Page 1

9

Translation of the Original

Operating and Assembly

Manual

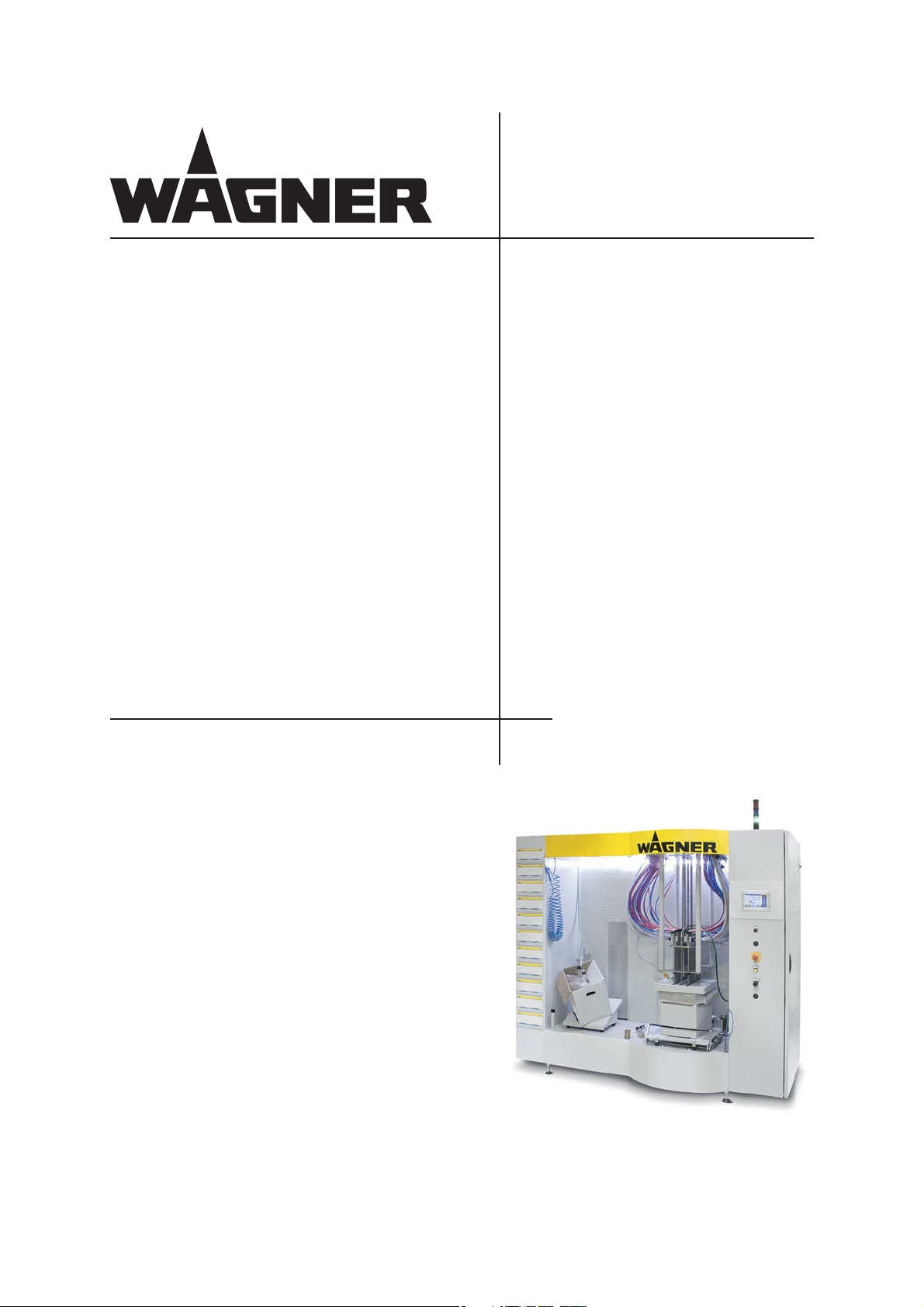

PXM

Powder Center

Version 08 / 2015

P_02519P_0251

Page 2

Page 3

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

Table of Contents

1 ABOUT THESE INSTRUCTIONS 7

1.1 Preface 7

1.2 Warnings, Notices, and Symbols in this Operating Manual 7

1.3 Languages 8

1.4 Abbreviations 8

1.5 Terminology for the Purpose of this Manual 9

2 CORRECT USE 10

2.1 Device Type 10

2.2 Type of Use 10

2.3 Use in Potentially Explosive Areas 10

2.4 Safety Parameters 10

2.5 Processible Working Materials 11

2.6 Reasonably Foreseeable Misuse 11

2.7 Residual Risks 11

PXM

3 IDENTIFICATION 12

3.1 Explosion Protection Identi cation 12

3.2 Permissible Device Combinations 12

3.3 Type Plate 12

3.4 Note on the Ex-Zone Classi cation by the Operator 13

4 GENERAL SAFETY INSTRUCTIONS 14

4.1 Safety Instructions for the Operator 14

4.1.1 Electrical Devices and Equipment 14

4.1.2 Personnel Quali cations 14

4.1.3 Safe Work Environment 14

4.2 Safety Instructions for Sta 15

4.2.1 Safe Handling of WAGNER Powder Spray Devices 15

4.2.2 Grounding the Device 15

4.2.3 Product Hoses 15

4.2.4 Cleaning 16

4.2.5 Handling Powder Lacquers 16

5 DESCRIPTION 17

5.1 Components 17

5.1.1 Version with Integrated Filter 18

5.1.2 Version for Final Filter 19

5.1.2 Version with Ultrasonic Sieve 20

5.2 Mode of Operation 21

5.3 Protective and Monitoring Equipment 21

5.4 Scope of Delivery 22

5.4.1 Design Variants of the PXM Powder Center 22

5.4.2 Type with Ultrasonic Screening Unit 23

5.4.3 Installation Dimensions for Ultrasonic Screening Unit 23

5.5 Technical Data 24

5.6 Controls 25

5.7 Screen Layout of the Touch Screen 26

5.8 Explanation of the Screen Page Numbers 27

5.9 Inputs on the Touch Panel 28

3

Page 4

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

Table of Contents

5.10 Displays on the Warning Lamp 28

5.11 User Rights 29

6 ASSEMBLY AND COMMISSIONING 30

6.1 Training the Assembly Sta 30

6.2 Storage Conditions 30

6.3 Installation Conditions 30

6.4 Transportation 31

6.5 Assembly and Installation 32

6.6 Grounding 37

6.7 Safety Checks 37

6.8 Commissioning 38

6.9 Standard Settings 39

6.9.1 Machine Parameters Operation 39

6.9.2 Machine Parameter Cleaning 40

6.9.3 CAN Addresses for MCM System 41

6.9.4 EPG S2 Settings 42

6.10 Function Test 44

PXM

7 OPERATION 46

7.1 Training the Operating Sta 46

7.2 Safety Instructions 46

7.3 Touch Screen Operation Standard Equipment 47

7.3.1 Equipment with Final Filter 47

7.3.2 Equipment with Integrated Exhaust System 48

7.4 Set Language 49

7.5 Logging a User On/O 50

7.6 Starting/Stopping Coating 51

7.6.1 Paint Change Components 52

7.6.2 Cleaning Positions Powder Hoses 53

7.7 Con guring the Powder Center 54

7.7.1 Settings 55

7.7.2 Machine Parameters Operation 56

7.7.3 Machine Parameter Cleaning 62

7.7.4 Machine Parameters Diagnosis 64

7.7.5 System 66

8 CLEANING AND MAINTENANCE 69

8.1 Cleaning 69

8.1.1 Cleaning Sta 69

8.1.2 Safety Instructions 69

8.2 Paint Change 70

8.2.1 Paint Change Components 70

8.2.2 Cleaning Positions Powder Hoses 71

8.2.3 Cleaning Functions 72

8.2.4 Cleaning Parameters 72

8.2.5 Start Cleaning (Example: Pro Tech M) 73

8.2.6 Cleaning/Paint Change on the PXM with Ultrasonic Sieve 82

8.3 Maintenance 85

8.3.1 Maintenance Sta 85

8.3.2 Safety Instructions 85

4

Page 5

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

Table of Contents

8.3.3 Maintenance Procedures 86

8.3.4 Safety Checks 87

8.3.4.1 Grounding Check 87

9 TROUBLESHOOTING AND RECTIFICATION 88

9.1 Fault Messages 88

9.2 Types of Fault Messages 89

9.3 Current 89

9.4 History 90

10 REPAIR 93

10.1 Repair Personnel 93

10.2 Safety Instructions 93

11 FUNCTION TEST AFTER THE REPAIR 95

12 INSPECTIONS IN ACCORDANCE WITH DIN EN 50177: 2010 96

PXM

13 DISASSEMBLY AND DISPOSAL 99

14 ACCESSORIES 100

15 SPARE PARTS 103

15.1 How Can Spare Parts Be Ordered? 103

15.2 Workstation 22 Injectors 104

15.3 Workstation 20 Injectors with Fluidization 106

15.3 Workstation 34 Injectors 108

15.4 Cylinder Workstation (22 Injectors) 110

15.5 Cylinder Workstation (34 Injectors) 111

15.6 Scraper Assembly Intake Tubes 112

15.7 Cleaning System Tank Version (22 Injectors) 114

15.8 Cleaning System Box Version (22 Injectors) 116

15.9 Vibration Table 118

15.10 Feed lance 120

15.11 Vibrating Table Fresh Powder 122

15.12 Compressed Air Tank for 22 Injectors (1 Outlet) 123

15.13 Compressed air tank for 22 injectors 124

15.14 Compressed Air Tank for 34 Injectors 125

15.15 Pressure Regulator, Complete 126

15.12 Powder Tank, Fluidized (22 Injectors) 127

15.13 Final Filter Adapter 128

15.14 Exhaust System Throttle Valve 130

15.15 Exhaust system throttle valve (version with US sieve) 132

15.16 Housing 134

15.17 Control Unit Cabinet (1 IP 5000) 136

15.18 Control Unit Cabinet (2 IP 5000) 138

15.19 Control Unit Cabinet (18 EPG) 140

15.20 Control Unit Cabinet Control Panel 142

15.21 LED Lamp 1500 143

15.22 LED Lamp 700 144

15.23 Final Filter 145

15.24 PI-F1 Powder Injector 147

15.25 PI-P1 Powder Injector 148

5

Page 6

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

Table of Contents

15.26 HiCoat-ED Pump P 149

15.27 HiCoat-ED Pump F 150

15.28 Fresh Powder Feed Unit 151

15.29 Ultrasonic Screening Unit 152

15.30 Level Sensor 153

16 WARRANTY DECLARATION AND DECLARATION OF INCORPORATION 154

16.1 Important Notes Regarding Product Liability 154

16.2 Warranty Claim 154

16.3 Declaration of Incorporation (Statement of Conformity) 155

17 ELECTRICAL CONNECTION PLANS 158

PXM

6

Page 7

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

1 ABOUT THESE INSTRUCTIONS

1.1 PREFACE

The operating manual contains information about safely operating, maintaining, cleaning

and repairing the device.

The operating manual is part of the device and must be available to the operating and

service personnel.

The device may only be operated by trained personnel and in compliance with this

operating manual.

Operating and service personnel should be instructed according to the safety instructions.

This equipment can be dangerous if it is not operated according to the instructions in this

operating manual.

PXM

1.2 WARNINGS, NOTICES, AND SYMBOLS IN THIS OPERATING MANUAL

Warning instructions in this operating manual highlight particular dangers to users and to

the device and state measures for avoiding the hazard. These warning instructions fall into

the following categories:

Danger - immediate risk of danger.

Non-observance will result in death or serious injury.

Warning - possible imminent danger.

Non-observance may result in death or serious injury.

Caution - a possibly hazardous situation.

Non-observance may result in minor injury.

DANGER

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions.

The signal word indicates the hazard level.

The measures for preventing the danger and its consequences.

WARNING

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions.

The signal word indicates the hazard level.

The measures for preventing the danger and its consequences.

CAUTION

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions.

The signal word indicates the hazard level.

The measures for preventing the danger and its consequences.

Notice - a possibly hazardous situation.

Non-observance may result in damage to property.

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions. The signal word

indicates the hazard level.

The measures for preventing the danger and its consequences.

NOTICE

Note - provides information about particular characteristics and how to proceed.

7

Page 8

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

1.3 LANGUAGES

The operating manual is available in the following languages:

Language: Order No. Language: Order No.

German 2350371 English 2350372

French 2361466 Italian 2361468

Spanish 2361471 Russian 2361472

Chinese 2361473

1.4 ABBREVIATIONS

Number of pieces

Position

Marking in the spare parts lists

Order No. Order number

Spare part

FP Fresh powder

RP Reclaimed powder

Version with integrated suction

Version with nal lter

PXM

8

Page 9

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

1.5 TERMINOLOGY FOR THE PURPOSE OF THIS MANUAL

Cleaning Manual cleaning of devices and device parts with cleaning agent

Flushing Internal ushing with compressed air of parts carrying paint

Sta quali cations

Trained person Is instructed in the tasks assigned to him/her, the potential risks

associated with improper behavior as well as the necessary

protective devices and measures.

Electrically trained

person

Electrician Can assess the work assigned to him/her and detect possible

Skilled person A person, who, based on his/her technical training, experience

In accordance with

TRBS 1203 (2010)

Is instructed by an electrician about the tasks assigned to him/her,

the potential risks associated with improper behavior as well as

the necessary protective devices and measures.

hazards based on his/her technical training, knowledge and

experience in relevant provisions.

and recent vocational experience, has su cient technical

knowledge in the areas of explosion protection, protection

from pressure hazards and electric hazards (if applicable) and

is familiar with the relevant and generally accepted rules of

technology so that he/she can inspect and assess the status of

devices and coating systems based on workplace safety.

PXM

9

Page 10

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

2 CORRECT USE

2.1 DEVICE TYPE

Powder center for feeding uidized powder lacquers

2.2 TYPE OF USE

The PXM powder center is used to feed uidized powder lacquers from a powder tank

(including original tank) to several guns at the same time.

PXM

2.3 USE IN POTENTIALLY EXPLOSIVE AREAS

The PXM powder center is intended for construction outside of the dust Ex-zone (Zone 22).

2.4 SAFETY PARAMETERS

WAGNER accepts no liability for any damage arising from incorrect use.

Use the device only to work with the products recommended by WAGNER.

Operate only the device as a whole.

Do not deactivate safety xtures.

Use only WAGNER original spare parts and accessories.

The device may only be operated under the following conditions:

The operating personnel must be trained on the basis of this operating manual.

The safety regulations listed in this operating manual must be observed.

The operating, maintenance and repair information in this operating manual must be

observed.

The statutory requirements and accident prevention regulation standards in the country

of use must be observed.

The powder center may only be used if all parameters are set and all measurements/safety

checks are carried out correctly.

10

Page 11

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

2.5 PROCESSIBLE WORKING MATERIALS

Electrostatically charged powder types

Metallic powder

2.6 REASONABLY FORESEEABLE MISUSE

Use of damp powder lacquer

Working with liquid coating products

Use of defective components and accessories

Use for foodstu s

PXM

2.7 RESIDUAL RISKS

Residual risks are risks which cannot be ruled out even in the event of correct use.

If necessary, warning and prohibition signs at the relevant points of risk indicate residual

risks.

Residual risk Source Consequences Speci c measures Lifecycle phase

Skin contact with

powder lacquers

and cleaning agents

Powder lacquer

in air outside the

de ned working

area

Noise Exhaust system Hearing damage Wear ear protection Operation

Handling powder

lacquers and

cleaning agents

Lacquering outside

the de ned working

area

Blowing-out system Cleaning

Skin irritations, Wear protective

clothing

allergies Observe safety data

sheets

Inhalation of

substances

hazardous to health

Observe work and

operation instructions

Operation,

maintenance,

disassembly

Operation,

maintenance

11

Page 12

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

3 IDENTIFICATION

3.1 EXPLOSION PROTECTION IDENTIFICATION

The PXM powder center is intended for construction outside of the dust Ex-zone (Zone 22).

3.2 PERMISSIBLE DEVICE COMBINATIONS

The following components may be used in the PXM powder center:

PI-F1 injector

Hi-Coat ED injector

Ultrasonic screening device (version for PXM with replaceable lter)

IP 5000 powder pump

EPG S2 control unit

EPG-Sprint X control unit

MCC controller

MCS 1 controller

CPD 1

PXM

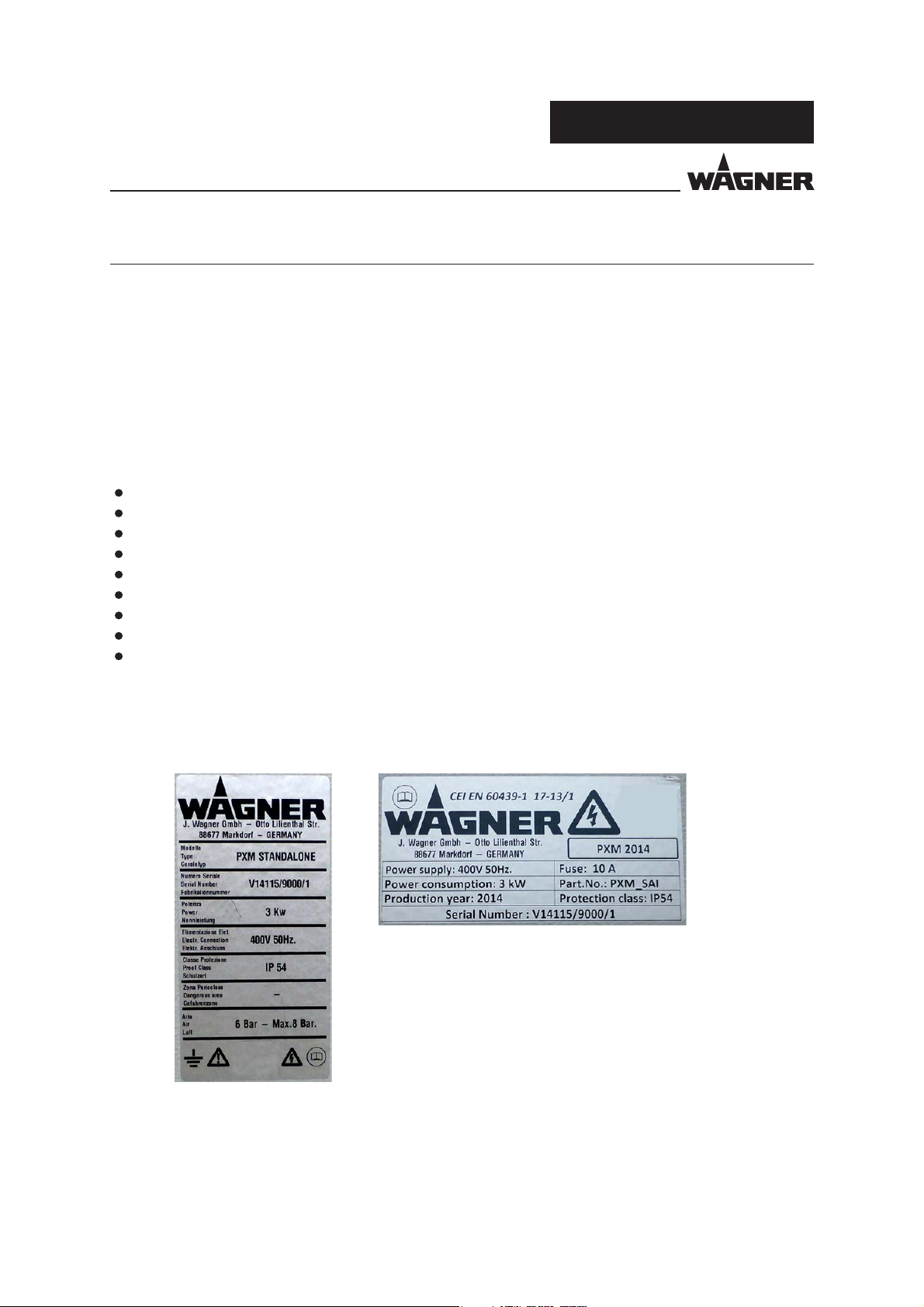

3.3 TYPE PLATE

Powder center Control cabinet

P_02628

P_02627

Note:

The type plate may only be attached with the CE mark if the complete installation

(powder center, controller, add-on parts, etc.) complies with the provisions of the

EC directives.

12

Page 13

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

3.4 NOTE ON THE EXZONE CLASSIFICATION BY THE OPERATOR

Decreased intrinsic emission is used by the PXM powder center to create a reduced zone

extension as compared to classi cation and presentation as per EN 12981 (version 2010/06)*

and BGI 764 (version 2009/10, as per 2014/02)*.

The permanent openings are facilitated. It is ensured by design and construction.

Therefore, operation is permitted only upon compliance with all the following requirements:

– The minimum air extraction rate corresponds to the operating manual and is ensured

– The powder center can only be operated when technical ventilation equipment is

active (interlock with exhaust air)

– The open box is not uidized, the uidized box is only operated with "cover for box"

– The uidized tank is closed with "cover for uidized tank"

– The powder hoses and connections are airtight

– Necessary cleaning times are kept short

– The notes in the operating manual on safe operation are being observed.

PXM

Compliance with all the requirements and measures results in no relevant powder

discharge. The zone extension caused by the powder center can be seen in the following

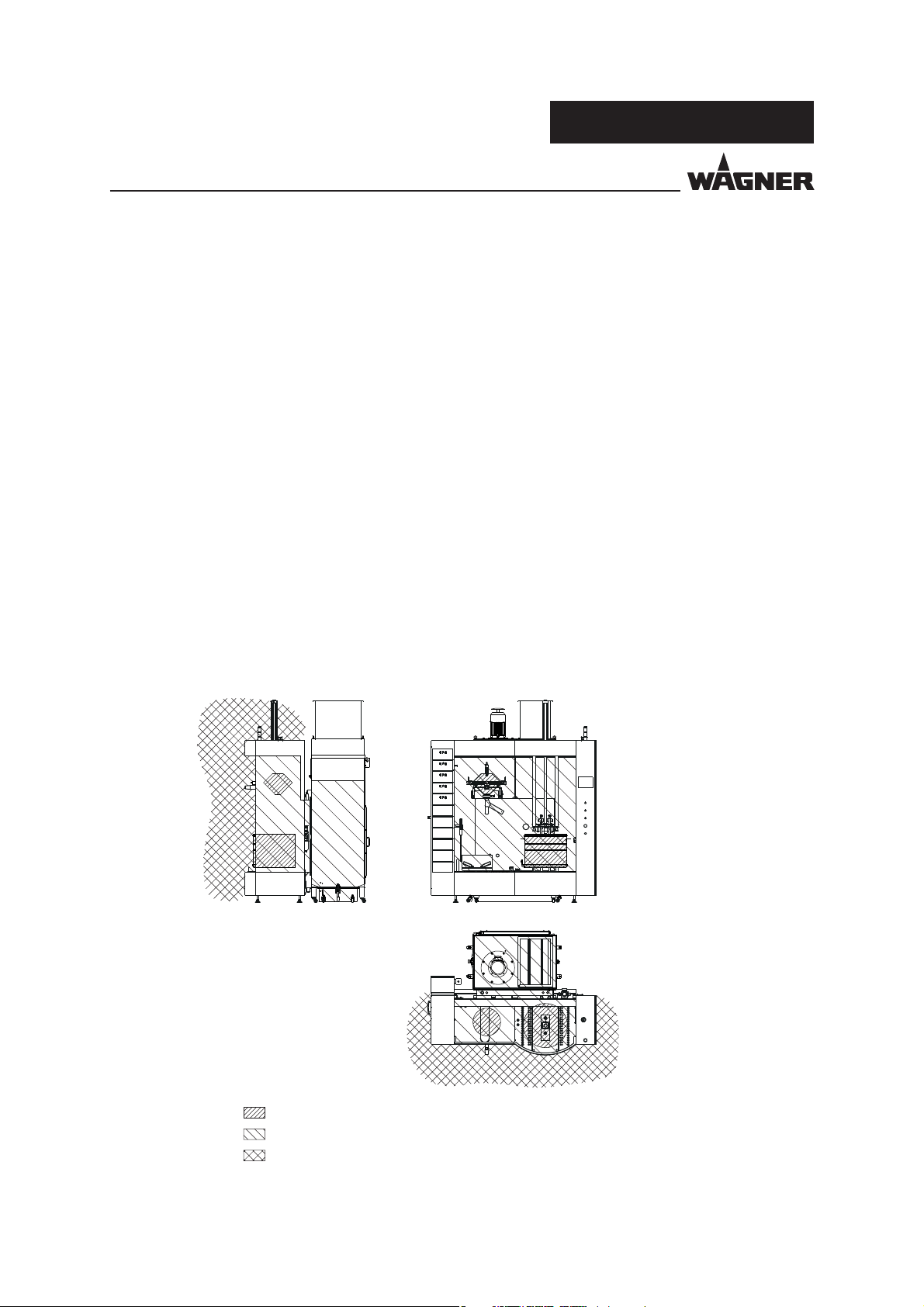

images:

P_02590

Zone 20 in the tank and in the sieve chamber of the ultrasonic sieve

Zone 22 within the powder center

No zone caused by the powder center

* The EU standard and BG information are being revised. The exemptions shall be taken

into account in future versions.

13

Page 14

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

4 GENERAL SAFETY INSTRUCTIONS

4.1 SAFETY INSTRUCTIONS FOR THE OPERATOR

Keep this operating manual on hand near the device at all times.

Always follow local regulations concerning occupational safety and accident prevention.

4.1.1 ELECTRICAL DEVICES AND EQUIPMENT

To be provided in accordance with the local safety requirements with regard to the

operating mode and ambient in uences.

May only be maintained by skilled electricians.

Must be operated in accordance with the safety regulations and electrotechnical

regulations.

Must be repaired immediately in the event of problems.

Must be decommissioned if they pose a hazard.

Must be de-energized before work is commenced on active parts.

Secure the device against being switched back on without authorization. Inform sta

about planned work.

Observe electrical safety regulations.

PXM

4.1.2 PERSONNEL QUALIFICATIONS

Ensure that the device is only operated, maintained and repaired by trained persons.

4.1.3 SAFE WORK ENVIRONMENT

The oor in the working area must be electrostatically conductive (measurements

according to EN 1081).

Make sure that all persons within the working area are wearing electrostatic-conductive

shoes.

Ensure that gloves worn are made of conductive material.

The powder release must be electrically interlocked with the powder spray system's

exhaust air equipment.

Excess coating product (overspray) must be collected up safely.

Ensure that there are no ignition sources such as naked ames, sparks, glowing wires,

or hot surfaces in the vicinity. Do not smoke.

Maintain su cient quantities of suitable re extinguishers and ensure that they are

serviceable.

The operating company must ensure that an average concentration of powder lacquer

in the air does not exceed 50% of the lower explosion limit (LEL = max. permitted

concentration of powder to air). If no reliable LEL value is available, the average

concentration must not exceed 10 g/m³.

14

Page 15

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

4.2 SAFETY INSTRUCTIONS FOR STAFF

Always follow the information in this manual, particularly the general safety instructions

and the warning instructions.

Always follow local regulations concerning occupational safety and accident

prevention.

Under no circumstances may people with pacemakers enter the area where the

high-voltage eld between the spray gun and the work piece to be coated builds up!

4.2.1 SAFE HANDLING OF WAGNER POWDER SPRAY DEVICES

Do not point spray guns at people.

Before all work on the device, in the event of work interruptions and functional faults:

- Switch o the energy/compressed air supply.

- Secure the spray gun against actuation.

- Relieve pressure on spray gun and device.

- In case of functional faults: Identify and correct the problem, proceed as described

in the "Fault Recti cation" chapter.

PXM

4.2.2 GROUNDING THE DEVICE

The electrostatic charge may, in certain cases, give rise to electrostatic charges on the

device. This may result in the formation of sparks or ames when discharging.

Ensure that the device is grounded before each coating process.

Ground the work pieces to be coated.

Make sure that all persons inside the working area are grounded, e.g., that they are

wearing electrostatically conductive shoes.

The functionality of grounding cables must be checked regularly (see EN 60204).

4.2.3 PRODUCT HOSES

Only use an original WAGNER powder hose.

15

Page 16

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

4.2.4 CLEANING

Before starting cleaning or any other manual work, the high-voltage in the spray area

must be shut down and locked to prevent it from being switched back on.

Lock the compressed air supply and decompress the device.

Secure the device against being switched back on without authorization.

Use only electrically conducting and grounded tanks for cleaning uids.

Preference should be given to non- ammable cleaning uids.

Flammable cleaning liquids may only be used if, after switching o the high-voltage,

all high-voltage conducting parts are discharged to a discharge energy of less than

0.24 mJ before they can be accessed.

Most ammable solvents have an ignition energy of around 0.24 mJ or 60 nC.

The cleaning agent's ash point must be at least 15 K above the ambient temperature.

Only mobile industrial vacuum cleaners of design 1 (see EN 60335-2) may be used to

remove dust deposits.

PXM

4.2.5 HANDLING POWDER LACQUERS

When preparing or processing the powder and cleaning the device, take note of the

processing regulations laid down by the manufacturer of the powder lacquers being

used.

Take note of the manufacturer’s instructions and the relevant environmental protection

regulations when disposing of powder lacquers.

Implement the prescribed safety measures, in particular the wearing of safety glasses

and safety clothing as well as the use of protective hand cream.

Use a mask or breathing apparatus if necessary.

To ensure su cient protection of health and the environment, only operate the device

in a powder booth or on a spray wall with activated ventilation (exhaust air).

16

Page 17

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

5 DESCRIPTION

5.1 COMPONENTS

PXM

2

1

P_02520

6789

1 Rack for EPG control units

2 Warning lamp with built-in alarm horn

3 Control cabinet with operating elements

4 Reciprocator with powder injectors and intake systems

5 Level sensor

6 Holder for box or container

7 Cleaning station for reclaimed powder; park station for loss mode of operation

8 Fresh powder supply

9 Cleaning position for fresh powder lance

3

4

5

17

Page 18

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

5.1.1 VERSION WITH INTEGRATED FILTER

10

PXM

11

P_02521

14

10 Filter suction

11 Fresh powder pump

12 Pressure switch for monitoring the mains pressure

13 Adapter for lter suction

Alternatively: Adapter to connect to the nal lter

14 Powder catch basin

13

12

18

Page 19

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

5.1.2 VERSION FOR FINAL FILTER

PXM

P_02674

19

Page 20

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

5.1.2 VERSION WITH ULTRASONIC SIEVE

PXM

1

2

3

P_02675

1 Sieve frame with converter

2 Sieve housing

3 Powder spout

20

Page 21

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

5.2 MODE OF OPERATION

The PXM powder center is a system from which uidized powder is conveyed simultaneously

from a powder tank (option) to several spray guns. Powder consumption is compensated

by the fresh powder feed device (option) in the powder center or by manually re lling.

The linear motion unit suction system is immersed directly into the powder tank.

A homogenous powder/air mixture is created through the uidization and vibration

(option) of the tank. The injectors convey the powdered paint to the guns in the coating

system. A lowered powder level in the tank is detected by the level sensor in conjunction

with sensors on the reciprocator. The level sensor also triggers the lowering of the suction

system and the fresh powder supply (option) when necessary. A warning is triggered

automatically in the event of a powder shortage and the warning lamp lights up yellow.

If the minimum level is not reached after a certain time, the alarm lights up red and the

system registers a malfunction. Powder level monitoring is active only in automatic mode.

PXM

5.3 PROTECTIVE AND MONITORING EQUIPMENT

Protective and monitoring equipment must not be removed, modi ed or rendered

unusable.

Regularly check for perfect functioning.

If defects are detected on protective and monitoring equipment, the system must not

be operated until these defects are remedied.

Safety Device E ect

EMERGENCY STOP button – Powder feed blocked

– Linear motion unit blocked

– Fluidization and vibrator deactivated

21

Page 22

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

5.4 SCOPE OF DELIVERY

Quantity Order No. Designation

1 see Chapter 5.4.1 PXM powder center

The standard equipment includes:

1 Declaration of incorporation

1 2350371 Operating and assembly manual, German

1 see Chapter 1.3 Operating and assembly manual in the local language

5.4.1 DESIGN VARIANTS OF THE PXM POWDER CENTER

Basic Module:

Order No. Designation

2350977 Powder center PXM 20/22 IF standalone, without ultrasonic sieve

2350980 Powder center PXM 20/22 FF standalone, without ultrasonic sieve

2359437 Powder center PXM 34 IF standalone, without ultrasonic sieve

Powder center PXM 34 FF standalone, without ultrasonic sieve

PXM

Expansion Modules*:

Order No. Designation

2350981 Injector set PI-F1

2350982 Injector set HiCoat-ED

2350983 Set EPG S2

2350984 EPG rack 1–11 for PXM 20/22

2359443 EPG rack 1–18 for PXM 34

2350987 Vibration table container/box

2350988 Box uidizing device (only possible for PXM 20/22)

2350990 Box fresh powder addition

2341584 External valve cabinet for single-plug conveyor

2353462 Extension set ultrasonic sieve device 160 μm

2353306 Extension set ultrasonic sieve device 200 μm

2353302 Controller extension bigbag (without bigbag)

2350985 Set connection material for injectors and EPG including installation

* Expansion modules can be used only in conjunction with an order of the basic module.

Product-speci c limitations, e.g., ow rates must be observed and taken into account during the con guration.

22

Page 23

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

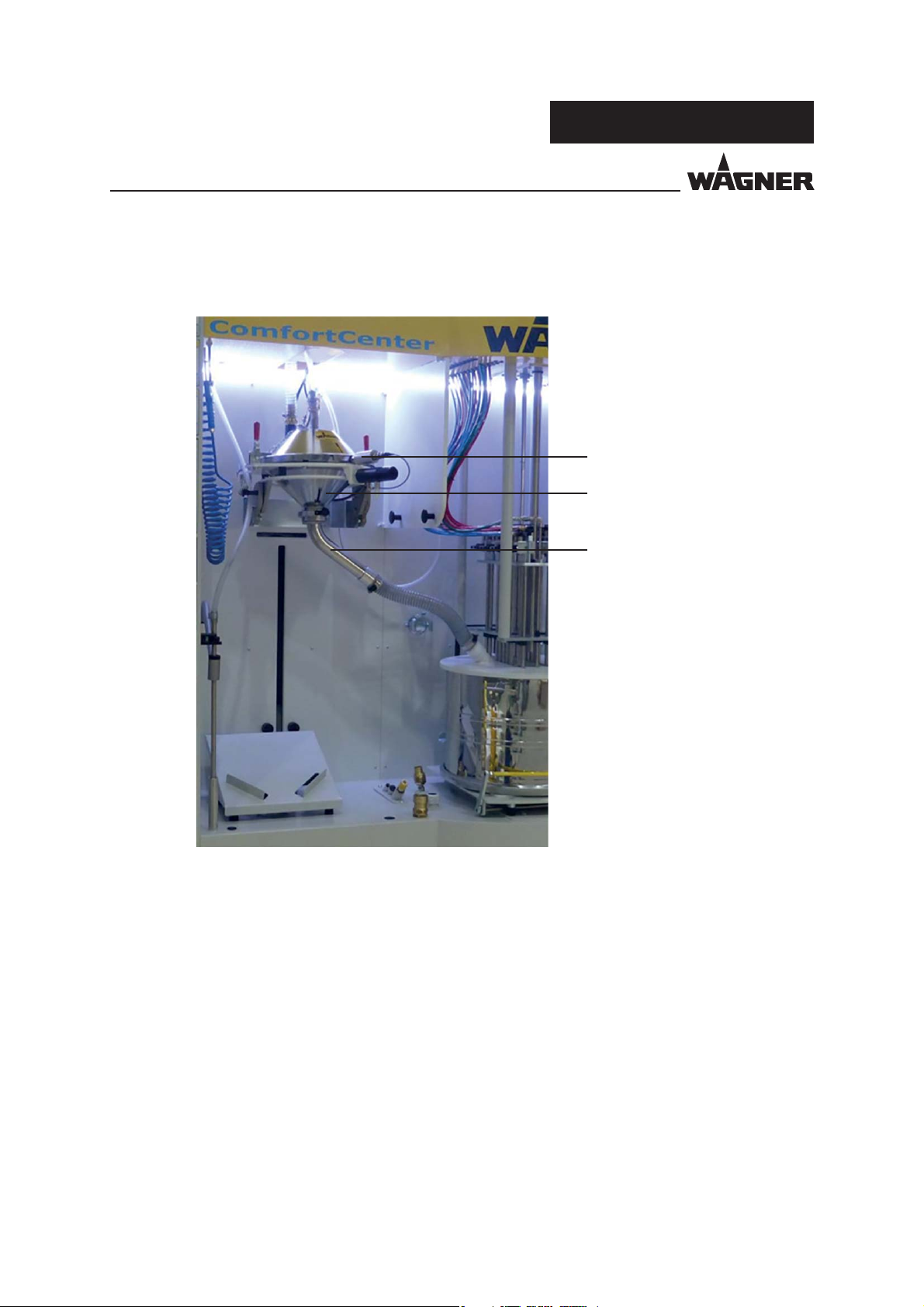

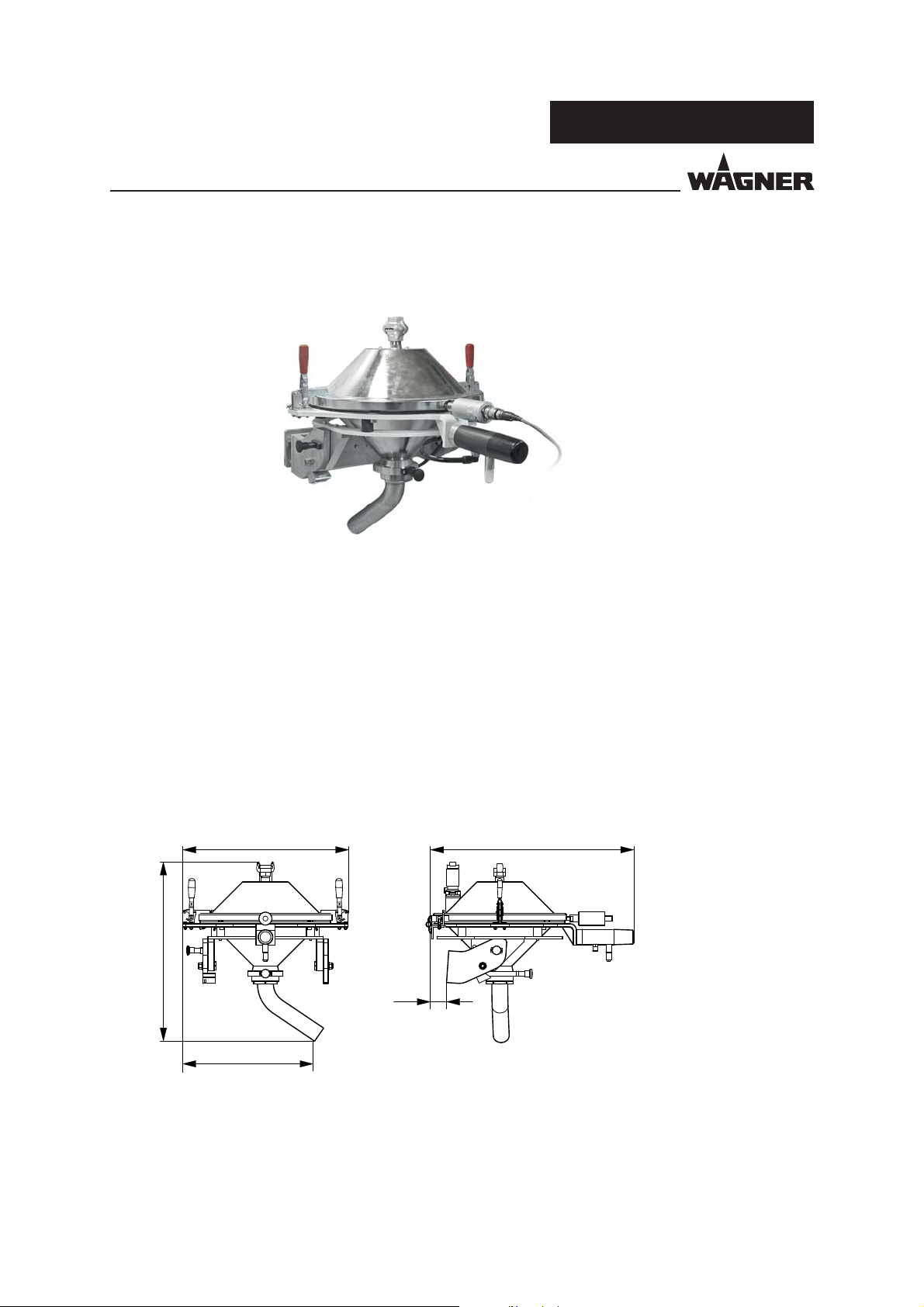

5.4.2 TYPE WITH ULTRASONIC SCREENING UNIT

P_02370

PXM

For more information on the ultrasonic screening unit, see operating manual for ultrasonic

screening unit.

5.4.3 INSTALLATION DIMENSIONS FOR ULTRASONIC SCREENING UNIT

678520

78

P_02561

450

23

Page 24

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

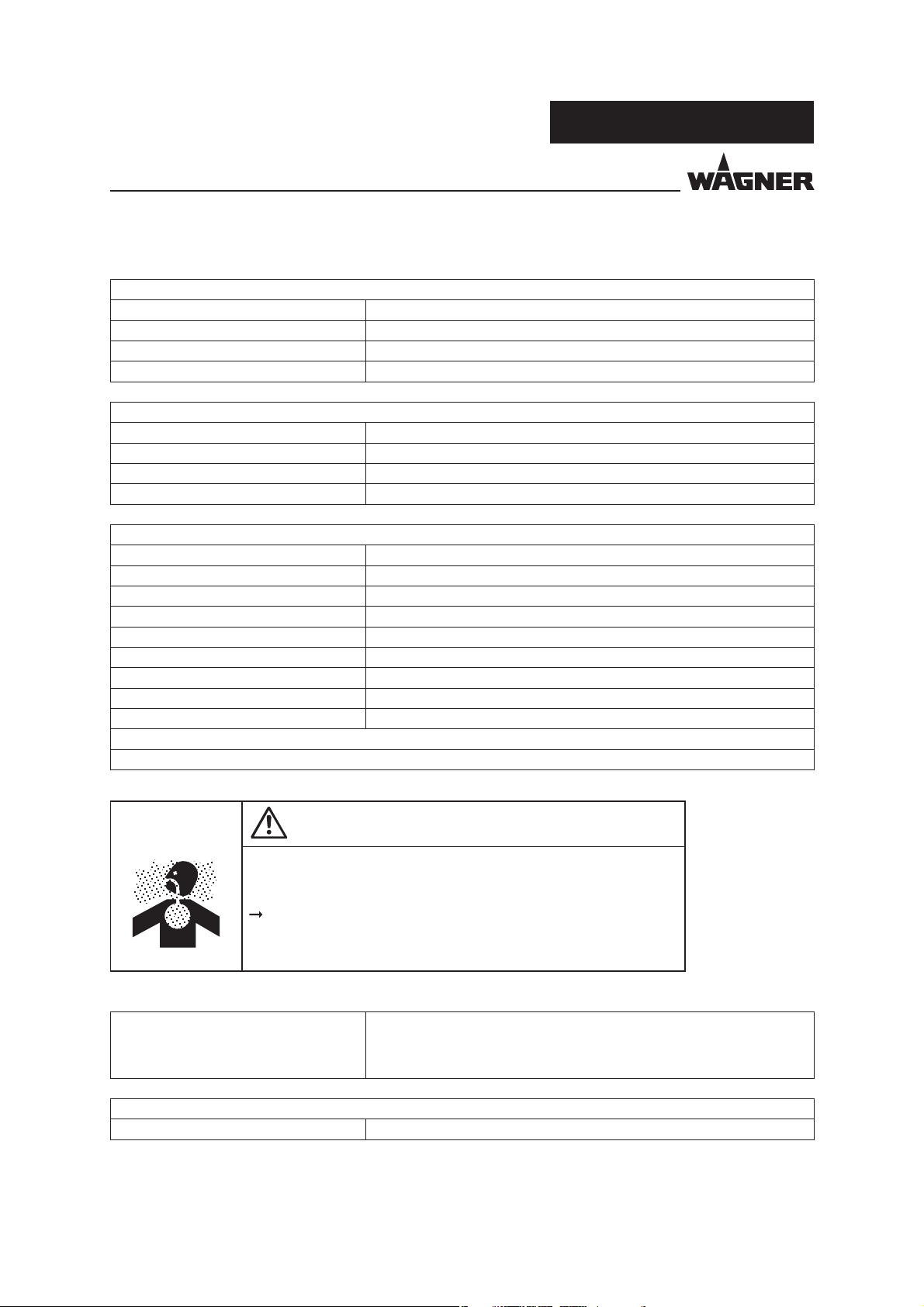

5.5 TECHNICAL DATA

Dimensions:

Maximum height 2,660 mm; 104.72 inches

Maximum width 2,170 mm; 85.43 inches

Maximum depth 1,400 mm; 55.12 inches

Weight Approx. 500 kg + 150 kg lter suction

Electrical:

Three-phase current connection 230/400 V 3P/N/PE 50 Hz

Frequency 50 Hz

Total power consumption 1.5 kW (without lter)/3.7 kW (with lter)

Protection class IP 54

Pneumatic:

Compressed air connection 0.6 – 0.8 MPa; 6 – 8 bar; 87 – 116 psi

Cross-section of compressed air line At least 1.5"

Compressed air quality 6.5.2 according to ISO 8573.1: 2010

Air throughput coating mode 45 Nm³/h; 1,588.88 cf/h

Air throughput cleaning mode 100 – 150 Nm/h in approx. 30 sec.

Suction capacity, exhaust 4,000 m³ at 1,300 Pa; 5,230.86 cubic yards at 0.19psi

Filter surface area (version with lter) 40 m²; 430.55 square foot

Number of lters 2

Filter capacity > 99%

Permanent suction output for version with connection to a nal lter: 1,000 Nm/h; 35,308.34 cf

Equipment:

PXM

WARNING

Exhaust air containing oil!

Risk of poisoning if inhaled.

Provide compressed air free from oil and water

(Quality Standard 7.5.4 as per ISO 8573.1, 2010)

7.5.4 = 5-10mg/m³ / ≤7 °C; 44.6 °F / 5 mg/m³.

Number of injectors PXM 20/22: 20 injectors when feeding from the box

PXM 20/22: 22 injectors when feeding from the uid tank

PXM 34: 34 injectors when feeding from the uid tank

Ambient conditions:

Operating temperature range 5 – 45 °C; 41 – 113 °F

24

Page 25

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

5.6 CONTROLS

PXM

1

2

3

4

5

6

P_02522

1 Touch screen for operating the PXM

2 Fault display: Lights up red when the emergency stop chain is interrupted

Button to reset the EMERGENCY STOP safety relay

3 EMERGENCY STOP switch

4 Safety button for two-hand control function

5 Pressure gauge for uid air

6 Fluid air regulator

25

Page 26

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

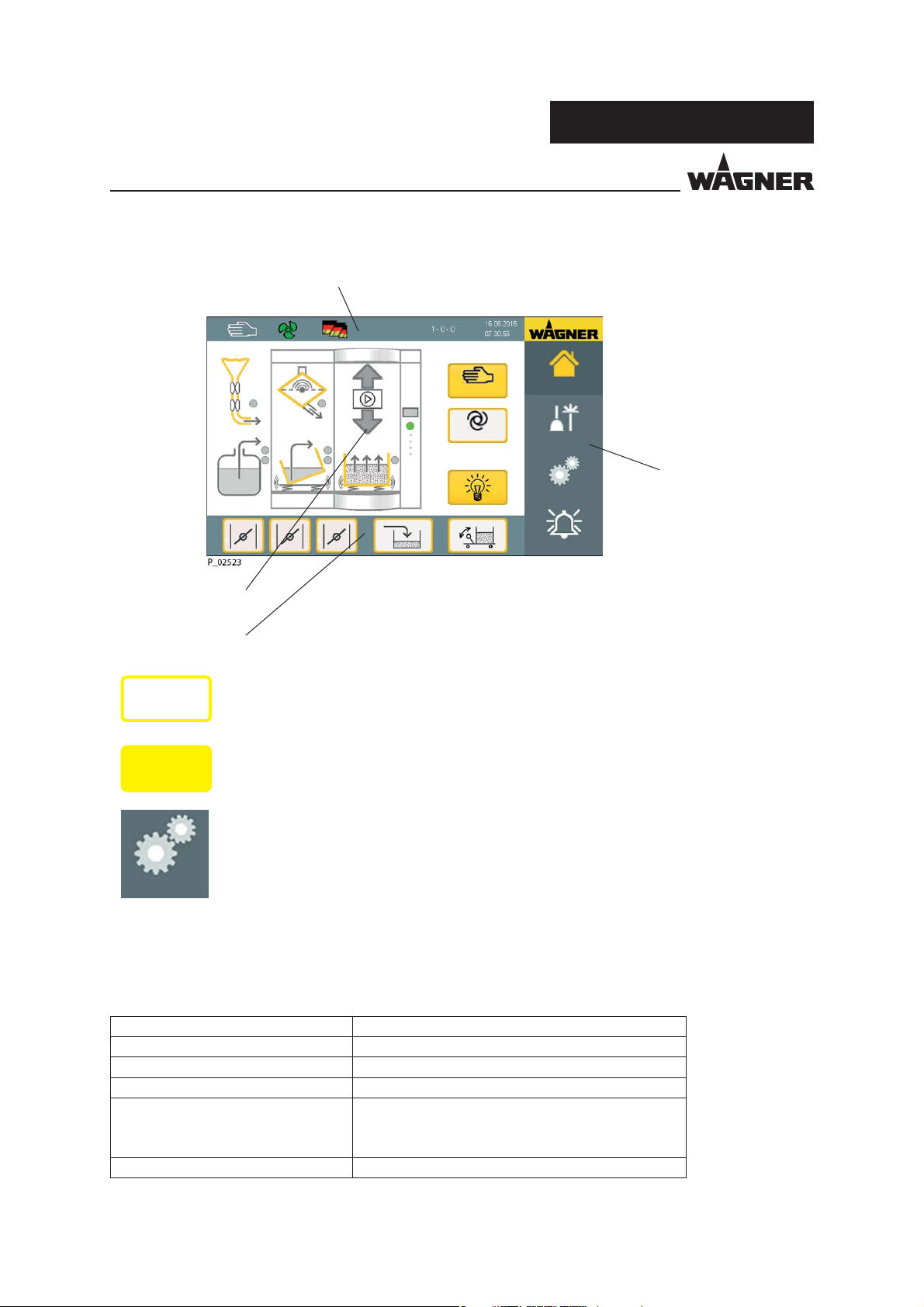

5.7 SCREEN LAYOUT OF THE TOUCH SCREEN

Information bar

Service

PXM

Function graphic

Function bar 1

On

P_02591

On

P_02592

Manual

Auto

Home page

Cleaning

Menu bar

Settings

Alarm

Released functions and components are marked by a yellow frame.

Activated functions and components are depicted by yellow highlighted

icons or buttons.

Non-activatable functions are depicted by a gray font for each function

button and a gray frame.

Settings

P_02593

Tap on the respective component/function on the touch screen to switch things on and o .

The status of the individual components is depicted on the screen by di erent colors of the

points on the respective components:

Status Display Description

Gray Not active

Green Ready

Flashes yellow Warning

Lights up yellow During fresh powder feed in automatic mode:

The fresh powder conveyor is ready to feed powder,

but enough powder is available

Flashes red Malfunction

26

Page 27

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

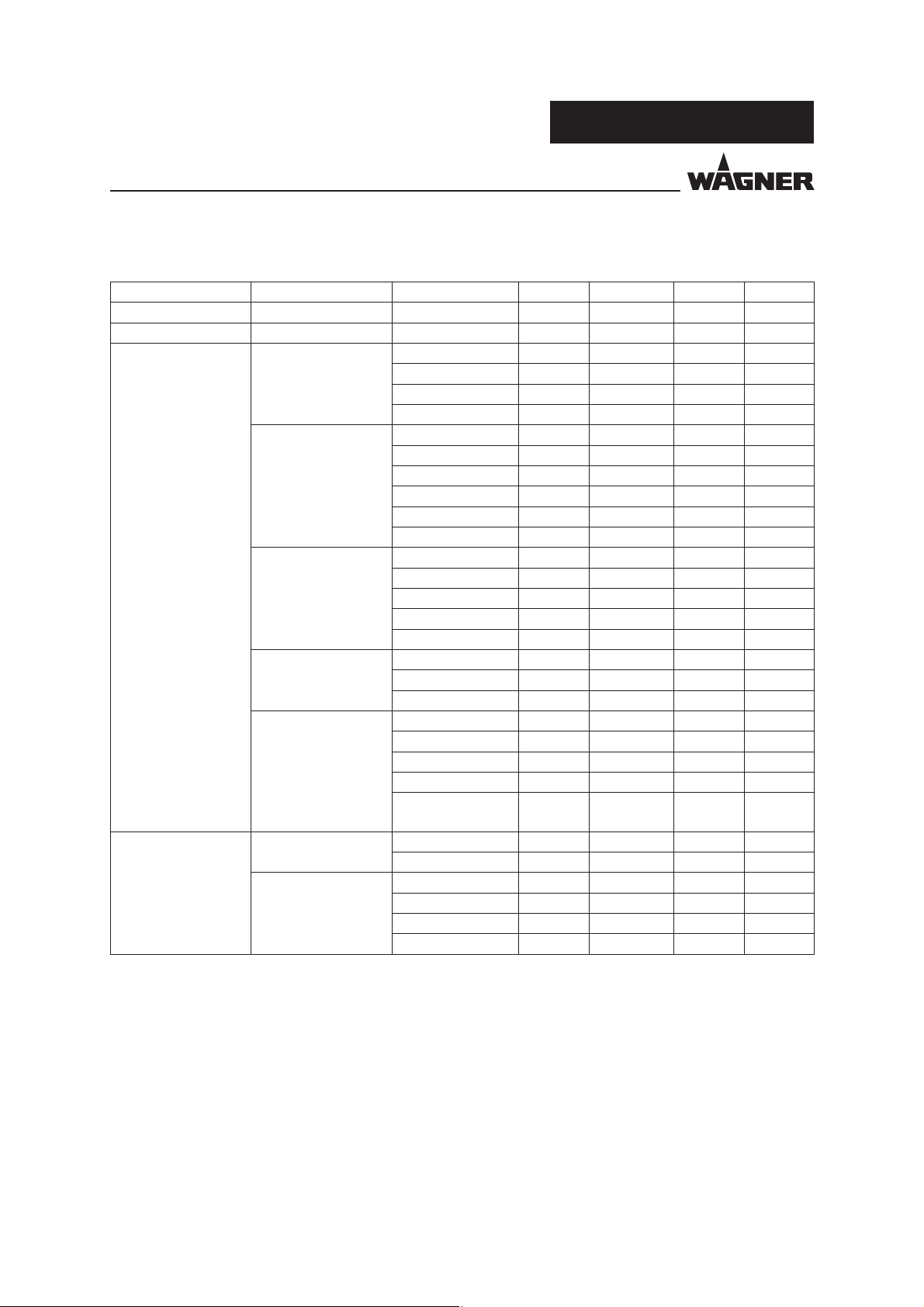

5.8 EXPLANATION OF THE SCREEN PAGE NUMBERS

The screen pages are numbered from top to bottom (1-4) in the menu bar and from left to

right (1-5) in the function bar.

3 - 2 - 3

Button number in function bar 2

Button number in function bar 1

Button number in the menu bar

PXM

Page number

Service

RP supply

Operating mode

RP feed time [sec]

RP break time [sec]

Message recovery system [sec]

Work station

Settings System

FP

supply

MP

operation

No Yes

Duration Eco

Standard

Standard

RP

supply

MP

cleaning

Exhaust

system

Diagnosis

SAT

Function bar 1

Function bar 2

"Scroll forwards/backwards" buttons

Home page

Cleaning

Settings

Alarm

Menu bar

27

Page 28

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

5.9 INPUTS ON THE TOUCH PANEL

Pulse time [sec]

Exhaust system

PXM

Home page

Filter cleaning

Filter cleaning

Work station

Settings System

MP

operation

MP

cleaning

Diagnosis

Cleaning

Settings

Alarm

To modify number values, touch the value that is to be modi ed and the keypad shown

above appears.

The minimum and maximum setting values are displayed on the right; lower or higher values

are not applied.

Button assignment:

BACK Cancel: the entered value is not applied.

EXIT The input eld is left without applying the set value.

ENTER The entered value is applied.

5.10 DISPLAYS ON THE WARNING LAMP

Illuminated Display Description

Green

Flashes red brie y Warning

Flashes red at regular intervals Malfunction

Blue Cleaning is active

Alarm horn sounds Malfunction

Powder center ok ➔ No malfunction

– Exhaust air OK

– Ventilator is running

28

Page 29

VERSION 08/2015 ORDER NUMBER DOC2350372

PXM

OPERATING AND ASSEMBLY MANUAL

5.11 USER RIGHTS

Main menu Sub-menu Function Worker Supervisor Service Facility

Home page x x x x

Cleaning x x x x

Settings Settings Workstation x x x x

Powder supply x x x x

US Sieve x x x x

Test x

MP operation Workstation x x x

FP supply x x x

RP supply x x x

Exhaust system x x x

US Sieve x x x

Hardware x x x

MP cleaning Interface x x x

Injectors x x x

FP supply x x x

RP supply x x x

US Sieve x x x

Diagnosis LogView x x

Diagnosis x x

Maintenance x x

System Password x x x

Data backup x x x

Backup x x x

IP setting x x

Exit visualization

software

Alarm Current View x x x x

Con rm x x x x

History View x x x x

Save as *.csv x x x

Save as *.xml x x x

Delete x

xx

29

Page 30

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

6 ASSEMBLY AND COMMISSIONING

6.1 TRAINING THE ASSEMBLY STAFF

WARNING

Incorrect installation/operation!

Risk of injury and damage to the device.

The assembly and commissioning sta must have the technical

skills to safely commission the device.

When assembling, commissioning and performing all work,

please read and observe the operating manual and safety

regulations of the additionally required system components.

PXM

A skilled person must check to ensure that the device is in a reliable state after it is installed

and commissioned.

6.2 STORAGE CONDITIONS

Until the point of assembly, the powder center must be stored in a dry location, free from

vibrations and with a minimum of dust. The powder center must be stored in closed rooms.

The air temperature at the storage location must be between +10 °C and +20 °C

(+50 °F and +68 °F).

The relative air humidity at the storage location must be between 20 and 70%

(without condensation).

6.3 INSTALLATION CONDITIONS

The air temperature at the installation site must lie between +10 °C and +30 °C

(+50 °F and +86 °F).

The relative air humidity at the installation site must be between 20 and 70%

(without condensation).

30

Page 31

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

6.4 TRANSPORTATION

WARNING

Parts have high weights and centers of gravity!

Risk of injury and damage to the device.

Only use appropriate lifting tackle (crane, fork lift) for assembly.

Secure the parts against tipping during transport.

Cordon o assembly area to keep out unauthorized persons.

The powder center is delivered completely mounted to the site of installation. This may be

supplied separately for a version with its own lter suction.

Final assembly is performed on-site.

PXM

Transportation and warehouse operations may only be performed by quali ed personnel,

especially in the use of industrial trucks, ladders and cranes.

The selected means of transport must be suitable and permissible for the respective

component weights.

For the insertion of parts at the installation site, an opening width of at least 2,000 mm

(6.56 ft.) must exist, and an opening height of 2,000 mm (6.56 ft.).

The PXM powder center is delivered upright.

P_02571

Support with wooden beams on the truck Loading/unloading with forklift

P_02572

31

Page 32

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

PXM

P_02573

Transport in the factory workshop Support with wooden beams on the

P_02574

lter module

6.5 ASSEMBLY AND INSTALLATION

WARNING

Danger from electric current!

Risk of injury and damage to the device.

Before connecting the device, ensure that the external controller

is switched o and the EMERGENCY STOP button is actuated.

The device may only be put into operation if it complies with the essential requirements of

Directive 2006/42/EC after installation.

The requirements of the relevant paragraphs must be met in particular:

– 1.1.4 Illumination

– 1.2.4.1 Normal shutdown

– 1.2.4.3 Emergency shutdown

– 1.2.4.4 Assemblies of machinery

– 1.2.5 Selecting the control or operating modes

– 1.2.6 Power supply malfunction

– 1.3.7 Risks from moving parts

– 1.3.8 Selection of protective equipment against risks from moving parts

– 1.5.6 Fire

– 1.5.16 Lightning

– 1.7.1.2 Warning devices

32

Page 33

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

P_02575

PXM

1. Fasten lter module (if available) to the powder center housing.

It is fastened with 12 screws from the back; two screws must have contact disks for

proper grounding.

P_02576

2. Connect the compressed air supply to the air connection point (air connection point1";

supply at least 1.5"; pressure regulator setting 6 bar).

3. Introduce the electrical cables from the top or from the back and connect these to

the main terminal.

33

Page 34

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

PXM

P_02577

P_02578

4. Erect the piston cylinder and guide the piston through the roof.

The limit switches must be located on the left side (seen from the front).

5. Use 4 screws to fasten piston cylinder onto the roof.

Workstation

Position switch of linear motion

unit

Powder level sensor

LogView Diagnosis Maintenance

Settings System

MP

operation

at the top

Warning

Minimum

Cleaning

MP

cleaning

Diagnosis

Home page

Cleaning

Settings

Alarm

6. Connect the compressed air and power supply.

7. Move the cylinder downwards via the touch screen (diagnostic page) and screw into place.

34

Page 35

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

P_02581

8. Align the ange by hand and use 3 screws to fasten onto the injector retaining plate.

PXM

Workstation

Position switch of linear motion

unit

Powder level sensor

LogView Diagnosis Maintenance

Settings System

MP

operation

at the top

Warning

Minimum

Cleaning

MP

cleaning

Diagnosis

Home page

Cleaning

Settings

Alarm

9. Move the piston cylinder via the diagnostic side to adjust the limit switches.

35

Page 36

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

2

3

1

4

P_02622

PXM

Limit switch 1: Top = Cylinder moved all the way up.

Setting: Uppermost cylinder position

Limit switch 2: Warning = Advance warning that the powder level will be reached soon.

Setting: 2 cm above limit switch 3

Limit switch 3: Minimum = Powder level minimum; cylinder does not move further

downwards.

Setting: Fluid tubes 1 cm from the uid oor of the tank; use tank

Order No. 3304505.

Limit switch 4: Cleaning = Intake tubes dip into blowout nozzles.

Setting: Intake tube 1 cm in blowout nozzle

P_02583

10. Horizontally align the PXM using the leveling feet on the frame.

11. Align the intake tubes so that they meet centrally in the blowout nozzles.

To do this, rst align the PXM with the leveling feet.

If necessary, loosen the four screws from the mounting plate of the blowout nozzles

and bring the nozzles into position.

36

Page 37

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

6.6 GROUNDING

For safety reasons the system must be properly grounded. WAGNER recommends the use

of a copper cable of at least 16 mm² with su cient mechanical resistance for connection

to the signal ground.

Good grounding of the work piece is also necessary for optimum powder coating.

A poorly grounded work piece causes:

dangerous electric charging of the work piece,

very poor wrap-around,

uneven coating,

back spraying to the gun, i.e., contamination

Prerequisites for perfect grounding and coating are:

Conducting suspension for the work piece that is to be coated.

Grounding of the powder coating booth, transport and suspension equipment to

be provided on site in accordance with the corresponding operating manuals or the

de nitions laid down by the manufacturer.

Regular cleaning of hangers from powder residues.

Grounding resistance for the work piece of a maximum of 1 MΩ (megaohm).

Grounding cable connected to the controller module or control cabinet.

PXM

Sparks between work piece and conveyor hooks (hangers) can occur if hooks or

other hanger parts are not completely cleaned! These sparks can cause heavy radio

frequency interference.

6.7 SAFETY CHECKS

Perform safety checks in accordance with Chapter 8.2.3.

37

Page 38

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

6.8 COMMISSIONING

The tank mounting and injector mounting plate must be horizontally aligned in all

directions.

The hose for the uid air must either be connected to the terminal for the box- uidizing

device ( oor) or on the powder tank.

PXM

P_02589

NOTICE

Positioning of powder tank and tank cover!

Danger of damage to the device.

Align the powder tank or powder box on the vibrator table so that the suction system

can move in and out unimpeded.

Only insert the cover into the guides and push it back to the limit stop after lowering

the suction tubes.

Remove cover before powering up the intake tubes.

38

Page 39

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

6.9 STANDARD SETTINGS

The most important settings for speedy commissioning of the powder center have already

been carried out by the manufacturer.

You can, however, change standard settings to suit your needs. The changes remain saved

even if the powder center is switched o with the main switch.

The following standard settings are made in the factory.

6.9.1 MACHINE PARAMETERS OPERATION

Workstation

Alarm delay powder shortage: 30 sec.

FP supply

FP station: 1

FP bigbag: 1

Bigbag type: IP 5000

FP redosing time manual: 30 sec.

FP redosing time automatic: 30 sec.

RP supply

RP supply: Yes

Operating mode: Eco

RP feed time: 50 sec.

RP break time: 10 sec.

Message recovery system: 60 sec.

RP supply: Cycle 1: 2.5 sec.

Cycle 2: 0.3 sec.

Cycle 3: 2.5 sec.

Cycle 4: 0.3 sec.

US sieve

US sieve: No

After-run time if US sieve available: 30 sec.

Dirt discharge: 3 pulses

After-run time before: 12 sec.

Wait time: 10 min.

Pulse time: 1.0 sec.

Break time: 5.0 sec.

Exhaust system

Exhaust system: Integrated

Filter cleaning pulse time: 0.2 sec.

Filter cleaning break time: 60 sec.

Final lter, automatic closing: 10 sec.

PXM

39

Page 40

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

6.9.2 MACHINE PARAMETER CLEANING

Interface

Communication with the application controller: No

Injectors

Preliminary cleaning Block 1

Number of pulses: 2

Pulse time: 0.2 secs

Break time: 1 secs

Preliminary cleaning Block 2

Number of pulses: 2

Pulse time: 0.2 secs

Break time: 1 secs

Cleaning Block 1

Number of pulses: 8

Pulse time: 0.5 secs

Break time: 2 secs

Cleaning Block 2

Number of pulses: 8

Pulse time: 0.5 secs

Break time: 2 secs

Dynamics: O

FP supply

Pre-cleaning

Number of pulses: 2

Pulse time: 0.5 secs

Break time: 2.0 secs

Cleaning

Pulse time: 1.0 secs

Break time: 2.0 secs

RP supply

Cleaning

Number of pulses: 10

Pulse time: 1.0 secs

Break time: 2.0 secs

US sieve

Pre-cleaning

Number of pulses: 5

Pulse time: 0.2 secs

Break time: 2.0 secs

Cleaning

Number of pulses: 5

Pulse time: 0.5 secs

Break time: 2.0 secs

PXM

40

Page 41

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

6.9.3 CAN ADDRESSES FOR MCM SYSTEM

CAN Node Module Type Application

0 CAN Diagnosis Do not use

1 CAN Open Master 1 MCM CAN 1

2 CAN Open Master 2 MCM CAN 2

3 I/O Module MCM CPS

11 HU1 No. 1 Sliding table 1

12 HU1 No. 2 Sliding table 2

13 HU1 No. 3 Sliding table 3

14 HU1 No. 4 Sliding table 4

21 VU1 No. 1 Reciprocator 1

22 VU1 No. 2 Reciprocator 2

23 VU1 No. 3 Reciprocator 3

24 VU1 No. 4 Reciprocator 4

PXM

31 EPG S2 No. 1 Guns 1 and 2

32 EPG S2 No. 2 Guns 3 and 4

33 EPG S2 No. 3 Guns 5 and 6

34 EPG S2 No. 4 Guns 7 and 8

35 EPG S2 No. 5 Guns 9 and 10

36 EPG S2 No. 6 Guns 11 and 12

37 EPG S2 No. 7 Guns 13 and 14

38 EPG S2 No. 8 Guns 15 and 16

39 EPG S2 No. 9 Guns 17 and 18

40 EPG S2 No. 10 Guns 19 and 20

41 EPG S2 No. 11 Guns 21 and 22

42 EPG S2 No. 12 Guns 23 and 24

43 EPG S2 No. 13 Guns 25 and 26

44 EPG S2 No. 14 Guns 27 and 28

45 EPG S2 No. 15 Guns 29 and 30

46 EPG S2 No. 16 Guns 31 and 32

61 Light curtain portal Kontur 2, with Quattro CAN Open

62 CML 720 light curtain CML 720i height light curtain

63 CML 720 light curtain CML 720i depth light curtain, right

64 CML 720 light curtain CML 720i depth light curtain, left

65 CML 720 light curtain CML 720i code catching

81 Extension module for recipe selection (11 bit)

82 … 127 not de ned free application

41

Page 42

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

6.9.4 EPG S2 SETTINGS

Normally, these settings have been made prior to shipment. The description is for reference

purposes only and when an error message is displayed.

PXM

Mains power IN / OUT

Netz EIn / Ausgang

P_02714

Prim. Fuse

Sicherung

1.0 AT

(slow blow)

Feeding air

Förderluft

Air input

Lufteingang

Dosage air

Dosierluft

Made in Switzerland

J. Wagner AG

CH 9450 Altstätten

0102

Type / Typ:

EPG S2 FM

Voltage:

90-250 VAC 47-63 Hz

Spannung:

Line Power:

Eingangsleistung:

FM approved for CL II, Div 2 Grps E, F, & G

Ambient temp range 5C to 45C T5

Use in accordance with

control document:

Serial No.:

Serie Nr.:

max. 65 W

2309729

Do NOT connect or disconnect

when ENERGIZED !

Controller is suitable for Class II,

Division 2, Hazardous (Classified)

locations.

For operation all ports must be fitted

with a plug or the protection cap.

Overvoltage Category II

and pollution Degree 2

IN CAN Bus OUT

Data and Interlock

Daten und Verriegelung

B

Spraygun

Sprühpistole

A

Output to gun

Ausgang zur Pistole

U max. 22 Vpp

I max. 0,9 A

AABB

Atomizing air

Zerstäuberluft

Feeding air

Förderluft

Dosage air

Dosierluft

Atomizing air

Zerstäuberluft

CAN bus node ID setting

CAN bus baud rate setting/emergency operation mode

42

Page 43

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

Switch CAN baud rate Maximum

1234

0 0 0 X 1,000 kBit/s 25 m

10

1 2 3 4

Baud rate

P_01509

Shown example: Factory setting 250 kBit/s

Setting address of each EPG S2, starting from 31 for the rst EPG S2 (from top to bottom)

0 0 1 X 800 kBit/s 50 m

ON

0 1 0 X 500 kBit/s 100 m

0 1 1 X 250 kBit/s 250 m

1 0 0 X 125 kBit/s 500 m

1 0 1 X 100 kBit/s 1,000 m

1 1 0 X 50 kBit/s 1,000 m

1 1 1 X 20 kBit/s 1,000 m

cable length

PXM

CAN Node Module Type Application

31 EPG S2 No. 1 Guns 1 and 2

32 EPG S2 No. 2 Guns 3 and 4

33 EPG S2 No. 3 Guns 5 and 6

34 EPG S2 No. 4 Guns 7 and 8

35 EPG S2 No. 5 Guns 9 and 10

36 EPG S2 No. 6 Guns 11 and 12

37 EPG S2 No. 7 Guns 13 and 14

38 EPG S2 No. 8 Guns 15 and 16

39 EPG S2 No. 9 Guns 17 and 18

40 EPG S2 No. 10 Guns 19 and 20

41 EPG S2 No. 11 Guns 21 and 22

42 EPG S2 No. 12 Guns 23 and 24

43 EPG S2 No. 13 Guns 25 and 26

44 EPG S2 No. 14 Guns 27 and 28

45 EPG S2 No. 15 Guns 29 and 30

46 EPG S2 No. 16 Guns 31 and 32

3

4

2

5

1

6

0

7

9

8

3

4

2

5

1

6

0

7

9

8

Node ID 01 (0/1)

1

0

P_02715

3

4

2

5

6

7

9

8

3

4

2

5

1

6

0

7

9

8

Node ID 23 (2/3)

43

Page 44

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

6.10 FUNCTION TEST

The function test is performed after the system has been con gured.

Test all the functions on the touch screen in manual mode

Test the cleaning process

Test uidization

Test fresh powder pump

Test automatic operation

PXM

44

Page 45

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

PXM

45

Page 46

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

7 OPERATION

7.1 TRAINING THE OPERATING STAFF

WARNING

Incorrect operation!

Risk of injury and damage to the device.

The operating sta must be quali ed to operate the entire system.

The operating sta must be familiar with the potential risks

associated with improper behavior as well as the necessary

protective devices and measures.

Before work commences, the operating sta must receive

appropriate system training.

PXM

7.2 SAFETY INSTRUCTIONS

Observe safety instructions in Chapter 4.

WARNING

Incorrect operation!

Risk of injury and damage to the device.

Take appropriate precautionary measures, e.g. wear protective

clothing, if contact with powder products or cleaning agents

causes skin irritation.

The footwear worn by operating sta must comply with

EN ISO 20344. The measured insulation resistance must not

exceed 100 megohms.

The protective clothing, including gloves, must comply with

EN ISO 1149-5. The measured insulation resistance must not

exceed 100 megohms.

46

Page 47

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

7.3 TOUCH SCREEN OPERATION STANDARD EQUIPMENT

7.3.1 EQUIPMENT WITH FINAL FILTER

PXM

1 4 5 6

13 10

3

2

Manual

Auto

891112

Home page

Cleaning

Settings

Alarm

P_02524

7

1 Peristaltic pump On/O

2 Exhaust system status

3 Ultrasonic sieve device On/O

4 Language selection

5 Reciprocator Up/Down

6 Manual/automatic mode

7 Illumination On/O

8 Button for clamping the tank (box, powder container)*

9 Replenishing fresh powder (manual, time-controlled) On/O

10 Workstation/vibrator uidization On/O

11 Automatic fresh powder supply On/O (only in automatic mode)

12 Throttle valve Open/Closed

13 BigBag fresh powder On/O , as an alternative to the fresh powder supply from the box

* Additional actuation of the safety switch for two-handed operation below the touch

screen required

47

Page 48

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

7.3.2 EQUIPMENT WITH INTEGRATED EXHAUST SYSTEM

PXM

1 4 5 6

1 Peristaltic pump On/O

2 Exhaust system status

3 Ultrasonic sieve device On/O

4 Language selection

5 Reciprocator Up/Down

6 Manual/automatic mode

7 Illumination On/O

8 Button for clamping the tank (box, powder container)*

9 Replenishing fresh powder (manual, time-controlled) On/O

10 Workstation/vibrator uidization On/O

11 Automatic lter cleaning On/O

12 Automatic fresh powder supply On/O (only in automatic mode)

13 Exhaust system On/O // Switchover frequency

Press the button brie y: Switch on suction

Press the button brie y when suction is switched on: Switchover frequency ventilator

Press and hold the button: Switch o suction

14 Bigbag fresh powder On/O , as an alternative to the fresh powder supply from the

box

3

2

P_02529

8912

1114 13

10

7

* Additional actuation of the safety switch for two-handed operation below the touch

screen required

48

Page 49

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

7.4 SET LANGUAGE

Language

PXM

1. Tap "Flag" button in the information bar.

The depicted screen appears.

2. Select the desired language by tapping on the corresponding ag button.

The screen is now displayed in the selected language.

49

Page 50

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

7.5 LOGGING A USER ON/OFF

The currently logged in user is displayed in the information bar, in the example "Factory".

Press the button to change the user; the following display appears.

Factory

Set authorization

Log on user Log o user

PXM

Press the "Log in user" button; the following display appears.

Factory

Password

Enter the password for the desired user level and press the "Enter" button.

It is switched to the desired user level.

Press the "Log off user" button to go back to the lowest level (operator level).

50

Page 51

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

7.6 STARTING/STOPPING COATING

1. Switch the system on.

2. Move the reciprocator all the way to the top (reference).

3. Set the powder tank. For boxes, loosen powder beforehand.

4. When feeding from the powder box: Pull the foil over the box rim until it lies at on

the box walls.

5. Insert uidization and check pressure (start with 0.5 bar setting).

6. Plug the peristaltic pump tube and fresh powder hose onto the loss position.

7. Select the "Automatic" button; the retractor then moves downwards and determines

the powder level.

When using boxes, ensure that the uid device moves past the foil and does not

press it down.

If necessary, retighten the foil.

8. Check uidization and set if necessary.

When using a uid tank, the powder should ow like water without generating

larger bubbles.

When using powder boxes, the powder should be owable in the uid rod area

without generating larger bubbles or dust.

Note: An excessive uid air setting leads to a greater loss of powder.

9. Insert tank cover.

10. Plug the fresh powder hose*

11. Start coating.

12. First switch o the peristaltic pump on the touch screen according to an arbitrary

time, plug the hose *

13. For longer breaks and at the end of production, switch to manual mode and move

the suction system from the tank to the top in reverse order.

Attention: Remove the cover rst.

14. At the end of production, WAGNER recommends you rough clean the system and

ush the injectors, powder hoses and guns (via application controller) and perform

a normal cleaning for the IP 5000 fresh powder pump.

Move the suction device completely up before turning o the system.

Remove tank or box or close with a dummy cover so that no debris can fall into it.

Note: If the PXM is connected to the nal lter, the throttle valves can only be opened

if no coating is applied.

, **

, **

onto the tank cover.

on the tank cover and switch the peristaltic pump on again.

PXM

* When an automatic fresh powder supply is available

** When using an ultrasonic sieve, plug the fresh powder hose directly onto the

connection on the sieve and the peristaltic pump tube on the feedthrough socket

on the base plate of the powder center

51

Page 52

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

7.6.1 PAINT CHANGE COMPONENTS

PXM

P_02676

12345

1 Blowout nozzles for intake tubes

2 Blowout nozzle for the fresh powder hose and peristaltic pump tube

3 Parking station peristaltic pump tube during loss operation

4 Parking station, fresh powder hose

5 Cleaning position, fresh powder lance

52

Page 53

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

7.6.2 CLEANING POSITIONS POWDER HOSES

P_02679

P_02677

Cleaning fresh powder, standard

Loss position, reclaimed powder

PXM

P_02678

Cleaning fresh powder, intensive

P_02680

Cleaning, reclaimed powder

53

Page 54

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

7.7 CONFIGURING THE POWDER CENTER

The con guration of the powder center must be adjusted when rst commissioning or in

special cases.

Con guration is performed in the "Settings" menu item.

Different configuration settings are displayed depending on the user level selected.

Icon explanation:

Button for scrolling to the next screen page

Button for scrolling back to the previous screen page

PXM

P_02621

Number of pulses

Pulse time (duration)

Break time (duration)

54

Page 55

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

7.7.1 SETTINGS

The settings can be temporarily changed and adapted to the speci c work situation.

The maximum con guration is displayed below, i.e. the switches become visible depending

on the con guration.

Meaning of a deselection:

- Icon is nevertheless displayed on the home page (gray)

- Fresh powder feed cannot be switched on (manual mode)

- Deselected components do not work in automatic mode

Workstation

Home page

PXM

Vibrator

Work-

station

Settings

Powder

supply

MP

operation

Yes No

US sieve

MP

cleaning

Diagnosis

System

Cleaning

Settings

Alarm

Parameter: Explanation:

Vibrator Yes: Vibrator available at the workstation

No: No vibrator available at the workstation

Fresh powder supply

Home page

Internal

FP 1

Bigbag 1External Bigbag 2

Cleaning

Work-

station

Settings

Powder

supply

MP

operation

US sieve

MP

cleaning

Diagnosis

System

Settings

Alarm

Parameter: Explanation:

FP 1 Fresh powder pump 1 is active (selected)

55

Page 56

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

7.7.2 MACHINE PARAMETERS OPERATION

The settings in the "Operation" machine parameters are normally not changed since they

are defined by the installed hardware.

PXM

Fault trigger delay powder

shortage

WS cylinder lowering

Feeding rate [sec]

WS cylinder lowering

Break time [sec]

Time setting for level

controller [sec]

Work-

station

Settings System

FP

supply

MP

operation

RP

supply

MP

cleaning

Parameter: Explanation:

Fault trigger delay powder

shortage

WS cylinder lowering

Feeding rate [sec]

WS cylinder lowering

Break time [sec]

Time setting for level

controller [sec]

Delay time after which an error message is triggered in

the case of powder shortage

Period of time in which the workstation cylinder is

supplied with compressed air during raising and lowering

Period of time in which the workstation cylinder is not

supplied with compressed air during raising and lowering

Delay time after which the linear motion unit lowered

during a powder shortage and the fresh powder pump

is switched on

Exhaust

system

Diagnosis

Standard

Home page

Cleaning

Settings

Alarm

56

Page 57

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

PXM

FP station

FP bigbag

Bigbag type

FP redosing time man. [sec]

FP redosing time auto [sec]

Work-

station

Settings System

FP

supply

MP

operation

No

No

RP

supply

MP

cleaning

Standard

Exhaust

system

Diagnosis

Home page

Cleaning

Settings

Alarm

Parameter: Explanation:

FP station No: No fresh powder pump available

1: A fresh powder pump is available (installed)

2: Two fresh powder pumps are available (installed)

FP Bigbag No: No fresh powder pump available on the bigbag

1: An external fresh powder pump is available (installed)

2: Two external fresh powder pumps are available (installed)

Bigbag type

FP redosing time man. [sec] Redosing time of the fresh powder pump in manual mode

FP redosing time auto [sec] Redosing time of the fresh powder pump in automatic mode

If the "FP bigbag" parameter is set to 1 or 2, then the "Bigbag type" parameter is displayed.

57

Page 58

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

PXM

RP supply

Operating mode

Message recovery system [sec]

Work-

station

Settings System

FP

supply

MP

operation

Yes

Duration

RP

supply

MP

cleaning

No

Eco

Standard

Exhaust

system

Diagnosis

Home page

Cleaning

Settings

Alarm

Parameter: Explanation:

RP supply Yes: Reclaimed powder pump available

No: No reclaimed powder pump available

SAT: Speci c con guration for the SAT system

Operating mode Duration: Peristaltic pump operates continuously

Eco: Peristaltic pump works per cycle, that is, it

works during the "Feed time" adjustable time and

subsequently switches off for the "Break time"

adjustable time (power saving mode)

Message recovery system [sec] A timer runs at the speci ed time after the initial

feed after cleaning. After this time expires, a note is

displayed on the screen to plug the recovery hose

from the loss position to the recovery position.

58

Page 59

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

PXM

RP supply

Operating mode

RP feed time [sec]

RP break time [sec]

Message recovery system [sec]

Work-

station

FP

supply

MP

operation

Yes

Duration Eco

RP

supply

MP

cleaning

No

Standard

Standard

Exhaust

system

DiagnosisSettings System

Home page

Cleaning

Settings

Alarm

Parameter: Explanation:

RP supply Yes: Reclaimed powder pump available

No: No reclaimed powder pump available

SAT: Speci c con guration for the SAT system

Operating mode Duration: Peristaltic pump operates continuously

Eco: Peristaltic pump works per cycle, that is, it works

during the "Feed time" adjustable time and subsequently

switches off for the "Break time" adjustable time (power

saving mode)

RP feed time [sec] Period in which the reclaimed powder pump is running

RP break time [sec] Time in which the reclaimed powder pump is at a standstill

Message recovery system [sec] A timer runs at the speci ed time after the initial feed

after cleaning. After this time expires, a note is displayed

on the screen to plug the recovery hose from the loss

position to the recovery position.

Cycle 3

Exhaust

system

DiagnosisSettings System

Standard

Work-

station

Cycle 1 Cycle 4Cycle 2

FP

supply

MP

operation

cleaning

RP

supply

MP

Parameter: Explanation:

Cycle 1 – 4 Duration of the cycle 1 - 4

Home page

Cleaning

Settings

Alarm

59

Page 60

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

PXM

Integrated

Standard

Exhaust

system

DiagnosisSettings System

Home page

Cleaning

Settings

Alarm

Automatic closing [sec]

Fault trigger delay

ECO input [sec]

Work-

station

operation

FP

supply

MP

Final lterExhaust system

RP

supply

MP

cleaning

Parameter: Explanation:

Exhaust system Final lter: Final lter available

Integrated: Filter module available

Automatic closing [sec] Time in which the throttle valves are automatically closed

after the time expires

Fault trigger delay

ECO input [sec]

Integrated

Standard

Exhaust

system

DiagnosisSettings System

Home page

Cleaning

Settings

Alarm

Filter cleaning pulse time [sec]

Filter cleaning break time [sec]

Fault trigger delay

ECO input [sec]

Work-

station

FP

supply

MP

operation

Final lterExhaust system

RP

supply

MP

cleaning

Parameter: Explanation:

Exhaust system Final lter: Final lter available

Integrated: Filter module available

Filter cleaning pulse time [sec] Duration of the cleaning pulses

Filter cleaning break time [sec] Time in which no lter cleaning takes place

Fault trigger delay

ECO input [sec]

60

Page 61

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

No StandardYesUS Sieve

PXM

After-run time [sec]

Dirt discharge:

After-run time before [sec]

Wait time [min]

US sieve Hardware

MP

operation

MP

cleaning

DiagnosisSettings System

Home page

Cleaning

Settings

Alarm

Parameter: Explanation:

US Sieve Yes: Ultrasonic screening device available

No: No ultrasonic screening device available

After-run time [sec] Sieve continues to run during each switch-o power

signal so that no residual powder remains on the fabric

(damage while blowing out!)

Dirt discharge Number of suction cycles with pulse and break time

After-run time before [sec] Before activating the dirt discharge, the screen

continues running in order to sieve remnants of

powder on the fabric (reduction of powder loss)

Wait time [sec] Interval for debris discharge cycle

Home page

WAGO I/O assignment

Cleaning

US sieve Hardware

MP

operation

MP

cleaning

DiagnosisSettings System

Settings

Alarm

Parameter: Explanation:

WAGO I/O assignment This parameter is used to parameterize the various

con gurations of the powder center.

Each con guration has a di erent CAN node ID.

1: PXM without bigbag/node ID = 5

2: PXM with bigbag/node ID = 6

3: PXM with 34 injectors/node ID = 7

P_02716

61

Page 62

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

7.7.3 MACHINE PARAMETER CLEANING

The settings in the "Cleaning" machine parameters can be optimized for customer-specific

requirements.

Communication with the application controller

Home page

Yes

No

Cleaning

PXM

InjectorsInterface

Settings System

MP

operation

FP

supply

MP

cleaning

Parameter: Explanation:

Communication with the

application controller

Yes: The powder center controller communicates with the

application controller

In doing so, the following information is exchanged in

conjunction with MCC, Pro Tech M or S Pro Tech:

- Move the guns to the cleaning position for internal cleaning

- Switch on the gun air during internal cleaning

- Switch o the gun air after internal cleaning nishes

No: The powder center controller does not communicate

with the application controller

CleaningPre-cleaning Dynamics

Block 2Block 1

Block 1

RP

supply

Diagnosis

Block 2

US sieve

O

Settings

Alarm

Home page

Standard

Interface Injectors

MP

operation

FP

supply

MP

cleaning

Standard

RP

supply

DiagnosisSettings System

On

US sieve

Cleaning

Settings

Alarm

62

Page 63

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

CleaningPre-cleaning

PXM

Home page

Cleaning

Standard

Interface Injectors

MP

operation

InjectorsInterface

MP

operation

Cleaning

supply

cleaning

Standard

supply

cleaning

FP

MP

FP

MP

Standard

RP

supply

DiagnosisSettings System

RP

supply

DiagnosisSettings System

US sieve

US sieve

Settings

Alarm

Home page

Cleaning

Settings

Alarm

Standard

Interface Injectors

MP

operation

FP

supply

MP

cleaning

CleaningPre-cleaning

Standard

RP

supply

DiagnosisSettings System

US sieve

Home page

Cleaning

Settings

Alarm

63

Page 64

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

7.7.4 MACHINE PARAMETERS DIAGNOSIS

PXM

Time

HW version

SW version

Settings System

I/O node

Device name

HW version

SW version

HW con g

LogView Diagnosis

Area

No. Description

Cycle Time Avg

Cycle Time Max

DiagnosisLogView

operation

MP

Maintenance

cleaning

Set

Maintenance

MP

Visu SW version

Panel hours

Diagnosis

CAN OK

SDO parameterization

Process data OK

Home page

Cleaning

Settings

Alarm

Home page

Cleaning

Settings

MP

operation

Workstation

Position switch of linear motion unit

Powder level sensor

LogView Diagnosis

MP

operation

MP

cleaning

at the top

Warning

Minimum

Cleaning

Maintenance

MP

cleaning

DiagnosisSettings System

DiagnosisSettings System

Alarm

Home page

Cleaning

Settings

Alarm

This side is very helpful for adjusting the position switch on the reciprocators and for

testing the function of the level probe.

64

Page 65

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

Fresh powder pump

Ready

Running

Cleaning

Ready

Running

Cleaning

Ready

Running

Cleaning

PXM

Home page

Cleaning

DiagnosisLogView

operation

Interface

Emergency stop chain OK

Exhaust system OK

Appl. Interface: Cleaning ready

Appl. Interface: Cleaning start

Pressure air OK

Voltage supply OK

LogView Diagnosis

operation

US Sieve

Signal Running

Signal Malfunction

MP

MP

Maintenance

MP

cleaning

Maintenance

MP

cleaning

DiagnosisSettings System

DiagnosisSettings System

Settings

Alarm

Home page

Cleaning

Settings

Alarm

Home page

Ventilator

Signal Malfunction

LogView Diagnosis

operation

MP

Maintenance

MP

cleaning

DiagnosisSettings System

Cleaning

Settings

Alarm

65

Page 66

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

Factory

Maintenance

interval

Internal FP pump

External FP pump Reset

RP pump

US Sieve

DiagnosisLogView Maintenance

Maintenance

[h]

counter

[h]

Reset

Reset

Reset

Operating

hours

[h]

PXM

Home page

Cleaning

Settings

MP

operation

MP

cleaning

7.7.5 SYSTEM

Factory

Change passwords

Supervisor password

Service password

Factory password

Password

Settings System

Data

backup

MP

operation

Backup

MP

cleaning

IP

setting

Diagnosis

DiagnosisSettings System

Set

Exit

visualization

software

Home page

Cleaning

Settings

Alarm

Alarm

1. Press the "Settings" button in the righthand menu bar to call up the page.

2. Press the "System" button to call up the

page

3. The "Change passwords" page is

displayed.

4. Only the password for the current level

can be changed.

To change a password for another

level, the level in question must rst be

activated.

66

Page 67

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

Various functions can be called up on the following pages:

– Backing up and rebooting data

– Creating and booting a backup

– Adapting the IP settings

PXM

Data

backup

MP

operation

Data save / load

Load

Backup

cleaning

Completed

Active

Error

MP

Operating hours

SaveSave Load

IP setting

Diagnosis

Exit

visualization

software

Home page

Cleaning

Settings

Alarm

MP Data

Version

Date

Completed

Active

Error

Password

Settings System

Data backup is a mechanism for the service technician to, for example, secure the set

machine parameters after commissioning.

This mechanism is also required during a software update.

BackUp save/load

Date

Save

Completed

Active

Error

Load

Home page

Cleaning

Password Backup

Data

backup

MP

operation

MP

cleaning

setting

DiagnosisSettings

IP

Exit

visualization

software

System

Settings

Alarm

The backup is created automatically by the system after 24 hours of operation. Only one

le is available, which is always overwritten.

Manually save by pressing the "Save" button.

The time of storage is displayed by pressing the "Load" button.

67

Page 68

VERSION 08/2015 ORDER NUMBER DOC2350372

OPERATING AND ASSEMBLY MANUAL

IP Settings

Obtain an IP address via DHCP

Specify an IP address

IP address:

setting

DiagnosisSettings

GET

SET

IP

Exit

visualization

software

System

Subnet Mask:

Default Gateway:

Password Backup

Data

backup

MP

operation

MP

cleaning