Page 1

VM 500

II 3 G

B_03416

VM 500

Electrostatic Control Unit

for Electrostatic Manual Spray Guns

Version 08/2014

Translation of the Original

Operating Manual

Page 2

Page 3

3

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

Table of Contents

1 ABOUT THESE INSTRUCTIONS 5

1.1 Preface 5

1.2 Warnings, Notices and Symbols in these Instructions 5

1.3 Languages 6

1.4 Abbreviations 6

1.5 Terminology for the Purpose of this Manual 7

2 CORRECT USE 8

2.1 Device Type 8

2.2 Type of Use 8

2.3 Use in an Explosion Hazard Area 9

2.4 Safety Parameters 9

2.5 Reasonably Foreseeable Misuse 10

2.6 Residual Risks 10

3 IDENTIFICATION 11

3.1 CE Explosion Protection Identi cation 11

3.2 Identi cation "X" 12

3.3 Type Plate 13

4 GENERAL SAFETY INSTRUCTIONS 14

4.1 Safety Instructions for the Operator 14

4.1.1 Electrical Equipment 14

4.1.2 Personnel Quali cations 14

4.1.3 Safe Work Environment 14

4.2 Safety Instructions for Sta 15

4.2.1 Safe Handling of WAGNER Spray Devices 15

4.2.2 Grounding the Device 16

4.2.3 Material Hoses 16

4.2.4 Cleaning and Flushing 17

4.2.5 Handling Hazardous Liquids, Varnishes and Paints 17

4.2.6 Touching Hot Surfaces 18

4.3 Protective and Monitoring Equipment 18

4.4 Use in Areas Subject to Explosion Hazards 18

4.4.1 Safety Regulations 18

5 DESCRIPTION 19

5.1 Design 19

5.2 Mode of Operation 19

5.3 Scope of Delivery 19

5.4 Technical Data 20

5.5 Operating Elements and Connections 21

5.5.1 Operating Elements Front Side 21

5.5.2 Connections on the Rear Side 22

Page 4

4

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

Table of Contents

6 ASSEMBLY AND COMMISSIONING 23

6.1 Training Assembly/Commissioning Sta 23

6.2 Storage Conditions 23

6.3 Installation Conditions 23

6.4 Additional Components 24

6.5 Location of the Control Unit 25

6.6 Grounding 26

6.7 Example, AirCoat Spraying System 28

6.8 Verifying a Safe Operational Condition 29

7 OPERATION 30

7.1 Training the Operating Sta 30

7.2 Safety Instructions 30

7.2.1 Emergency Deactivation 31

7.3 Starting Up and Spraying 31

7.4 Standby Mode 32

8 CLEANING AND MAINTENANCE 33

8.1 Cleaning 33

8.1.1 Cleaning Sta 33

8.1.2 Safety Instructions 33

8.2 Maintenance 35

8.2.1 Maintenance Sta 35

8.2.2 Safety Instructions 35

8.2.3 Safety Checks 36

9 TROUBLE SHOOTING AND RECTIFICATION 37

10 REPAIR WORK 38

10.1 Repair Sta 38

10.2 Safety Instructions 38

10.3 Check the Control Unit for Leak-Tightness 38

11 DISPOSAL 39

12 ACCESSORIES 40

13 SPARE PARTS 41

13.1 How Can Spare Parts Be Ordered? 41

13.2 Control Unit VM 500 42

14 WARRANTY AND CONFORMITY DECLARATIONS 44

14.1 Important Notes Regarding Product Liability 44

14.2 Warranty Claim 44

14.3 CE Declaration of Conformity 45

14.4 Notes on National Regulations and Guidelines 46

Page 5

5

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

1 ABOUT THESE INSTRUCTIONS

1.2 WARNINGS, NOTICES AND SYMBOLS IN THESE INSTRUCTIONS

Warning instructions in this operating manual highlight particular dangers to users and to

the device and state measures for avoiding the hazard. These warning instructions fall into

the following categories:

Danger - immediate risk of danger.

Non-observance will result in death or serious injury.

Warning - possible imminent danger.

Non-observance may result in death or serious injury.

Caution - a possibly hazardous situation.

Non-observance may result in minor injury.

Notice - a possibly hazardous situation.

Non-observance may result in damage to property.

Note - provides information about particular characteristics and how to proceed.

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions.

The signal word indicates the hazard level.

The measures for preventing the danger and its

consequences.

DANGER

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions.

The signal word indicates the hazard level.

The measures for preventing the danger and its

consequences.

WARNING

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions.

The signal word indicates the hazard level.

The measures for preventing the danger and its

consequences.

CAUTION

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions. The signal word

indicates the hazard level.

The measures for preventing the danger and its consequences.

NOTICE

1.1 PREFACE

The operating manual contains information about safely operating, maintaining, cleaning

and repairing the device.

The operating manual is part of the device and must be available to operating and service

sta .

The device may only be operated by trained sta and in compliance with this operating

manual. Operating and service personnel should be instructed according to the safety

instructions.

This equipment can be dangerous if it is not operated according to the instructions in this

operating manual.

Page 6

6

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

1.3 LANGUAGES

1.4 ABBREVIATIONS

Number of pieces

Position

Marking in the spare parts lists

Order No. Order number

Spare part

Stainless steel

Two components

The VM 500 operating manual is available in the following languages:

Language Order No. Language Order No.

German 2310485 English 2318724

French 2318725 Italian 2318726

Spanish 2318728

Additional languages on request or at:

Page 7

7

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

1.5 TERMINOLOGY FOR THE PURPOSE OF THIS MANUAL

Cleaning Manual cleaning of devices and device parts with cleaning

agent

Flushing Internal ushing of ink-guiding parts with ushing agent

Sta quali cations

Trained person Is instructed in the tasks assigned to him/her, the potential

risks associated with improper behavior as well as the

necessary protective devices and measures.

Electrically trained

person

Is instructed by an electrician about the tasks assigned to him/

her, the potential risks associated with improper behavior as

well as the necessary protective devices and measures.

Electrician Can assess the work assigned to him/her and detect possible

hazards based on his/her technical training, knowledge and

experience in relevant provisions.

Skilled person A person who, based on his/her technical training, experience

and recent vocational experience, has su cient technical

knowledge in the area of electrostatic coating and is familiar

with the relevant and generally accepted rules of technology

so that he/she can inspect and assess the status of devices and

coating systems based on workplace safety.

in the context of BGI 764

Additional requirements for skilled persons can also be

referred to in TRBS1203(2010): Expert knowledge in the areas

of protection against excessive pressure, electrical hazards,

and explosion protection (where applicable).

Page 8

8

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

2.1 DEVICE TYPE

2 CORRECT USE

Control Unit for controlling GM 5000EA or GM 5000EAC electrostatic spray guns.

WAGNER's electrostatic control unit VM 500 controls and regulates the high-voltage supply

to the GM 5000EA or GM 5000 EAC spray guns used to apply liquid coating media.

The VM 500 may only be operated together with the above-mentioned manual spray

guns. If the control unit is operated in combination with devices other than the abovementioned spray guns, the SIRA authorization (type approval) ceases to be valid.

These electrostatic manual spray guns are suitable for spraying liquid products, in particular

coating products that follow AirCoat or Airspray techniques. Coating products containing

solvents of explosion class II A may be used.

WAGNER forbids any other use!

2.2 TYPE OF USE

Incorrect use!

Risk of injury and damage to the device.

Only connect original WAGNER GM 5000EA/GM 5000EAC spray

guns to the VM 500 control unit.

WARNING

Page 9

9

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

2.4 SAFETY PARAMETERS

WAGNER accepts no liability for any damage arising from incorrect use.

Use the device only to work with the products recommended by WAGNER.

Only operate the device as a whole.

Do not deactivate safety xtures.

Use only WAGNER original spare parts and accessories.

The device may only be operated under the following conditions:

The operating sta must be trained on the basis of this operating manual.

The safety regulations listed in this operating manual must be observed.

The operating, maintenance and repair information in this operating manual must be

observed.

The statutory requirements and accident prevention regulation standards in the

country of use must be observed.

The control unit may only be operated if all parameters are set and all measurements/

safety checks have been carried out correctly.

2.3 USE IN AN EXPLOSION HAZARD AREA

The control unit is designed together with the spray gun in accordance with the

94/9/EC (ATEX) directive. The spray gun is suitable for use in potentially explosive areas in

zone 1 and the control unit in the zone 2 area.

(See Chapter 3 "Explosion Protection Identi cation".)

The "Restricted breathing" type of explosion protection is only guaranteed if all sealed

elements in the control unit are present and undamaged. During operation, all electric

connections of the control unit have to be tightly sealed with the corresponding plug

connectors or closing elements.

Page 10

10

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

2.5 REASONABLY FORESEEABLE MISUSE

2.6 RESIDUAL RISKS

Residual risks are risks which cannot be ruled out even in the event of correct use.

If necessary, warning and prohibition signs at the relevant points of risk indicate residual

risks.

Residual risk Source Consequences Speci c measures Lifecycle phase

Skin contact with

lacquers and

cleaning agents

Handling of

lacquers and

cleaning agents

Skin irritations, Wear protective

clothing,

operation,

allergies observe safety data

sheets

maintenance,

disassembly

Lacquer in air

outside the de ned

working area

Lacquering outside

the de ned working

area

Inhalation of

substances

hazardous to health

Observe work and

operation instructions

operation,

maintenance

The forms of misuse listed below may result in physical injury or property damage:

use with non-authorized spray guns;

coating work pieces which are not grounded;

performing unauthorized conversions or modi cations to the device;

using defective components, spare parts or accessories other than those described

in the "Accessories" chapter of this operating manual;

working with incorrect settings.

Page 11

11

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

3 IDENTIFICATION

3.1 CE EXPLOSION PROTECTION IDENTIFICATION

The control unit is designed together with the spray gun in accordance with the

94/9/EC (ATEX) directive. The spray gun is suitable for use in potentially explosive areas in

zone 1 and the control unit in the zone 2 area.

VM 500 control unit

European Communities

Noti ed body: PTB

Explosion-proof equipment

Device class II (not mining)

E ective in zone

E ective in zone 1

Ex-atmosphere gas

Number of type examination certi cate

European Communities

Explosion-proof equipment

Device class II (not mining)

Category 3 device (suitable for zone 2)

Ex-atmosphere gas

Electrical device corresponds to ignition protection type

Ignition protection type "Restricted breathing"

Device class (Gas) IIA

Temperature class T4

Device protection level Gc

Page 12

12

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

3.2 IDENTIFICATION "X"

Notice

The EC Type Examination Certi cate from SIRA can be found in the operating manual for

the spray gun. This certi cate covers the control unit when used in conjunction with the

spray gun.

The manufacturer certi es that the control unit can be used in zone 2.

Cable connections

Only the corresponding cables for the device may be used (see chapter 12 and operating

manual for the spray gun).

Permissible Device Combinations

The following spray guns may be connected to the VM 500 control unit:

- Spray gun GM 5000EA

- Spray gun GM 5000EAC

Page 13

13

VM 500

Typ / Type: VM 5000

115VAC - 230VAC

50Hz / 60Hz

2307317

max. 40W

J. WAGNER AG

Industriestrasse 22

CH - 9450 Altstätten

Made in Switzerland

Serie Nr.:

Serial No.:

Spannung:

Voltage:

Artikel Nr.:

Article No.:

Eingangsleistung:

Input Power:

Schutzklasse:

Protection Class:

Norm:

Standard:

EN 50050

IP 54

Spannung:

Voltage:

Strom:

Current:

max. 20Vpp

max. 1,0A

Eingangsstrom:

Input Current:

max. 0.5A

I

0

Main Switch

Nicht unter Spannung trennen!

Do not disconnect under voltage!

Prim.

1.0 AT

0102

II (2) G

SIRA 11 ATEX 5374X

II 3 G

Ex nR IIA T4 Gc

2309228

1

2

4

5

6

7

8

9

10

11

12

18

13

14

15

16

17

21

19 20

B_04390

3

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

3.3 TYPE PLATE

1 Identi cation for category 3 (zone 2)

2 Identi cation for category 2 (zone 1)

3 Test center

4 Device type

5 Article number

6 Serial number

7 Input voltage

8 Input power

9 Input current

10 Protection class

11 Standard

12 Do not disconnect under voltage!

13 Primary fuse 1.0 ampere slow-acting

14 Mains supply switch

15 Gun connection

16 Maximum voltage

17 Maximum current

18 Grounding

19 Never spray device parts using electrostatic

equipment (electrostatic spray gun!).

20 Use only a damp cloth to clean the unit.

Remove deposits from the surfaces.

21 Do not dispose of used electrical equipment

with household refuse.

Page 14

14

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

4 GENERAL SAFETY INSTRUCTIONS

4.1 SAFETY INSTRUCTIONS FOR THE OPERATOR

4.1.1 ELECTRICAL EQUIPMENT

4.1.2 PERSONNEL QUALIFICATIONS

Keep this operating manual at hand near the device at all times.

Always follow local regulations concerning occupational safety and accident

prevention.

Ensure that the device is operated and repaired only by trained persons.

4.1.3 SAFE WORK ENVIRONMENT

Ensure that the oor in the working area is static dissipative in accordance with

EN61340-4-1 (resistance must not exceed 100 megohms).

Ensure that all persons within the working area wear static dissipative shoes. Footwear

must comply with EN 20344. The measured insulation resistance must not exceed

100megohms.

Ensure that during spraying, persons wear static dissipative gloves. Grounding takes

place via the spray gun handle.

If protective clothing is worn, including gloves, it has to comply with EN 1149-5.

The measured insulation resistance must not exceed 100 megohms.

Paint mist extraction systems/ventilation systems must be tted on site according to

local regulations.

Ensure that the following components of a safe working environment are available:

– Product/air hoses adapted to the working pressure.

– Personal safety equipment (breathing and skin protection).

Electrical devices and equipment

To be provided in accordance with the local safety requirements with regard to the

operating mode and ambient in uences.

May only be maintained by skilled electricians or under their supervision. With open

housings, there is a danger from line voltage.

Must be operated in accordance with the safety regulations and electrotechnical

regulations.

Must be repaired immediately in the event of problems.

Must be decommissioned if they pose a hazard or are damaged.

Must be de-energized before work is commenced on active parts. Inform sta about

planned work. Observe electrical safety regulations.

Connect all devices to a common grounding point.

Only operate the device with a properly installed socket with a protective ground wire

connection.

Keep liquids away from electrical devices.

Page 15

15

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

4.2 SAFETY INSTRUCTIONS FOR STAFF

Always follow the information in this manual, particularly the general safety instructions

and the warning instructions.

Always follow local regulations concerning occupational safety and accident

prevention.

Anyone tted with a pacemaker must not enter the high-voltage area!

4.2.1 SAFE HANDLING OF WAGNER SPRAY DEVICES

The spray jet is under pressure and can cause dangerous injuries.

Avoid injection of paint or ushing agents:

Never point the spray gun at people.

Never reach into the spray jet.

Before all work on the device, in the event of work interruptions and functional faults:

- Switch o the energy/compressed air supply.

- Relieve the pressure from the spray gun and device.

- Secure the spray gun against actuation.

- In the event of functional faults, remedy the fault as described in the "Troubleshooting"

chapter.

If necessary, or at least every 12 months, the liquid ejection devices should be checked

by an expert (e.g. Wagner service technician) to ensure their safe operational condition

in accordance with the guidelines for liquid ejection devices (ZH1/406 and BGR500

Part2 Chapter2.29 and 2.36).

- For shut down devices, the examination can be suspended until the next start-up.

Carry out the work steps as described in the "Pressure Relief" chapter:

- If pressure relief is required.

- If the spraying work is interrupted or stopped.

- Before the device is cleaned on the outside, checked or serviced.

- Before the spray nozzle is installed or cleaned.

In the event of skin injuries caused by paint or ushing agents:

Note the paint or ushing agent that you have been using.

Consult a doctor immediately.

Avoid risk of injury from recoil forces:

Ensure that you have firm footing when operating the spray gun.

Only hold the spray gun brie y in a position.

Ensure that there are no ignition sources such as naked ames, sparks, glowing wires,

or hot surfaces in the vicinity. Do not smoke.

Ensure that the pipe joints, hoses, equipment parts and connections are permanently,

technically leak-proof:

- Periodic preventative maintenance and service (replacing hoses, checking tightness

of connections, etc.).

- Regular monitoring of leaks and defects via visual inspection and odor testing, e.g.,

daily before commissioning, at the end of work or weekly.

In the event of defects, immediately bring the device or system to a stop and arrange

to have repairs carried out immediately.

Page 16

16

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

4.2.3 MATERIAL HOSES

Ensure that the hose material is chemically resistant to the sprayed products and the

ushing agents used.

Ensure that the product hose is suitable for the pressure generated.

Ensure that the following information can be seen on the high pressure hose:

- Manufacturer

- Permissible operating pressure

- Date of manufacture

Make sure that the hoses are laid only in suitable places. Hoses should not be laid in the

following places under any circumstances:

- In high-traffic areas

- At sharp edges

- On moving parts

- On hot surfaces

Ensure that the hoses are never run over by vehicles (e.g. fork lifts), or that the hoses are

never put under pressure from the outside in any other way.

Ensure that the hoses are never kinked. Observe maximum bending radii.

Make sure that the hoses are never used to pull or move the equipment.

Suction hoses may not be subjected to pressure.

Several liquids have a high expansion coe cient. In some cases their volume can rise with

consequent damage to pipes, ttings, etc. and cause uid leakage.

When the pump sucks liquid from a closed tank, ensure that air or a suitable gas can enter

the tank. Thus a negative pressure is avoided. The vacuum could implode the container

(squeeze) and can cause it to break. The container would leak and the liquid would ow

out.

The pressure created by the pump is a multiplication of the inlet air pressure.

4.2.2 GROUNDING THE DEVICE

Friction, owing liquids and air or electrostatic coating processes create charges. Flames or

sparks can form during discharge. Grounding prevents electrostatic charging.

Ensure that the device is grounded. See chapter "Grounding".

Ground the work pieces to be coated.

Ensure that all persons inside the working area are grounded, e.g., that they are wearing

static dissipative shoes.

Wear static dissipative gloves when spraying. The grounding takes place via the spray

gun handle.

The spray substance supply (spray substance tank, pump, etc.) must be grounded.

Page 17

17

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

4.2.4 CLEANING AND FLUSHING

Relieve the pressure from the device.

De-energize the device electrically.

Preference should be given to non- ammable cleaning and ushing agents.

Observe the speci cations of the paint manufacturer.

Ensure that the ash point of the cleaning agent is at least 15 K above the ambient

temperature or that cleaning is undertaken at a cleaning station with technical

ventilation.

Take measures for workplace safety (see Chapter 4.1.3).

When commissioning or emptying the device, please note that an explosive mixture

may temporarily exist inside the lines and components of equipment:

- depending on the coating product used,

- depending on the ushing agent (solvent) used,

explosive mixture inside the lines and items of equipment.

Only electrically conductive tanks may be used for cleaning and ushing agents.

The containers must be grounded.

An explosive gas/air mixture forms in closed containers.

Never spray into a closed tank when using solvents for ushing.

External cleaning

When cleaning the exterior of the device or its parts, also observe the following:

Disconnect the pneumatic supply line.

Use only moistened cloths and brushes. Never use abrasive agents or hard objects and

never spray cleaning agents with a gun. Cleaning the device must not damage it in any

way.

Ensure that no electrical component is cleaned with nor even immersed into solvent.

Which cleaning agent is used to clean the spray gun depends on which parts of the

spray gun have to be cleaned and which product has to be removed. When cleaning the

spray gun, only use non-polar cleaning agents to prevent conductive residues on the

surface of the spray gun. Should it however, be necessary to use a polar cleaning agent,

all residues of this cleaning agent have to be removed by using a non-conductive and

non-polar cleaning agent, once the cleaning is nished.

4.2.5 HANDLING HAZARDOUS LIQUIDS, VARNISHES AND PAINTS

When preparing or working with lacquer and when cleaning the device, follow the

working instructions of the manufacturer of the lacquers, solvents and cleaning agents

being used.

Take the speci ed protective measures, in particular wear safety goggles, protective

clothing and gloves, as well as skin protection cream if necessary.

Use a mask or breathing apparatus if necessary.

For su cient health and environmental safety: Operate the device in a spray booth or

on a spraying wall with the ventilation (extraction) switched on.

Wear suitable protective clothing when working with hot products.

Page 18

18

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

4.2.6 TOUCHING HOT SURFACES

Only touch hot surfaces if you are wearing protective gloves.

When operating the device with a coating product with a temperature of > 43 °C;

109.4°F:

- Identify the device with a warning label "Warning – hot surface".

Order No.

9998910 Instruction label

9998911 Protection label

Note: Order the two stickers together.

4.3 PROTECTIVE AND MONITORING EQUIPMENT

Protective and monitoring equipment must not be removed, modi ed or rendered

unusable.

Regularly check for perfect functioning.

If defects are detected on protective and monitoring equipment, the system must not

be operated until these defects are remedied.

Surface spraying, electrostatics

Never spray device parts using electrostatic equipment (electrostatic spray gun!).

Cleaning

If there are deposits on the surfaces, the device may form electrostatic charges. Flames or

sparks can form during discharge.

Remove deposits from the surfaces to maintain conductivity.

Use only a damp cloth to clean the device.

4.4 USE IN AREAS SUBJECT TO EXPLOSION HAZARDS

The control unit may be used in potentially explosive areas. The following safety regulations

must be observed and followed.

4.4.1 SAFETY REGULATIONS

Observe safety instructions in Chapter 3.2.

Page 19

19

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

5 DESCRIPTION

5.1 DESIGN

The VM 500 control unit supplies the control voltage for the spray gun, in which highvoltage is subsequently produced. The high-voltage supply is switched on and o via the

trigger of the spray gun.

The special linear characteristic for high voltage ensures that if the spray gun is brought too

close to the work piece (or ground), the high voltage is reduced automatically to prevent

an accidental spark discharge.

The VM 500 control unit also o ers a fault display.

5.2 MODE OF OPERATION

Quantity Order No. Designation

1 2310478 VM 500 control unit

The standard equipment includes:

Quantity Order No. Designation

1 241270 Mains cable with Stak200; 3 m; 9.8 ft

1 130215 Grounding cable 10 m; 32.8 ft

2 9951117 Delay-action fuse 1.0 AT

1 2310487 ES 5000 Declaration of Conformity, manual

1 2310485 VM 500 operating manual, German

1 see 1.1 Operating manual in local language

The delivery note shows the exact scope of delivery.

5.3 SCOPE OF DELIVERY

The VM 500 control unit, together with the matching GM5000EA or GM5000EAC spray

gun and other components, form an electrostatic manual spray system. An example of this

kind of spraying system can be found in Chapter 6.7.

Page 20

20

VM 500

A

B

C

B_03417

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

Dimensions

Input voltage 115 VAC - 230 VAC, 50 Hz / 60 Hz

Input power max. 40 W

Input current max. 0.5 A

Output voltage max. 20 Vpp

Output current max. 1.0 A AC

High-voltage limiting 80 kV DC

Spray current limitation 100 µA DC

Polarity for negative high-voltage generators

Protection class IP 54 *

Weight (without cables) 2.3 kg; 5.07 lb

Operating temperature range 0-40 °C; 32-104 °F

*

Splash water protection is only guaranteed when the gun cable socket is screwed to

the device plug and the mains cable plug is xed to the control unit plug with the

safety clip.

5.4 TECHNICAL DATA

VM 500

mm inch

A 230 9.06

B 180 7.09

C 120 4.72

Page 21

21

VM 500

VM 500

B_03418

3

4

1

2

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

1 Illuminated display: "High-voltage"

2 Illuminated display "Operating signal"

3 Push button: "Standby Mode"

4 Illuminated display "Standby"

5.5 OPERATING ELEMENTS AND CONNECTIONS

5.5.1 OPERATING ELEMENTS FRONT SIDE

Page 22

22

VM 500

Spannung:

Voltage:

Strom:

Current:

max. 20Vpp

max. 1,0A

Typ / Type: VM 500

115VAC - 230VAC

50Hz / 60Hz

2309228

max. 40W

J. WAGNER AG

Industriestrasse 22

CH - 9450 Altstätten

Made in Switzerland

Serie Nr.:

Serial No.:

Spannung:

Voltage:

Artikel Nr.:

Article No.:

Eingangsleistung:

Input Power:

Schutzklasse:

Protection Class:

Norm:

Standard:

EN 50050

IP 54

Eingangsstrom:

Input Current:

max. 0.5A

I

0

Main Switch

Prim.

1.0 AT

Nicht unter Spannung trennen!

Do not disconnect under voltage!

0102

II (2) G

SIRA 11 ATEX 5374X

II 3 G

Ex nR IIA T4 Gc

B_03419

5

6

7

8

9

10

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

5 Mains input terminal

Connection for mains cable with safety clip.

Warning - Do not disconnect under voltage.

6 Primary fuse

1.0 ampere slow-acting

7 Mains supply switch

0 = The control unit is deactivated.

I = The control unit is activated.

8 Gun connection

To connect a GM 5000EA or GM 5000EAC gun.

Warning - Do not disconnect under voltage.

9 Cover of the service connection

For Wagner service personnel only.

10 Knurled nut grounding

Grounding cable connection to the signal ground.

5.5.2 CONNECTIONS ON THE REAR SIDE

Page 23

23

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

6 ASSEMBLY AND COMMISSIONING

6.1 TRAINING ASSEMBLY/COMMISSIONING STAFF

Incorrect installation/operation!

Risk of injury and damage to the device.

The assembly and commissioning sta must have the technical

skills to safely undertake commissioning.

When assembling, commissioning and carrying out all work,

read and follow the operating manuals and safety regulations

for the additionally required system components.

WARNING

6.2 STORAGE CONDITIONS

Until the point of assembly, the device must be stored in a dry location, free of vibrations

and with a minimum amount of dust. The device must be stored in enclosed rooms.

The air temperature at the storage location must be between -20 °C and +60 °C (-4 °F and

+140 °F).

The relative air humidity at the storage location must be between 10 and 95% (without

condensation).

6.3 INSTALLATION CONDITIONS

The air temperature at the installation site must be in a range between 0 °C and 40 °C;

32 and 132 °F.

The relative air humidity at the installation site must be between 10 and 95% (without

condensation).

Do not open the control unit.

Observe safety instructions in Chapter 4.

A skilled person must check to ensure that the device is in a reliable state after it is installed

and commissioned.

Page 24

24

VM 500

Spannung:

Voltage:

Strom:

Current:

max. 20Vpp

max. 1,0A

Typ / Type: VM 500

115VAC - 230VAC

50Hz / 60Hz

2309228

max. 40W

J. WAGNER AG

Industriestrasse 22

CH - 9450 Altstätten

Made in Switzerland

Serie Nr.:

Serial No.:

Spannung:

Voltage:

Artikel Nr.:

Article No.:

Eingangsleistung:

Input Power:

Schutzklasse:

Protection Class:

Norm:

Standard:

EN 50050

IP 54

Eingangsstrom:

Input Current:

max. 0.5A

I

0

Main Switch

Prim.

1.0 AT

Nicht unter Spannung trennen!

Do not disconnect under voltage!

0102

II (2) G

SIRA 11 ATEX 5374X

II 3 G

Ex nR IIA T4 Gc

B_03420

1

2

3

4

5

Spannung:

Voltage:

Strom:

Current:

max. 20Vpp

max. 1,0A

Typ / Type: VM 500

115VAC - 230VAC

50Hz / 60Hz

2309228

max. 40W

J. WAGNER AG

Industriestrasse 22

CH - 9450 Altstätten

Made in Switzerland

Serie Nr.:

Serial No.:

Spannung:

Voltage:

Artikel Nr.:

Article No.:

Eingangsleistung:

Input Power:

Schutzklasse:

Protection Class:

Norm:

Standard:

EN 50050

IP 54

Eingangsstrom:

Input Current:

max. 0.5A

I

0

Main Switch

Prim.

1.0 AT

Nicht unter Spannung trennen!

Do not disconnect under voltage!

0102

II (2) G

SIRA 11 ATEX 5374X

II 3 G

Ex nR IIA T4 Gc

B_03421

1

2

3

4

5

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

This control unit can be used to complete an electrostatic manual spray system. To do

so, a suitable spray gun and the relevant components for the selected spray process are

required (see WAGNER accessories).

Spray guns that are compatible with the VM 500:

Air-Spray GM 5000EAR or GM 5000EAF AirCoat-Spray GM 5000EACR or GM 5000EACF

VM 500 VM 500

1 For the product supply system 3 Mains cable 5 Gun cable

2 For the compressed air supply 4 Grounding cable to the signal ground

6.4 ADDITIONAL COMPONENTS

Incorrect installation/operation!

Risk of injury and damage to the device.

When commissioning and for all work, read and follow the

operating manual and safety regulations for the additionally

required system components.

WARNING

Impurities in the spraying system!

Spray gun blockage, products harden in the spraying system.

Flush the spray gun and paint supply with a suitable ushing agent.

NOTICE

Page 25

25

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

6.5 LOCATION OF THE CONTROL UNIT

All sealed elements on the control unit must be present and undamaged. During operation,

all electric connections of the control unit have to be tightly sealed with the corresponding

plug connectors or closing elements. While under voltage, neither plug connectors nor

closing elements may be separated or opened.

Sparks form when live components are separated or connected!

Explosion hazard from electric sparks.

Do not disconnect plug connections under voltage.

Do not open fuse holders under voltage.

Do not remove the service plug cover under voltage.

WARNING

Incorrect installation of the device!

Explosion hazard and damage to the device.

Set up the device outside the spray booth / spray zone.

If possible, set up the device outside the Ex zone (Ex zone2 is

permissible).

Protect the device from signi cant temperature and moisture

changes.

Protect the device from contamination.

Lay and x the connecting cable correctly.

Ensure that the local mains voltage and tension of the device

match.

DANGER

Page 26

26

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

It is important for systems safety and to achieve an optimum coating that all system

components such as work pieces, conveyors, paint supply, control unit and booth or

spraying stand are perfectly grounded.

Discharge of electrostatically charged components in

atmospheres containing solvents!

Explosion hazard from electrostatic sparks or ames.

Ground all device components.

Ground the work pieces to be coated.

WARNING

6.6 GROUNDING

Heavy paint mist if grounding is insu cient!

Danger of poisoning.

Insu cient paint application quality.

Ground all device components.

Ground the work pieces to be coated.

WARNING

A poorly grounded work piece causes:

- very bad wrap around,

- uneven coating,

- back spraying to the spray gun (contamination) and coater.

Prerequisites for perfect grounding and coating are:

- Clean work piece suspension.

- Grounding of spray booth, conveyor system and suspension on the building side in

accordance with the operating manuals or the manufacturer's information.

- Grounding of all conductive parts within the working area.

- The earthing resistance of the work piece may not exceed 1 MΩ (megohm).

(Ground leakage resistance measured at 500 V or 1000 V)

- Connect the control unit to the signal ground.

- Connect all ground cables using a short and direct route.

- Safety shoes and gloves, if used, must be static dissipative.

Page 27

27

VM 500

B_03234

R max < 1 MΩ

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

Grounding scheme (example)

Conveyor

Control unit

Grounding

cable

Spraying stand

Floor, static dissipative

Work piece

Product

supply

Paint

container

Minimum cable cross-section

Control unit

Product supply

Paint container

Conveyor

16 mm / AWG 6Booth

Spraying stand

Grounding of spray gun

The spray gun is grounded via the spray gun cable.

The spray gun GM 5000EA or GM 5000EAC must be connected to the control unit

VM500 via the spray gun cable.

Note for the sprayer

Safety shoes and gloves, if used, must be static dissipative.

Page 28

28

VM 500

VM 500

7

6

8

4

5

9

17

1

2

16

15

14

21

12

11

10

B_03422

3

13

19

20

3

18

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

6.7 EXAMPLE, AIRCOAT SPRAYING SYSTEM

Description

1 Spray gun GM 5000EACF

2 Gun cable

3 Grounding cable

4 Pneumatic pump

5 Sliding table

6 Air pressure regulator + air

lter

7 Product suction system

Description

8 Return hose

9 High-pressure lter

10 Compressed air connection

11 Stop valve

12 Air pressure regulator

13 VM 500 control unit

14 Protective hose

Description

15 Air hose

16 Product hose

17 Return valve

18 Tank for return ow

19 Paint tank

20 Tank for ushing agent

21 Mains cable

Page 29

29

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

The following points should be noted before commissioning:

Lay grounding cable from the grounding screw on the device to the signal ground

and ensure that all other conductive parts within the working area are grounded.

Connect the VM 500 electrostatic control unit via the mains cable to the socket

interlocked with the extraction system.

Connect the gun cable to the connector socket and screw into place.

Connect the spray gun to the adjustable, clean air supply.

For compressed air quality, see operating manual for spray gun.

Connect the GM 5000EA or GM 5000EAC to the paint supply as described in the relevant

operating manuals.

Check that all product-conveying connections are correctly connected.

Check that all air-conveying connections are correctly connected.

Visually check the permissible pressures for all the system components.

Check the level of the separating agent in the pump and ll up if necessary.

Provide product tank, tanks for ushing agent and an empty tank for return ow.

The interface input on the back of the control unit has to be protected by the cover.

Connect the system to the air supply.

When rst commissioning the unit Flush the system in accordance with the operating

manuals for the other components.

A skilled person must check to ensure that the device and the spraying system are in a safe

state after they are installed and commissioned.

6.8 VERIFYING A SAFE OPERATIONAL CONDITION

Page 30

30

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

Discharge of electrostatically charged components in

atmospheres containing solvents!

Explosion hazard from electrostatic spark-over.

Use gun only with tted nozzle, air cap and union nut.

WARNING

7 OPERATION

7.1 TRAINING THE OPERATING STAFF

7.2 SAFETY INSTRUCTIONS

Incorrect operation!

Risk of injury and damage to the device.

If contact with lacquers or cleaning agents causes skin

irritation, appropriate precautionary measures must be taken,

e.g. wearing protective clothing.

The footwear worn by operating sta must comply with

EN ISO 20344. The measured insulation resistance must not

exceed 100 megohms.

The protective clothing, including gloves, must comply with

EN ISO 1149-5. The measured insulation resistance must not

exceed 100 megohms.

WARNING

Do not open the control unit.

Observe safety instructions in Chapter 4.

Incorrect operation!

Risk of injury and damage to the device.

The operating sta must be quali ed and t to operate the

entire system.

The operating sta must be familiar with the potential risks

associated with improper behavior as well as the necessary

protective devices and measures.

Before work commences, the operating sta must receive

appropriate system training.

WARNING

Page 31

31

VM 500

B_03423

VM 500

2

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

7.3 STARTING UP AND SPRAYING

1. Set main switch to position I.

For approx. 1 second all LED's light up

Display test

2. If the operating signal light (2) is green

after the display test, the control unit is

ready to be operated.

High-voltage eld!

Danger to life from malfunction of heart pacemakers.

Make sure that persons with pacemakers:

Do not work with the electrostatic spray gun.

Don't stay inside the area of the electrostatic spray gun/work piece.

DANGER

In the case of unforeseen occurrences, proceed as follows:

1. Switch o control unit.

2. Close the compressed air supply.

3. Relieve pressure according to the operating manual of the product pressure generator.

4. Point the spray gun toward the grounded collecting tray.

5. Pull the trigger of the spray gun until no further pressure is present.

7.2.1 EMERGENCY DEACTIVATION

Page 32

32

VM 500

B_03423

VM 500

3

4

B_03423

VM 500

1

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

If you want to spray without high-voltage, select the standby mode.

Press push button (3) brie y and the "Standby" illuminated display (4) lights up.

Note:

This function can be activated and used from the gun.

7.4 STANDBY MODE

3. When the spray gun trigger is pulled, highvoltage is switched on. This is indicated by

the high-voltage LED (1).

Page 33

33

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

8 CLEANING AND MAINTENANCE

Cleaning work should be undertaken regularly and carefully by quali ed and trained sta .

They should be informed of speci c hazards during their training.

The following hazards may arise during cleaning work:

- Use of unsuitable cleaning tools and aids

8.1 CLEANING

8.1.2 SAFETY INSTRUCTIONS

8.1.1 CLEANING STAFF

Do not open the control unit.

Observe safety instructions in Chapter 4.

DANGER

Incorrect maintenance/repair!

Danger to life and equipment damage.

Only a WAGNER service center or a suitably trained person may

carry out repairs and replace parts.

Only repair and replace parts that are listed in the "Spare Parts"

chapter and that are assigned to the device.

Before all work on the device and in the event of work

interruptions:

- Switch o the energy and compressed air supply.

- Relieve the pressure from the spray gun and device.

- Secure the spray gun against actuation.

Observe the operating manual and service manuals at all times

when carrying out work.

Page 34

34

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

Explosive powder/air mixes!

Danger to life and equipment damage.

Before starting the cleaning, de-energize the device.

Only electrically conductive tanks may be used for cleaning and

ushing agents. Earth the tank.

Clean the control unit with non- ammable cleaning agent.

Ensure that no electric component is cleaned with or immersed

into solvent.

DANGER

Incompatibility of cleaning/ ushing agent and working

medium!

Risk of explosion and danger of poisoning by toxic gases

Examine the compatibility of the cleaning and ushing agents

and working media on the basis of the safety data sheets.

WARNING

Cleaning the control unit

If there are deposits on the surfaces, the device may form electrostatic charges. Flames or

sparks can form during discharge.

Remove deposits from the surfaces to maintain conductivity.

Use only a damp cloth to clean the device.

Page 35

35

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

Incorrect maintenance/repair!

Danger to life and equipment damage.

Repair or replacement of devices or parts of devices are only

allowed to be performed outside the hazard area by quali ed

personnel.

DANGER

8.2 MAINTENANCE

Maintenance work should be undertaken regularly and carefully by quali ed and trained

sta . They should be informed of speci c hazards during their training.

The following hazards may arise during maintenance work:

- Use of unsuitable tools and aids

An authorized person must ensure that the device is checked for being in a reliable state

after maintenance work is completed.

8.2.1 MAINTENANCE STAFF

8.2.2 SAFETY INSTRUCTIONS

Observe the safety instructions in Chapter 4 and Chapter 8.1.2.

Prior to maintenance

- Flush and clean the system.

After maintenance

- Carry out a safety check in accordance with Chapter 8.2.3.

- Put the system into operation and check for leaks.

In accordance with the guideline for liquid ejection devices (ZH1/406 and BGR 500

Part2 Chapter 2.29 and Chapter 2.36):

- The liquid ejection devices should be checked by an expert (e.g. WAGNER service

technician) to ensure their safe operational condition as required and at least every

12 months.

- For shut down devices, the examination can be suspended until the next start-up.

Page 36

36

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

DANGER

Incorrect maintenance/repair!

Danger to life and equipment damage.

Only a WAGNER service center or a suitably trained person may

carry out repairs and replace parts.

Only repair and replace parts that are listed in the "Spare Parts"

chapter and that are assigned to the device.

Before all work on the device and in the event of work

interruptions:

- Switch o the energy and compressed air supply.

- Relieve the pressure from the spray gun and device.

- Secure the spray gun against actuation.

Observe the operating manual and service manuals at all times

when carrying out work.

8.2.3 SAFETY CHECKS

The functionality and completeness of the control unit must be checked regularly.

All sealed elements on the control unit must be present and undamaged. During operation,

all electric connections of the control unit have to be tightly sealed with the corresponding

plug connectors or closing elements.

Leak test

The leakage tightness of the device has to be checked at least every 3 years. The "Restricted

breathing" requirements according to DIN EN 60079-15:2011 have to be ful lled.

This inspection may only be carried out by a skilled person or by trained WAGNER service

personnel. When carrying out the leakage tightness test, the mains input terminal serves

as a test port.

Sparks form when live components are separated or connected!

Explosion hazard from electric sparks.

Do not disconnect plug connections under voltage.

Do not open fuse holders under voltage.

Do not remove the service plug cover under voltage.

WARNING

Page 37

37

VM 500

B_03423

VM 500

12

34

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

9 TROUBLE SHOOTING AND RECTIFICATION

Functional fault Cause Remedy

Green illuminated display (2)

does not light up

- Mains supply not switched on. - Check and switch on mains

supply

- Fuses defective - Replace fuses

No illuminated display lights up

- Wagner Service

Green illuminated display (1)

does not light up, no highvoltage

- Spray gun cable not connected or

defective

- Connect spray gun cable

- Wagner Service

- Spray gun not connected or

defective

Green illuminated display (1)

always lights up

- Spray gun or control unit

defective

- Wagner Service

Green illuminated display (1)

lights up, no high-voltage

- Excessive conductivity of the

lacquer

- See operating manual of spray

gun

Page 38

38

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

Sparks form when live components are separated or connected!

Explosion hazard from electric sparks.

Do not disconnect plug connections under voltage.

Do not open fuse holders under voltage.

Do not remove the service plug cover under voltage.

WARNING

10 REPAIR WORK

10.1 REPAIR STAFF

Repair work must be carried out carefully by quali ed and trained sta . They should be

informed of speci c hazards during their training.

The following hazards may arise during repair work:

- Use of unsuitable tools and aids

A skilled person must ensure that the device is checked for being in a reliable state after

repair work is completed.

10.2 SAFETY INSTRUCTIONS

Observe the safety instructions in Chapter 4 and Chapter 8.1.2.

Before repair: Flush and clean the system.

After repair work

- Check leak-tightness of control unit as described in Chapter 10.3.

- Carry out a safety check in accordance with Chapter 8.2.3.

- Put the system into operation and check for leaks.

In accordance with the guideline for liquid ejection devices (ZH1/406 and BGR 500

Part2 Chapter 2.29 and Chapter 2.36):

- The liquid ejection devices should be checked by an expert (e.g. WAGNER service

technician) to ensure their safe operational condition as required and at least every

12 months.

- For shut down devices, the examination can be suspended until the next start-up.

10.3 CHECK THE CONTROL UNIT FOR LEAKTIGHTNESS

The "Restricted breathing" requirements according to DIN EN 60079-15:2011 have to be

ful lled. When carrying out the leakage tightness test, the mains input terminal serves as

a test port.

Page 39

39

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

11 DISPOSAL

Do not dispose of used electrical equipment with household

refuse!

In accordance with European Directive 2002/96/EC on the disposal

of used electrical equipment and its implementation in national

law, this product may not be disposed of with the household refuse,

but must be recycled in an environmentally correct manner.

WAGNER or one of our dealers will take back your used WAGNER

electric or electronic equipment and will dispose of it for you in an

environmentally-friendly manner. Please contact one of our service

points, one of our representatives or us directly to arrange this.

NOTICE

Consumable products

Consumable products (lacquers, adhesives, ushing and cleaning agents) must be

disposed of in accordance with all applicable legal requirements.

Page 40

40

VM 500

"?

"?

"?

B_03735

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

12 ACCESSORIES

Order No. Designation

241270 Mains cable Europe 3 m; 9.8 ft

2330628 Mains cable Europe 10 m; 32.8 ft

241271 Mains cable Switzerland 3 m; 9.8 ft

264626 Mains cable USA 2 m; 6.6 ft

264625 Mains cable Japan 3 m; 9.8 ft

130215 Grounding cable 10 m; 32.8 ft

264332

Grounding cable connection 0.75 m; 2.5 ft

2327509 Mounting control unit, complete

Hose sets and spray gun cable

see operating manual of spray gun.

Page 41

41

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

13 SPARE PARTS

13.1 HOW CAN SPARE PARTS BE ORDERED?

Always supply the following information to ensure delivery of the right spare part:

Order number, designation and quantity

The quantity need not be the same as the number given in the quantity column "

" on

the list. This number merely indicates how many of the respective parts are used in each

component.

The following information is also required to ensure smooth processing of your order:

Address for the invoice

Address for delivery

Name of the person to be contacted in the event of any queries

Type of delivery (normal mail, express delivery, air freight, courier etc.)

Identi cation in spare parts lists

Explanation of column "

" (labeling) in the following spare parts lists:

Wearing parts

Note: These parts are not covered by warranty terms.

Not part of standard equipment, available, however, as additional extra.

Incorrect maintenance/repair!

Risk of injury and damage to the device.

Have repairs and part replacements be carried out only by

specially trained sta or a WAGNER service center.

Before all work on the device and in the event of work

interruptions:

- Switch o the energy/compressed air supply.

- Relieve the pressure from the spray gun and device.

- Secure the spray gun against actuation.

Observe the operating manuals for any work.

WARNING

Page 42

42

VM 500

Spannung:

Voltage:

Strom:

Current:

max. 20Vpp

max. 1,0A

Typ / Type:

VM 500

115VAC - 230VAC

50Hz / 60Hz

2309228

max. 40W

J. WAGNER AG

Industriestrasse 22

CH - 9450 Altstätten

Made in Switzerland

Serie Nr.:

Serial No.:

Spannung:

Voltage:

Artikel Nr.:

Article No.:

Eingangsleistung:

Input Power:

Schutzklasse:

Protection Class:

Norm:

Standard:

EN 50050

IP 54

Eingangsstrom:

Input Current:

max. 0.5A

I

0

Main Switch

Prim.

1.0 AT

Nicht unter Spannung trenne

n!

Do not disconnect under voltage!

0102

II (2) G

SIRA 11 ATEX 5374X

II 3 G

Ex nR IIC T4 Gc

32

B_03424

19

20

21

22

23

34

24

26

29

30

33

31

32

6

17

18

16

15

14

13

12

1

11

35

10

7

9

8

4

5

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

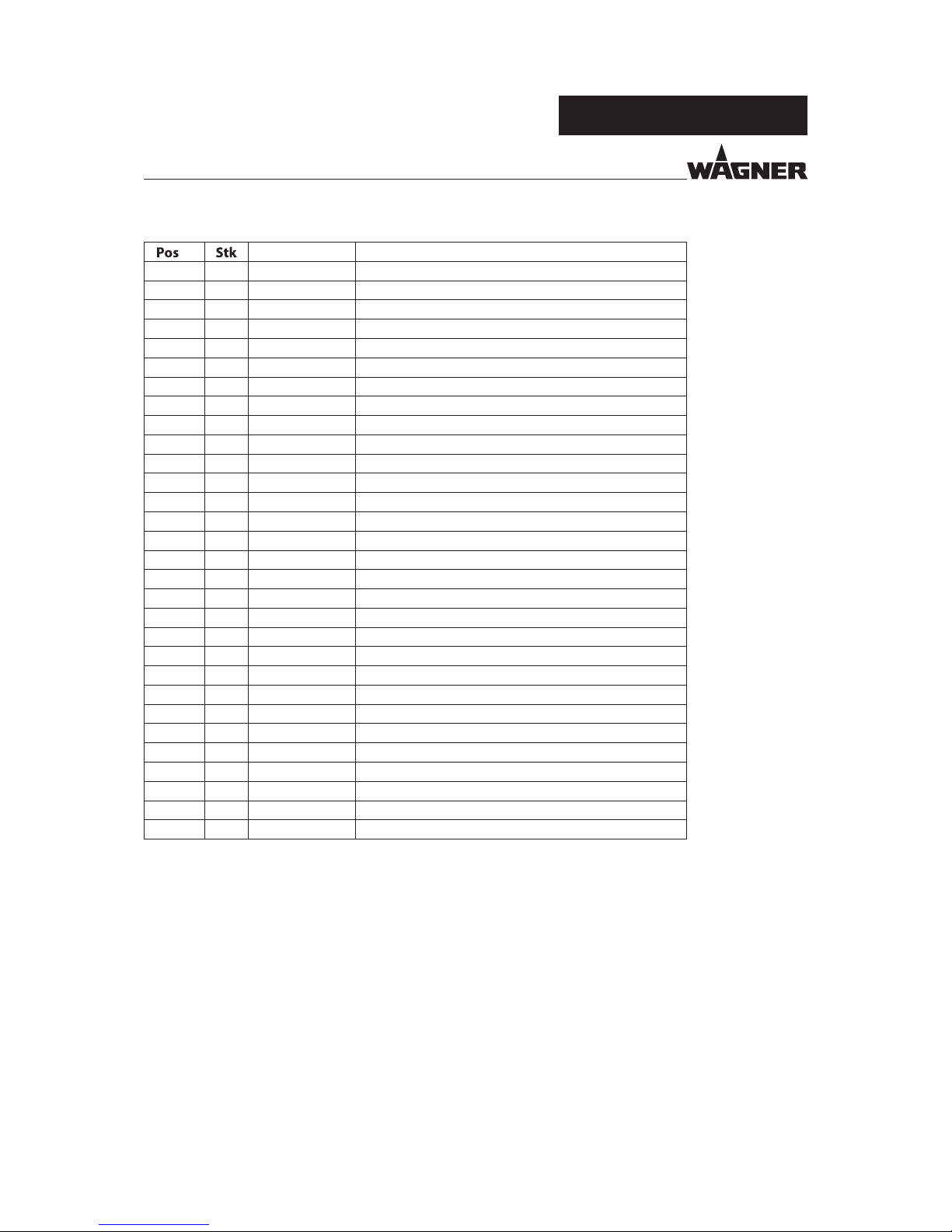

13.2 CONTROL UNIT VM 500

Page 43

43

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

Spare parts list for VM 500 control unit

Order No. Designation

1 1 2310478 VM 500 control unit

4 1 9950330 Safety clip for device sockets

5 2 9903306 Recessed head raised llister head screw, H form

6 1 9910102 Hexagon nut

7 1 9910522 High knurled nut

8 1 9920118 Washer

9 1 9922017 Serrated lock washer, externally toothed

10 2 9903311 Recessed head raised llister head screw, H form

11 1 241323 Cover, white

12 1 2317597 Print complete VM 500 ET

13 3 263400 Distance bush

14 3 9922011 Serrated lock washer, externally toothed

15 3 9910103 Hexagon nut

16 5 2312348 Hexagon lock nut

17 4 9922011 Serrated lock washer, externally toothed

18 4 9903312 Recessed head raised llister head screw, H form

19 8 2306405 Recessed countersunk at head screw, Z form

20 1 2307315 Gasket

21 1 2307309 Cover

22 4 9990839 Bu er

23 1 9955176 Switching power supply

24 5 2309112 Spacer

26 1 2317598 Print complete VM 500 display

29 1 9953536 2-pin toggle switch

30 1 9952587 Connector plug

31 1 9955021 Fuse socket

32 2 9951117 Delay-action fuse 1.0 AT

33 1 9971519 Rubber seal

34 1 9955601 Fast-acting fuse, 2.5 A

35 1 2325264 Gasket

Page 44

44

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

14 WARRANTY AND CONFORMITY DECLARATIONS

14.1 IMPORTANT NOTES REGARDING PRODUCT LIABILITY

14.2 WARRANTY CLAIM

Full warranty is provided for this device:

We will at our discretion repair or replace free of charge all parts which within 24 months

in single-shift, 12 months in 2-shift or 6 months in 3-shift operation from date of receipt by

the purchaser are found to be wholly or substantially unusable due to causes prior to the

sale, in particular faulty design, defective materials or poor workmanship.

The type of warranty provided is such that the device or individual components of the

device are either replaced or repaired as we see t. The resulting costs, in particular

shipping charges, road tolls, labour and material costs will be borne by us except where

these costs are increased due to the subsequent shipment of the device to a location other

than the address of the purchaser.

We do not provide warranty for damage that has been caused or contributed to for the

following reasons:

Unsuitable or improper use, faulty assembly or commissioning by the purchaser or a

third party, normal wear, negligent handling, defective maintenance, unsuitable coating

products, substitute products and the in uence of chemical, electrochemical or electrical

agents, except when the damage is attributable to us.

Abrasive coating products such as red lead, emulsions, glazes, liquid abrasives, zinc dust

paints and so forth reduce the service life of valves, packings, spray guns, nozzles, cylinders,

pistons etc. Signs of wear traced back to these products are not covered by this warranty.

Components that have not been manufactured by WAGNER are subject to the original

warranty of the manufacturer.

Replacement of a component does not extend the period of warranty of the device.

The device should be inspected immediately upon receipt. To avoid losing the warranty,

we or the supplier company are to be informed in writing about obvious faults within

14days upon receipt of the device.

We reserve the right to have the warranty compliance met by a contracting company.

The services provided by this warranty are dependent on evidence being provided in the

form of an invoice or delivery note. If the examination discovers that no warranty claim

exists, the costs of repairs are charged to the purchaser.

It is clearly stipulated that this warranty claim does not represent any constraint on statutory

regulations or regulations agreed to contractually in our general terms and conditions.

J. Wagner AG

As a result of an EC regulation e ective from January 1, 1990, the manufacturer shall only

be liable for his product if all parts originate from him or are approved by him, and if the

devices are properly mounted, operated and maintained.

The manufacturer will not be held liable or will only be held partially liable if third-party

accessories or spare parts have been used.

With genuine WAGNER accessories and spare parts, you have the guarantee that all safety

regulations are complied with.

Page 45

45

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

14.3 CE DECLARATION OF CONFORMITY

CE declaration of conformity as de ned by Atex-directive 94/9/EC.

Herewith we declare that the supplied version of

Electrostatic manual spraying system

VM 500 VM 5000 GM 5000EA GM5000EAC

comply with the following guidelines:

94/9/EC 2004/108/EC 2002/96/EC

2006/42/EC 2002/95/EC

Applied standards, in particular:

DIN EN 50050:2007 DIN EN 61000-6-2:2006 DIN EN ISO 12100:2011

DIN EN 1953:2010 DIN EN 61000-6-4:2011 DIN EN 60079-0: 2010

DIN EN 60079-15: 2011 DIN EN 60204-1: 2007

Applied national technical standards and speci cations, in particular:

BGI 764

EC type approval certi cate:

SIRA 11 ATEX 5374X issued by SIRA Certi cation,

CH4 9JN, Chester, England, noti ed body no. 0518

2310487

Spray gun:

0102

II 2 G EEx 0.24mJ

SIRA 11 ATEX 5374X

EC Certi cate of Conformity

The CE certi cate of conformity is enclosed with this product. If needed, further copies

can be ordered through your WAGNER dealer by specifying the product name and serial

number.

Order number:

Identi cation:

Control unit:

0102

II (2) G

SIRA 11 ATEX 5374X

II 3 G Ex nR IIA T4 Gc

Page 46

46

VM 500

OPERATING MANUAL

EDITION 08/2014 ORDER NUMBER DOC2318724

14.4 NOTES ON NATIONAL REGULATIONS AND GUIDELINES

Technical rule for operating safety

Part 2, Chapter 2.36 Working with Liquid Ejection Devices

Part 2, Chapter 2.29 Working with Coating Products

Avoiding ignition risks

Equipment for cleaning work pieces with solvents

Guidelines for liquid ejection devices

Painting rooms and equipment

Electrostatic coating

Plant Safety Ordinance

Note: All titles can be ordered from Heymanns Publishing House in Cologne, or they

can be found on the Internet.

Page 47

Page 48

C

E

R

T

I

F

I

E

D

Order No. 2318724

Edition 08/2014

Germany

Phone

Telefax

E-mail

Switzerland

Phone

Telefax

More contact addresses on the internet at:

Company/Locations/WAGNER worldwide

Subject to changes without notice

Document No. 11122756

Version C

Loading...

Loading...