Page 1

Metering Pumps

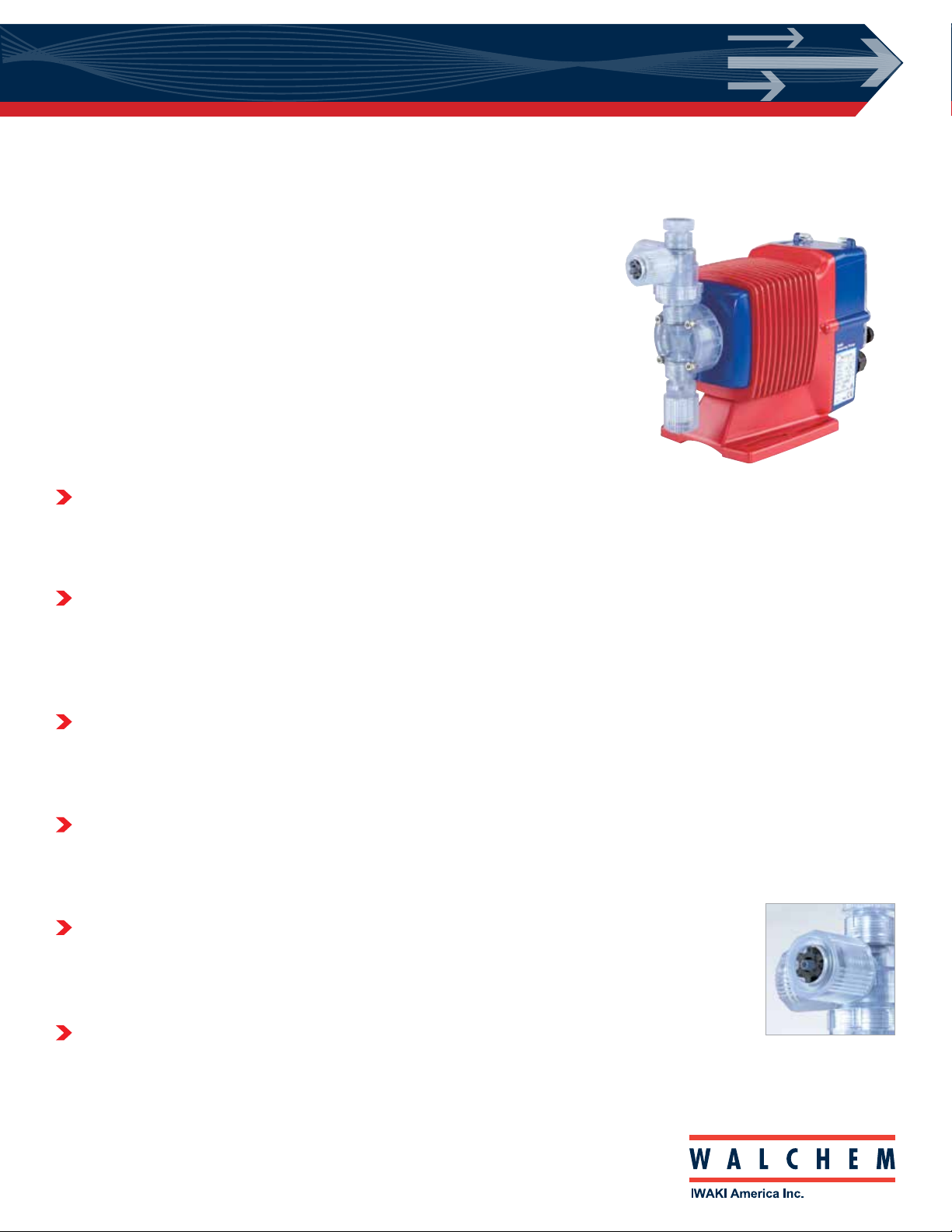

EWN-R Series Electromagnetic Metering Pumps

The EWN-R Series electronic metering pumps offer superior high speed

dosing capability with more standard features. The flexibility of the EWN-R

pump enable it be integrated into virtually any chemical feed application using

a universal-voltage, digital controller with an expanded set of control features.

Superb valve performance and advanced solenoid engineering combine to

make a highly precise pump for the most demanding applications.

EWN pumps have outputs to 6.7 GPH (25.2 L/h) and a maximum pressure

of 290 PSI (20 bar). The high speed of operation results in high resolution

chemical feed and long service life. Quiet and compact, the EWN pumps

prime in seconds and hold prime reliably.

High Speed Performance

E-Series pumps operate up to 360 strokes-per-minute with adjustments in 1 spm increments, providing high resolution

chemical feed. Adjustable stroke length further increases the ability to refine the output, making the E-Series one of the

most versatile solenoid metering pumps on the market.

Multi-function Digital Controller

The controller in the EWN-R pump provides for flexible pump control including scalable Analog control, Digital Input

with both Multiply and Divide capability, external stop control, or simple speed and stroke length control. Display

can be adjusted between flow rate units or % speed for easy-to-read output and quick adjustment. The controller is

universal voltage so it can be used anywhere in the world.

Engineered Longevity

All E-Series pumps feature dual bearing support. The armature and shaft are supported with a bearing on each

end, which ensures proper axial movement, enabling the E-Series to operate at 360 SPM while extending the life of

the diaphragm.

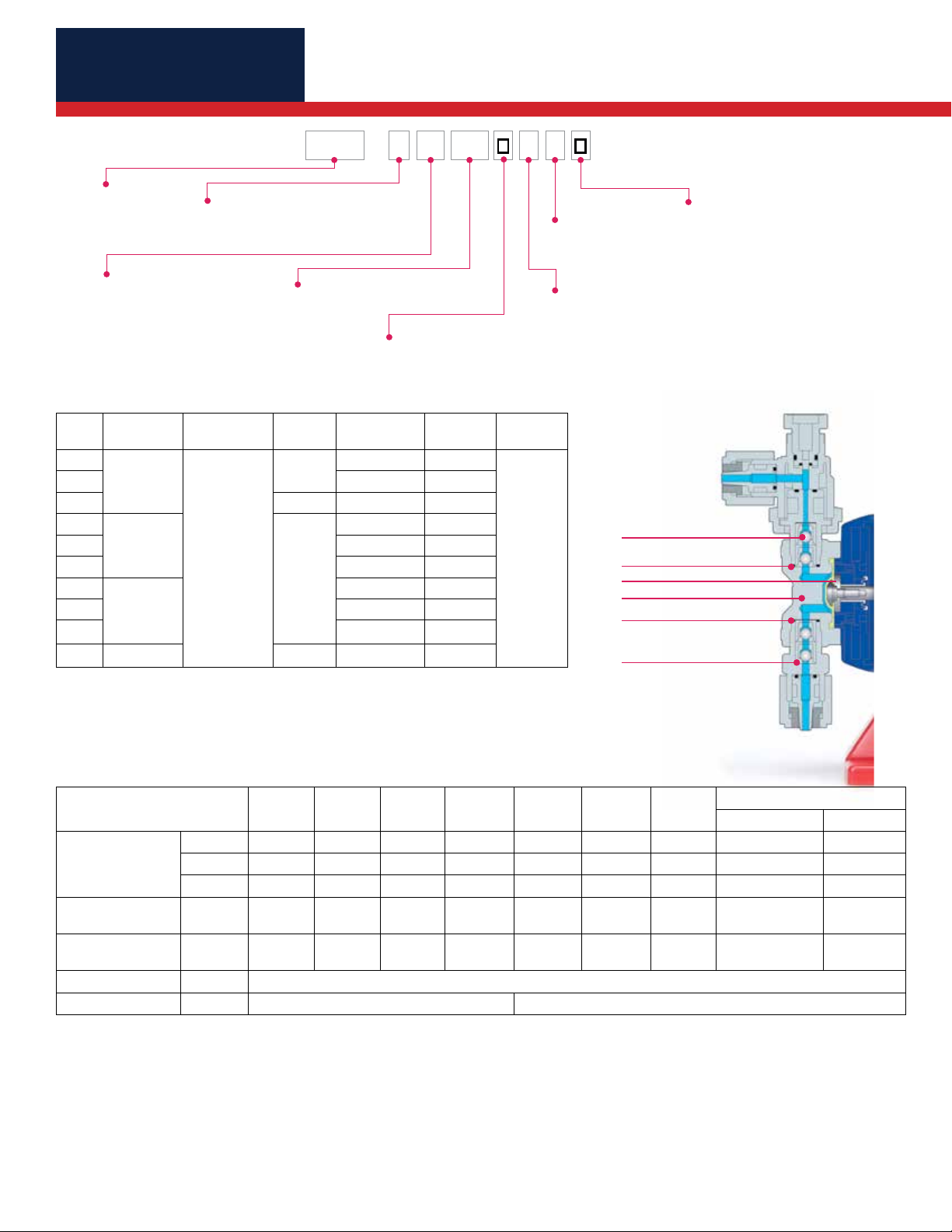

Superior Check Valve Performance

Dual Check Valve Assemblies in both suction and discharge fittings feature precision ball guides and tapered

seats. Precise machining and molding of parts limit valve ball travel, ensuring that balls fully seat and seal with

every stroke. This superior check valve design guarantees fast priming and reliable performance.

Flexible Connections

A removable tubing insert provides flexibility of tubing sizes and eliminates twisting of the

tubing during connection. A threaded insert can be used in place of the tubing adapter to

easily convert any connection to NPT.

High Compression Ratio

The compression ratio of a metering pump is important because it affects the pump’s ability to prime and vent.

The compression ratio is raised when you reduce the dead volume of the pump head during operation. All

E-Series pumps feature a very high compression ratio that ensures proper feed especially with off-gassing

products (i.e. Sodium Hypochlorite).

Page 2

Specifications

(10.5)

Model Identication

Series symbol

EWN-R series

Diaphragm diameter

Eective diaphragm dia.

09: 8mm 11: 10mm 16: 15mm

21: 20mm 31: 30mm 36: 35mm

Drive unit symbol

Average power consumption

B: 20W C: 24W

EWN - B 11 VC U R

Wet-end material symbol

For details, see the table of materials.

Tubing Connection

Blank: 1/4” x 3/8” (B09, B11, B16, B21, C16, C21)

3/8” x 1/2” (B31, C31, C36)

1/4” FNPT (SH/FC, FC also supplied with tubing ttings)

(For other options, contact your distributor)

Wet End Materials

Pump Head Diaphragm

VC

VE EPDM EPDM

VF PTFE EPDM EPDM

PC

PE EPDM EPDM

PA PCTFE AFLAS®

FC

TC FKM FKM

TA

SH 316SS

CE Alumina ceramic EPDM Ethylene propylene diene monomer

FKM Fluoroe lastomer GFRP P Glass fiber reinforced polypropylene

PTFE Polytetrafluoroethylene PVC Polyvinylchloride (translucent)

PCTFE Polychlorotrifluoroethylene HC Hastelloy C276

PVDF Polyvinylidenefluoride 316SS 316 Stainless Steel

PVC

GFRPP

PTFE +EPDM

PVDF

Valve

Balls

CE

CE

HC 316SS PTFE

Valve Seat

FKM FKM

FKM FKM

PCTFE PTFE

PCTFE AFLAS®

O-ring

Seal

Gasket

PTFE

Controller

function code

R: Standard type

Power code

U: 115V US plug

2: 230V US plug

Valve

O-ring

Diaphragm

Pump head

Gasket

Valve seat

Options

C: High compression version + ADV

(available on 09-21-VC/VE)

H: High pressure version (250 PSI)

(available on B11/C16-PC/PE/PA/SH)

H2: High pressure version (290 PSI)

(available on B11-PC/PE/PA/SH)

V: High Viscosity version

(available on C31-PC/P6)

A: Auto Degassing valve included

(available on 11-21-VC/VE)

M: Multifunction valve included

(available on all models except FC/SH

or with other options)

N: No Manual Air Vent Valve (SH only)

Pump Specications (Standard pumps and pumps with MFV)

Model B11 B16 B21 B31 C16 C21 C31

Maximum output

capacity

Maximum rated

discharge pressure

Maximum useable

pressure

Stroke rate % (spm)

Stroke length rate % (mm)

Note 1: Maximum output capacity shown is at Maximum Rated Discharge Pressure (stroke length 100%, stroke rate 100%) and increases as a discharge pressure reduces.

Note 2: Maximum Useable pressure rating is the maximum useable capability of the pump. Maximum output capacities may be lower than published at pressures

higher than Maximum Rated Discharge Pressure. Maximum pressure of PVC type is 174 PSI. Please contact your distributor for more information.

Note 3: The performance is based on pumping clean water at ambient temperature at rated discharge pressure and voltage.

Note 4: Liquid temperature: PVC liquid ends: 14 to 104°F (-10 to 40ºC) GRFPP/PVDF/SS liquid ends: 14 to 140°F (-10 to 60ºC)

Note 5: Ambient temperature: 32 to 122°F (0 to 50°C) Relative humidity: to 85% (non-condensing)

Note 6: All pumps include a manual air vent valve except FC/SHN/HV models. All pumps include one foot valve, injection valve, 20 ft. of PE tubing and ceramic

weight except for SH/H2/HV models.

Input/Output Connectors (Sold Separately):

E90495 5-pin connector: Use for Analog, Pulse & AUX inputs + Output Relay on EWN-R

E90496 5-pin reverse key connector: Use for Stop & Pre-Stop inputs on EWN-R

GPH

mL/min

mL/shot

PSI

PSI

0.6 1.0 1.6 3.2 1.3 2.1 4.3 6.7 6.5

38 65 100 200 80 130 270 420 410

0.02-0.11 0.04-0.18 0.06-0.28 0.11-0.56 0.04-0.22 0.07-0.36 0.15-0.75 0.23-1.17 0.23-1.14

150 105 60 30 150 105 50 30 30

203 116 73 30 174 116 50 30 30

0.1 to 100 (1 to 360)

20 to 100 (0.2 to 1.0) 20 to 100 (0.25 to 1.25)

VC/VE/PC/PE FC/SH/TC

C36

Page 3

Specifications

(10.5)

Controller Specications

MAN 0.1 to 100% stroke rate

Operational

mode

Display

Keypad 5 keys

Control

function

Input

Output

Note 1: If the max. stroke rate by calculation exceeds 100% stroke rate because of the relation between the setting and input signal when the pump is in EXT operation,

the operation is xed at Maximum stroke rate speed of manual operation.

Note 2: By changing the setting, the pump can run when the contact signal comes in. Note 3: The max. frequency of input pulse is 200 Hz. ON time of input pulse is

10 to 100 mS.

Note 4: The max. potential voltage at a contact is 12V and current is 0.1mA. If a contact such as relay is used, the minimum application load should be 0.1mA or less.

EXT control

LCD 14 segment 5 digits %, ml/m, L/H, GPH, STOP, PRIME, AUX etc

LED

STOP/Pre-STOP

Prime

Key lock Keypad can be locked and unlocked.

Calibration

Buffer memory

Pulse No voltage contact or open collector. Max 200 Hz. NO/NC selectable

Current DC0 - 20mA (Input resistance 200 Ω)

Stop/Pre-stop No Voltage contact or open collector

AUX Pump runs at max.stroke rate when made. No Voltage contact or open collector

Photo-MOS relay AC/DC24V 0.1A

STOP, Synchronous with stroke

DIV (Dividing) /1 to 9999

MULT (Multiply) x1 to 9999

ANA. R (Analog, rigid) 4 to 20, 0 to 20, 20 to 4, 20 to 0 mA

ANA. V (Analog, variable) 2 points 0.0 to 20.0 mA range 0.0 to 100% stroke rate

ON Green Green lights when ON blinks OFF synchronous with stroke.

STOP Orange/Red Orange lights when Pre-STOP is made, red when STOP is made.

START/STOP, EXT,

Pump keeps running when Pre-STOP is made. Pump stops when STOP is made.

Pump runs at max. stroke rate while up and down keys are pressed.

Discharge capacity per shot is calculated automatically by operating and stopping pump in the

calibration mode to determine the flow rate.

ON or OFF selectable. Max. 65535 stroke pulses are stored in memory.

(UP), (DOWN), Disp

Safety Certifications

The EWN series metering

pumps* are WQA tested and

certified to NSF/ANSI Standard

50 and Standard 61.

* See www.wqa.org for specific chemicals and

certification parameters.

The EWN series metering pumps

are tested by Intertek to UL and

CSA standards.

Electrical Specifications

EWN EWN-B EWN-C

50/60 Hz, 1 phase 20 Watt avg. 24 Watt avg.

100-240VAC ±10% 0.8 Amp max. 1.2 Amp max.

Shipping weight

EWN-B: 10 lbs (4.5 kg)

EWN-C: 12 lbs (5.5 kg)

*SH liquid ends increase weight up to 50%

Dimensions (in inches)

(10.5)

(2.7)

RS

(2.7)

L(3)

4.9

T

L(3)

4.9

d

c

Bottom View

X

Y

d

c

.39

ZZ

1/4”

FNPT

.39

PC/PE/PA/VC/VE/

VF/TC/TA Models

3.9

a

℄

U

V

Y

SH Models

3.9

a

Material Model H L a b c d

PC/PE/PA

VC/VE/VF

H

b

TC/TA

SH

EWN-11,16, 21 7.83 10.43 0.94 6.45 0.90 1.85

EWN-31 8.34 10.51 0.23 6.97 0.98 1.89

EWN-36 8.30 10.51 0.27 6.93 0.94 1.89

EWN-11,16, 21 7.91 9.13 1.73 6.10 0.86 0.59

EWN-31 8.38 9.17 1.34 6.49 0.90 0.59

EWN-36 8.50 9.17 1.26 6.69 0.90 0.59

EWN-11,16, 21 6.53 9.09 1.57 6.31 0.90 0.51

FC

EWN-31 6.97 9.29 0.90 6.97 0.98 0.63

EWN-36 6.97 9.25 0.90 6.97 0.94 0.63

Mounting Dimensions

EW Model R S T U V X Y Z

11,16, 21

31, 36

H

b

4.57 3.94 0.24 3.15 4.17 1.57 0.59 0.79

(3)

L

d

FC Models

(10.5)

(2.7)

4.9

1/4”

FNPT

.39

c

H

b

3.9

a

Page 4

Options

Valve

O-Ring

Diaphragm

Pump Head

Gasket

Valve Seat

Wet-end material

Auto Degassing Valve Model

Chemicals that outgas, such as Sodium

Hypochlorite or Hydrogen Peroxide,

can generate enough gas to gas lock

metering pumps. Using a dual check

valve system, the Auto Degassing

Valve vents any gas to atmosphere to

eliminate gas lock conditions and keep

the pump primed.

Valve

O-ring

Diaphragm

Pump head

Gasket

Valve seat

High Compression Model

Increasing the compression ratio by

minimizing dead volume in the liquid

end combined with the auto degassing

valve further helps to eliminate gas in

the pump heads. In addition to

reducing air lock conditions, the

increased compression ratio helps with

accuracy at low output ranges.

High Pressure Model

The high pressure models are capable

of operating at flow rates up to 0.6GPH

(40mL/min) at a maximum discharge

pressure up to 290PSI. This makes it

suitable for applications such as

chemical injection into boiler makeup

wate r.

High Viscosity Model

The High Viscosity pump has a uniquely

designed liquid end with oversized flow

paths and spring loaded valve checks.

Coupled with a reduced max speed,

the HV pumps are designed for

polymer/coagulant injection in water

treatment applications.

Valve

O-Ring

Diaphragm

Pump Head

Gasket

Spring

Valve Seat

Wet-end material

Material code

Pump head

Valve

Valve seat

Gasket

O-ring

Diaphragm

Specifications (Special versions)

Max. Output Capacity

Rated Discharge Pressure

Stroke Rate

Stroke Length Range

Max. Output Capacity

Rated Discharge Pressure

Stroke Rate

Stroke Length Range

Note 1: Max. output capacity shown is at Rated Discharge Pressure (stroke length 100%, stroke rate 100%) and increases as a discharge pressure reduces.

Note 2: The performance is based on pumping clean water at ambient temperature at rated voltage.

Walchem, Iwaki America Inc. Five Boynton Road Hopping Brook Park Holliston, MA 01746 USA

Phone: 508-429-1110 www.walchem.com

VC-A VE-A

PVC

CE

FKM EPDM

PTFE

FKM EPDM

PTFE+EPDM

Model C21B09 B11 B16 C16B21

mL/min

mL/shot 0.09 - 0.43

% (mm)

Model

GPH

Wet-end material

0.5

30

0.02 - 0.08

PSI

150

GPH

mL/min

mL/shot

PSI

% (mm)

Material code

Pump head

Valve

Valve seat

Gasket

O-ring

Diaphragm

VC-C VE-C

PVC

CE

FKM EPDM

PTFE

FKM EPDM

PTFE+EPDM

Auto Degassing Valve

0.9

55

0.03 - 0.15

105

20 - 100 (0.2 - 1.0) 20 - 100 (0.25 - 1.25)

1.4

86

0.05 - 0.24

60

0.1 - 100 (1-360)

1.0

65

0.04 - 0.18

150

High Pressure Models High Pressure Models (290 psi) High Viscosity Models

B11

0.4

25

0.02 - 0.1

250

0.1 - 100 (1-240)% (spm)

20 - 100 (0.2 - 1.0)

C16

0.6

40

0.03 - 0.17

250

20 - 100 (0.25 - 1.25)

Material code

Pump head

Valve

Valve seat

Gasket

O-ring

Diaphragm

C21B11 B16 C16B21

1.7

110

0.06 - 0.31

105

0.2

12

0.01 - 0.07

150

0.1 - 100 (1-240)

70 - 100 (0.5 - 0.9)

Wet-end material

PC-H

GFRPP

CE

FKM

FKM

PTFE+EPDM

PE-H

EPDM

PTFE

EPDM

SH-H

SUS316

HC

SUS316

—

High Compression Models (ADV included)

0.4

23

0.03 - 0.13

150

20 - 100 (0.25 - 1.25) 20 - 100 (0.3 - 1.50)

B11

0.3

17

0.05 - 0.07

290

0.6

40

0.04 - 0.22

105

0.1 - 100 (1-180)% (spm)

Material code

Pump head

Valve

Valve seat

Spring Hastelloy C276

Gasket

O-ring

Diaphragm

1.0

63

0.07 - 0.35

60

0.9

54

0.06 - 0.30

150

C31

2.4

150

0.13 - 0.63

73

0.1 - 100 (1-240)

20 - 100 (0.25 - 1.25)

180623.I Jan 2017

PC-V

CE

FKM

PTFE+EPDM

1.2

78

105

GFRPP

PCTFE

PTFE

P6-V

316 SS

316 SS

EPDM

Loading...

Loading...