Page 1

Translation of the Original

Operating Manual

Version 12/2015

Piston Pump

Flow Rate 15

cm

3

II 2G IIB c T3/T4 X

B_04119

Page 2

Page 3

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

Table of Contents

1 ABOUT THESE INSTRUCTIONS 6

1.1 Preface 6

1.2 Warnings, Notices and Symbols in these Instructions 6

1.3 Languages 7

1.4 Abbreviations in the Text 7

1.5 Terminology for the Purpose of this Manual 8

2 CORRECT USE 9

2.1 Device Types 9

2.2 Type of Use 9

2.3 Use in an Explosion Hazard Area 9

2.4 Safety Parameters 9

2.5 Processible Working Materials 10

2.6 Reasonably Foreseeable Misuse 11

2.7 Residual Risks 11

3 IDENTIFICATION 12

3.1 Explosion Protection Identi cation 12

3.2 Identi cation X 12

3.3 Type Plate 13

4 GENERAL SAFETY INSTRUCTIONS 14

4.1 Safety Instructions for the Operator 14

4.1.1 Electrical Equipment 14

4.1.2 Personnel Quali cations 14

4.1.3 Safe Work Environment 14

4.2 Safety Instructions for Sta 15

4.2.1 Safe Handling of WAGNER Spray Devices 15

4.2.2 Grounding the Device 16

4.2.3 Product Hoses 16

4.2.4 Cleaning and Flushing 17

4.2.5 Handling Hazardous Liquids, Varnishes and Paints 18

4.2.6 Touching Hot Surfaces 18

5 DESCRIPTION 19

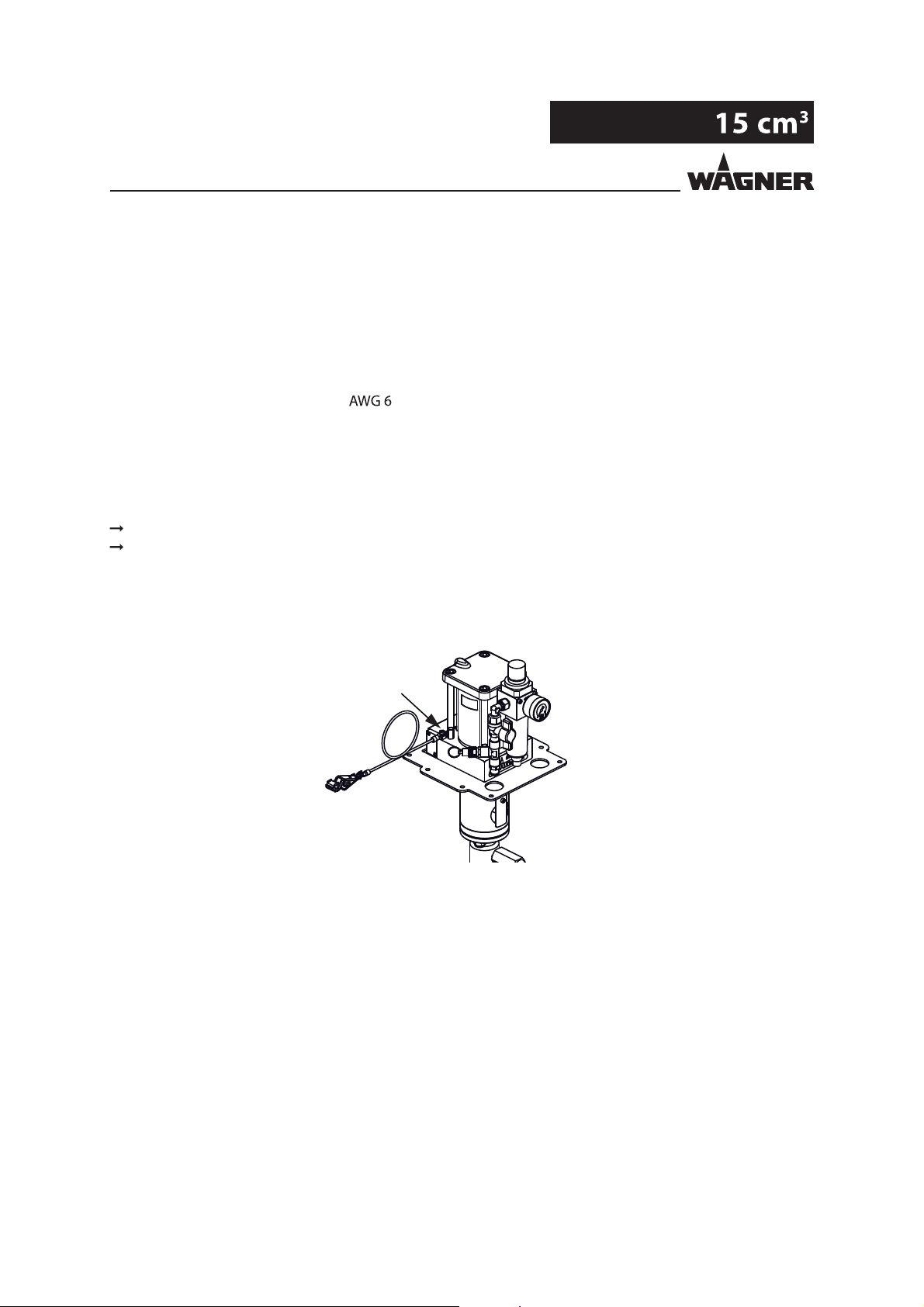

5.1 Components 19

5.2 Mode of Operation 19

5.3 Protective and Monitoring Equipment 20

5.4 Scope of Delivery 20

5.5 Data 21

5.5.1 Materials of Paint-wetted Parts 21

5.5.2 Technical Data 21

5.5.2.1 Technical Data 22

5.5.2.2 Measurements and Connections 23

5.5.3 Performance Diagrams 24

5.6 Pressure Regulator Unit 25

5.6.1 Safety and Motor Pressure Relief Valve 26

5.6.2 Return Valve 26

3

Page 4

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

Table of Contents

6 ASSEMBLY AND COMMISSIONING 27

6.1 Training Assembly/Commissioning Sta 27

6.2 Storage and Installation Conditions 27

6.3 Transportation 27

6.4 Assembly and Installation 28

6.4.1 Ventilation of the Spray Booth 28

6.5 Grounding 29

6.6 Commissioning 31

7 OPERATION 33

7.1 Training the Operating Sta 33

7.2 Safety Instructions 33

7.2.1 General Rules for Making Adjustments to the Spray Gun 34

7.3 Emergency Stop 35

7.4 Spraying 36

7.5 Pressure Relief/Work Interruption 37

7.6 Basic Flushing 38

7.6.1 Filling with Working Material 39

8 CLEANING AND MAINTENANCE 40

8.1 Cleaning 40

8.1.1 Cleaning Sta 40

8.1.2 Safety Instructions 40

8.1.3 Decommissioning and Cleaning 41

8.1.4 Long-term Storage 41

8.2 Maintenance 42

8.2.1 Maintenance Sta 42

8.2.2 Safety Instructions 42

8.2.3 Regular Maintenance Work 43

8.2.4 Filling Separating Agent 43

8.2.5 Emptying the Pump 44

8.2.6 Filling the Empty Pump 46

8.2.7 Product Hoses, Tubes and Couplings 48

9 TROUBLESHOOTING AND RECTIFICATION 49

10 REPAIR 50

10.1 Repair Personnel 50

10.2 Mounting Materials 50

11 DISPOSAL 51

12 ACCESSORIES 52

12.1 EvoMotion 40-15 accessories 52

12.2 Accessories for Product Outlet 52

12.3 Accessories for Product Inlet 52

12.4 Wall Mount and Trolley 55

4

Page 5

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

Table of Contents

13 SPARE PARTS 56

13.1 How Can Spare Parts Be Ordered? 56

13.2 Overview of the Components 57

13.3 Air Motor 58

13.3.1 Reversing Valve 61

13.4 Fluid Section 15 62

13.5 Air Regulator Set for EvoMotion 40-15 65

13.6 Air Regulator Set for AirCoat Air 66

13.7 Trolley 4" 67

13.8 4-Wheel Trolley 68

14 WARRANTY AND CONFORMITY DECLARATIONS 69

14.1 Important Notes Regarding Product Liability 69

14.2 Warranty Claim 69

14.3 CE Declaration of Conformity 70

14.4 Notes on German Regulations and Guidelines 70

5

Page 6

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

1 ABOUT THESE INSTRUCTIONS

1.1 PREFACE

The operating manual contains information about safely operating, maintaining, cleaning

and repairing the device.

The operating manual is part of the device and must be available to operating and service

sta .

Operating and service personnel should be instructed according to the safety instructions.

The device may only be operated in compliance with this operating manual.

This equipment can be dangerous if it is not operated according to the instructions in this

operating manual.

1.2 WARNINGS, NOTICES AND SYMBOLS IN THESE INSTRUCTIONS

Warning instructions in this operating manual highlight particular dangers to users and

to the device and state measures for avoiding the hazard. These warning instructions fall

into the following categories:

DANGER

Danger - immediate risk of danger.

Non-observance will result in death or serious injury.

Warning - possible imminent danger.

Non-observance may result in death or serious injury.

Caution - a possibly hazardous situation.

Non-observance may result in minor injury.

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions.

The signal word indicates the hazard level.

The measures for preventing the danger and its

consequences.

WARNING

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions.

The signal word indicates the hazard level.

The measures for preventing the danger and its

consequences.

CAUTION

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions.

The signal word indicates the hazard level.

The measures for preventing the danger and its

consequences.

Notice - a possibly hazardous situation.

Non-observance may result in damage to property.

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions. The signal word

indicates the hazard level.

The measures for preventing the danger and its consequences.

NOTICE

Note - provides information about particular characteristics and how to proceed.

6

Page 7

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

1.3 LANGUAGES

The operating manual is available in the following languages:

Language Order No. Language Order No.

German 2333557 English 2333558

French 2333559 Spanish 2333561

Italian 2333560 Hungarian 2352156

Russian 2367138

Additional languages on request or at:

1.4 ABBREVIATIONS IN THE TEXT

Number of pieces

Position

Marking in the spare parts lists

Order No. Order number

Double stroke

DN Nominal diameter

PN Nominal pressure

Two components

Materials

Stainless steel

Polyethylene

Ultra-high molecular weight

polyethylene

Polytetra uorethylene

PTFE with graphite

PTFE

Leather

7

Page 8

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

1.5 TERMINOLOGY FOR THE PURPOSE OF THIS MANUAL

Cleaning Manual cleaning of devices and device parts with cleaning

agent

Flushing Internal ushing of paint-wetted parts with ushing agent

Sta quali cations

Trained person Is instructed in the tasks assigned to him/her, the potential

risks associated with improper behavior as well as the

necessary protective devices and measures.

Electrically trained

person

Electrician Can assess the work assigned to him/her and detect possible

Skilled person A person who, based on his/her technical training, experience

In the context of

TRBS1203 (2010 /

Revision 2012)

Is instructed by an electrician about the tasks assigned to him/

her, the potential risks associated with improper behavior as

well as the necessary protective devices and measures.

hazards based on his/her technical training, knowledge and

experience in relevant provisions.

and recent vocational experience, has su cient technical

knowledge and is familiar with the relevant and generally

accepted rules of technology so that he/she can inspect and

assess the status of devices and coating systems based on

workplace safety.

Additional requirements for skilled persons are given in

the TRBS1203(2010/Revision 2012): Expert knowledge in

the areas of protection against excessive pressure, electrical

hazards, and explosion protection (where applicable).

8

Page 9

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

2 CORRECT USE

2.1 DEVICE TYPES

Pneumatic pump with spraypack:

40-15

2.2 TYPE OF USE

The device is suitable for processing liquid materials like paints and lacquers in accordance

with the classi cation into explosion classes IIA or IIB.

2.3 USE IN AN EXPLOSION HAZARD AREA

The pneumatic pump can be employed in explosion hazard zones (Zone 1).

See Chapter 3.

2.4 SAFETY PARAMETERS

WAGNER accepts no liability for any damage arising from incorrect use.

Use the device only to work with the products recommended by WAGNER.

Only operate the device as a whole.

Do not deactivate safety xtures.

Use only WAGNER original spare parts and accessories.

The pneumatic pump may only be operated under the following conditions:

The operating sta must be trained on the basis of this operating manual.

The safety regulations listed in this operating manual must be observed.

The operating, maintenance and repair information in this operating manual must

be observed.

The statutory requirements and accident prevention regulation standards in the

country of use must be observed.

9

Page 10

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

2.5 PROCESSIBLE WORKING MATERIALS

Application

Water-based products

Solvent-based products

Low viscosity (<40 sec. DIN No. 4)

Medium viscosity (40 to 60 sec. DIN No. 4)

High viscosity ( >60 sec. DIN No. 4)

UV - sensitive products

Shear sensitive products

Humidity sensitive products

Legend

recommended limited suitability less suitable

NOTICE

Abrasive working materials and pigments!

Greater wear of parts carrying the product.

Do not use any grainy and abrasive working materials with large, sharp-edged

pigments.

Use the application-related model ( ow rate/cycle, material packaging, valve seat,

etc.), as speci ed in Chapter 5.5.

Check if the uids and solvents used are compatible with the pump construction

materials as indicated in Chapter 5.5.1.

Wear caused by abrasive working materials is not covered by the warranty.

10

Page 11

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

2.6 REASONABLY FORESEEABLE MISUSE

The forms of misuse listed below may result in physical injury or property damage:

coating work pieces which are not grounded;

unauthorized conversions or modi cations to the pneumatic pump;

processing dry or similar coating products, e.g., powder;

using defective components, spare parts or accessories other than those described in

the "Accessories" chapter of this operating manual;

continuing work with a defective or kinked product hose;

working with incorrectly set values;

processing food.

2.7 RESIDUAL RISKS

Residual risks are risks which cannot be ruled out even in the event of correct use.

If necessary, warning and prohibition signs at the relevant points of risk indicate residual

risks.

Residual risk Source Consequences Speci c measures Lifecycle phase

Skin contact with

lacquers and

cleaning agents

Lacquer in air

outside the de ned

working area

Handling of

lacquers and

cleaning agents

Lacquering outside

the de ned

working area

Skin irritation,

allergies

Inhalation of

substances

hazardous to

health

Use personal safety

equipment.

Observe safety data

sheets

Observe work and

operation instructions.

Use personal safety

equipment

Operation,

maintenance,

disassembly

Operation,

maintenance

11

Page 12

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

3 IDENTIFICATION

3.1 EXPLOSION PROTECTION IDENTIFICATION

As de ned in Directive 94/9/EC (ATEX 95), the device is suitable for use in potentially

explosive areas.

CE CE mark (European Communities)

Explosion-proof equipment

II Device class II (not mining)

2 Category 2 device (suitable for zone 1)

G Ex-atmosphere gas

c Constructional security

IIB Device class (Gas) IIB

T3 Temperature class T3: maximum surface temperature 200 °C; 392 °F

T4 Temperature class T4: maximum surface temperature 135 °C; 275 °F

X Special instructions exist for safe operation.

Chapter "Identi cation X".

See the following

3.2 IDENTIFICATION X

Maximum surface temperature

The maximum surface temperature of the piston pump can be reached if it runs dry.

Ensure that the piston pump is lled with su cient working or ushing agent.

Ensure that the separating agent tank is lled with su cient separating agent.

Temperature class T3: No dry running protection

Temperature class T4: With dry running protection

Ignition temperature

Ensure that the ignition temperature of the surrounding gases (pumping product,

cleaning agents) is higher than the maximum permitted surface temperature of the

device.

Ambient temperature

The permissible ambient temperature is: +5 °C to +50 °C; +41 °F to +122 °F.

Medium supporting atomizing

To atomize the product, use only weakly oxidizing gases, e.g., air.

12

Page 13

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

Safe handling of WAGNER spray devices

Mechanical sparks can form if the device comes into contact with metal.

In an explosive atmosphere:

Do not knock or push the device against steel or rusty iron.

Do not drop the device.

Use only tools that are made of a permitted material.

Surface spraying, electrostatics

Do not spray device parts using electrostatic equipment.

Cleaning

If there are deposits on the surfaces, the device may form electrostatic charges. Flames or

sparks can form during discharge.

Remove deposits from the surfaces to maintain conductivity.

Use only a damp cloth to clean the device.

National regulations

Ensure that the national explosion prevention rules and regulations are observed when

setting up the device.

Air in the pump uid

Flammable gas mixtures can form if air reaches the pump uid.

Prevent the pump from taking in air and running dry.

If air has been taken in, x the leak. Then, ll slowly and in a controlled manner until the

air has escaped.

Air in the pumped uid can be caused by damaged packings.

Avoid operating the pump with damaged packing.

Ensure that the separating uid tank is lled with su cient separating uid.

Periodically check that the pump is working smoothly, paying special attention to the

presence of air in the pumped uid.

Filling and emptying

Flammable gas mixtures can form in the uid section or product hoses if the pump must

be emptied for maintenance.

Empty and ll the device slowly and in a controlled manner.

Avoid potentially explosive atmosphere in the surroundings.

3.3 TYPE PLATE

1 Manufacturer and CE

J. WAGNER AG

1

Pumpentyp / Pump type

2

Max. Materialdruck / Fluid pressure

3

Übersetzungsverhältnis / Ratio

4

Fördermenge DH / Delivery DS

5

Max. Luftdruck / Air pressure

6

Max. Temp. Material / Fluid

7

Baujahr - Serie Nr. / Year of manufacture - Serial No.

8

Vor Gebrauch Betriebsanleitung beachten / Check manual before use!

9

CH-9450 ALTSTÄTTEN

MADE IN SWITZERLAND

II 2 G c IIB T3/T4 X

Identi cation

2 Pump type

3 Maximum product pressure

4 Pump ratio

5 Flow rate per double stroke

6 Maximum air inlet pressure

7 Maximum product temperature

8 Model year - serial number

9 Read operating manual before use!

B_05439

13

Page 14

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

4 GENERAL SAFETY INSTRUCTIONS

4.1 SAFETY INSTRUCTIONS FOR THE OPERATOR

Keep this operating manual at hand near the device at all times.

Always follow local regulations concerning occupational safety and accident

prevention.

4.1.1 ELECTRICAL EQUIPMENT

Electrical devices and equipment

To be provided in accordance with the local safety requirements with regard to the

operating mode and ambient in uences.

May only be maintained by skilled electricians or under their supervision. With open

housings, there is a danger from line voltage.

Must be operated in accordance with the safety regulations and electrotechnical

regulations.

Must be repaired immediately in the event of problems.

Must be decommissioned if they pose a hazard or are damaged.

Must be de-energized before work is commenced on active parts. Inform sta about

planned work. Observe electrical safety regulations.

Ground all devices to a common grounding point.

Only operate the device with a properly installed socket with a protective ground wire

connection.

Keep liquids away from electrical devices.

4.1.2 PERSONNEL QUALIFICATIONS

Ensure that the device is only operated, maintained and repaired by trained persons.

4.1.3 SAFE WORK ENVIRONMENT

Ensure that the oor in the working area is static dissipative in accordance with

EN61340-4-1 (resistance must not exceed 100 megohms).

Paint mist extraction systems/ventilation systems must be tted on site according to

local regulations.

Ensure that product / air hoses adapted to the working pressure are used.

Ensure that personal protective equipment is available and is used.

Ensure that all persons within the working area wear static dissipative shoes. Footwear

must comply with EN 20344. The measured insulation resistance must not exceed

100megohms.

14

Page 15

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

Ensure that during spraying, persons wear static dissipative gloves. The grounding

takes place via the spray gun handle.

Protective clothing, including gloves, must comply with EN 1149-5. The measured

insulation resistance must not exceed 100 megohms.

Ensure that there are no ignition sources such as naked ames, sparks, glowing wires,

or hot surfaces in the vicinity. Do not smoke.

Ensure that the pipe joints, hoses, equipment parts and connections are permanently,

technically leak-proof:

- Periodic preventative maintenance and service (replacing hoses, checking tightness

strength and connections etc.).

- Regular monitoring of leaks and defects via visual inspection and odor testing, e.g.,

daily before commissioning, at the end of work or weekly.

In the event of defects, immediately bring the device or system to a stop and arrange

to have repairs carried out immediately.

Grounding

Make sure that the ground and potential equalization of all system parts are performed

reliably and continuously and can withstand the expected stress (e.g., mechanical

stress, corrosion).

4.2 SAFETY INSTRUCTIONS FOR STAFF

Always follow the information in this manual, particularly the general safety instructions

and the warning instructions.

Always follow local regulations concerning occupational safety and accident

prevention.

In electrostatics application: Anyone tted with a pacemaker must not enter the high-

voltage area!

4.2.1 SAFE HANDLING OF WAGNER SPRAY DEVICES

The spray jet is under pressure and can cause dangerous injuries.

Avoid injection of paint or ushing agents:

Never point the spray gun at people.

Never reach into the spray jet.

Before all work on the device, in the event of work interruptions and functional faults:

- Relieve pressure from spray guns and devices.

- Secure spray guns against actuation.

- Switch o the energy/compressed air supply.

- Disconnect the control unit from the mains.

- In the event of functional faults, remedy the fault as described in the "Troubleshooting"

chapter.

15

Page 16

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

If necessary or at least every 12 months, the liquid ejection devices should be checked for

safe working conditions by an expert (e.g., WAGNER Service Technician) in accordance

with the guidelines for liquid ejection devices (DGUV regulation 100-500).

- For shut down devices, the examination can be suspended until the next start-up.

Carry out the work steps as described in the "Pressure Relief" chapter:

- If pressure relief is required.

- If the spraying work is interrupted or stopped.

- Before the device is cleaned on the outside, checked or serviced.

- Before the spray nozzle is installed or cleaned.

In the event of skin injuries caused by paint or ushing agents:

Note the paint or ushing agent that you have been using.

Consult a doctor immediately.

Avoid risk of injury from recoil forces:

Ensure that you have firm footing when operating the spray gun.

Only hold the spray gun brie y in a position.

4.2.2 GROUNDING THE DEVICE

Friction, owing liquids and air or electrostatic coating processes create charges. Flames or

sparks can form during discharge. Grounding prevents electrostatic charging.

Ensure that the device is grounded. See chapter "Grounding".

Ground the work pieces to be coated.

Ensure that all persons inside the working area are grounded, e.g., that they are wearing

static dissipative shoes.

Wear static dissipative gloves when spraying. The grounding takes place via the spray

gun handle.

The spray substance supply (spray substance tank, pump, etc.) must be grounded.

4.2.3 PRODUCT HOSES

Ensure that the hose material is chemically resistant to the sprayed products and the

ushing agents used.

Ensure that the product hose is suitable for the pressure generated.

Ensure that the following information can be seen on the high-pressure hose:

- Manufacturer

- Permissible operating pressure

- Date of manufacture

16

Page 17

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

Make sure that the hoses are laid only in suitable places. Do not lay hoses:

- in high-traffic areas,

- on sharp edges,

- on moving parts or

- on hot surfaces.

Ensure that the hoses are never run over by vehicles (e.g., fork lifts), or that the hoses are

never put under pressure from the outside in any other way.

Ensure that the hoses are never kinked. Observe maximum bending radii.

Make sure that the hoses are never used to pull or move the equipment.

The electrical resistance of the product hose, measured at both valves, must be less

than 1 megohm.

Suction hoses may not be subjected to pressure.

Several liquids have a high expansion coe cient. In some cases their volume can rise with

consequent damage to pipes, ttings, etc. and cause uid leakage.

When the pump sucks liquid from a closed tank, ensure that air or a suitable gas can

enter the tank. Thus a negative pressure is avoided. The vacuum could implode the tank

(squeeze) and can cause it to break. The tank would leak and the liquid would ow out.

The pressure created by the pump is a multiplication of the inlet air pressure.

4.2.4 CLEANING AND FLUSHING

Relieve the pressure from the device.

De-energize the device electrically.

Preference should be given to non- ammable cleaning and ushing agents.

When carrying out cleaning work with ammable cleaning agents, make sure that all

equipment and resources (e.g., collection tank, funnel, transport cart) are conductive or

static dissipative and grounded.

Observe the speci cations of the paint manufacturer.

Ensure that the ash point of the cleaning agent is at least 15 K above the ambient

temperature or that cleaning is undertaken at a cleaning station with technical

ventilation.

Take measures for workplace safety (see Chapter 4.1.3).

When commissioning or emptying the device, please note that an explosive mixture

may temporarily exist inside the lines and components of equipment:

- depending on the coating product used,

- depending on the ushing agent (solvent) used,

explosive mixture inside the lines and items of equipment.

17

Page 18

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

Only electrically conductive tanks may be used for cleaning and ushing agents.

The tanks must be grounded.

An explosive gas/air mixture forms in closed tanks.

Never spray into a closed tank when using solvents for ushing.

External cleaning

When cleaning the exterior of the device or its parts, also observe the following:

Disconnect the pneumatic supply line.

Use only moistened cloths and brushes. Never use abrasive agents or hard objects and

never spray cleaning agents with a gun. Cleaning the device must not damage it in any

way.

Ensure that no electric component is cleaned with or immersed into solvent.

4.2.5 HANDLING HAZARDOUS LIQUIDS, VARNISHES AND PAINTS

When preparing or working with lacquer and when cleaning the device, follow the

working instructions of the manufacturer of the lacquers, solvents and cleaning agents

being used.

Take the speci ed protective measures. In particular, use personal protective equipment:

safety goggles, protective clothing and gloves, as well as respiratory protection and

skin protection cream if necessary.

Use a mask or breathing apparatus if necessary.

For su cient health and environmental safety: Operate the device in a spray booth or

on a spraying wall with the ventilation (extraction) switched on.

Wear suitable protective clothing when working with hot products.

4.2.6 TOUCHING HOT SURFACES

Only touch hot surfaces if you are wearing protective gloves.

When operating the device with a coating product with a temperature of > 43 °C;

109 °F: identify the unit with a warning label that says "Warning - Hot Surface".

- Instruction label Order no. 9998910

- Protection label Order no. 9998911

Note: Order the two stickers together.

18

Page 19

VERSION 12/2015

OPERATING MANUAL

5 DESCRIPTION

5.1 COMPONENTS

1 Air motor

2 Air inlet

3 Mounting ange

4 Separating uid tank

5 Product outlet

6 Fluid section

7 Product inlet

8 Grounding connection

9 Reversing valve

10 Safety valve (air motor

vent)

11 Air pressure regulator

12 Ball valve

13 Air outlet to the

reversing valve

14 Air inlet into the

reversing valve

ORDER NUMBER DOC2333558

1

8

4

10

13

6

B_04121

7

5

11

2

3

9

8

12

14

7

5.2 MODE OF OPERATION

The piston pump is driven with compressed air (11). The compressed air moves the air

piston in the air motor (1) and the associated pump pistons in the uid section(6) up and

down. At the end of each stroke, the compressed air is redirected by a reversing valve (9).

The working material is sucked up during the upwards stroke and is continuously conveyed

towards the product outlet (5) in both stroke directions.

Air motor (1)

The air motor with its pneumatic reverse (9) does not require pneumatic oil.

The compressed air is fed to the motor via an air regulator (11) and the ball valve (12).

The air motor must be equipped with a safety valve (10) in accordance with

Chapter 5.4.3. The safety valve (10) has been set and sealed at the factory. In case of

pressures over and above the permissible operating pressure, the valve, which is held with

a spring, automatically opens and releases the excess pressure.

Fluid section (9)

The uid section has been designed as a piston pump with exchangeable ball valves. The

hard chrome-plated pump piston runs in two xed packings which are self-adjusting by

means of a pressure spring, thus resulting in a long service life.

Between the air motor and the uid section there is a separating agent cup (4) for separating

the separating agent.

19

Page 20

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

5.3 PROTECTIVE AND MONITORING EQUIPMENT

Safety valve

The air motor is tted with a safety valve. The safety valve has been set and sealed at the

factory. In case of pressures over and above the permissible operating pressure, the valve,

which is held with a spring, automatically opens and releases the excess pressure.

WARNING

Overpressure!

Risk of injury from bursting components.

Never change the safety valve setting.

5.4 SCOPE OF DELIVERY

Pneumatic piston pump

Consists of:

- Fluid section

- Air motor

- Connection set for air motor - uid section

- Air pressure regulator for air motor

The scope of delivery also includes:

Separating agent 250 ml; 250 cc order no.: 9992504

Declaration of conformity see Chapter 14.3

Operating manual, German order no.: 2333537

Operating manual in the local language see Chapter 1.3

The delivery note shows the exact scope of delivery. Accessories: see Chapter 12.

20

Page 21

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

5.5 DATA

5.5.1 MATERIALS OF PAINTWETTED PARTS

Pump housing Stainless steel

Piston Stainless steel

Valve balls Stainless steel

Valve seats Stainless steel

Static seals PTFE

Packings

= Ultra high molecular weight polyethylene

PTFE (Polytetra uorethylene)

5.5.2 TECHNICAL DATA

WARNING

Exhaust air containing oil!

Risk of poisoning if inhaled.

Air motor switching problems.

Provide water-free and oil-free compressed air

21

Page 22

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

5.5.2.1 TECHNICAL DATA

Description Units

Pump ratio 40:1

Volume ow per double stroke cm/cc 15

Maximum operating overpressure MPa 25.0

bar 250

psi 3626

Maximum possible strokes in operation /min. 60

Minimum/maximum air inlet pressure MPa 0.2-0.8

bar 2-8

psi 28-116

Quality standard 7.5.4 according to ISO 8573.1, 2010

Compressed air quality: free from oil and water

Ø air inlet connection (inside thread) mm; inch 8.0; 0.1

Minimum Ø of the compressed air supply line mm; inch 9.0; 0.35

Air consumption at 0.6 MPa; 6 bar; 87 psi per

double stroke

Air motor piston diameter mm; inch 80; 3.15

Air motor piston stroke mm; inch 60; 2.4

Sound pressure level at maximum permissible

air pressure*

Sound pressure level at 0.6 MPa; 6 bar; 87 psi

air pressure*

Sound pressure level at 0.4 MPa; 4 bar; 58 psi

air pressure*

Product inlet (outside thread) mm M36x2

Product outlet (outside thread) inch NPS 1/4"

Weight kg 9

Product pH value pH 3.5 ÷ 9

Maximum product pressure at pump inlet

Product temperature °C; °F +5...+80; +41...+176

Ambient temperature °C; °F +5...+60; +41...+140

Relative humidity % 10–95 (without condensation)

Allowable inclination for operation

nl 3.9

scf 0.14

dB(A) 72

dB(A) 69

dB(A) 65

lb 19.8

MPa 2

bar 20

psi 90

7: Particle concentration 5–10mg/m

5: Humidity: pressure dew point ≤ +7 °C

4: Oil content ≤ 5mg/m

± 10

A rated sound pressure level measured at 1 m distance, LpA1m according to DIN EN 14462: 2005.

22

Page 23

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

5.5.2.2 MEASUREMENTS AND CONNECTIONS

H1

L

A 104 4.09

B 108.5 4.27

C 621 24.45

D 276.5 10.89

E 134 5.28

F1 G 1/4"

F2 NPS 1/4"

G M36x2

H1 G 1/4"

H2 8 0.31

I 210 8.27

J 207 8.15

K 86 3.39

A

L 7 0.28

M 182 7.17

N 80 3.15

O 106 4.17

P 96.5 3.8

Q ø 9 ø 0.35

B

H2

R ø 7 ø 0.28

S 149 5.87

T ø 25 ø 1

K

J

I

E

F1

F2

Wall mount

S

N

C

T

R

D

Q

O

G

B_04120

M

M/2

P

23

Page 24

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

5.5.3 PERFORMANCE DIAGRAMS

Example

Product pressure bar (MPa) psi

"?

Water ow rate l/min <gpm>

Diagram EvoMotion 40-15

Stroke frequency /min

BAR

BAR

BAR

BAR

BAR

BAR

Air consumption nl/min <scfm>

bar (MPa)

<psi>

300 (30)

<4350>

240 (24)

<3480>

180 (18)

<2610>

120 (12)

<1740>

60 (6)

<870>

Product pressure

C_00054

Stroke frequency /min

10 20 30 40 50 60

0

A

B

C

0

0.60

0.45

0.30

0.15

0

<0.04>

<0.08>

<0.12>

<0.16>

Product ow - water

A = 8 bar (0.8 MPa; 116 psi) air pressure

B = 6 bar; 0.6 MPa; 87 psi air pressure

C = 4 bar; 0.4 MPa; 58 psi air pressure

0.75

<0.20>

A

B

C

0.90

<0.24>

nl/min

<scfm>

300

<11>

240

<8>

180

<6>

120

<4>

60

<2>

0

l/min

<gpm>

Air consumption

24

Page 25

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

5.6 PRESSURE REGULATOR UNIT

1 Pressure regulator

2 Ball valve

3 Pressure gauge (air inlet pressure)

4 Pressure gauge for AirCoat air (option)

5 Compressed air inlet

6 Pressure regulator AirCoat (option)

7 Safety and motor pressure relief valve

2

1

3

4

6

7

5

B_04122

Ball valve positions:

1 Open: working position

2 Closed: the air motor may still be under

pressure.

2

7

1

3

5

open

1

2

closed

B_04123

25

Page 26

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

5.6.1 SAFETY AND MOTOR PRESSURE RELIEF VALVE

Safety valve

The safety valve (10) has been factory adjusted so as to ensure that if pressure exceeds the

permitted operating pressure, the valve, which is held with a spring, automatically opens

and releases the excess pressure.

As well as handling pressure limits, the valve is also used as a pressure relief valve for the

air motor.

WARNING

Overpressure!

Risk of injury from bursting components.

Never change the safety valve setting.

10

Pressure relief of the air motor:

1 Close ball valve (2).

2 Pull back the ring on the safety

valve (10) and hold it there until the

pressure in the air motor has been

equalized.

5.6.2 RETURN VALVE

So that the complete pressure relief of the pump can be performed

(see Chapter 7.2.2), the installation of a return valve is mandatory.

The suitable return valves (ball valves), return pipes and hoses for

the device can be found in the accessories list.

1 Product outlet

2 Return valve

3 Material return line

10

B_04124

2

2

1

B_04075

3

26

Page 27

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

6 ASSEMBLY AND COMMISSIONING

6.1 TRAINING ASSEMBLY/COMMISSIONING STAFF

The assembly and commissioning sta must have the technical skills to safely

commission the device.

When assembling, commissioning and carrying out all work, read and follow the

operating manuals and safety regulations for the additionally required system

components.

A skilled person must check to ensure that the device is in a reliable state after it is installed

and before commissioning.

6.2 STORAGE AND INSTALLATION CONDITIONS

Until the point of assembly, the device must be stored in a dry location, free from vibrations

and with a minimum of dust. The device must be stored in closed rooms. For speci cations

on temperatures and relative humidity, see Technical Data.

Long-term storage: Thoroughly clean the pump, if a long-term decommissioning is

planned. See Chapter "Cleaning". For recommissioning, proceed according to following

chapters.

6.3 TRANSPORTATION

The pump can be moved on a trolley or manually without lifting

equipment.

B_04065

WARNING

Inclined ground!

Risk of accidents if the device rolls away/falls.

Position the trolley with the piston pump horizontally.

If the surface is inclined, position the feet of the trolley towards

the gradient.

Secure the trolley.

27

Page 28

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

6.4 ASSEMBLY AND INSTALLATION

Note:

This pump can be used as part of a spraying system for Airless or AirCoat applications. Individual supplement

components for this pump can be found in the Wagner Accessories Catalogue, or can be put together with

the Spraypack Con gurator. The nozzles must be selected according to the gun instructions. In the case of

spraypack orders, the pump (1) is already pre-mounted on a trolley (6) or on a frame at the factory.

Procedure:

1 Mount pump (1) on frame, trolley (6) or wall mount.

2 Mount an AirCoat system with the pressure regulator (7) and secure the thread at the air inlet to the

pump (1) with Loctite 270.

3 Mount suction system (5).

4 Mount the return valve (8) for pressure relief or product circulation.

5 Mount return tube (4) or return hose.

6 Connect the high-pressure hose (2) and gun (3) in accordance with the gun operating manual.

Example:

Airless system

3

6

2

1

8

4

5

B_04076

6.4.1 VENTILATION OF THE SPRAY BOOTH

Example:

AirCoat system

3

2

5

7

1

8

4

6

B_04077

Observe the safety instructions in Chapter 4.1.3.

Operate the device in a spray booth approved for the working materials.

– or –

Operate the device on an appropriate spraying wall with the ventilation (extraction)

switched on.

Observe national and local regulations for the exhaust air speed.

28

Page 29

VERSION 12/2015

OPERATING MANUAL

6.5 GROUNDING

Discharge of electrostatically charged components in

atmospheres containing solvents!

Explosion hazard from electrostatic sparks.

Clean the piston pump only with a damp cloth.

Ground all device components.

Ground the work pieces to be coated.

Heavy paint mist if grounding is insu cient!

Danger of poisoning.

Insu cient paint application quality.

ORDER NUMBER DOC2333558

WARNING

WARNING

Ground all device components.

Ground the work pieces to be coated.

Grounding scheme (example)

Paint tank

B_00304

Floor, static dissipative

Conveyor

Work piece

Spraying stand

R max < 1 M:

Cable cross sections

Pump 4 mm; Conveyor 16 mm;

Product tank 6 mm; Booth 16 mm;

Spraying stand 16 mm;

29

Page 30

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

Safe operation of the EvoMotion pump is only guaranteed with a ground

connection.

Connect all ground cables using a short and direct route.

Procedure:

1. Ground the pump, connect the grounding cable to

potential equalization on-site.

2. Ground the product tank.

3. Ground the other parts of the system to an on-site

grounding connection. 16 mm;

Ex zone

All devices and equipment must be suitable for use in

potentially explosive areas.

Tank

All paints, ushing agents and waste tanks have to be electrically conductive.

All tanks must be grounded.

Grounding cable

B_04127

30

Page 31

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

6.6 COMMISSIONING

Observe all safety regulations in accordance with Chapter 4 and Chapter 7.2.

Emergency stop, see Chapter7.3.

Preparation

Before every start-up, the following points should be observed as laid down in the

operating manual:

- Secure gun with safety clip.

- Check the permissible pressures.

- Check all connections for leaks.

- Check hoses for damage in accordance with Chapter 8.2.9.

Fill the pump with ushing agent

The devices are tested during manufacturing with emulsifying oil, pure oil or solvent.

Possible residues must be ushed out of the circuits with a solvent ( ushing agent) before

commissioning.

- Fill the separating agent in accordance with Chapter 8.2.4.

- Fill the empty device with ushing agent in accordance with Chapter 8.2.7.

Pressure tightness test

- Gradually increase the pressure in pump with the pressure regulator until maximum

pressure is reached. Maintain the pressure for 3 minutes and check all connection

points for leaks.

- Depressurization in accordance with Chapter 7.5.

Filling with working material

- In accordance with Chapter 7.6.1.

31

Page 32

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

Before every start-up, the following points should be observed as laid down in the operating manual:

- Check the permissible pressures.

- Check all connections for leaks.

- Check hoses for damage.

It should be ensured that the device is in the following state before carrying out any work on it:

- Interrupt the air supply (2).

- Depressurize the air motor (pull the ring on the safety valve (10)).

- Relieve the pressure from the uid section.

10

closed

10

2

open

B_04124

C_00157

32

Page 33

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

7 OPERATION

7.1 TRAINING THE OPERATING STAFF

The operating sta must be quali ed and t to operate the entire system.

The operating sta must be familiar with the potential risks associated with improper

behavior as well as the necessary protective devices and measures.

Before work commences, the operating sta must receive appropriate system training.

7.2 SAFETY INSTRUCTIONS

Before carrying out any work, the following points must be observed in accordance with

the operating manual:

Observe all safety regulations in accordance with Chapter 4.

Carry out commissioning in accordance with Chapter 6.6.

WARNING

Incorrect operation!

Risk of injury and damage to the device.

If contact with lacquers or cleaning agents causes skin irritation,

appropriate precautionary measures must be taken, e.g.,

wearing protective clothing.

The footwear worn by operating sta must comply with

EN ISO 20344. The measured insulation resistance must not

exceed 100 megohms.

The protective clothing, including gloves, must comply with

EN ISO 1149-5. The measured insulation resistance must not

exceed 100 megohms.

WARNING

Unintentional putting into operation!

Risk of injury

Before any work on the device, in the event of work interruptions

and malfunctions:

Relieve the pressure from the spray gun and unit.

Secure the spray gun against actuation.

Switch o the energy/compressed air supply.

Disconnect the control unit form the network.

In the event of functional faults: remedy the fault as described in

the "Troubleshooting" chapter.

33

Page 34

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

WARNING

Gas mixtures can explode if there is an incompletely filled

pump!

Danger to life from ying parts.

Ensure that the pump and suction system are always completely

filled with ushing agent or working material.

Do not spray the device empty after cleaning.

7.2.1 GENERAL RULES FOR MAKING ADJUSTMENTS TO THE SPRAY GUN

Observe the operating manual of the spray gun.

WARNING

High pressure spray jet!

Danger to life from injecting paint or solvent.

Never reach into the spray jet.

Never point the spray gun at people.

Consult a doctor immediately in the event of skin injuries caused

by paint or solvent. Inform the doctor about the paint or solvent

used.

Never seal defective high-pressure parts; instead relieve the

pressure from them and replace them immediately.

Use personal protective equipment (protective clothing, gloves,

eyewear and respiratory protection).

34

Page 35

VERSION 12/2015

OPERATING MANUAL

7.3 EMERGENCY STOP

ORDER NUMBER DOC2333558

In the case of unexpected processes, close the ball

valve (2) immediately, open safety valve (10) and

depressurize the parts carrying the product via the

return valve (3).

2

3

B_04078

35

Page 36

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

7.4 SPRAYING

1 Secure the gun and insert the nozzle into the gun.

2 Close return valve (3).

3 Slowly open the ball valve (2).

4 Set required working pressure on the pressure regulator (1).

5 Optimize the spraying results according to the data in the gun operating manual.

6 Start work process.

System example

EvoMotion 40-15 for

AirCoat procedure

closed

open

8

1

2

9

7

3

4

6

5

B_04080

36

Page 37

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

7.5 PRESSURE RELIEF/WORK INTERRUPTION

Pressure relief of the product

1 Close the spray gun.

2 Close ball valve (2).

3 Relieve the system pressure, either by opening the gun or by opening the return

valve (3).

4 Close and secure gun.

5 Open and close the return valve (3) to completely depressurize the system.

Pressure relief of the air (in case of longer work interruptions)

1 Carry out pressure relief of the product (as mentioned above).

2 Ensure that the ball valve (2) is closed.

3 Pull back the ring on the safety valve (10) and hold it there until the pressure in the

air motor has been equalized.

10

10

B_04124

If the system has been used with 2K products:

2

NOTICE

Hardened working material in the spraying system when 2K product is processed!

Destruction of pump and injection system.

Follow the manufacturer‘s processing rules, particularly regarding the pot life.

Flush thoroughly before the end of the pot life.

The pot life is decreased by warmth.

37

Page 38

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

7.6 BASIC FLUSHING

Before each basic ushing, the nozzle must be removed from the gun. The data in the gun's operating manual

are to be observed.

With AirCoat systems, carry out the basic ushing of the system without atomizing air (8).

1. Visual check: personal safety equipment, grounding and all devices ready to use.

2. Place empty tank (5) under return tube (4).

3. Place suction hose (7) in the tank with ushing agent (6).

4. Open return valve (3).

5. Slowly open the ball valve (2).

6. Adjust the air pressure on the pressure regulator (1) so that the pump runs smoothly.

7. Flush the system until clean ushing agent ows into the tank (5).

8. Close ball valve (2).

9. Close return valve (3).

10. Point the gun (9), without nozzle, into tank (5) and open it.

11. Slowly open the ball valve (2).

12. Rinse until clean ushing agent ows from the gun.

13. Close ball valve (2).

14. Relieve the system pressure, either by opening the return valve (3) or via the trigger on the gun (9).

15. When there is no pressure remaining in the system, close the gun (9) or the return valve (3).

16. Secure the gun.

17. Dispose of the contents of the tank (5) according to the local regulations.

closed

open

1

8

2

Flush regularly

Regular ushing, cleaning and

maintenance ensures the pumps' high

pumping and suction capacity.

7

Hardener pumps in 2K systems

Do not ush hardener pumps with

water, rather only using suitable

3

ushing agents (solvents).

4

6

9

5

B_04079

38

Page 39

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

7.6.1 FILLING WITH WORKING MATERIAL

After basic ushing, the system can be lled with working material.

Proceed according to Chapter 7.6, but use working material instead of ushing agent.

39

Page 40

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

8 CLEANING AND MAINTENANCE

8.1 CLEANING

8.1.1 CLEANING STAFF

Cleaning work should be undertaken regularly and carefully by quali ed and trained sta .

They should be informed of speci c hazards during their training.

The following hazards may arise during cleaning work:

- Health hazard from inhaling solvent vapors

- Use of unsuitable cleaning tools and aids

8.1.2 SAFETY INSTRUCTIONS

Clean the piston pump only with a damp cloth.

Observe safety instructions in Chapter 4.

DANGER

Incorrect maintenance/repair!

Danger to life and equipment damage.

Only a WAGNER service center or a suitably trained person may

carry out repairs and replace parts.

Only repair and replace parts that are listed in the "Spare parts"

chapter and that are assigned to the unit.

Before all work on the device and in the event of work

interruptions:

- Relieve pressure from spray guns and devices.

- Secure spray guns against actuation.

- Switch o the energy/compressed air supply.

- Disconnect the control unit from the mains.

Observe the operating and service manual for all work.

40

Page 41

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

8.1.3 DECOMMISSIONING AND CLEANING

The device should be cleaned for maintenance purposes. Ensure that no remaining

product dries on and sticks to the device.

1. Carry out work interruption Chapter 7.5.

2. Carry out basic ushing in accordance with Chapter 7.6.

3. Empty the pump in a controlled manner in accordance with Chapter 8.2.6.

4. Maintain the gun according to the operating manual.

5. Clean and check the suction system and the suction lter.

6. When using a material lter, check lter insert and lter housing and clean or replace

them. Chapter 8.2.8.

7. Clean the outside of the system.

WARNING

Brittle lter pressure regulator!

The tank on the lter pressure regulator becomes brittle through

contact with solvents and can burst.

Flying parts can cause injury.

Do not clean the tank on the lter pressure regulator with

solvents.

8. Fully assemble the system.

9. Check ll level of the separating agent Chapter 8.2.4.

10. Fill the system with ushing agent in accordance with Chapter 8.2.7.

WARNING

Gas mixtures can explode if there is an incompletely filled

pump!

Danger to life from ying parts.

Ignition of potentially explosive surrounding atmosphere.

Ensure that the pump and suction system are always completely

filled with ushing agent or working material.

Do not spray the device empty after cleaning.

8.1.4 LONGTERM STORAGE

When storing the device for longer periods of time, it is necessary to thoroughly clean it

and protect it from corrosion. Replace the water or solvent in the product pump with a

suitable preservative, ll separating agent cup with separating agent.

Procedure:

1. Carry out points 1 to 9 of Chapter 8.1.3 "Decommission and clean".

2. Fill the system with preservative in accordance with Chapter 8.2.7.

3. Empty the pump in a controlled manner in accordance with Chapter 8.2.6 and seal the

openings.

41

Page 42

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

8.2 MAINTENANCE

8.2.1 MAINTENANCE STAFF

Maintenance work should be undertaken regularly and carefully by quali ed and trained

sta . They should be informed of speci c hazards during their training.

The following hazards may arise during maintenance work:

- Health hazard from inhaling solvent vapors

- Use of unsuitable tools and aids

An authorized person must ensure that the device is checked for being in a reliable state

after maintenance work is completed.

8.2.2 SAFETY INSTRUCTIONS

Observe the safety instructions in Chapter 4 and Chapter 8.1.2.

Prior to maintenance

It should be ensured that the device is in the following state before carrying out any work

on it:

- Release pressure from the pump, high-pressure hose and gun.

- The gun should be secured with the safety clip.

- The air supply should be interrupted.

After maintenance

- Commissioning in accordance with Chapter 6.6.

In accordance with DGUV regulation 100-500 (BGR 500 Chapter 2.29 and 2.36):

- The liquid ejection devices should be checked by an expert (e.g., WAGNER service

technician) for their safe working conditions as required and at least every

12months.

- For shut down devices, the examination can be suspended until the next start-up.

DANGER

Incorrect maintenance/repair!

Danger to life and equipment damage.

Repair or replacement of devices or parts of devices are only

allowed to be performed outside the hazard area by quali ed

personnel.

42

Page 43

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

8.2.3 REGULAR MAINTENANCE WORK

1. Check the level of separating agent in the separating agent cup every day, and top

up if necessary.

2. Check and clean the high-pressure lter every day or as required (see Chapter 8.2.8.).

3. Every shut down should be carried out as laid down in Chapter 8.1.3!

4. Check hoses, pipes, and couplings every day and replace if necessary.

If the pump has to be emptied for maintenance work, proceed according to

Chapter8.2.6.

The service manual is available in German and English.

For order number see Chapter 1.3.

8.2.4 FILLING SEPARATING AGENT

NOTICE

Piston pump dry run!

High wear/damage to the packings.

Paint or solvent can escape if the seals are dry.

Ensure that the separating uid tank is lled with su cient separating uid. Filling

level 1 cm; 0.4 inch under the cup edge.

Place the supplied separating agent into the separating agent cup.

Filling level: 1 cm; 0.4 inch under the cup edge.

Separating agent: Order no. 9992504

Inclination angle of the pump

Maximum permissible inclination of pump for moving, transportation,

etc. after lling it with separating agent ±30°.

The pump must be vertical during operation.

B_03918

43

Page 44

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

8.2.5 EMPTYING THE PUMP

WARNING

Gas mixtures can explode if there is an incompletely filled

pump!

Danger to life from ying parts.

Ignition of potentially explosive surrounding atmosphere.

Empty the device slowly and in a controlled manner.

Avoid potentially explosive atmosphere in the surroundings.

If the pumping product becomes heated, switch o all heaters and let the product

cool o .

1. Visual check: personal safety equipment, grounding and all devices ready to use.

2. Carry out basic ushing in accordance with Chapter 7.6.

3. Place grounded collection tank (5) under the return tube (4).

4. Place the suction hose (7) in an empty, grounded tank (6).

5. Close pressure regulator (1) (0MPa; 0bar; 0psi).

Empty using return line

6. Open return valve (3).

7. Slowly open the ball valve (2).

8. Slowly turn air pressure up on the pressure regulator (1) and only until the pump is

running normally (approx. 0.05 MPa; 0.5 bar; 7.25 psi).

9. Be ready for the switch from working material to air. Turn down pressure regulator

(1) far enough that the pump is still running normally (approx. 0–0.05MPa; 0–0.5bar;

0–7.25psi).

10. As soon as working material is no longer owing from the return tube (4), close ball

valve (2).

11. Close return valve (3).

Empty up to the gun

12. Point the gun, without nozzle, into tank (5) and open it.

13. Slowly open the ball valve (2). Be ready for the switch from working material to air.

14. As soon as working material is no longer owing from the return tube, close the ball

valve (2).

15. Close and secure gun.

16. Depressurization in accordance with Chapter 7.5.

17. Dispose of the contents of the tank (5) according to the local regulations.

44

Page 45

VERSION 12/2015

OPERATING MANUAL

closed

open

7

ORDER NUMBER DOC2333558

1

8

2

System example

EvoMotion 40-15 for the

AirCoat procedure.

3

4

6

9

5

B_04079

45

Page 46

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

8.2.6 FILLING THE EMPTY PUMP

Note:

Before each lling, the nozzle must be removed from the gun. The data in the gun's

operating manual are to be observed.

In case of AirCoat systems, carry out the lling of the system without atomizing air (8).

1. Place empty tank (5) under return tube (4).

2. Place suction hose (7) in the tank with working material (6).

3. Open return valve (3).

4. Slowly open the ball valve (2).

5. Adjust the air pressure on the pressure regulator (1) so that the pump runs

smoothly.

6. Spray until clean working material ows into the tank (5).

7. Close ball valve (2).

8. Close return valve (3).

9. Point the gun (9), without nozzle, into tank (5) and open it.

10. Slowly open the ball valve (2).

11. Spray until clean working material ows from the gun (9).

12. Close ball valve (2).

13. Relieve the system pressure, either by opening the return valve (3) or via the trigger

on the gun (9).

14. When there is no pressure remaining in the system, close the gun (9) or the return

valve (3).

15. Secure the gun.

16. Dispose of the contents of the tank (5) according to the local regulations.

46

Page 47

VERSION 12/2015

OPERATING MANUAL

closed

open

7

ORDER NUMBER DOC2333558

1

8

2

System example

EvoMotion 40-15 for the

AirCoat procedure.

3

4

6

9

5

B_04079

47

Page 48

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

8.2.7 PRODUCT HOSES, TUBES AND COUPLINGS

DANGER

Bursting hose, bursting threaded joints!

Danger to life from injection of product and from ying parts.

Ensure that the hose material is chemically resistant to the

sprayed products and the used ushing agents.

Ensure that the spray gun, threaded joints, and product hose

between the device and the spray gun are suitable for the

generated pressure.

Ensure that the following information can be seen on the hose:

- Manufacturer

- Permissible operating pressure

- Date of manufacture.

The service life of the complete hoses between product pressure generator and application

device is reduced due to environmental in uences even when handled correctly.

Check hoses, pipes, and couplings every day and replace if necessary.

Before every commissioning, check all connections for leaks.

Additionally, the operator must regularly check the complete hoses for wear and tear

as well as for damage at intervals that he/she has set. Records of these checks must

be kept.

Undamaged complete hoses are to be replaced when one of the two following

intervals has been exceeded:

– 6 years from the date of the hose crimping (see tting embossing).

– 10 years from the date of the hose imprinting.

Fitting

embossing

(if present)

xxx bar Pressure

yymm

XX Internal code

Meaning

Crimping date

(year/month)

Hose imprinting Meaning

WAGNER

yymm

xxx bar (xx MPa)

e.g., 270 bar (27

MPa)

XX Internal code

DNxx (e.g., DN10) Nominal diameter

Name /

Manufacturer

Date of

manufacture (year/

month)

Pressure

48

Page 49

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

9 TROUBLESHOOTING AND RECTIFICATION

Problem Cause Remedy

The pump does not

work

Poor spray pattern See the gun instructions.

Irregular operation of

the pump: spray jet

collapses (pulsation)

The pump runs

smoothly but does not

suck up any product

Pump runs when the

gun is closed

The air motor is iced upThere is a lot of condensation water

Air motor does not work or stops. Open and close ball valve on the pressure

regulator unit or brie y disconnect

compressed air supply.

No pressure indication on the

pressure gauge (air pressure

regulator defective).

Spray nozzle is clogged. Clean the nozzle according to the

Insu cient compressed air supply. Check compressed air supply.

Filter insert in spray gun is clogged. Clean the parts and use a suitable working

Fluid section or high-pressure

hose are blocked (e.g., 2K product

hardened).

Sometimes, the pump stops at a

switching point.

Viscosity is too high. Thin spraying product.

Spraying pressure is too low. Increase incoming air pressure.

Valves are clogged. Clean pump, if necessary leave it to soak in

Foreign body in suction valve. Dismantle suction valve housing, clean and

Diameter of compressed air line too

small.

Valves, packings, or pistons are worn

out.

Pressure regulator lter is clogged. Check lter and clean it if necessary.

The suction system's union nut is

loose; the pump is taking in air.

Suction lter is clogged. Clean lter.

Ball in suction or piston valve is stuck. Clean balls and valve seats.

Packings, valves, or pistons are worn

out.

in the air supply.

Disconnect compressed air supply brie y or

repair or change pressure regulator.

instructions.

material.

Dismount and clean uid section, replace

high-pressure hose.

Press the starter on the reverse valve and

restart the pump.

Clean the slide on the reversing valve

carefully and if necessary lubricate it with a

light layer of oil.

Use a smaller nozzle.

solvent.

check valve seat.

Assemble a larger incoming line

-> Technical Data, Chapter 5.3.2.

Replace the parts.

Tighten union nut.

Replace the parts.

Install a water separator.

If none of the causes of malfunction mentioned are present, the defect can be remedied by a WAGNER Service

Center.

49

Page 50

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

10 REPAIR

10.1 REPAIR PERSONNEL

Repair work should be undertaken carefully by quali ed and trained personnel. They

should be informed of speci c hazards during their training. The repairs must be carried

out in accordance with the corresponding service manual.

The following hazards may arise during repair work:

- Health hazard from inhaling solvent vapors

- Use of unsuitable tools and aids

A skilled person must check to ensure that the device is in a reliable state after it is repaired.

10.2 MOUNTING MATERIALS

In Chapter 13 the order numbers for device spare parts can be found, as well as for wearing

parts such as seals.

Use torques, greases and glues in accordance with Chapter 13.

Mounting materials

Order No. Quantity Designation Smaller tanks

9992590 1 pc ≙ 50 ml Loctite 222

9992511 1 pc ≙ 50 ml Loctite 243

9992528 1 pc ≙ 50 ml Loctite® 270

9992831 1 pc ≙ 50 ml Loctite 542

9998808 1 pc ≙ 18 kg ! Mobilux EP 2 grease 400 g tube ≙ Order no. 2355418

9992616 1 pc ≙ 1 kg can Molykote DX grease 50 g tube ≙ Order no. 2355419

9992609 1 pc ≙ 100 g Anti-seize paste

9992816 1 pc ≙ 70 g Miranit contact adhesive

Brand notice

The brands speci ed in this document are property of the respective owners. Loctite , for

example, is a registered brand of Henkel.

50

Page 51

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

11 DISPOSAL

When the equipment must be scrapped, please di erentiate the disposal of the waste

materials.

The following materials have been used:

Steel Aluminum Plastics Carbide

Consumable products

Consumable products (lacquers, adhesives, ushing and cleaning agents) must be

disposed of in accordance with all applicable legal requirements.

51

Page 52

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

12 ACCESSORIES

12.1 EVOMOTION 4015 ACCESSORIES

Order No. Designation

1 2329450 EvoMotion 40-15 PE/T

2 T6145.00A AirCoat regulator set

3 236219 Grounding cable, complete 3 m; 9.8 ft

4 9992504 Separating agent 250 ml

5 9992505 Separating agent 500 ml

= Wearing part

12.2 ACCESSORIES FOR PRODUCT OUTLET

Order No. Designation

11 2334488 Ball valve R1/4"-G1/4"-PN350-SSt

12 2334472 Ball valve R1/4"-G1/4"-PN350-CS

13 2331752 Return tube DN6-G1/4"-100mm-PA

14 2329046 Return hose DN6-PN310-G1/4"-PA

= Wearing part

12.3 ACCESSORIES FOR PRODUCT INLET

Order No. Designation

15 2324158 Suction tube DN16-SSt, complete

16 2324110 Suction hose DN16-SSt, complete

17 2323225 Suction elbow for top reservoir SSt

18 2332169 Top reservoir set, 5 l for piston pump

19 2323396 Suction lter DN16-18mesh-SSt

Wearing part

52

Page 53

VERSION 12/2015

OPERATING MANUAL

ORDER NUMBER DOC2333558

3

14

11

x

1

12

13

x

4/5

2

15

18

16

17

19

B_04081

53

Page 54

VERSION 12/2015

OPERATING MANUAL

ORDER NUMBER DOC2333558

54

Page 55

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

12.4 WALL MOUNT AND TROLLEY

Order No. Designation

21 2332143 Wall mount 4", complete

22 2332374 4-leg stand

23 T6196.00 Trolley, 4 wheels

24 2325901 Trolley 4", complete

22

21

23

24

B_04113

55

Page 56

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

13 SPARE PARTS

Observe "Repair" chapter: Repair personnel and mounting materials.

DANGER

Incorrect maintenance/repair!

Danger to life and equipment damage.

Only a WAGNER service center or a suitably trained person may

carry out repairs and replace parts.

Only repair and replace parts that are listed in the "Spare parts"

chapter and that are assigned to the unit.

Before all work on the device and in the event of work

interruptions:

- Relieve pressure from spray guns and devices.

- Secure spray guns against actuation.

- Switch o the energy/compressed air supply.

- Disconnect the control unit from the mains.

Observe the operating and service manual for all work.

13.1 HOW CAN SPARE PARTS BE ORDERED?

Always supply the following information to ensure delivery of the right spare part:

Order number, designation and quantity

The quantity need not be the same as the number given in the quantity column " " on

the list. This number merely indicates how many of the respective parts are used in each

component.

The following information is also required to ensure smooth processing of your order:

- Address for the invoice

- Address for delivery

- Name of the person to be contacted in the event of any queries

- Type of delivery (normal mail, express delivery, air freight, courier, etc.)

Identi cation in spare parts lists.

Explanation of column "

Wearing parts

Note: These parts are not covered by warranty terms.

Not part of standard equipment, available, however, as additional extra.

" (labeling) in the following spare parts lists:

56

Page 57

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

13.2 OVERVIEW OF THE COMPONENTS

Order No. Designation

1 1 2329450 EvoMotion 40-15 PE/T

2 1 2329635 Fluid section 15 PE/T EM

3 1 U3B08018060 Air motor M80 EM

4 1 A359.71A Spacer

5 1 E516.71A Safety xture spacer

6 2 9900353 Hexagon socket cylinder head screw

7 1 2332394 Holder plate

8 4 9920106 Washer

9 4 9900330 Hexagon socket cylinder head screw

10 3 3055157 Hexagon nut with clamp

11 3 H115.62 Tie rod

12 1 T6140.00A Pump air regulator set

13 1 9998253 Male stud elbow 8-1/4

13

12

3

7

8

20 Nm; 14.7 lbft

1

9

4

6

5

11

2

10

30 Nm; 22.1 lbft

B_04135

57

Page 58

VERSION 12/2015

OPERATING MANUAL

13.3 AIR MOTOR

Incorrect maintenance/repair!

Danger to life and equipment damage.

Only a WAGNER service center or a suitably trained person may

Only repair and replace parts that are listed in the "Spare parts"

Before all work on the device and in the event of work

- Relieve pressure from spray guns and devices.

- Secure spray guns against actuation.

- Switch o the energy/compressed air supply.

- Disconnect the control unit from the mains.

Observe the operating and service manual for all work.

ORDER NUMBER DOC2333558

DANGER

carry out repairs and replace parts.

chapter and that are assigned to the unit.

interruptions:

Air motor spare parts list EM M80

Order No. Designation

1 1 U3B08018060 Air motor EM M80

2 1 F132.91C Motor ange, upper, M50 EM

3 2 L108.06 O-ring

4 1 D608.81 Cylinder motor

5 1 3055157 Hexagon nut with clamp

6 1 9920106 Washer

7

8 1 L413.06 Gasket DE 80

9 1 A164.01 Motor piston

10 1 L802.08 Sliding ring

11 1 L110.06 O-ring

12 1 D404.12 Piston rod, M80 EM

13

14 1 A408.12 Air tube, M80 EM

15 1 T616.00C Motor ange, complete M80 EM, at bottom

16

17 1 367258 Grounding, complete

18

19

20 2 K606.02 Lock washer for shaft

21 1 A160.01A Washer

= Wearing parts

= Included in service set.

= Not part of the standard equipment but available as an accessory.

2 G903.06 Steamer

2 L109.06 O-ring

1 P498.00KNE Reversing valve ISO N/1 (spare parts list see

Chapter 11.3.1.)

1 L403.06 Rod seal

1 2339340 Sensor below, M80

58

Page 59

VERSION 12/2015

OPERATING MANUAL

ORDER NUMBER DOC2333558

30 Nm; 22 lbft

28

2

3

29

4

5

6

7

35 Nm; 25.8 lbft

30

29

8

9

29

13

30

7

29

1

10

11

13

4.5 Nm; 3.3 lbft

14

29

3

29

17

B_03431

27

20 Nm; 14.7 lbft

29

18

15

22

12

20

16

24

19

27

25

23

Installation instructions:

Mount piston rod (12) always

from bottom to top by the

assigned rod seal (18).

21

20

59

Page 60

VERSION 12/2015

ORDER NUMBER DOC2333558

OPERATING MANUAL

Air motor spare parts list EM M80

Order No. Designation

22 1 2341115 Pilot valve

23 1 9992757 Threaded elbow tting

24 2 H505.07 Silencer

25 1 M432.00 Reducing tting

27 1 9992831 Loctite® 542

28 4 9907241 Hexagon socket cylinder head screw

29 1 9998808 Mobilux® EP 2 grease

30 1 9998157 Loctite® 480

1 T910.00 Service set EM Air motor M80

= Wearing parts

= Included in service set.

= Not part of the standard equipment but available as an accessory.

60

Page 61

VERSION 12/2015

OPERATING MANUAL

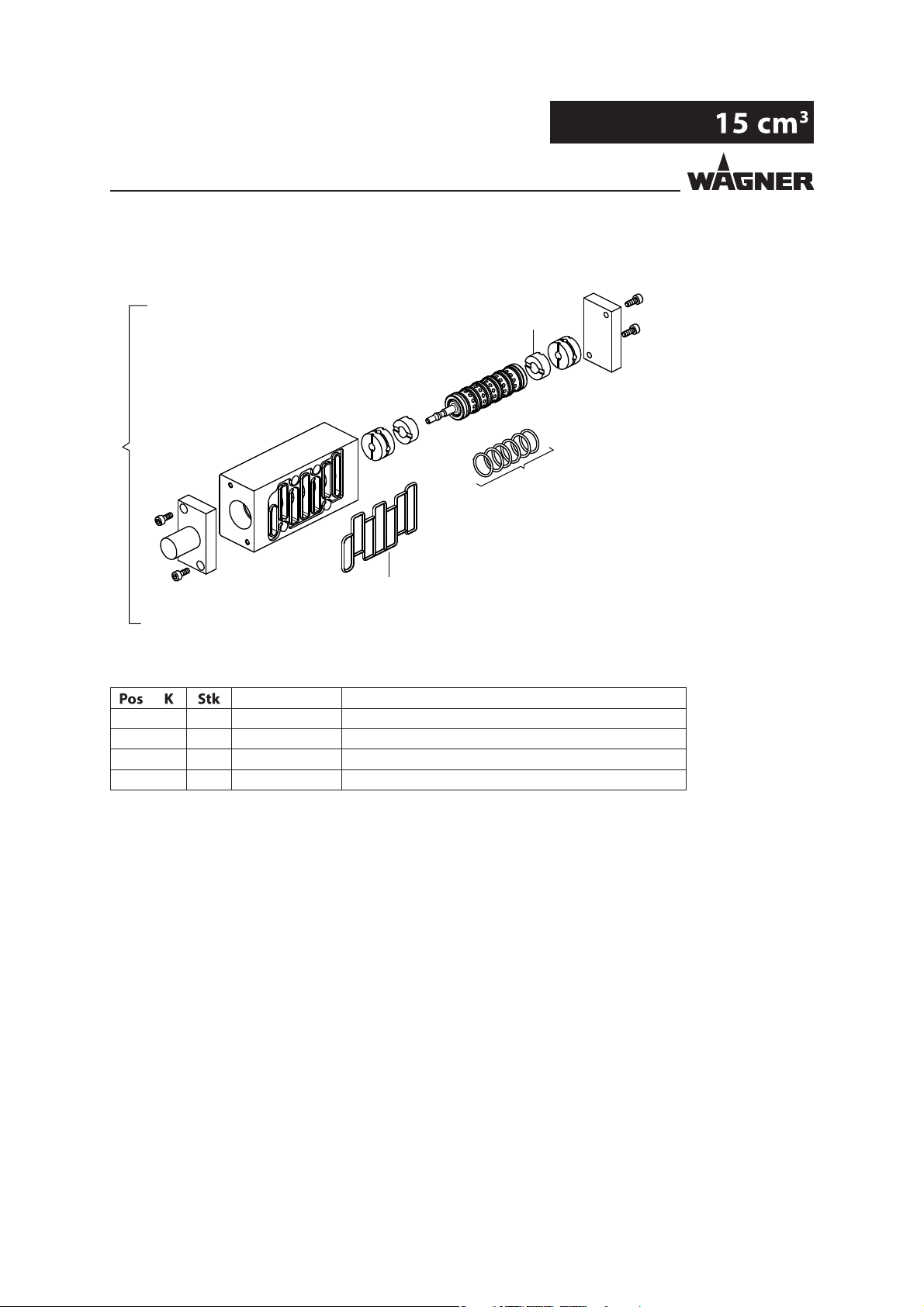

13.3.1 REVERSING VALVE

1

ORDER NUMBER DOC2333558

4

2

3

B_03139

Spare parts list for the reversing valve, 40-15

Order No. Designation

1 1 G498.00 Reversing valve

2 6 9971123 O-ring

3 1 G521.00 Reversing valve gasket

4 2 G520.00 Steamer

61

Page 62

VERSION 12/2015

OPERATING MANUAL

13.4 FLUID SECTION 15

Incorrect maintenance/repair!

Danger to life and equipment damage.

Only a WAGNER service center or a suitably trained person may

carry out repairs and replace parts.

Only repair and replace parts that are listed in the "Spare parts"

chapter and that are assigned to the unit.

Before all work on the device and in the event of work

interruptions:

- Relieve pressure from spray guns and devices.

- Secure spray guns against actuation.

- Switch o the energy/compressed air supply.

- Disconnect the control unit from the mains.

Observe the operating and service manual for all work.

ORDER NUMBER DOC2333558

DANGER

Spare parts list for uid section 15

No. Designation

1 1 2329635 Fluid section 15 SS PE/T EM

2 1 A661.12 Connecting ange 15

3 1 K617.03 Snap ring

4 1 A662.12 Snap ring ange 15

5

6 1 H204.03 Spring, upper

7 1 A658.03 Tube 15

8 1 H203.03 Spring

9

10 2 L107.06 O-ring

11 1 B534.03 Cylinder 15

12 1 T6157.00I Piston 15 SS

13 1 A170.03 Support spring

14 1 K801.03 Ball

15 1 A169.03 Valve screw 15

16 1 K803.03 Ball

17 1 K601.03 Securing ring

18 1 2323838 Inlet housing 15

19 1 9992831 Loctite 542

20 1 A171.03 Support ring, outside

21 1 A172.03 Support ring, inside

22 1 A411.03 Support ring, inside

23 1 A410.03 Support ring, outside

= Wearing parts

= Included in service set.

= Not part of the standard equipment but available as an accessory.

1 T9037.00E Packing PE/T 13/25

1 T9038.00E Packing PE/T 18/29

62

Page 63

VERSION 12/2015

OPERATING MANUAL

ORDER NUMBER DOC2333558

24

30 Nm; 22.1 lbft

25

25

22

8

26

26

9

29

36

2.5 Nm; 1.84 lbft

2

30

3

30

4

23

20

27

28

27

28

30