Page 1

Operator’s Manual

5100016561

Pump

PT2 / PT2A / PT2H

PT3 / PT3A / PT3H

EN

5100016561 02 0915

Page 2

Copyright

notice

© Copyright 2015 by Wacker Neuson Production Americas LLC

All rights, including copying and distribution rights, are reserved.

This publication may be photocopied by the original purchaser of the machine. Any

other type of reproduction is prohibited without express written permission from

Wacker Neuson Production Americas LLC.

Any type of reproduction or distribution not authorized by Wacker Neuson Production

Americas LLC represents an infringement of valid copyrights. Violators will be

prosecuted.

T ra d emarks

Manufacturer

Original

instructions

All trademarks referenced in this manual are the property of their respective owners.

Wacker Neuson Production Americas LLC

N92W15000 Anthony Avenue

Menomonee Falls, WI 53051 U.S.A.

Tel: (262) 255-0500 · Fax: (262) 255-0550 · Tel: (800) 770-0957

www.wackerneuson.com

This Operator’s Manual presents the original instructions. The original language of this

Operator’s Manual is American English.

Page 3

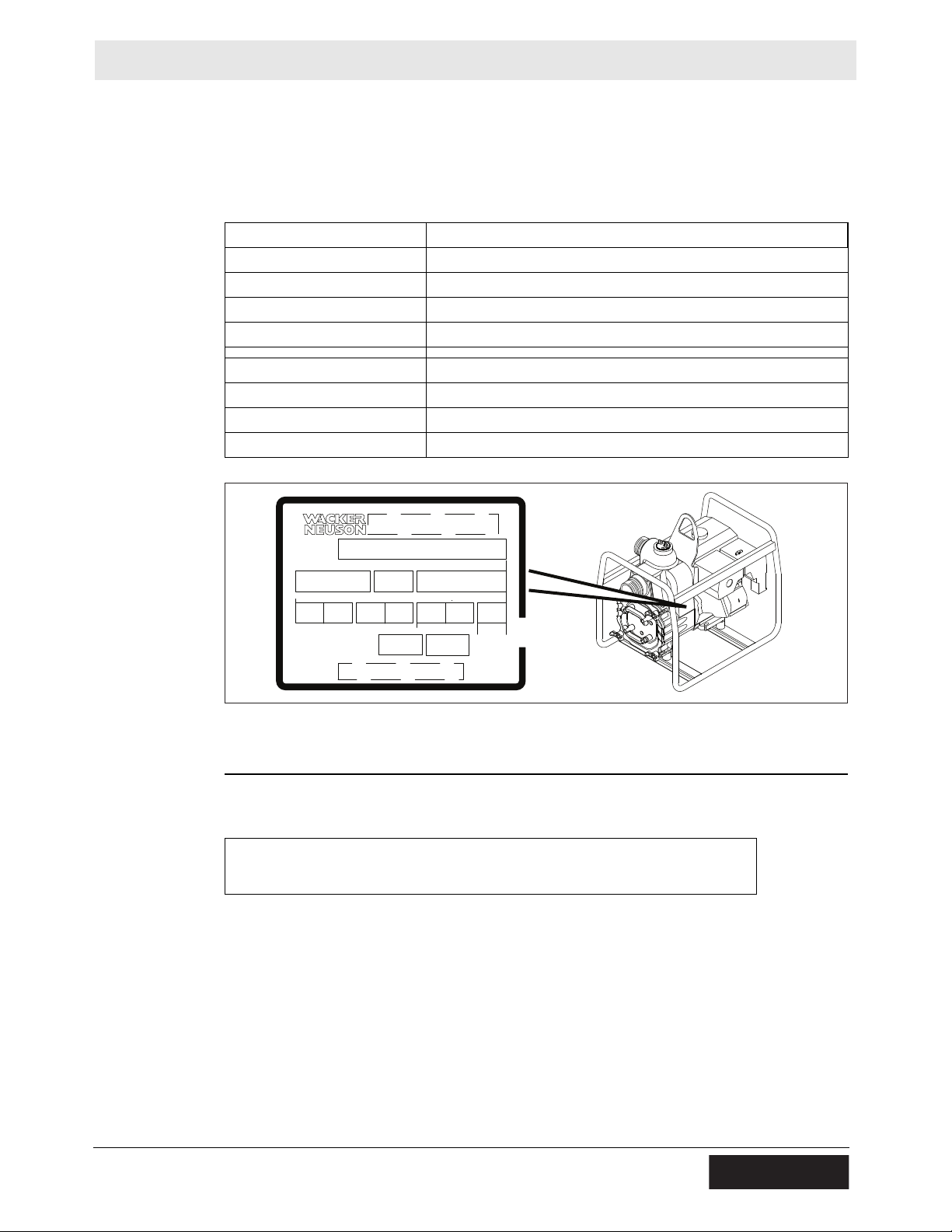

PT2 / PT3 Foreword

wc_gr012659

MADE IN USA

kg

kW

lbs

hp

gpm

Item Number

Type/Model

Rev.

m

ft

Manuf.Yr.

m3/hr

179096

Serial Number

Foreword

SAVE THESE INSTRUCTIONS—This manual contains important instructions for

the machine models below. These instructions have been written expressly by

Wacker Neuson Production Americas LLC and must be followed during inst allation,

operation, and maintenance of the machines.

Machine Item Number

PT2 5000009318

PT2A, PT2A(I) 5000009092, 5000009095, 5000009237

PT2(I) 5000620725

PT2H, PT2H(I) 5000009094, 5000009097

PT3 5000009321, 5000009322

PT3A, PT3A(I) 5000009098, 5000009101, 5000009240, 5000620800

PT3(I) 5000620726

PT3H, PT3H(I) 5000009100, 5000009103

Machine

identification

Serial number

(S/N)

A nameplate listing the model number, item number, revision number, and serial

number is attached to this machine. The location of the nameplate is shown above.

For future reference, record the serial number in the space provided below . You will

need the serial number when requesting parts or service for this machine.

Serial Number:

Machine

documentation

From this point forward in this documentation, Wacker Neuson Production

Americas LLC will be referred to as Wacker Neuson.

Keep a copy of the Operator’s Manual with the machine at all times.

For spare parts information, please see your Wacker Neuson Dealer, or visit

the Wacker Neuson website at http://www.wackerneuson.com/.

When ordering parts or requesting service information, be prepared to provide

wc_tx004018gb_FM10.fm 3

the machine model number, item number, revision number, and serial number.

Page 4

Foreword PT2 / PT3

Expectations

for

information in

this manual

CALIFORNIA

Proposition

65 Warning

Laws

pertaining to

spark

arresters

This manual provides information and procedures to safely operate and

maintain the above Wacker Neuson model(s). For your own safety and to

reduce the risk of injury , carefully read, underst and, and observe all instructions

described in this manual.

Wacker Neuson expressly reserves the right to make technical modifications,

even without notice, which improve the performance or safety standards of its

machines.

The information contained in this manual is based on machines manufactured

up until the time of publication. Wacker Neuson reserves the right to change

any portion of this information without notice.

The illustrations, parts, and procedures in this manual refer to Wacker Neuson

factory-installed components. Your machine may vary depending on the

requirements of your specific region.

Combustion exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to the State of California to cause cancer and

birth defects or other reproductive harm.

NOTICE: State Health Safety Codes and Public Resources Codes specify that in

certain locations spark arresters be used on internal combustion engines that use

hydrocarbon fuels. A spark arrester is a device designed to prevent accidental

discharge of sparks or flames from the engine exhaust. Spark arresters are

qualified and rated by the United States Forest Service for this purpose. In order to

comply with local laws regarding spark arresters, consult the engine distributor or

the local Health and Safety Administrator.

Manufacturer’s

approval

This manual contains references to approved parts, attachments, and

modifications. The following definitions apply:

Approved parts or attachments are those either manufactured or provided by

Wacker Neuson.

Approved modifications are those performed by an authorized Wacker

Neuson service center according to written instructions published by Wacker

Neuson.

Unapproved parts, attachments, and modifications are those that do not

meet the approved criteria.

Unapproved parts, attachments, or modifications may have the following

consequences:

Serious injury hazards to the operator and persons in the work area

Permanent damage to the machine which will not be covered under warranty

Contact your Wacker Neuson dealer immediately if you have questions about

approved or unapproved parts, attachments, or modifications.

4 wc_tx004018gb_FM10.fm

Page 5

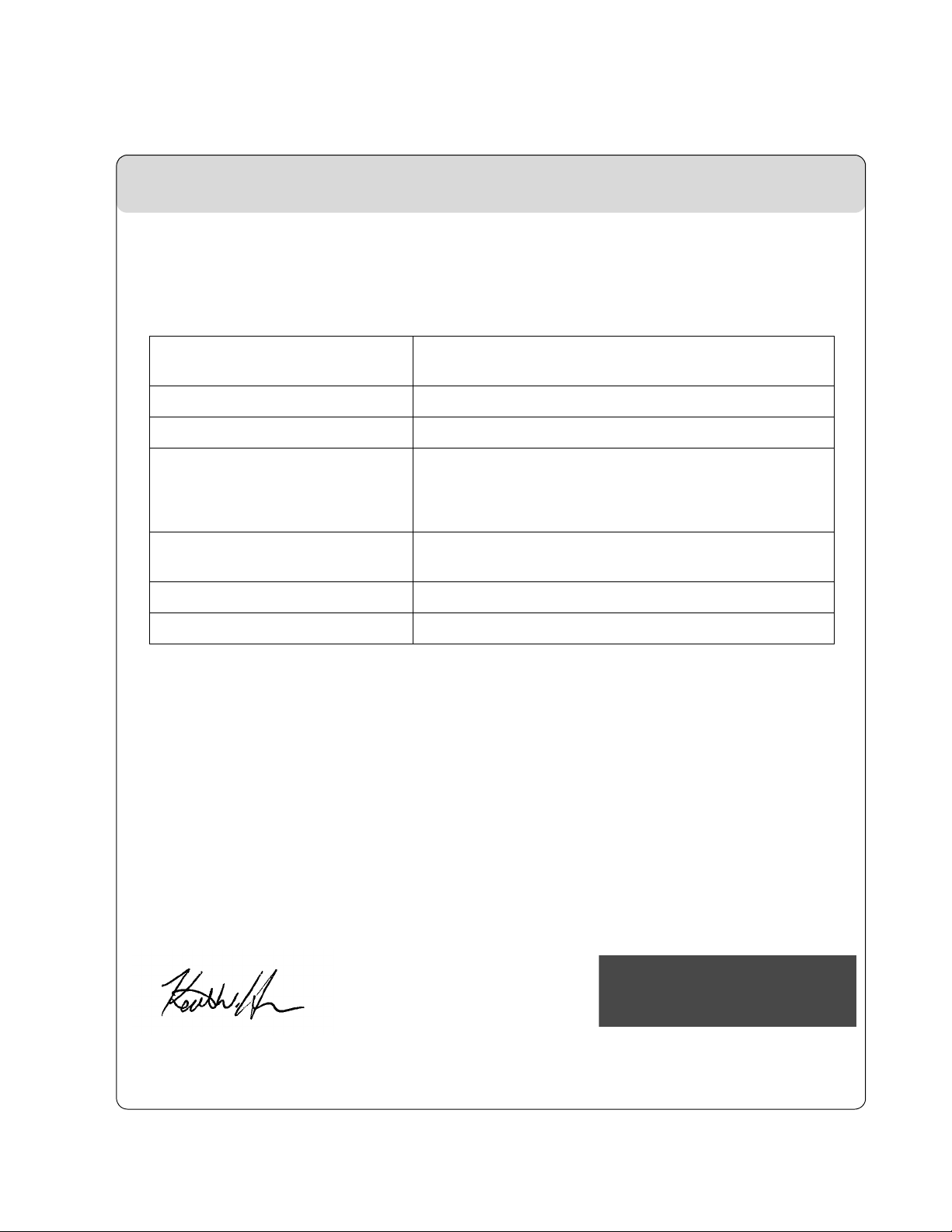

EC Declaration of Conformity

Manufacturer

Wacker Neuson Production Americas LLC, N92W15000 Anthony Avenue,

Menomonee Falls, Wisconsin 53051 USA

Product

Product

Product category

Product function

Item number

Net installed power

Measured sound power level

Guaranteed sound power level

PT2A, PT2H

Water Pump Units

To pump fluid

5000009095, 5000009097, 5000009 237

PT 2A: 3.6 kW; PT 2H: 3.4 kW

PT 2A: 99 dB(A); PT 2H: 102 dB(A)

PT 2A: 101 dB(A); PT 2H: 103 dB(A)

Conformity Assessment Procedure

According to 2000/14/EC ANNEX V

Directives and Standards

We hereby declare that this product meets and complies with the relevant regulations and

requirements of the following directives and standards:

2006/42/EC, 2000/14/EC

Authorized Person for Technical Documents

Leo Goeschka, Wacker Neuson Produktion GmbH & Co. KG, Preußenstra ß e 41,

80809 München

Menomonee Falls, WI, USA, 24.08.15

Keith Herr

Vice President and Managing Director

For Wacker Neuson

2015-CE-PT2_en_812_FM10.fm

Dan Domanski

Technical Director

For Wacker Neuson

Travis Pound

Manager, Product Engineering

For Wacker Neuson

Original Declaration of Conformity

Page 6

Page 7

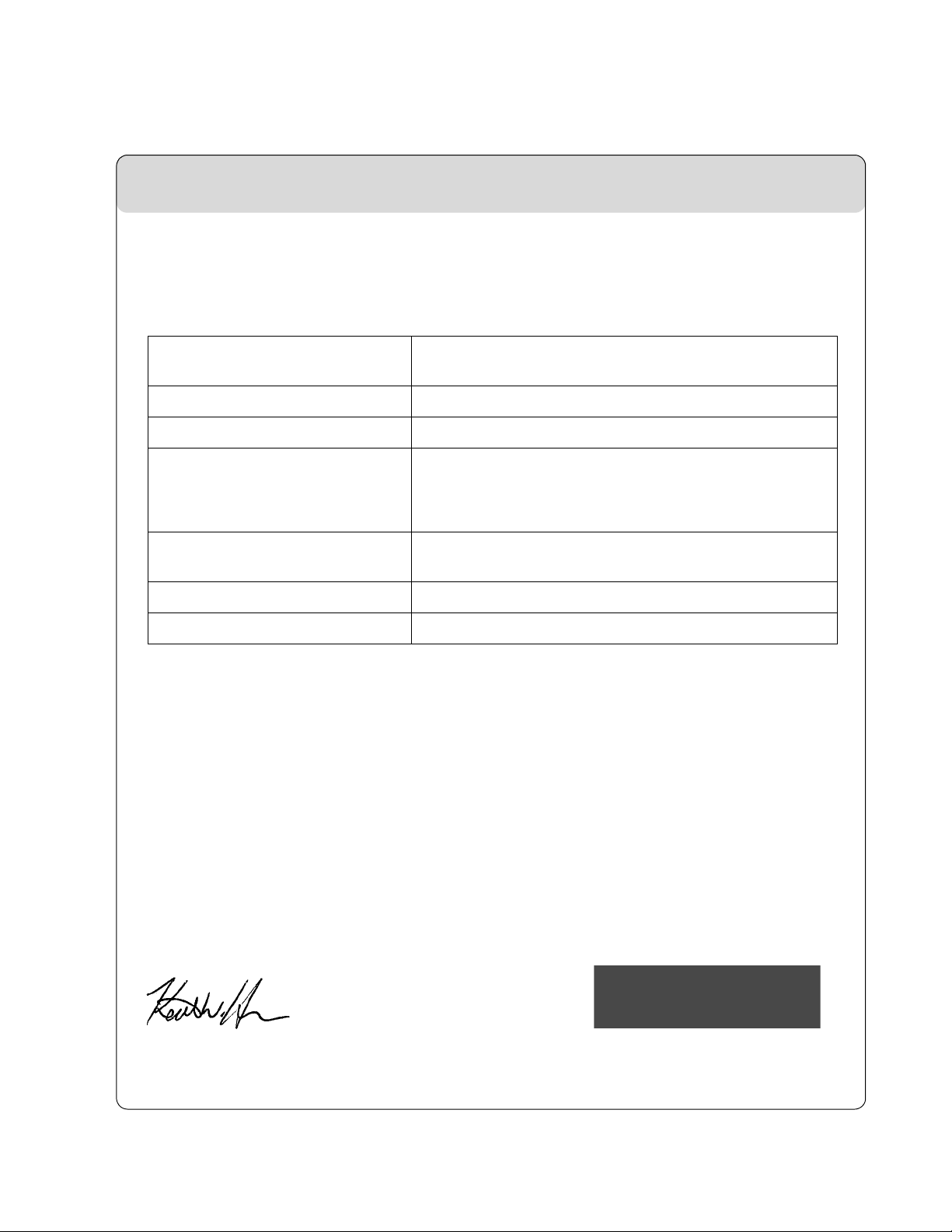

EC Declaration of Conformity

Manufacturer

Wacker Neuson Production Americas LLC, N92W15000 Anthony Avenue,

Menomonee Falls, Wisconsin 53051 USA

Product

Product

Product category

Product function

Item number

Net installed power

Measured sound power level

Guaranteed sound power level

PT3, PT3A, PT3H

Water Pump Units

To pump fluid

5000009101, 5000009240, 5000009103, 5000009322,

5000620800

PT 3: 6.6 kW; PT 3A: 5.9 kW; PT 3H: 5.0 kW

PT 3: 102 dB(A); PT 3A: 101 dB(A); PT 3H: 106 dB(A)

PT 3: 103 dB(A); PT 3A: 102 dB(A); PT 3H: 106 dB(A)

Conformity Assessment Procedure

According to 2000/14/EC ANNEX V

Directives and Standards

We hereby declare that this product meets and complies with the relevant regulations and

requirements of the following directives and standards:

2006/42/EC, 2000/14/EC

Authorized Person for Technical Documents

Leo Goeschka, Wacker Neuson Produktion GmbH & Co. KG, Preußenstra ß e 41,

80809 München

Menomonee Falls, WI, USA, 27.03.15

Keith Herr

Vice President and Managing Director

For Wacker Neuson

2015-CE-PT3_en_FM10.fm

Dan Domanski

Technical Director

For Wacker Neuson

Travis Pound

Manager, Product Engineering

For Wacker Neuson

Original Declaration of Conformity

Page 8

Page 9

PT2 / PT3

Table of Contents

Foreword 3

EC Declaration of Conformity 5

EC Declaration of Conformity 7

1 Safety Information 11

1.1 Signal Words Used in this Manual ..................................................... 11

1.2 Machine Description and Intended Use ............................................. 12

1.3 Safety Guidelines for Operating the Machine ..................................... 13

1.4 Service Safety .................................................................................... 15

1.5 Operator Safety while Using Internal Combustion Engines ............... 17

2 Labels 18

2.1 Label Locations ................................................................................... 18

2.2 Label Meanings .................................................................................. 19

3 Lifting and Transporting 22

3.1 Lifting the Machine ............................................................................. 22

3.2 Preparing the Machine for Transport on a Truck or Trailer ................ 23

4 Operation 24

4.1 Preparing the Machine for First Use ................................................... 24

4.2 Recommended Fuel ........................................................................... 25

4.3 Recommended Fuel (Hatz powered machines only) ......................... 25

4.4 Refueling the Machine ........................................................................ 26

4.5 Positioning and Preparing the Machine for Operation ........................ 27

4.6 Before Starting the Machine ............................................................... 28

4.7 Starting and Stopping the Machine (WM 170 / WM 270) ................... 29

4.8 Starting and Stopping the Machine (Honda) ...................................... 30

4.9 Starting and Stopping the Machine (Hatz) ......................................... 31

4.10 Emergency Shutdown Procedure ....................................................... 32

5 General Maintenance 33

5.1 Maintaining the Emission Control System .......................................... 33

5.2 Periodic Maintenance Schedule ......................................................... 33

wc_bo5100016561_02_FM10TOC.fm

9

Page 10

Table of Contents

5.3 Inspecting the Impeller ........................................................................34

5.4 Storage ...............................................................................................36

5.5 Machine Disposal and Decommissioning ...........................................37

PT2 / PT3

6 Engine Maintenance: WM 130 / WM 170 / WM 270 38

7 Engine Maintenance: Honda GX160 40

8 Engine Maintenance: Honda GX390 42

9 Engine Maintenance: Hatz 1B 20 / 1B 30 44

10 Troubleshooting 47

11 Technical Data 48

11.1 Engine—PT2 / PT2(I) / PT2H / PT2H(I) ..............................................48

11.2 Engine—PT2A / PT2A(I) .....................................................................49

11.3 Engine—PT3 / PT3A / PT3(I) / PT3H .................................................50

11.4 Pump—PT2 / PT2(I) / PT2A / PT2H ...................................................51

11.5 Pump—PT3 / PT3(I) / PT3A / PT3H ...................................................51

11.6 Sound Measurements .........................................................................52

11.7 Dimensions .........................................................................................53

12 Emission Control Systems Information

and Warranty 55

12.1 Emission Control Systems Warranty Statement .................................55

13 AEM Safety Manual 57

10

wc_bo5100016561_02_FM10TOC.fm

Page 11

PT2 / PT3 Safety Information

1 Safety Information

1.1 Signal Words Used in this Manual

This manual contains DANGER, WARNING, CAUTION, NOTICE, and NOTE

signal words which must be followed to reduce the possibility of personal injury,

damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential personal hazards.

► Obey all safety messages that follow this symbol.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

► To avoid death or serious injury from this type of hazard, obey all safety

messages that follow this signal word.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

► To avoid possible death or serious injury from this type of hazard, obey all safety

messages that follow this signal word.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

► To avoid possible minor or moderate injury from this type of hazard, obey all

safety messages that follow this signal word.

NOTICE: Used without the safety alert symbol, NOTICE indicates a situation

which, if not avoided, could result in property damage.

Note: A Note contains additional information important to a procedure.

wc_si000938gb_FM10.fm

11

Page 12

Safety Information PT2 / PT3

1.2 Machine Description and Intended Use

This machine is a centrifugal trash pump. The Wacker Neuson Trash Pump

consists of a tubular steel frame surrounding a gasoline or diesel engine, a fuel

tank, and an impeller pump with ports for water suction and discharge. The engine

rotates the impeller during operation. Waste water is drawn into the pump through

the suction port and expelled through the discharge port. The operator connects

hoses to the pump and routes them so that water and solids are drained from the

work area and discharged into an appropriate location.

This machine is intended to be used for general de-watering applications. This

machine is intended for the pumping of clear water , or water containing solids up to

the size stated within the product specifications, and up to the flow, head, and

suction lift limits also stated within the product specifications.

This machine has been designed and built strictly for the intended use described

above. Using the machine for any other purpose could permanently damage the

machine or seriously injure the operator or other persons in the area. Machine

damage caused by misuse is not covered under warranty.

The following are some examples of misuse:

■ Pumping flammable, explosive, or corrosive fluids

■ Pumping hot or volatile fluids that result in pump cavitation

■ Operating the pump outside of product specifications due to incorrect diameter

hoses, incorrect length hoses, other inlet or outlet restrictions, or excessive

suction lift or head

■ Using the machine as a ladder, support, or work surface

■ Operating the machine outside of factory specifications

■ Operating the machine in a manner inconsistent with all warnings found on the

machine and in the Operator’s Manual

This machine has been designed and built in accordance with the latest global

safety standards. It has been carefully engineered to eliminate hazards as far as

practicable and to increase operator safety through protective guards and labeling.

However, some risks may rema in even after protective measures have been t aken.

They are called residual risks. On this machine, they may include exposure to:

■ Heat, noise, exhaust, and carbon monoxide from the engine

■ Fire hazards from improper refueling techniques

■ Fuel and its fumes

■ Personal injury from improper lifting techniques

■ Projectile hazard from discharge

■ Crushing hazards from a tipping or falling pump

To protect yourself and others, make sure you thoroughly read and understand the

safety information presented in this manual before operating the machine.

wc_si000938gb_FM10.fm

12

Page 13

PT2 / PT3 Safety Information

1.3 Safety Guidelines for Operating the Machine

Operator

training

Operator

qualifications

Application

area

Before operating the machine:

■ Read and understand the operating instructions contained in all manuals

delivered with the machine.

■ Familiarize yourself with the location and proper use of all controls and safety

devices.

■ Contact Wacker Neuson for additional training if necessary.

When operating this machine:

■ Do not allow improperly trained people to operate the machine. People

operating the machine must be familiar with the potential risks and hazards

associated with it.

Only trained personnel are permitted to start, operate, and shut down the machine.

They also must meet the following qualifications:

■ have received instruction on how to properly use the machine

■ are familiar with required safety devices

The machine must not be accessed or operated by:

■ children

■ people impaired by alcohol or drugs

Be aware of the application area.

■ Keep unauthorized personnel, children, and pets away from the machine.

■ Remain aware of changing positions and the movement of other equipment and

personnel in the application area/job site.

■ Identify whether special hazards exist in the application area, such as toxic

gases or unstable ground conditions, and take appropriate action to eliminate

the special hazards before using the machine.

Be aware of the application area.

■ Do not operate the machine in areas that contain flammable objects, fuels, or

Safety

devices,

controls, and

attachments

Only operate the machine when:

■ All safety devices and guards are in place and in working order.

■ All controls operate correctly.

■ The machine is set up correctly according to the instructions in the Operator’s

■ The machine is clean.

■ The machine’s labels are legible.

To ensure safe operation of the machine:

■ Do not operate the machine if any safety devices or guards are missing or

■ Do not modify or defeat the safety devices.

■ Only use accessories or attachments that are approved by Wacker Neuson.

wc_si000938gb_FM10.fm

products that produce flammable vapors.

Manual.

inoperative.

13

Page 14

Safety Information PT2 / PT3

Safe

operating

practices

Personal

Protective

Equipment

(PPE)

Safe

operating

practices

When operating this machine:

■ Remain aware of the machine’s moving parts. Keep hands, feet, and loose

clothing away from the machine’s moving parts.

When operating this machine:

■ Do not operate a machine in need of repair.

Wear the following Personal Protective Equipment (PPE) while operating this

machine:

■ Close-fitting work clothes that do not hinder movement

■ Safety glasses with side shields

■ Hearing protection

■ Safety-toed footwear

■ Do not open the priming plug when the pump is hot. Do not loosen or remove

inlet or discharge hose fittings when the pump is hot. Hot water inside could be

pressurized much like the radiator on an automobile. Allow the pump to cool to

the touch before loosening the plug and before loosening or removing the inlet

or discharge hose fittings.

■ Do not position the pump on a loose, uneven, or unstable surface where it can

tip, roll, slide or fall! The pump must be secure before operating. Position the

pump on a firm and flat surface

■ Do not open the pump housing cover while the pump is operating or start the

pump with the cover off. The rotating impeller inside the pump can cut or sever

objects caught in it.

■ Do not block or restrict flow from the inlet line or the discharge line. Remove

kinks from the discharge line before starting the pump. Operation with a blocked

inlet line or discharge line can cause water inside the pump to overheat.

■ Do not reach into or insert anything into the pump while the engine is on! The

impeller inside the pump housing is turning at all times while the engine is

running.

■ Do not allow anyone to stand in front of the discharge port when starting the

engine or while priming the pump! The sudden out-rush of water could push or

knock a person down.

■ Always make sure the hose connections on the pump are tight. A loose

connection could cause water to spray or result in a hose falling off the pump

while it is in operation.

■ Always make sure the water stream from the pump discharge is not directed in

such a way so as to cause erosion to the surrounding ground or damage or

weakening of nearby structures!

14

wc_si000938gb_FM10.fm

Page 15

PT2 / PT3 Safety Information

1.4 Service Safety

Service

training

Precautions

Before servicing or maintaining the machine:

■ Read and understand the instructions contained in all manuals delivered with

the machine.

■ Familiarize yourself with the location and proper use of all controls and safety

devices.

■ Only trained personnel shall troubleshoot or repair problems occurring with the

machine.

■ Contact Wacker Neuson for additional training if necessary.

When servicing or maintaining this machine:

■ Do not allow improperly trained people to service or maintain the machine.

Personnel servicing or maintaining the machine must be familiar with the

associated potential risks and hazards.

When servicing or maintaining the machine:

■ Read and understand the service procedures before performing any service to

the machine.

■ All adjustments and repairs must be completed before operating the machine.

Do not operate the machine with a known problem or deficiency.

■ All repairs and adjustments shall be completed by a qualified technician.

■ Turn off the machine before performing maintenance or making repairs.

■ Remain aware of the machine’s moving parts. Keep hands, feet, and loose

clothing away from the machine’s moving parts.

■ Re-install the safety devices and guards after repair and maintenance

procedures are complete.

Machine

modifications

Replacing

parts and

labels

When servicing or maintaining the machine:

■ Use only accessories/attachments that are approved by Wacker Neuson.

When servicing or maintaining the machine:

■ Do not defeat safety devices.

■ Do not modify the machine without the express written approval of Wacker

Neuson.

■ Replace worn or damaged components.

■ Replace all missing and hard-to-read labels.

■ When replacing electrical components, use components that are identical in

rating and performance to the original components.

■ When replacement parts are required for this machine, use only Wacker

Neuson replacement parts or those p arts equivalent to the original in a ll types of

specifications, such as physical dimensions, type, strength, and material.

wc_si000938gb_FM10.fm

15

Page 16

Safety Information PT2 / PT3

Cleaning

Personal

Protective

Equipment

(PPE)

After Use

When cleaning and servicing the machine:

■ Keep the machine clean and free of debris such as leaves, paper, cartons, etc.

■ Keep the labels legible.

When cleaning the machine:

■ Do not clean the machine while it is running.

■ Never use gasoline or other types of fuels or flammable solvents to clean the

machine. Fumes from fuels and solvents can become explosive.

Wear the following Personal Protective Equipment (PPE) while servicing or

maintaining this machine:

■ Close-fitting work clothes that do not hinder movement

■ Safety glasses with side shields

■ Hearing protection

■ Safety-toed footwear

In addition, before servicing or maintaining the machine:

■ Tie back long hair.

■ Remove all jewelry (including rings).

■ Stop the engine when the machine is not being operated.

■ Close the fuel valve on engines equipped with one when machine is not being

operated.

■ Ensure that the machine will not tip over, roll, slide, or fall when not being

operated.

■ Store the machine properly when it is not being used. The machine should be

stored in a clean, dry location out of the reach of children.

16

wc_si000938gb_FM10.fm

Page 17

PT2 / PT3 Safety Information

1.5 Operator Safety while Using Internal Combustion Engines

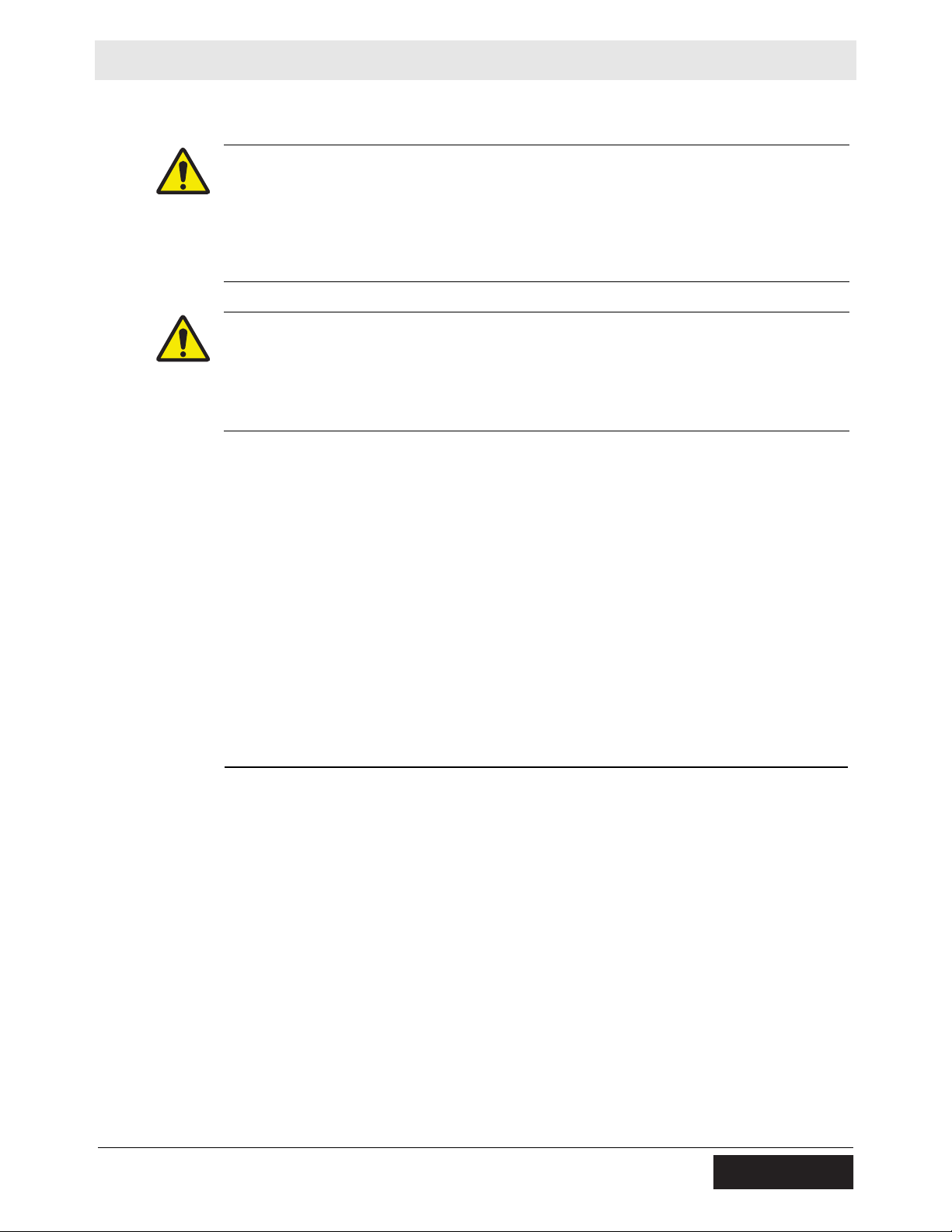

WARNING

Internal combustion engines present special hazards during operation and fueling.

Failure to follow the warnings and safety standards could result in severe injury or

death.

► Read and follow the warning instructions in the engine owner’s manual and the

safety guidelines below.

DANGER

Exhaust gas from the engine contains carbon monoxide, a deadly poison.

Exposure to carbon monoxide can kill you in minutes.

► NEVER operate the machine inside an enclosed area, such as a tunnel, unless

adequate ventilation is provided through such items as exhaust fans or hoses.

Operating

safety

Refueling

safety

When running the engine:

■ Keep the area around the exhaust pipe free of flammable materials.

■ Check the fuel lines and the fuel tank for leaks and cracks before starting the

engine. Do not run the machine if fuel leaks are present or the fuel lines are

loose.

When running the engine:

■ Do not smoke while operating the machine.

■ Do not run the engine near sparks or open flames.

■ Do not touch the engine or muffler while the engine is running or immediately

after it has been turned off.

■ Do not operate a machine when its fuel cap is loose or missing.

■ Do not start the engine if fuel has spilled or a fuel odor is present. Move the

machine away from the spill and wipe the machine dry before starting.

When refueling the engine:

■ Clean up any spilled fuel immediately.

■ Refill the fuel tank in a well-ventilated area.

■ Re-install the fuel tank cap after refueling.

■ Do not smoke.

■ Do not refuel a hot or running engine.

■ Do not refuel the engine near sparks or open flames.

■ Use suitable tools for refueling (for example, a fuel hose or a funnel).

■ Do not refuel if the machine is positioned in a truck fitted with a plastic bed liner.

Static electricity can ignite the fuel or fuel vapors.

wc_si000938gb_FM10.fm

17

Page 18

Labels PT2 / PT3

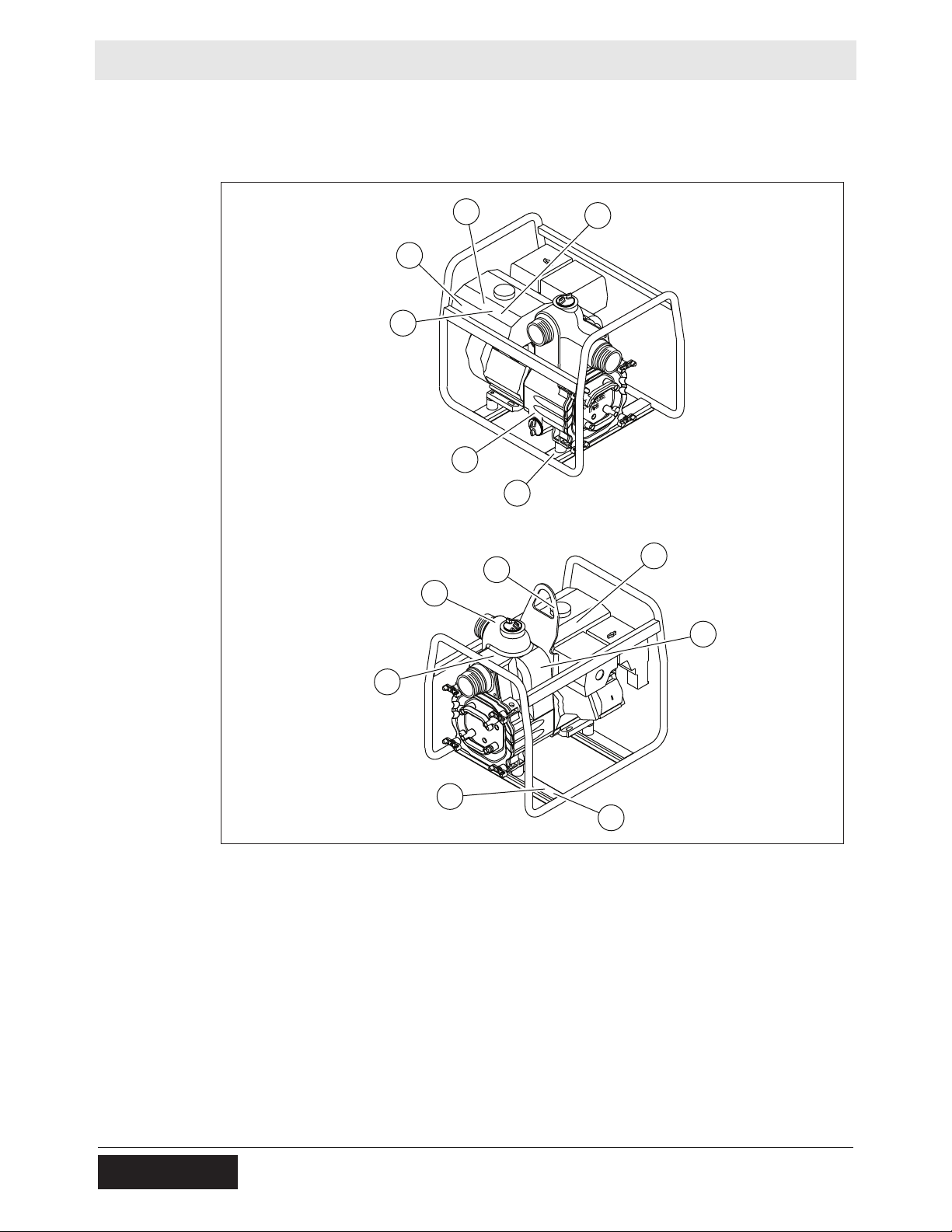

wc_gr012671

A

B

C

D

E

F

G

H

D

C

J

K

M

2 Labels

2.1 Label Locations

18

wc_si000939gb_FM10.fm

Page 19

PT2 / PT3 Labels

GEFAHRGEFAHR

DANGERDANGER

117034

HONDA

DANGERDANGER

STOPSTOP

PELIGROPELIGRO

STOP

117039

ADVERTENCIAADVERTENCIA

AVERTISSEMENTAVERTISSEMENT

WARNINGWARNING

178713

ATTENTIONATTENTION

CAUTIONCAUTION

VORSICHTVORSICHT

ATENCIONATENCION

110167110167

178714178714

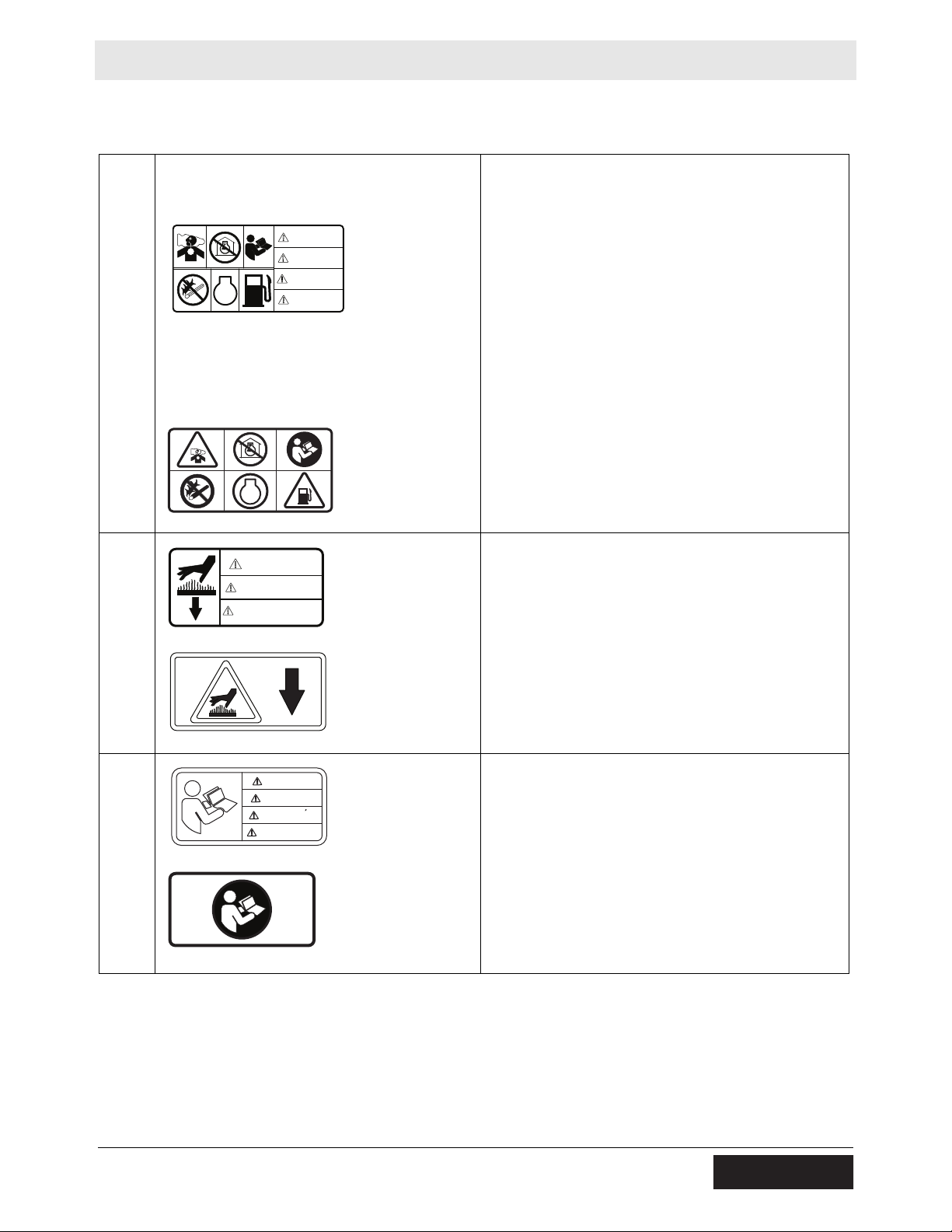

2.2 Label Meanings

DANGER

Asphyxiation hazard.

■ Engines emit carbon monoxide.

■ Do not run the machine indoors or in an

enclosed area.

■ NEVER use inside a home or garage, EVEN IF

doors and windows are open.

■ Only use OUTSIDE and far away from windows,

doors, and vents.

A

STOP

178715

■ Read the Operator’s Manual.

■ No sparks, flames, or burning objects near the

machine.

■ Stop the engine before refueling.

■ Use only clean, filtered diesel fuel.

WARNING

Hot surface

B

178713

CAUTION

Read and understand the supplied Operator’s

Manual before operating this machine. Failure to

do so increases the risk of injury to yourself and

others.

C

wc_si000939gb_FM10.fm

19

Page 20

Labels PT2 / PT3

110164

ADVERTENCIA

AVERTISSEMENT

WARNING

5100015564

ADVERTENCIAADVERTENCIA

WARNUNGWARNUNG

110164110164

WARNINGWARNING

AVERTISSEMENTAVERTISSEMENT

5100015565

NE JAMAIS POMPER DESNE JAMAIS POMPER DES

LIQUIDES VOLATILES, LIQUIDES VOLATILES,

INFLAMMABLES OU A BAS POINT INFLAMMABLES OU A BAS POINT

CES LIQUIDES CES LIQUIDES

POURRAIENT PRENDRE FEU OU POURRAIENT PRENDRE FEU OU

EXPLOSER.EXPLOSER.

NUNCA BOMBEAR LIQUIDOS NUNCA BOMBEAR LIQUIDOS

VOLATILES INFLAMABLES O DE VOLATILES INFLAMABLES O DE

PUNTO BAJO DE ENCENDIDO. PUNTO BAJO DE ENCENDIDO.

ESTOS FLUIDOS PUEDEN ESTOS FLUIDOS PUEDEN

ENCENDERSE O EXPLOTAR.ENCENDERSE O EXPLOTAR.

AVERTISSEMENTAVERTISSEMENT

ADVERTENCIAADVERTENCIA

151049151049

NEVER PUMP VOLATILE, NEVER PUMP VOLATILE,

FLAMMABLE OR LOW FLASH FLAMMABLE OR LOW FLASH

POINT FLUIDS. THESE FLUIDSPOINT FLUIDS. THESE FLUIDS

COULD IGNITE OR EXPLODE.COULD IGNITE OR EXPLODE.

WARNUNGWARNUNG

WARNINGWARNING

178764178764

181145

WARNING

WARNING

ADVERTENCIA

AVERTISSEMENT

110164

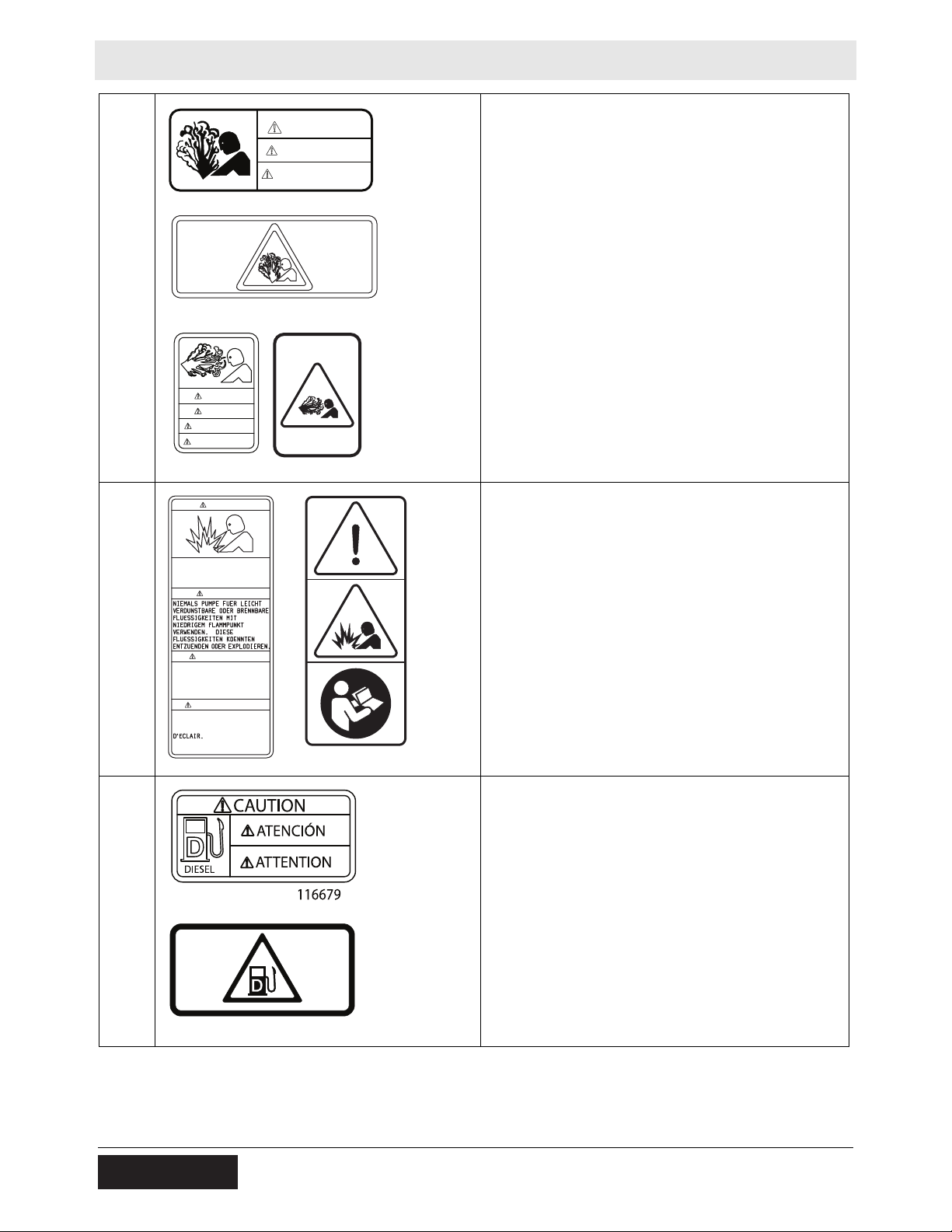

D

5100015564

5100015565

Pressurized contents. Do not open when hot!

WARNING

Never pump volatile, flammable, or low-flash-point

fluids. These fluids could ignite or explode.

E

CAUTION

Use only clean, filtered diesel fuel

(Hatz powered machines only)

F

181145

20

wc_si000939gb_FM10.fm

Page 21

PT2 / PT3 Labels

5200015473 PT2

73 kg

(160 LBS)

5200015474 PT3

91 kg

(200 LBS)

WARNING

Operation of This Equipment May Create Sparks That Can Start Fires Around Dry

Vegetation. A Spark Arrestor May be Required. The Operator Should Contact Local

Fire Agencies For Laws or Regulations Relating to Fire Prevention Requirements.

Per CAL. PRC. CODE

NOTICE

73 kg

(160 LBS)

91 kg

(200 LBS)

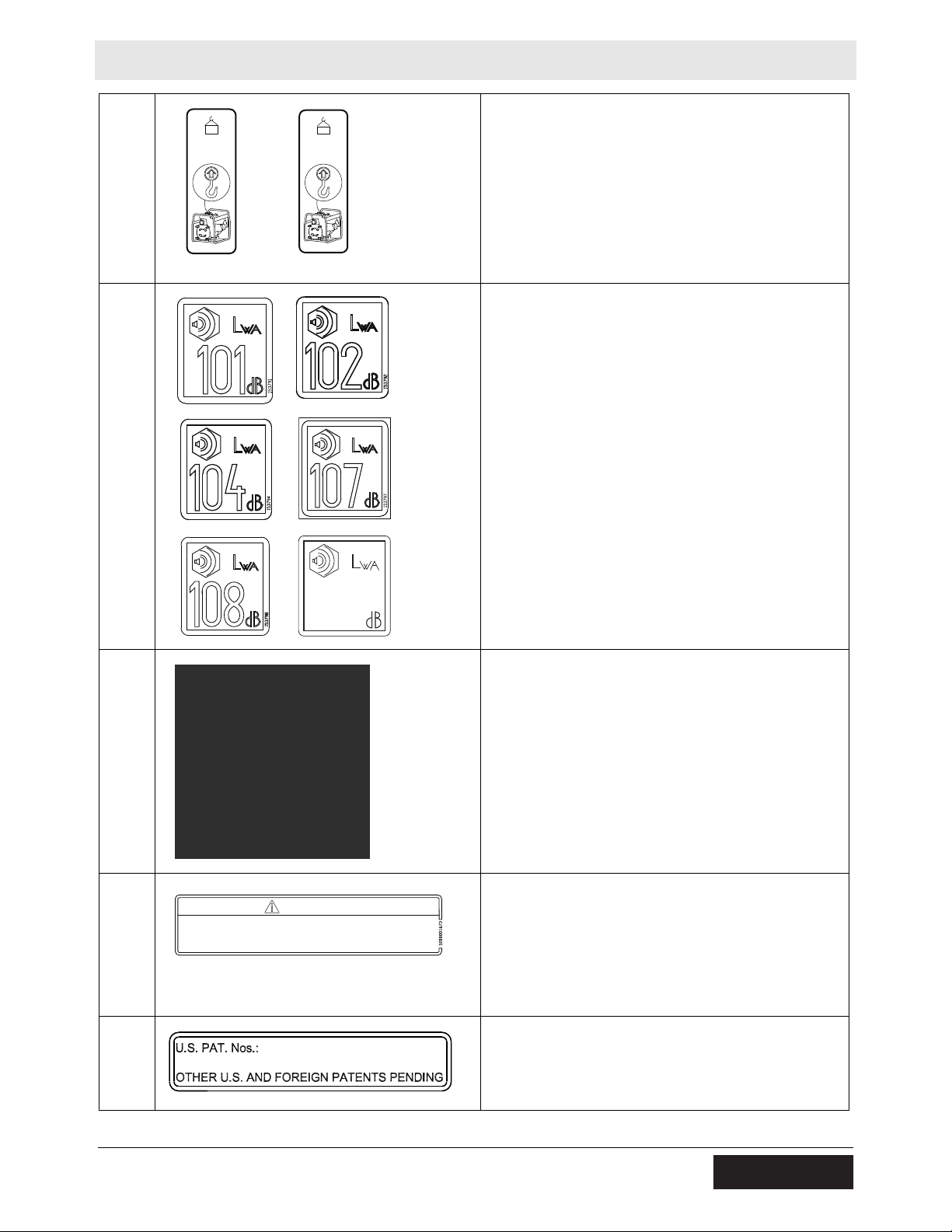

G

Lifting point

5200015473 PT2

5200015474 PT3

Guaranteed sound power level in dB(A)

H

99

153789

Certified Performance

Contractors Pump Bureau

A Bureau of AEM

The manufacturer of this pump certifies that it was

manufactured in accordance with the standards of

J

the Contractors Pump Bureau.

K

M

wc_si000939gb_FM10.fm

WARNING

Operation of this equipment may create sparks that

can start fires around dry vegeta tion. A spark

arrester may be required. The operator should

contact local fire agencies for laws or regulations

relating to fire prevention requirements.

This machine may be covered by one or more

patents.

21

Page 22

Lifting and Transporting PT2 / PT3

wc_gr012660

3 Lifting and Transporting

3.1 Lifting the Machine

Requirements

Lifting the

machine

■ Lifting equipment (crane, hoist, or fork truck) capable of supporting the

machine’s weight

■ Lifting devices (hooks, chains, and shackles) capable of supporting the

machine’s weight

■ Engine stopped

A lifting eye is used for lifting the machine.

Perform the procedure below to lift the machine.

1. Attach the lifting devices and equipment to the lifting eye. Do not attach lifting

devices to any other part of the machine.

2. Lift the machine a small distance.

WARNING

Crushing hazard. An unstable machine may cause the lifting devices and

equipment to fail. You may be crushed if the lifting devices and equipment fail.

► Check for stability before continuing.

3. Check for stability . If necessary, lower the machine, reposition the lifting devices,

and lift the machine a small distance again.

4. Continue lifting the machine only when it is stable.

22

wc_tx004019gb_FM10.fm

Page 23

PT2 / PT3 Lifting and Transporting

3.2 Preparing the Machine for Transport on a Truck or Trailer

Requirements

Checklist

■ Machine stopped

■ Flatbed truck or trailer capable of supporting the machine’s weight

■ Chains, hooks, or straps capable of supporting the machine’s weight

Before transporting the machine, check the following items:

Check that the transport vehicle or trailer can support the weight of the machine.

Check that the transport vehicle or trailer is wide enough to support the

machine.

Check that the wheels of the transport vehicle or trailer are chocked during the

loading process.

Check that the transport vehicle or trailer is clean and free of grease, oil, ice,

and other loose material.

Check that any ramps used in the loading process:

■ Can support the weight of the machine.

■ Are clean and free of grease, oil, ice, and other loose material.

■ Are securely connected to the transport vehicle or trailer.

■ Are of sufficient length to keep the loading angle 15° or less.

In addition:

Check that the loading area is flat and the ground is stable.

Check the overall height of the machine once it is loaded on the truck or trailer.

Plan your travel route so there will be adequate clearance for overpasses, road

signs, buildings, etc.

Check local regulations regarding transporting and obey these regulations.

wc_tx004019gb_FM10.fm

23

Page 24

Operation PT2 / PT3

4 Operation

4.1 Preparing the Machine for First Use

1. Make sure all loose packaging materials have been removed from the machine.

2. Check the machine and its components for damage. If there is visible damage,

do not operate the machine! Contact your Wacker Neuson dealer immediately

for assistance.

3. Take inventory of all items included with the machine and verify that all loose

components and fasteners are accounted for.

4. Attach component parts not already attached.

5. Add fluids as needed and applicable, such as fuel and engine oil.

6. Move the machine to its operating location.

24

wc_tx004020gb_FM10.fm

Page 25

PT2 / PT3 Operation

4.2 Recommended Fuel

The engine requires regular grade unleaded gasoline. Use only fresh, clean

gasoline. Gasoline containing water or dirt will damage the fuel system. Consult the

engine owner’s manual for complete fuel specifications.

Use of

oxygenated

fuels

Some conventional gasolines are blended with alcohol. These gasolines are

collectively referred to as oxygenated fuels. If you use an oxygenated fuel, be sure

it is unleaded and meets the minimum octane rating requirement.

Before using an oxygenated fuel, confirm the fuel’s contents. Some states and

provinces require this information to be posted on the fuel pump.

The following is the Wacker Neuson approved percentage of oxygenates:

ETHANOL - (ethyl or grain alcohol) 10% by volume. You may use gasoline

containing up to 10% ethanol by volume (commonly referred to as E10). Gasoline

containing more than 10% ethanol (such as E15, E20, or E85) may not be used

because it could damage the engine.

If you notice any undesirable operating symptoms, try another service station, or

switch to another brand of gasoline.

Fuel system damage or performance problems resulting from the use of an

oxygenated fuel containing more than the percentages of oxygenates mentioned

above are not covered under warranty.

4.3 Recommended Fuel (Hatz powered machines only)

Low temperatures cause diesel fuel to gel. Always use the proper fuel for the

conditions. Follow the guidelines in the table below.

Lowest expected ambient

temperature

Above freezing

> 0°C (32°F)

Below freezing

< 0°C (32°F)

1

Your engine may require ultra low sulfur fuel. Consult the engine owner’s manual.

Recommended fuel

#2 diesel plus additives

Winter-blend diesel

1

CAUTION

Fire hazard.

► Do not use gasoline, crankcase oil, or any oil containing gasoline.

wc_tx004020gb_FM10.fm

25

Page 26

Operation PT2 / PT3

wc_gr012714

a

4.4 Refueling the Machine

Requirements

Procedure

■ Machine shut down

■ Engine cool

■ Machine/fuel tank level with the ground

■ Fresh, clean fuel supply

Perform the procedure below to refuel the machine.

WARNING

Fire hazard. Fuel and its vapors are extremely flammable. Burning fuel can cause

severe burns.

► Keep all sources of ignition away from the machine while refueling.

► Do not refuel if the machine is positioned in a truck fitted with a plastic bed liner.

Static electricity can ignite the fuel or fuel vapors.

► Refuel only when the machine is outdoors.

► Clean up spilled fuel immediately.

1. Remove the fuel cap (a).

2. Fill the fuel tank to the base of the neck.

CAUTION

Fire and health hazard. Fuel expands when heated. Expanding fuel in an ove r-filled

tank can lead to spills and leaks.

► Do not overfill the fuel tank.

3. Re-install the fuel cap.

Result

The procedure to refuel the machine is now complete.

wc_tx004020gb_FM10.fm

26

Page 27

PT2 / PT3 Operation

wc_gr012715

d

a

b

c

e

f

g

4.5 Positioning and Preparing the Machine for Operation

WARNING

Personal injury hazard. Failure to follow the listed procedures may cause injury to

personnel or damage to the machine.

► All persons setting up the machine must be fully trained on the installation of the

machine.

Pre-operation

setup

Perform the procedure below to position and prepare the machine for operation.

1. Position the pump as near to the water as possible, on a firm, flat surf ace. Keep

the pump level.

2. Connect the suction hose (a) to the suction port (b).

■ Suction hoses must be rigid enough not to collapse.

■ At least two T-bolt clamp s are recommended for connecting the suction hose

to the suction port. Position the hose clamps at 90° intervals for best seal.

wc_tx004020gb_FM10.fm

WARNING

Personal injury hazard. A loose connection between the suction hose and the

suction port can result in personal injury should the suction hose break loose while

the pump is operating.

► Only operate the machine when the suction hose is securely fastened to the

suction port.

This procedure continues on the next page.

27

Page 28

Operation PT2 / PT3

Continued from the previous page.

3. Connect the strainer (c) to the suction hose.

■ Always use a strainer on the end of the suction hose to prevent pulling in

large debris which could clog the pump or jam the impeller.

■ Do not use a strainer with holes larger than the maximum solid-size rating of

the pump.

Machine Maximum solid-size rating

PT2 25 mm (1.0 in.)

PT3 38 mm (1.5 in.)

4. Submerge the suction hose.

■ Do not place the strainer directly into mud or sand. Always keep the strainer

suspended (d) in the liquid being pumped.

5. Connect the discharge hose (e) to the discharge port (f).

Note: Lay the discharge hose as straight as possible. Avoid sharp bends and

turns.

6. Prime the pump. To do so:

a.Remove the priming plug (g).

b.With the suction hose submerged, fill the pump housing with water.

c.Close the priming plug.

4.6 Before Starting the Machine

Before starting the machine, perform each item on the following checklist.

Pre-operation

checks

External

checks

Internal

checks

Read and understand the engine owner’s manual.

Review and follow the safety instructions found in the front of this Operator’s

Manual.

Check the suction hose and discharge hose for holes or tears.

Make sure that the hose couplings and hose clamps are attached.

Check that the priming plug is closed.

Check the tightness of the external fasteners—tighten the external fasteners as

necessary.

Check engine oil and fuel levels—fill as required.

Check the condition of the air cleaner—remove debris or replace air cleaner.

28

wc_tx004020gb_FM10.fm

Page 29

PT2 / PT3 Operation

wc_gr012716

e

d

1

d

2

c

2

c

1

b

2

b

1

a

2

a

1

d

3

4.7 Starting and Stopping the Machine (WM 170 / WM 270)

Requirements

Starting the

machine

■ Suction and discharge hoses properly attached and positioned

■ There is fuel in the tank

Perform the procedure below to start the machine.

1. Set the fuel valve to the open position (a

).

1

Note: If the engine is cold, set the choke lever to the closed position (b

engine is hot, set the choke lever to the open position (b

).

2

). If the

1

2. Turn the engine start switch to the “ON” position (c

3. Move the throttle lever slightly to the left (d

4. Pull the starter rope (e).

Note: If the oil level in the engine is low, the engine will not start. If this happens,

add oil to the engine.

5. Open the choke (b

6. Set the throttle lever to the high speed position (d

Stopping the

machine

Perform the procedure below to stop the machine.

1. Set the throttle lever to the slow/idle position (d

2. Turn engine start switch to the “OFF” position (c

3. Set the fuel valve to the closed position (a

wc_tx004020gb_FM10.fm

high speed position (d

).

1

) as the engine warms.

1

29

).

1

), about 1/3 of the way toward the

2

) to operate the machine.

1

) to reduce engine RPM.

3

).

2

).

2

Page 30

Operation PT2 / PT3

wc_gr012718

c

1

c

2

d

2

d

3

e

b

1

b

2

a

1

a

2

f

d

1

4.8 Starting and Stopping the Machine (Honda)

Requirements

Starting the

machine

■ Suction and discharge hoses properly attached and positioned

■ There is fuel in the tank

Perform the procedure below to start the machine.

1. Set the fuel valve to the open position (a

).

1

Note: If the engine is cold, set the choke lever to the closed position (b

engine is hot, set the choke lever to the open position (b

).

2

). If the

1

2. Turn the engine start switch to the “ON” position (c

3. Move the throttle lever slightly to the left (d

high speed position (d

).

1

), about 1/3 of the way toward the

2

).

1

4. Pull the starter rope (e).

Note: If the oil level in the engine is low, the engine will not start. If this happens,

Stopping the

machine

add oil to the engine. Y our engine may be equipped with an oil alert light (f) that will

illuminate while pulling the starter rope.

5. Open the choke (b

) as the engine warms.

1

6. Set the throttle lever to the high speed position (d

) to operate the machine.

1

Perform the procedure below to stop the machine.

1. Set the throttle lever to the slow/idle position (d

2. Turn engine start switch to the “OFF” position (c

3. Set the fuel valve to the closed position (a

) to reduce engine RPM.

3

).

2

).

2

wc_tx004020gb_FM10.fm

30

Page 31

PT2 / PT3 Operation

wc_gr012719

a

b

1/2

StartStop

4.9 Starting and Stopping the Machine (Hatz)

Requirements

Starting the

machine

■ Suction and discharge hoses properly attached and positioned

■ There is fuel in the tank

Perform the procedure below to start the machine.

1. Set the engine speed control lever (a) to the 1/2 START or START position, as

desired or necessary.

Note: Starting the engine at a lower speed will help to prevent exhaust smoke.

2. Pull the starter rope (b) lightly until you feel slight resistance.

Stopping the

machine

3. Allow the recoil starter to pull the starter rope back in. This allows the entire

length of the starter rope to be used to start the engine.

4. Grip the starter rope handle with both hands.

5. Pull the starter rope briskly. Repeat until the engine starts.

Note: If after several attempts to start the engine and exhaust begins to emit white

smoke, move the speed control lever to the STOP position. Then, pull the starter

rope out slowly 5 times. Repeat the starting the machine procedure at step 1.

Set the engine speed control lever to the STOP position.

wc_tx004020gb_FM10.fm

31

Page 32

Operation PT2 / PT3

4.10 Emergency Shutdown Procedure

Perform the procedure below if a breakdown or accident occurs while the machine

is operating.

1. Stop the engine.

2. Remove the obstruction.

3. Un-kink the hoses.

4. Allow the machine to cool.

5. Contact the rental yard or machine owner.

32

wc_tx004020gb_FM10.fm

Page 33

PT2 / PT3 General Maintenance

5 General Maintenance

WARNING

A poorly maintained machine can malfunction, causing injuries or permanent

damage to the machine.

► Keep the machine in safe operating condition by performing periodic

maintenance and making repairs as needed.

5.1 Maintaining the Emission Control System

For machines sold in North America:

Normal maintenance, replacement, or repair of emission control devices and

systems may be performed by any repair establishment or individual; however,

warranty repairs must be performed by a dealer/service center authorized by

Wacker Neuson. The use of service parts that are not equivalent in performance

and durability to authorized parts may impair the effectiveness of the emission

control system and may have a bearing on the outcome of a warranty claim.

5.2 Periodic Maintenance Schedule

The table below lists basic machine and engine maintenance. Tasks designated

with check marks may be performed by the operator . Tasks designated with square

bullet points require special training and equipment.

Refer to the engine owner’s manual for additional information.

Check external hardware.

Open pump housing cover and remove any debris from

inside of pump housing.

Inspect for leaks between pump and engine.

Check the condition of the fuel tank cap and drain plug

cap.

Check housing cover O-rings.

Inspect shockmounts for damage.

Daily before starting

wc_tx004021gb_FM10.fm

33

Page 34

General Maintenance PT2 / PT3

wc_gr012673

a

b

5.3 Inspecting the Impeller

Background

Requirements

Procedure

Sand, dirt, and debris will cause the impeller to wear. If the pump’s performance

drops over time, check and adjust the clearance between the impeller and the

insert.

■ Machine shut down

■ Bleach and source of clean water

■ Shims (if needed)

WARNING

Personal injury hazard.

► Do not reach into or insert anything into the pump while the engine is running.

► Do not run the pump with the pump housing cover removed.

Perform the procedure below to inspect the impeller.

1. Open the drain plug (a) and drain the pump.

2. Remove the pump housing cover (b) from the front of the pump.

WARNING

Personal injury hazard. Impeller edges can become sharp.

► Use care when working on the pump to reduce the risk of being cut.

This procedure continues on the next page.

34

wc_tx004021gb_FM10.fm

Page 35

PT2 / PT3 General Maintenance

wc_gr012674

d

e

c

Continued from the previous page.

3. Remove the volute (c) and clean the impeller (d) with a 50-50 mixture of bleach

and water before working on it.

Note:

Result

4. Check clearance between the impeller and the insert by slowly pulling the

starter rope to turn the impeller. If starter rope is difficult to pull, or rubbing is

heard from inside pump, the impeller and insert are too close to each other.

Remove a shim (e) from behind the insert and check again for rubbing.

Continue removing shims until the impeller turns easily.

■ It is important not to remove too many shims or the clearance between the

impeller and the insert will become too wide and pump performance will be

reduced.

■ As the impeller wears down, additional shims may be required to maintain the

clearance between the impeller and the insert.

5. Re-install the pump housing cover.

The impeller has now been inspected.

wc_tx004021gb_FM10.fm

35

Page 36

General Maintenance PT2 / PT3

5.4 Storage

Introduction

When

Preparing for

storage

Extended storage of equipment requires preventive maintenance. Performing

these steps helps to preserve machine components and ensures the machine will

be ready for future use. While not all of these steps necessarily apply to this

machine, the basic procedures remain the same.

Prepare your machine for extended storage if it will not be operated for 30 days or

more.

Follow the procedures below to prepare your machine for storage.

■ Complete any needed repairs.

■ Replenish or change oils (engine, exciter, seal and bearing housings, and

gearcase) per the intervals specified in the Periodic Maintenance Schedule.

■ Grease all fittings and, if applicable, repack bearings.

■ Inspect engine coolant. Replace coolant if it appears cloudy, is more than two

seasons old, or does not meet the average lowest temperature for your area.

■ If your machine has an engine equipped with a fuel valve, start the engine, close

the fuel valve, and run the engine until it stops.

■ Flush the pump and the hose lines by pumping clean water for a few minutes. If

the pump was used for pumping salt water, be sure to use fresh water when

flushing it.

■ Remove the covers and clean the pump’s interior. Wipe or spray all interior

surfaces with a rust-inhibiting oil.

■ Consult the engine owner’s manual for instructions on preparing the engine for

storage.

Stabilizing the

fuel

Storing the

machine

After completing the procedures listed above, fill the fuel tank completely and add a

high-quality stabilizer to the fuel.

■ Choose a stabilizer that includes cleaning agents and additives designed to

coat/protect the cylinder walls.

■ Make sure the stabilizer you use is compatible with the fuel in your area, fuel

type, grade and temperature range. Do not add extra alcohol to fuels which

already contain it (for example, E10).

■ For engines with diesel fuel, use a stabilizer with a biocide to restrict or prevent

bacteria and fungus growth.

■ Add the correct amount of stabilizer per the manufacturer’s recommendations.

Perform these remaining steps to store your machine.

■ Wash the machine and allow it to dry.

■ Move the machine to a clean, dry, secure storage location. Block or chock

wheels to prevent machine movement.

■ Use touch-up paint as needed to protect exposed metal against rust.

■ If the machine has a battery, either remove or disconnect it.

NOTICE: Allowing the battery to freeze or completely discharge is likely to cause

permanent damage. Periodically charge the battery while the machine is not in

use. In cold climates, store and charge the battery indoors or in a warm location.

36

wc_tx004021gb_FM10.fm

Page 37

PT2 / PT3 General Maintenance

■ Cover the machine. Tires and other exposed rubber items should be protected

from the weather. Either cover them or use a readily available protectant.

5.5 Machine Disposal and Decommissioning

Introduction

Preparation

Disposal

This machine must be properly decommissioned at the end of its service life.

Responsible disposal of recyclable components, such as plastic and metal,

ensures that these materials can be reused—conserving landfill space and

valuable natural resources.

Responsible disposal also prevents toxic chemicals and materials from harming

the environment. The operating fluids in this machine, including fuel, engine oil,

and grease, may be considered hazardous waste in many areas. Before

decommissioning this machine, read and follow local safety and environmental

regulations pertaining to the disposal of construction equipment.

Perform the following tasks to prepare the machine for disposal.

Move the machine to a protected location where it will not pose any safety

hazards and cannot be accessed by unauthorized individuals.

Ensure that the machine cannot be operated from the time of final shutdown to

disposal.

Drain all fluids, including fuel, engine oil, and coolant.

Seal any fluid leaks.

Perform the following tasks to dispose of the machine.

Disassemble the machine and separate all parts by material type.

Dispose of recyclable parts as specified by local regulations.

Dispose of all non-hazardous components that cannot be recycled.

Dispose of waste fuel, oil, and grease in accordance with local environmental

protection regulations.

wc_tx004021gb_FM10.fm

37

Page 38

Engine Maintenance: WM 130 / WM 170 / WM 270

CLASSIFICATION BY OIL VISCOSITY

SAE (Society of Automotive Engineers)

Ambient

temperature

Single grade

Multigrade

5W

10W

20W

#20

#30

#40

10W

-

30

10W

-

40

770081

6 Engine Maintenance: WM 130 / WM 170 / WM 270

The viscosity of the engine oil is an important factor when determining the correct

engine oil to use in your machine. Use an engine oil of appropriate viscosity based

on the expected outside air temperature. See the table below.

WARNING

Most used liquids from this machine such as oil, gasoline, grease, etc., contain

small amounts of materials that can cause cancer and other health problems if

inhaled, ingested, or left in contact with skin for prolonged periods of time.

► Take steps to avoid inhaling or ingesting used liquids.

► Wash skin thoroughly after exposure to used liquids.

wc_tx004022gb_FM10.fm

38

Page 39

Engine Maintenance: WM 130 / WM 170 / WM 270

The engine maintenance schedule(s) in this chapter are reproduced from the

engine owner’s manual. For additional information, see the engine owner’s

manual.

Daily

before

starting

After

rst 20

hours

Every

2 weeks

or

50 hrs.

Every

month

or

100 hrs.

Every

300 hrs.

Check fuel level.

Check engine oil level.

Inspect fuel lines.

Inspect air lter. Replace as

needed.

Check external hardware.

Clean air cleaner elements.

Change engine oil.

*

Clean sediment cup / fuel lter.

Check and clean spark plug.

Check and adjust valve clearance.

Replace spark plug.

* Perform initially after rst 20 hours of operation.

Maintenance, replacement or repair of emission control devices and systems may be performed by

any repair establishment or individual.

year

or

Every

500 hrs.

770082

wc_tx004022gb_FM10.fm

39

Page 40

Engine Maintenance: Honda GX160

A

A

7 Engine Maintenance: Honda GX160

The information in this chapter comes from copyrighted Honda material.

The viscosity of the engine oil is an important factor when determining the correct

engine oil to use in your machine. Use an engine oil of appropriate viscosity based

on the expected outside air temperature. See the table below.

WARNING

Most used liquids from this machine such as oil, gasoline, grease, etc., contain

small amounts of materials that can cause cancer and other health problems if

inhaled, ingested, or left in contact with skin for prolonged periods of time.

► Take steps to avoid inhaling or ingesting used liquids.

► Wash skin thoroughly after exposure to used liquids.

Recommended Oil

Use 4-stroke motor oil that meets or exceeds the requirements for

PI service category SJ or later (or equivalent). Always check the

PI service label on the oil container to be sure it includes the

letters SJ or later (or equivalent).

AMBIENT TEMPERA TURE

SAE 10W-30 is recommended for general use. Other viscosities

shown in the chart may be used when the average temperature in

your area is within the indicated range.

770077

40

wc_tx004023gb_FM10.fm

Page 41

Engine Maintenance: Honda GX160

The engine maintenance schedule(s) in this chapter are reproduced from the

engine owner’s manual. For additional information, see the engine owner’s

manual.

MAINTENANCE SCHEDULE

REGULAR SERVICE PERIOD (3)

Perform at every

indicated month or

operating hour interval,

whichever comes first.

ITEM

Engine oil

Reduction case oil

(applicable types)

Air cleaner

Sediment cup

Spark arrester

(applicable types)

Idle speed

Valve clearance

Combustion

chamber

Fuel tank &

filter

Fuel tube Check Every 2 years

Check level

Change

Check level

Change

Check

Clean

Replace

Clean

Check-adjustSpark plug

Replace

Clean

Check-adjust

Check-adjust

Clean Shop

Clean

* Internal vent carburetor with dual element type only.

Cyclone type every 6 months or 150 hours.

INTERNAL VENT

CARBURETOR TYPE

Each

First

Use

Month

or

20 Hrs

After every 500 Hrs. (2)

(Replace if necessary) (2)

Every 3

Every 6

Months

Months

or

or

50 Hrs

100 Hrs

(1)

(1)

STANDARD TYPE

Every

Refer

Year

to

or

Page

300 Hrs

9

9

9–10

10

10

11–12

12

12

(4)

(2)

13

(2)

13

(2)

Shop

manual

manual

Shop

manual

Shop

manual

BREATHER TUBE

TUBE CLIP

BREATHER TUBE

** Replace paper element type only.

Cyclone type every 2 years or 600 hours.

(1) Service more frequently when used in dusty areas.

(2) These items should be serviced by your servicing dealer,

unless you have the proper tools and are mechanically

proficient. Refer to the Honda shop manual for service

procedures.

(3) For commercial use, log hours of operation to determine

proper maintenance intervals.

(4) In Europe and other countries where the machinery directive

2006/42/EC is enforced, this cleaning should be done by your

servicing dealer.

Failure to follow this maintenance schedule could result

in non-warrantable failures.

770078

wc_tx004023gb_FM10.fm

41

Page 42

Engine Maintenance: Honda GX390

Recommended Oil

Use 4-stroke motor oil that meets or exceeds the requirements for

API service category SJ or later (or equivalent). Always check the

API service label on the oil container to be sure it includes the

letters SJ or later (or equivalent).

AMBIENT TEMPERATURE

SAE 10W-30 is recommended for general use. Other viscosities

shown in the chart may be used when the average temperature in

your area is within the indicated range.

770079

8 Engine Maintenance: Honda GX390

The information in this chapter comes from copyrighted Honda material.

The viscosity of the engine oil is an important factor when determining the correct

engine oil to use in your machine. Use an engine oil of appropriate viscosity based

on the expected outside air temperature. See the table below.

WARNING

Most used liquids from this machine such as oil, gasoline, grease, etc., contain

small amounts of materials that can cause cancer and other health problems if

inhaled, ingested, or left in contact with skin for prolonged periods of time.

► Take steps to avoid inhaling or ingesting used liquids.

► Wash skin thoroughly after exposure to used liquids.

42

wc_tx004030gb_FM10.fm

Page 43

The engine maintenance schedule(s) in this chapter are reproduced from the

BREATHER TUBE

INTERNAL VENT

CARBURETOR TYPE

BREATHER TUBE

STANDARD TYPE

TUBE CLIP

770080

MAINTENANCE SCHEDULE

REGULAR SERVICE PERIOD (3)

Perform at every

indicated month or

operating hour interval,

whichever comes first.

Each

Use

First

Month

or

20 Hrs

Every 3

Months

or

50 Hrs

Every 6

Months

or

100 Hrs

Every

Year

or

300 Hrs

Refer

to

Page

ITEM

Engine oil

Check level

Change

Failure to follow this maintenance schedule could result

in non-warrantable failures.

(4) In Europe and other countries where the machinery directive

2006/42/EC is enforced, this cleaning should be done by your

servicing dealer.

(3) For commercial use, log hours of operation to determine

proper maintenance intervals.

(2) These items should be serviced by your servicing dealer,

unless you have the proper tools and are mechanically

proficient. Refer to the Honda shop manual for service

procedures.

(1) Service more frequently when used in dusty areas.

** Replace paper element type only.

Cyclone type every 2 years or 600 hours.

* Internal vent carburetor with dual element type only.

Cyclone type every 6 months or 150 hours.

Air cleaner

Check

Clean

Check-adjustSpark plug

Spark arrester

(applicable types)

Idle speed

Clean

Valve clearance

Combustion

chamber

Fuel tank &

filter

Clean

Check-adjust

Check-adjust

Replace

Reduction case oil

(applicable types)

Replace

(1)

(4)

(2)

(2)

After every 1000 Hrs. (2)

(2)

Fuel tube Check Every 2 years

(Replace if necessary) (2)

Shop

manual

Shop

manual

Clean Shop

manual

Shop

manual

13

13

12

12

11–12

10

10

9–10

9

9

(1)

Sediment cup

Clean

Check level

Change

engine owner’s manual. For additional information, see the engine owner’s

manual.

Engine Maintenance: Honda GX390

wc_tx004030gb_FM10.fm

43

Page 44

Engine Maintenance: Hatz 1B 20 / 1B 30

9 Engine Maintenance: Hatz 1B 20 / 1B 30

The information in this chapter comes from copyrighted Hatz material.

The viscosity of the engine oil is an important factor when determining the correct

engine oil to use in your machine. Use an engine oil of appropriate viscosity based

on the expected outside air temperature. See the table below.

WARNING

Most used liquids from this machine such as oil, gasoline, grease, etc., contain

small amounts of materials that can cause cancer and other health problems if

inhaled, ingested, or left in contact with skin for prolonged periods of time.

► Take steps to avoid inhaling or ingesting used liquids.

► Wash skin thoroughly after exposure to used liquids.

Oil viscosity

OIL: SAE...

Choose the recommended viscosity based on the type of start (recoil, crankhandle or electric) and on the engine temperature at which the engine will be

operated.

CAUTION

Engine damage from unsuitable engine oil.

Using engine oil that does not meet the above specifications

considerably shortens the engine service life.

wc_tx003915gb_FM10.fm

44

770062

Page 45

Engine Maintenance: Hatz 1B 20 / 1B 30

The engine maintenance schedule(s) in this chapter are reproduced from the

engine owner’s manual. For additional information, see the engine owner’s

manual.

wc_tx003915gb_FM10.fm

770063

45

Page 46

Engine Maintenance: Hatz 1B 20 / 1B 30

770064

46

wc_tx003915gb_FM10.fm

Page 47

PT2 / PT3 Troubleshooting

10 Troubleshooting

Problem / Symptom Reason Remedy

Engine does not start.

Engine is hard to start.

Impeller does not turn

and pump is hard to

start.

Engine starts but

pump does not take in

water.

Pump takes in water

but discharges little or

no water.

Suction hose leaks at

inlet.

Discharge hose does

not stay on coupling.

Engine stops by itself.

■ No fuel in tank

■ Old fuel

■ Engine oil pressure/oil level low

■ Impeller rubbing on insert

■ Dirt or debris inside pump housing

blocking movement of impeller

■ Impeller jammed or blocked

■ Impeller rubbing on insert

■ Pump housing not filled with water

■ Suction strainer partially clogged

■ Suction hose damaged

■ Air leak at suction port

■ Pump too high above water line

■ Engine speed too low

■ D ebris collecting in pump housing

■ Too much clearance between

impeller and insert.

■ Impeller worn

■ D ischarge hose kinked or blocked

■ Engine speed too low

■ Volute insert worn or damaged

■ Clamps not sealed properly

■ Suction hose diameter too large

■ Suction hose damaged

■ Pressure is too high for clamps

being used

■ D ischarge hose kinked or blocked

■ No fuel in tank

■ Engine oil pressure/oil level low

■ Engine too hot

■ Add fuel.

■ Drain fuel tank, change fuel filter,

and fill with fresh fuel.

■ Add engine oil.

■ Inspect impeller and remove

shims as necessary .

■ Clean or remove debris.

■ Remove pump housing cover and

clean or remove debris.

■ Inspect impeller and remove

shims as necessary .

■ Prime the pump.

■ Clean or remove debris.

■ Repair or replace suction hose.

■ Repair air leak.

■ Move pump closer to water.

■ Run pump at maximum operating

speed.

■ Clean or remove debris.

■ Inspect impeller and add shims as

necessary.

■ Inspect impeller and add shims as

necessary.

■ Un-kink discharge hose or remove

obstruction.

■ Run pump at maximum operating

speed.

■ Adjust clearance or replace volute

insert.

■ Tighten, replace, or add clamps.

■ Use a hose with a smaller

diameter.

■ Replace suction hose.

■ Add another clamp.

■ Un-kink discharge hose or remove

obstruction.

■ Add fuel.

■ Add engine oil.

■ Allow the engine to cool. Check/

add coolant.

wc_tx004024gb_FM10.fm

47

Page 48

Technical Data PT2 / PT3

11 Technical Data

11.1 Engine—PT2 / PT2(I) / PT2H / PT2H(I)

Machine PT2

5000009318

Engine type 4-stroke, overhead valve,

single cylinder

Engine make Wacker Neuson Hatz

Engine model WM170 1B 20

Maximum rated power at rated

1

speed

Displacement cm³ (in.³) 169 (10.3) 232 (14.2)

Spark plug (NGK) BR 6HS

Electrode gap mm (in.) 0.6–0.7

Operating speed rpm 3500

Maximum engine speed—no load rpm 3700 ± 100 3700 ± 50

Valve clearance (cold)

kW (hp) 4.2 (5.7) @ 4000 rpm 3.4 (4.6) @ 3600 rpm

Champion RL86C

(0.024–0.028)

Intake and exhaust:

mm (in.)

0.12–0.15

(0.005–0.006)

4-stroke, air cooled,

PT2H

5000009094

5000009097

diesel

—

—

Air cleaner type Dual element Dry pleated paper

element

Engine lubrication oil grade SAE 10W30

Service class SJ, SL

Engine oil capacity L (qt) 0.60 (0.63) 0.90 (.95)

Fuel type Regular unleaded

gasoline

Fuel tank capacity L (qt) 3.6 (3.8) 3.0 (3.2)

1

Net engine power rating per SAE J1349 and ISO 3046. Actual power output may vary due to

conditions of specific use.

CH, CI, CJ rated

No. 2 diesel

48

wc_td000650gb_FM10.fm

Page 49

PT2 / PT3 Technical Data

11.2 Engine—PT2A / PT2A(I)

Machine PT2A

5000009092 (100–200)

5000009095 (100–201)

5000009237 (100–201)

Engine type 4-stroke, overhead valve,

single cylinder

Engine make Honda

Engine model GX 160 K1 TX2 GX 160 UT2 TX2

Maximum rated power at rated

1

speed

Displacement cm³ (in.³) 163 (9.9)

Spark plug (NGK) BPR 6ES

Electrode gap mm (in.) 0.7–0.8

Operating speed rpm 3500

Maximum engine speed—no load rpm 3700 ± 100

Valve clearance (cold)

intake:

exhaust:

kW (hp) 3.6 (4.8) @ 3600 rpm

BOSCH WR7DC

(0.028–0.031)

mm (in.) 0.15 ± 0.02 (.006)

0.20 ± 0.02 (.008)

5000009092 (201–)

5000009095 (202–)

5000009237 (202–)

PT2A

Air cleaner type Dual element

Engine lubrication oil grade SAE 10W30

Service Class SJ, SL

Engine oil capacity L (qt) 0.6 (0.63)

Fuel type Regular unleaded gasoline

Fuel tank capacity L (qt) 3.1 (3.3)

1

Net engine power rating per SAE J1349 and ISO 3046. Actual power output may vary due to

conditions of specific use.

wc_td000650gb_FM10.fm

49

Page 50

Technical Data PT2 / PT3

11.3 Engine—PT3 / PT3A / PT3(I) / PT3H

Machine PT3

5000009321

5000009322

Engine type 4-stroke, overhead valve,

single cylinder

Engine make Wacker Neuson Honda Hatz

Engine model WM270 GX240 UT2PA2 1B 30

Maximum rated power

at rated speed

Displacement cm³

Spark plug (NGK) BR 6HS

Electrode gap mm (in.) 0.6–0.7

Operating speed rpm 3500

Maximum engine

speed—no load

1

kW (hp) 6.6 (9)

@ 4000 rpm

265 (16.17) 270 (16.5) 347 (21.2)

(in.³)

Champion RL86C

(0.024–0.028)

rpm 3700 ± 100 3700 ± 50

(DENSO) W20EPR-U

PT3A

5000009098

5000009101

5000009240

5000620800

5.9 (7.9)

@ 3600 rpm

(NGK) BPR 6ES

0.7–0.8

(0.028–0.031)

PT3H

5000009100

5000009103

4-stroke, air cooled,

diesel engine

5.0 (6.8)

@ 3600 rpm

—

—

Valve clearance (cold)

Intake and exhaust mm (in.) — 0.10 (0.004)

Air cleaner type Dual element Dry pleated paper

element

Engine lubrication oil grade SAE 10W30

Service class SJ

Engine oil capacity L (qt) 1.1 (1.2)

Fuel type Regular unleaded gasoline No. 2 diesel

Fuel tank capacity L (qt) 6.0 (6.4) 5.3 (5.6) 5.0 (5.3)

1

Net engine power rating per SAE J1349 and ISO 3046. Actual power output may vary due to

conditions of specific use.

CD, CE, CF, CG

rated

50

wc_td000650gb_FM10.fm

Page 51

PT2 / PT3 Technical Data

11.4 Pump—PT2 / PT2(I) / PT2A / PT2H

Machine PT2(I)

5000620725

PT2

5000009318

PT2A

5000009092

5000009095

PT2H

5000009094

5000009097

5000009237

Dimensions mm (in.) 550 x 465 x 500

(21.7 x 18.3 x 19.6)

590 x 495 x 510

(23.2 x 19.4 x 20.0)

Operating weight kg (lb) — 43 (96) 59 (131)

Maximum suction lift

1

m (ft) 7.5 (25)

Maximum total head m (ft) 32 (106)

Maximum pressure ba r (psi) 3.2 (46)

Maximum flow rate

Suction / discharge

2

L/min

(gpm)

652

(172)

mm (in.) 50 (2)

diameter

Maximum solid size mm (in.) 25 (1)

1

Based on pump operating at sea level. Maximum suction lift will be less at higher altitudes.

2

Zero net head

11.5 Pump—PT3 / PT3(I) / PT3A / PT3H

Machine PT3(I)

5000620726

Dimensions mm (in.) 675 x 505 x 570

Operating weight kg (lb) — 64 (140) 68 (149) 77 (169)

Maximum suction lift

1

m (ft) 7.5 (25)

Maximum total head m (ft) 29 (93)

Maximum pressure bar (psi) 2.8 (40)

Maximum flow rate

2

L/min

(gpm)

Suction / discharge diameter mm (in.) 75 (3)

Maximum solid size mm (in.) 38 (1.5)

PT3

5000009321

5000009322

5000009323

(26 x 20 x 23)

5000009098

5000009101

5000009240

5000620800

1350

(356)

PT3A

PT3H

5000009100

5000009103

5000009242

wc_td000650gb_FM10.fm

1

Based on pump operating at sea level. Maximum suction lift will be less at higher altitudes.

2

Zero net head

51

Page 52

Technical Data PT2 / PT3

11.6 Sound Measurements

Products are tested for sound pressure level in accordance with EN ISO

11201:2010.

Sound power level is tested in accordance with European Directive 2000/14/EC Noise Emission in the Environment by Equipment for use outdoors.

Machine Sound Pressure at Operator’s

Location dB(A)

PT2A 99 101

PT2H 102 103

PT3A 101 102

PT3H 106 106

Guaranteed Sound Power

dB(A)

52

wc_td000650gb_FM10.fm

Page 53

PT2 / PT3 Technical Data

A

C

B

wc_gr012713

11.7 Dimensions

Machine A B C

PT2

PT2A

PT2H 590 (23.2) 495 (19.4) 510 (20.0)

PT3

PT3(I)

PT3A

PT3H

mm (in.)

mm (in.) 675 (26.0) 505 (20.0) 570 (23.0)

550 (21.7) 465 (18.3) 500 (19.6)PT2(I)

wc_td000650gb_FM10.fm

53

Page 54

Technical Data PT2 / PT3

54

wc_td000650gb_FM10.fm

Page 55

Emission Control Systems Information and Warranty

12 Emission Control Systems Information

and Warranty

The Emission Control Warranty and associated information is valid only for the

U.S.A., its territories, and Canada.

12.1 Emission Control Systems Warranty Statement

See the supplied engine owner’s manual for the applicable exhaust and

evaporative emission warranty statement.

wc_tx001753gb_FM10.fm 55

Page 56

Emission Control Systems Information and Warranty

56 wc_tx001753gb_FM10.fm

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

Page 63

Page 64

Page 65

Page 66

Page 67

Page 68

Page 69

Page 70

Important: For spare parts information, please see your Wacker Neuson Dealer, or visit the

Wacker Neuson website at http://www.wackerneuson.com/.

Wichtig! Informationen über Ersatzteile erhalten Sie von Ihrem Wacker Neuson Händler oder

besuchen Sie die Wacker Neuson Website unter http://www.wackerneuson.com/.

Important : Pour des informations sur les pièces détachées, merci de consulter votre

distributeur Wacker Neuson, ou de visiter le site Internet de Wacker Neuson sur

http://www.wackerneuson.com/.