Page 1

wagner-group.com

AUS

CONTROL PRO 150

HIGH PERFORMANCE AIRLESS SPRAYER

OPERATING INSTRUCTIONS

! NOT FOR COMMERCIAL USE !

Page 2

2

Control Pro 150

AUS

Warning!

Never put your ngers, hands or any other parts of the body into the

spray jet!

Never point the spray gun at yourself, other persons or animals.

Never use the spray gun without safety guard.

Do not treat a spraying injury as a harmless cut. In case of injury to

the skin through coating materials or solvents, consult a doctor

immediately for quick and expert treatment. Inform the doctor

about the coating material or solvent used.

The operating instructions state that the following points must

always be observed before starting up:

1. Faulty units must not be used.

2. Secure spray gun using the safety catch on the trigger.

3. Ensure that the unit is properly earthed. The connection

must take place through a correctly earthed two-pole and earth

socket outlet.

4. Check allowable operating pressure of high-pressure hose and

spray gun.

5. Check all connections for leaks.

The instructions regarding regular cleaning and maintenance of the

unit must be strictly observed.

Before any work is done on the unit or for every break in work the

following rules must be observed:

1. Release the pressure from spray gun and hose.

2. Secure the spray gun using the safety catch

on the trigger.

3. Switch o unit.

Be safety-conscious !

Attention: Danger of injury by injection!

Airless units develop extremely high spraying pressures.

Danger

1

2

3

Page 3

3

Control Pro 150

AUS

Congratulations for the purchase of your

WAGNER Airless high pressure spray gun.

Read this manual carefully before the initial use of this

equipment and observe the safety instructions. Keep

manual and safety instructions carefully stored.

You have purchased a quality product which requires careful

maintenance and care in order to function perfectly.

Important! After each use, the equipment should be

cleaned.

Not cleaning the equipment leads to malfunctioning! For

faults caused by crud, no guarantee claim will be granted.

In case of malfunctioning, check the cleaned equipment once

again prior to sending it in to the service department.

Explanation of symbols used

Danger

Indicates an immediate danger. Unless

avoided, death or serious injuries will

result.

i

Indicates tips for use and other

particularly useful information.

Wear suitable ear protection when

working.

Wear suitable respiratory equipment

when working.

Wear suitable safety gloves when

working.

General Safety Instructions

Warning!

Read all safety notications and instructions.

Failure to comply with the safety notications

and instructions provided may result in electric

shock, re and/or serious injury. The term

"power tool" used below covers both mainsoperated power tools (with mains lead) and

accumulator-operated power tools (without

mains lead).

Danger

1. Work area safety

a) Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

b)

Do not operate power tools in explosive

atmospheres, such as in the presence of ammable

liquids, gases or dust. Power tools create sparks which

may ignite the dust or fumes.

c)

Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose control.

2. Electrical Safety

a)

Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools.

Unmodied plugs and matching outlets will reduce risk

of electric shock.

b) Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c)

Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d)

Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of electric

shock.

f) If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock.

3. Personal safety

a)

Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the inuence of drugs, alcohol or medication. A

moment of inattention while operating power tools may

result in serious personal injury.

b)

Use personal protective equipment. Always

wear eye protection. Protective equipment such as

dust mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure the switch

is in the o-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your nger on the

switch or energising power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control of

the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts.

Page 4

4

Control Pro 150

AUS

g) This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience

and knowledge, unless they have been given

supervision or instruction concerning use of the

appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not

play with the appliance.

h)

Do not lull yourself into a false sense of security

and do not think yourself above the safety rules

for electric tools, even if you are familiar with

the electric tool following extensive practical

experience. Careless use can lead to serious injuries in

fractions of a second.

4. Power tool use and care

a)

Do not force the power tool. Use correct power tool

for your application. The correct power tool will do the

job better and safer at the rate for which it was designed.

b)

Do not use the power tool if the switch does not

turn it on and o. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

c)

Disconnect the plug from the power source and/

or the battery pack from the power tool before

making any adjustments, changing accessories, or

storing power tools. Such preventive safety measures

reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of reach of children and

do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may aect the power

tool's operation. If damaged, have the power tool

repaired before use. Many accidents are caused by

poorly maintained power tools.

f)

Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to

be performed. Use of the power tool for operations

dierent from those intended could result in a hazardous

situation.

g) Keep the handles and grip surfaces dry, clean and

free of oil and grease. Slippery handles and grip

surfaces hamper safe operation and control of the

electric tool in unforeseen situations.

5. Service

a)

Have your power tool serviced by a qualied repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is maintained.

b) If the supply cord is damaged, it must be replaced

by the manufacturer or it’s service agent or a

similarly qualied person in order to avoid a safety

hazard.

Health protection

Danger

Caution! Wear breathing equipment: Paint

mist and solvent vapors are damaging to

health. Always wear breathing equipment

and only work in well ventilated rooms

or using supplementary ventilating

equipment. It is advisable to wear working

clothing, safety glasses, ear protection

and gloves

Flammable materials

Danger

Do not use the spray guns to spray

ammable substances.

Explosion protection

Danger

Do not use the unit in work places which

are covered to the explosion protection

regulations.

Danger of explosion and re through

sources of ame during spraying work

Danger

There may be no sources of ame such

as, for example, open res, smoking

of cigarettes, cigars or tobacco pipes,

sparks, glowing wires, hot surfaces, etc.

in the vicinity.

Electrostatic charging (formation of

sparks or ame)

Danger

Under certain circumstances, electrostatic

charging can occur on the unit due to

the rate of ow of the coating material

when spraying. On discharging this can

result in the emergence of sparks or re.

It is therefore necessary that the unit is

always earthed through the electrical

installation. The connection must take

place through a correctly earthed twopole-and-earth socket outlet.

Ventilation

Good natural or articial ventilation must be ensured in

order to avoid the risk of explosion or re and damage to

health during spray work.

Page 5

5

Control Pro 150

AUS

Secure device and spray gun

All hoses, ttings, and lter parts must be secured

before operating spray pump. Unsecured parts

can eject at great force or leak a high pressure uid

stream causing severe injury.

Always secure the spray gun when mounting or

dismounting the nozzle and in case of interruption to

work.

Recoil of spray gun

Danger

In case of high operating pressure, pulling

the trigger can eect a recoil force of up

to 15 N.

If you are not prepared for this, your

hand can be thrust backwards or your

balance lost. This can lead to injury.

Continuous stress from this recoil can

cause permanent damage to health.

Max. operating pressure

Max. permissible operating pressure for spray gun,

spray gun accessories and high-pressure hose may

not fall short of the maximum operating pressure of

110 bar (11 MPa) stated on the unit.

Coating substance

Caution against dangers that can arise from the sprayed

substance and observe the text and information on the

containers or the specications given by the substance

manufacturer.

Do not spray any liquid of unknown hazard potential.

High-pressure hose (safety note)

Danger

Attention, danger of injury by injection!

Wear and tear and kinks as well as usage

that is not appropriate to the purpose

of the device can cause leakages to form

in the high-pressure hose. Liquid can be

injected into the skin through a leakage.

High-pressure hoses must be checked thoroughly before

they are used.

Replace any damaged high-pressure hose immediately.

Never repair defective high-pressure hoses yourself!

Avoid sharp bends and folds: the smallest bending radius

is about 20 cm.

Do not drive over the high-pressure hose. Protect against

sharp objects and edges.

Never pull on the high-pressure hose to move the device.

Do not twist the high-pressure hose.

Do not put the high-pressure hose into solvents. Use only

a wet cloth to wipe down the outside of the hose.

Lay the high-pressure hose in such a way as to ensure

that it cannot be tripped over.

Electrostatic charging of spray guns and the high-

pressure hose is discharged through the high-pressure

hose. For this reason the electric resistance between the

connections of the high-pressure hose must be equal or

lower than 197 kΩ/m (60 kΩ/ft.).

i

For reasons of function, safety and

durability, only use genuine WAGNER

high-pressure hoses and spray nozzles.

For overview see „Spare parts lists“.

i

The risk of damage rises with the age of

the high-pressure hose.

Wagner recommends replacing highpressure hoses after 6 years.

Connecting the device

A properly earthed socket outlet with earthing

contact must be used for connection. The connection

must be equipped with a residual current protective

device with INF ≤ 30 mA.

Setting up the unit

Danger

When working indoors:

Vapors containing solvents may not be

allowed to build up in the area of the

device.

Setting up the unit on the side a way

from the sprayed object.

A minimum distance of 5 m between the

unit and spray gun is to be maintained.

When working outdoors:

Vapors containing solvents may not be

allowed to blow toward the unit.

Note the direction of the wind.

Set the unit up in such a way that vapors

containing solvents do not reach the unit

and build up there.

A minimum distance of 5 m between the

unit and spray gun is to be maintained.

Maintenance and repairs

Danger

Before carrying out any work on the device,

relieve the pressure and unplug the power

plug from the socket.

Cleaning the unit

Danger

Danger of short circuit through

penetrating water!

Never spray down the unit with highpressure or high-pressure steam

cleaners.

Cleaning units with solvents

Danger

When cleaning the unit with solvents,

the solvent should never be sprayed or

pumped back into a container with a

small opening (bunghole). An explosive

gas/air mixture can be produced. The

container must be earthed.

Do not use ammable materials for

cleaning purposes.

Page 6

6

Control Pro 150

AUS

Earthing of the object

The object to be coated must be earthed.

i

If liquids collect in the area underneath the

outlet valve, this could be due to a leak in

the set of pistons. If operations continue, the

liquid can leak and dirt might get under the

device.

Usable materials

•

Dispersion and latex paints for interior use.

•

Water-based and solvent-containing lacquers and

glazes. Paints, oils, release agents, synthetic enamels,

PVC lacquers, undercoats, base coats, llers and anti-rust

paints.

i

Another tip size and gun lter may be used,

depending on the material to be processed.

Information about all the available tips and

lters can be found in the section about

"Accessories".

Unsuitable materials

•

Materials that contain highly abrasive components,

facade paint, caustic solutions and acidic coating

substances.

•

Flammable materials, materials containing acetone or

cellulose thinner

Field of application

Coating of interior walls as well as small and mediumsized objects outdoors (e.g. garden fences, garage doors,

etc.).

Industrial use is excluded.

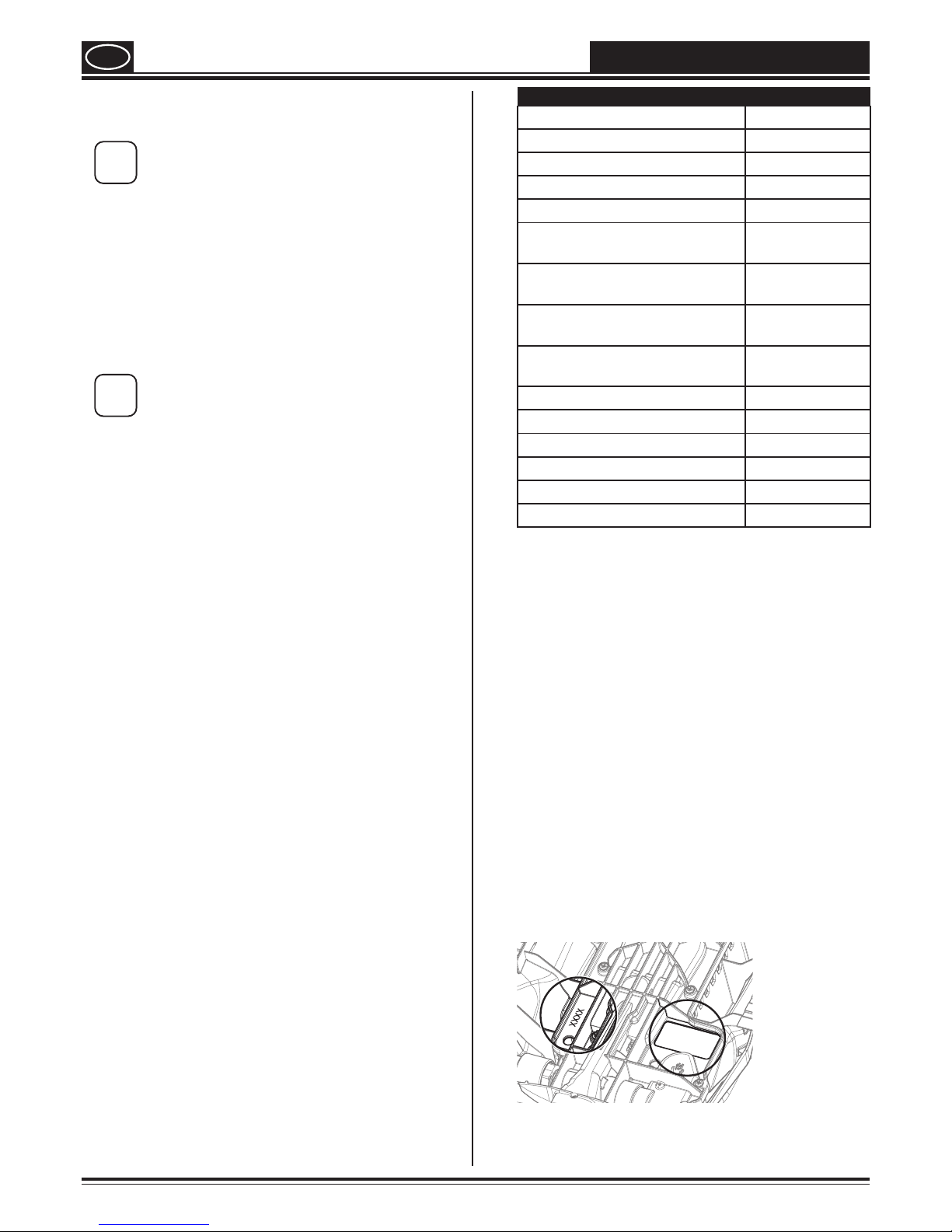

Technical data

Voltage 230-240 V, 50 Hz

Power consumption 350 W

Protection class I

Maximum pressure 11 MPa (110 bar)

Flow rate at 69 bar (0 bar) 0.9 l/min (2.0 l/min)

Maximum temperature of coating

material

43°C

Sound pressure level*

Uncertainty

78 dBA

K= 4 db

Sound pressure output*

Uncertainty

91 dBA

K= 4 db

Oscillation level**

Uncertainty

3.8 m/s²

K = 1.5 m/s²

Maximum ambient temperature 40°C

Pump system piston pump

volume upper container, max. 5.5 l

Max. nozzle size 515 HEA

Max. hose length 22.5 m

Empty weight (pump, hose, gun) 4.1 kg

* Measured in accordance with EN 50580

** Measured in accordance with EN 60745-1

Information about the oscillation level

The specied oscillation level has been measured according

to a standard test procedure and can be used to compare

against electric tools.

The oscillation level is also for determining an initial

assessment of the vibrational strain.

Attention! The vibration emission value can dier from

the specied value when the electric tool is actually in

use, depending on how the electric tool is being used.

It is necessary to specify safety measures to protect the

operating personnel. These measures are based on an

estimated shutdown during the actual conditions of use

(all parts of the operating cycle are taken into consideration

here, for example periods when the electric tool is switched

o, and, when it is switched on but running without any

load).

The rating plate and production code are located on the

underside of the device.

Page 7

7

Control Pro 150

AUS

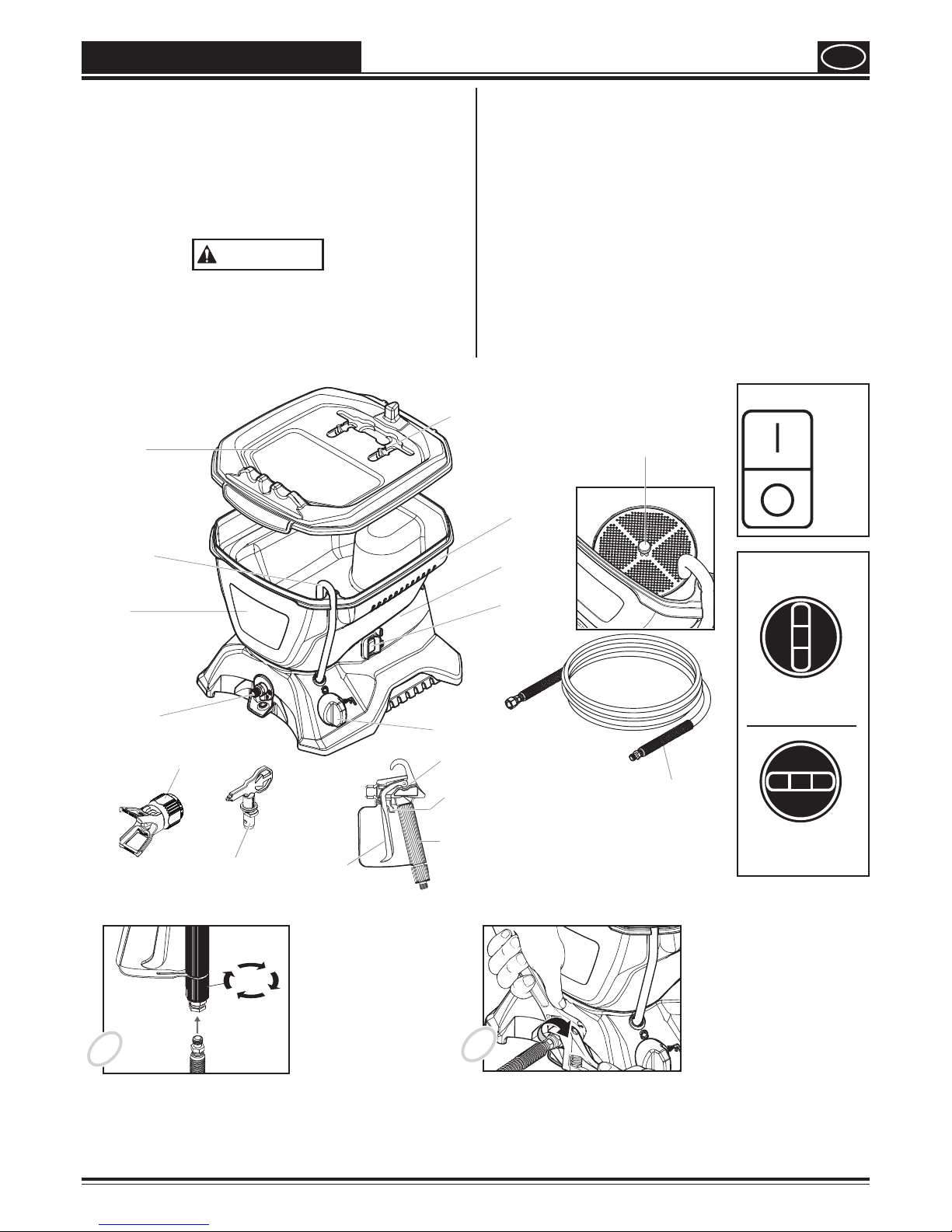

Components

•

Spray gun with lter

•

Spray tip assembly

•

7.5 mtr. long

Tools needed for assembly

•

Two adjustable wrenches.

WARNING

Do not plug in the unit until setup is complete.

Controls and functions

ON/OFF switch The ON/OFF switch turns the unit

on and o (O = OFF, l = ON)

Spray Gun The spray gun controls the

delivery of the uid being

pumped.

Spray Hose The spray hose connects the gun

to the pump.

Return Tube Fluid is sent back out through the

return tube to the hopper when

priming.

PRIME/SPRAY knob The PRIME/SPRAY knob directs

uid to the spray hose when set

to SPRAY, or the return tube when

set to PRIME.

= ON

= OFF

ON/OFF Switch

Assembly

1

2

Place the spray gun against the tapered end of the hose

and twist the gun onto the hose. Firmly tighten the

thread using a wrench

Twist the thread at the other end of the hose onto the hose

connection. Using a wrench, hold the hose connection rmly and

tighten the hose with another wrench.

COMPONENTS AND ASSEMBLY

Spray hose

Motor

housing

ON/OFF

switch

PRIME/SPRAY knob

Trigger lock

Trigger

Inlet lter

(inside of hopper)

Return tube

Outlet valve

Tip storage

Spray gun

Hopper lid

Hopper

Tip guard

Tip 515

Filter (yellow)

preassembled

in gun

Handle

PRIME/SPRAY

knob

PRIME

Position

SPRAY

Position

Page 8

8

Control Pro 150

AUS

Paint straining

It is recommended that in order to avoid premature tip

and lter clogging you should strain your paint before

spraying. Follow manufacturer’s recommendations.

Locking and unlocking the gun

WARNING

Always lock the trigger o when attaching the spray tip

or when the spray gun is not in use.

Locking the gun

The gun is secured when the

trigger lock is at a 90° angle

(perpendicular) to the trigger

in either direction.

Unlocking the gun

To unlock the gun, turn the

trigger lock to be in line with

the trigger.

Plugging in the sprayer

1)

Check that the ON/OFF switch is in the OFF

postion.

O

2) The connection must be made by

correctly grounded plug socket.

Pressure relief procedure

WARNING

Be sure to follow the pressure relief procedure when

shutting the unit o FOR ANY PURPOSE. This procedure

is used to relieve pressure from the spray hose.

1)

Lock the spray gun o and

ip the ON/OFF switch to the

OFF position.

O

2) Turn the PRIME/SPRAY knob

to PRIME.

3) Unlock the spray gun and

then trigger it onto a scrap

piece of wood or cardboard.

4) Lock the spray gun.

Important information

Page 9

9

Control Pro 150

AUS

Make pump ready for operation

1) Make sure the inlet lter is in

place inside the hopper. If it

is not, snap in place as shown.

2)

Press down the button

on the filter once. This

will ensure proper

operation of the inlet valve.

3) Turn the PRIME/SPRAY knob

to PRIME.

4) Plug in the sprayer, and

move the ON/OFF switch to

the ON position.

Button

l

5) Switch the pump to OFF.

O

We recommend performing the following steps with

water rst of all, in order to check that the system and all

connections are watertight.

6) Fill your hopper with the

material you plan to spray.

Do not exceed the ll line as

shown. Replace the hopper

lid.

Fill line

7) Leave the PRIME/SPRAY

knob on PRIME and switch

your unit ON once more

and make sure that material

is owing from the return

tube.

l

i

Mount the cover during operation. The cover

does not close airtight. Therefore, do not tilt

the device when lled.

Suck in material

Perform the following steps, without the spray tip

mounted to the gun.

1)

Unlock the spray gun and

turn the PRIME/SPRAY knob

to PRIME.

2) Trigger and HOLD the spray

gun into a waste container.

3) Switch the pump on.

WARNING

Keep hands clear from uid

stream.

4)

While holding the trigger,

turn the PRIME/SPRAY knob

to SPRAY. Hold the trigger

until all air, water, or solvent

is purged from the spray hose

and paint is owing freely.

l

5) Release trigger, turn the

PRIME/SPRAY knob to

PRIME and turn pump OFF .

O

6) Trigger the gun into the waste container once more to

be sure that no pressure is left in the hose.

7) Lock the spray gun o.

8) Thread the spray tip assembly onto the gun. Tighten by

hand.

Begin

tightening

the tip at

this angle

to achieve

the desired

spray angle

when tight.

9) Insert spray tip (tip pointing in the spray direction).

Your device is now ready for operation.

Preparation

Page 10

10

Control Pro 150

AUS

Practice

CAUTION

Be sure that the paint hose is free of kinks and clear of

objects with sharp cutting edges.

1)

Switch the pump ON and

turn the PRIME/SPRAY knob

to SPRAY.

2) When the motor shuts o,

unlock the spray gun and

spray a test area to check

the spray pattern.

When enough pressure has

built up in the hose, the motor

will shut off automatically.

The motor will cycle on and

o automatically as it needs

pressure.

l

Good spray pattern

Bad spray pattern (tailing)

If your pattern is tailing, your spray tip might have an

obstruction, your spray gun lter might be clogged or

your spray tip might be worn or color is diluted too few.

Refer to Spraying Troubleshooting on the next page.

Spraying technique

The key to a good paint job is an even coating over the

entire surface. This is done by using even strokes. Follow

the TIPS, below.

TIP: Keep your arm moving at a constant speed and

keep the spray gun at a constant distance from

the surface. The best spraying distance is 25 to

30 cm between the spray tip and the surface.

Keep stroke smooth and at an even speed.

Even coat throughout

Approximately

25-30cm

TIP: Keep the spray gun perpendicular to the

surface, otherwise one end of the pattern will

be thicker than the other.

Approximately

25-30cm

Right way

Wrong way

TIP: Keep the spray gun at right angles to the

surface. This means moving your entire arm

back and forth rather than just exing your

wrist.

Heavy Coat

Do not flex wrist while spraying.

Light Coat Light Coat

TIP: The spray gun should be triggered by turning

it on and o with each stroke. Do not trigger

the gun during the middle of a stroke. This

will result in an uneven spray and splotchy

coverage.

Proper way to trigger the spray gun

Approximately

25-30cm

Keep stroke

even

Start stroke End stroke

Pull trigger Release triggerKeep steady

ADDITIONAL TIPS

Overlap each stroke by about 30%. This will ensure an

even coating.

When you stop painting, follow PRESSURE RELIEF

PROCEDURE and unplug electrical cord.

Keep the hopper lid placed on the hopper during

spraying.

This will prevent debris from falling into your spray

material.

IF YOU EXPECT TO BE AWAY FROM YOUR SPRAYER FOR

MORE THAN ONE HOUR, FOLLOW THE SHORT-TERM

STORAGE PROCEDURE DESCRIBED IN THE STORAGE

SECTION OF THIS MANUAL (page 14).

SPRAYING

Page 11

11

Control Pro 150

AUS

The following is a short list of minor diculties you might

encounter while spraying. If any of these occur, it will reduce the

ow of material, making your spray pattern poor, or material

will fail to spray from the gun.

Follow the guidelines on this page to correct any one of

these problems.

Unclogging the spray tip

WARNING

Do not attempt to unclog or clean the tip with your

nger.

CAUTION

Do not use a needle or other sharp pointed instrument

to clean the tip. The hard tungsten carbide can chip.

If the spray pattern becomes distorted or stops completely

while the gun is triggered, follow these steps:

1)

Turn the pump o, and release the trigger and lock the

gun o.

O

2) Rotate the reversible tip arrow 180° so that the point of

the arrow is toward the rear of the gun.

Under pressure, the spray tip

may be very dicult to turn.

Turn the PRIME/SPRAY knob

to PRIME and trigger the gun.

This will relieve pressure and

the tip will turn more easily.

3) Turn the PRIME/SPRAY knob

to SPRAY.

4) Unlock the gun and squeeze the trigger, pointing the

gun at a scrap piece of wood or cardboard. This allows

pressure in the spray hose to blow out the obstruction.

When the nozzle is clean, paint will come out in a high

pressure stream.

If paint still will not spray from the spray tip, follow the

steps on the next column.

5) Release the trigger and lock

the gun o.

6) Reverse the tip so the arrow

points foward again (SPRAY

position).

7) Unlock the gun and resume spraying.

Unclogging the spray gun lter

This lter must be cleaned every time you use your

sprayer. When using thicker paints, the lter might need

to be cleaned more often.

1) Perform Pressure Relief Procedure (page 8).

2)

Unclip the trigger guard from the lter housing by pulling

outward from the lter housing. Unscrew the housing.

Hole

Filter top

(tapered

end)

Housing

Filter

T

rigger

guard

3) Remove the lter from the spray gun housing and clean

with the appropriate cleaning solution (warm, soapy

water)

When cleaning lter, look for sediments in the spraying

material you are using. Refer to Paint Straining, (page 8).

4) Inspect the lter for holes (see Hole picture, above).

Replace if holes are found.

CAUTION

NEVER POKE THE FILTER WITH A SHARP INSTRUMENT!

5) Replace the cleaned lter, tapered end rst, into the

gun housing.

The tapered end of the lter must be loaded properly

into the gun. Improper assembly will result in a plugged

tip or no ow from the gun.

6)

Replace the housing and spring and snap the trigger

guard back into the housing.

Unclogging the inlet lter

1) Perform Pressure Relief Procedure, (page 8).

2)

Empty the hopper of all spraying material (see Emptying

the Hopper, page 12).

3)

Remove the inlet lter from

the hopper. You may need to

use a screwdriver to pry the

lter loose.

4) Clean the inlet lter using

the appropriate cleaning

solution (warm, soapy

water).

5) Replace lter.

Inlet

lter

If after having completed all of the steps on this page

you are still experiencing problems spraying, refer to

the TROUBLESHOOTING page (page 16)

SPRAYING TROUBLESHOOTING

Page 12

12

Control Pro 150

AUS

Important cleaning notes

READ THESE NOTES AND WARNINGS

BEFORE YOU START TO CLEAN YOUR

SPRAYER!

•

Thorough cleaning and lubrication

of the sprayer is the most important

step you can take to ensure proper

operation after storage.

•

Clean the spray device and components

with a suitable cleaning agent (e.g.

warm soapy water for water-soluble

spray materials).

•

Make sure to dispose cleaning

solution properly when nished

cleaning your sprayer.

Emptying the hopper

O

1)

Perform all the steps of the Pressure

Relief Procedure (page 8).

2) Remove the lid from the hopper.

3)

Hold the device by the two handles

on the left and right.

4)

Lift and tilt the sprayer so that material

will pour from one of the front corners

of the hopper and into its original

container.

WARNING

The unit, when lled with spraying

material, can be heavy. Make sure to

lift with your legs and not your back in

order to reduce the risk of injury.

CAUTION

Make sure your oors and furnishings

are protected with drop cloths to avoid

property damage.

Rinsing the hopper

1) Thoroughly rinse out the hopper

using the appropriate cleaning

solution.

Make sure you do not drip any

cleaning solution into the motor

housing.

2)

Remove the inlet filter from the

bottom of the hopper and clean. You

may need to use a screwdriver to pry

the lter loose.

Inlet

lter

3)

Replace the lter and properly dispose

of the cleaning solution.

Flushing the sprayer

1) Fill the hopper with NEW cleaning

solution.

2) Turn the PRIME/SPRAY knob to

PRIME, turn the pump to ON .

l

3)

Let the pump circulate the cleaning

solution out the return tube for 2-3

minutes.

4) Turn the pump OFF .

O

5) Properly dispose of cleaning

solution and move on to Cleaning

the Spray Gun Components, next

page.

Purging the paint hose

These steps will allow you to recover

excess paint left over in the paint hose.

1)

Lock the gun, remove spray tip

assembly, and turn the PRIME/SPRAY

knob to PRIME.

2) Fill the hopper with the appropriate

cleaning solution.

3) Hold the spray gun against the

side of the paint can and hold the

trigger.

4) While holding the trigger, turn the

pump ON, and turn the PRIME/

SPRAY knob to SPRAY.

l

Let the pump run until all paint is

purged from the hose and cleaning

solution is coming out of the gun.

5) Release the trigger and turn the

PRIME/SPRAY knob to PRIME.

6) Hold the spray gun against the side

of a separate container and hold

the trigger.

7) Turn the PRIME/SPRAY knob to

SPRAY and trigger the gun until the

uid coming out of the gun is clear.

You might need to add more

cleaning solution to the hopper.

8) Turn the PRIME/SPRAY knob to

PRIME and trigger gun once more to

relieve pressure.

CLEANUP

Page 13

13

Control Pro 150

AUS

Cleaning the spray gun components

1) Perform Pressure Relief Procedure, page 25.

2)

Remove spray gun from the

paint hose using adjustable

wrenches.

3)

Remove lter from spray gun

(refer to Unclogging the

Spray Gun Filter, page 11).

4) Remove spray tip from spray

guard assembly.

Housing

Filter

5) Clean spray tip and lter with a soft-bristled brush and

the appropriate cleaning solution. Be sure to remove and

clean the washer and saddle seat located in the rear of

the spray tip assembly.

WasherSaddle seat

6)

Pour a few drops of household oil inside the gun housing

(see area indicated below by arrow).

7) Reassemble spray gun:

•

Insert gun lter with the

tapered end rst and screw

down closure with spring.

•

Install spray tip, saddle seat

and washer, and replace spray

guard assembly.

Housing

Filter

8) Thread the paint hose back onto the spray gun. Tighten

with a wrench.

IMPORTANT!

If you cleaned your pump, it is recommended that you

ush the pump again using warm, soapy water to prepare

it for storage. Repeat Flushing the Pump instructions.

Cleaning the inlet valve

Cleaning or servicing the inlet valve may be required

if the unit has priming problems. This may be caused

by improper cleaning and/or storage.

1)

Remove the inlet lter from

the bottom of the hopper.

Inlet

lter

2) Loosen and remove the inlet

valve housing (1) with an

Allen key (8 mm).

3) Remove the valve seat

(2), ball (3), spring (4)

and O-ring seal (5) with a

suitable tool (e.g. needlenose pliers, tweezers).

Tip: alternatively, turn the

device upside down with the

cover on and release the parts

by tapping on the underside of

the device.

4) Check all parts and the valve

area (6) in the container and

clean thoroughly. Replace

damaged parts.

5) Ensure the O-ring seal on the

inlet valve housing (1) is well

lubricated.

6) Replace all parts as shown in

the illustration. The conical

side of the inlet valve seat

(2) must point downwards.

7)

Securely re-tighten the inlet

valve housing (1) with an

Allen key (8 mm).

1

2

5

3

4

6

2

CLEANUP / MAINTENANCE

Page 14

14

Control Pro 150

AUS

Replacing the outlet valve

Replacement of the outlet valve may be necessary if

your spray performance remains poor after having

performed all the steps contained in the Spraying

Troubleshooting section of this manual.

1)

Remove the high-pressure

hose from the outlet

valve using two spanners.

2) Loosen the screw (2.5 mm

Allen key) on the bottom of

the outlet valve, but do not

remove it.

3) Remove the outlet valve

from the base unit using a

spanner.

4) Check the outlet valve and

clean thoroughly (especially

the ball seat on the back).

Replace if necessary.

5) Inspect the inside of the

outlet valve housing.

Remove any accumulated

paint.

6) Reinsert the new or cleaned

outlet valve (tighten into

outlet valve housing with an

adjustable wrench).

7) Re-tighten the screw.

WARNING

Securely tighten the screw to ensure grounding of the

hose and gun.

MAINTENANCE / STORAGE

Short-term storage (up to 8 hours)

Shutdown

1)

Perform all the steps of the PRESSURE RELIEF

PROCEDURE (page 8).

O

2) Pour 1/2 cup water slowly on top of the paint to prevent

it from drying. Replace the hopper lid.

3) Wrap the spray gun assembly in a damp cloth and place

it in a plastic bag. Seal the bag shut.

4) Unplug the sprayer.

5)

Place the sprayer in a safe place out of the sun for

shortterm storage.

Startup

1)

Remove the gun from the

plastic bag and stir the water

into the paint.

2) Check to be sure the PRIME/

SPRAY knob is set to PRIME.

3) Plug sprayer in and turn the

switch to ON.

4) Turn the PRIME/SPRAY knob

to SPRAY.

5) Test the sprayer on a

practice piece and begin

spraying.

l

Page 15

15

Control Pro 150

AUS

Preparing the sprayer for longterm storage

1)

Make sure you have already completed the Cleanup

steps on pages 29-30.

2)

Remove the inlet lter. You may need to use a screwdriver

to pry it loose.

Inlet

lter

3)

Pour approximately 60 ml of light household oil into

the inlet valve.

HOUSEHOLD

OIL

4)

Remove hose from outlet valve, place a rag over the

outlet valve, and turn the switch ON. Let the unit run

for ve seconds.

l

5) Switch the pump OFF.

O

6)

Reinstall the inlet lter and press the button on the lter.

Button

7) Wipe the entire unit, hose and gun with a damp cloth to

remove accumulated paint.

8) Replace the high pressure hose to the outlet valve and

replace the hopper lid.

STORAGE

Storage/Conservation of the gun

1)

Unclip the trigger guard from the lter housing by

pulling outward from the lter housing.

2) Unscrew the housing.

3) Turn the gun over and ll with a few drops of oil.

HOUSEHOLD

OIL

4) Reassemble the gun.

Page 16

16

Control Pro 150

AUS

WARNING

Before servicing, always release system pressure by following PRESSURE RELIEF PROCEDURE (page 8).

PROBLEM CAUSE SOLUTION

A. The sprayer does not start. 1) The sprayer is not plugged in.

2) The ON/OFF switch is set to OFF.

3) The sprayer shuts o while still under

pressure.

4) No voltage is coming from the wall plug.

5) The extension cord is damaged or has too

low a capacity.

6) There is a problem with the motor.

1) Plug the sprayer in.

2) Turn the ON/OFF switch to ON.

3)

Motor will cycle ON and OFF while spraying as it needs

pressure. This is normal. Resume painting.

4) Properly test the power supply voltage.

5) Replace the extension cord.

6) Take sprayer to Wagner Authorized Service Center.

B. The sprayer starts but does

not draw in paint when

the PRIME/SPRAY knob is

set to PRIME.

1) The unit will not prime properly or has lost

prime.

2) The hopper is empty.

3) The unit is not on level ground.

4) The inlet lter is clogged.

5) The inlet or outlet valve is stuck.

6) The inlet valve is worn or damaged.

7) The PRIME/SPRAY valve is plugged.

1) Try to prime the unit again.

2) Rell the hopper.

3) Relocate unit to level ground.

4) Clean the inlet lter.

5)

Clean the inlet and outlet valves and replace any worn parts.

Inlet may be stuck from old paint. Push inlet lter tab to

release.

6) Replace the inlet valve.

7) Take sprayer to Wagner Authorized Service Center.

C. The sprayer draws up

paint but the pressure

drops when the gun is

triggered.

1) The spray tip is worn.

2) The inlet lter is clogged.

3) The gun or spray tip lter is plugged.

4) The paint is too heavy or coarse.

5) The outlet valve assembly is dirty or worn.

6)

The inlet valve assembly is damaged or

worn.

1) Replace the spray tip with a new tip.

2) Clean the inlet lter.

3)

Clean or replace the proper lter. Always keep extra lters

on hand.

4) Thin or strain the paint.

5) Clean or replace the outlet valve assembly.

6) Replace the inlet valve.

D. The PRIME/SPRAY valve is

on SPRAY and there is ow

through the return tube.

1) The PRIME/SPRAY valve is dirty or worn. 1) Take sprayer to Wagner Authorized Service Center.

E. The spray gun leaks. 1) Internal parts of the gun are worn or dirty. 1) Take the sprayer to a Wagner Authorized Service Center.

F. The tip assembly leaks. 1) The tip was assembled incorrectly.

2) A seal is worn.

1) Check the tip assembly and assemble properly.

2) Replace the seal.

G. The spray gun will not

spray.

1)

The spray tip or the gun lter is plugged.

2) The spray tip is in the CLEAN position.

3) PRIME/SPRAY knob not set on SPRAY.

1)

Clean the spray tip or gun lter. Review Unclogging the

Spray Tip.

2) Put the tip in the SPRAY position.

3) Turn the PRIME/SPRAY knob to SPRAY.

H. The paint pattern is tailing. 1)

The gun, the tip, or the inlet lter is plugged.

2) The tip is worn.

3) The paint is too thick.

4) Pressure loss.

1) Clean the lters and strain the paint.

2) Replace the spray tip.

3) Thin the paint.

4) Refer to Causes and Solutions for problem C.

TROUBLESHOOTING

Page 17

17

Control Pro 150

AUS

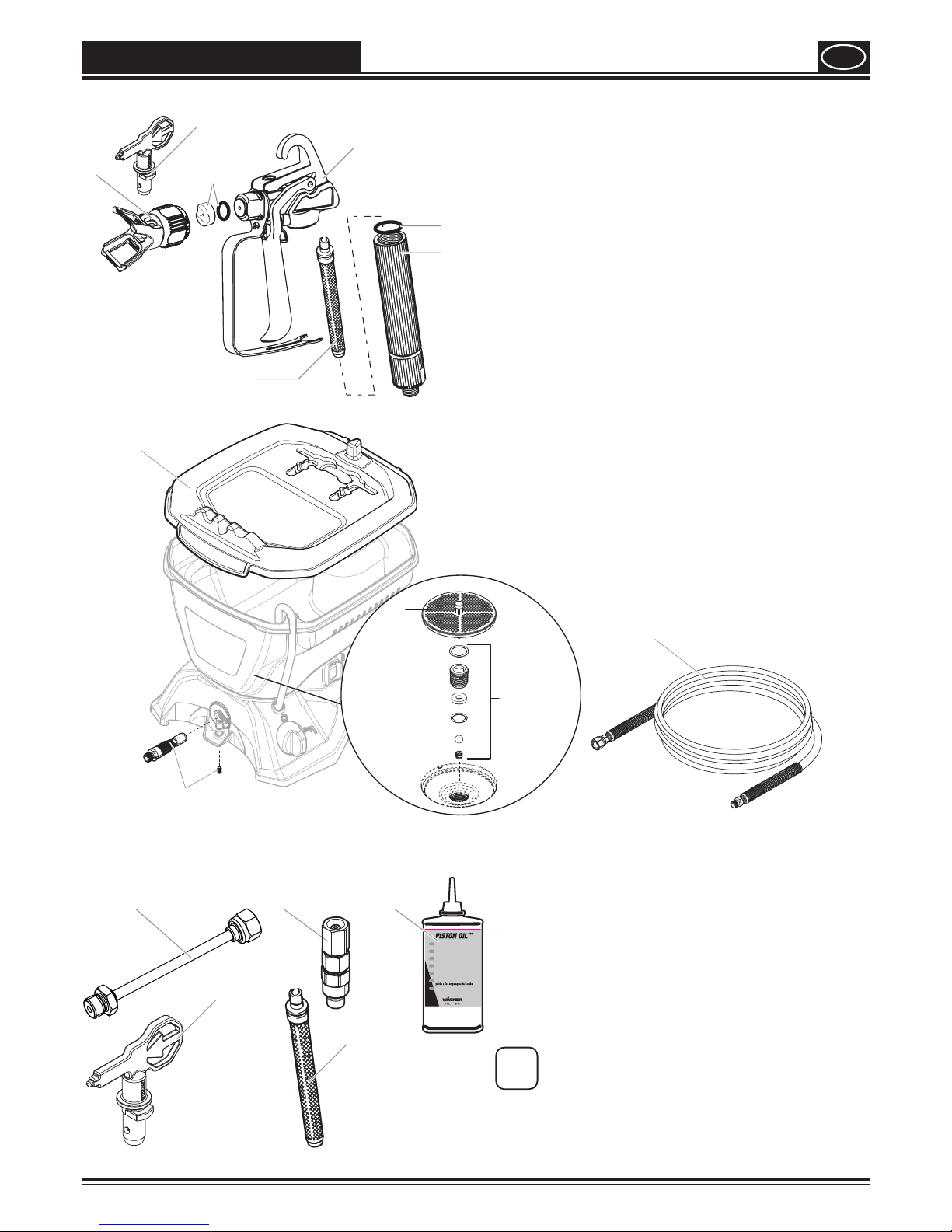

SPRAY GUN

SPRAYER

Spare Parts List / Accessories

i

If using another nozzle, the right lter must also be

used.

Tip 311, 313

Filter red

Tip 515

Filter yellow

6

7

3

1

2

5

4

Item

Part # Description Quantity

1 0517 200 Guard Assembly 1

2* 0517 515 Tip 515 1

3* 0517 900 Saddle seat and washer 1

4* 2400 975 Complete gun assembly

(incl pos. 1,5,6,7)

1

5* 0418 712 Filter yellow 2

6* 2337 235 Seal 1

7 2337 245 Filter housing 1

* Wear parts: Not covered by guarantee

1

2

3

4

5

Item

Part # Description Quantity

1 2399 762 Hopper lid 1

2 2399 767 Outlet valve kit 1

3* 2399 777 Inlet lter 1

4* 2399 783 Inlet valve kit 1

5 2398 073 7.5 m spray hos 1

* Wear parts: Not covered by guarantee

Accessories (not included in the delivery)

Item

Part # Description Quantity

1 0517 700 Gun extension (30 cm) 1

2 2397 787 Swivel point for gun 1

3 2319 722 Oil (118ml) 1

4 0517 311 Tip 311 (for very thin materials) 1

5 0517 313 Tip 313 (for thin materials) 1

6 0418 711 Filter red 2

Reduziert die Abnutzung der

Kolbenstangen und Pumpendichtungen

Reduces wear on cylinders rods

and pump packings

Réduit I‘usure des cylindres, des

tiges et des bourrages de pompe

Verminderd slijttage aan de

cilinders, pomp en dichtingen

Disminuye el desgaste de los cilindro,

pistón y empaquetaduras de la bomba

Diminui o desgaste do cilindro, do

Zmniejsza zużycie cylindrów

i uszczelnień pompy

D

GB

F

PL

NL

E

P

1

3

2

4

5

Page 18

18

Control Pro 150

AUS

3+1 years guarantee

The guarantee runs for three years, counting from the date of sale (sales slip). The guarantee is extended by a further 12 months if

the device is registered online within 4 weeks of the purchase at www.wagner-group.com/3plus1. Registration is only possible if

the buyer is in agreement with the data being stored that is entered during registration. The guarantee covers and is restricted to

free-of-charge rectication of faults which are demonstrably attributable to the use of faulty materials in manufacture, or assembly

errors; or free-of-charge replacement of the defective parts. The guarantee does not cover incorrect use or commissioning or

tting or repair work which is not stated in our operating instructions. Wearing parts are also excluded from the guarantee. The

guarantee excludes commercial use. We expressly reserve the right to full the guarantee. The guarantee expires if the tool is

opened up by persons other than WAGNER service personnel. Transport damage, maintenance work and loss and damage due to

faulty maintenance work are not covered by the guarantee. Under any guarantee claim, there must be proof of purchase of the tool

through submission of the original receipt. Wherever legally possible, we exclude all liability for injury, damage or consequential

loss, especially if the tool has been used for a purpose other than that stated in the operating instructions, commissioned or

repaired other than in accordance with our operating instructions or if repairs are performed by someone who is unqualied.

We reserve the right to perform any repairs in excess of those stated in our operating instructions. In case of guarantee or repair,

please refer to your point of sale.

Environmental protection

The device and all accessories and packaging have to be re-used in an environmentally friendly manner. Do

not dispose of the appliance with household waste. Support environmental protection by taking the appliance

to a local collection point or obtain information from a specialist retailer.

Leftover paint and solvents may not be emptied into drains, the sewage system or disposed of as household rubbish. It has

to be disposed of separately as special waste. Please pay special attention to the instructions on the product packaging.

Important Note regarding Product Liability!

According to an EU directive, the manufacturer is only liable without limitation for faults in the product if all parts come from the

manufacturer or have been approved by the manufacturer and have been mounted to the device and are operated properly. If

third-party accessories or spare parts are used, the manufacturer is exonerated wholly or partly from his/her liability if use of the

third-party accessories or spare parts have caused a defect in the product.

Page 19

19

Control Pro 150

AUS

Page 20

Irrtümer und Änderungen vorbehalten.

Not responsible for errors and changes.

Sous réserves d’erreurs et de modifications.

Fouten en wijzigingen voorbehouden.

J. WAGNER GMBH

Otto-Lilienthal-Str. 18

88677 Markdorf

T +49 0180 - 55 92 46 37

F +49 075 44 -5 05 11 69

WAGNER SPRAYTECH (UK) LTD

Innovation Centre

Silverstone Park

Silverstone

Northants NN12 8GX

T + 44 (0) 1327 368410

WAGNER FRANCE S.A.R.L.

12 Avenue des Tropiques

Z.A. de Courtaboeuf

91978 Les Ulis Cedex

T +33 0825 011 111

F +33 (0) 1 69 81 72 57

MAKIMPORT

HERRAMIENTAS, S.L.

C/ Méjico nº 6

Pol. El Descubrimiento

28806 Alcalá de Henares (Madrid)

T 902 199 021 / 91 879 72 00

F 91 883 19 59

ORKLA HOUSE CARE DANMARK A/S

Stationsvej 13

3550 Slangerup

Danmark

T +45 47 33 74 00

F +45 47 33 74 01

WAGNER SPRAYTECH

AUSTRALIA PTY. LTD.,

14 -16 Kevlar Close

Braeside, VIC 3195

T +61 3 95 87 - 20 00

F +61 3 95 80 - 91 20

J. WAGNER AG

Industriestraße 22

9450 Altstätten

T +41 71 - 7 57 22 11

F +41 71 - 7 57 23 23

HONDIMPEX KFT.

Kossuth L. u. 48-50

8060 Mór

T +36 (-22) - 407 321

F +36 (- 22) - 407 852

E-CORECO SK S.R.O.

Kráľovská ulica 8/7133

927 01 Šaľa

T +42 1948882850

F +42 1313700077

PUT WAGNER SERVICE

ul. E. Imieli 27

41-605 Swietochlowice

T +48/32/346 37 00

F +48/32/346 37 13

D

F

DK

S

CH

AUS

H

PL

GB

E

SK

P

ORKLA HOUSE CARE AB

Box 133

564 23 Bankeryd

Sweden

T +46(0)36 37 63 00

ROMIB S.R.L.

str. Poligonului nr. 5 - 7

100070 Ploiesti ,judet Prahova

T +40-344801240

F +40-344801239

ROM

ORKLA HOUSE CARE NORGE AS

Nedre Skøyen vei 26,

PO Box 423, Skøyen

0213 Oslo

T +47 22 54 40 19

NOR

E-CORECO S.R.O.

Na Roudné 102

301 00 Plzeň

T +42 734 792 823

F +42 227 077 364

CZ

Part. No. 2400973 A

12/2018_RS

© Copyright by J.Wagner GmbH

EL-ME-HO

Horvatinčićev put 2

HR-10436 Rakov Potok

T +385 (-1)65 86 - 028

F +385 (-1)65 86 - 028

HR

OOO МЕФФЕРТ ПОЛИЛЮКС

142407 Россия, Московская обл,

Ногинский р-н, территория

«Ногинск-Технопарк» д.14

T +7 495 221 6666

F +7 495 99 55 88 2

RUS

ROMIB S.R.L.

str. Poligonului nr. 5 - 7

100070 Ploiesti ,judet Prahova

T +40-344801240

F +40-344801239

ROM

TEHOMIX OY

Telekatu 10

20360 TURKU

T +385 (0) 2 2755 999

F +385 (0) 2 2755 995

SF

FHC SRL

Via Stazione 94,

26013 Crema (CR)

T 0373 204839

F 0373 204845

I

Loading...

Loading...