Page 1

Pump

PTS 4V

PTK 4

OPERATOR’S MANUAL

0154628en 005

0107

0154628EN

Page 2

Page 3

PTS 4V / PTK 4 Table of Contents

wc_bo0154628en_005TOC.fm 1

1. Foreword 3

2. Safety Information 4

2.1 Laws Pertaining to Spark Arresters ...................................................... 4

2.2 Operating Safety .................................................................................. 5

2.3 Operator Safety while using Internal Combustion Engines .................. 6

2.4 Service Safety ...................................................................................... 7

2.5 Label Locations ................................................................................. 8

2.6 Safety Labels ........................................................................................ 9

3. Technical Data 11

3.1 Engine ................................................................................................ 11

3.2 Pump .................................................................................................. 12

3.3 Sound Measurements ........................................................................ 13

3.4 Dimensions ......................................................................................... 13

4. Operation 14

4.1 Application .......................................................................................... 14

4.2 Recommended Fuel ........................................................................... 14

4.3 Before Starting ................................................................................... 14

4.4 To Start ............................................................................................... 16

4.5 To Stop ............................................................................................... 17

4.6 Operation ............................................................................................ 17

4.7 Pump Wrench ..................................................................................... 17

4.8 Accessories ........................................................................................ 18

4.9 Hoses and Clamps ............................................................................. 18

Page 4

Table of Contents PTS 4V / PTK 4

wc_bo0154628en_005TOC.fm 2

5. Maintenance 19

5.1 Periodic Maintenance Schedule ..........................................................19

5.2 Engine Lubrication ...............................................................................20

5.3 Changing Oil Filter ...............................................................................21

5.4 Air Cleaner ..........................................................................................22

5.5 Spark Plug ...........................................................................................23

5.6 Fuel Filter ............................................................................................24

5.7 Carburetor Adjustment ........................................................................24

5.8 Mechanical Seal Lubrication ...............................................................25

5.9 Adjusting Impeller Clearance ..............................................................26

5.10 Cleaning Pump ....................................................................................27

5.11 Storage ................................................................................................28

5.12 Lifting ...................................................................................................28

5.13 Troubleshooting ...................................................................................29

Page 5

wc_tx000001gb.fm 3

CALIFORNIA

Proposition 65 Warning:

Engine exhaust, some of its constituents, and certain vehicle

components, contain or emit chemicals known to the State of

California to cause cancer and birth defects or other reproductive

harm.

1. Foreword

This manual provides information and procedures to safely operate

and maintain this Wacker model. For your own safety and protection

from injury, carefully read, understand and observe the safety

instructions described in this manual.

Keep this manual or a copy of it with the machine. If you lose this

manual or need an additional copy, please contact Wacker

Corporation. This machine is built with user safety in mind; however,

it can present hazards if improperly operated and serviced. Follow

operating instructions carefully! If you have questions about operating

or servicing this equipment, please contact Wacker Corporation.

The information contained in this manual was based on machines in

production at the time of publication. Wacker Corporation reserves the

right to change any portion of this information without notice.

All rights, especially copying and distribution rights, are reserved.

Copyright 2007 by Wacker Corporation.

No part of this publication may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without

express written permission from Wacker Corporation.

Any type of reproduction or distribution not authorized by Wacker

Corporation represents an infringement of valid copyrights and will be

prosecuted. We expressly reserve the right to make technical

modifications, even without due notice, which aim at improving our

machines or their safety standards.

WARNING

Page 6

Safety Information PTS 4V / PTK 4

wc_si000130gb.fm 4

2. Safety Information

This manual contains DANGER, WARNING, CAUTION, and NOTE

callouts which must be followed to reduce the possibility of personal

injury, damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

CAUTION: Used without the safety alert symbol, CAUTION indicates

a potentially hazardous situation which, if not avoided, may result in

property damage.

Note: Contains additional information important to a procedure.

2.1 Laws Pertaining to Spark Arresters

Notice: State Health Safety Codes and Public Resources Codes

specify that in certain locations spark arresters be used on internal

combustion engines that use hydrocarbon fuels. A spark arrester is a

device designed to prevent accidental discharge of sparks or flames

from the engine exhaust. Spark arresters are qualified and rated by

the United States Forest Service for this purpose.

In order to comply with local laws regarding spark arresters, consult

the engine distributor or the local Health and Safety Administrator.

DANGER

WARNING

CAUTION

Page 7

PTS 4V / PTK 4 Safety Information

wc_si000130gb.fm 5

2.2 Operating Safety

Familiarity and proper training are required for the safe operation of

equipment. Equipment operated improperly or by untrained personnel

can be dangerous. Read the operating instructions contained in both

this manual and the engine manual and familiarize yourself with the

location and proper use of all controls. Inexperienced operators should

receive instruction from someone familiar with the equipment before

being allowed to operate the machine.

2.2.1 NEVER allow anyone to operate this equipment without proper

training. People operating this equipment must be familiar with the

risks and hazards associated with it.

2.2.2 NEVER use accessories or attachments that are not recommended by

Wacker. Damage to equipment and injury to the user may result.

2.2.3 NEVER touch the engine or muffler while the engine is on or

immediately after it has been turned off. These areas get hot and may

cause burns.

2.2.4 NEVER pump volatile, flammable or low flash point fluids. These fluids

could ignite or explode.

2.2.5 NEVER pump corrosive chemicals or water containing toxic

substances. These fluids could create serious health and

environmental hazards. Contact local authorities for assistance.

2.2.6 NEVER open the priming plug when the pump is hot. Never loosen or

remove inlet or discharge hose fittings when the pump is hot. Hot water

inside could be pressurized much like the radiator on an automobile.

Allow the pump to cool to the touch before loosening the plug and

before loosening or removing the inlet or discharge hose fittings.

2.2.7 NEVER open pump housing cover while pump is operating, or start

pump with the cover off. The rotating impeller inside the pump can cut

or sever objects caught in it.

2.2.8 NEVER block or restrict flow from inlet line or discharge line. Remove

kinks from discharge line before starting pump. Operation with a

blocked inlet line or discharge line can cause water inside pump to

overheat.

2.2.9 ALWAYS be sure operator is familiar with proper safety precautions

and operation techniques before using machine.

2.2.10 ALWAYS read, understand, and follow procedures in the Operator’s

Manual before attempting to operate the equipment.

2.2.11 ALWAYS be sure the machine is on a firm, level surface and will not

tip, roll, slide, or fall while operating.

2.2.12 ALWAYS close fuel valve on engines equipped with one when

machine is not being operated.

WARNING

Page 8

Safety Information PTS 4V / PTK 4

wc_si000130gb.fm 6

2.2.13 ALWAYS store the equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of the reach of

children.

2.2.14 ALWAYS wear hearing protection when operating equipment.

2.3 Operator Safety while using Internal Combustion Engines

Internal combustion engines present special hazards during operation

and fueling. Read and follow the warning instructions in the engine

owner’s manual and the safety guidelines below. Failure to follow the

warnings and safety guidelines could result in severe injury or death.

2.3.1 DO NOT run the machine indoors or in an enclosed area such as a

deep trench unless adequate ventilation, through such items as

exhaust fans or hoses, is provided. Exhaust gas from the engine

contains poisonous carbon monoxide gas; exposure to carbon

monoxide can cause loss of consciousness and may lead to death.

2.3.2 DO NOT smoke while operating the machine.

2.3.3 DO NOT smoke when refueling the engine.

2.3.4 DO NOT refuel a hot or running engine.

2.3.5 DO NOT refuel the engine near an open flame.

2.3.6 DO NOT spill fuel when refueling the engine.

2.3.7 DO NOT run the engine near open flames.

2.3.8 ALWAYS refill the fuel tank in a well-ventilated area.

2.3.9 ALWAYS replace the fuel tank cap after refueling.

DANGER

Page 9

PTS 4V / PTK 4 Safety Information

wc_si000130gb.fm 7

2.4 Service Safety

Poorly maintained equipment can become a safety hazard! In order

for the equipment to operate safely and properly over a long period of

time, periodic maintenance and occasional repairs are necessary.

2.4.1 DO NOT attempt to clean or service the machine while it is running.

Rotating parts can cause severe injury.

2.4.2 DO NOT crank a flooded engine with the spark plug removed on

gasoline-powered engines. Fuel trapped in the cylinder will squirt out

the spark plug opening.

2.4.3 DO NOT test for spark on gasoline-powered engines if the engine is

flooded or the smell of gasoline is present. A stray spark could ignite

the fumes.

2.4.4 DO NOT use gasoline or other types of fuels or flammable solvents to

clean parts, especially in enclosed areas. Fumes from fuels and

solvents can become explosive.

2.4.5 ALWAYS operate machine with all safety devices and guards in place

and in working order. DO NOT modify or defeat safety devices. DO

NOT operate machine if any safety devices or guards are missing or

inoperative.

2.4.6 ALWAYS keep the area around the muffler free of debris such as

leaves, paper, cartons, etc. A hot muffler could ignite the debris and

start a fire.

2.4.7 ALWAYS replace worn or damaged components with spare parts

designed and recommended by Wacker Corporation.

2.4.8 ALWAYS disconnect the spark plug on machines equipped with

gasoline engines, before servicing, to avoid accidental start-up.

2.4.9 ALWAYS keep the machine clean and labels legible. Replace all

missing and hard-to-read labels. Labels provide important operating

instructions and warn of dangers and hazards.

2.4.10 ALWAYS handle impeller carefully. The impeller can develop sharp

edges which can cut.

WARNING

Page 10

Safety Information PTS 4V / PTK 4

wc_si000130gb.fm 8

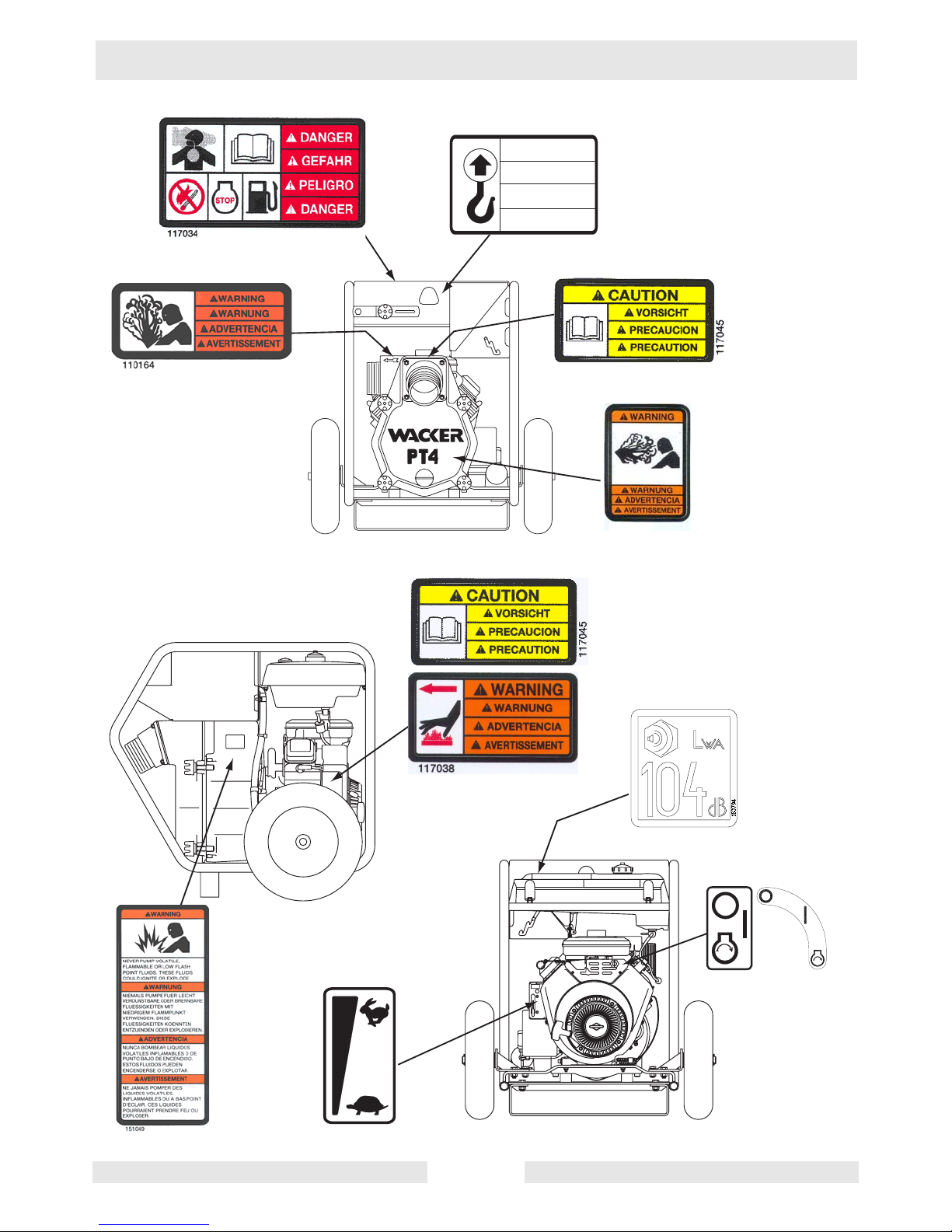

2.5 Label Locations

wc_gr001479

PRECAUTION

PRECAUCION

VORSICHT

CAUTIO

N

Page 11

PTS 4V / PTK 4 Safety Information

wc_si000130gb.fm 9

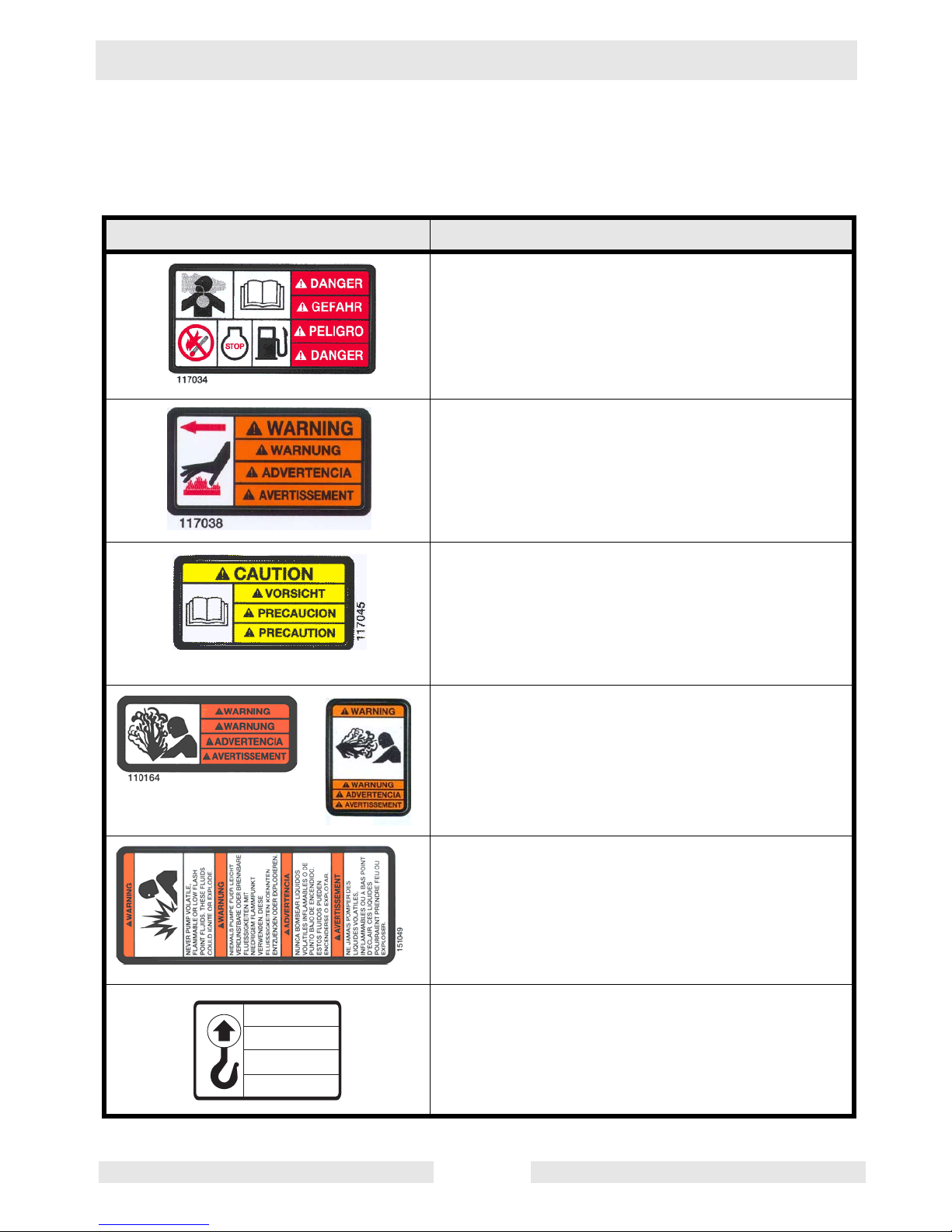

2.6 Safety Labels

Wacker machines use international pictorial labels where needed.

These labels are described below:

Label Meaning

DANGER!

Engines emit carbon monoxide; operate only in

well-ventilated area. Read the Operator’s Manual.

No sparks, flames, or burning objects near the

machine. Shut off the engine before refueling.

WARNING!

Hot surface!

CAUTION!

Read and understand the supplied Operator’s

Manuals before operating this machine. Failure to

do so increases the risk of injury to yourself or

others.

WARNING!

Do not open if pump is hot. Hot water and/or

steam inside could be pressurized.

WARNING!

Never pump volatile, flammable or low flash point

fluids. These fluids could ignite or explode.

CAUTION!

Lifting point

PRECAUTION

PRECAUCION

VORSICHT

CAUTIO

N

Page 12

Safety Information PTS 4V / PTK 4

wc_si000130gb.fm 10

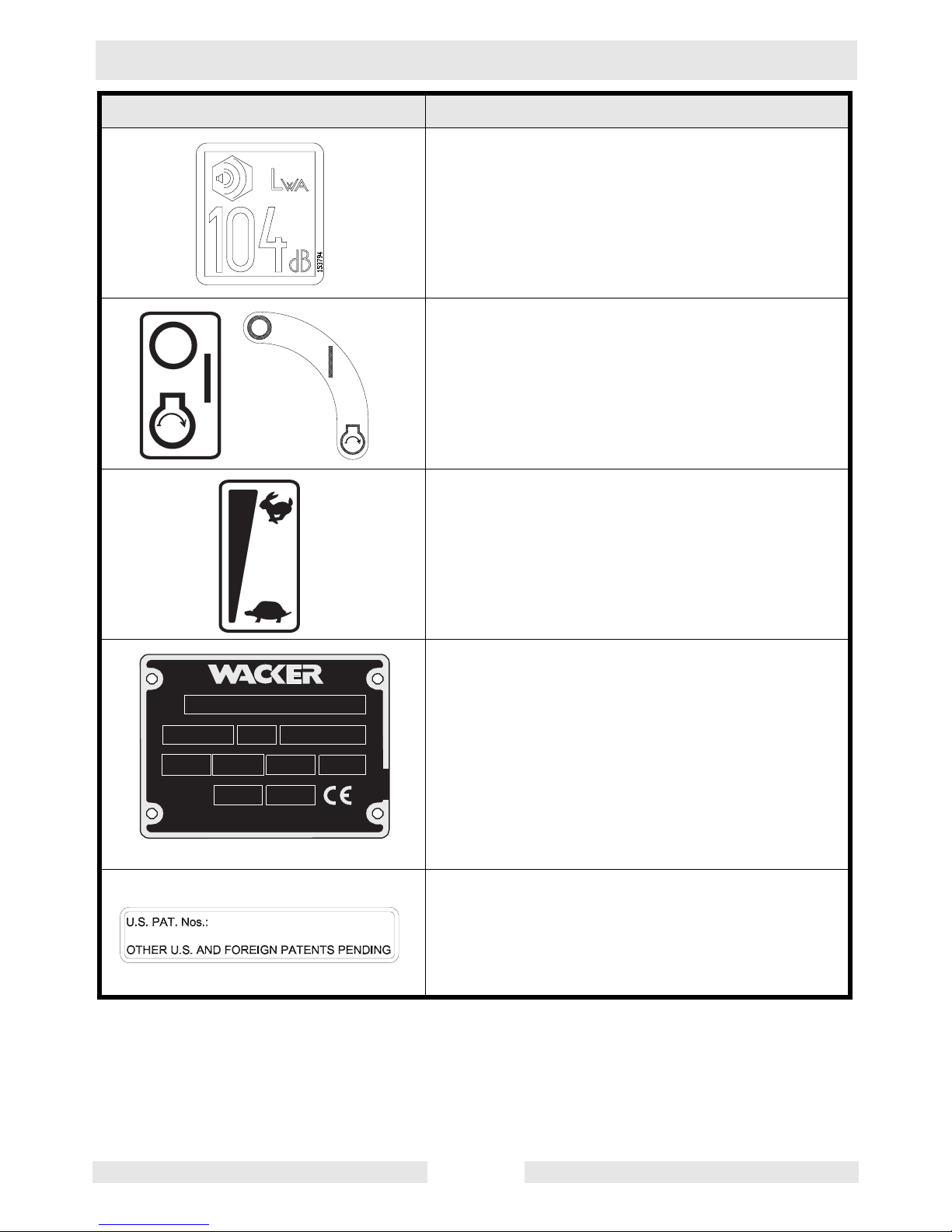

Guaranteed sound power level in dB(A)

Key switch:

off

on

start

Throttle control lever:

Rabbit = Full or Fast

Turtle = Idle or Slow

A nameplate listing the model number, item number, revision number, and serial number is

attached to each unit. Please record the information found on this plate so it will be available

should the nameplate become lost or damaged.

When ordering parts or requesting service information, you will always be asked to specify the

model number, item number, revision number,

and serial number of the unit.

This machine may be covered by one or more

patents.

Label Meaning

R e v . S e r i a l N u m b e r

M E N O M O N E E F A L L S , W I U S A 5 3 0 5 1

h pk Wl b s

d B ( A ) M a n u f . Y r .

M o d e l

k g

M A D E

I N U S A

I t e m N u m b e r

8 8 2 2 3

Page 13

PTS 4V / PTK 4 Technical Data

wc_td000132gb.fm 11

3. Technical Data

3.1 Engine

Item No. PTS 4V

0007683 Rev 115 & lower

0007691 Rev 116 & lower

0007692

PTS 4V

0007683 Rev 116 & higher

0007691 Rev 117 & higher

Engine

Engine Make Briggs and Stratton

Engine Model Vanguard 303447-

1256-E2

Vanguard 305447-

0144-E1

Rated Power

kW (Hp)

12 (16)

Spark Plug Champion RC12YC

Electrode Gap

mm (in.)

0.76 (0.030)

Engine Speed

rpm

3600

Air Cleaner

type

Dual element

Battery

V/CCA/

amp-hr./size

12 / 230 / 32 / 22NF

Engine Lubrication

oil grade /

service class

>5°C (40°F) SAE 10W30 / SG, SF, or SE

<5°C (40°F) SAE 30W / SG, SF, or SE

Engine Oil Capacity

ml (oz.)

1400 (48)

Fuel

type

Regular unleaded gasoline

Fuel Tank Capacity

l (gal.)

17 (4.5)

Page 14

Technical Data PTS 4V / PTK 4

wc_td000132gb.fm 12

3.2 Pump

Item number: PTS 4V

0007683, 0007691, 0007692

Pump

Weight

kg (lbs.)

163 (360)

*Max. Suction Lift

m (ft.)

7.5 (25)

Max. Total Head

m (ft.)

32 (106)

Mechanical Seal Lubrication

oil grade

ml (oz.)

SAE 30

150 (5)

Suction / Discharge Diameter

mm (in.)

100 (4)

Max. Solid Size

mm (in.)

50 (2)

*Based on pump operating at sea level. Maximum suction lift will be less at higher altitudes.

Page 15

PTS 4V / PTK 4 Technical Data

wc_td000132gb.fm 13

3.3 Sound Measurements

The required sound specifications per Appendix 1, Paragraph 1.7.4 of

the EC-Machine Regulations, is:

• the guaranteed sound power level (L

WA

) = 104 dB(A)

These sound values were determined according to ISO 3744 for the

sound power (L

WA

).

The sound measurements were obtained with the unit operating on

pavement at nominal speed.

3.4 Dimensions

mm (in.)

890 (35)

915 (36)

890

(35)

wc_gr001478

Page 16

Operation PTS 4V / PTK 4

wc_tx000339gb.fm 14

4. Operation

4.1 Application

This pump is intended for removing clean water and water containing

some debris and solids. Refer to “Technical Data” for maximum solid

size.

4.1.1 NEVER pump volatile, flammable or low flash point fluids. These fluids

could ignite or explode.

4.1.2 NEVER pump corrosive chemicals or water containing toxic

substances. These fluids could create serious health and

environmental hazards. Contact local authorities for assistance.

4.2 Recommended Fuel

The engine requires regular grade unleaded gasoline. Use only fresh,

clean gasoline. Gasoline containing water or dirt will damage fuel

system. Consult engine Owner’s Manual for complete fuel

specifications.

4.3 Before Starting

See Graphic: wc_gr000013

4.3.1 Read safety instructions at the beginning of manual.

4.3.2 Place pump as near to water as possible, on a firm, flat, level surface.

4.3.3 To prime pump, remove prime plug (a) and fill pump case with water.

If the pump case is not filled with water before starting, it will not begin

pumping.

DO NOT open priming plug, discharge plug, or loosen hose fittings if

pump is hot! Water or vapor inside pump may be under pressure.

4.3.4 Check for leaks between pump and engine. If water is leaking, the seal

inside pump is worn or damaged. Continued operation may cause

water damage to engine.

WARNING

WARNING

WARNING

Page 17

PTS 4V / PTK 4 Operation

wc_tx000339gb.fm 15

4.3.5 Check that hoses are securely attached to pump. Suction hose (b)

must not have any air leaks. Tighten hose clamps (c) and couplings

(d). Check that discharge hose (e) is not restricted. Lay hose out as

straight as possible. Remove any twists or sharp bends from hose

which may block the flow of water.

4.3.6 Make sure suction strainer (f) is clean and securely attached to end of

hose. The strainer is designed to protect the pump by preventing large

objects from being pulled into the pump.

CAUTION: Strainer should be positioned so it will remain completely

under water. Running the pump with the strainer above water for long

periods can damage the pump.

4.3.7 Check fuel level, engine oil level, and condition of air cleaner.

Page 18

Operation PTS 4V / PTK 4

wc_tx000339gb.fm 16

4.4 To Start

See Graphic: wc_gr001480

Follow the instructions below and read starting and stopping

instuctions found in the engine owner’s manual.

4.4.1 Open the fuel valve (b1).

4.4.2 If the engine is cold, pull out the choke control (a1). If the engine is hot,

push in the choke control (a2).

4.4.3 Move the throttle control to the fast position (c1).

4.4.4 Turn the key switch to the start position (d3) and hold it until the engine

starts.

CAUTION: Do not crank engine longer than 15 seconds at a time.

Extended cranking can damage the starter motor.

4.4.5 To start the engine using manual start:

• Turn the key switch to the run position (d2).

• Rapidly pull the starter rope (e) to start the engine.

• Leave key in run position (d2) while engine is running.

Note: The engine is equipped with a low oil protection system, which

does not allow the engine to start if the oil level is low. This device will

not protect the engine if a low oil level occurs while running. The switch

opens on a pressure rise of 4 psi +/-1.5 psi.

4.4.6 Push the choke in as the engine warms (a2).

4.4.7 Keep the engine throttle in the fast position while operating pump.

wc_gr001480

d1

d2

d3

b2

b1

c1

c2

a1 a2

Page 19

PTS 4V / PTK 4 Operation

wc_tx000339gb.fm 17

4.5 To Stop

See Graphic: wc_gr001480

4.5.1 Reduce engine RPM by moving the throttle completely to the idle

position (c2).

4.5.2 Turn the engine switch to the stop position (d1).

4.5.3 Close the fuel valve (b2).

4.6 Operation

Pump should begin pumping water within a minute depending on

length of suction hose and height of pump above water. Longer hoses

will require more time.

If pump does not prime, check for loose fittings or air leak in suction

hose. Make sure strainer in water is not blocked.

Run engine at full speed while operating pump.

4.6.1 NEVER pump corrosive chemicals or water containing toxic

substances. These fluids could create serious health and

environmental hazards. Contact local authorities for assistance.

4.7 Pump Wrench

See Graphic: wc_gr001481

The wrench (a) supplied with the pump can be used to loosen and

tighten: hose couplings, knobs on pump cover, priming plug, and drain

plug on front cover.

Store wrench on pump frame.

WARNING

a

wcgr001481

Page 20

Operation PTS 4V / PTK 4

wc_tx000339gb.fm 18

4.8 Accessories

Wacker offers a complete line of fittings, hoses, and clamps to properly

connect the pump to match various job conditions.

4.9 Hoses and Clamps

See Graphic: wc_gr000021

Suction hoses (a) must be rigid enough not to collapse when pump is

operating.

Discharge hoses (b) are usually thin-walled collapsible hoses. Rigid

hoses similar to those used as suction hoses may also be used as

discharge hoses.

Note: Suction and discharge hoses are available from Wacker.

Contact your nearest dealer for more information.

Two clamps (c) are recommended for connection of suction hoses to

inlet coupling.

Note: This connection is important. Even a small air leak on the suction

side of pump will prevent the pump from priming.

For other hose connections, one T-bolt or worm-gear type clamp is

usually sufficient to hold hoses in place. In some cases, slight

variances in hose diameters may make it necessary to add more

clamps in order to maintain tight connections.

Page 21

PTS 4V / PTK 4 Maintenance

wc_tx000340gb.fm 19

5. Maintenance

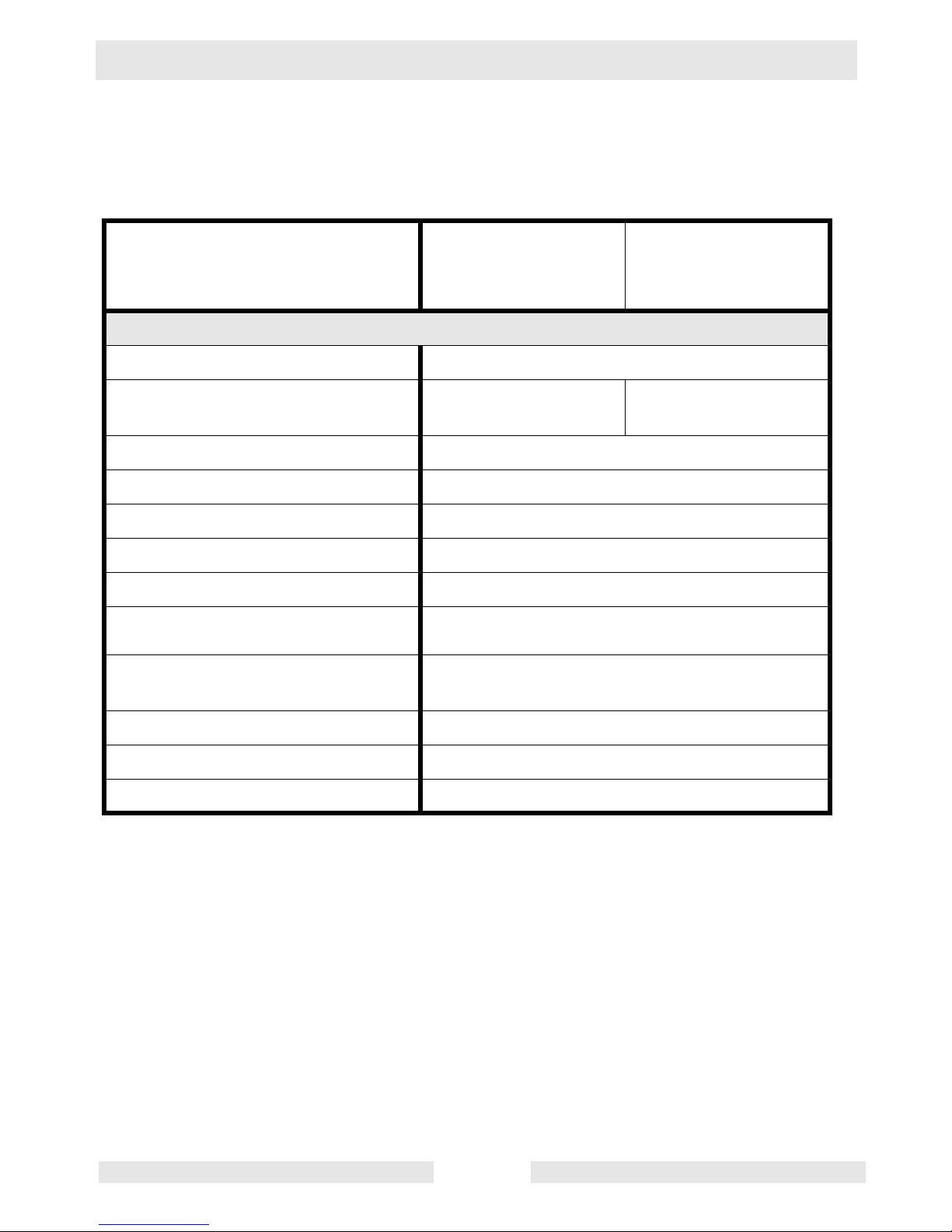

5.1 Periodic Maintenance Schedule

The chart below lists basic machine and engine maintenance. Refer to

the engine manufacturer’s Operator’s Manual for additional

information on engine maintenance.

Daily

before

starting

After

first

5 hrs.

Every

50

hrs.

Every

100

hrs.

Every

year

Check fuel level.

Check engine oil level.

Inspect for leaks between pump and

engine.

Inspect air filter. Clean as needed.

Check external hardware.

Inspect shock mounts for damage.

Change oil in pump housing.

Change engine oil and replace filter.

Replace air cleaner.

Check and clean spark plug.

Replace in-line fuel filter.

Check and adjust valve clearances.

Page 22

Maintenance PTS 4V / PTK 4

wc_tx000340gb.fm 20

5.2 Engine Lubrication

See Graphic: wc_gr000562

Check engine oil level daily before starting engine. Add oil as required.

5.2.1 To check oil level, place machine on a level surface.

5.2.2 Clean area around oil fill and remove dipstick.

5.2.3 Pour oil (a) slowly, checking oil level occasionally with dipstick.

5.2.4 Fill to full mark on dipstick (b). DO NOT overfill.

5.2.5 When measuring oil level, screw dipstick (c) firmly in place until cap

bottoms on tube.

w c _ g r 0 0 0 5 6 2

F U L L A D D

=

>

?

Page 23

PTS 4V / PTK 4 Maintenance

wc_tx000340gb.fm 21

5.3 Changing Oil Filter

See Graphic: wc_gr001482

Replace the oil filter after every 100 hours of operation.

5.3.1 Drain the engine oil and replace it with fresh oil before removing the

used oil filter. See Technical Data for oil quantity and type.

Note: In the interests of environmental protection, place a plastic sheet

and a container under the machine to collect any liquid which drains

off. Dispose of this liquid in accordance with environmental protection

legislation.

5.3.2 Remove the used filter before installing a new filter, lightly oil the filter

gasket with fresh, clean engine oil.

5.3.3 Screw the filter (a) on by hand until the gasket makes contact, then

tighten an additional 1/2 to 3/4 turn.

5.3.4 Start and run the engine to check for leaks. Stop the engine. Recheck

the oil level and add oil if required. See Engine Lubrication.

a

wc_gr001482

Page 24

Maintenance PTS 4V / PTK 4

wc_tx000340gb.fm 22

5.4 Air Cleaner

See Graphic: wc_gr000564

Service air cleaner frequently to prevent carburetor malfunction.

CAUTION: NEVER run the engine without the air cleaner. Severe

engine damage will occur.

NEVER use gasoline or other types of low flash point solvents for

cleaning the air cleaner. A fire or explosion could result.

The engine is equipped with a dual element air cleaner. To service air

cleaner:

5.4.1 Remove cover (a), knob (b), and retaining plate (c).

5.4.2 Remove foam precleaner (d) from filter cartridge (e).

5.4.3 Wash precleaner in liquid detergent and water. Squeeze dry in a clean

cloth. Saturate precleaner in engine oil, squeeze out excess oil.

Replace precleaner if it is damaged or heavily soiled.

5.4.4 To clean cartridge, remove and tap lightly on a flat surface. Replace

cartridge if it is damaged or heavily soiled.

Note: Do not use petroleum solvents to clean precleaner or cartridge.

Petroleum type solvents will damage them. Do not use pressurized air

to clean cartridge. Pressurized air can also damage the cartridge.

w c _ g r 0 0 0 5 6 4

=

>

?

@

A

Page 25

PTS 4V / PTK 4 Maintenance

wc_tx000340gb.fm 23

5.5 Spark Plug

See Graphic: wc_gr000028

Clean or replace the spark plug as needed to ensure proper operation.

Refer to the engine owner’s manual.

The muffler becomes very hot during operation and remains hot for a

while after stopping the engine. Do not touch the muffler while it is hot.

Note: Refer to the Technical Data for the recommended spark plug

type and the electrode gap setting.

5.5.1 Remove the spark plug and inspect it.

5.5.2 Replace the spark plug if the insulator is cracked or chipped.

5.5.3 Clean the spark plug electrodes with a wire brush.

5.5.4 Set the electrode gap (a).

5.5.5 Tighten the spark plug securely.

CAUTION: A loose spark plug can become very hot and may cause

engine damage.

WARNING

Page 26

Maintenance PTS 4V / PTK 4

wc_tx000340gb.fm 24

5.6 Fuel Filter

See Graphic: wc_gr001483

5.6.1 Change in-line fuel filter (a) once a year.

5.6.2 Check fuel lines and fittings frequently for cracks or leaks. Replace as

needed.

Allow engine to cool and close fuel valve before replacing fuel filter.

5.7 Carburetor Adjustment

See Graphic: wc_gr000566

Note: the air cleaner must be in place and the engine warm when

making adjustments to carburetor.

5.7.1 With engine running, place throttle in SLOW position and rotate

carburetor throttle lever against the idle speed screw (a) and hold it

there.

5.7.2 Turn the idle speed screw to obtain 1300 to 1500 rpm.

5.7.3 While still holding the throttle lever against the idle speed screw, turn

the idle mixture valve (b) midway between limits.

5.7.4 Readjust the idle speed to 1200 rpm and release carburetor throttle

lever. Engine should accelerate smoothly when throttle is opened. If it

does not, readjust idle mixture valve slightly counterclockwise.

a

b

wc_gr000566

wc_gr001483

a

Page 27

PTS 4V / PTK 4 Maintenance

wc_tx000340gb.fm 25

5.8 Mechanical Seal Lubrication

See Graphic: wc_gr001484

Change seal lubricant every 50 hours using SAE 30W oil.

5.8.1 Remove plugs (a) from both sides of pump housing for venting.

5.8.2 Remove bottom plug (b) and allow oil to drain from oil cavity.

5.8.3 Install bottom drain plug.

5.8.4 Fill oil cavity through one of the side plug (a) holes until oil is level with

top of hole or flows out hole on opposite side.

Oil quantity - approximately 150 ml (5 ounces).

5.8.5 Install all plugs before operating pump.

a

b

wc_gr001484

Page 28

Maintenance PTS 4V / PTK 4

wc_tx000340gb.fm 26

5.9 Adjusting Impeller Clearance

See Graphic: wc_gr001485

If it is necessary to replace impeller or volute insert, be sure clearance

between impeller and insert is adjusted correctly.

The impeller (e) should be as close to the insert (a) as possible without

rubbing against it. Clearance is adjusted by adding or removing shims

(b) from behind insert. Inserts are attached to the pump cover and

must be unbolted (c) before they can be removed.

Check clearance (d) between impeller and insert by slowly pulling

starter rope to turn impeller.

Note: Remove spark plug to make it easier to turn impeller. On diesel

engines open decompression device before cranking engine.

If starter or crank is difficult to turn, or rubbing is heard from inside

pump, the impeller and insert are too close to each other. Remove a

shim from behind insert and check again for rubbing. Continue

removing shims until impeller turns easily.

Note: It is important not to remove too many shims or the clearance

between the impeller and insert will become too wide and pump

performance will be reduced.

As the impeller wears down, additional shims may be required to

maintain the clearance between the impeller and insert.

wc_gr001485

e

a

b

c

d

Page 29

PTS 4V / PTK 4 Maintenance

wc_tx000340gb.fm 27

5.10 Cleaning Pump

See Graphic: wc_gr001486

After pumping water containing a large amount of dirt or debris, clean

out inside of pump housing.

5.10.1 Remove drain plug (a) from pump housing and drain any water left in

pump.

5.10.2 Loosen the four knobs (b) holding the pump cover and remove cover.

5.10.3 Clean out dirt and debris. Inspect impeller and volute insert for wear.

Note: Tighten cover evenly at all four corners using a wrench.

CAUTION: The impeller may develop sharp edges. Use care when

cleaning around impeller to prevent getting cut.

a

b

wc_gr001486

Page 30

Maintenance PTS 4V / PTK 4

wc_tx000340gb.fm 28

5.11 Storage

If pump is being stored for more than 30 days:

NEVER open priming plug, discharge plug, or cover when pump is hot.

5.11.1 Remove discharge plug from pump casing and drain out any water left

in the housing after pump has cooled.

5.11.2 Remove pump cover and clean inside of pump housing. Coat inside of

pump with a light film of oil to reduce corrosion. A spray can of oil works

well for this.

5.11.3 Tape up suction and discharge ports to prevent anything from falling

into pump.

5.11.4 Change engine oil and follow procedures described in engine manual

for engine storage.

5.11.5 Cover pump and engine and store in a clean, dry area.

5.12 Lifting

See Graphic: wc_gr001487

To lift machine mechanically:

CAUTION: Before attempting to lift, be sure that lifting devices can

safely handle weight of machine. See Technical Data for weight of

machine.

Attach hook, harness, or cable to machine as shown and lift as

desired.

WARNING

wc_gr001487

Page 31

PTS 4V / PTK 4 Maintenance

wc_tx000340gb.fm 29

5.13 Troubleshooting

Problem / Symptom Reason / Remedy

Pump does not take in water. • Not enough priming water in housing.

• Engine speed too low. Adjust speed.

• Strainer plugged. Clean strainer.

• Suction hose damaged. Replace or repair hose.

• Air leak at suction port. Check that fittings are tight and

sealing properly.

• Pump too high above water.

• Debris collecting in pump housing. Clean pump housing.

• Too much clearance between impeller and insert.

Pump takes in water, little or

no discharge.

• Engine speed too low. Adjust speed.

• Suction strainer partially plugged. Clean strainer.

• Impeller worn. Adjust clearance by adding shims or

replace impeller.

• Volute insert worn or damaged. Adjust clearance or

replace insert.

Suction hose leaks at inlet. • Clamps are not sealing properly. Tighten, replace, or

add clamp.

• Hose diameter is too large.

• Hose is damaged.

Discharge hose does not

stay on coupling.

• Pressure may be too high for clamps being used. Add

another clamp.

• Hose kinked or end blocked. Check hose.

Impeller does not turn; pump

is hard to start.

• Impeller jammed or blocked. Open pump cover and

clean dirt and debris from inside of pump housing.

• Impeller and insert binding. Adjust clearance by removing shim from behind insert.

Engine does not start or

stops during operation.

• Debris in pump housing, blocking impeller.

• Low oil level in engine.

• Impeller rubbing on insert.

Page 32

Maintenance PTS 4V / PTK 4

wc_tx000340gb.fm 30

Notes

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

2005-CE-PTS4V-Q.fm

William Lahner Dan Domanski

Vice President of Engineering Manager, Product Engineering

WACKER CORPORATION

Date / Datum / Fecha / Date

EC DECLARATION OF CONFORMITY

CE-KONFORMITÄTSERKLÄRUNG

DECLARACIÓN DE CONFORMIDAD DE LA CE

DÉCLARATION DE CONFORMITÉ C.E.

WACKER CORPORATION, N92 W15000 ANTHONY AVENUE, MENOMONEE FALLS, WISCONSIN USA

hereby certifies that the construction equipment specified hereunder / bescheinigt, daß das Baugerät / certifica que la máquina de

construcción / atteste que le matériel :

1. Category / Art / Categoría / Catégorie Water Pump Units

Wasserpumpen

Equipos de Bomba de Agua

Groupe Motopompe à Eau

2. Type - Typ - Tipo - Type PTS 4V

PTS 4V(I)

3. Item number of equipment / Artikelnummer / Número de referencia de la máquina / Numéro de référence du matériel :

0007683, 0007691

4. Net installed power / absolute installierte Leistung / Potencia instalada neta / Puissance installée nette :

12 kW

Has been sound tested per Directive 2000/14/EC / In Übereinstimmung mit Richtlinie 2000/14/EG bewertet worden ist / Ha sido

ensayado en conformidad con la norma 2000/14/CE / A été mis à l’épreuve conforme aux dispositions de la directive 2000/14/CEE :

and has been produced in accordance with the following standards:

und in Übereinstimmung mit folgenden Richtlinien hergestellt worden ist:

y ha sido fabricado en conformidad con las siguientes normas:

et a été produit conforme aux dispositions des directives européennes ci-après :

2000/14/EC

2002/88/EC

89/336/EEC

98/37/EEC

AUTHORIZED REPRESENTATIVE IN THE EUROPEAN UNION

BEVOLLMÄCHTIGTER VERTRETER FÜR DIE EUROPÄISCHE GEMEINSCHAFT

REPRESENTANTE AUTORIZADO EN LA UNIÓN EUROPEA

REPRÉSENTANT AGRÉÉ AUPRÈS DE L’UNION EUROPÉENNE

WACKER CONSTRUCTION EQUIPMENT AG

Preußenstraße 41

80809 München

Conformity Assessment Procedure /

Konformitätsbewertungsverfahren / Procedimiento

para ensayar conformidad / Procédé pour

l’épreuve de conformité

Measured sound power level / Gemessener

Schall-leistungspegel / Nivel de potencia

acústica determinado / Niveau de puissance

acoustique fixé

Guaranteed sound power level/ Garantierter

Schallleistungspegel / Nivel de potencia

acústica garantizado / Niveau de puissance

acoustique garanti

Annex V / Anhang V

Anexo V / Annexe V

103 dB(A) 104 dB(A)

20.12.04

Page 46

Wacker Construction Equipment AG · Preußenstraße 41 · D-80809 München · Tel.: +49-(0)89-3 54 02 - 0 · Fax: +49 - (0)89-3 54 02-3 90

Wacker Corporation · P.O. Box 9007 · Menomonee Falls, WI 53052-9007 · Tel. : (262) 255-0500 · Fax: (262) 255-0550 · Tel. : (800) 770-0957

Wacker Asia Pacific Operations · Skyline Tower, Suite 2303, 23/F · 39 Wang Kwong Road, Kowloon Bay, Hong Kong · Tel. +852 2406 60 32 · Fax: +852 2406 60 21

Loading...

Loading...