Page 1

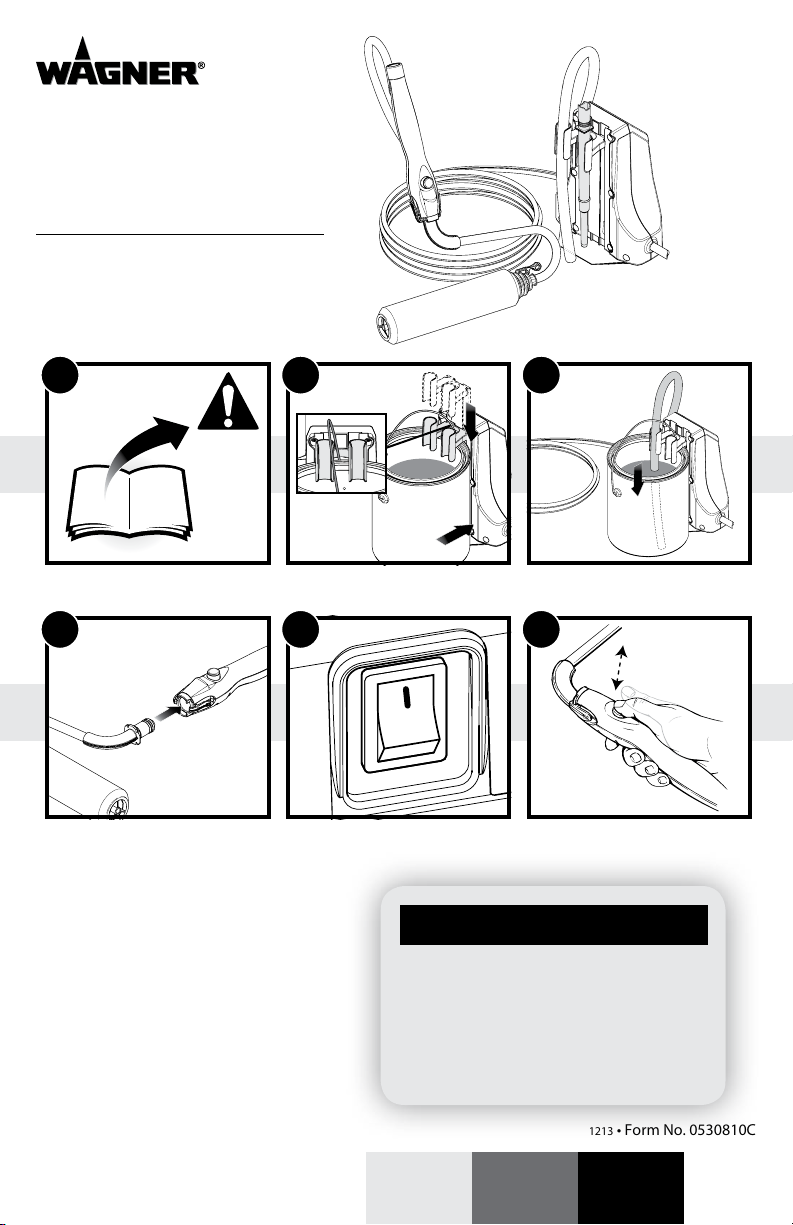

SMART

™

SideKick

Multi-Room Powered Roller for

Continuous Painting

Owner’s Manual

Read this manual for complete instructions

Quick-Start Guide

1

Read all warnings!

2

Secure container to pump

4 5

Attach the roller arm

Contents

2 / 3 Important Safety Information

4 / 5 Parts and Components

6 / 7 Setup

8 / 9 Practice / Usage

10 / 11 Cleanup

12 Storage / Maintenance

13 Troubleshooting

14 Warranty

43 Parts List

44 Optional Accessories

Français (page 15) / Español (página 29)

Plug in, turn switch on (l)

3

Insert suction tube

6

Press and release to start

Questions?

Call Wagner Technical Service at:

1-800-760-3844

Register your product online at:

www.wagnerspraytech.com

1213 • Form No. 0530810C

EnglishFrançaisEspañol

Page 2

Important Safety Information

Read all safety information before

operating the equipment. Save these

instructions.

Indicates a hazardous situation which,

if not avoided, could result in death or

serious injury.

To reduce the risks of re or explosion,

electrical shock and the injury to

persons, read and understand all

instructions included in this manual. Be

familiar with the controls and proper

usage of the equipment.

HAZARD: EXPLOSION OR FIRE

Solvent and paint fumes can

explode or ignite, causing

property damage and/or

severe injury.

PREVENTION:

• Exhaust and fresh air introduction must be

provided to keep the air within the work area

free from accumulation of ammable vapors.

• Avoid all ignition sources such as static

electricity sparks, open ames, pilot lights, hot

objects, cigarettes, and sparks from connecting

and disconnecting power cords or working light

switches.

• Fire extinguishing equipment must be present

and in working order.

• Do not use materials with a ashpoint below

100° F (38° C). A uid’s ashpoint is the

temperature at which vapors from the uid

could ignite if exposed to a ame or spark.

Consult your paint supplier for information

about a uid’s ashpoint.

• Keep the unit in a well ventilated location away

from the work area. The pump contains arcing

parts which emit sparks.

HAZARD: HAZARDOUS VAPORS

Paints, solvents, insecticides, and other

materials may be harmful if inhaled,

causing severe nausea, fainting, or

poisoning.

PREVENTION:

• Use a respirator or mask whenever there is a

chance that vapors may be inhaled. Read all

instructions with the mask to insure that it will

provide the necessary protection against the

inhalation of harmful vapors.

HAZARD: GENERAL

May cause property damage or severe

injury.

PREVENTION:

• Read all instructions and safety precautions

before operating any equipment. Never leave

the unit running while unattended. Unplug

whenever not in use.

• Never immerse the unit into any liquid.

• Comply with all appropriate local, state and

national codes governing ventilation, re

prevention, and operation.

• This paint roller system is designed to be used

with authorized parts only. When using this

system with parts that do not comply with the

minimum specications and safety devices of

the system manufacturer, the user assumes all

risks and liabilities.

• Before each use, check all hoses for cuts,

leaks, abrasion or bulging of cover or damage

or movement of couplings. If any of these

conditions exist, call Customer Service.

Note: Additional warnings are contained on the

tag molded to the electrical cord of the unit. Be

sure to read this tag before operating the unit.

2 © Wagner Spray Tech. - All Rights Reserved

English

Page 3

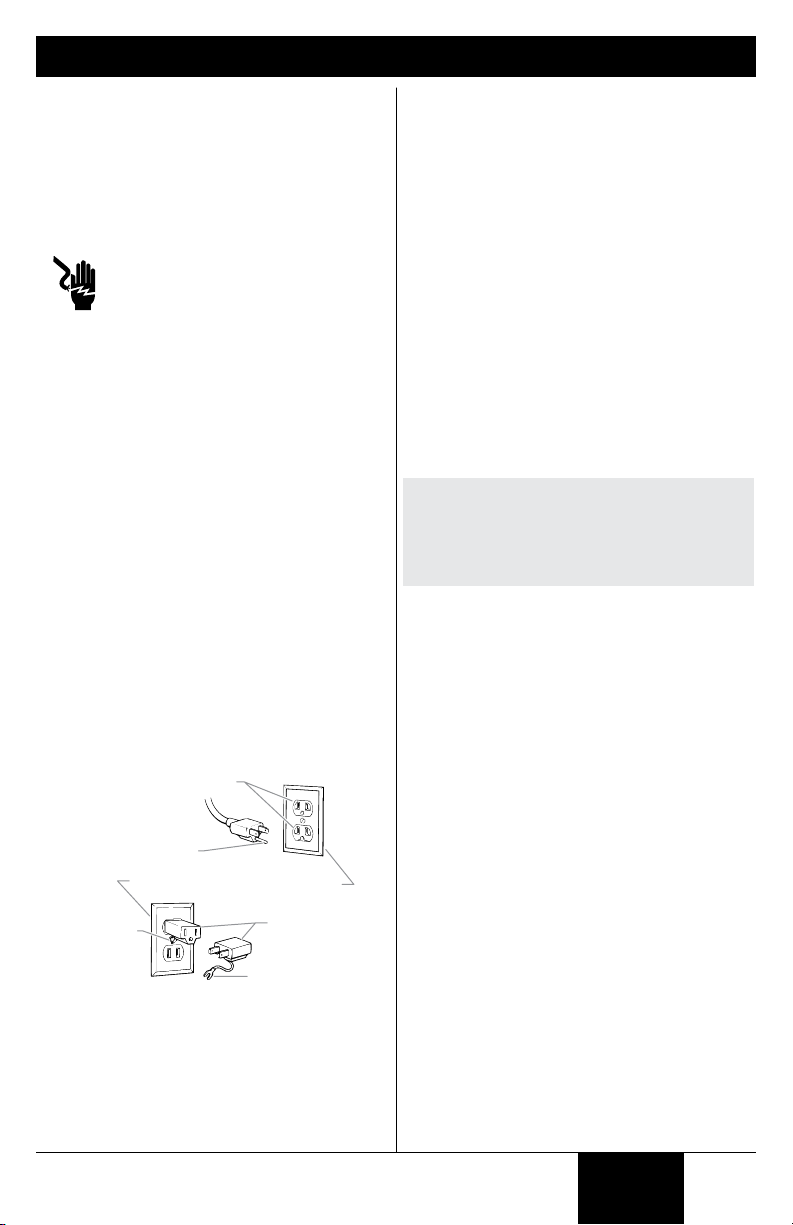

Important Safety Information

Grounded Outlet

Tab for Grounding

Screw

Metal Screw

Grounding Instructions

This product must be grounded. In the event of an

electrical short circuit, grounding reduces the risk

of electric shock by providing an escape wire for

the electric current. This product is equipped with a

cord having a grounding wire with an appropriate

grounding plug. The plug must be plugged into an

outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

WARNING - Improper installation of

the grounding plug can result in a risk

of electric shock.

If repair or replacement of the cord or plug is

necessary, do not connect the green grounding wire

to either at blade terminal. The wire with insulation

having a green outer surface with or without yellow

stripes is the grounding wire and must be connected

to the grounding pin.

Check with a qualied electrician or serviceman

if the grounding instructions are not completely

understood, or if you are in doubt as to whether the

product is properly grounded. Do not modify the

plug provided. If the plug will not t the outlet, have

the proper outlet installed by a qualied electrician.

This product is for use on a nominal 120 volt circuit

and has a grounding plug that looks like the plug

illustrated below. A temporary adapter which looks

like the adapter illustrated in the gure below may

be used to connect this plug to a 2 pole receptacle as

shown if a properly grounded outlet is not available.

The temporary adapter should be used only until a

properly grounded outlet as shown below can be

installed by a qualied electrician. The green colored

rigid ear lug or the grounding wire extending from

the adapter must be connected to a permanent

ground such as a properly grounded outlet box

cover. Whenever the adapter is used, it must be held

in place by a metal screw.

Extension Cord Selection

If an extension cord is used, make sure that it is of

the 3-conductor type with NEMA connectors so a

continuous grounding circuit is provided from the

tool to the power circuit receptacle. Make sure your

extension cord is in good condition. Also, be sure

that the conductor size is large enough to prevent

excessive voltage drop which will cause loss of power

and possible motor damage to the unit. A 14 or 12

gauge cord is recommended.

If an extension cord is to be used outdoors, it must be

marked with the sux W-A following the cord type

designation. For example, SJTW-A to indicate that it

is acceptable for outdoor use.

General Description

This high performance power roller is a precision

power tool used for both interior and exterior

painting and may be used with both water (latex)

and oil based paints.

IMPORTANT: Use of oil-based paints must

be limited to only those paints which can be

cleaned with mineral spirits. Latex paints can

be cleaned with soapy, lukewarm water. DO

NOT use hot water when cleaning or flushing

the unit.

Specications

Flow rate: up to 8 - 20 uid oz. per minute (ow rate

will depend on thickness of paint)

Power source: 120 VAC

Power requirement: 60 Hz current.

Capability: Most oil and water based paints and

stains. Do not use with lacquers, lacquer thinners

or any other solvent with a ash point below 100° F

(38°C).

Grounding Pin

Cover for grounded outlet box

Adapter

© Wagner Spray Tech. - All Rights Reserved 3

English

Page 4

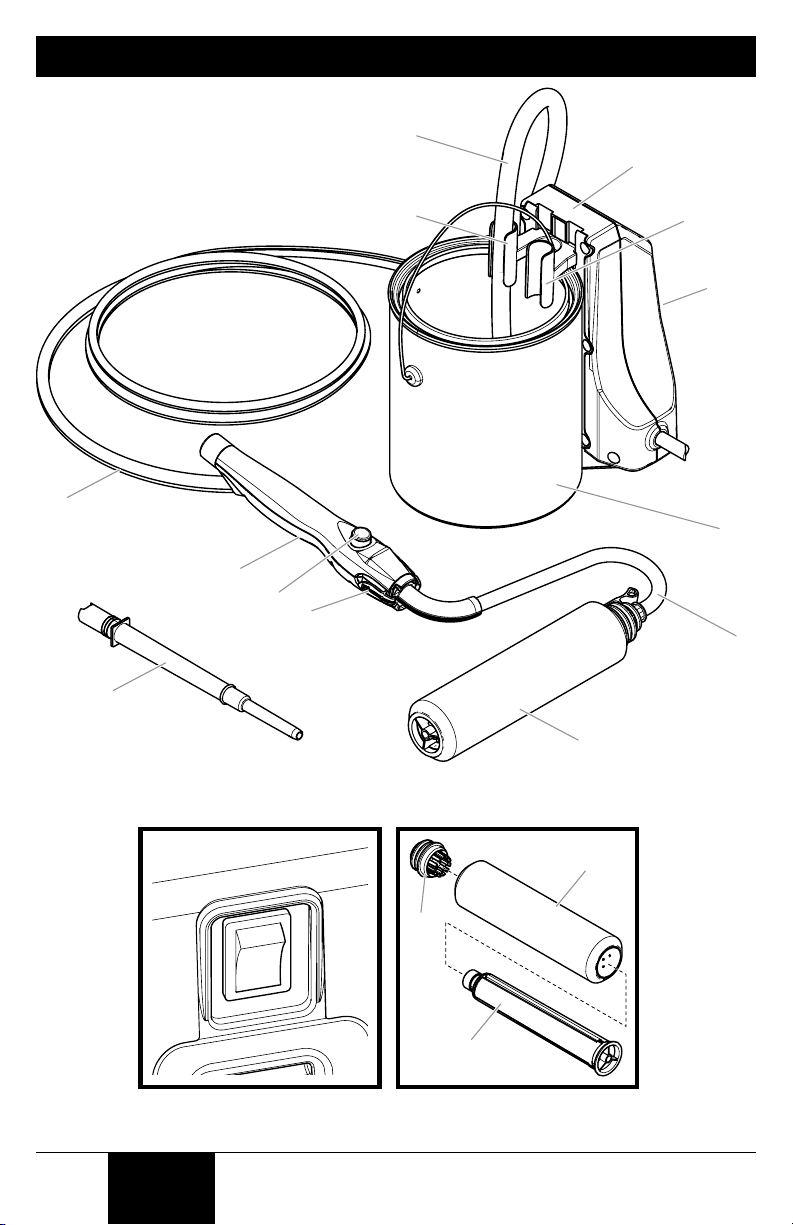

Parts and Components

a

c

b

f

g

h

i

j

k

d

e

**

l

e

k2

k3

4 © Wagner Spray Tech - All Rights Reserved

English

k1

Page 5

Parts and Components

Note: Some of the parts listed on this page can

be replaced by calling technical service. See page

43 for part numbers.

Note: Some parts are not assembled out of the

box. See “Setup” section, page 6-7.

Item Description

a Suction tube

b Tube guide

c Pump assembly

d Extension holder

e ON/OFF switch

f Paint hose

g Roller handle

h Handle button

**

Paint can shown for reference only. Not included.

Item Description

i Quick-release tabs

j Extension

k 9” Roller assembly

h1 - 3/8” nap roller cover

h2 - Roller cap

h3 - Roller core

l Roller arm

© Wagner Spray Tech. - All Rights Reserved 5

English

Page 6

Setup

Material Preparation:

Make sure the material you plan on using is

thoroughly stirred and free from debris. Strain if

necessary. Any impurities in the material can cause

clogs in the pump system or roller assembly.

Note: The SideKick™ Roller can be used with any

type of one-gallon or five-gallon paint container.

Scan this QR code with your

mobile device and you will be

directed to a video on how to set

up your Power Roller.

Setup:

1. Pull the suction tube (a) and extension (b) from

their place holders. This will allow the tube guide

to move more easily.

Lift the suction tube guide (c) to provide

clearance for the material container.

2. Position the material container next to the pump

assembly (d) as shown. The container handle

(e) should be vertical and placed in between the

suction tube guide and the extension holder.

Slide the suction tube guide (f) down until it

touches the top of the material container.

Note: The container is now secured to the pump

and the entire unit can be carried by the container

handle.

IMPORTANT: The container handle must be

placed between the suction tube guide and the

extension holder, or the container will tip when

carried due to the added weight of the pump

assembly.

Continued on next page.

2

One-gallon Five-gallon

(f)

(e)

(e)

1

(a)

(c)

(b)

(f)

(d)

(d)

6 © Wagner Spray Tech. - All Rights Reserved

English

Page 7

Setup (continued)

3. If using a ve-gallon container, insert the

small end of the extension into the suction

tube.

4. Place the suction tube back into position in

the suction tube guide. Make sure the tube

(or the extension) reaches the bottom of the

material container.

5. Press the quick-release tabs on the handle

and attach the roller arm assembly to the

handle.

6. If you want to use an extension, a standard,

household broom handle or other threaded

extension can be threaded into the roller

handle as shown.

4

One-gallon Five-gallon

3

65

© Wagner Spray Tech - All Rights Reserved 7

English

Page 8

Practice / Usage

Scan this QR code with your

mobile device and you will be

directed to a video on Practice

and Usage tips.

IMPORTANT: Make sure your oors and

furnishings are covered with drop cloths during

usage.

Break Periods

During break periods, the handle assembly should

be placed at with the roller sitting on a clean piece

of cardboard or on top of the container.

• During break periods, make sure that the roller

is not saturated with paint, or it will drip and

accumulate.

• Avoid leaving the roller exposed to the sun or

excessive heat during break periods.

• During extended break periods (more than 1/2

hour) wrap the roller in a plastic bag to keep it

from drying out. Place it away from any heat

sources and out of the sun.

Handle Button

When the handle button is pressed and released,

the pump motor will turn on and material will begin

owing into the paint hose.

To shut the motor o and stop the ow of material,

press and release the handle button again.

Note: Make sure to fully press and release the

handle button. If the handle button is only partially

pressed, the motor will start, but will shut down

again after the button is released.

IMPORTANT: Do not submerge handle into any

liquids, and avoid getting any spillage around

the handle button.

Practice / Usage

1. Turn the ON/OFF switch to ON.

2. To start the motor, fully press and release the

handle button.

When paint starts to show through the roller,

press and release the handle button to shut o

the motor.

Tips:

• Practice rolling on a scrap piece of wood or

cardboard.

• Press the handle button to start and stop the

pump as needed.

8 © Wagner Spray Tech - All Rights Reserved

English

Page 9

Practice / Usage

Prepping the Room

Remove all pictures, mirrors, and decorations from

the walls and draperies from the windows. Remove

all nails, hardware and switch and receptacle covers.

Cover furniture and oor with drop cloths.

Surface Preparation

• Always remove wallpaper before painting.

Wash o old adhesive and rinse with water.

Allow the walls to dry before painting.

• Wash and rinse dirt, grease and oil build-up o

the walls with soap and water.

• Fill all nail holes, joints and cracks with patching

paste. Let dry and sand the surface until

smooth. Clean sanded area with a damp cloth.

• Spot prime all patched areas and any marker

and/or pen marks before applying rst coat.

Tip: Write the important information from your

paint can - color, formula, brand and paint type - on

the back of a switch plate for future reference.

Painting the Room

Tip: If you need more than one gallon of paint to do

the room’s walls, mix them together to ensure color

uniformity.

• Always make sure to open a window or door to

ensure proper ventilation.

• If you are painting both the ceiling and walls in

your room, start with the ceiling rst and then

move to the walls.

Ceilings:

• Paint across the short width of the ceiling.

Walls:

• Paint one wall at a time.

• Pick an area to start where you can saturate

the roller cover and evenly distribute the

paint. Working in three-foot sections, begin by

cutting-in around windows, doors, cabinets,

base and other breaks in the wall surface.

• Press and release the handle button until paint

appears through the roller cover.

• Start painting at one end of a wall and roll out

the letter “W”. Fill it in with crosswise strokes,

working your way across the wall in 3’ x 3’

sections. Finish the sections by painting one

solid swipe from ceiling to oor. This will give

you a nice even paint nish.

• Press and release the handle button as needed

for more paint. Be careful not to over-saturate

the roller cover as it may drip, slide on the wall

or spatter.

• Make sure to run the roller cover over the areas

you cut-in around the trim and baseboards to

even out the texture.

• If you need to stop and take a break; nish

painting the entire wall, or stop at a break in the

wall such as a doorway or corner to prevent lap

marks.

© Wagner Spray Tech. - All Rights Reserved 9

English

Page 10

Cleanup

Scan this QR code with your

mobile device and you will be

directed to a video on Cleanup

tips.

IMPORTANT: Make sure your floors and

furnishings are covered with drop cloths

during cleanup.

You will need:

• A waste container

• A minimum of one gallon of warm, soapy

water if you used latex paints

• A minimum of one quart of mineral spirits if

you used oil-based paints

IMPORTANT: DO NOT SUBMERGE THE

ROLLER HANDLE INTO ANY LIQUIDS!

Notes:

• Thoroughly cleaning your unit and its

components is the best way to ensure the

prolonged life of your unit.

• A light paint lm residue may remain in the

paint hose after cleaning. This is normal and

will not aect the future performance of your

unit.

• Switch the unit OFF (0) prior to removing any

accessories or components.

• A Roller Cleanup Kit™ is available for separate

purchase. See Accessories, page 44 for

ordering information.

1

2

PRESS

3

To Clean:

1. Submerge suction tube into a bucket of the

appropriate cleaning solution.

2. Press locking tab and drop roller cover

assembly into a bucket of the appropriate

cleaning solution.

3. Place the roller arm in the material container

in order to catch paint.

4. Turn the switch ON. Fully press and release

the handle button to switch the motor on.

Let the motor run for 15 seconds to push

paint from the hoses back into the paint can.

Fully press and release the handle button to

switch the motor o.

4

15 SECONDS

10 © Wagner Spray Tech. - All Rights Reserved

English

Page 11

Cleanup (continued)

5. Remove container from pump. Leave suction tube

submerged into the bucket of the appropriate cleaning

solution.

6. Hang the roller arm from the bucket.

7. Fully press and release the handle button to run the

appropriate cleaning solution through the hoses and

roller arm.

Note: Allow the pump to circulate the cleaning solution

for about 10 minutes. If desired, refill the bucket with new

cleaning solution and repeat for another 5 minutes.

8. While unit is self-cleaning, disassemble the roller

assembly*, and thoroughly clean the roller cover, core,

and cap by hand.

* Insert thumb to rst knuckle, pry and pull the cap from

the roller cover. Once the cap is removed, push the core

out the other end. DO NOT throw away the core and

cap.

9. Fully press and release the handle button to switch the

motor o.

Remove suction tube from solution and run motor until

all cleaning solution is purged from the unit. Turn the

switch OFF. Unplug power cord.

10. Press quick-release tabs and remove the roller arm from

the roller handle. Remove any remaining paint with the

appropriate cleaning solution and a damp cloth.

IMPORTANT: If you used mineral spirits to clean your

unit, you must repeat all the steps on this page using

warm, soapy water.

7

5

CLEANING

SOLUTION

6

8

ON

9

© Wagner Spray Tech - All Rights Reserved 11

10

English

Page 12

Storage / Maintenance

Quick-release tabs

O-ring

ting

Connecting area

You will need:

• Petroleum jelly

• An old toothbrush or other similar cleaning brush

Cleaning and Storage Tips:

• Wrap the paint hose around the extension

holder and rest the roller arm assembly on the

pump underneath the suction tube for easy

storage.

In addition to thoroughly cleaning your unit after

every use, you must clean and lubricate the areas on

the roller arm indicated below. Use a thin layer of

petroleum jelly to lubricate the indicated areas.

Proper lubrication will prolong O-ring and seal life,

and keep your unit functioning smoothly.

Seal

Connec

area

• Keep water, paint, and other residues away from

the handle button. A clogged handle button

will aect the performance of your unit.

• Be sure that your unit is free from all uids

before storage. After storing your unit in

extreme cold temperatures, allow unit to reach

room temperature before using.

• When storing your unit, be sure the paint hose

is stored in a large loop without any kinks. If it is

bent, it could be damaged.

IMPORTANT: Store the unit indoors with the

power cord wrapped safely around the pump.

This unit contains no serviceable

electrical parts. Do not attempt to

service the unit yourself.

Maintenance

The areas on the roller handle indicated below must

be cleaned thoroughly and lubricated after each use.

ALL paint should be removed from the areas

highlighted in gray below, especially the quickrelease tabs and all other areas that connect

with other parts. This can be done by using the

appropriate cleaning solution and an old toothbrush.

Reassembly

When all of the components have been throughly

cleaned, dried, and lubricated, you can now

reassemble the roller assembly and roller arm for

storage.

1. Reassemble the cap and core into the roller

cover.

2. Reattach the roller assembly (cap, core and

cover) to the roller arm.

3. Press the quick-release tabs on the roller handle

and attach the the roller assembly to the roller

handle.

Connecting area

IMPORTANT: Do not submerge roller handle.

12 © Wagner Spray Tech. - All Rights Reserved

English

Page 13

Troubleshooting

PROBLEM CAUSE SOLUTION

Problem A: The pump

will not run.

Problem B: Paint fails

to load the roller.

Problem C: The motor

does not turn o.

Problem D: There is

paint leakage.

1. The power cord is unplugged, or no

power in outlet.

2. The power switch is turned to 0

(OFF) and handle button has not

been pressed.

3. There is a kink in the air hose.

4. Fluids have entered the handle

assembly.

1. The suction tube is not immersed in

the paint.

2. There is an obstruction in the

suction tube.

3. The paint can is empty.

1. The handle button is activated.

2. There is a kink in the air hose.

3. There is an air switch malfunction.

1. The seal on the roller arm is

backwards.

2. The seal and cap were not properly

cleaned.

3. The O-ring and the connecting area

were not cleaned properly.

4. Paint residue on connecting areas.

5. The O-rings are damaged or

missing.

6. The roller cover is worn or

damaged.

7. The roller core or cap is worn or

damaged.

8. The bearing areas on the roller arm

are worn.

9. The pump tube is punctured.

10. The paint hose is damaged.

1. Plug the power cord into 120V

outlet

2. Turn power switch ON and press

handle button.

3. Unkink the air hose. If unit

still fails to run, call Customer

Service.

4. Call Customer Service.

1. Fully immerse the tube into the

paint.

2. Remove the obstruction.

3. Fill the paint can.

1. Press and release handle button.

2. Unkink the air hose.

3. Unplug unit, then call Customer

Service.

1. Turn the seal around.

2. Clean and properly lubricate.

3. Clean and properly lubricate (pg

9-10).

4. Clean connecting areas.

5. Replace the O-rings*

6. Replace the roller cover*.

7. Replace the roller core or cap*.

8. Call Customer Service

9. Call Customer Service

10. Call Customer Service

* Replacement parts available by calling customer service

© Wagner Spray Tech. - All Rights Reserved 13

English

Page 14

Warranty

Wagner one year limited warranty - Keep on le

This product, manufactured by Wagner Spray Tech Corporation (Wagner) is warranted against defects in

material and workmanship for one year following date of purchase if operated in accordance with Wagner’s

printed recommendations and instructions. This warranty does not cover damage resulting from improper

use, accidents, user’s negligence or normal wear. This warranty does not cover any defects or damages

caused by service or repair performed by anyone other than a Wagner Authorized Service Center.

ANY IMPLIED WARRANTY OF MERCHANTABlLITY OR FITNESS FOR A PARTICULAR PURPOSE IS LIMITED

TO ONE YEAR FOLLOWING DATE OF PURCHASE. THIS PRODUCT IS DESIGNED FOR HOME USAGE ONLY. IF

USED FOR COMMERCIAL OR RENTAL PURPOSES, THIS WARRANTY APPLIES ONLY FOR 30 DAYS FROM DATE

OF PURCHASE. WAGNER SHALL NOT IN ANY EVENT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES OF ANY KIND, WHETHER FOR BREACH OF THIS WARRANTY OR ANY OTHER REASON. THIS

WARRANTY DOES NOT APPLY TO ACCESSORIES.

If any product is defective in material and/or workmanship during the applicable warranty period, return it

with proof of purchase, transportation prepaid, to any Wagner Authorized Service Center. Call the Wagner

Technical Service at 1-800-760-3844 Monday through Friday between 8:00 AM and 4:30 PM Central time.

Thank you for your purchase!

Questions? Product Registration

Call Wagner Technical Service at:

1-800-760-3844

Monday - Friday

8:00 am to 4:30 pm CST

14 © Wagner Spray Tech - All Rights Reserved

English

In order to register your product today, visit:

www.wagnerspraytech.com/registration

We value your opinion. To complete your review,

please visit:

www.wagnerspraytech.com/reviews

Page 15

Parts List • Liste de pièces • Lista de piezas

1

2

3

7

4

5

6

(**)

# Part No.

Nº de piéce

Pieza No.

1 0514118 Roller core and cap Corps du rouleau et

2 0155206A 3/8” nap roller

3 0284432 Fill tube Tube de remplissage Tubo de llenar 1

4 0530216A Roller arm

5 0514112 Seal and O-rings Joint d’étanchéité et joints

6 0530251A Handle assembly

7 --------- Pump Pompe Bomba 1

8 0530554 Strap (not shown) Courroie (non représentés) Correa (no ilustrado) 1

(**) --------- For reference only À titre de référence

© Wagner Spray Tech - All Rights Reserved 43

English

Description

cover

assembly (includes

item 5)

(does not include

hoses)

Français

Description

capuchon

Manchon de rouleau à

grain de 3/8 po

Ensemble de bras de

rouleau (inclut l’article 5)

toriques

Ensemble de la poignée

(ne comprend pas les

tuyaux)

seulement

Español

Descripción

Centro y tapa del rodillo 1

Cubierta del rodillo con

lanilla de 3/8”

Conjunto del brazo

del rodillo (incluye el

artículo 5)

Sello y juntas tóricas 1

Conjunto de la manilla

(no incluye mangueras)

Sólo para referencia

EnglishFrançaisEspañol

Qty.

Qte.

Cant.

1

1

1

Page 16

Optional Accessories • Accessoires Optional • Accesorios Opciónal

Part No.

Nº de piéce

Pieza No.

0155206A 3/8” nap roller cover (9”) Manchon de rouleau à grain

0155208A 3/4” nap roller cover (9”) Manchon de rouleau à grain

0284112B Roller Cleanup Kit™ Roller Cleanup Kit™ Roller Cleanup Kit™

0514026 Trim pad Rouleau pour garnitures Almohadilla para bordes

0514028 Corner pad Rouleau pour coins Almohadilla para esquinas

0530251A Handle assembly Ensemble de la poignée Conjunto de la manilla

0530201A SMART Edge Roller arm

0530206A SMART Mini Roller arm

0530217A Roller arm adapter Adaptateur de bras de

0514230 Spatter guard Garde-éclaboussures Protección contra

English

Description

assembly*

assembly*

* Must be used along

with 0530217A

Français

Description

de 3/8 po (22 cm)

de 3/4 po (22 cm)

Bras de rouleau SMART

Edge*

Bras de rouleau SMART Mini

Roller*

rouleau

* Doit être utilisé avec la

pièce 0530217A

Español

Descripción

Cubierta del rodillo con

lanilla de 3/8” (9”)

Cubierta del rodillo con

lanilla de 3/4” (9”)

Brazo del rodillo SMART

Edge*

Brazo del rodillo SMART

Mini Roller*

Adaptador de brazo del

rodillo

salpicaduras

* Se debe usar junto con

0530217A

44 © Wagner Spray Tech - All Rights Reserved

EspañolFrançaisEnglish

Loading...

Loading...