Page 1

II 3(2)D IP64 80 °C

0102

P_01486

A

B

S2

EPG

P_00309

Universal Control Unit for

Powder Coating Guns

EPG S2

EPG S2 FM

Version 09/2017

Translation of the Original

Operating Manual

Page 2

Page 3

3

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

Table of Contents

1 GENERAL 5

1.1 Preface 5

1.2 Warnings, Notices and Symbols in these Instructions 5

1.3 Languages 6

1.4 Abbreviations 6

2 CORRECT USE 7

2.1 Device Type 7

2.2 Type of Use 7

2.3 Use in an Explosion Hazard Area 7

2.4 Safety Parameters 8

2.5 Reasonably Foreseeable Misuse 8

2.6 Residual Risks 8

3 IDENTIFICATION 9

3.1 Explosion Protection Identi cation 9

3.2 Permissible Device Combinations 9

4 GENERAL SAFETY INSTRUCTIONS 10

4.1 Safety Instructions for the Operator 10

4.1.1 Electrical Devices and Equipment 10

4.1.2 Personnel Quali cations 10

4.1.3 Safe Work Environment 10

4.2 Safety Instructions for Sta 11

4.2.1 Safe Handling of WAGNER Powder Spray Devices 11

4.2.2 Grounding the Device 11

4.2.3 Product Hoses 11

4.2.4 Cleaning 12

4.2.5 Handling Powder Lacquers 12

4.3 Protective and Monitoring Equipment 13

4.4 Safety Feature Identi cation 14

5 DESCRIPTION 15

5.1 Fields of Application, Correct Use 15

5.2 Technical Data 16

5.3 Permitted Accessories 18

5.4 Scope of Delivery 18

5.5 Display and Operating Elements 19

5.5.1 Display Elements, Front Side 19

5.5.2 Connections on the Rear Side of the EPG S2 20

5.5.3 Connections on the Rear Side of the EPG S2 FM 22

5.5.4 CAN Bus Connection on the Rear Side 23

6 ASSEMBLY AND COMMISSIONING 24

6.1 Training Assembly/Commissioning Sta 24

6.2 Storage Conditions 24

6.3 Installation Conditions 24

6.4 Connecting the Automatic Spray Guns 25

6.5 Connecting the Manual Guns 26

6.6 Connection Diagram in the Rack 27

Page 4

4

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

6.7 Grounding 28

6.7.1 Grounding the Powder Coating System 30

6.8 Device Settings 31

6.8.1 CAN Bus Baud Rate Setting 31

6.8.2 CAN Bus Node ID Setting 32

7 OPERATION 33

7.1 Training the Operating Sta 33

7.2 Safety Instructions 33

7.3 Controllable Spray Guns 34

7.4 Gun Cable Lengths 34

7.5 Control Functions on EPG S2 Control Unit 35

7.5.1 Setting the High Voltage 35

7.5.2 Setting of Current Limiting 36

7.5.3 Settings of High-voltage Characteristic 37

7.5.4 Setting the Air Volume 38

7.5.5 Air Supply Pressure 38

7.6 Diagnosis and Monitoring 39

7.6.1 LED Displays 39

7.7 Emergency Operation 40

7.7.1 Activation of Emergency Mode 40

7.7.2 Functioning of the Emergency Mode 40

8 CLEANING AND MAINTENANCE 41

8.1 Cleaning 41

8.1.1 Cleaning Sta 41

8.1.2 Safety Instructions 41

8.1.3 Cleaning Procedures 42

8.2 Maintenance 43

8.2.1 Maintenance Sta 43

8.2.2 Safety Instructions 43

8.2.3 Maintenance Procedures 44

9 INSPECTIONS ACCORDING TO DIN EN 50177: 2010 45

10 DISASSEMBLY AND DISPOSAL 49

10.1 Disassembly 49

10.2 Disposal 49

11 TROUBLE SHOOTING AND RECTIFICATION 50

11.1 Faults 51

12 ACCESSORIES 52

13 SPARE PARTS 53

13.1 How Can Spare Parts Be Ordered? 53

13.2 EPG S2 Control Unit 54

14 WARRANTY AND CONFORMITY DECLARATIONS 55

14.1 Important Notes Regarding Product Liability 55

14.2 Warranty Claim 55

14.3 CE Declaration of Conformity 56

14.4 EC Type Examination Certi cate 57

14.5 FM Identi cation EPG S2 FM 58

Page 5

5

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

1.2 WARNINGS, NOTICES AND SYMBOLS IN THESE INSTRUCTIONS

1 GENERAL

Warning instructions in this operating manual highlight particular dangers to users and to

the device and state measures for avoiding the hazard. These warning instructions fall into

the following categories:

Danger - immediate risk of danger.

Non-observance will result in death or serious injury.

Warning - possible imminent danger.

Non-observance may result in death or serious injury.

Caution - a possibly hazardous situation.

Non-observance may result in minor injury.

Note - provides information about particular characteristics and how to proceed.

Notice - a possibly hazardous situation.

Non-observance may result in damage to property.

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions.

The signal word indicates the hazard level.

The measures for preventing the hazard and its consequences.

DANGER

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions.

The signal word indicates the hazard level.

The measures for preventing the hazard and its consequences.

WARNING

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions.

The signal word indicates the hazard level.

The measures for preventing the hazard and its consequences.

CAUTION

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions. The signal word

indicates the hazard level.

The measures for preventing the hazard and its consequences.

NOTICE

The operating manual contains information about safely operating, maintaining, cleaning

and repairing the device.

The operating manual is part of the device and must be available to the operating and

service personnel.

Operating and service personnel should be instructed according to the safety instructions.

The device may only be operated in compliance with this operating manual.

This equipment can be dangerous if it is not operated according to the instructions in this

operating manual.

1.1 PREFACE

Page 6

6

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

1.3 LANGUAGES

The operating manual is available in the following languages:

German 2317573 English 2317574

French 2317575 Italian 2317576

Russian 2334207 Chinese 2335799

Hungarian 2338270 Czech 2348860

Spanish 2355652 Danish 2371619

Swedish 2371624 Portuguese 2392066

1.4 ABBREVIATIONS

Number of pieces

Position

Marking in the spare parts lists

Order No. Order number

No. Number

Spare part

Page 7

7

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

2 CORRECT USE

2.1 DEVICE TYPE

Universal control unit for controlling two electrostatic manual or automatic powder spray guns.

2.2 TYPE OF USE

The EPG S2 control unit is intended for controlling electrostatic manual and automatic

powder spray guns of type A-P (2 mJ) according to DIN EN 50177.

2.3 USE IN AN EXPLOSION HAZARD AREA

The EPG S2 control unit are intended for use with powder spray guns of types A-P up to 2 mJ

in accordance with the prototype test PTB 12 ATEX 5001.

The EPG S2 control unit may be used in the dust explosion zone (zone 22) under the

following conditions:

– Control unit correctly tted and connections on rear correctly and securely sealed with

associated cover.

– Not used electrical connections are sealed with protective caps.

Incorrect use!

Risk of injury and damage to the device.

Only connect original WAGNER spray guns to the EPG S2 control

unit.

WARNING

Page 8

8

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

2.5 REASONABLY FORESEEABLE MISUSE

– Coating work pieces which are not grounded

– Use of defective components and accessories

– Use with non-authorized power spray guns

2.4 SAFETY PARAMETERS

The control unit is only suited for controlling powder spray guns.

Wagner International AG prohibits any other use!

The use of the control unit is only permissible under the following conditions:

– the operating sta have previously been trained on the basis of this operating manual,

– the safety regulations listed in this operating manual are observed,

– the operating, maintenance and repair information in this operating manual is observed,

– and the statutory requirements and accident prevention regulations standards in the

country of use are observed.

The control unit may only be used if all parameters are set and all measurements/safety

checks are carried out correctly.

2.6 RESIDUAL RISKS

Residual risks are risks which cannot be ruled out even in the event of correct use.

If necessary, warning and prohibition signs at the relevant points of risk indicate residual

risks.

Residual risk Source Consequences Speci c measures Lifecycle

phase

Skin contact with

powder lacquers

and cleaning

agents

Handling powder

lacquers and

cleaning agents

Skin irritation, allergies Wear protective

clothing

Operation,

observe safety data

sheets

maintenance,

disassembly

Powder lacquer

in air outside the

de ned working

area

Lacquering outside

the de ned

working area

Inhalation of substances

which are hazardous to

health

Observe work and

operation instructions

Operation,

maintenance

Page 9

9

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

3 IDENTIFICATION

3.1 EXPLOSION PROTECTION IDENTIFICATION

The device is suited for use in potentially explosive areas, in accordance with Test Certi cate

PTB 12 ATEX 5001.

0102

II 3(2)D IP 64 80 °C

CE: European Communities

0102: Noti ed body

Ex: Symbol for explosion protection

II: Device class II

3: Category 3 (Zone 22)

(2): Impact on equipment of category 2

D: Ex-atmosphere dust

IP64: Protection class 64

80 °C: Temperature class: maximum surface temperature < 80 °C; 176 °F

3.2 PERMISSIBLE DEVICE COMBINATIONS

The following powder spray guns may be connected to the EPG S2:

Automatic spray guns

– Corona spray gun PEA-C3, PEA-C4

– Corona spray gun PEA-C3XL, PEA-C4XL

– Tribo spray gun PEA-T3

– Tribo spray gun PEA-T3XL

Manual spray guns

– Corona spray gun PEM-C3, PEM-C4 HiCoat, PEM-C4 Ergo,

PEM-X1

Older or other gun types may only be connected to the control unit after rst checking

their suitability with WAGNER.

Page 10

10

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

4 GENERAL SAFETY INSTRUCTIONS

4.1 SAFETY INSTRUCTIONS FOR THE OPERATOR

4.1.1 ELECTRICAL DEVICES AND EQUIPMENT

4.1.2 PERSONNEL QUALIFICATIONS

4.1.3 SAFE WORK ENVIRONMENT

To be provided in accordance with the local safety requirements with regard to the

operating mode and ambient in uences.

May only be maintained by skilled electricians.

Must be operated in accordance with the safety regulations and electrotechnical

regulations.

Must be repaired immediately in the event of problems.

Must be decommissioned if they pose a hazard.

Must be de-energized before work is commenced on active parts.

Secure the device against being switched back on without authorization. Inform sta

about planned work.

Observe electrical safety regulations.

The oor in the working area must be electrostatically conductive (measurements according

to EN 1081).

Make sure that all persons within the working area are wearing electrostatic-conductive

shoes.

Ensure that gloves worn are made of conductive material.

The powder release must be electrically interlocked with the powder spray system's

exhaust air equipment.

Excess coating product (overspray) must be collected up safely.

Ensure that there are no ignition sources such as naked ames, sparks, glowing wires,

or hot surfaces in the vicinity. No smoking.

Maintain su cient quantities of suitable re extinguishers and ensure that they are

serviceable.

The operating company must ensure that an average concentration of powder lacquer

in the air does not exceed 50% of the lower explosion limit (LEL = max. permitted

concentration of powder to air). If no reliable LEL value is available, the average

concentration must not exceed 10 g/m³.

Keep this operating manual at hand near the device at all times.

Always follow local regulations concerning occupational safety and accident prevention.

Ensure that the device is operated, maintained and repaired only by trained persons.

Page 11

11

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

4.2.1 SAFE HANDLING OF WAGNER POWDER SPRAY DEVICES

4.2.2 GROUNDING THE DEVICE

4.2.3 PRODUCT HOSES

4.2 SAFETY INSTRUCTIONS FOR STAFF

Use only an original WAGNER powder hose.

Always follow the information in this manual, particularly the general safety instructions

and the warning instructions.

Always follow local regulations concerning occupational safety and accident prevention.

Under no circumstances may anyone tted with active implants (e.g., a pacemaker)

enter the area where the high-voltage eld between the spray gun and the work piece

to be coated builds up!

Do not point spray guns at people.

Before all work on the device, in the event of work interruptions and functional faults:

– Switch o the energy/compressed air supply.

– Secure the spray gun against actuation.

– Relieve pressure on spray gun and device.

– In case of functional faults: Identify and correct the problem, proceed as described in

the "Fault Recti cation" chapter.

The electrostatic charge may, in certain cases, give rise to electrostatic charges on the

device. This may result in the formation of sparks or ames when discharging.

Ensure that the device is grounded before each coating process.

Ground the work pieces to be coated.

Ensure that all persons inside the working area are grounded, e.g., by wearing electrostatically

conductive shoes.

The functionality of grounding cables must be checked regularly (see EN 60204).

Page 12

12

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

4.2.5 HANDLING POWDER LACQUERS

When preparing or processing the powder and cleaning the device, take note of the

processing regulations laid down by the manufacturer of the powder lacquers being

used.

Take note of the manufacturer’s instructions and the relevant environmental protection

regulations when disposing of powder lacquers.

Implement the prescribed safety measures, in particular the wearing of safety glasses

and safety clothing as well as the use of protective hand cream.

Use a mask or breathing apparatus if necessary.

To ensure su cient protection of health and the environment, only operate the device

in a powder booth or on a spray wall with activated ventilation (exhaust air).

4.2.4 CLEANING

Before starting cleaning or any other manual work, the high voltage in the spray area

must be shut down and locked to prevent it from being switched back on.

Lock the compressed air supply and decompress the device.

Secure the device against being switched back on without authorization.

Use only electrically conducting and grounded tanks for cleaning uids.

Preference should be given to non- ammable cleaning uids.

Flammable cleaning liquids may only be used if, after switching o the high voltage, all

high-voltage conducting parts are discharged to a discharge energy of less than 0.24 mJ

before they can be accessed.

Most ammable solvents have an ignition energy of around 0.24 mJ or 60 nC.

The cleaning agent's ash point must be at least 15 K above the ambient temperature.

Only mobile industrial vacuum cleaners of design 1 (see EN 60335-2) may be used to

remove dust deposits.

Page 13

13

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

4.3 PROTECTIVE AND MONITORING EQUIPMENT

Protective and monitoring equipment!

Risk of injury and damage to the device.

Protective and monitoring equipment must not be removed,

modi ed or rendered unusable.

Regularly check for perfect functioning.

If defects are detected on protective and monitoring equipment,

the system must not be operated until these defects are remedied.

WARNING

Page 14

14

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

4.4 SAFETY FEATURE IDENTIFICATION

Plates bearing information for the user have been attached to the work openings of the powder

coating booth.

The plate size corresponds to the standard category

100 mm; 3.94 inches.

The label plates, which must be attached, are shown below:

High voltage!

In the control cabinet:

(25 mm; 0.98 inches)

Voltage before main switch

Forbidden for unauthorized

persons!

Explosive atmosphere!

Forbidden for anyone

tted with active implants

(e.g., a pacemaker) must!

Follow the instructions in the

operating manual!

Smoking, re, and open

ames are prohibited!

Wear electrostatically

conductive footwear!

Danger of crushing!

Risk of tripping!

Do not jump on the

booth oor!

Danger of slipping!

Page 15

15

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

5 DESCRIPTION

5.1 FIELDS OF APPLICATION, CORRECT USE

The EPG S2 control unit is used to supply air and voltage to two WAGNER automatic or

manual powder spray guns, in Corona or Tribo versions.

The control unit has no controls; various operating statuses are simply displayed.

The module is operated with a superordinate controller (e.g. PLC) from which it receives

the necessary information.

The interface between the EPG S2 and master controller takes place by means of the CANopen.

Incorrect use!

Risk of injury and damage to the device.

Only connect original WAGNER spray guns to the EPG S2 control

unit.

WARNING

Page 16

16

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

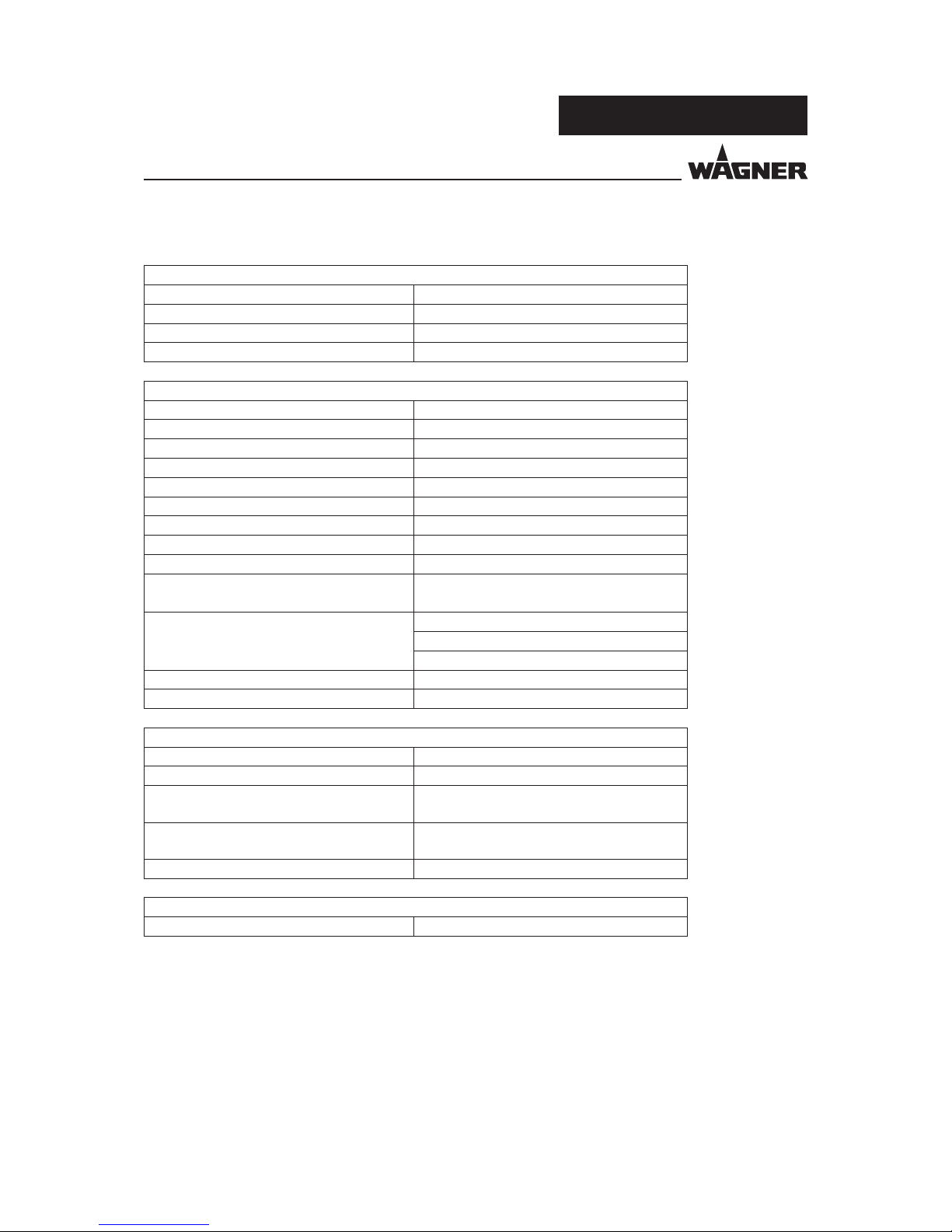

Dimensions:

Height 136 mm; 5.35 inches

Width 270 mm; 10.63 inches

Depth (without operating elements) 300 mm; 11.81 inches

Weight 5.5 kg; 12.13 lb

Electrical:

Mains (AC) 90 VAC–250 VAC

Frequency 47 Hz–63 Hz

AC input power maximum 60 W

Output voltage to guns 2x maximum 22 Vpp

Output current 2x maximum 0.9 A

High voltage 2x 10-100 kV (adjustable in 1 kV steps)

Corona current limitation 5 μA - 120 μA (adjustable in 1 μA steps)

Tribo current measurement 0 μA - 20 μA (resolution 0.1 μA)

Minimum Tribo current limit 0 μA - 5 μA (adjustable in 0.1 μA steps)

Maximum Tribo current cut o greater than 12 μA

(ATEX: switching o of the unit)

CAN bus IN/OUT Signal optically separated

Protocol: CANopen

Release 24 V DC

Protection class IP 64

Ex zone II 3(2)D 80 °C; 176 °F

Pneumatic:

Input air pressure 0.6–0.8 MPa; 6–8 bar; 87–116 psi

Air ow maximum 30 m³/h

6 x air quantity regulator with

ACTUAL value measurement

0.00 - 6.00 m³/h

(adjustable in 0.025 m³/h steps)

Required compressed air quality as per

ISO8573.1

6.5.2 (5 μm/+7 °C; +44.6 °F/0.1 mg/m³)

Connection hose diameter 8 mm; 0.315 inches

Ambient conditions:

Operating temperature range +5 °C up to +45 °C; +41 °F up to +113 °F

5.2 TECHNICAL DATA

Page 17

17

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

Exhaust air containing oil!

Risk of poisoning if inhaled.

Provide compressed air free from oil and water

(Quality Standard 3.5.2 according to ISO 8573.1)

3.5.2 = 5 μm / +7 °C; +44.6 °F / 0.1 mg/m³.

WARNING

NOTICE

Compressed air quality, accessories

Danger of damage to the device.

Operate the control unit only with the prescribed compressed air quality.

Only use the control unit with original WAGNER accessories.

Non-observance of these conditions results in the warranty expiring!

Ambient conditions:

If low-melting powders are used, the ambient temperature may have to be lower than +30 °C;

+86 °F.

Volume measures:

for volumes speci ed in Nm³ (standard cubic meters). One cubic meter of a gas at 0 °C and

1.013 bar is called norm cubic meter.

Page 18

18

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

Stk Order No. Designation

1 2316991 EPG S2

1 2343176 EPG S2 FM (USA edition)

The standard equipment includes:

1 2322580 Declaration of Conformity

1 2317573 Operating manual, German

1 see Chapter 1.3 Operating manual in local language

5.4 SCOPE OF DELIVERY

5.3 PERMITTED ACCESSORIES

Only the accessories listed in the "Accessories" chapter of this operating manual may be

connected to the EPG S2 control unit.

The accessories listed in the chapter "Accessories" were included in the EC type examination

and are approved for use with the control unit.

Page 19

19

EPG S2

P_01487

A B

S2

EPG

654312456

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

5.5 DISPLAY AND OPERATING ELEMENTS

5.5.1 DISPLAY ELEMENTS, FRONT SIDE

1 LED display: "Operating voltage"

– The LED lights up green when the operating voltage is activated

2 LED display: "CAN Data Communication"

– The LED lights up green during data communication with the master

3 LED display: "Release"

– The LED lights up green when enabling has taken place

4 LED display: "Air"

– The LED lights up green when the air module is activated

5 LED display: "High voltage"

– The LED lights up green when the high voltage is activated

6 LED display: "Warning/Malfunction"

– The LED ashes in the event of a warning and lights up red in the event of a malfunction

Displays 4 - 6 exist for both gun A and gun B.

Page 20

20

EPG S2

Year of build:

Baujahr:

B

Für den Betrieb in der Zone 22

müssen alle Anschlüsse mit Stecker

oder Schutzkappe versehen sein.

Prim. Fuse

Sicherung

1.0 AT

(slow blow)

Spraygun

Sprühpistole

IN CAN Bus OUT

Data and Interlock

Daten und Verriegelung

Ausgang zur Pistole

Output to gun

I max. 0,9 A

U max. 22 Vpp

Dosage air

Dosierluft

Feeding air

Förderluft

Atomizing air

Zerstäuberluft

Mains power IN / OUT

Netz EIn / Ausgang

6.....8 bar

87..116 psi

Clean and

dry air

Saubere und

trockene Luft

3.5.2 (ISO 8573.1)

Do NOT disconnect under voltage!

NICHT unter Spannung trennen!

Air input

Lufteingang

Dosage air

Dosierluft

Feeding air

Förderluft

Atomizing air

Zerstäuberluft

A

AABB

Type / Typ:

Serial No.:

Serie Nr.:

Voltage:

Spannung:

Line Power:

Eingangsleistung:

Prot. Class:

Schutzklasse:

EPG S2

90-250 VAC 47-63 Hz

max. 60 W

IP 64

CH 9450 Altstätten

Made in Switzerland

II 3(2)D IP64 80ºC

Tested / Geprüft EN50050, EN50177

For operation all ports must be fitted

with a plug or the protection cap.

PTB 12 ATEX 5001

Wagner International AG

1 2

8 17 16 15 11 10 9 8

73 4

P_01488

14

5 6

1213

0102

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

5.5.2 CONNECTIONS ON THE REAR SIDE OF THE EPG S2

1 Primary fuse

– 1 ampere, slow-acting

2 Grounding connection

– To connect the signal ground

3 Compressed air Inlet

– The LED lights up green when enabling has taken place

– Pressure range: 0.6-0.8 MPa; 6-8 bar; 87-116 psi

– Air volume: 2x maximum 15 m³/h

– Connection hose diameter 8 mm; 0.315 inches

4 Input: CAN bus connector plug

– CANopen communication signal

– Release signal

5 Output: CAN bus bushing

– CANopen communication signal

– Release signal

Page 21

21

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

6 Gun connection B

– To connect a Corona or Tribo gun

7 Gun connection A

– To connect a Corona or Tribo gun

8 Fixations

– For screwing to the rack

9 Cover of the service connection

– Once the cover has been removed, the DIP switches and rotary switches for the

CAN bus address, CAN bus baud rate and the switch for emergency mode can be set.

10 Air outlet for atomizing air gun A

11 Air outlet for dosing air gun A

12 Air outlet for feed air gun A

13 Air outlet for atomizing air gun B

14 Air outlet for dosing air gun B

15 Air outlet for feed air gun B

16 Mains input terminal

– Universal input 90 - 250 VAC

17 Mains output terminal

– To loop the mains through the system

Page 22

22

EPG S2

Serial No. / Year of build:

Serie Nr. / Baujahr:

B

Prim. Fuse

Sicherung

1.0 AT

(slow blow)

Spraygun

Sprühpistole

IN CAN Bus OUT

Data and Interlock

Daten und Verriegelung

Ausgang zur Pistole

Output to gun

I max. 0,9 A

U max. 22 Vpp

Dosage air

Dosierluft

Feeding air

Förderluft

Atomizing air

Zerstäuberluft

Mains power IN / OUT

Netz EIn / Ausgang

Air input

Lufteingang

Dosage air

Dosierluft

Feeding air

Förderluft

Atomizing air

Zerstäuberluft

A

AABB

Overvoltage Category II

and pollution Degree 2

FM approved for CL II, Div 2 Grps E, F, & G

Use in accordance with

control document:

2309729

Made in Switzerland

CH 9450 Altstätten

Voltage:

Spannung:

Line Power:

Eingangsleistung:

90-250 VAC 47-63 Hz

max. 65 W

Type / Typ:

EPG S2 FM

For operation all ports must be fitted

with a plug or the protection cap.

Controller is suitable for Class II,

Division 2, Hazardous (Classified)

locations.

Do NOT connect or disconnect

when ENERGIZED !

Ambient temp range 5C to 45C T5

Wagner International AG

1 2

8 17 16 15 11 10 9 8

73 4

P_02472

14

5 6

1213

0102

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

5.5.3 CONNECTIONS ON THE REAR SIDE OF THE EPG S2 FM

The model di ers only in the version of the rear label from the EPG S2 variant described in

Chapter 5.5.2.

From a technical standpoint, the FM version is identical to the one described in Chapter 5.5.2.

Page 23

23

EPG S2

4

1

5

323

2

4

1

P_01508

5

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

5.5.4 CAN BUS CONNECTION ON THE REAR SIDE

Connector plug Equipment socket

5-pin plug M12, A coded

No. Signal

1 Shield/housing

2 +24 VDC release

3 GND

4 CAN_H

5 CAN_L

IN OUTCAN bus

Data and interlock

Page 24

24

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

6 ASSEMBLY AND COMMISSIONING

6.1 TRAINING ASSEMBLY/COMMISSIONING STAFF

Incorrect installation/operation!

Risk of injury and damage to the device.

The commissioning sta must have the technical skills to safely

undertake commissioning.

The commissioning sta must be familiar with the provisions of

the European standards DIN EN 50050-2 and DIN EN 50177.

When commissioning and for all work, read and follow the

operating manual and safety regulations for the additionally

required system components.

WARNING

6.2 STORAGE CONDITIONS

Until the point of assembly, the control unit must be stored in a dry location, free from

vibrations and with a minimum of dust. The control unit must be stored in closed rooms.

The air temperature at the storage location must be between +5 °C and +45 °C; +41 and

+113 °F.

The relative air humidity at the storage location must not exceed 75%.

6.3 INSTALLATION CONDITIONS

The air temperature at the installation site must lie between +5 °C and +45°C; +41 °F and

+113 °F.

Depending on the powder lacquer used, the maximum permissible ambient temperature

for reliable operation can be signi cantly below +40 °C; +104 °F.

The relative air humidity at the assembly location must not exceed 75%.

Page 25

25

EPG S2

BA

AABB

P_01490

BA

BA

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

6.4 CONNECTING THE AUTOMATIC SPRAY GUNS

Tribo spray gun* Corona spray gun

Mains input

terminal

Signal ground

e.g., from the powder tank

Powder injector

Mains output to

next control unit

Atomizing air

* A Y distributor is needed to divide the di erent types of air (order No.: 9990149)

e.g., from the powder tank

Powder injector

Compressed air Inlet

CAN bus input

CAN bus output

Page 26

26

EPG S2

BA

AABB

P_01489

BA

BA

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

6.5 CONNECTING THE MANUAL GUNS

Mains input

terminal

e.g., from the powder tank

Powder injector

Compressed air Inlet

Mains output

to next control

unit

Powder injector

CAN bus input

CAN bus output

e.g., from the powder tank

Signal ground

Page 27

27

EPG S2

BA

AABB

BA

AABB

BA

AABB

BA

AABB

BA

AABB

BA

AABB

BA

AABB

BA

AABB

P_01512

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

6.6 CONNECTION DIAGRAM IN THE RACK

Mains input

terminal

Master controller

Close on last device with

terminating plug

(order No. 2321402)

Air di user

Terminate BUS end on

master controller

CAN bus

The CAN bus must be closed at the start and end.

Compressed-air

connection, min. 1"

Page 28

28

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

6.7 GROUNDING

No Grounding!

Risk of explosion and risk of electric shock.

Electrostatic control units and the associated spray equipment

may only be connected to mains supplies with a protective

conductor connection (PE conductor)!

DANGER

Heavy paint mist if grounding is insu cient!

Danger of poisoning.

Insu cient paint application quality:

Ground all device components.

Ground the work pieces to be coated.

WARNING

For safety reasons, the control unit must be properly grounded. The grounding connection

to the energy supply (socket) takes the form of the mains connection cable's protective

conductor, while that to the work piece/system is via the knurled screw on the rear of the

control unit. Both connections are absolutely essential. If installed correctly as described

above, the spray gun is grounded via the gun cable between the control unit and spray

gun.

Good grounding of the work piece is also necessary for optimum powder coating.

A poorly grounded work piece causes:

– dangerous electric charging of the work piece,

– very poor wrap-around,

– uneven coating,

– back spraying to the spray gun, i.e., contamination.

Prerequisites for perfect grounding and coating are:

– clean suspension of the work piece to be coated,

– grounding of spraying booth, conveyor system and suspension on the part of the

building site in accordance with the operating manual or the manufacturer's information,

– grounding of all conductive parts within the working area.

– The grounding resistance of the work piece must not exceed 1 MΩ (megohm).

(Resistance to ground measured at 500 V or 1000 V).

– The footwear worn by the operators must comply with the requirements of ENISO 20344.

The measured insulation resistance must not exceed 100 MΩ (megohms).

Page 29

29

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

– The protective clothing, including gloves, must comply with the requirements

of EN ISO 1149-5. The measured insulation resistance must not exceed 100 MΩ

(megohms).

Sparks between conveyor, conveyor hooks (hangers) and work piece can occur

if electric contact points between conveyor, conveyor hooks (hangers) and work

piece are not su ciently cleaned and therefore the work pieces are not su ciently

grounded!

These sparks can cause heavy radio frequency interference (EMC).

Page 30

30

EPG S2

P_01506

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

6.7.1 GROUNDING THE POWDER COATING SYSTEM

1 Only use mains cables with grounding strand!

2 Connect grounding cable with booth and signal ground!

3 Connect grounding cable to an uncoated metal part of the booth!

4 Remove all paint from hooks and other hanger parts!

5 Do not wear non-conducting gloves!

6 Wear electrostatically conductive footwear!

7 The oor must be electrostatically conductive!

8 Connect oor and booth with system ground!

The control unit is grounded with the grounding cable supplied. The grounding cable is

secured to the control unit's grounding connection and the rack with the screws provided.

Page 31

31

EPG S2

1 2 3 4

P_01509

ON

10

P_01510

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

6.8 DEVICE SETTINGS

6.8.1 CAN BUS BAUD RATE SETTING

The settings described below must be made and/or checked on the EPG S2 control unit

before commissioning.

The baud rate and node number setting for the CAN bus are set mechanically using the

switches under the service cover.

The bit rate is set on the 4-way DIP switch using switches 1, 2 and 3. The switch statuses

are only read in when the control unit is switched on (powered up). In order for a change in

baud rate to take e ect, the device must be switched o and on again.

The possible settings are described in the following table:

Switch CAN baud rate Maximum

cable length

1234

0 0 0 X 1000 kBit/s 25 m

0 0 1 X 800 kBit/s 50 m

0 1 0 X 500 kBit/s 100 m

0 1 1 X 250 kBit/s 250 m

1 0 0 X 125 kBit/s 500 m

1 0 1 X 100 kBit/s 1000 m

1 1 0 X 50 kBit/s 1000 m

1 1 1 X 20 kBit/s 1000 m

Baud rate

CAN bus node ID setting

CAN bus baud rate setting/emergency operation mode

Shown example: Factory setting 250 kBit/s

Page 32

32

EPG S2

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

P_01511

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

6.8.2 CAN BUS NODE ID SETTING

The node IDs for the CAN bus are set using two rotary buttons under the service cover.

The node IDs can be set between 1 and 100 as follows:

Node ID = 10 x value of rotary button on left + value of rotary button on right

Examples:

Node ID 01 (0/1)

Node ID 23 (2/3)

The node ID is only read in and calculated when the control unit is switched on (powered

up). For a change to the node ID to take e ect, the control unit must be switched o and

on again.

Exception:

Node ID 100 (0/0)

Page 33

33

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

7 OPERATION

7.1 TRAINING THE OPERATING STAFF

7.2 SAFETY INSTRUCTIONS

Incorrect operation!

Risk of injury and damage to the device.

The operating sta must be quali ed to operate the entire system.

Before work commences, the operating sta must receive

appropriate system training.

The operating sta must be familiar with the provisions of

European standards DIN EN 50050-2 and DIN EN 50177.

WARNING

Incorrect operation!

Risk of injury and damage to the device.

If contact with powder products or cleaning agents causes skin

irritation, appropriate precautionary measures must be taken,

e.g., wearing protective clothing.

The footwear worn by operating sta must comply with

EN ISO 20344. The measured insulation resistance must not

exceed 100megohms.

The protective clothing, including gloves, must comply with

EN ISO 1149-5. The measured insulation resistance must not

exceed 100 megohms.

WARNING

Page 34

34

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

7.3 CONTROLLABLE SPRAY GUNS

Two powder spray guns can be connected to the EPG S2 control unit. These two guns are

controlled totally independently of one another.

The automatic guns are activated and deactivated via the superordinate controller. The gun

types which can be controlled are listed in Chapter 3.2.

7.4 GUN CABLE LENGTHS

Gun cables are available in the following standard lengths: 5 m; 16.40 ft, 10 m; 32.81 ft and

20 m; 65.62 ft.

Note:

– Maximum permitted gun cable length 35 m; 114.83 ft.

– Keep the cable length as short as possible as the performance of the gun is reduced

with each additional meter of cable.

Incorrect installation/operation!

Risk of injury and damage to the device.

When commissioning and for all work, read and follow the

operating manual and safety regulations for the additionally

required system components.

WARNING

Page 35

35

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

7.5 CONTROL FUNCTIONS ON EPG S2 CONTROL UNIT

7.5.1 SETTING THE HIGH VOLTAGE

The set point high voltage of both channels on the control unit can be set independently

of each other and the actual calculated high voltage value can be shown on the central

controller.

Note:

The speci ed high voltage value is only reached when idling and is reduced as soon as

current ows.

The high voltage can be prede ned in 1 kV steps between 10 and 100 kV.

The graphic shows the characteristic curves for three di erent high-voltage settings.

You can see from the blue curve that a setting of 60 kV allows a maximum current of 110 μA.

Voltage [kV]

Current [μA]

The EPG S2 control unit does not have its own operating or display elements. All speci cations

(set points) and displays (actual values) are transferred by electric signals from a master

controller via the CAN bus. The software in the master controller determines the input

options for set points and displays of the current actual values.

Page 36

36

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

7.5.2 SETTING OF CURRENT LIMITING

The spray current limitation can be set and measured independently in both of the control

unit's channels. If the measured spray current reaches or exceeds the set value, the high

voltage is adjusted downwards until the set spray current is reduced to maximum.

The current limitation can be prede ned in 1 μA steps between 5 and 120 μA.

The graphic shows the characteristic curves for three di erent current restrictions.

You can see from the blue curve that the voltage reduces quickly with a low current

restriction.

Voltage [kV]

Current [μA]

Page 37

37

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

7.5.3 SETTINGS OF HIGHVOLTAGE CHARACTERISTIC

Regardless of the high voltage and spray current limitation set, the characteristic curve of

the voltage/current curve can be set on the EPG S2 control unit.

Three levels are possible:

1. Standard level -> maximum EPG S2 performance

2. Medium level ->reduced EPG S2 performance

3. Soft level -> greatly reduced EPG S2 performance

Properties of the characteristic curve Field of application/remarks

Standard level – for poorly rechargeable types of powder

– Open-circuit voltage 100 kV – for high powder application

– Maximum current 120 μA

(Current limiting)

– This setting corresponds to the usual

WAGNER high-voltage modules and

control units.

Medium level – for small surfaces

– Open-circuit voltage 100 kV – for types of powder that recharge well

– Maximum current 120 μA

(Current limiting)

– To reduce the e ects of overcoating such

as craters and orange peel.

– Increasing the open-circuit voltage

allows for a greater distance between

the spray gun and the work piece while

maintaining su cient powder charging.

Soft level – for types of powder that recharge well

– Open-circuit voltage 100 kV – for small powder application

– Maximum current 80 μA – for post-coatings

The characteristic slope can be set at three levels.

The graphic shows the characteristic curves for the three di erent slopes.

Voltage [kV]

Current [μA]

Page 38

38

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

The de ned eld of application should only be seen as a guideline and must be adjusted to

the type of powder, the distance to the work piece and the work piece geometry.

The combination of high-voltage setting, current limitation and characteristic slope results

in a large number of settings options for each coating situation.

7.5.4 SETTING THE AIR VOLUME

The set point air volume in all 6 channels on the control unit can be set independently of

each other and the actual air volume measured can be shown on the central controller.

The air volume can be set in 0.025 Nm³/h steps between 0.00 Nm³/h and 6.00 Nm³/h. Note that

depending on the application, cases may arise where the maximum ow rate cannot be

reached. In this case, the control unit will issue a warning and the maximum set point must

be reduced.

These maximum values can be found in the instructions for the various injectors and guns.

7.5.5 AIR SUPPLY PRESSURE

The EPG S2 control units are calibrated in the factory to a primary pressure of between

0.6-0.8 MPa; 6-8 bar; 87-116 psi. It is important that the atmospheric pressure supply

line has a large cross-section and that the air supply pressure does not drop during high

demand.

Page 39

39

EPG S2

P_01505

4 5 63126 5 4

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

7.6 DIAGNOSIS AND MONITORING

7.6.1 LED DISPLAYS

9 colored LEDs show various states, activities and malfunctions.

1 LED Power

– Lights up green as soon as the device is switched on

2 LED CAN

– Lights up green during the data communication with the master controller

3 LED Release

– Lights up green when the 24 V release is present

4 LED air ON (gun A/gun B)

– Lights up green when the air controller works

5 LED high voltage ON (gun A/gun B)

– Lights up green when high voltage is switched on

6 LED malfunction

– Lights up red when an error has occurred

Page 40

40

EPG S2

1 2 3 4

1 2 3 4

P_01507

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

7.7 EMERGENCY OPERATION

The EPG S2 has a simple emergency mode. The aim of the emergency mode is to permit

minimal further work should the CAN bus or superordinate controller fail.

The emergency mode parameters must be set before the CAN bus fails, otherwise emergency

mode does not function.

7.7.1 ACTIVATION OF EMERGENCY MODE

In order to activate emergency mode, the DIP switch 4 must be set to "ON" (see gure below).

The switch status is only read in when the device is switched on (powered up). So rst set the

switch and then restart the device.

Emergency mode deactivated

Emergency mode activated

7.7.2 FUNCTIONING OF THE EMERGENCY MODE

The coating system is activated and deactivated using the release hardware line. If the

release is present, the coating system is activated. Unless the set points in the emergency

mode parameter set are set to "0", both guns are always activated.

When emergency mode is activated, the power LED ashes and the CAN LED remains dark.

In addition to emergency mode activation, an error reset is performed for every positive

ank of the release signal.

The device's CAN transceiver is switched o . This means that the device cannot send or

receive messages.

Page 41

41

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

8 CLEANING AND MAINTENANCE

Cleaning work should be undertaken regularly and carefully by quali ed and trained sta .

The sta must be familiar with the DIN EN 50050-2 and DIN EN 50177 provisions. They should

be informed of speci c hazards during their training.

The following hazards may arise during cleaning work:

– Health hazard from inhaling powder lacquer

– Use of unsuitable cleaning tools and aids

8.1 CLEANING

8.1.2 SAFETY INSTRUCTIONS

8.1.1 CLEANING STAFF

Explosive powder/air mixes!

Danger to life and equipment damage.

Before starting cleaning or other manual work, the high voltage

must be shut down and locked to prevent it from being switched

back on!

The spray gun must be separated from the high-voltage supply

before any cleaning work is started!

Use only electrically conductive tanks for cleaning liquids!

Ground the tank!

Preference should be given to non- ammable cleaning uids.

Flammable cleaning liquids may only be used if, after switching

o the high voltage, all high-voltage conducting parts are

discharged to a discharge energy of less than 0.24 mJ before they

can be accessed.

Most ammable solvents have an ignition energy of around

0.24 mJ or 60 nC.

The cleaning agent's ash point must be at least 15 K above the

ambient temperature.

Only mobile industrial vacuum cleaners of design 1

(see EN 60335-2) may be used to remove dust deposits.

DANGER

Page 42

42

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

The cleaning intervals should be adapted by the operator depending on the level of use

and if necessary the level of soiling.

If in doubt, we recommend contacting WAGNER's specialist personnel.

The valid health and safety speci cations and the safety instructions provided in Chapter 4

must be adhered to for all cleaning work.

8.1.3 CLEANING PROCEDURES

Incorrect maintenance!

Risk of injury and damage to the device.

If contact with powder products or cleaning agents causes skin

irritation, appropriate precautionary measures must be taken,

e.g., wearing protective clothing.

The footwear worn by operating sta must comply with

EN ISO 20344. The measured insulation resistance must not

exceed 100megohms.

The protective clothing, including gloves, must comply with

EN ISO 1149-5. The measured insulation resistance must not

exceed 100 megohms.

WARNING

Page 43

43

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

8.2 MAINTENANCE

Maintenance work should be undertaken regularly and carefully by quali ed and trained

sta . They should be informed of speci c hazards during their training.

The following hazards may arise during maintenance work:

– Health hazard from inhaling powder lacquer

– Use of unsuitable tools and aids

Once the maintenance work is complete, the device must be checked by a quali ed person

to ensure a reliable condition.

8.2.1 MAINTENANCE STAFF

8.2.2 SAFETY INSTRUCTIONS

Incorrect maintenance/repair!

Danger to life and equipment damage.

Repair or replacement of devices or parts of devices are only

allowed to be performed outside the hazard area by quali ed

personnel.

DANGER

Incorrect maintenance/repair!

Risk of injury and damage to the device.

Repairs and part replacement may only be carried out by

specially trained sta or a WAGNER service center.

Before all work on the device and in the event of work interruptions:

- Switch o the energy/compressed air supply.

- Relieve spray gun and device pressure.

- Secure the spray gun against actuation.

Observe the operating and service manual for all work.

DANGER

Page 44

44

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

The maintenance intervals should be adapted by the operator depending on the level of

use and if necessary the level of soiling.

If in doubt, we recommend contacting WAGNER's specialist personnel.

The valid health and safety speci cations and safety instructions provided in Chapter 4

must be adhered to for all maintenance work.

Maintenance work Time stamp

per shift weekly

Blow out gun and check for sintering x

Check gun settings x

Check gun discharge pressure x

Blow out powder hoses x

Check grounding x

Check compressed air quality x

Check gun voltage x

Check powder hoses for bends and sintering x

8.2.3 MAINTENANCE PROCEDURES

Incorrect maintenance!

Risk of injury and damage to the device.

If contact with powder products or cleaning agents causes skin

irritation, appropriate precautionary measures must be taken,

e.g., wearing protective clothing.

The footwear worn by operating sta must comply with

EN ISO 20344. The measured insulation resistance must not

exceed 100megohms.

The protective clothing, including gloves, must comply with

EN ISO 1149-5. The measured insulation resistance must not

exceed 100 megohms.

WARNING

Page 45

45

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

9 INSPECTIONS ACCORDING TO DIN EN 50177: 2010

If the system is used for electrostatic coating with ammable coating powders, testing

should be undertaken in accordance with DIN EN 50177: 2010-04 as per Table 3 and Table 4.

Page 46

46

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

Section Type of inspection Requirements Inspection

by

Type of inspection Inspection

interval

1 Checking the e ectiveness of

technical ventilation

Checking the e ectiveness of

technical ventilation

TP/SP

ME

Measurements of air ow speed/

air quantities

Check the di erential pressure

indicator

continuously

2 Link between technical ventilation

equipment and high voltage,

compressed air and coating

material supply

The technical ventilation should

be interlocked such that the

powder feed and high voltage

cannot be switched on, while the

technical ventilation is not working

e ectively.

SP

FI

Test whether the system is safely

stopped and the product supply,

supply air, and high voltage

are switched o when the

ventilation is shut down.

annually

3 Parts carrying high voltage outside

the spray area

Parts carrying high voltage outside

the spray area must be routed such

that discharges which put people at

risk do not occur.

SP

FI

Inspect and test (e.g., by

measurement) whether all parts

carrying high voltage do not

result in discharge which puts

people at risk.

weekly

Legend:

MF = Manufacturer

ER = Employer

SP = Skilled person

FPO = Fire prevention o cer

ELT = Electrician

TP = Trained person

FI = Function inspection

ME = Measurement

OC = Organization check

VI = Visual inspection

CM = Constant monitoring

TT = Technical testing

Page 47

47

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

Section Type of inspection Requirements Inspection

by

Type of inspection Inspection

interval

4E ectiveness of grounding All the system's conductive

elements, such as oors, walls,

ceilings, protective grating,

transport equipment, work

pieces, powder tanks, machines or

construction parts etc. in the spray

area, with the exception of parts

which carry high voltage during

operation, must be connected to

the grounding system. Parts of

the booth must be grounded in

accordance with EN 12215.

SP

VI/ME/CM

Visual check of ground

connections, perform function

test on grounding switch,

measurement of grounding

resistors.

weekly

5 Measures to take if conductive

components are insu ciently

grounded

If su cient grounding of

conductive parts cannot be

ensured, their discharge energy

must not exceed the permissible

value.

SP ME/CM

Measurement of discharge

energy.

weekly

6 Ground leaking resistance from the

work piece attachment point

The resistance to ground of

every work piece's locating point

must not exceed 1 megohm

(measurement voltage must be

1000 V). The form of construction

of the work piece mount must

guarantee that the work pieces

remain grounded during coating.

SP ME/CM

Measure resistance to ground

(work piece receiver - ground

potential) max. 1 megohm @

1000 V.

weekly

Legend:

MF = Manufacturer

ER = Employer

SP = Skilled person

FPO = Fire prevention o cer

ELT = Electrician

TP = Trained person

FI = Function inspection

ME = Measurement

OC = Organization check

VI = Visual inspection

CM = Constant monitoring

TT = Technical testing

Page 48

48

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

Section Type of inspection Requirements Inspection

by

Type of inspection Inspection

interval

7 Measures to take if the work pieces

are insu ciently grounded

If su cient work piece grounding

in accordance with section 6

cannot be ensured, appropriate

equipment, e.g., ionizers, must

be used to discharge electric

charges on the work piece. Such

equipment must not exceed the

permitted discharge energy of the

spray systems with which it is used.

In terms of permitted discharge

energy, this equipment must be

put through the same inspections

as the powder spray systems used

with it. The discharge equipment

must be interlocked with the spray

system such that the high voltage

is switched o and that coating

cannot take place if the discharge

equipment malfunctions.

SP ME/FU/SÜ

Measurement of discharge

energy, check the monitoring

equipment's test function by

triggering it.

weekly

8E ectiveness of the manually

or automatically actuated re

extinguishing systems

(room protection system)

E ectiveness of the manually

or automatically actuated re

extinguishing systems

(room protection system).

HE/BSB FI

Trigger re extinguishing

system, observe manufacturer's

requirements.

6 months

Legend:

MF = Manufacturer

ER = Employer

SP = Skilled person

FPO = Fire prevention o cer

ELT = Electrician

TP = Trained person

FI = Function inspection

ME = Measurement

OC = Organization check

VI = Visual inspection

CM = Constant monitoring

TT = Technical testing

Page 49

49

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

10 DISASSEMBLY AND DISPOSAL

10.1 DISASSEMBLY

Procedure:

1. Switch o the system.

2. Lock the compressed air supply and decompress system.

3. Release electrical cable on control unit.

4. Detach hose for compressed air supply on control unit.

5. Disconnect hoses for feed air, dosing air and atomizing air on the control unit.

6. Remove grounding cable on control unit.

7. Loosen retaining nuts and dismount control unit.

WARNING

Incorrect disassembly!

Risk of injury and damage to the device.

Before starting disassembly:

- Switch o the energy/compressed air supply.

- Ensure that all system components are grounded.

- Secure system against being switched back on without

authorization.

Observe the operating manuals for any work.

10.2 DISPOSAL

Do not dispose of used electrical equipment with household

refuse!

In accordance with European Directive 2012/19/EU on the disposal

of used electrical equipment and its implementation in national

law, this product may not be disposed of with the household refuse,

but must be recycled in an environmentally correct manner.

WAGNER or one of our dealers will take back your used WAGNER

waste electrical or electronic equipment and will dispose of it for

you in an environmentally friendly way. Please contact one of our

service points, one of our representatives or us directly to arrange this.

NOTICE

Page 50

50

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

11 TROUBLE SHOOTING AND RECTIFICATION

Incorrect maintenance/repair!

Danger to life and equipment damage.

WAGNER devices, protective systems and safety, monitoring

and control equipment may only be maintained/repaired as

de ned in Directive 2014/34/EC (ATEX) by trained WAGNER

service personnel or capable persons in accordance with TRBS

1203! Note national regulations!

Repair or replacement of devices or parts of devices may only be

performed outside the hazard area!

DANGER

Incorrect maintenance/repair!

Risk of injury and damage to the device.

Repairs and part replacement may only be carried out by specially

trained sta or a WAGNER service center.

Before all work on the device and in the event of work interruptions:

- Switch o the energy/compressed air supply.

- Relieve spray gun and device pressure.

- Secure the spray gun against actuation.

Observe the operating and service manual for all work.

DANGER

Page 51

51

EPG S2

P_01498

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

11.1 FAULTS

In the event of malfunctions, the red "Malfunction" LED lights up.

The malfunction is described in detail in the superordinate controller.

Page 52

52

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

12 ACCESSORIES

Pos K Stk Order No. Designation

1 2321402 CAN bus termination

1 2320127 CAN bus connection cable, 0.6 m; 1.97 ft

1 2320128 CAN bus connection cable, 2.0 m; 6.56 ft

1 2320129 CAN bus connection cable, 5.0 m; 16.40 ft

1 2320130 CAN bus connection cable, 10.0 m; 32.81 ft

1 2321529 Connection set EPG S2

1 2321744 Set of stickers, gun numbers 1-32

Page 53

53

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

13 SPARE PARTS

13.1 HOW CAN SPARE PARTS BE ORDERED?

Incorrect maintenance/repair!

Risk of injury and damage to the device.

Repairs and part replacement may only be carried out by specially

trained sta or a WAGNER service center.

Before all work on the device and in the event of work interruptions:

- Switch o the energy/compressed air supply.

- Ensure that all system components are grounded.

- Secure the device against being switched back on without

authorization.

Observe the operating and service manual for all work.

WARNING

Always supply the following information to ensure delivery of the right spare part:

Order number, designation and quantity

The quantity need not be the same as the number given in the quantity column "Stk" on

the list. This number merely indicates how many of the respective parts are used in each

component.

The following information is also required to ensure smooth processing of your order:

Identi cation in spare parts lists

Explanation of column "K" (labeling) in the following spare parts lists.

– Address for the invoice

– Address for delivery

– Name of the person to be contacted in the event of any queries

– Type of delivery (normal mail, express delivery, air freight, courier, etc.)

= Wearing parts

Note: These parts are not covered by warranty terms

= Not part of standard equipment, available, however, as additional extra.

Page 54

54

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

13.2 EPG S2 CONTROL UNIT

Pos K Stk Order No. Designation

1 2316991 EPG S2 control unit

1 2343176 EPG S2 FM control unit (USA version)

2 9951117 Slow fuses 1.0 A (included in EPG S2)

Page 55

55

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

14 WARRANTY AND CONFORMITY DECLARATIONS

14.1 IMPORTANT NOTES REGARDING PRODUCT LIABILITY

14.2 WARRANTY CLAIM

Full warranty is provided for this device:

We will at our discretion repair or replace free of charge all parts which within 24 months

in single-shift, 12 months in 2-shift or 6 months in 3-shift operation from date of receipt by

the purchaser are found to be wholly or substantially unusable due to causes prior to the

sale, in particular faulty design, defective materials or poor workmanship.

The type of warranty provided is such that the device or individual components of the

device are either replaced or repaired as we see t. The resulting costs, in particular

shipping charges, road tolls, labour and material costs will be borne by us except where

these costs are increased due to the subsequent shipment of the device to a location other

than the address of the purchaser.

We do not provide warranty for damage that has been caused or contributed to for the

following reasons:

Unsuitable or improper use, faulty assembly or commissioning by the purchaser or a

third party, normal wear, negligent handling, defective maintenance, unsuitable coating

products, substitute products and the in uence of chemical, electrochemical or electrical

agents, except when the damage is attributable to us.

Components that have not been manufactured by WAGNER are subject to the original

warranty of the manufacturer.

Replacement of a component does not extend the period of warranty of the device.

The device should be inspected immediately upon receipt. To avoid losing the warranty,

we or the supplier company are to be informed in writing about obvious faults within

14days upon receipt of the device.

We reserve the right to have the warranty compliance met by a contracting company.

The services provided by this warranty are dependent on evidence being provided in the

form of an invoice or delivery note. If the examination discovers that no warranty claim

exists, the costs of repairs are charged to the purchaser.

It is clearly stipulated that this warranty claim does not represent any constraint on statutory

regulations or regulations agreed to contractually in our general terms and conditions.

Wagner International AG

As a result of an EC regulation e ective from January 1, 1990, the manufacturer shall only

be liable for his product if all parts originate from him or are approved by him, and if the

devices are properly mounted, operated and maintained.

The manufacturer will not be held liable or will only be held partially liable if third-party

accessories or spare parts have been used.

With genuine WAGNER accessories and spare parts, you have the guarantee that all safety

regulations are complied with.

Page 56

56

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

14.3 CE DECLARATION OF CONFORMITY

EPG S2 2322580

Herewith we declare that the supplied version of

EPG S2, Order No. 2316991

complies with the following provisions applying to it:

2014/34/EC (ATEX Directive)

2014/30/EC (EMC Directive)

2011/65/EC (RoHS Directive)

2012/19/EC (WEEE Directive)

Applied standards, in particular:

– EN ISO 12100: 2010

– EN 60204-1:2006+A1:2009+B:2010

– EN 60529:1991+A1:2000+A2:2013

– EN 50050-2:2013

– EN 50177:2009+A1:2012

– EN 60079-0:2012+A11:2013

– EN 60079-31:2014

– EN 1127-1:2011

– EN 61000-6-2:2005+B:2011

– EN 61000-6-4:2007+A1:2011

– EN ISO/IEC 80079-34:2011

Applied national technical standards and speci cations:

– DGUV-I 209-052

Identi cation:

CE Declaration of Conformity

The Declaration of Conformity is enclosed with this product. If needed, further copies

can be ordered through your WAGNER dealer by specifying the product name and serial

number.

Order number:

0102

II 3(2)D IP 64 80 °C

Page 57

57

EPG S2

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

14.4 EC TYPE EXAMINATION CERTIFICATE

Page 58

58

EPG S2

Specialconditionsofuse:

ThesourceelectricalconnectionfortheControlUnitsaretobeconnectedinanunclassified

(ordinary)locationonly.

P_00309

OPERATING MANUAL

VERSION 09/2017 ORDER NUMBER DOC2317574

14.5 FM IDENTIFICATION EPG S2 FM

The EPG S2 FM control unit is FM approved in the USA and Canada using con guration

drawing no. 2309729.

Page 59

Page 60

C

E

R

T

I

F

I

E

D

Order No. 2317574

Version 09/2017

Germany

88677

Phone

Telefax

E-mail ts-powder@wagner-group.com

Switzerland

9450

Phone

Telefax

More contact addresses:

Company/Locations/WAGNER worldwide

Subject to changes without notice

Document No. 11123662

Version C

Loading...

Loading...