Page 1

Pump

PS (3-Phase)

Series

OPERATOR’S MANUAL

0154623en 002

0107

0154623EN

Page 2

Page 3

PS (3-Phase) Series Table of Contents

wc_bo0154623002enTOC.fm 1

1. Foreword 3

2. Safety Information 4

2.1 Operating and Electrical Safety ............................................................ 5

2.2 Information Labels ................................................................................ 5

3. Technical Data 6

3.1 Standard Specifications ........................................................................ 6

3.2 Operating Specifications (60 Hz) .......................................................... 7

4. Operation 11

4.1 Names of Parts ................................................................................... 11

4.2 Prior to Operation ............................................................................... 12

4.3 Installation .......................................................................................... 12

4.4 Electrical Wiring .................................................................................. 16

4.5 Operation ............................................................................................ 19

5. Maintenance 23

5.1 Periodic Maintenance Schedule ......................................................... 23

5.2 Maintenance and Inspection .............................................................. 24

5.3 Disassembly and Reassembly ........................................................... 27

5.4 Troubleshooting .................................................................................. 34

Page 4

Table of Contents PS (3-Phase) Series

wc_bo0154623002enTOC.fm 2

Page 5

Foreword

wc_tx000001gb elec tr ic. fm 3

1. Foreword

This manual provides information and procedures to safely operate

and maintain this Wacker m odel. For you r own safet y and prote ction

from injury, carefully read, understand and observe the safety

instructions described in this manual.

Keep this manual or a copy of it with the machine. If you lose this

manual or need an additional copy, please contact Wacker

Corporation. This machine is built with user safety in mind; however,

it can present hazards if improperly operated and serviced. Follow

operating instructions carefully! If you have questions about operating

or servicing this equipment, please contact Wac ker Corporation.

The information contained in this manual was based on machines in

production at the time of publication. Wacker Corporation reserves the

right to change any portion of this information without notice.

All rights, especially copying and distribution rights, are reserved.

Copyright 2007 by Wacker Corporation.

No part of this publication may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without

express written permission fr om Wacker Co rp or at io n.

Any type of reproduction or distribution not authorized by Wacker

Corporation represents an infringement of valid cop y rights and will be

prosecuted. We expressly reserve the right to make technical

modifications, even without due notice, which aim at improving our

machines or their safety standards.

Page 6

Safety Information PS 3 1500 / PS 3 2200

wc_si000044gb.fm 4

2. Safety Information

This manual contains DANGER, WARNING, CAUTION, and NOTE

callouts which must be followed to reduce the possibility of personal

injury, damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

CAUTION: Used without the safety alert symbol, CAUTION indicates

a potentially hazardous situation which, if not avoided, may result in

property damage.

Note:

Contains additional information important to a procedure.

DANGER

WARNING

CAUTION

Page 7

PS 3 1500 / PS 3 2200 Safety Information

wc_si000044gb.fm 5

2.1 Operating and Electrical Safety

To reduce risk of electric shock, connect only to a properly grounded,

grounding-type receptacle.

Risk of electric shock - This pump has n ot be en inve stigated for use i n

swimming pool areas.

An acceptable motor-control switch shall be provided at the time of

installation according to local codes and regulations.

To reduce risk of electric shock, see instruction manual for proper

installation.

CAUTION: This pump may automatically restart. Prior to working on

the pump or control panel all supply circuits must be disconnected.

CAUTION: Risk of shock - Do not remove cord and strain relief.

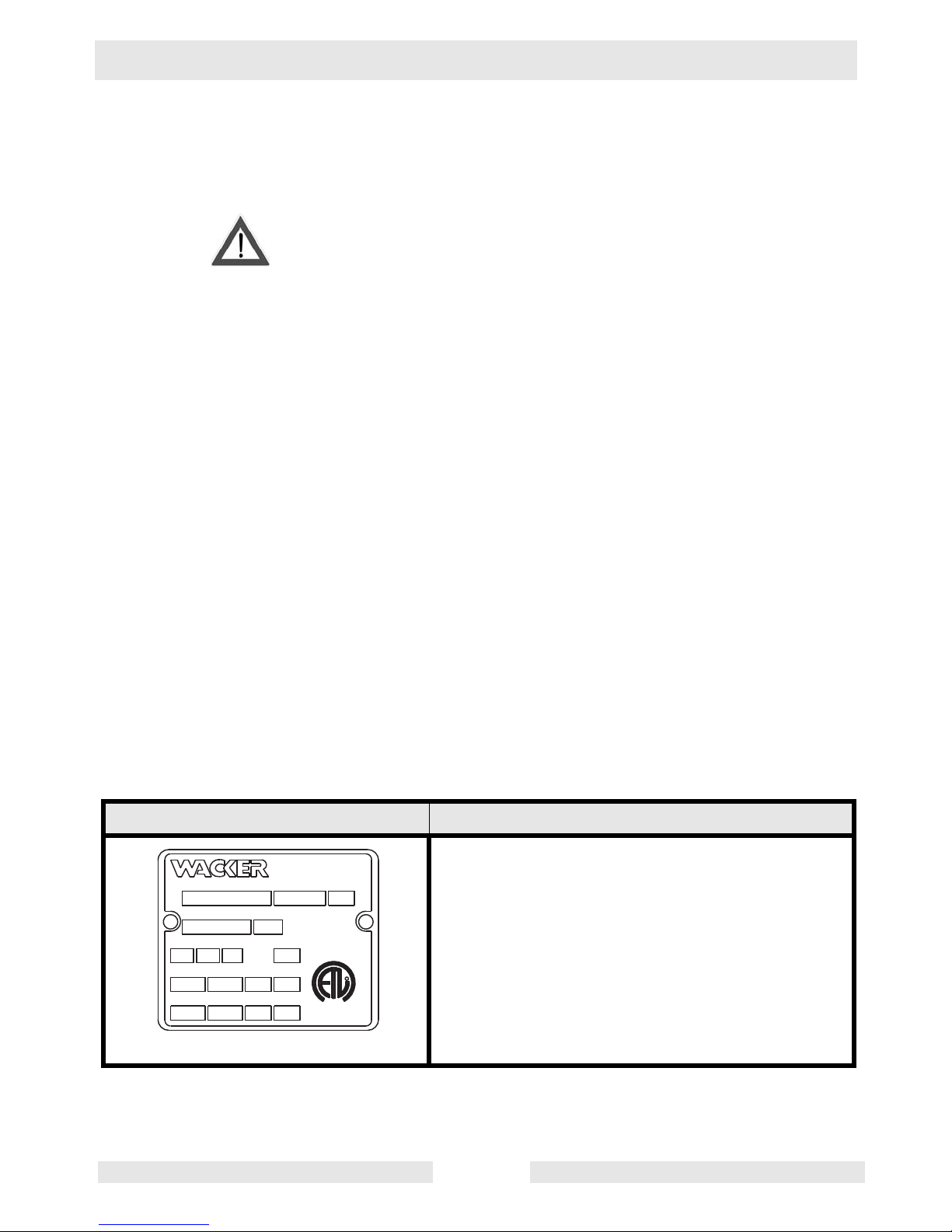

2.2 Information Labels

Label Meaning

A nameplate listing the Model Number, Item

Number, Revision, and Serial Number is

attached to each unit. Please record the information found on this plate so it will be available

should the nameplate become lost or damaged.

When ordering parts or requesting service information, you will always be asked to specify the

model, item number , revision number, and serial

number of the unit.

WARNING

Wacker Corporation

Menomonee Falls, WI 53051 USA

Model Item No. Rev.

Serial No.

VHz

kWkgMax. L/minMax. m

MADE IN

JAPAN

HPlbsMax. GPMMax.

ft

CUS

L

I

S

T

E

D

R

Phase

C22.2 No. 108-M89

2001992

Conforms to UL Std. 778

Cert. to CAN/CSA St

d.

Amp.

Man. Y/

M

THERMALLY PROTECTED

INDOORS OR OUTDOORS

CSA ENCLOSURE

3

Page 8

Technical Data PS (3-Phase) Series

wc_td000044gb.fm 6

3. Technical Data

3.1 Standard Specifications

Applicable Liquids,

Consistency and

Temperature

Work drainage and Sand-Carrying Water

0–40°C (32–104°F)

Pump Impeller Open Type

Shaft Seal Double Mechanical Seal

Bearing Shielded Ball Bearing

Motor Specification Dry Submersible Induction Motor (2-P ole)

Insulation Class B: 10 to 15 HP

Class E: 2 to 7.5 HP

Protection Sys tem Circle Thermal Protector

Lubricant SAE 10W/20W

Such as:

–Turbine Oil ISO VG #32

–Shell Victrolia Oil #27

–British Pet Energol THB #32

–Gulf Paramount #32

–Tellus #T22 Shell Oil

–Shell Turbo T32

Connection Coupling (NPT)

Page 9

PS (3-Phase) Series Technical Data

wc_td000044gb.fm 7

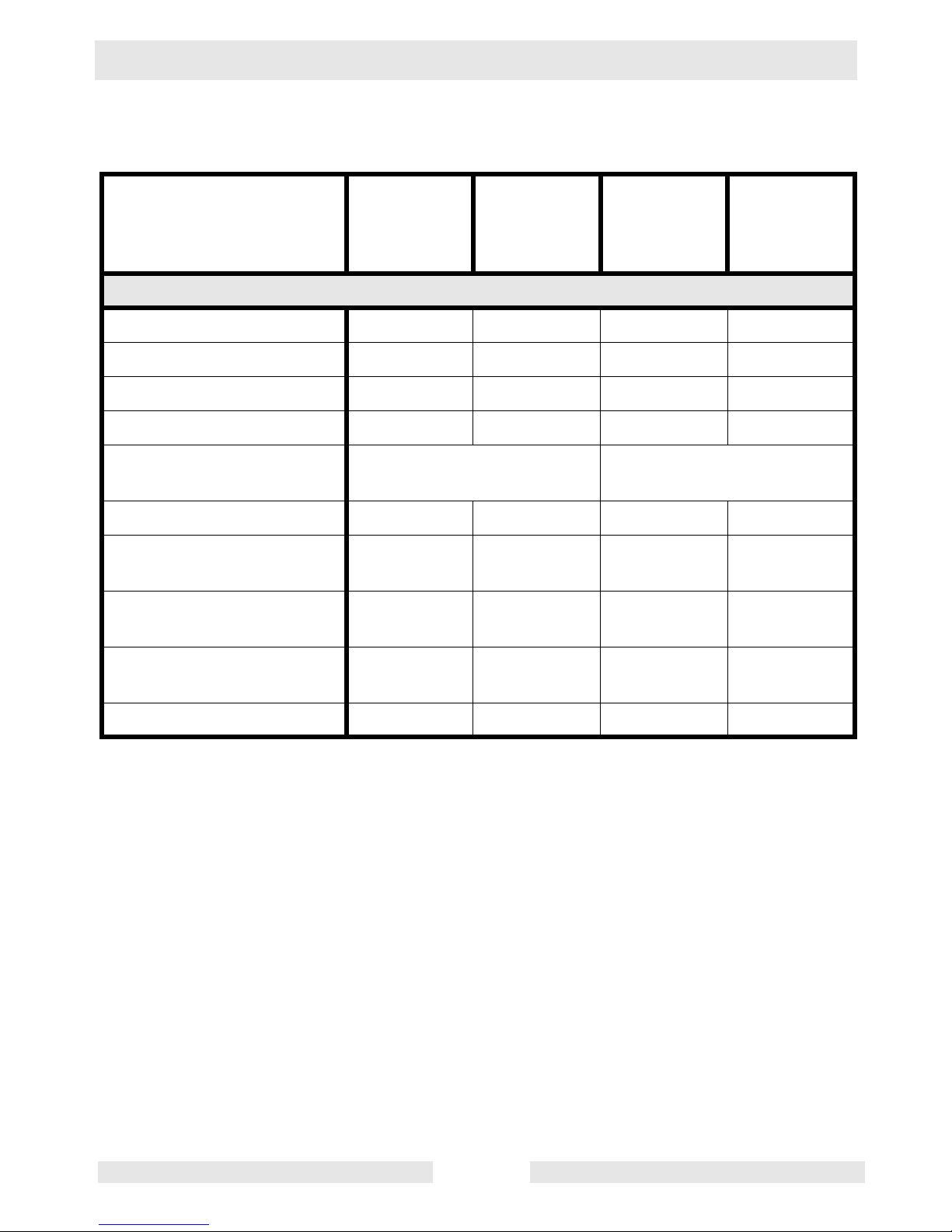

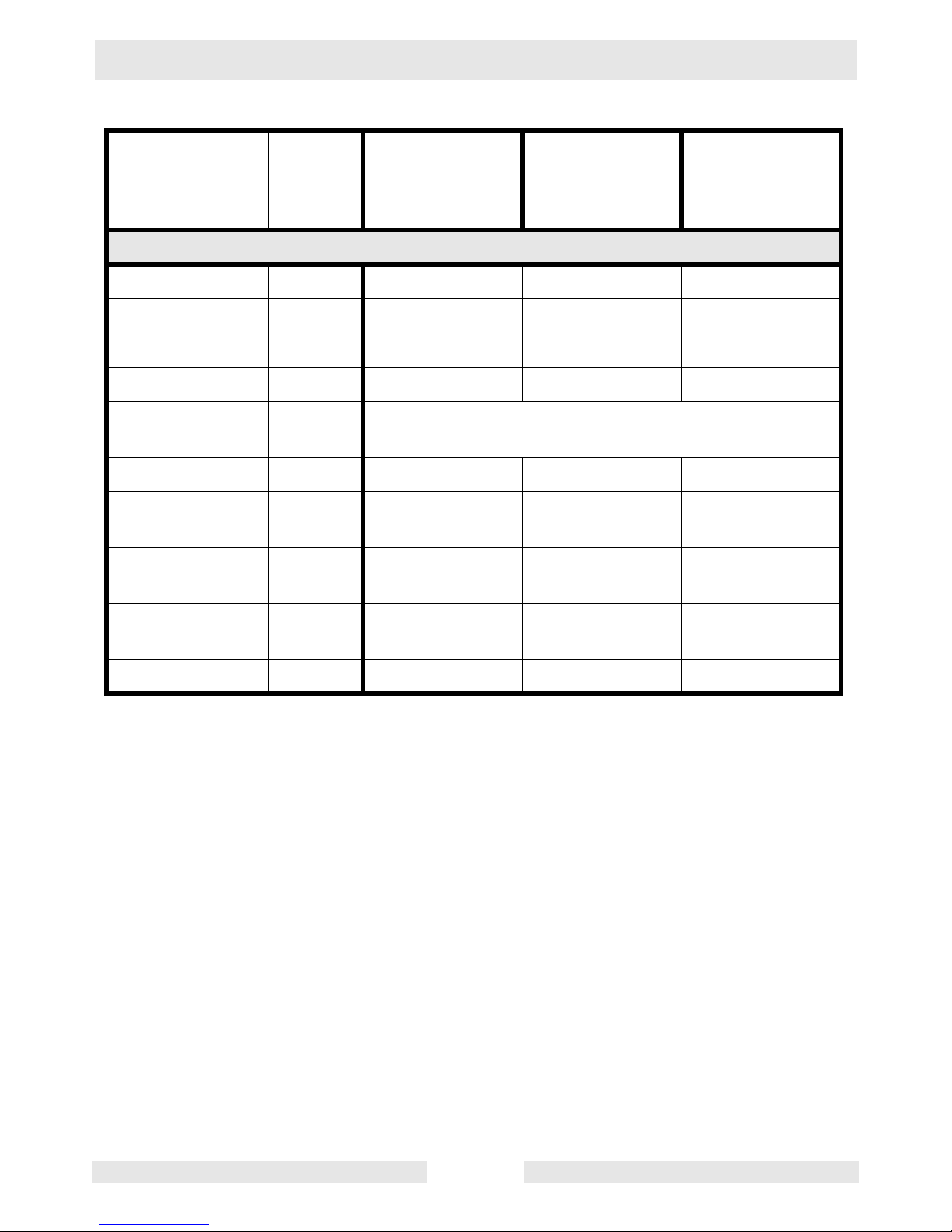

3.2 Operating Specifications (60 Hz)

*The weight (mass) given above is the operating weight of the pump itself, not including the cable

assembly

Part No. PS2 1503

0009120

0009121

0009122

PS3 1503

0009123

0009124

0009125

PS2 2203

0009126

0009127

0009128

PS3 2203

0009129

0009130

0009131

Pump

Bore

mm (in.)

50 (2) 80 (3) 50 (2) 80 (3)

Phase 3 3 3 3

Starting Method Direct Online Direct Online Direct Online Direct Online

Output

kW (Hp)

1.5 (2) 1.5 (2) 2.2 (3) 2.2 (3)

Rated Current

A

(V)

6.1/3.1/2.3

(220/440/575)

9.3/4.7/3.5

(220/440/575)

Maximum Head

m (ft.)

23 (75) 14.4 (47) 30.5 (100) 20.4 (67)

Maximum

Capacity

L/min

(GPM)

400

(106)

680

(180)

500

(132)

770

(203)

Maxmum

Pressure

psi

33 21 43 29.4

Solid Size

Capacity

mm (in.)

8.5 (0.3) 8.5 (0.3) 8.5 (0.3) 8.5 (0.3)

Weight*

Kg (lbs.)

29 (64) 29 (64) 32 (71) 32 (71)

Page 10

Technical Data PS (3-Phase) Series

wc_td000044gb.fm 8

*The weight (mass) given above is the operating weight of the pump itself, not including the cable

assembly

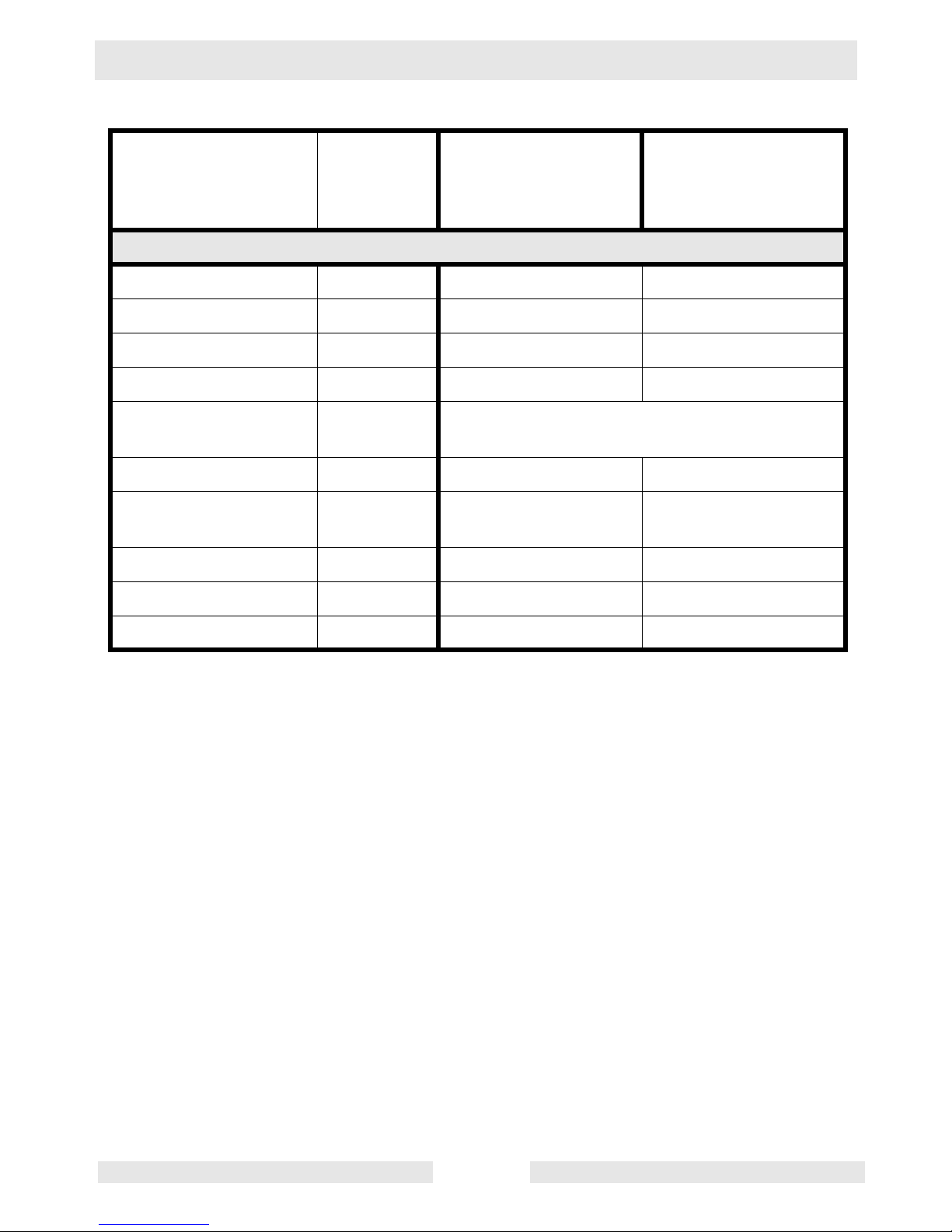

Part No. PS2 3703

0009132

0009133

0009134

PS3 3703

0009135

0009136

0009137

PS4 3703

0009138

0009139

0009140

Pump

Bore

mm (in.)

50 (2) 80 (3) 100 (4)

Phase 3 3 3

Starting Method Direct Online Direct Online Direct Online

Output

kW (Hp)

3.7 (5) 3.7 (5) 3.7 (5)

Rated Current

A

(V)

13.3/6.8/5.3

(220/440/575)

Maximum Head

m (ft.)

35 (115) 31 (102) 18.5 (61)

Maximum

Capacity

L/min

(GPM)

540

(143)

830

(219)

1460

(386)

Maximum

Pressure

psi

50 44 26.4

Solid Size

Capacity

mm (in.)

8.5 (0.3) 8.5 (0.3) 8.5 (0.3)

Weight*

Kg (lbs.)

55 (121) 55 (121) 55 (121)

Page 11

PS (3-Phase) Series Technical Data

wc_td000044gb.fm 9

*The weight (mass) given above is the operating weight of the pump itself, not including the cable

assembly

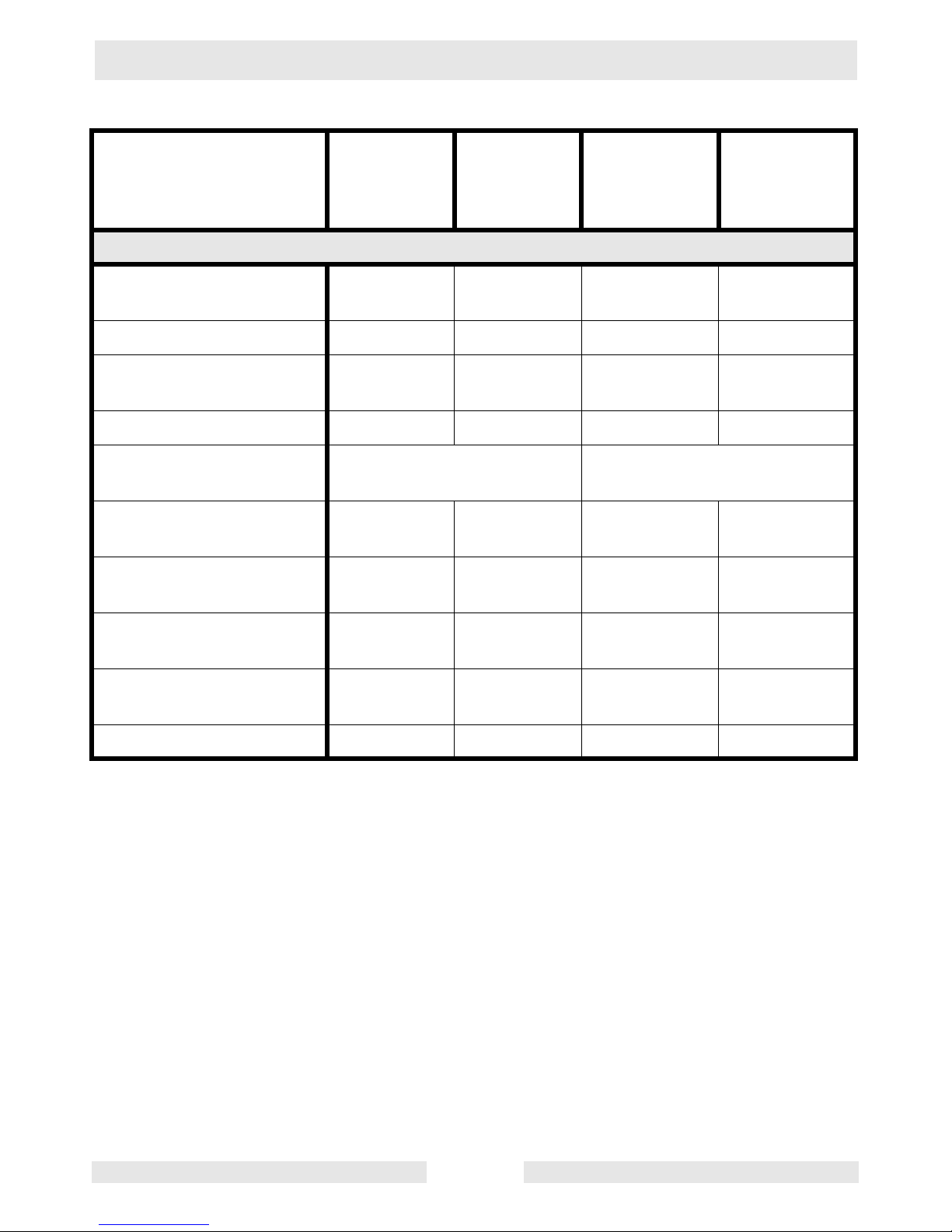

Part No. PS3 5503

0009141

0009142

0009143

PS4 5503

0009144

0009145

0009146

Pump

Bore

mm (in.)

80 (3) 100 (4)

Phase 3 3

Starting Method Direct Online Direct Online

Output

kW (Hp)

5.5 (7.5) 5.5 (7.5)

Rated Current

A

(V)

19.5/9.8/7.3

(220/440/575)

Maximum Head

m (ft.)

38 (125) 24 (79)

Maximum Capacity

L/min (GPM)

985

(260)

1620

(428)

Maximum Pressure

psi

54 34.6

Solid Size Capacity

mm (in.)

8.5 (.3) 8.5 (.3)

Weight*

Kg (lbs.)

66 (146) 66 (146)

Page 12

Technical Data PS (3-Phase) Series

wc_td000044gb.fm 10

*The weight (mass) given above is the operating weight of the pump itself, not including the cable

assembly.

Part No. PS4 7503HH

0009147

0009148

0009149

PS4 7503HF

0009150

0009151

0009152

PS4 11003HH

0009153

0009154

0009155

PS4 11003HF

0009156

0009157

0009158

Pump

Bore

mm

(in.)

100

(4)

100 / 150

(4 / 6)

100

(4)

100 / 150

(4 / 6)

Phase 3 3 3 3

Starting

Method

Direct Online Direct Online Direct Online Direct Online

Output

kW (Hp)

7.5 (10) 7.5 (10) 11 (15) 11 (15)

Rated Current

A

(V)

25.5/12.8/9.7

(220/440/575)

38.0/19.0/14.3

(220/440/575)

Maximum

Head

m (ft.)

42 (137) 31 (102) 51 (167) 32.5 (107)

Maximum

Capacity

L/min

(GPM)

1320

(349)

2079

(549)

1427

(377)

2440

(645)

Maximum

Pressure

psi

60 44 72.7 45.8

Solid Size

Capacity

mm

(in.)

8.5 (.3) 8.5 (.3) 8.5 (.3) 8.5 (.3)

Weight*

Kg (lbs.)

93 (205) 93 (205) 130 (287) 130 (287)

Page 13

PS (3-Phase) Series Operation

wc_tx000131gb.fm 11

4. Operation

4.1 Names of Parts

See Graphic: wc_gr00032 7

Note:

This diagram shows the parts layout of a typical PS (Three-Phase) model. The external

appearance and the internal construction may vary slightly, depending on your particular model.

Ref. Description Ref. Description

1. Discharge Outlet 8. Lifting Handle

2. Coupling 9. Mechanical seal

3. Oil Housing 10. Oil plug

4. Lubricant 11. Sleeve

5. Impeller 12. Volute

6. Suction cover 13. Strainer

7. Cable Assem b ly 14. Plate

7

1

2

8

9

10

11

12

13

14

6

5

4

3

Page 14

Operation PS (3-Phase) Series

wc_tx000131gb.fm 12

4.2 Prior to Operation

When the pump is delivered, first perform the following checks:

• Inspection

While unpacking, inspect the product for damage during shipment, and

make sure all bolts and nuts are tightened properly.

• Specification check

Check the model number to make sure it is the product that was

ordered. Be certain it is the correct voltage and frequency.

Note:

If there is any problem wi th the product as sh ipped, contact yo ur

nearest dealer or Wacker representative at once.

• Product specifications

Do not operate this product under any conditions other than those for

which it is specified. Failure to observe this precaution can lead to

electrical shock, current leakage, fire, water leakage or other

problems.

4.3 Installation

If the pump is used to drain a swimming pool, the pump must be

connected to a Ground Fault Interruptor (GFI).

If the pump is used in fountains, the pump must be connected to a

Ground Fault Interruptor (GFI).

The pump must not be used when people ar e in the water.

Leakage of pum p lubricants may cause pollution of water.

Proper plug must be provided according t o local cod es and stan dards.

Refer to wiring diagram.

The supply voltage should be within ± 5% of the rated voltage.

DO NOT use in water temperatures outside the range of 0–40°C (32–

104°F), which can lead to failure, electrical leakage or shock.

The pump should be used only for pumping plain water. The pump

should not be used to pump fluids such as oil, salt water, or organic

solvents.

The pump must never be used to pump explosive liquids and should

never be operated in an area where explosive elements might be

present.

The pump must not be used in a partially disassembled state.

CAUTION

WARNING

Page 15

PS (3-Phase) Series Operation

wc_tx000131gb.fm 13

Note:

Consult your local dea ler or Wacker r epresentative before usi ng

with any liquids other than those indicated in this document.

Critical Pressure

Do not use the pump i n an area whe re the water pressure exceeds t he

values given below , as it may dama ge the pump, or cause a short or

electrical shock.

Preparing for Installation

Before installing the pump at a work site, you will need to have the

following tools and instruments ready:

• Insulation resistance tester (megohmme ter )

• AC voltmeter

• AC ammeter (clamp-on ty pe )

• Bolt and nut tighteners

• Power supply connection tools (screwdriver or box wrench)

Note:

Please also read the instru ctions that come with ea ch of the test

instruments.

Checks to Make Before Installation

With the megohmmeter, measure the insulation resistance between

each of the power wires and grounding wire to verify the insulation

resistance of the motor.

Reference insulation resistance: 20MW or greater

Note:

The reference insulation resistance (20MW or greater) is the

value when the pump is new or has been repaired. For the reference

value after installation, see Maintenance and Inspection.

Model Critical Pressure

PS2 1503

PS2 2203

PS2 3703

PS4 3703

PS4 5503

PS3 1503

PS3 2203

PS3 3703

PS3 5503

0.5 MPa (71 PSI)

– discharge pressure during use

= critical pressure

PS4 7503HH

PS4 11003HH

PS4 7503HF

PS4 11003HF

critical pressure = 0.5 MPa (71 PSI)

CAUTION

Page 16

Operation PS (3-Phase) Series

wc_tx000131gb.fm 14

Precautions During Insta llation

4.3.1 The pump is supplied with a threaded discharge fitting. Tighten hose

coupling or discharge pipe securely and with proper gaskets.

When installing the p ump, be mindful of th e pump’s center of gra vity

and weight. If the pump is not suspended properly, the pump may fall

and break, which may lead to injury.

When installing or moving the pump, do not suspend the pump by the

cable assembly. Doing so w ill damage the cable, whi ch may cause a

short, electrical shock, or fire.

When transporting the pump manually, be sure to have a sufficient

number of people to carry out the task. To prevent back injury when

lifting, bend your knees without bending your back.

4.3.2 Handle the pump carefully. Do not drop it or expose it to strong

impacts. When suspending the pump to raise or to lower it, attach a

wire rope (a) or a chain to the pump’s lifting handle.

Note:

For proper proced ur es for h an dl ing the cable assembly, re fer t o

“Electrical Wiring” in this manual.

Do not operate the pump dry. Doing so will prevent the pump from

attaining its full potential and may also damage the pump and lead to

a short and electrical shock.

In order to properly discharge water, provide adequate piping to the

area where the pump is mounted. Improper piping may lead to water

leakage or other malfunctions.

4.3.3 Install the pump on ly in an area th at can ma intain a pro per water level.

Note:

For details on the water level necessary for pump operation,

refer to “Water Level During Operation” in Operation.

4.3.4 When using a hose to provide piping to the pump, observe the

following:

Use the shortest possible length of discharge hose and minimize the

number of bends. Verify that the end of the hose (discharge side) is

lifted above the wat er surf a ce (b). If the end of the hose is sub m erge d

in water, it may cause the water to flow back (c) wh en the pump ha s

been stopped. If the end of the hose is located at a level that is lower

than that of the source water surface, water may continue to flow out

even after the pump has been stopped.

Note:

Appropriate piping materials must be provided by the user.

Piping materials are not included with the product.

If an excessive amount of sediment is drawn into the pump, it may

cause the pump to wear, which can lead to current leakage or electrical

shock.

4.3.5 The pump must be placed upright during operation. If there is a risk

that the pump co ul d be bu ri ed u nder the sediment, place the pump o n

a base made up of materials such as concrete blocks.

WARNING

CAUTION

CAUTION

Page 17

PS (3-Phase) Series Operation

wc_tx000131gb.fm 15

4.3.6 If used in a permanent installation, where the pump is not readily

accessible after installation, please contact Wacker for a duplicate

nameplate to be install ed at th e w ell he ad o r on the cont ro l box so th at

it will be readily visible.

See Graphic: wc_gr000328, wc_gr000329 and wc_gr000330

wc_gr000330

wc_gr000329

b

c

wc_gr000328

a

Page 18

Operation PS (3-Phase) Series

wc_tx000131gb.fm 16

4.4 Electrical Wiring

Performing electrical wiring

Electrical wiring should be performed by a qualified person in accord

with all applicable regulations. Failure to observe this precaution not

only risks breaking the law but is extremely dangerous.

Incorrect wiring can lead to current leakage, electrical shock or fire.

ALWAYS make sure the pum p is equi pped w ith the specif ied ov erload

protectors and fuses or br eakers, so as to prevent electri cal shock from

a current leak or pump malfunction.

Operate within the capacity of the power supply and wiring.

Grounding

DO NOT use the p ump without first grou nding it properly. Fa ilure to

ground it can lead to electrical shock from a current leak or pump

malfunction.

DO NOT attach the gr ou nd ing wire to a g as p ipe, water pipe, li gh tni n g

arrestor or tele phone ground ing wire. Improper grounding ca n result in

electrical shock.

Cable Assembly

If it is neces sary t o ext end the c abl e ass embl y, us e a c ore size equal

to or larger than the original. This is necessary not only for avoiding a

performance drop, but to preven t cable overhea ting which can result in

fire, electrical leaka ge or ele ctr ical shock.

If a cable with cut insulation or other damage is submerged in the

water, there is a danger of damage to the pump, electrical leakage,

electrical shock, or fire.

Be careful not to let the cable assembly be cut or become twisted. This

may result in damage to the pump , electrical leakage , electrical shock,

or fire.

If it is necessary to submerge the connection wires of the cable

assembly in water, first seal the wires completely in a molded

protective sleeve, to prevent electrical leakage, electr ical shock, or fire .

DO NOT allow the cable assembly wires or power supply plug to

become wet.

Make sure the cable does not become excessive ly bent or twisted, and

does not rub against a structure in a way that might damage it.

If used in a deep-well installation, the cable assembly should be

secured every twenty feet.

WARNING

WARNING

CAUTION

CAUTION

Page 19

PS (3-Phase) Series Operation

wc_tx000131gb.fm 17

Connecting the power supply

Before connecting leads to the terminal strip, make certain the power

supply is turned off (circuit breaker, etc.), to avoid electrical shock,

shorting, or unexpected starting of the pump, leading to injury.

4.4.1 Tighten the ends of the cable assembly securely against the terminal

board.

4.4.2 The fi gure shows how to connect the ca ble assembly properly.

See Graphic: wc_gr000331

Wire Colors

B Black R Red Y Yellow Or Orange

G Green T Tan Br Brown Pr Purple

L Blue V Violet Cl Clear Sh Shield

P Pink W White Gr Gray LL Light Blue

WARNING

U

V

W

G

R

W

B

G

wc_gr000331

Page 20

Operation PS (3-Phase) Series

wc_tx000131gb.fm 18

Wiring Diagram

Direct-on-line starting

See Graphic: wc_gr000 33 2

If connected to a circuit protecte d by a fuse, use a time-de lay fuse with

this pump.

Ref. Description Ref. Description

1. Coil 2. Circle thermal protecto r

Wire Colors

B Black R Red Y Yellow Or Orange

G Green T Tan Br Brown Pr Purple

L Blue V Violet Cl Clear Sh Shield

P Pink W White Gr Gray LL Light Blue

1

2

G

B

W

R

wc_gr000332

CAUTION

Page 21

PS (3-Phase) Series Operation

wc_tx000131gb.fm 19

4.5 Operation

Before Operation

Improper voltage and freque ncy of the power supply will prevent the

pump from attaining its full potential, and may also lead to current

leakage, electrical shock, or fire.

4.5.1 Once again, check the nam eplate o f the pump to ver ify th at its vol tage

and frequency are correct.

4.5.2 Check the wiring, power supply voltage, the capacity of the ground

leakage circuit breaker, and the insulation resistance of the motor.

Insulation resistance reference value = 20MW min.

Note:

The insulation refer e nce va lue of 20MW min. is based on a ne w

or repaired pump. For reference values for a pump that has already

been installed, refer to Maintenance and Inspection in this manual.

4.5.3 Adjus t the set ting of t he over load pr otecto r (i.e. cir cuit br eaker) to the

pump’s rated current.

Note:

Verify the rated current on the pump’s nameplate.

4.5.4 When using a generator, as much as possible avoid operating the

pump in conjunction with other types of equipment.

Trial Operation

NEVER start the pump while it is suspended, as the pump may jerk

and cause a serious accident inv olv ing injury.

NEVER start the pump where people are present, as they may suffer

electrical shock from current leakage.

Be sure to check the pump’s direction of rotation when the pump is

exposed to atmosphere (a). Utilize a hoist to stabilize the pump on a

level surface while performing this check. Operating the pump in

reverse while it is submerged in wa ter will damage the pump, which

may lead to current leakage, electrical shock, or fire.

4.5.5 The impeller will rotate counterclockwise (b), as viewed from the

bottom of the pump. Opera te the pump for a short time (1 to 2 second s)

to check the rotational direction of the impeller.

Before changing the connections for reverse rotation, make sure that

the power supply (i.e. circuit br eaker) is properly disconnected and th at

the impeller has stopped completely. Failure to observe this may lead

to serious accidents, including electrical shock, short, or injury.

• To reverse the rotation, the following countermeasure must be taken.

COUNTERMEASURE: Interchange two of the three wires designated

U, V and W respective ly (c), or follow control system manufacturer's

instructions to utilize rotary field control and phase inverter function of

the control system supplied with the pump.

CAUTION

WARNING

CAUTION

WARNING

Page 22

Operation PS (3-Phase) Series

wc_tx000131gb.fm 20

4.5.6 Operate the pump for a short time (3 to 10 minutes) and perform the

following checks:

Operating current

Using an AC ammeter (cla mp), mea sure t he curr ent at th e phases U,

V, and W that are connected to the terminal board.

COUNTERMEASURE: Because an overload condition may be

present at the motor i f the operati ng current excee ds the rated curr ent,

refer to Section

Installation

in this manual for procedures on reverting

the motor to the correct state.

Operating voltage

Use an AC voltmeter (tester) to measure the voltage at the terminal

board.

Power supply voltage tolerance = within ±5% of the rated voltage

COUNTERMEASURE: If the power supp ly voltag e deviates f rom the

tolerance va lue, the deviation may be caused by t he capacity of t he

power supply or the extension cable that is used. Refer to Section

Electrical Wiring

in this manual to provide correct voltage.

Vibration

If the pump generates a considerable amount of vibration, noise, or

smell, disconnect the power supply immediately and contact the dealer

where you purchased the equipment, or the Wacker sales office in

your area.

See Graphic: wc_gr000 33 3

CAUTION

U

V

W

G

wc_gr000333

c

b

a

Page 23

PS (3-Phase) Series Operation

wc_tx000131gb.fm 21

Operation

The pump may be extre mely hot during operation. To pr event burns,

do not touch the pump with bare hands.

Do not insert your finger o r a stick into the pum p’s inl et openin g. Doing

so may cause injury, electrical shock, short, or fire.

When the pump is not used for a long time, make sure that the power

supply (such as a breaker) is properly disconnected. If the wiring

insulation deteriorates with the power supply connected, it may cause

current leakage, electrical shock, or fire.

Pay attention to the water le vel during the pump operation. The pump

will become damaged if it is allowed to operate dry.

Note:

Refer to “Water Level During Operation” at the end of this

section.

The pump is equipped with an internal motor protective device (circle

thermal protector).

Motor Protector

During inspection and repair, disconnect the power supply to avoid

starting the pump unintentionally. Failure to disconnect the power

supply may lead to serious accidents including electrical shock, a

short, and injury.

During a power outage, disconnect the power supply to the pump.

Unintentional operation of the pump after power resumption would be

extremely dangerous to people around the pump.

Unless the cause of a problem is rem oved, the pump will repeat the

stop-and-go cycle, eventually resulting in damage to the pump, and

causing current le akage and electr ical shock. Therefo re, after verify ing

that the power supply is disconnected, find and correct the cause of the

problem through inspection and repair.

DO NOT operate the pump at unusually low head, or when the strainer

is clogged with debris. Doing so will prevent the pump fr om attaining

its full potential, and may also generate abnormal noise and vibration

and cause damage to the pump, which may lead to current leakage,

electrical shock, and fire.

To protect the motor, if a current overload occurs in the motor or if the

motor overheats under the conditions given below, the pump will stop

automatically, regardless of the wat er level during operation.

• Extreme fluctuation of power supply voltage

• Pump operated under overload condition

• Pump operated at open phase or binding condition

CAUTION

WARNING

CAUTION

Page 24

Operation PS (3-Phase) Series

wc_tx000131gb.fm 22

Water Level During Operation

Do not operate t he pump bel ow Co ntin uous Ru nnin g Wat er L evel (a),

as doing so will damage the pump, causing current leakage and

electrical shock.

The table below shows the water level during operation by output.

Make sure that the water level will not be under these levels.

See Graphic: wc_gr000 33 5

Model Continuous Running Water Level

PS2 1503

PS2 2203

PS3 1503

PS3 2203

120 mm (4¾”)

PS2 3703

PS4 3703

PS4 5503

PS3 3703

PS3 5503

150 mm (6”)

PS4 7503HH

PS4 11003HH

PS4 7503HF

PS4 11003HF

190 mm (7½”)

CAUTION

a

wc_gr000335

Page 25

PS (3-Phase) Series Maintenance

wc_tx000132gb.fm 23

5. Maintenance

5.1 Periodic Maintenance Schedule

Pump

Monthly Every

3000

hrs.

Every

6000

hrs.

Every

2–5

years

Measure insulation resistance.

Reference insulation resistance =

1MW or greater. (1)

•

Measure operatin g current.

Compare with rated current.

•

Measure supply voltage. Compare with allowable

range (within ±5% of rated voltage).

•

Pump inspection. A noticeable drop in performance

may indicate wear in the impeller, etc., or else clogging of the strainer, etc. Remove the cl og ge d deb r is

and replace any worn parts.

•

Lubricant insp ection. •

Change lubricant. •

Designated lubricant: SAE 10W/20W. (2)

Change mechanical seal. (3) •

Overhaul. This should be carried out even if there

are no problems with the pump. The frequency

depends on how continuously the pump is in use. (4)

•

(1)

If the insulation resistance has become noticeably lower than the previous

inspection, an inspection of the motor will be necessary.

(2)

See Lubricant Inspection and Change in this section.

(3)

Specialized knowledge is required for inspecting and replacing the mechanical

seal. Consult with your nearest dealer or Wacker representative.

(4)

Consult with your nearest dealer or Wacker representative regarding overhauls.

Page 26

Maintenance PS (3-Phase) Series

wc_tx000132gb.fm 24

5.2 Maintenance and Inspection

Regular maintenance and inspections are a necessity for continued

efficient functioning of the pump. If any abnormal conditions are

noticed, refer to

Troubleshooting

section and take corrective m easures

immediately. It is recommended that a spare pump be kept ready in

case of any problems.

Prior to inspecting

Before inspecting the pump, make certain the power supply (circuit

breaker, etc.) is turned off. Then, unplug the cable assembly from the

receptacle or detach it from the terminals. Failure to follow this

precaution may result in a serious accident from electrical shock or

unexpected starting of the pump motor.

5.2.1 Washing the pump

Remove accumulated matter from the surface of the pump and wash

it with clean water. Take special care to remove any de bris from the

impeller.

5.2.2 Inspecting the pump exterior

Look for any peeling or chipped paint, and make sure the nuts and

bolts are fastened tigh tly. Any cracks in the surface should be re paired

by cleaning that area, drying it and then applying a touch-up coating.

Note:

Touch-up paint is not supplied. Note that some kinds of damage

or looseness may require that the unit be disassembled for repairs.

Please consul t with your nearest dealer or Wacker representa tive.

Storage

When the pump is out of use for an extended period, wash it and dry it

thoroughly, then store it indoors.

Note:

Always run a test operation before putting the pump back into

service.

If the pump is lef t in the wat er, it shou ld be run a minimum of once a

week.

WARNING

Page 27

PS (3-Phase) Series Maintenance

wc_tx000132gb.fm 25

Lubricant Inspection and Changing Procedures

• Inspection interval: Every 3,000 ho ur s o r 6 months, whichever co m es

first.

• Changing interval: Every 6,000 hours or 12 months, whichever comes

first.

• Des ignated lubrican t: Turbine oil VG32 (SAE 10W/20W).

• Lubricant capacity: Specified capacity (Refer to the table, “Specified

Lubricant Capacity”.)

Inspecting Lubricant

Remove the oil plug and take out a small am ount of oil. The oil can be

extracted easily by ti lting the pump so that the oi l plug faces downward.

If the oil appears discolored or intermixed with water, a likely cause is

a defective shaft-sealing device (i.e. mechanical seal), which requires

that the pump be disassembled and repaired.

See Graphic: wc_gr000336

Changing Lubricant

Remove the oil plug and drain the oil completely. Pour a specified

volume of oil into the oil filler inlet.

Note:

The drained oil must be disposed of by waste disposal

contractors in compliance with the laws of the locale where th e pump

is being used.

Ref. Description Ref. Description

1. Oil Inlet 3. Oil Plug

2. Gasket 4. Allen Wrench

wc_gr000336

Page 28

Maintenance PS (3-Phase) Series

wc_tx000132gb.fm 26

Note:

The gasket and the O-ring for the oil plug must be replaced with

a new part at each oil inspection and change

.

Replacement Parts

The table lists the parts that need to be replaced periodically. Replace

these using the recommended frequency as a guideline.

Model Specified Lubricant Capacity

PS2 1503

PS2 2203

PS3 1503

PS3 2203

740 ml (25.0 fl.oz.)

PS2 3703

PS4 3703

PS3 3703 960 ml (32.5 fl.oz.)

PS4 5503 PS3 5503 1100 ml (37.2 fl.oz.)

PS4 7503HH

PS4 11003HH

PS4 7503HF

PS4 11003HF

760 ml (25.7 fl.oz.)

Part Replacement Frequency

Mechanical seal Lubrication oil discolored

Lubricant (SAE 10W/20W) Every 6,000 hours or 12 mon ths, which ever co mes fi rst.

Gasket and O-ring Each time pump is disassembled or inspected.

Oil seal (1.5 to 5.5 kW)

[2 to 2.7 HP]

Each time pump is disassembled or inspected or if th e

sealing lip is worn

Ring-sealing (7.5/11 kW)

[10/15 HP]

When it becomes worn.

Sleeve (except 3.7/5.5 kW)

[5 / 7.5 HP]

When it becomes worn.

Page 29

PS (3-Phase) Series Maintenance

wc_tx000132gb.fm 27

5.3 Disassembly and Reassembly

Prior to Disassembling and Reassembling

Before disassembling and reassembling the pump, be sure that the

power supply (i.e. circuit breaker) is disconnected, and remove the

cable assembly from the term inal board. To prevent seri ous accidents,

DO NOT perform a conducting test during disassembly and

reassembly.

Be sure to perform a trial operation when starting the pump after a

reassembly. If the pump was assembled improperly, it may lead to

abnormal operation, electrical shock, or water damage.

This section explains the disassembly and reassembly processes that

are involved up to the casing (or oil casing, in the case of 7.5 kW and

11 kW [10/15 HP] models). Refer to the structural drawing for the

respective model before disassembling. Operations involving the

disassembly and reassembly of the sealing portion (i.e. mechanical

seal) and of the motor require a sp ecialized facility including vacuum

and electrical equ ipment. For these oper ations, contact the de aler from

whom you purchased the equipment, or the Wacke r sales office in your

area.

WARNING

CAUTION

Page 30

Maintenance PS (3-Phase) Series

wc_tx000132gb.fm 28

1

2

3

4

5

AA

CC

8

9

10

BB

DD

11

12

13

14

15

16

17

18

19

20

21

22

23

24

wc_gr000337

Page 31

PS (3-Phase) Series Maintenance

wc_tx000132gb.fm 29

Parts List

See Graphic: wc_gr000337

Disassembly Procedur e for 2 HP, 3 HP, 5 HP and 7.5 HP

Note:

Before disassembling, be sure to drain the lubricant from the

pump.

The breakdown of pump shown is based on the construction of 2 HP

model PS 2 (3) 1503. However, 3 HP, 5 HP, and 7.5 HP PS threephase models have the same construction as PS 2 1503 and PS 3

1503, except that the sle eve (12) will not be applied to the 5 HP and

7.5 HP models.

5.3.1 Removin g the strainer (22):

Remove the nut (24) and the washer (23) from the botto m and remove

the strainer (22) from the pump.

5.3.2 Removin g the suction cover:

Remove the bo lt and the nut (exce pt 2 HP / 3 HP), was her (20), an d

the stud bolt (21), and remove the suction cover (19), from the pump.

5.3.3 Removing the impeller (14):

An impeller puller is available from manufacturer.

Using a box wrench, remove the acorn nut (17), lockwasher (16), and

thread cover (15); then remove the impeller (14), sleeve (12) (except 5

HP / 7.5 HP) from the main shaft.

Ref. Description Ref. Description

1. Bolt 12. Sleeve

2. Lock washer 13. Shim

3. Gasket 14. Impeller

4. Oil pl ug 15. Thread cover

5. Mechanical seal 16. Lock washer

AA Screw 17. Acorn nut

BB Oil Lifter 18. Gasket

CC Screw 19. Suction cover

DD Retaining plate 20. Lock washer

8. O-Ring 21. Stud bolt

9. Gasket 22. Strainer

10. Volute 23. Washer

11. Oil seal 24. Nut

Page 32

Maintenance PS (3-Phase) Series

wc_tx000132gb.fm 30

A worn impeller may have sharp edges that can cause injury, and

should be handled with care.

5.3.4 If necessary, remove the volute (10) and remove the mechanical seal

(5).

After removing the bolt (1) and the lockwasher (2), remove the vo lute

(10) from the pump. At this time, be careful not to damage the sliding

surface of th e mechanical seal (5). Remove the mechanical seal (5)

from the main shaft.

Note:

Also refer to the “Mechanical Seal Handling Procedure” that

comes with the mechanical seal sold separately as a spare part.

See Graphic: wc_gr000337

Reassembly Procedure

5.3.5 The reassembly procedure is the reverse sequence of disassembly.

Note:

After completing reassembly, do not forget to pour the specified

amount of lubricant into the pump.

Note:

The gaskets and O-ring s must be replace d with n ew parts. Also

replace any parts that are worn or damaged.

5.3.6 Using a clean rag without lubricant, wipe the sliding surface of the

mechanical seal (5). Apply lubricant to the outer circumference of the

cushion rubber to facilitate insertion.

Note:

For further details on how to install the mechanical seal (5), refer

to the “Mechanical Seal Handling Procedure” that comes with the

mechanical seal (5) that is sold separately as a spare part.

5.3.7 After installing the impeller (14), and after completing the reassembly,

check that the impeller (14) rotates smoothly and that it does n ot come

in contact with the suction cover (1 9) .

5.3.8 To make sure that the pump operates normally, perform a trial

operation before placing the pump back into service.

CAUTION

Page 33

PS (3-Phase) Series Maintenance

wc_tx000132gb.fm 31

wc_gr000338

1

2

3

10

8

9

BB

DD

AA

CC

11

6

7

12

13

15

16

17

14

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

Page 34

Maintenance PS (3-Phase) Series

wc_tx000132gb.fm 32

Parts List

See Graphic: wc_gr000338

Disassembly Procedure for 10 HP and 15 HP

Note:

Before disa ssembling, be sure to dr ain the lubricant from the

pump.

The breakdown of pum p show n is ba sed on th e co nstruction of 10 HP

model PS4 7503HH/HF.

5.3.9 Removing the plate (31) and the strainer (30):

After removing the nut (33) and the washer (32) from the bottom,

remove the plate (31) and the strainer (30) from the pump.

5.3.10 Removing the suction cover (25):

After removing the bolt (27), washer (26), stud bolt (29), and the

lockwasher (28), remove the suction cover (25) from the pump.

Ref. Description Ref. Description

1. Bolt 17. O-Ring

2. Lock washer 18. Sealing ring

3. Mechanical seal 19. Shim

AA Screw 20. Impeller

BB Oil Lifter 21. Thread cover

CC Screw 22. Nut

DD Retaining plate 23. Acorn nut

6. O-Ring 24. Gasket

7. Gasket 25. Suction cover

8. Oil casing 26. Lock washer

9. Gasket 27. Bolt

10. Oil plug 28. Lock washer

11. Lock washer 29. Stud bolt

12. Bolt 30. Strainer

13. Sleeve 31. Plate

14. Volute 32. Lock washer

15. Lock washer 33. Nut

16. Bolt

Page 35

PS (3-Phase) Series Maintenance

wc_tx000132gb.fm 33

5.3.11 Removing the impeller (20):

Using a box wrench, remove the acorn nut (23), nut (22), and the

thread cover (21); then remove the impeller (20) and the sleeve (13)

from the main shaft.

A worn impeller may have sharp edges that can cause injury, and

should be handled with care.

5.3.12 Removing the volute (14):

After removing the bolt (16) and the lockwasher (15), remove the

volute (14) from the pump.

5.3.13 Remove the oil casing (8) if necessary, and remove the mechanical

seal (3). After removing the bolt (12) and the lockwasher (11), remove

the oil casing (8) from the pump . At this time, be careful no t to damage

the sliding surf ace of the mechan ical seal (3). Remove the mechanical

seal (3) from the main shaft.

Note:

Also refer to the “Mechanical Seal Handling Procedure” that

comes with the mechanical seal that is sold sep arately as a spare part.

See Graphic: wc_gr000338

Reassembly Procedure

5.3.14 The reassembly procedure is the reverse sequence of disassembly.

Note:

After completing reassembly, do not forg et to pour the specified

amount of lubricant into the pump.

Note:

The gaskets and O-rings must be replaced with new parts. Also

replace any parts that are worn or damaged.

5.3.15 Using a clean rag without lubricant, wipe the sliding surface of the

mechanical seal (3). Apply lubricant to the outer circumference of the

cushion rubber to facilitate inser tion.

Note:

For further details on how to install the mechanical seal (3), refer

to the “Mechanical Seal Handling Procedure” that comes with the

mechanical seal (3) that is sold separately as a spare part.

5.3.16 After installing the impeller (20), and after completing the reassembly,

check that the impeller (20) rotates smoothly and that it does not come

in contact with the suction cover (25).

5.3.17 To make sure that the pump operates normally, perform a trial

operation before placing the pump back into service.

WARNING

Page 36

Maintenance PS (3-Phase) Series

wc_tx000132gb.fm 34

5.4 Troubleshooting

Before ordering repairs, carefully read through this manual, then

repeat the inspection. If the problem remains, contact your nearest

dealer or Wacker representative.

ALWAYS turn off the power before inspecting the pump. Failure to

observe this precaution can result in serious accident.

Problem / Symptom Reason / Remedy

Pump fails to start. • No power is supplied (i.e. power outage). Contact

the electric power compa ny or an electri cal repair

shop.

• Open circuit or poor connection of the cable assembly. Check if there is an open circuit in the cable

assembly or wiring.

• Impeller is obstructed. Inspect the pum p and remove

the obstruction.

Pump starts but stops immediately, causing the motor protector to actuate.

• Impeller is obstructed. Inspect the pum p and remove

the obstruction.

• Voltage drop. Correct the voltage to the rated voltage, or use an extension cable that meets the standard.

• A 50 Hz model is operated at 60 Hz. Check the

nameplate and replace the pump or the impeller.

• The strainer is obstructed, and the pump was operated dry for long periods. Remove the obstruction.

• Motor abnormal. Repair the motor or replace with a

new motor.

• The pump is picking up too much sediment. Place a

concrete block under the pump to prevent the pump

from picking up sediment.

WARNING

Page 37

PS (3-Phase) Series Maintenance

wc_tx000132gb.fm 35

The pump's head an d pumping volume is decreased.

• The im peller is worn. Replace.

• The hose may be kinked or clogged. Minimize the

number of bends in the ho se. (In an area with a lar ge

amount of debris, use the pump in a meshed enclosure.)

• The strainer is obstructed or buried. Remove the

obstruction. Place a concrete block under the pump

to prevent the pump from picking up debris.

• The motor rotates in reverse. Interchange the power

supply terminal leads.

The pump generates noise or

vibration.

• The bearing of the motor may be damaged. To

replace the bearing, contact the dealer from whom

you purchased the equipment, or the Wacker sales

office in your area.

Problem / Symptom Reason / Remedy

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Wacker Construction Equipment AG · Preußenstraße 41 · D-80809 München · Tel.: +49-(0)89-354 02 - 0 · Fax: +49 - (0)89-354 02-390

Wacker Corporation · P.O. Box 9007 · Menomonee Falls, WI 53052-9007 · Tel. : +1-(1)(262) 255-0500 · Fax: +1-(1)(262) 255-0550 · Tel. : (800) 770-0957

Wacker Asia Pacific Operations · Sunley Center, Unit 912, 9/F · 9 Wing Qin Street, Kwai Chung, N.T. · Hong Kong · Tel. + 852 2406 60 32 · Fax: + 852 2406 60 21

Loading...

Loading...