Page 1

1-800-328-8251

Wagner Technical Service

http://www.wagnerspraytech.com

Or visit us on the world wide web!

¡O visitenos en Internet!

Owner’s manual: Read this manual for complete instructions

1-800-328-8251

Wagner Technical Service

http://www.wagnerspraytech.com

Or visit us on the world wide web!

¡O visitenos en Internet!

Manual del propietario: Le este manual para obtener instrucciones completas

English - Table of Contents

Safety Information

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Spraying. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Maintenance

Troubleshooting

Registration card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Technical service hours:

Monday through Friday, 8:00 am to 4:30 Central Time

Español - Tabla de Contenido

Información de seguridad

Componentes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Preparación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Rociado

Limpieza . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Solución de problemas . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Targeta de registro del producto . . . . . . . . . . . . . . . . . . . . .13

Lista de piezas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-15

Garantía limitada

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

8-9

1

16

1

1106 • Form No. 0518878A

De lunes a viernes, de 8 a.m. a 4:30 p.m., Hora Central

Need Help?

Call us first for answers fast. Call

Wagner toll-free if you have any comments

or problems with this W

agner product.

Horario del servicio técnico:

¿Necesita Ayuda?

Llámenos primero para obtener

respuestas rápidas.

gratuita de Wagner si quiere hacer un

comentario o tiene problemas con este

producto de Wagner.

Llame a la línea

Page 2

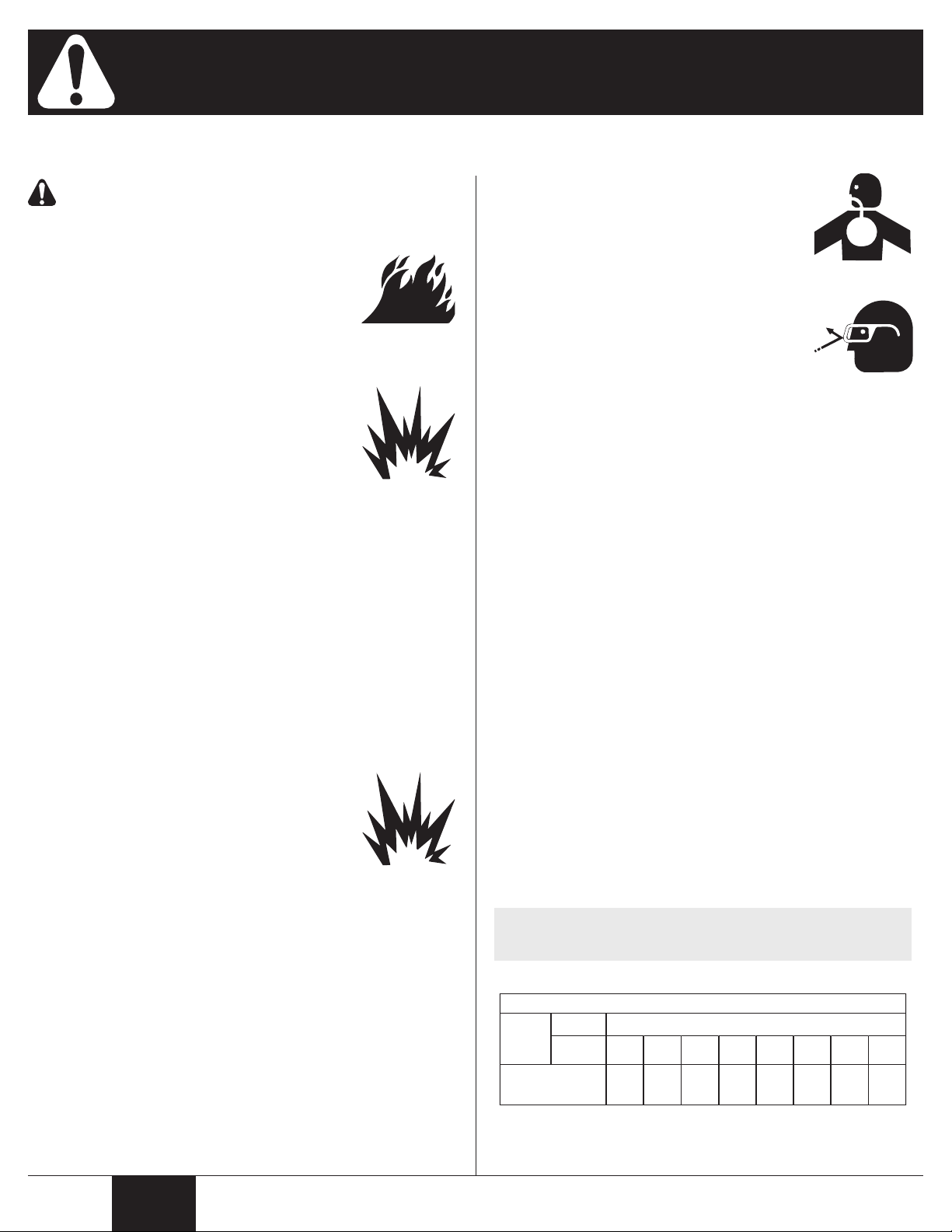

Important Safety Information • Read all safety information before

Minimum gauge for extension cords

Cord length (feet)Voltage

Ampere

rating

range

2 - 3

120V

25-50

100 150 200 250 300 400 500

18

16 14 14 12 12 10 10

operating the equipment. Save these instructions

To reduce the risks of fire or explosion, electrical shock and the injury to persons, read and understand all instructions included in

his manual. Be familiar with the controls and proper usage of the equipment.

t

ndicates a hazardous situation which, if not avoided,

I

could result in death or serious injury.

HAZARD: EXPLOSION OR FIRE

Solvent and paint fumes can explode or ignite.

evere injury or property damage can occur.

S

PREVENTION:

• Provide extensive exhaust and fresh air introduction to keep

the air within the spray area free from accumulation of

flammable vapors.

• Avoid all ignition sources such as static electric

sparks, open flames, pilot lights, electrical

appliances, and hot objects. Connecting or

disconnecting power cords or working light

switches can make sparks.

• Do not smoke in spray area.

• Fire extinguisher must be present and in good working order.

• Use only outdoors in a well-ventilated area. Flammable vapors

are often heavier than air. The turbine contains arcing parts

that emit sparks and can ignite vapors.

• Follow the material and solvent manufacturer’s warnings and

instructions.

• Do not use materials with a flashpoint below 70°F (21°C).

Flashpoint is the temperature that a fluid can produce enough

vapors to ignite (see coating supplier).

• Plastic can cause static sparks. Never hang plastic to enclose

the spray area. Do not use plastic drop cloths when spraying

flammable materials.

HAZARD: EXPLOSION HAZARD DUE TO

INCOMPA

Will cause property damage or severe injury.

REVENTION:

P

• Do not use materials containing bleach or

chlorine.

• Do not use halogenated hydrocarbon solvents such as bleach,

mildewcide, methylene chloride and 1,1,1--trichloroethane.

They are not compatible with aluminum.

• Contact your coating supplier about the compatibility of

material with aluminum.

TIBLE MATERIALS.

AZARD: HAZARDOUS VAPORS

H

Paints, solvents, insecticides, and other

aterials can be harmful if inhaled or come in

m

contact with the body. Vapors can cause

severe nausea, fainting, or poisoning.

REVENTION:

P

• Use a respirator or mask if vapors can be

inhaled. Read all instructions supplied with the

mask to be sure it will provide the necessary

protection.

• Wear protective eyewear.

• Wear protective clothing as required by coating manufacturer.

HAZARD: GENERAL

Can cause severe injury or property damage.

PREVENTION:

• Read all instructions and safety precautions before operating

equipment.

• Follow all appropriate local, state, and national codes

governing ventilation, fire prevention, and operation.

• The United States Government Safety Standards have been

adopted under the Occupational Safety and Health Act

(OSHA). These standards, particularly part 1910 of the

General Standards and part 1926 of the Construction

Standards should be consulted.

• Use only manufacturer authorized parts. User assumes all

risks and liabilities when using parts that do not meet the

minimum specifications and safety devices of the turbine

manufacturer.

• Power cord must be connected to a grounded circuit.

• All swivels, guns and accessories must be rated at or above 10

PSI.

Do not spray outdoors on windy days.

•

• Wear protective clothing to keep paint off skin and hair.

• Never aim spray gun at any part of the body.

Household use only

materials having flashpoint above 70ºF (21ºC).

. Intended for outdoor use ONLY with

English

2

Page 3

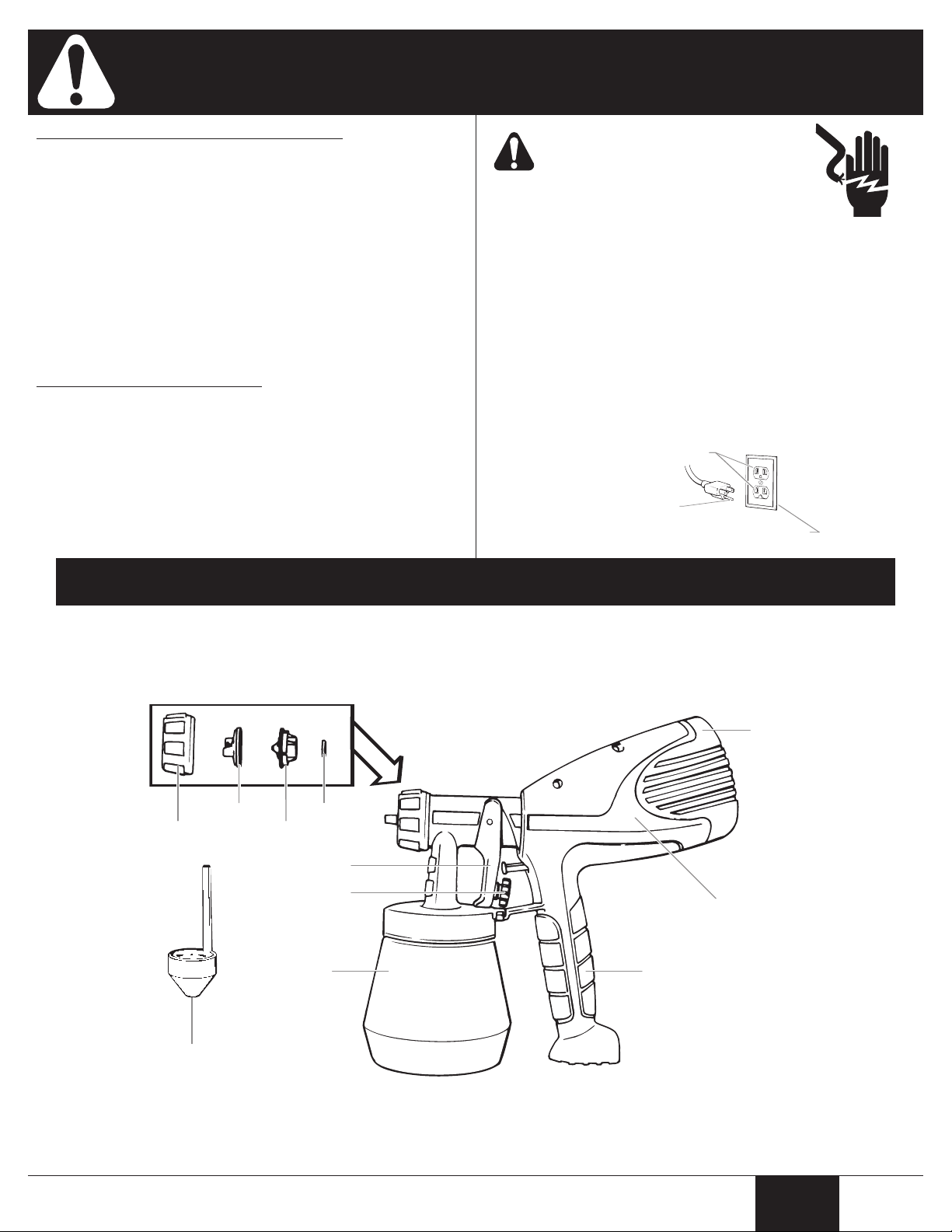

Grounded Outlet

Grounding Pin

Cover for grounded outlet box

Important Safety Information • Read all safety information before

Viscosity

cup

Handle

Filter

housing

Fluid

container

Turbine

Trigger

Material

adjustment

knob

Nut

Air cap Seal

Nozzle

operating the equipment. Save these instructions

Important Electrical Information

NOTICE

Use only a 3-wire extension cord that has a 3-blade grounding plug

and a 3-slot receptacle that will accept the plug on the product.

ake sure your extension cord is in good condition. When using

M

an extension cord, be sure to use one heavy enough to carry the

current your product will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power and overheating. A 14

gauge (200 feet maximum) or 12 gauge cord (300 feet maximum) is

recommended. If an extension cord is to be used outdoors, it must

be marked with the suffix W-A after the cord type designation. For

example, a designation of SJTW-A would indicate that the cord

would be appropriate for outdoor use.

Grounding Instructions

This product must be grounded. In the event of an electrical short

circuit, grounding reduces the risk of electric shock by providing an

escape wire for the electric current. This product is equipped with a

cord having a grounding wire with an appropriate grounding plug.

The plug must be plugged into an outlet that is properly installed

and grounded in accordance with all local codes and ordinances.

DANGER--Improper installation of the

rounding plug can result in a risk of

g

electric shock.

If repair or replacement of the cord or plug is

necessary, do not connect the green grounding

ire to either flat blade terminal. The wire with insulation having a

w

green outer surface with or without yellow stripes is the grounding

wire and must be connected to the grounding pin.

Check with a qualified electrician or serviceman if the grounding

instructions are not completely understood, or if you are in doubt as

to whether the product is properly grounded. Do not modify the

plug provided. If the plug will not fit the outlet, have the proper

outlet installed by a qualified electrician.

This product is for use on a nominal 120 volt circuit and has a

grounding plug that looks like the plug illustrated below. Make sure

that the product is connected to an outlet having the same

configuration as the plug.

Components

3

English

Page 4

Setup

Thinning Chart

Material Runout Time

1) Oil enamel

2) Oil based primer

3) Oil stain

4) Clear sealer

5) Polyurethane

6) Varnish

25-40

30-45

No thinning required

No thinning required

No thinning required

20-50

Assembly

1. Align the arrow on the spray gun with the “unlock” symbol

on the turbine.

2. Insert and twist the spray gun into the turbine toward the

“lock” symbol on the turbine. The tab below the trigger will

lock the two pieces into place.

Aligning the Suction Tube

If you are going to be spraying in a downward direction,

the angled end of the suction tube should be pointing

toward the front of the gun.

Material Preparation

Before spraying, the material being used may need to be

thinned with the proper solvent as specified by the

material manufacturer. Never exceed the thinning

advice given by the coating manufacturer.

Do not use materials with a flashpoint below 70°F

(21°C). Follow the instructions below.

1. Stir the spraying material thoroughly before measuring

viscosity.

2. Dip the viscosity test cup completely into the spraying

material.

3. Hold the test cup up and measure the time in seconds until

the liquid empties out. This time is referred to below as

Runout Time.

If you are going to be spraying in an upward direction,

the angled end of the suction tube should be pointing

toward the rear of the gun.

By pointing the suction tube in the proper direction, you

will not have to refill the container as often.

English

Material to be sprayed should always be strained to

remove any impurities in the paint which may enter and

clog the system. Impurities in the paint will give poor

performance and a poor finish.

MATERIAL FLASH POINT MUST BE 70°F (21°C) OR

HIGHER.

Fill Container

1. Unscrew the cup from the spray gun.

2. After the material has been properly thinned and strained,

fill the container to the top of the neck.

3. Carefully screw the cup back onto the spray gun.

4

Page 5

Spraying

Nut

Air cap

Round pattern

Horizontal pattern

Vertical pattern

Incorrect

Do not flex wrist while spraying.

Light coat Heavy coat Light coat

1 to 12 inches

Correct

Even coat throughout

Keep stroke smooth and at an even speed

Adjust Spray Pattern

The spray pattern shape is adjusted by turning the ears

f the air cap to either the vertical, horizontal, or

o

diagonal positions. The positions of the air cap and the

corresponding spray pattern shapes are illustrated

below.

Test each pattern and use whichever pattern is suitable

for your application.

Proper Spraying Technique

If spraying with an HVLP spray system is new or

unfamiliar to you, it is advisable to practice on a piece of

scrap wood or cardboard before beginning on your

intended workpiece.

Surface Preparation

All objects to be sprayed should be thoroughly cleaned before

praying material on them. Areas not to be sprayed may, in

s

certain cases, need to be masked or covered.

Spray Area Preparation - outdoor use only

The spray area must be clean and free of dust in order to avoid

blowing dust onto your freshly sprayed surface.

How to Spray Properly

Position the spray gun perpendicular to and one (1) or more

•

inches from the spray surface, depending upon the spray

pattern size desired.

• Spray parallel to the surface with smooth passes at a

consistent speed as illustrated below. Doing this will help

avoid irregularities in the finish (i. e. runs and sags).

• Always apply a thin coat of material on the first pass and

allow to dry before applying a second, slightly heavier coat.

• The closer your sprayer is to the object being sprayed the

lower the overspray.

NEVER trigger the gun while adjusting the ears on

the air cap. NEVER point the spray gun at any part

of the body.

Material Flow Adjustment

Set the material volume by turning the regulator on the

trigger of the spray gun.

• When spraying, always trigger the spray gun after spray

pass has begun and release trigger before stopping the

pass. Always keep the gun pointed squarely at the spray

surface and overlap passes slightly to obtain the most

consistent and professional finish possible.

5

English

Page 6

Cleanup

(a)

(b)

Cleaning the Spray Gun

Special cleanup instructions for use with

flammable solvents (must have a flashpoint above

0ºF (21ºC):

7

• Always flush spray gun outside.

Area must be free of flammable vapors.

•

• Cleaning area must be well-ventilated.

DO NOT SUBMERGE TURBINE!

•

1. Unplug the spray gun, and

trigger the spray gun so that

the material inside the spray

gun flows back into the

container.

2. Unscrew the container.

Empty any remaining material

back into the material

container.

6. Spray the solution through the

gun for two seconds in a safe

area. Spray again for two

seconds. Unplug the spray

gun, and trigger the spray gun

so that the material inside the

pray gun flows back into the

s

container.

. Wipe the exterior of the cup

7

and gun until clean.

Unscrew the nut and

8.

remove the air cap

and nozzle.

9. Clean the container,

suction tube, air cap

and nozzle with a

cleaning brush and

the appropriate

cleaning solution.

3. Pour a small amount of the

appropriate cleaning solution

into the cup (warm, soapy

water for latex materials;

mineral spirits for oil-based

materials).

properly dispose of

cleaning solution.

4. Refill the cup with NEW

cleaning solution.

5. Attach the cup to the gun and

plug in the sprayer.

Clean cup and

Never clean nozzle or air holes in the spray gun with

sharp metal objects. Do not use solvents or lubricants

containing silicone.

10. Push the tab below

the trigger, twist and

separate the spray

gun from the turbine.

11. Clean the rear of the

spray gun

appropriate cleaning

solution. Use a thin

layer of petroleum

jelly to lubricate the

O-ring

Reassemble spray

gun.

(a) with the

(b).

English

6

Page 7

Maintenance

You should inspect the air filter in the turbine to see if it

is excessively dirty. If it is dirty, follow the steps below

to replace it.

1. Unplug the spray

gun. Remove the

filter cover from the

urbine by removing

t

the two screws

holding it in place.

Troubleshooting

Problem

A. Little or no material flow

B. Material leaking

Cause

1. Nozzle clogged.

2. Suction tube clogged.

3. Material volume setting turned too low (-).

4. Suction tube loose.

5. No pressure build up in container.

6. Air filter clogged.

1. Nozzle loose.

2. Nozzle worn.

3. Nozzle seal worn.

4. Material build-up on air cap and nozzle

. Remove the dirty

2

filters and replace

ith new ones. The

w

smooth side of the air

filter must be placed

toward the turbine.

3. Secure the cover back onto the turbine.

Never operate your unit without the air filters. Dirt could

be sucked in and interfere with the function of the unit.

Solution

1. Clean.

2. Clean.

3. Increase volume setting (+).

4. Insert.

5. Tighten container.

6. Change.

1. Tighten.

2. Replace.

3. Replace.

4. Clean.

C. Atomization is too coarse

D. Spray jet pulsates

Pattern runs or sags

E.

oo much overspray

T

.

F

Pattern is very light and

G.

splotchy

.

1. Viscosity of material too high.

2. Material volume too large.

3. Material volume setting too high (+).

4. Nozzle clogged.

5. Air filter clogged.

6. Too little pressure build-up in container.

1. Material in container running out.

2. Air filter clogged.

Applying too much material.

1.

Gun too far from spray object.

1.

oo much material applied.

T

2.

Moving the spray gun too fast.

1.

1. Thin.

2. Decrease volume setting (-).

3. Decrease volume setting (-).

4. Clean.

5. Change.

6. Tighten container.

1. Refill.

2. Change.

Adjust material flow or increase

1.

movement of spray gun.

Reduce distance.

1.

Decrease volume setting (-).

2.

Adjust material flow or decrease

1.

movement of spray gun.

Have you tried the recommendations above and are still having problems? In the United States, to speak to a

customer service representative, call our Customer Service at 1-800-328-8251 Monday through Friday between 8:00

AM and 4:30 PM Central time. An automated Self-Help option is also available at 1-800-328-8251, seven days a week,

twenty-four hours a day.

Product Registration Card

Send in your product registration card or register online at www.wagnerspraytech.com. Proper registration will serve as proof of

purchase in the event your original receipt becomes misplaced or lost. Returning this card will expedite the processing of your warranty.

Be sure you write your unit’s date code on the card before sending it. The date code is located underneath the base of your unit

(for example, S087R).

The additional information will also help us to develop new products that best meet your needs and desires.

7

English

Page 8

Parts List • Lista de pieza

2

1

4

6

7

5

3

14

Page 9

Parts List • Lista de pieza

Item

Articulo

1) 0417210 Sprayer assembly Rociador 1

2) 0414364 Container seal Sello de recipiente 1

3) 0414363 Suction tube Tubo de succión 1

4) 0414336 1 1/2 quart container Recipiente de 1.4 litros 1

5) 0417323 Air filter Filtro de aire 1

6) 0202303 Viscocity cup Cubeta de viscosidad 1

7) 9892550 Lubricant Lubricante 1

Part No.

Pieza No.

English Description

Replacement parts available by

calling customer service.

Español Descripción

Los repuestos están disponibles

llamanado al servicio a clientes.

Quantity

Cantidad

15

Page 10

Warranty • Garantía

LIMITED WARRANTY

HVLP PAINT SPRAY EQUIPMENT

This product, manufactured by Wagner Spray Tech Corporation (Wagner), is warranted against defects in material and work-manship for one year

following date of purchase if operated in accordance with Wagner’s printed recommendations and instructions. This warranty does not cover damage

resulting from improper use, accidents, user’s negligence or normal wear. This warranty does not cover any defects or damages caused by service

or repair performed by anyone other than a Wagner Authorized Service Center.

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE IS LIMITED TO ONE YEAR FOLLOWING

DATE OF PURCHASE. WAGNER SHALL NOT IN ANY EVENT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY

KIND, WHETHER FOR BREACH OF THIS WARRANTY OR ANY OTHER REASON. THIS WARRANTY DOES NOT APPLY TO ACCESSORIES.

THIS PRODUCT IS DESIGNED FOR HOME USAGE ONLY. IF USED FOR COMMERCIAL OR RENTAL PURPOSES, THIS WARRANTY APPLIES

ONLY FOR 30 DAYS FROM DATE OF PURCHASE.

If any product is defective in material and/or workmanship during the applicable warranty period, return it with proof of purchase, transportation

prepaid to any Wagner Authorized Service Center. (Service Center listing is enclosed with this product.) Wagner’s Authorized Service Center will

either repair or replace the product (at Wagner’s option) and return it to you, postage prepaid.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS OR THE EXCLUSION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION AND EXCLUSION MAY NOT APPLY TO YOU. THIS WARRANTY GIVES YOU

SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

GARANTÍA LIMITADA--EQUIPO DE ATOMIZACIÓN DE PINTURA HVLP

Este producto, fabricado por la Wagner Spray Tech Corporation (Wagner), está garantizado contra defectos de materiales y de mano de obra por un

año a partir de la fecha de compra siempre y cuando se utilice de acuerdo con las recomendaciones e intrucciones impresas de Wagner. Esta

garantía no cubre daños ocasionados por el uso incorrecto, accidentes, negligencia por parte del usario o el desgaste normal. Esta garantía no

cubre cualquier defecto o daño ocasionado por el servicio o las reparaciones llevadas a cabo fuera de un Centro de Servicio Wagner Autorizado.

CUALQUIER GARANTÍA IMPLÍCITA RFERENTE AL POTENCIAL COMERCIAL O ADAPTABILIDAD PARA UN USO PARTICULAR SE LIMITA A UN

AÑO A PARTIR DE LA FECHA DE COMPRA. WAGNER EN NINGÚN CASO SERÁ RESPONSABLE DE CUALQUIER DAÑO DIRECTO O

INDIRECTO DE CUALQUIER TIPO, YA SEA POR VIOLACIÓN DE ESTA GARANTÍA O CUALQUIER OTRA RAZÓN. ESTA GARANTÍA NO SE

APLICA A LOS ACCESORIOS.

ESTE PRODUCTO ESTÁ DISEÑADO PARA SER UTILIZADO EN EL HOGAR ÚNICAMENTE. SI SE UTILIZA PARA PROPÓSITOS

COMERCIALES O DE ALQUILER, ESTÁ GARANTÍA ES VÁLIDA ÚNICAMENTE DURANTE 30 DÍAS A PARTIR DE LA FECHA DE COMPRA.

Si cualquier producto está defectuoso con respecto a los materiales o mano de obra, regréselo porte pagado junto con el recibo de compra a

cualquier Centro de Servicio W

Autorizado reparará o reemplazará el producto (a la discreción de Wagner) y se lo regresará porte pagado.

ALGUNOS EST

GARANTÍA IMPLÍCITA NI LA EXCLUSIÓN DE DAÑOS DIRECTOS O INDIRECTOS. POR LA TANTO, LA LIMITACIÓN Y LA EXCLUSIÓN

ANTERIOR PUEDEN NO APLICARSE A USTED.

ESTA GARANTÍA LE OTORGA DERECHOS LEGALES ESPECÍFICOS Y USTED TAMBIÉN PUEDE TENER OTROS DERECHOS QUE VARÍAN DE

LOCALIDAD

UNA

ADOS, DEPARTAMENTOS O PROVINCIAS NO PERMITEN LIMITACIONES EN CUANTO AL PERÍODO DE VALIDEZ DE UNA

A OTRA.

Autorizado (la lista de Centros de Servicio se adjunta con este producto). El Centro de Servicio W

agner

agner

Wagner Spray Tech Corporation

1770 Fernbrook Lane

Plymouth, MN 55447

Telephone 1-800-328-8251

Copyright © 2006 Wagner Spray Tech Corporation.

All rights reserved, including right of reproduction in

whole or in part, in any form.

Loading...

Loading...