recommended for liquids

that out-gas

Figure 2 Shelf mount Figure 3 Tank mount

If ooded suction mounting is not possible, a shelf adjacent to (but not directly above) the supply tank often works

well. (See Figure 2.) The supply tank or cover can also be used if it has provisions for mounting a pump. (See Figure

3.) In any case, the total suction lift should not exceed 5 ft (1.5m).

6

Page 10

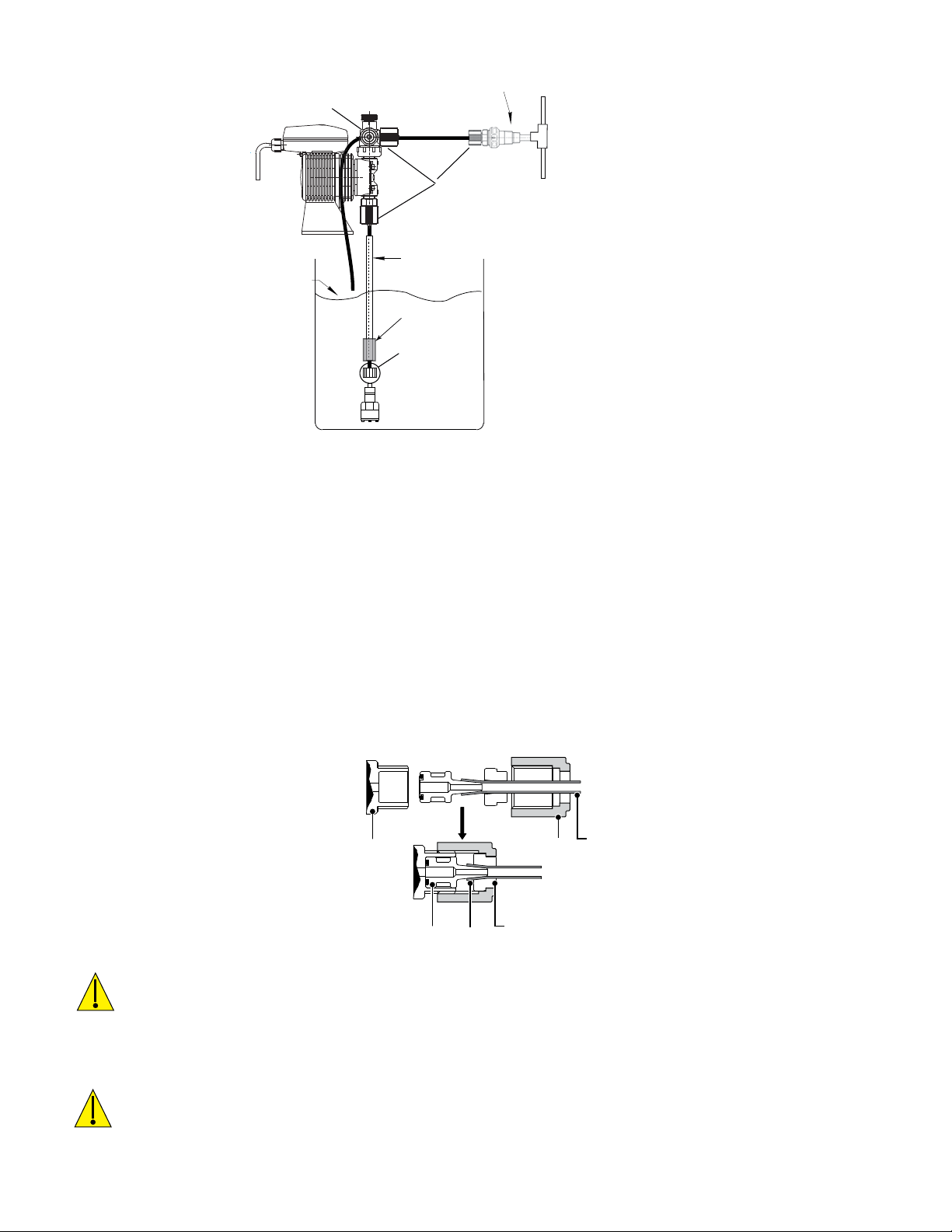

Coupling Nut

(Air Vent Valve)

Injection

Valve

Point of

Injection

Coupling Nut

Return Line

Air Gap

PVC Pipe Tubing Straightener

(user supplied)

or

Ceramic weight

Coupling Nut

Foot Valve

Figure 4 Connection Tubing

2.3 Supply Tubing

The supply tubing run should be as short as possible. For ooded suction mounting, install a shut-off valve with an

appropriate tubing connector at the tank outlet. Cut a length of tubing from the coil supplied and install between

the shut-off valve and the pump inlet tting. For suction lift applications, slide on the ceramic weight, then install a

foot valve on one end of suction tubing. Cut the tubing to a length such that the foot valve hangs vertically about 1 in

(25mm) above the bottom of the tank. Avoid any loops in the tubing run that could form a vapor trap. Running the

tubing through a length of pipe will help to keep tubing straight. Total vertical suction lift should be no more than 5ft.

(1.5m). Reference Figure 4.

Attach tubing as shown in Figure 5. First slide the coupling nut, small end rst, then the tubing clamp onto the tubing.

Push the tubing over the tubing adapter tip all the way to the valve housing shoulder. (Tip: if the tubing is stiff from

cold, dip the tubing end in hot tap water for a few minutes so it will slide on and are out more easily. Push the tubing

adapter into the tting on the pump and coupling nut onto the threads. Apply some pressure on the coupling nut and

tubing while tightening the nut, making sure the tubing has not backed off of the shoulder of the valve housing.

Fitting

on pump

Coupling

Nut

Tubing

Figure 5

Tubing

adapter

WARNING: All ttings and coupling nuts should be tightened by hand only. If necessary, a small tool may

Slide

tubing

down

Tubing clamp

be used to make it snug. DO NOT use excessive force or large wrenches.

The coupling nut should not bottom out completely against the tting. If this happens during connection, check the

tubing and tubing clamp connection. Remove the coupling nut, re-cut the tubing and re-connect if necessary.

WARNING: If there is any leakage around the coupling nut and it appears to have been installed correctly,

DO NOT TIGHTEN the coupling further! Release pressure in the line, disconnect tubing, re-cut and re-connect.

Tightening of misinstalled tubing may cause the tubing to be cut off under pressure.

7

Page 11

2.4 Discharge Tubing

Figure 6 Air Vent Valve Tubing

Cut a length of tubing long enough to go from the pump to the application (injection) point. Additional tubing can be

ordered from your distributor. Avoid sharp turns or bends and hot surfaces. Routing tubing through rigid pipe such

as PVC pipe is recommended for long runs and/or as protective shielding against corrosive chemicals. If applicable,

install the injection valve in 1/2” NPT thread at the injection point (see section 2.5) and connect the discharge tubing

to the injection valve.

Attach tubing as described in section 2.3 and as shown in Figures 5 and 6. Note: Some models have an air vent valve

with two outlet connections. The connection marked ‘OUT’ is the discharge side to the application point. (Fig 6).

Attach a second length of tubing to the air vent side marked (‘AIR’) and route back to the chemical solution tank or

drum. On the larger pumps (31 & 36 sizes), the air vent valve connections are not marked, however, the discharge

side is the vertical (UP) connection and the air vent connection is on the side of the valve.

Drains back to tank

Discharges to injection point

"AIR"

"OUT"

2.5 Installing Injection/BackPressure Valve

A tting or tee with 3/8”or 1/2” NPTF threads and with sufcient depth will accept the injection valve assembly. If

required, trim off an amount of the extension tip until it ts your tting or tee. (Fig. 7.)

The position of the injection/back pressure valve can be at any orientation as long as the spring is retained in the

valve. DO NOT REMOVE THE SPRING. Be sure to check and replace the spring as needed. Attach the tubing following the same instructions in section 2.3, connecting the supply tubing.

CAUTION: Some chemicals may have reactions as they are injected into the main ow. For exam-

ple, sulfuric acid may react with water causing excess heat. If the chemical is heavier than water, mount the

injection valve as close as possible to vertical coming into the bottom of the pipe. This will keep the injection

nozzle facing up and keep the heavier chemistry from draining into the pipe and causing adverse reactions

within the injection valve and pipe.

In addition to preventing backow from pressurized lines, the injection valve acts as a back pressure valve when

pumping into atmosphere or low pressure applications. However, the back pressure by the injection valve can vary

and the valve does NOT act as an anti-siphon valve. If siphoning is a possibility, or if pumping downhill into open

atmosphere (open tank), a Walchem MultiFunction valve or a separate back pressure/anti-siphon valve must be installed.

Note: Siphoning can also occur at the tip of the injection valve because of the high ow rate in the main pipe owing

past the small injection nozzle (venturi effect). In this case, an anti-siphon device must be installed to avoid over

feeding or siphoning of chemistry.

See Section 5.0 for complete liquid ends parts list and exploded view.

8

Page 12

3/8" NPT

1/2" NPT

Figure 7 Injection Valve

Outer Diameter 1/2"

Trim back as needed to t

tee or tting

2.6 Interlocking Pump

CAUTION! Control of pump operation is critical. Operation and chemical addition during no ow

situations can create hazardous situations from elevated chemical concentrations and chemical gasses trapped

in the line.

Ensure that during no ow conditions such as when the well pump, main line or recirculation pump is off, and for

pools/spas, in times of backwash, that the metering pump is not allowed to operate. If using a controller (pH/ORP/

pool) for automated control and ow indication is tied into it, pump operation can be interlocked to the controller.

Interlocking the pump operation can also be done directly using a ow switch located in the water, main or pool/spa

recirculation lines. The ow switch can be tied directly into the pumps to stop operation during no ow conditions.

2.7 Electrical

WARNING Risk of electrical shock! This pump is supplied with a grounding conductor and grounding-type attachment plug. To reduce the risk of electrical shock, be certain that it is connected only to a properly grounded, grounding type receptacle.

CAUTION! The electronics within the pump can be damaged by excessive surges in voltage. Do

not install the pump near high-power electrical equipment that generate high surge voltages. Avoid branch

circuits that also supply power to heavy or other equipment that could generate electrical interference. If necessary, install a surge suppression device (such as a varistor with a resistance greater than 2000A) or a noise

reducing transformer at the pump’s power connection.

3.0 OPERATION

3.1 Priming

Install the pump as described above. With the pump turned on, set frequency at 100%. If the pump is equipped with

an air vent valve, open the knob 1/2 turn. Liquid should move through the suction tubing and into the pump head.

When liquid starts running through the vent side tubing, close the air vent knob and continue with output adjustment

described below. If the pump has no air vent valve, disconnect the discharge tubing from the injection valve. When

liquid enters the discharge tubing at the pump head, stop the pump. Then reconnect the discharge tubing to the injection valve.

If the pump does not self prime, remove the check valve housing on discharge & suction sides to make sure valve

cartridges and gaskets are in correct positions (see section 4.2 for correct orientation).

Note: It is recommended that pumps with FC liquid ends use ooded suction when priming, due to the hard valve seat

material.

9

Page 13

3.2 Adjustment and Control

4

2

3

5 6 7

8

Power

Ground

Stop Input

Sensor Power

DC 12V

20 mA max.

+

_

White

NEU

Black

HOT

Green

P 3 6 0

EH-T Controller

5.THU 6.FRI 7.SAT 8.STOP

2nd

ON

SEL

1.SUN 2.MON

3.TUE 4.WED SET

ON

Num

MODE

HOUR

MIN

3.2.1 EZ Pumps using the ‘D’ Control Module

If less than full output is required, set the frequency to the appropriate percentage of maximum desired.

Example: Model EZB21D1-VE has maximum output of 1.5 GPH.

Desired output is 1.2 GPH. 1.2 ÷ 1.5 = 0.8 or 80%

Set the frequency of the pump to 0.8 x 360 = 288 spm by pushing the UP or DOWN

arrow keys.

3.2.2 EZ Pumps using the ‘T’ Control Module

The EZB-Timer Series is able to operate in Daily, Weekly and 2-Week modes. An external stop input and

12VDC output are also available.

Alphanumeric display. Indicates

WAIT mode, stroke frequency, time

Timer Display/Keypad Overview

NUM/DAY indicator. Becomes

backlit when programming

or operating at programmed

number/day.

MODE key. Scrolls user

through TIMER, WAIT

and MAN modes. Use to

exit from any programming

mode.

or pump on-time.

NUM indicator. Becomes

backlit when the pump is in

DAILY mode to indicate the

timer program number.

SET indicator. Becomes

backlit when pump is being

programmed.

2nd indicator. Becomes

backlit when pump is in the

nd

week of the 2-WEEK

2

mode.

UP/HOUR. Increases

numeric values and sets

the hours. Used with SEL

key to set pump on-time

and duration.

SEL. Manually starts or stops

the pump from WAIT mode.

Used to select program number

or day of week while programming.

DOWN/MIN key. Decreases

ON light. Indicates AC

power to the pump with

continuous green. Flashes

numeric values and sets the

minutes. Used with SEL key to

select the Timer Pump Mode.

off with each stroke.

Figure 8

10

Page 14

EZ-T Quick Reference Guide

FROM:

PRESS:

TO:

Mode Key

Select Key

WAIT

+

+

Move to MANUAL menu

Changes pump frequency (1 to 360 SPM)

Starts and stops manual operation

OR

Sets the Hour (incrementing only)

(Hold for 3 seconds)

MODE

SEL

MODE

SEL

SEL

SEL

MIN

HOUR

Move to TIME / DATE setting menu

Move to TIMER programming menu

Move to TIMER MODE selection menu

MANUAL

MIN

HOUR

SEL

TIME / DATE

(24 Hour Clock)

MIN

HOUR

SEL

Sets the Minutes (incrementing only)

Selects the Day of the week

MODE

MODE

Move to TIMER RUN mode (shows TIME)

Exits back to WAIT menu

Move to WAIT menu

MODE

TIMER RUN

MENU

Scrolls between DAILY, WEEK or 2-WEEK

Timer modes

TIMER MODE

MENU

MIN

HOUR

MODE

Exits back to WAIT menu

OR

TIMER

P

MENU

Sets the Hour / Sets On-Time Minutes

MIN

HOUR

SEL

Sets the Minutes / Sets On-Time Minutes

Scrolls through the week days / program #

MODE

Exits back to WAIT menu

WAIT

MANUAL

TIMER RUN

POWER ON

TIMER MODE

SELECTION

TIMER

PROGRAMMING

MODE

MODE

HOUR

SEL

+

MIN

SEL

+

MODE

MODE

MODE

TIME / DATE

SETTING

SEL

(

)

MODE

MENU

MENU

MENU

ROGRAMMING

3 Seconds

11

Page 15

Programming and Timer Use

CAUTION! Before use, check the time and date. Set to the local time and date before programming.

Incorrect time/date can result in incorrect operation.

1. Manual Operation

From the WAIT menu, pressing the MODE key will enter the manual mode. Pressing SEL will toggle the

pump on and off manually. The speed can be changed with the UP and DOWN arrows both running and

waiting. NOTE: The pump speed set in this menu will be the speed that the pump will run during timed operations.

2. Time/Date Setting

From the WAIT menu, holding the SEL key down for 3 seconds will enter into the Time/Date SET menu.

Using the HOUR and MIN keys, the time can be set using a 24-hour clock. The SEL key will cycle through

the days of the week.

Once the correct time and day of the week are set, pressing the MODE key will go back to the WAIT menu.

3. Timer Mode Selection

Pressing the MIN and SEL keys at the same time will bring up the Mode Selection menu. This menu is where

the Timer module is set to control in daily, weekly, or in 2-week modes. Use the UP and DOWN keys to cycle through the three options and MODE to get back to the WAIT menu. Daily mode allows a max of up to 8

timed operations repeated every day. Weekly and 2-week modes allow a max of one timed operation per day.

4. Timer Operation Programming

Pressing the HOUR and SEL keys at the same time will bring up the Timer Programming menu. This menu is

where the individual operations are set – both start time and run time.

DAILY MODE:

Initially, the 1-SUN and NUM will both be backlit. NUM is backlit to signal that the number backlit is

used – i.e. program 1 in this case. Using the HOUR and MIN keys, the time for the rst program can

be set (24-hour clock). Pressing the SEL key will change the menu to program the on-time to run the

pump (initially shows “ 0M”). Use the UP and DOWN keys to program the # of minutes for the pump

to run. Pressing SEL again will then move to program the second program and the backlight will move

from 1-SUN to 2-MON. The clock and on-time settings are set in the same manner. Pressing MODE

will go back to the WAIT menu.

WEEKLY MODE:

Initially, the 1-SUN will be backlit signifying that Sunday is being programmed. If a program is desired for Sunday, use the HOUR and MIN keys to set the time of the program. If no program is desired

for Sunday, pressing the SEL key will scroll through each day’s two programmed settings – the time to

start and the run time. Pressing MODE will go back to the WAIT menu at any point in the programming.

2-WEEK MODE:

Two week mode is similar and set just as the weekly mode, only after the rst 7-SAT is programmed or

nd

passed by and 1-SUN is again backlit, the “2

nd

week. All programming functions are the same and SEL will scroll through each setting. Press-

the 2

” will also become backlit showing that the day is in

ing MODE will go back to the WAIT menu at any point in the programming.

From the WAIT mode, pressing MODE will move to the MANUAL menu. Check to make sure that the pump

speed is set at the rate desired during the timed operations. If not, use the UP and DOWN keys to change the

pump speed.

Pressing MODE again will display the current time and date. The pump is now operating in the TIMER mode

and will come on at the next programmed timer operation.

12

Page 16

3.3 Calibration

If exact output calibration is required, rst prime and adjust the pump as above. Then connect a calibration column to

the suction side of the pump. Turn the pump on for one minute and read the amount of liquid pumped from the column. Adjust the frequency up or down as necessary and check the output again. When the desired output is reached,

disconnect the calibration column and reconnect the suction tubing. (See Figure 9) Calibration must be performed

with application equivalent back pressure for accurate results. Published ow rates are based on maximum pressures.

Lower back pressures may result in slightly higher pump ow rates.

Figure 9 Calibration

3.4 STOP Function

Additionally, EZ pumps with a Timer Module can be controlled in start-stop mode. In this mode, AC power is applied

continuously and pump operation is stopped by completing the circuit between the positive ‘stop’ and common terminals inside the T Control Module: 7 (positive) and 8 (common). A switch or solid state device capable of switching

5VDC at 2 mA should be used. Switch closed = pump stopped, switch open = pump running at the speed determined

by the frequency setting. This feature eliminates the need for a high voltage, high current AC relay to start and stop

the pump. (See Figure 8)

3.5 AC Power Interruption

If AC power is interrupted, the pump will power up as shown below:

State preceding power OFF State following power ON

WAIT WAIT

Running in Manual Operation Running in Manual Operation

Running in Timer Operation Running in Timer Operation

Setting Time WAIT

Programming Timer Set points WAIT

13

Page 17

3.6 Auto Degassing Valve Operation

The Auto Degassing Valve (ADV) is an option on select EZ pumps and is added under the standard Manual Air Vent

Valve when ordered. It is used primarily in applications where gassing is a problem and pumps can lose prime.

Unlike the Manual Air Vent Valve, the Auto Degassing Valve constantly bleeds a controlled amount of volume out

of the “Air” vent. Therefore, the “Air” vent should always be plumbed back to the source tank. During priming, the

access knob does not have to be loosened as with a manual air vent valve as pressure is relieved through the vent.

The check valve assembly in the ADV uses a bottom seat to ensure that air is not introduced into the discharge media

and utilizes a second top seat that allows air to be quickly purged but limits the amount of liquid returned to the tank.

Moving the pump check valves above the ADV maintains back pressure within the pump discharge, but allows the

pump head to bleed, helping to speed the purging of air and auto re-priming the pump.

Manual air vent valve

Vent port

Disharge

port

Discharge check

valves

AAVV – Cross Sectional View

Automatic

Degassing Valve

Check Valve

Pump head

Suction port

14

Page 18

3.7 MultiFunction Valve Operation

The MultiFunction Valve is optional on select E-Series pumps and replaces the standard Manual Air Vent Valve when

ordered. It integrates the air venting/bleeding functions with a back pressure, anti-siphon, and pressure relief valve.

For more detailed specications of the MultiFunction Valve, see its separate instruction sheet at walchem.com.

Air Vent / Bleed Function

1. Open the air vent by turning the relief valve knob 90 degrees to the “AV” position.

2. Operate the pump until all of the air is purged and only liquid is discharged from the air vent drain.

3. Turn the relief valve knob back 90 degrees to the “RV” position to set pressure relief.

Pressure Relief

Set

RV

RV

AV

AV

RV

AV

AV

RV

Pressure Relief

Relieved

RV

AV

AV

RV

RV

RV

AV

AV

Pressure Relief

1. In the “RV” position, the diaphragm under the relief valve knob provides a safety relief if the discharge line

pressure gets too high.

Line Pressure Relief

1. By rotating both the Relief valve knob to “AV” and the back pressure valve knob to “PF”, both the discharge line

and the pump head pressures are released out the air vent for full line pressure release.

Back Pressure / Anti-Siphon Valve

1. A spring-loaded diaphragm under the back pressure knob automatically adds approximately 36PSI (15 PSI

for low pressure versions) of back pressure to the discharge side of the pump when the knob is set to the “BP”

position.

2. The diaphragm also prevents siphoning of chemical through the pump.

Back Pressure

Set

BV

BV

PF

PF

PF

PF

BV

BV

CAUTION: Conrm that liquid is discharged from the air vent drain. If the liquid is not discharged, the pres-

Back Pressure

Relieved

BV

PF

PF

BV

BV

BV

PF

sure may not be released. If this is the case, repeat the Pressure Relief procedure.

15

PF

Page 19

4.0 MAINTENANCE

CAUTION! Before working on the pump, disconnect the power cord, depressurize the discharge tub-

ing and drain or ush any residual liquid from the pump head and valves. Always wear protective gear when

working around chemicals.

4.1 Diaphragm Replacement

Disconnect AC power to the pump and disconnect the suction tubing, discharge tubing, and air vent tubing. Remove

the four head bolts with a 4mm hex wrench. Unscrew the diaphragm and remove its retainer (small disk behind the

diaphragm). CAUTION: There may be small brass spacers between the retainer and the armature shaft. These

spacers need to be reused when replacing the diaphragm. Install the new retainer and diaphragm on the shaft. Turn

the diaphragm clockwise until it bottoms on the shaft. Use caution when handling the diaphragm – the PTFE surface

can be damaged by tools, nails or any sharp objects. Replace the pump head and tighten the head bolts to a torque of

19 lb-in (2.16 N-m).

4.2 Valve Replacement

Remove the suction and discharge tubing making sure discharge side has been

depressurized. Remove the suction tting, two valve cartridges, o-ring and gasket(s). Install the new o-ring, gasket(s) and valve cartridges. Be sure both valve

seats are in the same orientation. Refer to Figure below. Tighten the suction

tting. Similarly remove and replace the discharge valve cartridges, o-ring and

gasket(s). For a more detailed drawing, refer to the Section 6.0.

CAUTION: There are many small parts in the liquid end.

FLOW

These parts must be installed correctly for proper operation of the

pump.

4.3 Tubing

Check ends of tubing for splits, cracks, or thin spots. Examine the full length of

tubing for damage due to chang, abrasion, stress cracks, excessive temperature

or exposure to ultraviolet light (direct sunlight or mercury vapor lamps). If any

signs of deterioration exist, replace the entire length of tubing. It is a good idea to

replace discharge tubing on a regular preventive maintenance schedule every 12 months.

Gasket

Valve ball

Valve guide

Valve seat

16

Page 20

5.0 EXPLODED VIEW & PARTS GUIDE

PVC/GFRPP Liquid End Exploded View

For EZ pump model sizes 11-36

4

4

31

29

30

24

23

26

25

10

29

30

31

99

31

30

29

4

31

30

29

4

27

5

6

14

11

13

12

11

13

12

7

18

9

17

C Entire Head Assembly

D Valve Cartridge

F Multifunction Valve

Part numbers for these assemblies are on Page 26

19

1

17

14

11

13

12

11

13

12

3

31

30

29

4

17

Page 21

PVC/GFRPP Sizes 11-36 Liquid End Components

Item Part# Description Qty Material Size Liquid End Material

1

EH1947 Pump Head 1 PVC B11 VC, VE, VF

EH1948 1 PVC B16 VC, VE, VF

EH1949 1 PVC B21 VC, VE, VF

EH1950 1 PVC C16 VC, VE, VF

EH1951 1 PVC C21 VC, VE, VF,

EH1952 1 PVC B36 VC, VE, VF

EH1960 1 PVC C31 VC, VE, VF

EH1953 1 PVC C36 VC, VE, VF

EH1954 1 GFRPP B11 PC, PA, PE

EH1955 1 GFRPP B16 PC, PA, PE

EH1956 1 GFRPP B21 PC, PA, PE

EH1957 1 GFRPP C16 PC, PA, PE

EH1958 1 GFRPP C21 PC, PA, PE

EH1959 1 GFRPP B31 PC, PA, PE

EH1961 1 GFRPP C31 PC, PA, PE

EH1962 1 GFRPP C36 PC, PA, PE

3

EH2328 Housing, Valve (Suction) 1 PVC B11,16,21 / C16,21 VC, VE, VF

EH2329 1 PVC B31 / C31,36 VC, VE, VF

EH2349 1 GFRPP B11,16,21 / C16,21 PC, PE, PA

EH2350 1 GFRPP B31 / C31,36 PC, PE, PA

4

EH2330 Coupling Nut 3 PVC B11,16,21,31 / C16,21,31,36 VC, VE, VF

EH2351 3 GFRPP B11,16,21,31 / C16,21,31,36 PC, PE, PA

5

EH2331 Fitting, MAVV 1 PVC B11,16,21 /C16,21 VC, VE, VF

EH2332 1 PVC B31 / C31,36 VC, VE, VF

EH2352 1 GFRPP B11,16,21 /C16,21 PC, PE, PA

EH2353 1 GFRPP B31 / C31,36 PC, PA, PE

6

EH2333 Lock Nut, MAVV 1 PVC B11,16,21,31 / C16,21,31,36 VC, VE, VF

EH2354 1 GFRPP B11,16,21,31 / C16,21,31,36 PC, PE, PA

*7

EH1971 Diaphragm 1 PTFE+EPDM B 11 ALL

EH1972 1 PTFE+EPDM B16 / C16 ALL

EH1973 1 PTFE+EPDM B21 / C21 ALL

EH1974 1 PTFE+EPDM B31 / C31 ALL

EH1975 1 PTFE+EPDM C36 ALL

*9

EH0059 Retainer 1 PPS+GF B11 ALL

EH0083 1 PPS+GF B16 / C16 ALL

EH0067 1 PPS+GF B21 / C21 ALL

EH0087 1 PPS+GF B31 / C31 ALL

EH0158 1 PPS+GF C36 ALL

10

EH2334 Body, MAVV 1 PVC B11,16,21,31 / C16,21,31,36 VC, VE, VF

EH2355 1 GFRPP B11,16,21,31 / C16,21,31,36 PC, PE, PA

*11

EH0060 Guide, Valve 4 PVC B11 VC, VE, VF

EH0068 4 PVC B16,21 /C16,21 VC, VE, VF

EH0118 4 PVC B31 / C31,36 VC, VE, VF

EH0318 4 GFRPP B11 PC, PE, PA

EH1534 4 GFRPP B16,21 /C16,21 PC, PE, PA

EH0332 4 GFRPP B31 / C31,36 PC, PE, PA

18

Page 22

PVC/GFRPP Sizes 11-36 Liquid End Components (continued)

Item Part# Description Qty Material Size Liquid End Material

*12

EH0061 Seat, Valve 4 FKMA B11 VC, PC

EH0069 4 FKMA B16,21 / C16,21 VC, PC

EH0119 4 FKMA B31 / C31,36 VC, PC

EH0048 4 EPDM B11 VE, VF, PE

EH0071 4 EPDM B16,21 / C16,21 VE, VF, PE

EH0125 4 EPDM B31 / C31,36 VE, VF, PE

EH2415 4 PCTFE B11 PA

EH2416 4 PCTFE B16, 21/ C16, 21 PA

EH0593 4 PCTFE B31 / C31, 36 PA

*13

EH0025 Ball, Valve 4 CE B11 VC, VE, PC, PE, PA

EH0084 4 CE B16,21 / C16,21 VC, VE, PC, PE, PA

EH0120 4 CE B31 / C31,36 VC, VE, PC, PE, PA

E00063 4 PTFE B11 VF

E00064 4 PTFE B16, 21 / C16, 21 VF

E00062 4 PTFE B31 / C31, 36 VF

*14

EH0026 Gasket, Valve 2 (6) PTFE B11,16, 21 / C16,21 VC, VE, VF (PA)

EH0121 2 (6) PTFE B31 / C31,36 VC, VE, VF, PC, PE (PA)

EH2178 2 PTFE B11 PC, PE

EH0580 2 PTFE B16, 21 / C16,21 PC, PE

*17

EH0027 O-Ring, S14 2 FKMA B11,16, 21 / C16,21 VC, PC

EH0050 2 EPDM B11,16, 21 / C16,21 VE, VF, PE

E00179 2 AFLAS™ B11,16, 21 / C16,21 PA

EH0122 O-Ring, P16 2 FKMA B31 / C31,36 VC, PC

EH0127 2 EPDM B31 / C31,36 VE, VF, PE

E00201 2 AFLAS™ B31 / C31,36 PA

19

EH1986 Bolt, Hex Soc. w/washers 4 M4x35 316SS C16,21,31 ALL

EH1987 4 M4x40 316SS B11,16,21,31 ALL

EH1988 4 M5x35 316SS C36 ALL

23

EH0299 Knob, MAVV 1 PVC B11,16,21,31 / C16,21,31,36 VC, VE, VF

EH0321 1 GFRPP B11,16,21,31 / C16,21,31,36 PC, PE, PA

24

EH1314 Label, MAVV Knob 1 B11,16,21,31 / C16,21,31,36 ALL

*25

EH0300 O-Ring, P4 1 FKMA B11,16,21,31 / C16,21,31,36 VC, PC

EH0301 1 EPDM B11,16,21,31 / C16,21,31,36 VE, VF, PE

E00176 1 AFLAS™ B11,16,21,31 / C16,21,31,36 PA

*26

EH0302 O-Ring, P10A 1 FKMA B11,16,21,31 / C16,21,31,36 VC, PC

EH0303 1 EPDM B11,16,21,31 / C16,21,31,36 VE, VF, PE

E00174 1 AFLAS™ B11,16,21,31 / C16,21,31,36 PA

*

27

EH2335 O-Ring, P10 1 FKMA B11,16,21,31 / C16,21,31,36 VC, PC

EH2336 1 EPDM B11,16,21,31 / C16,21,31,36 VE, VF, PE

E00173 1 AFLAS™ B11,16,21,31 / C16,21,31,36 PA

*

29

EH2337 Clamp Ring, 3/8" OD 3 PPS+GF B11,16,21 / C16,21 ALL

EH2338 Clamp Ring, 1/2" OD 3 PPS+GF B31 / C31,36 ALL

*30

EH2339 Adapter,Tubing, 3/8"OD 3 PVC B11,16,21 / C16,21 VC, VE, VF

EH2356 3 GFRPP B11,16,21 / C16,21 PC, PE, PA

EH2340 Adapter, Tubing, 1/2"OD 3 PVC B31 / C31,36 VC, VE, VF

EH2357 3 GFRPP B31 / C31,36 PC, PA, PE

*31

EH2341 O-Ring, P9 3 FKMA B11,16,21,31 / C16,21,31,36 VC, PC

EH1585 3 EPDM B11,16,21,31 / C16,21,31,36 VE, VF, PE

E00178 3 AFLAS™ B11,16,21,31 / C16,21,31,36 PA

18

------ Brass Spacers -- Brass Drive Specic. Reuse with Dia. change ALL

99 MFV-HTC-7 Multi-Function Valve 1 PVDF/PTFE/AFLAS B11,16 / C16,21 xxM

MFV-MTC-7 1 PVDF/PTFE/AFLAS B21 xxM

MFV-MTC-8 1 PVDF/PTFE/AFLAS C31 xxM

MFV-LTC-8 1 PVDF/PTFE/AFLAS B31 / C36 xxM

* Parts Included in the Spart Parts Kits

19

Page 23

VCA-VEA Liquid End Exploded View For EZ pump model sizes 11 thru 21

24

4

29

30

31

31

30

29

4

6

14

11

13

12

11

13

12

17

23

26

25

10

27

5

29

30

31

66

58

61

60

57

61

62

17

E

56

65

63

14

59

14

17

64

19

E Auto Degassing Valve

Part Numbers for these assemblies are on

Page 26

18

9

7

1

17

14

11

13

12

11

13

12

3

31

30

29

4

Item Part# Description Qty Material Size

1 EH1947 Pump Head 1 PVC B11 VCA,VEA

EH1948 1 PVC B16 VCA,VEA

EH1949 1 PVC B21 VCA,VEA

EH1950 1 PVC C16 VCA,VEA

EH1951 1 PVC C21 VCA,VEA

3 EH2328 Housing, Valve (Suction) 1 PVC B11,16,21 / C16,21 VCA,VEA

4 EH2330 Coupling Nut 4 PVC B11,16,21 / C16,21 VCA,VEA

5 EH2331 Fitting, MAVV 1 PVC B11,16,21 / C16,21 VCA,VEA

6 EH2333 Lock Nut, MAVV 1 PVC B11,16,21 / C16,21 VCA,VEA

*7 EH1971 Diaphragm 1 PTFE+EPDM B11 VCA,VEA

4

EH1972 1 PTFE+EPDM B16 / C16 VCA,VEA

EH1973 1 PTFE+EPDM B21 / C21 VCA,VEA

*9 EH0059 Retainer 1 PPS+GF B11 VCA,VEA

EH0083 1 PPS+GF B16 / C16 VCA,VEA

EH0067 1 PPS+GF B21 / C21 VCA,VEA

10 EH2334 Body, MAVV 1 PVC B11,16,21 / C16,21 VCA,VEA

*11 EH0060 Guide, Valve 4 PVC B11 / VCA,VEA

EH0068 4 PVC B16,21 /C16,21 VCA,VEA

*12 EH0061 Seat, Valve 4 FKMA B11 VCA

EH0069 4 FKMA B16,21 / C16,21 VCA

EH0048 4 EPDM B11 VEA

EH0071 4 EPDM B16,21 / C16,21 VEA

*13 EH0025 Ball, Valve 4 CE B 11 VCA,VEA

EH0084 4 CE B16,21 / C16,21 VCA,VEA

*14 EH0026 Gasket, Valve 4 PTFE B11,16,21 / C16,21 VCA,VEA

*17 EH0027 O-Ring, S14 4 FKMA B11,16,21 / C16,21 VCA

EH0050 4 EPDM B11,16,21 / C16,21 VEA

19 EH1986 Bolt, Hex Soc. w/washers 4 M4x35 316SS C16,21 VCA,VEA

EH1987 4 M4x40 316SS B11,16,21 VCA,VEA

23 EH0299 Knob, MAVV 1 PVC B11,16,21 / C16,21 VCA,VEA

24 EH1314 Label, MAVV Knob 1 B11,16,21 / C16,21 ALL

*25 EH0300 O-Ring, P4 1 FKMA B11,16,21 / C16,21 VCA

EH0301 1 EPDM B11,16,21 / C16,21 VEA

*26 EH0302 O-Ring, P10A 1 FKMA B11,16,21 / C16,21 VCA

EH0303 1 EPDM B11,16,21 / C16,21 VEA

*27 EH2335 O-Ring, P10 1 FKMA B11,16,21 / C16,21 VCA

EH2336 1 EPDM B11,16,21 / C16,21 VEA

*29 EH2337 Clamp Ring, 3/8" OD 4 PPS+GF B11,16,21 / C16,21 VCA,VEA

*30 EH2339 Adapter,Tubing, 3/8"OD 4 PVC B11,16,21 / C16,21 VCA,VEA

*31 EH2341 O-Ring, P9 3 FKMA B11,16,21 / C16,21 VCA

EH1585 3 EPDM B11,16,21 / C16,21 VEA

56 EH1682 Body, Auto Degassing Valve 1 PVC B11,16,21 / C16,21 VCA,VEA

*57 EH1684 Guide, Separation Pin, ADV 1 PVC B11,16,21 / C16,21 VCA,VEA

*58 EH1685 Top Disc, Guide, ADV 1 PVC B11,16,21 / C16,21 VCA,VEA

59 EH1683 Spacer, Valve Guides, ADV 1 PVC B11,16,21 / C16,21 VCA,VEA

*60 EH1686 Separation Pin, ADV 1 Titanium B11,16,21 / C16,21 VCA

EH1687 1 HC276 B11,16,21 / C16,21 VEA, VCA-H

*61 EH0025 Ball, Valve, ADV 2 CE B11,16,21 / C16,21 VCA,VEA

*62 EH0061 Seat, Valve, ADV 1 FKMA B11,16,21 / C16,21 VCA

EH0048 1 EPDM B11,16,21 / C16,21 VEA

63 EH0294 Fitting, ADV 1 PVC B11,16,21 / C16,21 VCA,VEA

64 EH0295 Lock Nut, ADV 1 PVC B11,16,21 / C16,21 VCA,VEA

*65 EH0304 O-Ring, P7 1 FKMA B11,16,21 / C16,21 VCA

EH0305 1 EPDM B11,16,21 / C16,21 VEA

66 EWN0157 Housing, Valve, ADV 1 PVC B11,16,21 / C16,21 VCA,VEA

18 ------ Brass Spacers -- Brass

Drive Specic. Reuse with

Dia. change

* Parts Included in the Spart Parts Kits

20

Liquid

End

Material

ALL

Page 24

TC/TA Liquid End Exploded View For EZ Pump Models 11-36

4

29

30

31

31

30

29

4

6

14

11

13

12

11

13

12

17

19

Part numbers for these assemblies

are on Page 26

* Parts Included in the Spart Parts Kits

24

23

26

25

10

27

5

18

9

7

1

17

14

11

13

12

11

13

12

3

31

30

29

4

Item Part# Description Qty Material Size

Material

1 EH2407 Pump Head 1 PVDF B11 TC, TA

EH2408 1 PVDF B16 TC, TA

EH2409 1 PVDF B21 TC, TA

EH1969 1 PVDF B31 TC, TA

EH2411 1 PVDF C16 TC, TA

EH2412 1 PVDF C21 TC, TA

EH1966 1 PVDF C31 TC, TA

EH1967 1 PVDF C36 TC, TA

3 EH2359 Housing, Valve (Suction) 1 PVDF B11,16,21 / C16,21 TC, TA

EH2360 1 PVDF B31 / C31,36 TC, TA

4 EH2363 Coupling Nut 3 PVDF B11,16,21 /C16,21,31,36 TC, TA

5 EH2364 Fitting, MAVV 1 PVDF B11,16,21 /C16,21 TC, TA

EH2365 1 PVDF B31 / C31,36 TC, TA

6 EH2366 Lock Nut, MAVV 1 PVDF B11,16,21,31 /C16,21,31,36 TC, TA

*7 EH1971 Diaphragm 1 PTFE+EPDM B11 ALL

EH1972 1 PTFE+EPDM B16 / C16 ALL

EH1973 1 PTFE+EPDM B21 / C21 ALL

EH1974 1 PTFE+EPDM B31 / C31 ALL

EH1975 1 PTFE+EPDM C36 ALL

*9 EH0059 Retainer 1 PPS+GF B11 ALL

EH0083 1 PPS+GF B16 / C16 ALL

EH0067 1 PPS+GF B21 / C21 ALL

EH0087 1 PPS+GF B31 / C31 ALL

EH0158 1 PPS+GF C36 ALL

10 EH2367 Body, MAVV 1 PVDF B11,16,21 /C16,21,31,36 TC, TA

*11 EH2413 Guide, Valve 4 PVDF B11 TC, TA

EH2414 4 PVDF B16,21 /C16,21 TC, TA

EH2368 4 PVDF B31 / C31,36 TC, TA

*12 EH0061 Seat, Valve 4 FKMA B11 TC

EH0069 4 FKMA B16,21 / C16,21 TC

EH0119 4 FKMA B31 / C31,36 TC

EH2415 4 PCTFE B11 TA

EH2416 4 PCTFE B16, 21/ C16, 21 TA

EH0593 4 PCTFE B31 / C31, 36 TA

*13 EH0025 Ball, Valve 4 CE B11 TC, TA

EH0084 4 CE B16,21 / C16,21 TC, TA

EH0120 4 CE B31 / C31,36 TC, TA

*14 EH0342 Gasket, Valve 2 (6) PTFE B11,16,21 / C16,21 TC (TA)

EH0354 2 (6) PTFE B31 / C31,36 TC (TA)

*17 EH0027 O-Ring, S14 2 FKMA B11,16,21 /C16,21 TC

E00179 2 AFLAS™ B11,16,21 /C16,21 TA

EH0122 O-Ring, P16 2 FKMA B31 / C31,36 TC

E00201 2 AFLAS™ B31 / C31,36 TA

19 EH1986 Bolt, Hex Soc. w/washers 4 M4x35 316SS B11,16,21/ C16,21,31 ALL

EH1987 4 M4x40 316SS B31 ALL

EH1988 4 M5x35 316SS C36 ALL

23 EH1049 Knob, MAVV 1 PVDF B11,16,21,31 / C16,21,31,36 TC, TA

24 EH1314 Label, MAVV Knob 1 B11,16,21,31 / C16,21,31,36 ALL

*25 EH0300 O-Ring, P4 1 FKMA B11,16,21,31 / C16,21,31,36 TC

E00176 1 AFLAS™ B11,16,21,31 / C16,21,31,36 TA

*26 EH0302 O-Ring, P10A 1 FKMA B11,16,21,31 / C16,21,31,36 TC

E00174 1 AFLAS™ B11,16,21,31 / C16,21,31,36 TA

*27 EH2335 O-Ring, P10 1 FKMA B11,16,21,31 / C16,21,31,36 TC

E00173 1 AFLAS™ B11,16,21,31 / C16,21,31,36 TA

*29 EH2337 Clamp Ring, 3/8" OD 3 PPS+GF B11,16,21 / C16,21 TC, TA

EH2338 Clamp Ring, 1/2" OD 3 PPS+GF B31 / C31,36 TC, TA

*30 EH2369 Adapter,Tubing, 3/8"OD 3 PVDF B11,16,21 / C16,21 TC, TA

EH2370 Adapter, Tubing, 1/2"OD 3 PVDF B31 / C31,36 TC, TA

*31 EH2341 O-Ring, P9 3 FKMA B11,16,21,31 / C16,21,31,36 TC

E00178 3 AFLAS™ B11,16,21,31 / C16,21,31,36 TA

18 ------ Brass Spacers -- Brass

21

Drive Specic. Reuse with Dia. change

ALL

Liquid

End

Page 25

FC Liquid End Exploded View For EZ Pump Models 11-36

Item Part# Description Qty Material Size

End

Material

1 EH2407 Pump Head 1 PVDF B11 FC

EH2408 1 PVDF B16 FC

Liquid

14

11

13

12

14

11

13

12

14

17

3

18

9

7

EH2409 1 PVDF B21 FC

EH1969 1 PVDF B31 FC

EH2411 1 PVDF C16 FC

EH2412 1 PVDF C21 FC

EH1966 1 PVDF C31 FC

EH1967 1 PVDF C36 FC

3 EH2361 Housing, Valve 2 PVDF B11,16,21 / C16,21 FC

EH2362 2 PVDF B31 / C31,36 FC

*7 EH1971 Diaphragm 1 PTFE+EPDM B 11 FC

EH1972 1 PTFE+EPDM B16 / C16 FC

19

EH1973 1 PTFE+EPDM B21 / C21 FC

EH1974 1 PTFE+EPDM B31 / C31 FC

1

17

14

11

13

12

14

11

13

12

14

3

25

(x2 supplied

with pump)

EH1975 1 PTFE+EPDM C36 FC

*9 EH0059 Retainer 1 PPS+GF B11 FC

EH0083 1 PPS+GF B16 / C16 FC

EH0067 1 PPS+GF B21 / C21 FC

EH0087 1 PPS+GF B31 / C31 FC

EH0158 1 PPS+GF C36 FC

*11 EH2413 Guide, Valve 4 PVDF B11 FC

EH2414 4 PVDF B16,21 /C16,21 FC

EH0352 4 PVDF B31 / C31,36 FC

*12 EH2415 Seat, Valve 4 PCTFE B11 FC

EH2416 4 PCTFE B16,21 / C16,21 FC

EH1722 4 PCTFE B31 / C31,36 FC

*13 EH0025 Ball, Valve 4 CE B 11 FC

EH0084 4 CE B16,21 / C16,21 FC

EH0120 4 CE B31 / C31,36 FC

*14 EH0354 Gasket, Valve 6 PTFE B31 / C31,36 FC

EH0342 6 PTFE B11,16,21 / C16,21 FC

*17 EH0591 Gasket, Valve Housing 2 PTFE B11,16,21 / C16,21 FC

EH0613 2 PTFE B31 / C31,36 FC

19 EH1986 Bolt, Hex Soc. w/washers 4 M4x35 316SS B11,16,21/ C16,21,31 FC

EH1987 4 M4x40 316SS B31 FC

EH1988 4 M5x35 316SS C36 FC

25 E00260 Fitting, 3/8"Tube x 1/4"MPT 2 PVDF B11,16,21 / C16,21 FC

E00261 Fitting, 1/2"Tube x 1/4"MPT 2 PVDF B31 / C31,36 FC

18 ------ Brass Spacers -- Brass

Drive Specic. Reuse

with Dia. change

ALL

* Parts Included in the Spart Parts Kits

22

Page 26

19

21

60

Stainless Steel (SH-N) Liquid End Exploded View For EZ Pump Models 11-36

Item Part# Description Qty Material Size

1 EH2021 Pump Head 1 316SS B 11

3

28

11

13

28

12

28

11

13

28

12

14

18

9

1

20

7

28

11

13

28

12

28

11

13

28

12

14

3

EH2176 1 316SS B16 / C16

EH2022 1 316SS B21 / C21

EH2023 1 316SS B31 / C31

EH2024 1 316SS C36

3 EH0429 Housing, Valve 2 316SS B11,16,21 / C16,21

EH0433 2 316SS B31 / C31,36

*7 EH1971 Diaphragm 1 PTFE+EPDM B11

EH1972 1 PTFE+EPDM B16 / C16

EH1973 1 PTFE+EPDM B21 / C21

EH1974 1 PTFE+EPDM B31 / C31

EH1975 1 PTFE+EPDM C36

*9 EH0059 Retainer 1 PPS+GF B 11

EH0083 1 PPS+GF B16 / C16

EH0067 1 PPS+GF B21 / C21

EH0087 1 PPS+GF B31 / C31

EH0158 1 PPS+GF C36

11 EH0360 Guide, Valve 4 316SS B11

EH1551 4 316SS B16,21 /C16,21

EH1552 4 316SS B31 / C31,36

12 EH1554 Seat, Valve 4 316SS B11

EH1555 4 316SS B16,21 / C16,21

EH1556 4 316SS B31 / C31,36

13 EH0049 Ball, Valve 4 HC B11

EH0072 4 HC B16,21 / C16,21

EH0126 4 HC B31 / C31,36

*14 EH0362 Gasket, Valve Housing 2 PTFE B11,16,21 / C16,21

EH0380 2 PTFE B31 / C31,36

19 EH2089 Bolt, Hex Socket 4 M4×45 B11,16,21,31 / C16,21

EH2090 4 M5×45 C-31,36

20 EH1999 Washer, Plate, M4 4 316SS B11,16,21,31 / C16,21

EH2011 Washer, Plate, M5 4 316SS C-31,36

21 EH2000 Washer, Split, M4 4 316SS B11,16,21,31 / C16,21

EH2012 Washer, Split, M5 4 316SS C-31,36

*28 EH0365 Gasket, Valve 8 PTFE B11,16,21 / C16,21

EH0382 8 PTFE B31 / C31,36

18 ------ Brass Spacers -- Brass Drive Specic. Reuse with Dia. change

* Parts Included in the Spart Parts Kits

23

Page 27

Accessories (Not Shown)

Part No. Description Size Liquid End Mtl

CAN-1VC-7 Valve, Injection 3/8 11, 16, 21 VC

CAN-1VE-7 Valve, Injection 3/8 11, 16, 21 VE, VF

CAN-1PA-7 Valve, Injection 3/8 11, 16, 21 PA

CAN-1PC-7 Valve, Injection, 3/8 11, 16, 21 PC

CAN-1PE-7 Valve, Injection, 3/8 11, 16, 21 PE

CAN-2VCL-8 Valve, Injection, 1/2 31, 36 VC

CAN-2VEL-8 Valve, Injection, 1/2 31, 36 VE, VF

CAN-2PAL-8 Valve, Injection, 1/2 31, 36 PA

CAN-2PCL-8 Valve, Injection, 1/2 31, 36 PC

CAN-2PEL-8 Valve, Injection, 1/2 31, 36 PE

E90238 Valve, Injection, 3/8 11, 16, 21 TC

E90020 Valve, Inj/Back Press, 3/8 11, 16, 21 FC, TA

E90022 Valve, Inj/Back Press, 1/2 31, 35 TC, FC, TA

E90013 Valve, Foot, 3/8 11, 16, 21 VC

E90015 Valve, Foot, 3/8 11, 16, 21 PC

E90016 Valve, Foot, 1/2 31, 36 VC

E90018 Valve, Foot, 1/2 31, 36 PC

E90034 Valve, Foot, 3/8 11, 16, 21 PE

E90919 Valve, Foot, 3/8 11, 16, 21 PA

E90954 Valve, Foot, 3/8 11, 16, 21 TA

E90035 Valve, Foot, 3/8 11, 16, 21 VE

E90961 Valve, Foot, 1/2 31, 36 PA

E90036 Valve, Foot, 1/2 31, 36 PE

E90967 Valve, Foot, 1/2 31, 36 TA

E90037 Valve, Foot, 1/2 31, 36 VE

E90193 Valve, Foot, 1/2 31, 36 VF

E90234 Valve, Foot, 3/8 11, 16, 21 VF

E90239 Valve, Foot, 1/2 31, 36 TC

E90240 Valve, Foot, 3/8 11, 16, 21 TC

E90241 Valve, Foot, 3/8 11, 16, 21 FC

E90275 Valve, Foot, 1/2 31, 36 FC

E00001 Tubing,1/2 OD LLDPE, 20 FT 31, 36 all

E00001-50 Tubing,1/2 OD LLDPE, 50 FT 31, 36 all

E00001-100 Tubing,1/2 OD LLDPE, 100 FT 31, 36 all

E00001-500 Tubing,1/2 OD LLDPE, 500 FT 31, 36 all

E00002 Tubing, 3/8 OD LLDPE, 20 FT 11, 16, 21 all

E00002-50 Tubing, 3/8 OD LLDPE, 50 FT 11, 16, 21 all

E00002-100 Tubing, 3/8 OD LLDPE, 100 FT 11, 16, 21 all

E00002-500 Tubing, 3/8 OD LLDPE, 500 FT 11, 16, 21 all

E00074-20 Tubing, 1/2 OD LLDPE, UV Resistant, 20 FT 31, 36 all

E00074-50 Tubing, 1/2 OD LLDPE, UV Resistant, 50 FT 31, 36 all

E00074-100 Tubing, 1/2 OD LLDPE, UV Resistant, 100 FT 31, 36 all

E00074-500 Tubing, 1/2 OD LLDPE, UV Resistant, 500 FT 31, 36 all

E00075-20 Tubing, 3/8 OD LLDPE, UV Resistant, 20 FT 11, 16, 21 all

E00075-50 Tubing, 3/8 OD LLDPE, UV Resistant, 50 FT 11, 16, 21 all

E00075-100 Tubing, 3/8 OD LLDPE, UV Resistant, 100 FT 11, 16, 21 all

E00075-500 Tubing, 3/8 OD LLDPE, UV Resistant, 500 FT 11, 16, 21 all

E00071 Weight, Ceramic all all

24

Page 28

B: D-CONTROL MODULE

55

56

38

44

48

Drive and Control Module

Exploded View

35

41

39

44

58

47

T-CONTROL MODULE

55

56

38

41

40

39

36

58

47

57

B D-Control Module

T-Control Module

A Drive Unit

59

Part numbers for these assemblies are on Page 26

53

A: DRIVE UNIT

Item Part No. Description Series

35 E00152 Cover, Keypad EZ-D

E00153 Membrane Keypad EZ-D

36 EH1036 Gasket, Terminal Box EZ-T

38 EH0261 Gasket, M3 x 35 Bolt EZ-D, EZ-T

39 EH0202 Grommet, Cord EZ-D, EZ-T

40 EH0204 Cap, Strain Relief EZ-D, EZ-T

41 EH0205 Nut, Strain Relief EZ-D, EZ-T

47 EH0269 Screw, Control Module EZ-D, EZ-T

48 EH0547 Gasket, Terminal Block EZ-D, EZ-T

53 1110027300 Base, EZ-C, Blue EZC

1120357900 Base, EZ-B, Blue EZB

55 EH0289 Plug, Control Module EZ-D, EZ-T

56 EH0241 Screw, M3 x 35 SS PH EZ-D, EZ-T

57 EH0549 Plug, Bolt EZ-D, EZ-T

58 EH1438 Screw, Self Tap, D-module EZ-D, EZ-T

59 EH1690 Spacer, Bracket, EZ-11 EZ-D, EZ-T

EH1431 Spacer, Bracket, EZ-16 EZ-D, EZ-T

EH1700 Spacer, Bracket, EZ-21 EZ-D, EZ-T

EH1702 Spacer, Bracket, EZ-31 EZ-D, EZ-T

EH1714 Spacer, Bracket, EZ-16 EZ-D

25

Page 29

Control

Module

B

Drive Unit

A

EZB, EZC

Head Assembly

C

D

Valve Cartridge

(not shown in this view)

Key letters:

A Drive Unit

B Control Module

C Head Assembly

D Valve Cartridge

26

Page 30

C

Head Assembly* (Spare Parts Kits)

A

Pump Model

EZB11D1- ZB11-D1 EZBD1

EZB11D2- N/A N/A

EZB16D1- ZB16-D1 EZBD1

EZB16D2- N/A N/A

EZB21D1- ZB21-D1 EZBD1

EZB21D2- N/A N/A

EZB31D1- ZB31-D1 EZBD1

EZB31D2- N/A N/A

EZC16D1- ZC16-D1 EZCD1

EZC16D2- ZC16-D2 EZCD2

EZC21D1- ZC21-D1 EZCD1

EZC21D2- ZC21-D2 EZCD2

EZC31D1- ZC31-D1 EZCD1

EZC31D2- ZC31-D2 EZCD2

EZC36D1- ZC36-D1 EZCD1

EZC36D2- ZC36-D2 EZCD2

D

Valve

Cartridge

Drive

Unit

Control

Module

11 E90041 E90042 E91232 E90038 E90039 E90302 E90305 E90044

16, 21 E90048 E90049 E91231 E90045 E90046 E90303 E90306 E90051

31, 36 E90055 E90056 --- E90052 E90053 E90304 --- ---

B

PC PE PA VC VE VF TC TA FC

NZB11

(N11-PK)

NZB16

(N16-PK)

NZB21

(N21-PK)

NZB31

(N31-PK)

N16

(N16-PK)

N21

(N21-PK)

N31

(N31-PK)

N36

(N36-PK)

PC PE PA VC VE VF TC FC

E

Automatic Air

Vent Valve

F

Multi-

Function Valve

Assembly

11, 16, 21 --- --- ---

11, 16, 21 MFV-HTC-7 (B11/16, C16/21) / MFV-MTC-7 (B21)

31, 36 MFV-MTC-8 (C31) / MFV-LTC-8 (B31/C36)

ADV-V-7

Notes: * The P/N in the block is the head assembly part number and the spare parts kit is shown underneath in parentheses. For head assemblies with a Multifunction Valve, add an “M” to the end of the part number.

Parts kits for pumps with Multifunction valves are the same as pumps without the “M” option. (Parts kits for MFVs

available separately)

For pump models using a “T” Control Module, change the ‘D” in the model number or part number to a “T” to create

the correct Control Module part number.

For head assemblies or parts kits with the Auto Degassing Valve, add “A” after the “VC” or "VE" code in the number.

--- --- ---

27

Page 31

6.0 TROUBLESHOOTING

CAUTION: Before working on the pump, disconnect the power cord, depressurize the discharge

tubing and drain or ush any residual liquid from the pump head and valves, using proper chemical handling

techniques.

Problem Possible Cause Corrective Action

Pump does not start Faulty wiring Correct wiring

Improper voltage Connect to proper voltage source

Electronic control unit is damaged Replace control unit (Contact distributor or

factory)

Pump does not prime Air in suction tubing Reroute suction tubing to eliminate air trap

Valve gasket is not installed Install valve gasket

Valve set assembly direction is wrong. Reassemble valve set

Pump is air locked Open air vent valve

Suction or discharge valve is clogged

with foreign matter

Ball stuck to valve seat Disassemble, inspect, clean

Disassemble, inspect, clean

Output uctuates Suction or discharge valve is clogged

with foreign matter

Air is trapped in pump Open air vent valve

Overfeeding Install injection valve or back pressure valve

Diaphragm is damaged Replace diaphragm

Liquid leaks Fitting or coupling nut is loose Re-install (see section 2.3/2.4)

Pump head is loose Tighten pump head bolts

Diaphragm is damaged Replace diaphragm

O-ring or valve gasket missing Install o-ring or valve gasket

Disassemble, inspect, clean

Torque: 19 lb-in (2.16 N-m)

7.0 SERVICE POLICY

The EZ Series electronic metering pumps have a 2-year warranty. Contact your Walchem distributor for service.

28

Loading...

Loading...