Page 1

www.wackergroup.com

Vibroplate

VPR 1330

OPERATOR’S MANUAL

0154577en 001

1102

0154577EN

Page 2

BELGIE

1730 ASSE-MOLLEM ASSESTEENWEG 17 Tel. (32) 02-4528509+07

4040 Herstal 4 Avenue

9800 Deinze Kortrijkse Steenweg 400 Tel. (09)-386 8529

B - 6041 Gosselies Rue Adrienne Bolland s/n Tel. 071-372450

ÇESKÁ REPUBLIKA

19402 PRAHA 9-HLOUBETIN KOLBENOVA 259 Tel. (0042) 2 862165

DANMARK

2690 KARLSLUNDE RØRGANGEN 6 Tel. 46 15 36 00

8200 Arhus N Randersvej 346 Tel. 86-231777

5250 Odense SV Holkebjergvej 56A Tel. 66-172170

ESPAÑA

28850 TORREJON DE ARDOZ (MADRID) POLIGONO INDUSTRIAL LAS MONJAS Tel. (34) 91-6757525 / 85

08780 PALLEJA (Barcelona) PRAT DE LA RIBA, 184 Tel. (93)-6632273

41700 Dos Hermanas (Sevilla) Poligono Industrial La Palmera Tel. (95)-4691129

46133 Meliana (Valencia) Calle Salvador Giner, 6 Tel. (96)-1492102

15890 Santiago de Compostela (La Coruña) Poligono Industrial el Tambre, Via Pasteur, 47a Tel. (981) 573366 / 67

CALLE PRIMAVERA 11

Nave 14 Tel. (95)-4691129

SUOMI

FIN 04250 KERAVA Peltomäenkatu 7 Tel. (358) 9-274 4740

FRANCE

77170 BRIE COMTE ROBERT 335, RUE GLORIETTE—ZAC DU TUBOEUF Tel. (33) 1-60623000

Aix en Provence 13540 Puyricard Tel. 4 42630526

Arras 62217 Beaurains Tel. 3 21235361

Bordeaux 33700 Merignac Tel. 5 56343346

Bourges 18390 St. Germain du Puy Tel. 2 48652015

Lyon 69740 Genas Tel. 4 78401384

Nancy 54180 Heillecourt Tel. 3 83565801

Rennes 35510 Cesson Sevigne Tel. 2 99321522

Toulouse 31270 Cugnaux Tel. 5 61075250

Kehl 77694 Kehl-Goldscheuer Tel. (0590) 9321

HUNGARIA

1106 BUDAPEST Kada u. 137 Tel. (36) 1-260 8668

IRELAND

DUBLIN 13 127A. BALDOYLE INDUSTRIAL ESTATE Tel. (00353) 01-8320218

ITALIA

40016 SAN GIORGIO DI PIANO (Bologna) Via Due Agosto, 1980, Strage di Bologna, 3 Tel. 39.05.665.566 - 665.1574

00125 ACILIA (Roma) Viale Enrico Ortolani, 262 Tel. 39 . 06 . 5219246

20041 Agrate Brianza (Mi) Via Archimede, 31 Tel. 39. 039.699 0136

NEDERLAND

3821 BJ AMERSFOORT COBOLWEG 1 Tel. 033 - 450 40 45

2984 BL Ridderker Glasblazerstraat 7 Tel. 0180 - 41 70 56

7418 EZ Deventer Arnbergstraat 9 Tel. 0570 - 63 00 87

5684 PS Best De Dintel 37 Tel. 0499 - 33 04 33

1704 RT Heerhugowaard Einsteinstraat 4d Tel. 072 - 574 20 78

9411 XN Beilen De Hanekampen 19 Tel. 0593 - 52 31 24

NORGE

1481 HAGAN TYRIVN. 7 Tel. (47) 6705-1310

POLSKA

05850 OŻARÓW MAZOWIECKI UL. KONOTOPSKA 4 Tel. (48) 22 722 20 59

62081 Wysogotowo k. Poznania ul. Kamienna 1 Tel. (061) 8143797

PORTUGAL

2785-S. Domingos De Rana Urbanização Industrial de Trajouce, Lote 1 Tel. (351) 21 4443561 / 87

4785-S. Romao do Coronado Lg. do Soeiro, Apartado 2 Tel. (351) 22 982 7992 / 93

SVERIGE

24734 SÖDRA SANDBY SKATTEBERGAVÄGEN 13 Tel. (46) 046-57870

16170 Bromma Karlsbodavägen 17E Tel. 08-282860

41749 Göteborg Knipplekullen 3A Tel. 031-551362

SCHWEIZ

8305 Dietlikon Bahnhofstrasse 3 Tel. (41) 1-8353939

TURKIYE

81120 K. Bakkalköy-ISTANBUL Karaman Çiftligi Cad. No: 55 Tel. (90) 216 573 0621

35350 Üçkuyular-Izmir Mithatpasa Cad. No. 1189 Tel. (90) 232 259 8944

Ostim 06370 Ankara Alinteri Bulvari No. 210 Tel. (90) 312 385 6438/6439

Page 3

VPR1330 Table of Contents

wc_bo0154577001enTOC.fm 1

1. Foreword 3

2. Safety Information 4

2.1 Laws Pertaining to Spark Arresters ...................................................... 4

2.2 Operating Safety .................................................................................. 5

2.3 Operator Safety while using Internal Combustion Engines .................. 6

2.4 Service Safety ...................................................................................... 7

2.5 Label Locations .................................................................................... 8

2.6 Warning and Informational Labels ........................................................ 9

2.7 Operating Labels ................................................................................ 12

3. Technical Data 14

3.1 Engine Data ........................................................................................ 14

3.2 Machine Data .......... ..... ..... .... ............................ ..... ............................ 15

3.3 Sound and Vibration Specifications .................................................... 15

3.4 Dimensions ......................................................................................... 16

4. Operation 17

4.1 Recommended Fuel ........................ .... ............................ ..... .............. 17

4.2 Before Starting ................................................................................... 17

4.3 To Start ....................................... ..... .... ............................ ..... ..... ......... 17

4.4 To Stop ....................................... ..... .... ............................ ..... ..... ......... 18

4.5 Application .......................................................................................... 18

4.6 Operation ............................................................................................ 19

Page 4

Table of Contents VPR1330

wc_bo0154577001enTOC.fm 2

5. Maintenance 20

5.1 Periodic Maintenance Schedule ..........................................................20

5.2 Cleaning Plate .................................................................. ..... ..... .........20

5.3 Drive Belt .............................................................................................21

5.4 Exciter Lubrication ...............................................................................22

5.5 Spark Plug ...........................................................................................23

5.6 Engine Oil ............................................................................................24

5.7 Air Cleaner ..........................................................................................25

5.8 Cleaning Fuel Strainer .........................................................................26

5.9 Throttle Adjustment .............................................................................26

5.10 Adjusting Idle Speed ...........................................................................27

5.11 Troubleshooting ...................................................................................28

5.12 Storage ................................................................................................28

5.13 Lifting Machine ....................................................................................29

5.14 Transporting Machine ..........................................................................30

Page 5

Foreword

wc_tx000001gb.fm 3

CALIFORNIA

Proposition 65 Warning:

Engine exhaust, some of its constituents, and certain vehicle

components contain or e mit chemicals known to th e State of California

to cause cancer and birth defects or other reproductive harm.

1. Foreword

This manual provides information and procedures to safely operate

and maintain this Wacker model. For your own safety and protection

from injury, carefully read, understand and observe the safety

instructions described in this manual.

Keep this manual or a copy of it with the machine. If you lose this

manual or need an additional copy, please contact Wacker

Corporation. This machine is built with user safety in mind; however,

it can present hazards if improperly operated and serviced. Follow

operating instructions carefully! If you have questions about operating

or servicing this equipment, please cont act Wacker Corporation.

The information contained in this manual was based on machines in

production at the time of publication. Wacker Corporation reserves the

right to change any portion of this information without notice.

All rights, espec i ally copying and distribution rights are reserved.

Copyright 2002 by Wacker Corporation.

No part of this publication may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without

express written permissi on fr om Wacker Corp or ation.

Any type of reproduction or distribution not authorized by Wacker

Corporation represents an infringement of valid copyrights and will be

prosecuted. We expressly reserve the right to make technical

modifications, even without due notice, which aim at improving our

machines or their safety standards.

WARNING

Page 6

Safety Information VPR 1330

wc_si000031gb.fm 4

2. Safety Information

This manual contains DANGER, WARNING, CAUTION, and NOTE

callouts which must be followed to reduce the possibility of personal

injury, damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

CAUTION: Used without the safety alert symbol, CAUTION indicates

a potentially hazardous situation which, if not avoided, may result in

property damage.

Note: Contains additional information important to a procedure.

2.1 Laws Pertaining to Spark Arresters

Notice: State Health Safety Codes and Public Resources Codes

specify that in certain locations spark arresters be used on internal

combustion engines that use hydr ocarbon fuels. A spar k arrester is a

device designed to prevent accidental discharge of sparks or flames

from the engine exhaust. Spark arresters are qualified and rated by

the United States Forest Service for this purpose.

In order to comply with local laws regarding spark arresters, consult

the engine distributor or the local Health and Safety Administrator.

DANGER

WARNING

CAUTION

Page 7

VPR 1330 Safety Information

wc_si000031gb.fm 5

2.2 Operating Safety

Familiarity and proper train ing are required for the safe operation of

equipment! Equi p me nt o pe ra te d i m pr op er l y or b y un tr ained personnel

can be dangerous! Read the operating instructions contained in both

this manual and the engine manual and familiarize yourself with the

location and prop er use of al l controls. In experienced op erators should

receive instruction from someone familia r with the equipment before

being allowed to operate the machi ne.

2.2.1 NEVER allow anyone to operate this equipment without proper

training. People operating this equipment must be familiar with the

risks and hazards associated with it.

2.2.2 NEVER touch the engine or muffler while the engine is on or

immediately after i t ha s been turned off. Th ese areas get hot an d m ay

cause burns.

2.2.3 NEVER use accesso ries or at tachments th at are n ot recomme nded by

Wacker. Damage to equipment and injury to the user may result.

2.2.4 NEVER operate the machine with the belt guard missing. Exposed

drive belt and pulleys create potentially dangerous hazards that can

cause serious injuries.

2.2.5 NEVER leave machine running unattended.

2.2.6 ALWAYS be sure op erator is familiar with proper safety precautions

and operation techniques before using machine.

2.2.7 ALWAYS wear protective clothing appropriate to the job site when

operating equ ipment.

2.2.8 ALWAYS wear hearing protection when operating equipment.

2.2.9 ALWAYS close fuel valve on engines equipped with one when

machine is not being operated.

2.2.10 ALWAYS store equipment properly when it is not being used.

Equipment should be st ored in a clean , dry l ocation out of the rea ch of

children.

2.2.11 ALWAYS operate ma chi n e w ith all safety device s an d guards in place

and in working orde r. DO NOT modify or defeat safe ty devices. DO

NOT operate machine if any safety devices or guards are missing or

inoperative.

2.2.12 ALWAYS read, understand, and follow procedures in Operator's

Manual before attempting to operate equipment.

WARNING

Page 8

Safety Information VPR 1330

wc_si000031gb.fm 6

2.3 Operator Safety while using Internal Combustion Engines

Internal combustion engine s prese nt special hazard s during oper ation

and fueling! Read and follow warning instructions in engine owner's

manual and safety guidelines below. Failure to follow warnings and

safety guidelines could result in severe injury or death.

2.3.1 DO NOT run machine indoors or in an enclosed area such as a deep

trench unless adequate ventilation, through such items as exhaust

fans or hoses, is provided. Exhaust gas from the engine contains

poisonous carbon monoxide gas; exposure to carbon monoxide can

cause loss of consciousness and may lead to death.

2.3.2 DO NOT smoke while operating machine.

2.3.3 DO NOT smoke when refueling eng i ne .

2.3.4 DO NOT refuel hot or running engine.

2.3.5 DO NOT refuel engine near open flame.

2.3.6 DO NOT spill fuel when refueling engine .

2.3.7 DO NOT run engine near open flames.

2.3.8 ALWAYS refill fuel tank in well-ventilated area.

2.3.9 ALWAYS replace fuel tank cap after refuel i ng .

2.3.10 ALWAYS check fuel lines and fuel tank for leaks and cracks before

starting en gine. Do not run machine if fu el leaks are present or fue l

lines are loose.

DANGER

Page 9

VPR 1330 Safety Information

wc_si000031gb.fm 7

2.4 Service Safety

Poorly maintained equipment can become a safety hazard! In order

for the equipment to operate safely and properly over a long period of

time, periodic maintenance and occasional repairs are necessary.

2.4.1 DO NOT attempt to clean or service machine while it is running.

Rotating parts can cause severe injury.

2.4.2 DO NOT crank a flooded engine with the spark plug removed on

gasoline-powered en gines. Fuel trappe d in the cylinder will sq uirt out

the spark plug opening.

2.4.3 DO NOT test for spark on gasoline-powered engines, if engine is

flooded or the smell of gasoline is present. A stray spark could ignite

fumes.

2.4.4 DO NOT use gasoline or oth er types of fuel s or flammable solvents to

clean parts, especially in enclosed areas. Fumes from fuels and

solvents can become explosive.

2.4.5 ALWAYS keep area around muffler free of debris such as leaves,

paper, cartons, etc. A hot muffler could ignite them, starting a fire.

2.4.6 ALWAYS replace worn or damaged components with spare parts

designed and recommended by Wacker.

2.4.7 ALWA YS disconn ect spa rk plug on mach ines equi pped with gasoline

engines, before servicing, to avoid accidental start-up.

2.4.8 ALWAYS keep machine clean and labels legible. Replace all missing

and hard-to-read labels. Labels provide important operating

instructions and warn of dangers and hazards.

WARNING

Page 10

Safety Information VPR 1330

wc_si000031gb.fm 8

2.5 Label Locations

wc_gr000182

1 2

3

4 5 6 7

1

2

WARNING

WARNUNG

ADVERTENCIA

AVERTISSEMENT

10W30

Page 11

VPR 1330 Safety Information

wc_si000031gb.fm 9

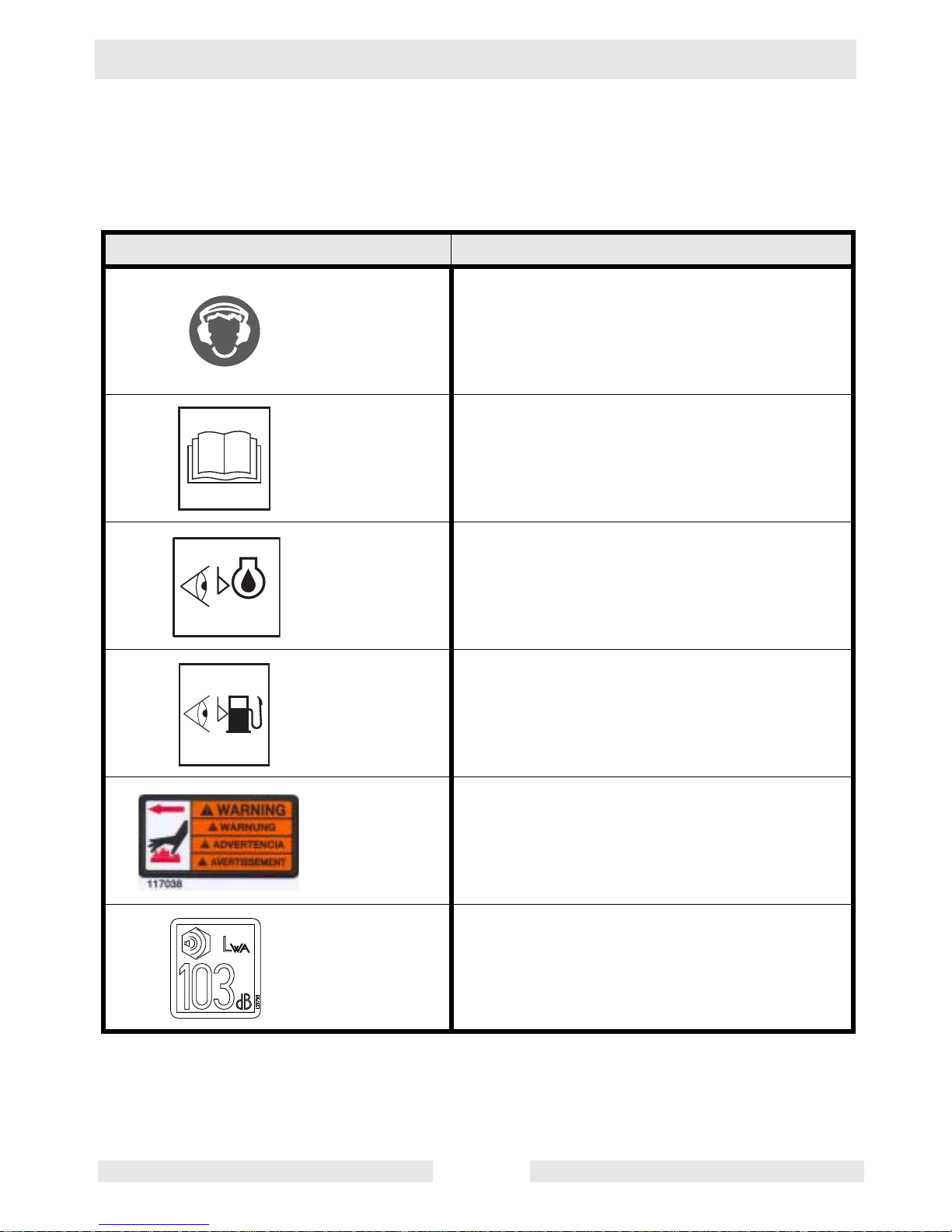

2.6 Warning and Informational Labels

Wacker machines use international pictorial labels where needed.

These labels are described below:

Label Meaning

To prevent hearing loss, wear hearing protection when operating this machine.

Read the operator's manual for machine information.

Check engine oil level.

Use SAE10W30.

Check fuel level.

WARNING!

Hot surface.

Machine sound power level in dB(A).

1 0W3 0

Page 12

Safety Information VPR 1330

wc_si000031gb.fm 10

WARNING!

Hand injury if caught in moving belt.

Always replace belt guard.

CAUTION!

Read and understand the supplied operator's

manual before oper a ting this machine. Failu r e

to do so increases the risk of injury to yourself

or others.

CAUTION!

Lifting point

DANGER!

Engines emit carbon monoxide; operate only

in well ventilated area.

Read the operator's manual for machine information.

DANGER!

Before fueling, stop the engine. No sparks,

flames or burning objects near machine.

A nameplate listing the Model Number, Item

Number, Revision, and Serial Number is

attached to each unit. Please record the information found on this plate so it will be available should the nameplate become lost or

damaged. When ordering parts or requesting

service information, you will alwa ys be asked

to specify the model, item number, revision

number, and serial number of the unit.

Label Meaning

Page 13

VPR 1330 Safety Information

wc_si000031gb.fm 11

This machine may be covered by one or more

patents.

Label Meaning

Page 14

Safety Information VPR 1330

wc_si000031gb.fm 12

2.7 Operating Labels

Wacker machines use international pictorial labels where needed.

These labels are described below:

Label Meaning

Open fuel flow valve.

Push or turn engine switch to ON position.

Close choke.

Place throttle in the IDLE position.

Pull rewind starter.

Close fuel flow valve.

Page 15

VPR 1330 Safety Information

wc_si000031gb.fm 13

Push or turn engine switch to OFF position.

Open choke.

Place throttle in the FAST position.

Throttle control lever:

Turtle = Idle or Slow

Rabbit = Full or Fast

Label Meaning

1

Page 16

Technical Data VPR 1330

wc_td000014gb.fm 14

3. Technical Data

3.1 Engine Data

VPR 1330

0006512

Rev. 102 and lower

VPR 1330

0006512

Rev. 103 and high er

Engine

Engine Make

Robin

Engine Model

EY15 (W1-145) EH122 (YD 4020)

Rated Power

kW (Hp) 2.6 (3.5) 2.9 (4.0)

Engine Speed - full load

rpm 3500 ± 100

Engine Speed - idle

rpm 1600 ± 200

Valve Cle ar an c e (col d )

mm (in.) 0.1 (0.004)

Air Cleaner

type Replaceable dry type, paper element with foam precleaner

Engine Lubrication

oil grade Above 4° C (40° F) use

SAE30; Between -9° C

(15°F) and 4° C (40° F)

SAE20; Below -9° C (15°F)

SAE 10W30

Between -20° C (-4°F) and

30° C (86° F) use either

10W30 or 10W40.

Above 30° C (86°F) to 40°C

(104°F) use only 10W40

service class SC or better

Engine Oil Capacity

ml (oz.) 600 (20)

Fuel

type Regular leaded or unleaded gasoline

Fuel Tank Capacity

l (qts.) 2.8 (3.0) 3.6 (3.8)

Spark Plug

NGK B6HS NGK B6ES

Electrode Gap

(mm) in. 0.6 –0.7 (0.02–0. 03)

Page 17

VPR 1330 Technical Data

wc_td000014gb.fm 15

3.2 Machine Data

3.3 Sound and Vibration Specifications

The required sound specification, Paragraph 1.7.4.f of 89/392/EEC

Machinery Directive, is:

• the sound press ure level at operator’s location (LpA) = 94 dB(A)

• the sound power le vel (LWA) = 103 dB(A)

These sound values were determined according to ISO 3744 for the

sound power level (LWA) and ISO 60 81 for the sound pre ssure level

(LpA) at the operator’s location.

The weighted effective acceleration value, determined according to

ISO 8662 Part 1, is 21 m/s

2

.

The sound and vibration specifications were obtained with the unit

operating on crushed gravel at nominal engine speed.

VPR 1330

0006512

Rev. 102 and lower

VPR 1330

0006512

Rev. 103 and higher

Plate

Operating wei gh t

kg (lbs.) 76 (167)

Exciter Speed

rpm 5800 ± 100

Exciter Lubrication

ml (oz.) 800 (27)

SAE 30W

Page 18

Technical Data VPR 1330

wc_td000014gb.fm 16

3.4 Dimensions

mm (in.)

w c _ g r 0 0 0 1 8 1

6 0 1 ( 2 3 . 5 )

6 5 9 ( 2 6 )

1 0 7 8 ( 4 2 . 5 )

3 0 0 ( 1 3 . 2 5 )

8 8 4 ( 3 5 )

Page 19

VPR 1330 Operation

wc_tx000106gb.fm 17

4. Operation

4.1 Recommended Fuel

The engine requires regular grade unleaded ga soline. Use only fresh,

clean gasoline. Gasoline containing water or dirt will damage fuel

system. Consult engine owner’s manual for complete fuel

specifications.

4.2 Before Starting

4.2.1 Read and understan d safety and operatin g instructions at begi nning of

this manual.

4.2.2 Check:

• Oil level in engine.

• Fuel level.

• Condition of air cleaner.

• Tightness of ex ternal fasteners.

• Condition of fuel lines.

4.3 To Start

See Graphic : wc_gr000183

4.3.1 Open fuel valve by moving lever down (a1).

4.3.2 Turn engine switch to "ON" (b1 ).

4.3.3 If engine is cold, move choke lever to close d position (c1). If engine is

hot, set choke to open position (c2).

4.3.4 Open throttle by moving it to the right (d2).

4.3.5 Pull starter rope (e).

Note: If the engine oil level is low, the engine will not run. If engine

does not run, check oil level and add oil as needed.

4.3.6 Open choke as engine warms (c2).

4.3.7 Open throttle fully to operate machine (d3).

Page 20

Operation VPR 1330

wc_tx000106gb.fm 18

4.4 To Stop

See Graphic: wc_gr000 18 3

4.4.1 Reduce engine RPM to idle by moving throttle completely to the left

(d1).

4.4.2 Turn engine switch to "OFF" (b2).

4.4.3 Close fuel valve (a2).

4.5 Application

This plate is designe d for compacting lo ose, granular soil s, gravel, and

paving stones. It is intended to be used in confined areas and areas

next to structures such as walls, curbs, and foundations. Plates

equipped with water tanks can be used for compacting asphalt.

This plate is no t recommended for comp acting cohesive soils with a

heavy clay content. For cohesive soil, use a vibratory rammer or

sheepsfoot roller.

Page 21

VPR 1330 Operation

wc_tx000106gb.fm 19

4.6 Operation

Run the engine at full throttle and allow the plate to pull itself along at

its normal speed. When op erating on an incline it ma y be necessary to

assist the plate by p ushing it fo rward sli ghtly. When operat ing dow nhill

hold the plate back slightly , if it begins to pick up speed. Depe nding on

the material bein g compacted, th ree or fo ur passes are r ecommend ed

to achieve the best compaction.

While a certain amount of moisture in the soil is necessary, excessive

moisture may cause soil particles to stick together and prevent good

compaction. If soil is extremel y wet, allow it to dry somewhat before

compacting.

If soil is so dr y as to create d ust clouds whil e operating plate, some

moisture should be added to the ground material to improve

compaction. This will also reduce service to the air filter.

For compacting asphalt, use a water tank to wet the asphalt and the

underside of plate. This will prevent asphalt material from sticking.

Two passes are usually sufficent to ensure good compaction.

When using the plate on paving stones, attach a pad to the bottom of

the plate to prevent chipping or grinding surface of stones. A special

polyurethane pad de signed fo r this pur pose is availa ble as an optio nal

accessory.

CAUTION: DO NOT operate the plate on concrete or on extremely

hard, dry, compacted surfaces. The plate will jump rather than vibrate

and could damage both the plate and the engine.

Page 22

Maintenance VPR 1330

wc_tx000107gb.fm 20

5. Maintenance

5.1 Periodic Maintenance Schedule

The chart below lists basic engine maintenance. Refer to engine

manufacturer’s Operation Manual for additional information on engine

maintenance.

5.2 Cleaning Plate

Clean plate after use to rem ove dirt, stones, and mud cau ght under th e

engine console. If plate is being used in a dusty area, check engine

cylinder cooling fin s fo r h eavy di r t accu mu l ation . Keep engine cyli nder

fins clean to prevent engine from overheating.

Daily

before

starting

After

first

20 hrs.

Every

2 weeks

or

50 hrs.

Every

month

or

100 hrs.

Every

year

or

300 hrs.

Check fuel level. •

Check engine oil level. •

Inspect fuel lines. •

Inspect air filter. Replace as needed. •

Check and tighten external hardware. •

Check and adjust drive belt. ••

Clean air cleaner elements. •

Inspect shockmounts for damage. •

Change engine oil. ••

Clean cooling system. •

Clean sediment cup / fuel filter. •

Check and clean spark plug. •

Check and adjust valve clearance. •

Change exciter oil. •

Page 23

VPR 1330 Maintenance

wc_tx000107gb.fm 21

5.3 Drive Belt

See Graphic : wc_gr000185

On new machines or after installing a new belt, check belt tension after

first 20 hours of operation. Check and adjust belt every 50 hours

thereafter.

To adjust belt:

5.3.1 Remove the two screws (b) at the bottom of the guar d and the two nuts

(a) located behind the guard.

5.3.2 Remove belt guard.

5.3.3 Loosen the four bolts (c) which hold the engine to the plate.

5.3.4 Slide engine back toward the handle to tighten belt, forward to loosen

belt.

5.3.5 Adjust belt so that it deflects 10-13 mm (3/8"-1/2") (d) when pressed

midway between belt pulleys.

w c _ g r 0 0 0 1 8 5

a

c

d

b

Page 24

Maintenance VPR 1330

wc_tx000107gb.fm 22

5.4 Exciter Lubrication

See Graphic: wc_gr000 18 4

The bearings in th e excite r assem bly ar e splas h lubri cated and rot ate

at very high speed. It is important to maintain the exciter oil at the

correct level and change it regularly.

Check oil level in exciter each day, before running plate.

5.4.1 To check the oil level, place the plate on a flat, level surface.

5.4.2 Oil level should appear near center of sight glass (a).

5.4.3 Add oil as required.

Change exciter oil every 300 hours of operation.

5.4.1 To drain oil, remove plug (b) from end of exciter and tilt plate up.

Note: In the interests of environmental protection, place a plastic sheet

and a container under the machine to collect any liquid which drains

off. Dispose of this l iquid in accor dance wi th envi ronm ental prot ection

legislation.

5.4.2 Place the plate on a level surface and add approximately 800 ml (27

oz.) of oil through plu g op en i ng u nti l oi l app ear s ne ar the cent er of th e

sight glass (a).

CAUTION: DO NOT overfill. Too much oil in exciter can reduce

performance and damage drive belt.

w c _ g r 0 0 0 1 8 4

a

b

Page 25

VPR 1330 Maintenance

wc_tx000107gb.fm 23

5.5 Spark Plug

See Graphic : wc_gr000028

Clean or replace spark plug as needed to ensure proper operation.

Refer to the engine Owner’s Manual.

The muffler bec omes ve ry ho t durin g oper atio n and r emains hot f or a

while after stop ping the engine. Do not touc h the muffle r while it is hot.

Note: Refer to the Technical Data for the recommended spark plug

type and the electrode gap setting.

5.5.1 Remove spark plug and inspect it.

5.5.2 Replace plug if the insulator is cracked or chipped.

5.5.3 Clean spark plug electrod es with a wire brush.

5.5.4 Se t the electrode gap (a).

5.5.5 Tighten spark plug securely.

CAUTION: A loose spark plug can become very hot and may cause

engine damage.

WARNING

Page 26

Maintenance VPR 1330

wc_tx000107gb.fm 24

5.6 Engine Oil

See Graphic: wc_gr000 08 7

5.6.1 Drain oil while engine is still warm.

Note: In the interests of environmental protection, place a plastic sheet

and a container under the machine to collect any liquid which drains

off. Dispose of this l iquid in accor dance wi th envi ronm ental prot ection

legislation.

5.6.2 Remove the oil drain plug (a).

5.6.3 Allow the oil to drain.

5.6.4 Install the drain plug.

5.6.5 Fill the engine cra nkcase thr ough the oil fille r openin g (b), to the upp er

mark on the dipstick (c). Do not thread in the dipstick to check the level.

See Technical Data for oil quantity and type.

5.6.6 When the crankcase is full, re-install the dipstick.

Page 27

VPR 1330 Maintenance

wc_tx000107gb.fm 25

5.7 Air Cleaner

See Graphic : wc_gr000088

The engine is equipped with a dual element air cleaner. Service the

air cleaner fre quently to prevent a carburetor malfunction.

CAUTION: NEVER run the engine without the air cleaner. Severe

engine damage will occur.

NEVER use gasoline or other types of low flash point solvents for

cleaning the air cleaner. A fire or explosion could result.

5.7.1 Remove the air cleaner cove r (c). Remove b oth el ements and inspect

them for holes or tears. Replace damaged elements.

5.7.2 Wash the foam element (b) in a solution of mild detergent and warm

water. Rinse it thoroughly in clean water. Allow the element to dry

thoroughly.

Soak the element in clean engine oil and squeeze out the excess oil.

5.7.3 Tap the paper element (a) lightly to remove excess dirt or blow

compressed air through the filter from the inside out. Replace the

paper element if it appears heavily soiled.

Page 28

Maintenance VPR 1330

wc_tx000107gb.fm 26

5.8 Cleaning Fuel Strainer

See Graphic: wc_gr000 08 9

5.8.1 Turn fuel valve off.

5.8.2 Remove bowl (a) gasket (b) and screen (c).

5.8.3 Wash them thoroughly in a nonflammable solvent. Dry them and

reinstall.

5.8.4 Turn fuel valve on and check for leaks.

5.9 Throttle Adjustment

See Graphic: wc_gr000090

5.9.1 Place machine on a rubber test mat to prevent it from moving.

5.9.2 Start engine and allow it to warm up to operating temperature.

5.9.3 Move throttle control to high speed position (a).

5.9.4 Adjust throttle stop screw (b) to set operating speed.

CAUTION: Running plate at a speed higher than that listed in

Technical Data can damage both the plate and the engine.

Page 29

VPR 1330 Maintenance

wc_tx000107gb.fm 27

5.10 Adjusting Idle Speed

See Graphic : wc_gr000186

Adjust the idle when the engine is warm.

5.10.1 Start the engine and allow it to warm up for a minute.

5.10.2 With the throttle in lowest (slowest) position, adjust the idle speed

screw (a) to obtain the correct idl e spee d. See Technical Data.

w c _ g r 0 0 0 1 8 6

a

Page 30

Maintenance VPR 1330

wc_tx000107gb.fm 28

5.11 Troubleshooting

5.12 Storage

If plate is being stored for more than 30 days:

5.12.1 Remove loose stones and dirt from plate.

5.12.2 Clean engine cylinder cooling fins.

5.12.3 Clean or replace air filter.

5.12.4 Change exciter oil.

5.12.5 Change engine oil and follow procedures described in engine manual

for engine storage.

5.12.6 Cover plate and engine and store in a clean, dry area.

Problem / Symptom Reason / Remedy

Plate does not develop full

speed. Poor compaction.

• Engine throttle control not completely open.

• Throttle control not adjusted correctly.

• Ground too wet, plate sticking. Allow soil to dry

before compacting.

• Drive belt loose or worn, slipping on pulleys. Adjust

or replace belt. Check that engine mounting bolts

are tight.

• Exciter bearings binding. Check condition and level

of oil in excite r. Add or change oil.

• Air filter clogged with dust, reducing engine performance. Clean or replace air filter.

• Engine speed too low. Check engine speed with

tachometer. Adjust or repair engine to run at correct

speed. Refer to engin e ma nual.

Engine running, no vibration • Engine throttle not open.

• Drive belt loose or broken. Adjust or replace.

• Clutch damaged. Inspect and replace clutch.

• Engine speed too low. Check engine speed.

• Too much oil in exciter. Adjust oil to correct level.

Plate jumps or compacts

unevenly.

• Ground surface too hard.

• Shockmounts loose or damaged.

Page 31

VPR 1330 Maintenance

wc_tx000107gb.fm 29

5.13 Lifting Machine

See Graphic : wc_gr000359

See Technical Data for the weight of the machine.

To lift machine manually:

5.13.1 Stop the engine.

5.13.2 Obtain help from a partner and plan the lift.

5.13.3 Grasp the machine by its cage (a) and lifting handle (b).

5.13.4 Lift the machine as shown.

To reduce risk of back injury while lifting, keep your feet flat on ground

and shoulder width apart. Keep your head up and back straight.

To lift machine mechanically:

CAUTION: Before attempting to lift, be sure that all lifting devices can

safely handle the weight of the machine. See Technical Data for the

weight of the machine.

5.13.5 Attach hook, harness, or cable to the machine as shown and lift as

desired.

CAUTION: DO NOT lift the vibroplate by its guide handle. The

vibroplate can shift, causing it to fall.

WARNING

wc_gr000359

a

b

Page 32

Maintenance VPR 1330

wc_tx000107gb.fm 30

5.14 Tr ansporting Ma chine

See Graphic: wc_gr000356

To avoid burns or fire hazards, let engine cool before transporting

machine or storing indoors.

5.14.1 Turn fuel valve to t he off position and kee p the engine leve l to p re v en t

fuel from spilling.

5.14.2 Tie down machine on vehicle to prevent machine from sliding or tipping

over. Tie machine to vehicle at points shown on graphic.

WARNING

wc_gr000356

Page 33

EC - CONFORMITY CERTIFICATE

EG-KONFORMITÄTSERKLÄRUNG

CE-CERTIFICADO DE CONFORMIDAD

CERTIFICAT DE CONFORMITÉ DE LA CEE

WACKER CORPORATION, N92 W15000 Anthony Avenue, MENOMONEE FALLS, WISCONSIN USA

hereby certifies that the construction equipment specified hereunder:

bescheinigt, daß das Baugerät:

certifica que la máquina de construcción:

atteste que le matériel:

1. Category / Art / Categoría / Catégorie

Vibroplate

Vibrationsplatte

Plancha Vibradora

Patin Vibrant

2. Type - Typ - Tipo - Type

3. Item number of equipment / Gerätetypnummer /

Número de referencia de la máquina / Numéro de référence du matériel :

VPR 1330

0006512

4. Net installed power / absolute installierte Leistung /

Potencia instalada neta / Puissance installée nette:

Has been sound tested per Directive 2000/14/EC / in Übereinstimmung mit Richtlinie 2000/14/EG bewertet worden ist /

Ha sido ensayado en conformidad con la norma 2000/14/CE / a été mis à l’épreuve conforme aux dispositions de la directive

2000/14/CEE :

Conformity Assessment Procedure

Konformitätsbewertungsverfahren

Procedimiento para ensayar

conformidad / Procédé pour

l’épreuve de conformité

Annex VIII

Name and address of notified

body /

Bei folgender einbezogener

Prüfstelle / Oficina matriculadora

/ Organisme agrée

BSI, 389 Chiswick High Road

London W4 4AL United Kingdom

2,9 kW

Measured sound power level /

Gemessener Schallleistungspegel / Nivel de potencia

acústica determinado / Niveau de

puissance acoustique fixé

102 dB(A)

Guaranteed sound power level/

Garantierter Schallleistungspegel / Nivel de potencia

acústica garantizado / Niveau

de puissance acoustique

garanti

103 dB(A)

and has been produced in accordance with the following standards:

und in Übereinstimmung mit folgenden Richtlinien hergestellt worden ist:

y ha sido fabricado en conformidad con las siguientes normas:

et a été produit conforme aux dispositions des directives européennes ci-après :

2000/14/EC

EMC 89/336/EEC

EN 50082-1

VDE 0879-1

98/37/EEC

EN 500-1

EN 500-4

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

2002-CE-WP1550.p65

29.10.01

Date / Datum / Fecha / Date

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

William Lahner Greg Orzal

WACKER CORPORATION

Page 34

Page 35

UNITED KINGDOM

LONDON LEA ROAD Tel. (44)(01992) 707200

Washington Washington/Tyne N37 1LH Tel. (0191) 4 16 63 92

Warrington Winwick Quay, Warrington WA2 8RE Tel. (01925) 57 39 55

Worksop Worksop S81 7BE Tel. (01909) 48 45 06

Redditch Washford, Redditch B98 0DQ Tel. (01527) 2 45 56

Pontypool Pontypool, Gwent NP4 6PD Tel. (01495) 75 05 95

Ashford Ashford, Kent TN23 2NF Tel. (01233) 64 52 27

Exeter Clyst, Honiton, Exeter EX5 2LG Tel. (01392) 6 97 71

Hungerford Hungerford R617 OYX Tel. (01488) 68 14 28

Lanarks Bellshill, Lanarks ML4 3NN Tel. (01698) 84 58 15

WALTHAM CROSS, HERTS EN9 1AW

ÖSTERREICH

1110 WIEN SCHEMMERLSTR.82 Tel. (43) 01-7671515

4050 Traun Wiener Bundesstr. 147 Tel. 07229-73739

9020 Klagenfurt Wiegelegasse 18 Tel. 0463-262716

8054 Graz-Strassgang Kärntner Str. 512 Tel. 0316-281690

6122 Fritzens Innstr. 11 Tel. 05224-51351

5300 Hallwang b. Sbg. Wiener Bundesstr. 17 Tel. 0662-661741

3106 St. Pölten Hnilickastr. 9 Tel. 02742-73170

DEUTSCHLAND

80809 MÜNCHEN PREUSSENSTR. 41 Tel. 089/35 40 21

85757 Karlsfeld (WLZ) Tel. 018131-59780

21109 Hamburg Fax 040/75 73 90 Tel. 040/75 15 66

24145 Kiel Fax 0431/71 46 25 Tel. 0431/71 15 25

23566 Lübeck Fax 0451/62 56 15 Tel. 0451/62 56 19

28307 Bremen-Mahndorf Fax 0421/48 15 36 Tel. 0421/48 15 01

26789 Leer-Bingum Fax 0491/6 25 39 Tel. 0491/6 72 20

30165 Hannover Fax 0511/3 52 49 69 Tel. 0511/3 52 40 61

38112 Braunschweig Fax 0531/31 29 24 Tel. 0531/31 21 80

34233 Fuldatal Fax 0561/81 10 58 Tel. 0561/81 10 59

40721 Hilden Fax 02103/4 69 31 Tel. 02103/3 10 48

41065 Mönchengladbach Fax 02161/4 25 44 Tel. 02161/48 11 41

46485 Wesel Fax 0281/5 16 37 Tel. 0281/8 98 79

45326 Essen Fax 0201/32 13 02 Tel. 0201/31 17 93

48291 Telgte Fax 02504/71 47 Tel. 02504/26 68

49565 Bramsche Fax 05461/49 22 Tel. 05461/6 21 21

44319 Dortmund Fax 0231/21 82 27 Tel. 0231/21 82 26

33659 Bielefeld Fax 0521/40 31 14 Tel. 0521/4 07 77

52355 Düren Fax 02421/6 21 22 Tel. 02421/6 30 51

53842 Troisdorf Fax 02241/4 65 75 Tel. 02241/4 40 31

56218 Mülheim-Kärlich Fax 0261/2 65 55 Tel. 0261/2 65 10

57080 Siegen Fax 0271/31 10 49 Tel. 0271/31 50 55

60388 Frankfurt Fax 069/41 71 89 Tel. 069/42 40 80

35398 Gießen Fax 0641/2 98 19 Tel. 0641/2 22 69

55129 Mainz-Hechtsheim Fax 06131/50 79 80 Tel. 06131/59 20 70

66119 Saarbrücken Fax 0681/85 15 30 Tel. 0681/85 20 11

67133 Maxdorf Fax 06237/50 08 Tel. 06237/72 00

74172 Neckarsulm-Obereisesheim Fax 07132/4 36 19 Tel. 07132/4 36 18

71254 Ditzingen Fax 07156/1 82 04 Tel. 07156/60 54

72336 Balingen-Frommern Fax 07433/3 76 86 Tel. 07433/47 53

76327 Pfinztal Fax 0721/46 86 60 Tel. 0721/46 04 67

77746 Schutterwald Fax 0781/5 97 13 Tel. 0781/5 23 43

78315 Radolfzell Fax 07732/5 65 08 Tel. 07732/5 64 85

79112 Freiburg-Opfingen Fax 07664/5 97 76 Tel. 07664/10 14

89155 Erbach Fax 07305/86 10 Tel. 07305/61 22

88353 Kißlegg-Zaisenhofen Fax 07563/85 73 Tel. 07563/82 76

85716 Unterschleißheim Fax 089/3 17 13 07 Tel. 089/3 10 60 31

85077 Manching Fax 08459/76 02 Tel. 08459/69 97

82538 Geretsried Fax 08171/3 14 09 Tel. 08171/3 12 68

83064 Raubling Fax 08035/39 79 Tel. 08035/22 22

94491 Hengersberg Fax 09901/32 13 Tel. 09901/21 99

93128 Regenstauf Fax 09402/33 66 Tel. 09402/45 01

90765 Fürth-Stadeln Fax 0911/76 34 90 Tel. 0911/76 40 24

95326 Kulmbach Fax 09221/8 44 87 Tel. 09221/26 20

97080 Würzburg Fax 0931/9 81 58 Tel. 0931/9 17 08

63741 Aschaffenburg Fax 06021/8 36 17 Tel. 06021/8 36 16

86167 Augsburg Fax 0821/70 78 58 Tel. 0821/70 22 07

13627 Berlin Fax 030/349 919-12 Tel. 030/349 919-0

13627 Berlin-Nord (Land-Brandenburg) Fax 030/344 13 52 Tel. 030/344 30 47

14974 Genshagen (Berlin-Süd) Fax 03378/81 06 23 Tel. 03378/81 06 21

19061 Schwerin/Görrîes Fax 0385/660 513 Tel. 0385/650 55

01097 Dresden Fax 0351/803 60 91 Tel. 0351/8036090

04430 Blenltz/OT Dölzlg (Leipzig) Fax 034205/5 89 83 Tel. 034205/58982

99428 Nohra (Erfurt) Fax 03643/82 58 28 Tel. 03643/825826

09247 Röhrsdorf (Chemnitz) Fax 03722/50 24 85 Tel. 03722/502 484

39167 Irxleben (Magdeburg) Fax 039204/6 64 78 Tel. 039204/56 78

17033 Neubrandenburg Fax 0395/369 00 41 Tel. 0395/3690040

Fax 089/35 40 23 90

Page 36

UNITED STATES

CORPORATE OFFICE

MENOMONEE FALLS, WI 53052 N92 W15000 ANTHONY AVE. Tel. (262) 255-0500

CANADA

MISSISSAUGA, ONT. L5T 2N6 160 ADMIRAL BLVD. Tel. (905) 795-1661

Calgary, Alta. T2H 2H9 #11, 6115-4 St. S.E. Tel. (403) 255-3336

St. Laurent, Quebec H4R 2C1 3526 Rue Ashby Tel. (514) 337-1708

MEXICO

MEXICO CITY 2A. CERRADA NORTE 147 NO. 20 Tel. (55) 53-53-15-03

Monterrey, Nuevo León Calle Nardo #970, Col. Cementos, C. P. 64520 Tel. (81) 83-31-12-85

C. P. 45010, Zapopan, Jalisco Periférico Poniente No. 2100-Int. F, Tel. (33) 36271499

C. P. 37530 León, Guanajuato Privada Manzanares #103, Fracc.San Isidro de Jerez Tel. (477)7-11-34-35

C. P. 91700 Veracruz, Ver. Miguel Alemán N

COL. SAN MIGUEL AMANTLA 02700 Mexico D.F.

Col. Lomas del Colli

o

. 1001B, Col. Centro Tel. (229)9-35-10-44

ARGENTINA Colectora Oeste de Ruta Panamerica Tel. 5411-4-748-6800

BUENOS AIRES 1611 Km 28.5 Don Torcuato

BRASIL Avda. Arquimedes 1070 Tel. 5511-4582-4333

SÃO PAULO Unidade Autonoma No. 6

Jundiai, São Paulo

CHILE

SANTIAGO El Rosal 5000, Huechuraba, Casilla 130 - Correo 30 Tel. (56) 2-7400014

Antofagasta Orella 975 Tel. (56) 55-227250

Temuco Balmaceda 298 Tel. (56) 45-214425

AUSTRALIA

CLAYTON, VIC. 3169 PO Box 1315 RMDC Tel . (61) 03-95474033

Norwood, S.A. 5067 45 Beulah Road Tel. 08-3622331

Woodridge, QLD 4114 Unit 2, 6-8 Pendrey Court Tel. 07-32089577

Osborne Park, W.A. 6017 Unit P, 69-73 Hector Street Tel. 09-4452911

Auburn, N.S.W. 2144 14 Vore Street Tel. 02-7480366

JAPAN

OHTA-KU, TOYKO 144 2-CHOME 18-1, MINAMI-KAMATA Tel. (81) 03-37329281/5

Hirano-ku, Osaka-shi Miyake Nishi, 4-Chome Tel. 0723 30-0571

Sendai-shi Tachimachi 1-7-21 Tel. 022 284-8032

Fukuoka-shi Sannoh 1-7-1, Hakata-ku Tel. 092 451-1083

MALAYSIA

46150 PETALING JAYA 5. JALAN PJS 11/22 Tel. (03) 7364770

Selangor Darul Ehsan Bandar Sunway

NEW ZEALAND 4A Ponui Place

WIRI-AUCKLAND Mt. Wellington, Auckland Tel. (64) (9) 270 3784

SINGAPORE

JURONG TOWN SINGAPORE 2263 NO. 23, Tuas Ave. 18 Tel. (65) 861-0446

THAILAND 22/197 Pattanakarn Rd. Tel. (66) 2-319-9363/65

BANGKOK 10250 Soi Mooban Panya

www.wackergroup.com

SOUTH AFRICA 1031 KATROL AVE., ROBERTVILLE X10 Tel. H/O Jhb(011) 672-0847

JOHANNESBURG Roodepoort / P.O. Box 2163, Florida 1710, Gauteng.

Durban 10 Kinsman Rd. P.O. Box 420, New Germany 3620 Tel. Dbn(031) 702-3337

Capetown Cor. Beatrix & Carel, Marincowitz St.

P.O. Box 398, Brackenfell 7560 Tel. Cpt(021) 981-2197

CHINA Unit 611-612, 6/F Sunley Centre Tel. (852) 24068613

HONG KONG 9 Wing Yin Street

Wacker Corporation - P. O. Box 9007 - Menomonee Falls, WI 53052-9007 - Tel.: (262)-255-0500 - Fax: (262)-255-0550

Wacker-Werke GmbH & Co. KG - Preußenstraße 41 - 80809 München - Tel.: +49-(0)89-354 02-0 - Fax: +49-(0)89-35 402-390

Kwai Chung, New Territories

0902

Loading...

Loading...