Page 1

Laser Level

Nivel láser

Niveau électronique

PAL 450

OPERATOR’S MANUAL

Manual de Operación

Notice d’Emploi

www.wackerneuson.com

0171957 003

0509

0171957

Page 2

Page 3

PAL 450 Table of Contents

wc_bo0171957q4_003TOC.fm 3

Foreword EN-5

1. Safety Information EN-7

1.1 Operating Safety ............................................................................ EN-8

1.2 Service Safety ................................................................................ EN-8

1.3 Label Locations .............................................................................. EN-9

1.4 Safety and Operating Labels .......................................................... EN-9

2. Operation EN-10

2.1 Application .................................................................................... EN-10

2.2 Calibration .................................................................................... EN-10

2.3 Setup and Operation Locations .................................................... EN-10

2.4 Using the Laser ............................................................................ EN-11

2.5 Laser Detector .............................................................................. EN-12

2.6 Other Accessories ........................................................................ EN-14

3. Maintenance EN-15

3.1 Calibration overview ..................................................................... EN-15

3.2 Checking Calibration .................................................................... EN-15

3.3 Calibration Adjustment ................................................................. EN-16

3.4 Battery Pack ................................................................................. EN-17

3.5 Care and Handling ....................................................................... EN-19

4. Troubleshooting EN-19

5. Technical Data EN-20

5.1 PAL 450 Laser Level .................................................................... EN-20

5.2 Laser Detector .............................................................................. EN-21

Page 4

Page 5

Foreword

wc_tx001230gb.fm EN-5

Foreword

This manual provides information and procedures to safely operate

and maintain this Wacker Neuson model. For your own safety and

protection from injury, carefully read, understand and observe the

safety instructions described in this manual.

Keep this manual or a copy of it with the machine. If you lose this

manual or need an additional copy, please contact Wacker Neuson

Corporation. This machine is built with user safety in mind; however,

it can present hazards if improperly operated and serviced. Follow

operating instructions carefully! If you have questions about operating

or servicing this equipment, please contact Wacker Neuson

Corporation.

The information contained in this manual was based on machines in

production at the time of publication. Wacker Neuson Corporation

reserves the right to change any portion of this information without

notice.

All rights, especially copying and distribution rights, are reserved.

Copyright 2009 by Wacker Neuson Corporation.

No part of this publication may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without

express written permission from Wacker Neuson Corporation.

Any type of reproduction or distribution not authorized by Wacker

Neuson Corporation represents an infringement of valid copyrights

and will be prosecuted. We expressly reserve the right to make

technical modifications, even without due notice, which aim at

improving our machines or their safety standards.

Page 6

Foreword

wc_tx001230gb.fm EN-6

Page 7

PAL 450 Safety Information

wc_si000243gb.fm EN-7

1 Safety Information

This manual contains DANGER, WARNING, CAUTION, NOTICE, and

NOTE callouts which must be followed to reduce the possibility of

personal injury, damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

NOTICE: Used without the safety alert symbol, NOTICE indicates a

situation which, if not avoided, could result in property damage.

Note: Contains additional information important to a procedure.

DANGER

WARNING

CAUTION

Page 8

PAL 450 Safety Information

wc_si000243gb.fm EN-8

1.1 Operating Safety

1.1.1 Read, understand, and follow procedures in the Operator’s Manual

before attempting to operate the machine.

1.1.2 Store the machine properly when it is not being used. The machine

should be stored in a clean, dry location out of the reach of children.

1.1.3 Always operate the machine with all safety devices and guards in

place and in working order.

1.1.4

1.2 Service Safety

A poorly maintained machine can become a safety hazard! In order

for the machine to operate safely and properly over a long period of

time, periodic maintenance and occasional repairs are necessary.

1.2.1 All adjustments and repairs MUST be completed before operation. Do

not operate the machine with a known problem or deficiency! All

repairs and adjustments should be completed by a qualified

technician.

1.2.2 Do not modify the machine without the express written approval of the

manufacturer.

1.2.3 Keep the machine clean and labels legible. Replace all missing and

hard-to-read labels. Labels provide important operating instructions

and warn of dangers and hazards.

1.2.4 ALWAYS do periodic maintenance as recommended in the Operator’s

Manual.

WARNING

Page 9

PAL 450 Safety Information

wc_si000243gb.fm EN-9

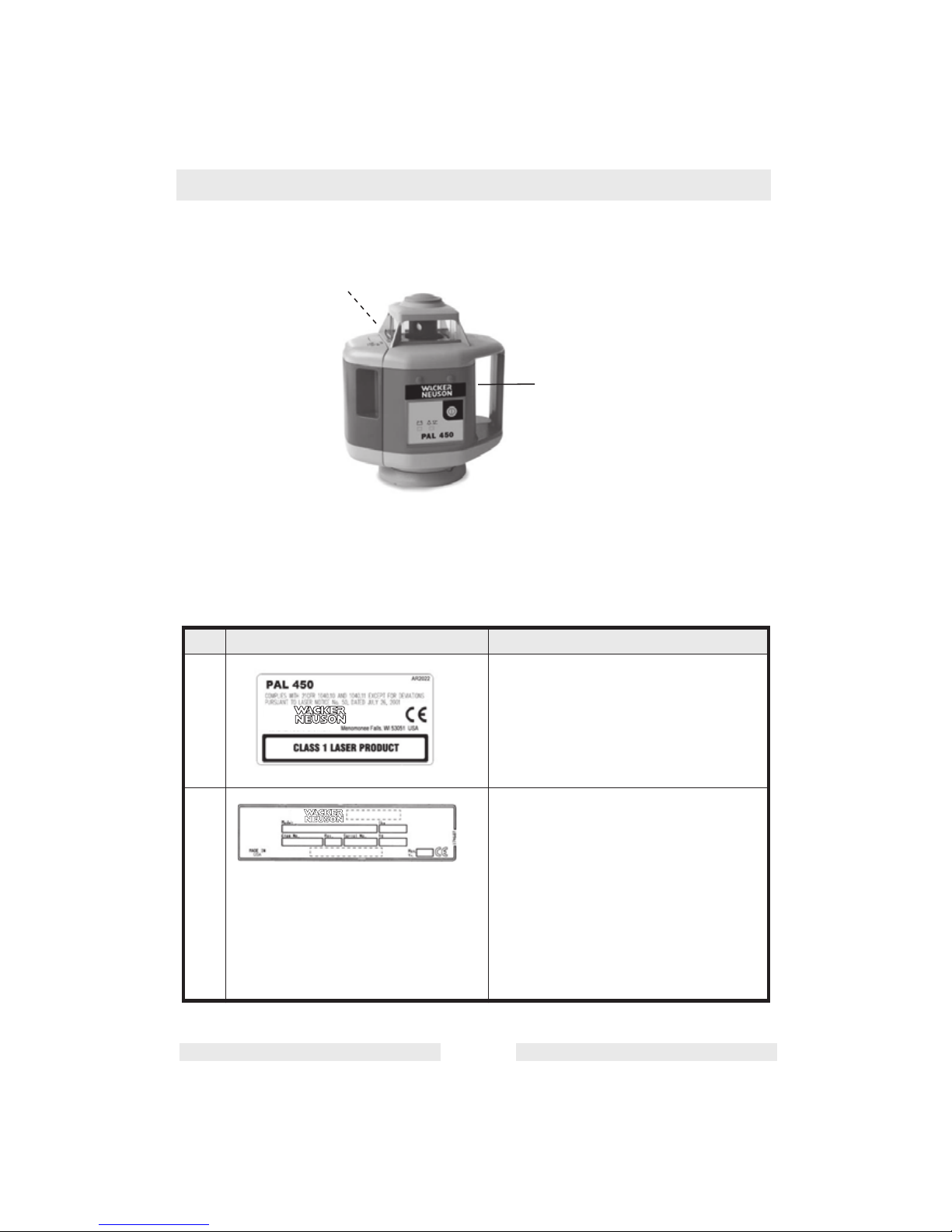

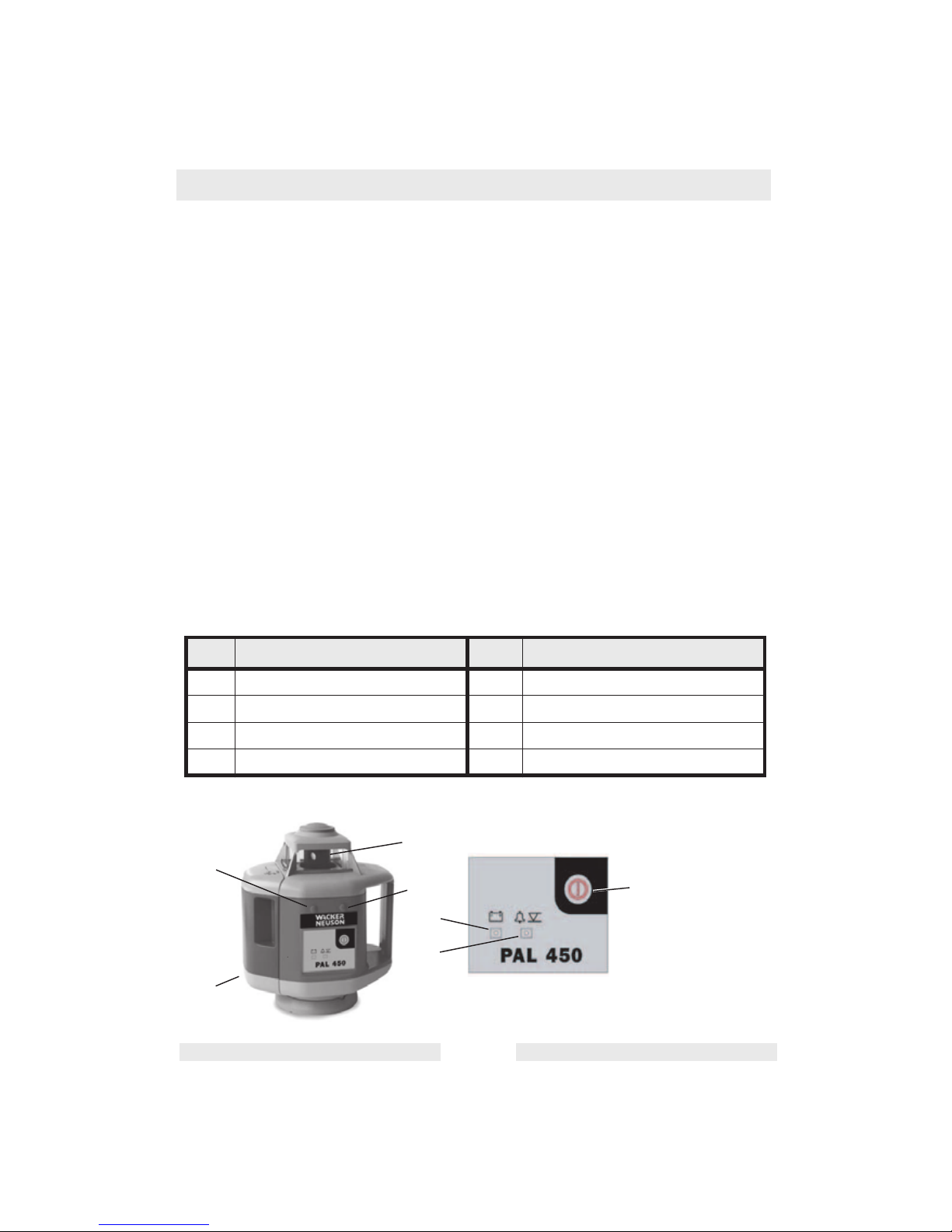

1.3 Label Locations

1.4 Safety and Operating Labels

Ref. Label Meaning

A The PAL 450 is a Class 1 laser product,

manufactured to comply with the rules of

the Code of Federal Regulations 1040.10

and 1040.11, except for deviations

pursuant to Laser Notice No. 50, dated

July 26, 2001.

B A nameplate listing the model number,

item number, revision number, and serial

number is attached to each unit. Please

record the information found on this plate

so it will be available should the

nameplate become lost or damaged.

When ordering parts or requesting

service information, you will always be

asked to specify the model number, item

number, revision number, and serial

number of the unit.

A

B

wc_gr004606

WACKER NEUSON CORPORATION

Page 10

PAL 450 Operation

wc_tx000804gb.fm EN-10

2 Operation

2.1 Application

This Wacker Neuson laser transmitter is simple to use, yet it has

several advanced features:

• Automatic self-leveling in horizontal

• High precision

• Ideal for screeding, general construction, site preparation, and

other leveling applications

2.2 Calibration

It is important to check your laser for proper calibration. The laser is a precision instrument and it is important that you keep it calibrated and in proper

condition. The accuracy of your work is completely your responsibility and you

should check your instrument before beginning each job, and especially after

the instrument has taken a sharp jolt or been dropped, or when temperature

changes greater than 50 degrees F (28 degrees C) have occurred. See “Maintenance” for calibration procedures.

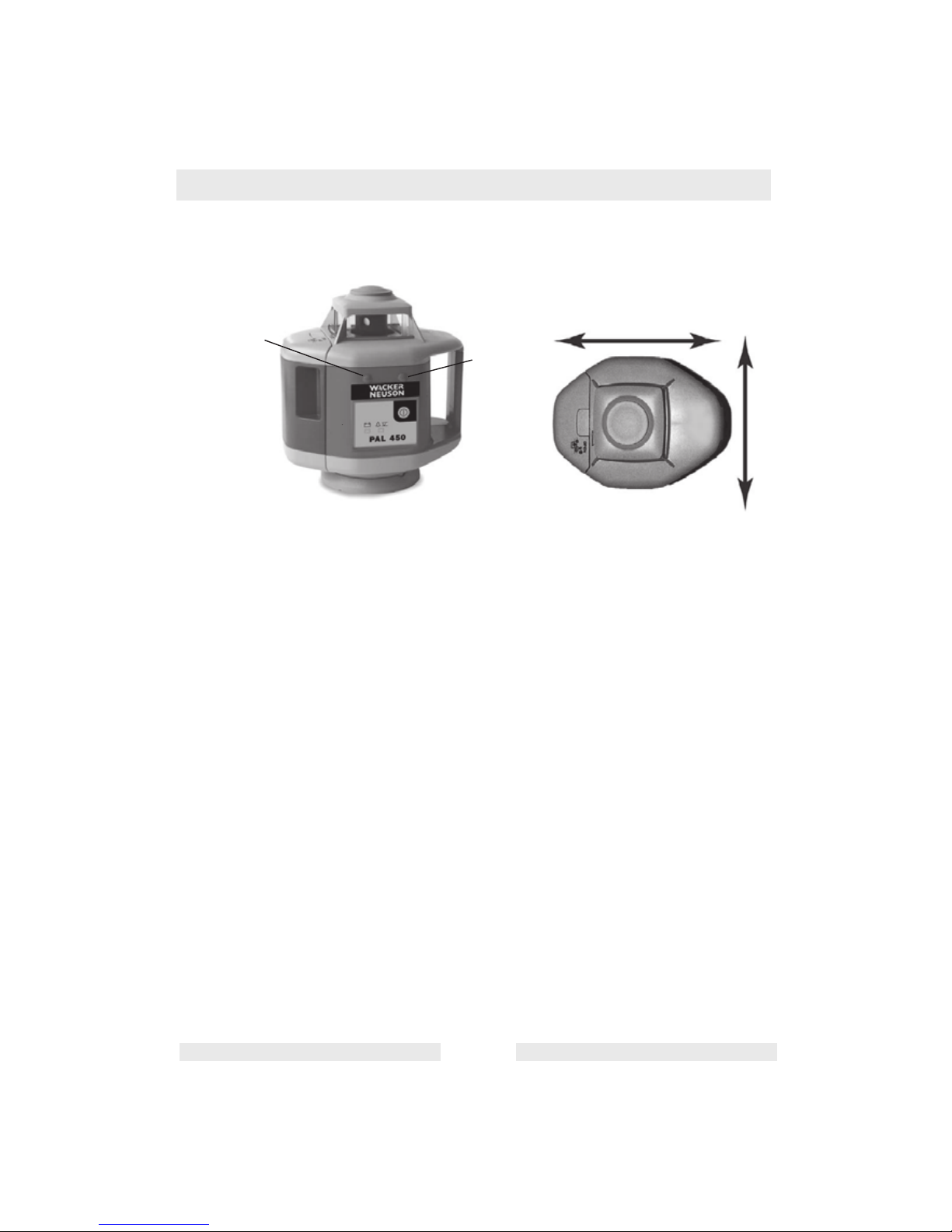

2.3 Setup and Operation Locations

Ref. Description Ref. Description

1 Rotating head 5 Level indicator

2 X-axis calibration port 6 Battery indicator

3 Y-axis calibration port 7 Battery pack

4 On / Off switch

2

3

7

1

6

5

wc_gr004579

4

Page 11

PAL 450 Operation

wc_tx000804gb.fm EN-11

2.4 Using the Laser

See Graphic: wc_gr004579

Setup:

The laser mounts to any 5/8" x 11 tripod (flathead or domed) or can

rest on any stable flat surface (floor, bricks, etc.). Position the tripod,

attach the laser, then adjust the tripod until it is rough leveled (within ±

4° self-leveling range).

Turning on the Laser:

Press the ON / OFF key (4) to power up the laser. The unit's selfchecking system will start automatically. Both LEDs (5 and 6) will flash

if anything goes wrong during the self-check procedure. The battery

LED should be green. If batteries are low, the battery LED will be red

or both LEDs will flash.

Leveling:

When the laser is turned on, the level indicator LED (5) will flash red

until the unit is level. If the laser fails to self-level within 90 seconds, the

LED will light and remain lit. Re-adjust the tripod to bring the laser into

self-leveling range. When the unit is level, the rotor head will begin

spinning at 600 rpm.

Level Alert:

If laser is disturbed, the level alert system will stop head rotation. The

laser will self-level and return to operation automatically unless it is

disturbed again while in the self-leveling range (± 4°). Always recheck

the beam height against a benchmark when releveling is required.

Power Sources:

The laser can be operated with the alkaline battery pack (4 D-size

batteries) or the optional NiCd rechargeable battery pack. If using a

NiCd battery pack, charge it completely before flrst use. The NiCd

battery pack can also be charged while working. If electricity is

available on the job site, simply plug in the charger and keep working.

Page 12

PAL 450 Operation

wc_tx000804gb.fm EN-12

2.5 Laser Detector

Your laser transmitter is provided with a laser detector to be used with

a grade rod or handheld applications.

See graphic: wc_gr004586

Ref. Description Ref. Description

1 Level vial 8 ON / OFF

2 LCD screen (front) 9 Turn to attach clamp to detector

3 Detection window 10 Turn to tighten or remove clamp

from grade rod

4 Rod clamp 11 9V battery compartment

(Follow polarity indications inside)

5 On-grade alignment notch 12 Bubble vial to plumb rod

6 Choice of sound level 13 LCD screen (rear)

7 Choice of accuracy

Page 13

PAL 450 Operation

wc_tx000804gb.fm EN-13

wc_gr004586

1

2

3

4

5

6

7

8

9

10

13

12

11

LCD Display

Page 14

PAL 450 Operation

wc_tx000804gb.fm EN-14

See graphic: wc_gr004586 and wc_gr004588

Using the detector:

2.5.1 Press the ON / OFF key (8) to turn on the detector.

2.5.2 Press the middle key (7) to select the accuracy (deadband).

2.5.3 Press the top key (6) to select the sound level.

2.5.4 Turn the detection window (3) towards the laser beam, and move the

detector up or down according to the information given on the LCD

screen (2). There are five channels of information, or grade indicators.

2.5.5 A down arrow indicates that you must move the detector down to reach

the laser reference; and up arrow indicates that you must move it up.

When a horizontal line appears on the display, the detector is at the

same level as the laser beam.

2.5.6 Press the ON / OFF key to turn the detector off. It will automatically

sound a warning beep and shut off after 10 minutes if not used.

2.5.7 Keep the detection window clean, using a soft cloth and glass cleaner.

2.6 Other Accessories

Contact your Wacker Neuson dealer for information about available

accessories.

Page 15

Maintenance PAL 450

wc_tx000807gb.fm EN-15

3 Maintenance

3.1 Calibration overview

THIS SECTION IS VERY IMPORTANT: Here are a few simple

instructions to check your laser for calibration. The laser is a precision

instrument and it is important that you keep it calibrated and in proper

condition. The accuracy of your work is completely your responsibility

and you should check your instrument before beginning each job, and

especially after the instrument has taken a sharp jolt or been dropped,

or when temperature changes greater than 28°C (50°F) have

occurred.

Calibration should be checked regularly. For convenience, you should

establish a range for routine and quick checks. Your Wacker Neuson

dealer can assist you in setting up this range. Allow at least 15 minutes

for the laser to warm up before checking or adjusting calibration.

3.2 Checking Calibration

3.2.1 Select a level range at least 100 ft. (30 m) long. Set up the laser on a

flat surface or tripod. Approximately 100 ft. (30 m) away, erect a

vertical pole or rod.

3.2.2 Position the laser so one axis is aligned toward pole at end of the

range.

3.2.3 Turn the laser on and allow it to self-level.

3.2.4 Using a detector, mark the elevation of the beam at the pole. This is

mark “A.”

3.2.5 Rotate the laser 180° so the axis is again aligned with the pole, but in

the opposite direction. Use the detector again to mark the elevation of

the beam at the pole. This is mark “B.”

3.2.6 If marks A and B are within 1/8" (2.5 mm), calibration is correct.

3.2.7 Repeat the above procedure for the other axis. If marks are more than

1/8” (2.5 mm) apart, proceed to “Calibration Adjustment.”

Page 16

PAL 450 Maintenance

wc_tx000807gb.fm EN-16

3.3 Calibration Adjustment

See graphics: wc_gr004603 and wc_gr004604

3.3.1 Make new “A” and “B” marks as directed in “Checking Calibration.”

Make a third mark halfway between the new A and B. Call this mark

“C.” This is the correct beam center.

3.3.2 The calibration port for each axis is located on the top front of the laser.

Choose the X axis port (2) or the Y axis port (3) as necessary. Open

only one cover at a time to avoid adjusting the wrong axis.

3.3.3 Using a small screwdriver, carefully turn the exposed calibration port

adjustment screw left or right until the beam is centered at mark C.

Make adjustments in small, careful increments. After each adjustment,

check beam movement at the pole.

3.3.4 Double check the axis. Rotate the laser 180° and again check the

beam. The beam should now strike within 1/16" (1.5 mm) of mark C. If

not, repeat steps 1–3, adjusting as needed until the axis is calibrated.

3.3.5 Check and adjust the calibration of the other axis. Calibration is

complete when mark C is the same for both axes in both directions.

2

3

wc_gr004604

wc_gr004603

FRONT

X Axis

Top View

Y Axis

Page 17

Maintenance PAL 450

wc_tx000807gb.fm EN-17

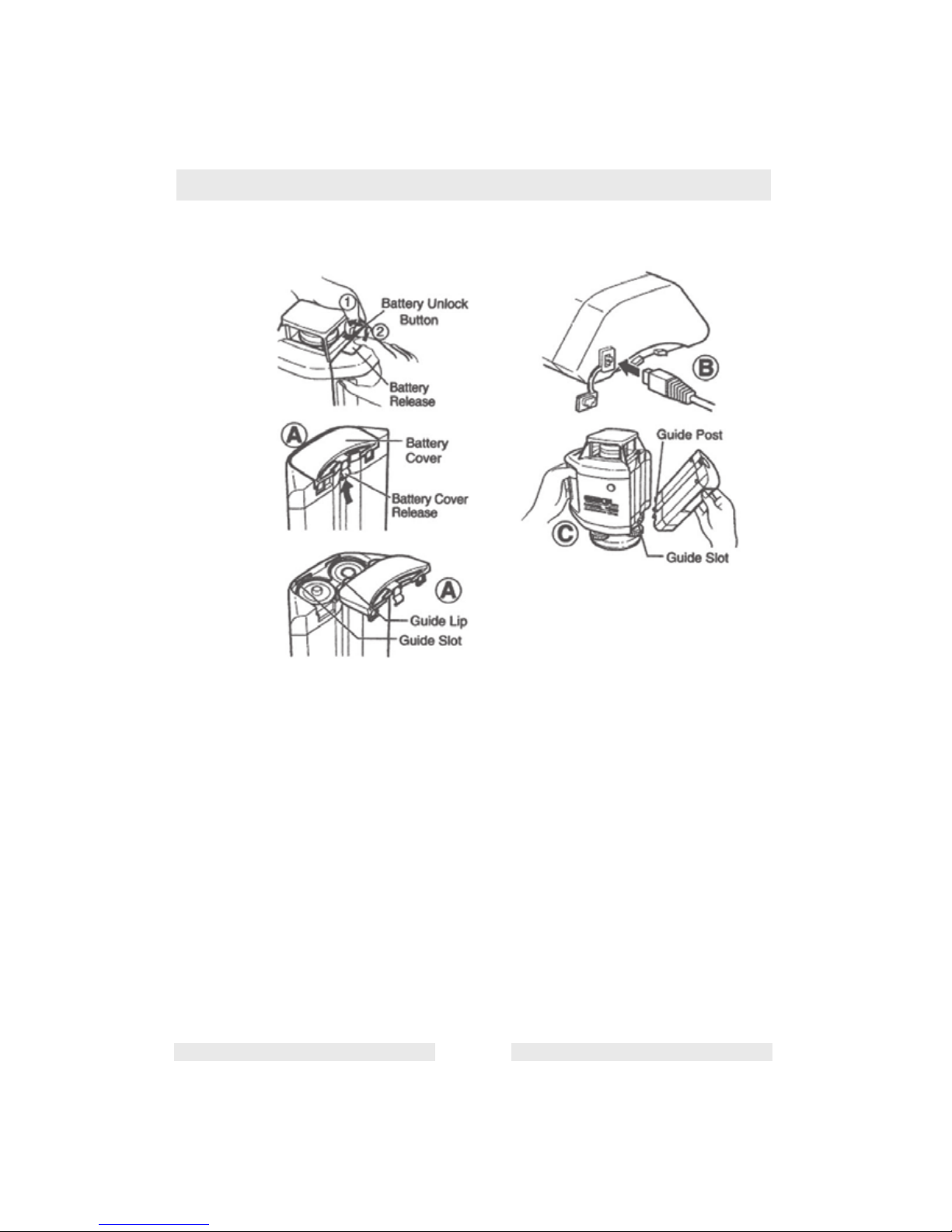

3.4 Battery Pack

See graphic: wc_gr004602

To replace the alkaline batteries, or to charge the NiCd pack, first

remove the battery pack. The NiCd pack must be charged before first

use.

Removing the Battery Pack

3.4.1 Press the battery unlock button -- see (1) in the graphic above.

3.4.2 Supporting the battery, press the battery release (2) to remove it.

A) Battery Replacement

3.4.1 Raise the battery cover release to remove the battery cover.

3.4.2 Insert 4 D batteries. The insertion direction of the batteries is indicated

on the battery pack.

3.4.3 Attach the battery cover, inserting the guide lips into the guide slots.

B) Recharging (optional NiCd pack)

3.4.1 Remove the charging connector cap on the battery pack and plug in

the charger.

3.4.2 Plug the charger into an electrical outlet. A red light on the charger

indicates that it is charging.

wc_gr004602

Page 18

PAL 450 Maintenance

wc_tx000807gb.fm EN-18

3.4.3 When the red light blinks (lights on for 6 seconds, off for 20 seconds),

the charging is finished. Charging time is about 7.5 hours. The unit can

be charged while working. For optimum life of the battery, recharge the

battery after it is fully discharged. To assure battery life, do not charge

over 20 hours.

C) Installing the Battery Pack

3.4.1 Fit the guide posts of the battery into the guide slots of the laser.

3.4.2 Attach the battery to the laser by pressing the top of the battery against

the laser until a click is heard.

Page 19

Troubleshooting PAL 450

wc_tx000807gb.fm EN-19

3.5 Care and Handling

The use of controls or adjustments or performance of procedures other

than those specified herein may result in hazardous radiation

exposure.

3.5.1 The laser is a precision instrument which must be handled with care.

Avoid shock and vibrations. Always store and transport the laser and

its accessories in the carrying case.

3.5.2 Although the laser is weather resistant, make sure to clean and dry it

with a soft cloth after each use. This will increase the battery life.

3.5.3 Do not store your laser at temperatures below -4°F (-20°C) or above

176°F (80°C) because some electronic components could be

damaged.

3.5.4 To avoid water condensation inside the instrument, do not store it

inside the case if the instrument or the case is wet.

3.5.5 To maintain the laser’s precision, check and calibrate the beam

regularly.

3.5.6 Keep the glass housing around the rotating head dry and clean. Use a

soft cloth and glass cleaner to clean it.

3.5.7 Charge the batteries regularly. However, charge them only when they

are nearly drained or completely out of power. Recharging batteries

that are still usable will shorten their capacity.

4. Troubleshooting

For laser repair, calibration, or warranty repair, please contact

EQUIPRO at 1-866-378-4776.

CAUTION

Page 20

PAL 450 Technical Data

wc_td000246gb.fm EN-20

5 Technical Data

5.1 PAL 450 Laser Level

Part No.

PAL 450

0620408

Laser Level

Operating range

m (ft)

450 (1500)

diameter

Self-leveling range ± 4° (± 7%)

Accuracy Better than ± 1/16-inch @ 100 feet

(± 4 mm / 100 m)

± 8 arc seconds

Rotation speed

rpm

600

Beam type / output Infrared diode; 785 nm; 1.0 mW,

Class 1

Power sources (1) 4 “D” size alkaline battery pack

(2) Optional NiCd rechargeable bat-

tery pack

(3) AC charger with optional NiCd

battery pack

Battery life

hours

Approximately 100 (alkaline)

40 (NiCd)

Mounting base 5/8-inch x 11 flat or domed

Environmental Water resistant, IP55

Operating temperature

C (F)

–10° to 50° (14° to 122°)

Storage temperature

C (F)

–20° to 60° (–4° to 140°)

Dimensions and weight

cm (in)

kg (lbs.)

20 x 16 x 15 (8 x 6.5 x 6)

2.3 (5)

Page 21

Technical Data PAL 450

wc_td000246gb.fm EN-21

5.2 Laser Detector

Part No.

Laser Detector

0147101

Laser Detector

Range

m (ft.)

225 (750)

Accuracy

mm (in.)

Fine: ± 1 (1/16)

Standard: ± 2.5 (1/8)

Grade indication LCD and audible tones

Battery life

hours

50

Power source 9V alkaline

Environmental Waterproof (IP 66+)

Dimensions and weight

cm (in.)

kg (lbs.)

15 x 8 x 3.5 (6 x 3.25 x 1.5)

0.2 (0.35)

Page 22

Page 23

PAL 450 Tabla de materias

wc_bo0171957es_001TOC.fm ES-1

Prefacio ES-2

1. Información sobre la seguridad ES-3

1.1 Seguridad en la operación ............................................................. ES-4

1.2 Seguridad en el mantenimiento ...................................................... ES-4

1.3 Ubicación de las calcomanías ........................................................ ES-5

1.4 Calcomanías de seguridad y operación ......................................... ES-5

2. Operación ES-6

2.1 Aplicación ....................................................................................... ES-6

2.2 Calibración ..................................................................................... ES-6

2.3 Configuración y ubicaciones de operación ..................................... ES-6

2.4 Uso del láser .................................................................................. ES-7

2.5 Detector de láser ............................................................................ ES-8

2.6 Otros accesorios .......................................................................... ES-10

3. Mantenimiento ES-11

3.1 Generalidades sobre la calibración .............................................. ES-11

3.2 Revisión de la calibración ............................................................. ES-11

3.3 Ajuste de la calibración ................................................................ ES-12

3.4 Paquete de pilas ........................................................................... ES-13

3.5 Cuidado y manipulación ............................................................... ES-15

3.6 Localización de problemas ........................................................... ES-15

4. Datos técnicos ES-17

4.1 Nivel a láser PAL 450 ................................................................... ES-17

4.2 Detector de láser .......................................................................... ES-18

Page 24

wc_tx001230es.fm ES-2

Prefacio

El presente manual proporciona información y procedimientos para

operar y mantener en forma segura este modelo de Wacker Neuson.

Para su propia seguridad y protección contra lesiones, lea, comprenda

y acate cuidadosamente las instrucciones de seguridad descritas en

este manual.

Mantenga este manual o una copia con la máquina. Si extravía este

manual o necesita una copia adicional, comuníquese con Wacker

Neuson Corporation. Esta máquina está construida teniendo en mente

la seguridad del usuario; sin embargo, puede presentar riesgos si se

opera o se le da servicio incorrectamente. ¡Siga cuidadosamente las

instrucciones de operación! Si tiene consultas acerca de la operación

o servicio de este equipo, comuníquese con Wacker Neuson

Corporation.

La información contenida en este manual se basa en las máquinas

que están en producción al momento de la publicación. Wacker

Neuson Corporation se reserva el derecho de cambiar cualquier parte

de esta información sin previo aviso.

Se reservan todos los derechos, especialmente de copia y

distribución.

Copyright 2009 de Wacker Neuson Corporation.

Ninguna parte de esta publicación se puede reproducir en modo

alguno, ni por ningún medio, ya sea electrónico o mecánico,

incluyendo fotocopia, sin la autorización expresada por escrito de

Wacker Neuson Corporation.

Todo tipo de reproducción o distribución no autorizada por Wacker

Neuson Corporation infringe los derechos de autor válidos y será

penado por la ley. La empresa se reserva expresamente el derecho de

efectuar modificaciones técnicas (incluso sin previo aviso) con el

objeto de perfeccionar nuestras máquinas o sus normas de seguridad.

Page 25

Información sobre la seguridad PAL 450

wc_si000243es.fm ES-3

1. Información sobre la seguridad

Este manual contiene notas de PELIGRO, ADVERTENCIA,

PRECAUCIÓN, AVISO y NOTA, las cuales precisan ser seguidas

para reducir la posibilidad de lesión corporal, daño a los equipos o

servicio incorrecto.

Este es el símbolo de alerta de seguridad. Se emplea para avisarle de

peligros potenciales de lesión corporal. Obedezca todos los mensajes

de seguridad a continuación de este símbolo para evitar posibles

daños corporales o la muerte.

PELIGRO indica una situación de riesgo que, si no se evita, causará

la muerte o lesión grave.

ADVERTENCIA indica una situación de riesgo que, si no se evita,

puede causar la muerte o lesión grave.

PRECAUCIÓN indica una situación de riesgo que, si no se evita,

puede causar lesión de grado menor o moderado.

AVISO: al usarse sin el símbolo de alerta de seguridad, AVISO indica

una situación de riesgo que, si no se evita, puede causar daños a

la propiedad.

Nota: Contiene información adicional importante para un

procedimiento.

PELIGRO

ADVERTENCIA

PRECAUCIÓN

Page 26

PAL 450 Información sobre la seguridad

wc_si000243es.fm ES-4

1.1 Seguridad en la operación

1.1.1 SIEMPRE lea, entienda y siga los procedimientos en el Manual de

operación, antes de intentar operar la máquina.

1.1.2 SIEMPRE almacene la máquina de manera adecuada cuando no la

utilice. La máquina deberá almacenarse en un lugar limpio y seco que

esté fuera del alcance de los niños.

1.1.3 SIEMPRE opere la máquina con todos los dispositivos de seguridad y

de protección colocados y en funcionamiento.

1.2 Seguridad en el mantenimiento

¡Las máquinas con mantenimiento deficiente pueden presentar un

riesgo para la seguridad! A fin de que la máquina funcione en forma

segura y adecuada durante un largo período, es necesario realizar un

mantenimiento periódico y reparaciones ocasionales.

1.2.1 DEBEN realizarse todos los ajustes y las reparaciones antes de la

operación. ¡NUNCA opere la máquina a sabiendas de que hay un

problema o una deficiencia! Un técnico calificado deberá realizar todas

las reparaciones y los ajustes.

1.2.2 NO modifique la máquina sin la expresa aprobación por escrito del

fabricante.

1.2.3 SIEMPRE mantenga la máquina en condiciones de limpieza y las

calcomanías legibles. Vuelva a colocar todas las calcomanías

faltantes y cambie las que sean difíciles de leer. Las calcomanías

proporcionan instrucciones de operación importantes y advierten

sobre peligros y riesgos.

1.2.4 SIEMPRE realice el Mantenimiento periódico según las

recomendaciones en el Manual de operación.

ADVERTENCIA

Page 27

Información sobre la seguridad PAL 450

wc_si000243es.fm ES-5

1.3 Ubicación de las calcomanías

1.4 Calcomanías de seguridad y operación

Ref. Calcomanía Significado

A El PAL 450 es un láser Clase 1, fabricado

para cumplir con las reglas del Código de

Reglamentaciones Federales 1040.10

y 1040.11, excepto por las variaciones

en conformidad con el aviso sobre láser

No. 50, con fecha 26 de julio de 2001.

B Cada unidad posee una placa de

identificación con el número de modelo,

el número de referencia, el nivel de

revisión y el número de serie. Favor de

anotar los datos contenidos en la placa

en caso de que la placa de identificación

se dañe o pierda. En todos los pedidos

para repuestos o cuando se solicite

información de servicio, siempre se le

pedirá que especifique el número de

modelo, el número de referencia, el

número de revisión y el número de serie

de la unidad.

A

B

wc_gr004606

WACKER NEUSON CORPORATION

Page 28

PAL 450 Operación

wc_tx000804es.fm ES-6

2. Operación

2.1 Aplicación

Este transmisor láser Wacker Neuson es muy fácil de usar, aunque

tiene diversas funciones avanzadas:

• Nivelación automática en horizontal

• Alta precisión

• Ideal para operación con reglas vibratorias, construcción general,

preparación de obras y otras aplicaciones de nivelación

2.2 Calibración

Es importante verificar la correcta calibración del láser. El láser es un

instrumento de precisión y es importante que se mantenga calibrado y en

condiciones óptimas. La precisión de su trabajo es una responsabilidad

completamente suya, por lo que debe revisar los instrumentos antes de

comenzar cada obra, y especialmente después de que el instrumento haya

sido sacudido bruscamente o se haya caído, o bien cuando se hayan

producido cambios de temperatura superiores a 50 grados F (28 grados C).

En la sección “Mantenimiento” encontrará los procedimientos de calibración.

2.3 Configuración y ubicaciones de operación

Ref. Descripción Ref. Descripción

1 Cabezal giratorio 5 Indicador de nivel

2 Puerto de calibración del eje X 6 Indicador de la pila

3 Puerto de calibración del eje Y 7 Paquete de pilas

4 Interruptor On / Off

(Encendido / Apagado)

2

3

7

1

6

5

wc_gr004579

4

Page 29

PAL 450 Operación

wc_tx000804es.fm ES-7

2.4 Uso del láser

Consulte el gráfico: wc_gr004579

Configuración:

El láser se instala en cualquier trípode de 5/8 x 11 pulg. (plano o

con cúpula) o bien puede posarse en cualquier superficie estable (piso,

ladrillos, etc.). Coloque el trípode, instale el láser, y luego ajuste el

trípode hasta que esté relativamente nivelado (en un margen de ± 4°

respecto de la autonivelación).

Encendido del láser:

Pulse la tecla ON / OFF (ENCENDIDO / APAGADO) (4) para

encender el láser. El sistema de autorrevisión de la unidad comenzará

automáticamente. Ambos diodos LED (5 y 6) destellarán si algo sale

mal durante el procedimiento de autorrevisión. El LED de la pila debe

estar verde. Si las pilas tienen poca carga, el LED correspondiente

estará en rojo o bien ambos LED destellarán.

Nivelación:

Cuando el láser esté encendido, el LED indicador de nivel (5)

destellará en rojo hasta que la unidad esté nivelada. Si el láser no se

autonivela en 90 segundos, el LED se encenderá y permanecerá así.

Vuelva a ajustar el trípode hasta que el láser quede en el margen de

autonivelación. Cuando la unidad esté nivelada, el cabezal del rotor

comenzará a girar a 600 RPM.

Alerta de nivel:

Si el láser sufre alguna alteración, el sistema de alerta de nivel detendrá

la rotación del cabezal. El láser se autonivelará y volverá a funcionar

automáticamente a menos que vuelva a sufrir una alteración en el

margen de autonivelación (± 4°). Siempre verifique la altura del haz

respecto de una referencia conocida cuando sea preciso renivelarlo.

Fuentes de alimentación:

El láser puede funcionar con el paquete de pilas alcalinas (4 pilas

tamaño D) o con el paquete opcional de pilas recargables de NiCd.

Si usará el paquete de pilas de NiCd, cárguelo completamente

antes de utilizarlo por primera vez. El paquete de pilas de NiCd

también se puede cargar cuando la máquina está funcionando. Si se

cuenta con electricidad en la obra, basta con enchufar el cargador y

continuar trabajando.

Page 30

PAL 450 Operación

wc_tx000804es.fm ES-8

2.5 Detector de láser

Su transmisor láser viene con un detector láser que se puede utilizar

con una varilla de rasante o en aplicaciones manuales.

Consulte el gráfico: wc_gr004586

Ref. Descripción Ref. Descripción

1 Nivel de burbuja de aire 8 ON / OFF (ENCENDIDO / APAGADO)

2 Pantalla LCD (delantera) 9 Gire para fijar la presilla al detector

3 Ventana de detección 10 Gire para apretar o desprender

la presilla de la varilla de rasante

4 Presilla de la varilla 11 Compartimiento de pilas de 9V

(Acate la polaridad en su interior)

5 Muesca, alineación

de graduación

12 Burbuja a varilla de plomada

6 Opción de nivel sonoro 13 Pantalla LCD (trasera)

7 Opción de precisión

Page 31

PAL 450 Operación

wc_tx000804es.fm ES-9

wc_gr004586

1

2

3

4

5

6

7

8

9

10

13

12

11

LCD Display

Page 32

PAL 450 Operación

wc_tx000804es.fm ES-10

Consulte los gráficos: wc_gr004586 y wc_gr004588

Uso del detector:

2.5.1 Pulse la tecla ON / OFF (ENCENDIDO / APAGADO) (8) para

encender el detector.

2.5.2 Pulse la tecla intermedia (7) para seleccionar la precisión (banda

muerta).

2.5.3 Pulse la tecla superior (6) para seleccionar el nivel de sonido.

2.5.4 Gire la ventana de detección (3) hacia el haz de láser, y suba o baje el

detector según la información que aparezca en la pantalla LCD (2).

Hay cinco canales de información, o indicadores de inclinación.

2.5.5 Una flecha hacia abajo indica que debe bajar el detector hasta que

alcance la referencia del láser; y la flecha hacia arriba indica que debe

subirlo. Cuando aparezca una línea horizontal en la pantalla, el

detector está al mismo nivel que el haz del láser.

2.5.6 Pulse la tecla ON / OFF (ENCENDIDO / APAGADO) para apagar el

detector. Sonará automáticamente un tono de advertencia y se apagará

al cabo de 10 minutos si es que no se usa.

2.5.7 Mantenga la ventana de detección limpia, usando un paño

humedecido con líquido limpiavidrios.

2.6 Otros accesorios

Comuníquese con su distribuidor Wacker Neuson para obtener

información sobre los accesorios disponibles.

Page 33

PAL 450 Mantenimiento

wc_tx000807es.fm ES-11

3. Mantenimiento

3.1 Generalidades sobre la calibración

ESTA SECCIÓN ES MUY IMPORTANTE: He aquí algunas sencillas

instrucciones para revisar la calibración del láser. El láser es un

instrumento de precisión y es importante que se mantenga calibrado

y en condiciones óptimas. La precisión de su trabajo es una

responsabilidad completamente suya, por lo que debe revisar los

instrumentos antes de comenzar cada obra, y especialmente después

de que el instrumento haya sido sacudido bruscamente o se haya

caído, o bien cuando se hayan producido cambios de temperatura

superiores a 50 grados F (28 grados C).

La calibración se debe revisar regularmente. Para mayor comodidad,

se debe establecer un margen para las revisiones rutinarias y rápidas.

Para ello, puede solicitar ayuda al distribuidor Wacker Neuson. Espere

al menos 15 minutos para que el láser se entibie antes de revisar o

ajustar la calibración.

3.2 Revisión de la calibración

3.2.1 Seleccione un margen de nivel de por lo menos 100 pies (30 m) de

largo. Configure el láser en una superficie plana o en un trípode.

A unos 100 pies (30 m) de distancia, disponga un poste o varilla.

3.2.2 Coloque el láser de modo que un eje quede alineado hacia el poste en

el extremo del margen.

3.2.3 Encienda el láser y deje que se autonivele.

3.2.4 Usando un detector, marque la elevación del haz en el poste. Esta es

la marca “A”.

3.2.5 Gire el láser 180° de modo que el eje quede nuevamente alineado con

el poste, pero en la dirección contraria. Use el detector nuevamente

para marcar la elevación del haz en el poste. Esta es la marca “B”.

3.2.6 Si las marcas A y B están a menos de 1/8 pulg. (2,5 mm) de distancia,

la calibración es correcta.

3.2.7 Repita el procedimiento antedicho para el otro eje. Si las marcas están

a más de 1/8 pulg. (2,5 mm) de distancia, proceda con el “Ajuste de la

calibración”.

Page 34

PAL 450 Mantenimiento

wc_tx000807es.fm ES-12

3.3 Ajuste de la calibración

Consulte los gráficos: wc_gr004603 y wc_gr004804

3.3.1 Haga nuevas marcas “A” y “B” según se indica en “Revisión de la

calibración.” Haga una tercera marca a medio camino entre las nuevas

marcas A y B. Denomínela marca “C”. Este es el centro correcto del haz.

3.3.2 El puerto de calibración para cada eje se encuentra en la parte

superior delantera del láser. Escoja el puerto del eje X (2) o el puerto

del eje Y (3) según sea necesario. Abra una sola tapa a la vez para

evitar ajustar el eje incorrecto.

3.3.3 Usando un pequeño destornillador, gire cuidadosamente el tornillo de

ajuste izquierdo o derecho expuesto del puerto de calibración hasta

que el haz quede centrado en la marca C. Haga ajustes en

incrementos pequeños y cuidadosos. Después de cada ajuste, revise

el movimiento del haz en el poste.

3.3.4 Revise dos veces el eje. Gire el láser 180° y vuelva a revisar el haz.

Este debe quedar ahora a no más de 1/16 pulg. (1,5 mm) de la marca

C. En caso contrario, repita los pasos 1–3, realizando ajustes hasta

que el eje esté calibrado.

3.3.5 Revise y ajuste la calibración del otro eje. La calibración está completa

cuando la marca C es igual en los dos ejes y en ambas direcciones.

2

3

wc_gr004604

wc_gr004603

FRONT

X Axis

Top View

Y Axis

Page 35

PAL 450 Mantenimiento

wc_tx000807es.fm ES-13

3.4 Paquete de pilas

Consulte el gráfico: wc_gr004602

Para reemplazar las pilas alcalinas, o para cargar el paquete de NiCd,

primero retire el paquete de pilas. El paquete de NiCd se debe cargar

antes de usarlo primera vez.

Retiro del paquete de pilas

3.4.1 Pulse el botón de desbloqueo de las pilas; consulte (1) en el gráfico

anterior.

3.4.2 Sujetando la pila, presione el pestillo (2) para retirarla.

A) Reemplazo de las pilas

3.4.1 Levante el pestillo de la tapa para retirarla.

3.4.2 Inserte 4 pilas tamaño D. La dirección de inserción se indica en el

paquete de las pilas.

3.4.3 Conecte la cubierta de las pilas, insertando los rebordes guía en las

ranuras respectivas.

B) Recarga (paquete opcional de NiCd)

3.4.1 Retire la tapa del conector de carga en el paquete de pilas y enchufe

el cargador

wc_gr004602

Page 36

PAL 450 Mantenimiento

wc_tx000807es.fm ES-14

3.4.2 Enchufe el cargador en un tomacorriente eléctrico. Una luz roja indica

que ya está cargando.

3.4.3 Cuando la luz roja parpadee (se enciende durante 6 segundos y luego

se apaga por 20), la carga ha finalizado. El tiempo de carga es de unas

7 horas y media. La unidad se puede cargar mientras esté

funcionando. Para una óptima vida útil de la pila, recárguela una vez

que se haya descargado por completo. Para garantizar la vida útil de

las pilas, no las cargue más de 20 horas.

C) Instalación del paquete de pilas

3.4.1 Encaje los bornes guía de la pila en las ranuras del láser.

3.4.2 Conecte la pila al láser presionando la parte superior contra el láser

hasta que se oiga un chasquido.

Page 37

PAL 450 Localización de problemas

wc_tx000807es.fm ES-15

3.5 Cuidado y manipulación

El uso de controles, ajustes o procedimientos distintos a los

especificados en este documento pueden producir una exposición

peligrosa a la radiación.

3.5.1 El láser es un instrumento de precisión que se debe manipular con

cuidado. Evite descargas y vibraciones. Siempre almacene y traslade

el láser y sus accesorios en el maletín de transporte.

3.5.2 Si bien el láser es impermeable, cerciórese de limpiarlo y secarlo con un

paño suave después de cada uso. Esto aumentará la vida útil de la pila.

3.5.3 No almacene el láser a temperaturas inferiores a los -4°F (-20°C) o

superiores a los 176°F (80°C) ya que algunos componentes

electrónicos se podrían dañar.

3.5.4 Para evitar la condensación del agua dentro del instrumento, no lo

almacene dentro de la caja si es que uno de los dos estuviera mojado.

3.5.5 Para mantener la precisión del láser, revise y calibre el haz

regularmente.

3.5.6 Mantenga seca y limpia la caja de vidrio alrededor del cabezal

giratorio. Use un paño suave y un líquido limpiavidrios para asearla.

3.5.7 Cargue las pilas con frecuencia. Sin embargo, hágalo sólo cuando

estén casi o totalmente descargadas. Si recarga pilas que aún estén

utilizables disminuirá su capacidad.

4. Localización de problemas

Para la calibración o reparación del láser, o para una reparación por

garantía, comuníquese con su distribuidor o representante de Wacker

Neuson más cercano.

PRECAUCIÓN

Page 38

PAL 450 Localización de problemas

wc_tx000807es.fm ES-16

Notas

Page 39

PAL 450 Datos técnicos

wc_td000246es.fm ES-17

5. Datos técnicos

5.1 Nivel a láser PAL 450

Parte no.

PAL 450

0620408

Nivel a láser

Margen de operación

pies (m)

1500 (450)

diámetro

Margen de autonivelación ± 4° (± 7%)

Precisión Superior a ± 1/16 pulg. a 100 pies

(± 4 mm / 100m)

± 8 segundos de arco

Velocidad de rotación

RPM

600

Tipo / potencia de salida del haz Diodo infrarrojo; 785 nm; 1,0 mW,

Clase 1

Fuentes de alimentación (1) Paquete de 4 pilas alcalinas

tamaño “D”

(2) Paquete opcional de pilas

recargables de NiCd

(3) Cargador de CA con paquete

opcional de pilas de NiCd

Duración de las pilas

horas

Aproximadamente 100 (alcalinas)

40 (NiCd)

Base de montaje 5/8 pulg. x 11, plana o con cúpula

Ambientales Impermeable, IP55

Temperatura de operación

F (C)

14° a 122° (–10° a 50°)

Temperatura de almacenamiento

F (C)

–4° a 140° (–20° a 60°)

Dimensiones y peso

pulg. (cm)

lb. (kg)

8 x 6,5 x 6 (20 x 16 x 15)

5 (2,3)

Page 40

PAL 450 Datos técnicos

wc_td000246es.fm ES-18

5.2 Detector de láser

Parte no.

Detector de láser

0147101

Detector de láser

Margen

pies (m)

750 (225)

Precisión

pulg. (mm)

Fina: ± 1 (1/16)

Estándar: ± 2,5 (1/8)

Indicación de inclinación LCD y tonos audibles

Duración de las pilas

horas

50

Fuente de energía Alcalina de 9V

Ambientales Impermeable (IP 66+)

Dimensiones y peso

pulg. (cm)

lb. (kg)

6 x 3,25 x 1,5 (15 x 8 x 3,5)

0,35 (0,2)

Page 41

PAL 450 Table des matières

wc_bo0171957fr_001TOC.fm FR-1

Préface FR-2

1. Information de sécurité FR-3

1.1 Mesures de sécurité liées au fonctionnement ................................ FR-4

1.2 Mesures de sécurité liées à l’entretien ........................................... FR-4

1.3 Emplacements des autocollants ..................................................... FR-5

1.4 Autocollants de sécurité et de fonctionnement ............................... FR-5

2. Fonctionnement FR-6

2.1 Application ...................................................................................... FR-6

2.2 Calibrage ........................................................................................ FR-6

2.3 Emplacements de configuration et de fonctionnement .................. FR-6

2.4 Utilisation du Laser ......................................................................... FR-7

2.5 Détecteur laser ............................................................................... FR-8

2.6 Autres accessoires ....................................................................... FR-10

3. Maintenance FR-11

3.1 Survol du calibrage ....................................................................... FR-11

3.2 Vérification du calibrage ............................................................... FR-11

3.3 Ajustement du calibrage ............................................................... FR-12

3.4 Bloc-batterie ................................................................................. FR-13

3.5 Entretien et manipulation .............................................................. FR-15

3.6 Dépannage ................................................................................... FR-15

4. Caractéristiques techniques FR-16

4.1 Niveau laser PAL 450 ................................................................... FR-16

4.2 Détecteur laser ............................................................................. FR-17

Page 42

Préface

FR-2

Préface

Cette notice fournit de l’information et des procédures sur l’utilisation

sécuritaire et le maintien de ce modèle de Wacker Neuson. Pour votre

propre sécurité et protection contre les risques de blessure, veuillez

lire attentivement, bien assimiler et observer les consignes de sécurité

fournies dans cette notice.

Conserver cette notice ou un exemplaire avec la machine. Si cette

notice est perdue ou si l’on a besoin d’un autre exemplaire, contacter

la société Wacker Neuson Corporation. Cette machine a été conçue

avec comme objectif primordial la sécurité de l’utilisateur; toutefois,

elle peut présenter des dangers si elle n’est pas utilisée ou entretenue

correctement. Veuillez suivre attentivement les instructions

d’utilisation ! Pour toute question sur l’utilisation ou l’entretien de cet

équipement, contacter la société Wacker Neuson Corporation.

Les informations contenues dans cette notice portent sur des

machines en production au moment de la mise sous presse. La

société Wacker Neuson Corporation se réserve le droit de modifier

toute information sans préavis.

Tous les droits, en particulier les droits de copie et de distribution, sont

réservés.

Droit d’auteur 2009 par Wacker Neuson Corporation.

Il est interdit de reproduire tout ou une partie de cette publication, sous

quelque forme ou par quelque moyen que ce soit, électronique ou

mécanique, y compris par photocopie, sans l’autorisation écrite

préalable expresse de Wacker Neuson Corporation.

Tout type de reproduction ou de distribution non autorisé par Wacker

Neuson Corporation représente une violation des droits d’auteur en

vigueur et fera l’objet de poursuites. Nous nous réservons

expressément le droit d’apporter des modifications techniques, même

sans préavis, visant à améliorer nos machines ou leurs normes de

sécurité.

Page 43

PAL 450 Information de sécurité

wc_si000243fr.fm FR-3

1. Information de sécurité

Ce manuel contient des notations de DANGER, AVERTISSEMENT,

PRÉCAUTION, ATTENTION et REMARQUE à suivre pour réduire les

risques de blessures, de dommages à l’équipement ou d’un service

inadéquat.

Ce symbole signale une Alerte sécuritaire. Il est utilisé pour vous

avertir qu’il existe un risque potentiel de blessure corporelle.

Respecter toutes les consignes de sécurité qui suivent ce symbole

pour éviter une éventuelle blessure corporelle voire mortelle.

DANGER indique une situation dangereuse immédiate qui, si elle n’est

pas évitée, risque d’entraîner des blessures corporelles graves voire

mortelles.

AVERTISSEMENT indique une situation dangereuse qui, si elle n’est

pas évitée, risque d’entraîner des blessures corporelles graves voire

mortelles.

PRÉCAUTION indique une situation dangereuse qui, si elle n’est pas

évitée, risque d’entraîner des blessures corporelles mineures ou

modérées.

ATTENTION : utilisé sans le symbole de sécurité, ATTENTION

indique une situation dangereuse qui, si elle n’est pas évitée, risque

d’entraîner des dommages matériels.

Remarque : contient des informations complémentaires importantes

pour une procédure.

DANGER

AVERTISSEMENT

PRÉCAUTION

Page 44

PAL 450 Information de sécurité

wc_si000243fr.fm FR-4

1.1 Mesures de sécurité liées au fonctionnement

1.1.1 TOUJOURS lire, comprendre et suivre les procédures dans la Notice

d’emploi avant de tenter d’utiliser l’équipement.

1.1.2 TOUJOURS ranger correctement l’équipement lorsqu’il n’est pas

utilisé. L’équipement doit être rangé dans un endroit propre et sec,

hors de portée des enfants

1.1.3 TOUJOURS faire fonctionner l’appareil avec tous les dispositifs de

sécurité et les protections en place et en bon état.

1.2 Mesures de sécurité liées à l’entretien

Une machine mal entretenue peut représenter un risque pour la

sécurité ! Pour que l’équipement fonctionne sans danger et

correctement pendant de longues périodes, il faut un entretien

périodique et des réparations occasionnelles.

1.2.1 Tous les réglages et toutes les réparations DOIVENT être complétés

avant l’opération. NE JAMAIS faire fonctionner l’appareil sachant

qu’un problème ou une défectuosité existe ! Toutes réparations et tous

les ajustements devraient être effectuées par un technicien qualifié.

1.2.2 NE PAS modifier l’appareil sans approbation écrite expresse du

fabricant.

1.2.3 TOUJOURS garder l’appareil propre et les autocollants lisibles.

Remplacer tous les autocollants manquants et difficiles à lire. Les

autocollants offrent des instructions opérationnelles importantes et

indiquent les dangers.

1.2.4 TOUJOURS effectuer la maintenance périodique tel que recommandé

dans le Manuel de l’utilisateur.

AVERTISSEMENT

Page 45

PAL 450 Information de sécurité

wc_si000243fr.fm FR-5

1.3 Emplacements des autocollants

1.4 Autocollants de sécurité et de fonctionnement

Réf. Autocollant Signification

A Le PAL 450 est un produit laser de classe

1, fabriqué de façon à satisfaire aux

normes du Code of Federal Regulations

1040.10 et 1040.11, sauf les déviations

selon le Laser Notice No. 50 daté du

26 juillet 2001.

B Une plaque signalétique mentionnant

le numéro de modèle, le numéro de

référence, le niveau de révision et le

numéro de série de l’appareil se trouve

sur chaque unité. Veuillez inscrire

l’information qui se trouve sur la plaque

signalétique pour qu’elle soit disponible

si la plaque est perdue ou endommagée.

En commandant des pièces ou en

demandant de l’information de service,

il faut toujours mentionner le numéro

de modèle, le numéro de référence,

le niveau de révision et le numéro de

série de l’unité.

A

B

wc_gr004606

WACKER NEUSON CORPORATION

Page 46

PAL 450 Fonctionnement

wc_tx000804fr.fm FR-6

2. Fonctionnement

2.1 Application

Ce transmetteur laser Wacker Neuson est simple à utiliser, mais il

possède plusieurs fonctions avancées :

• Autonivellement à l’horizontale

• Haute précision

• Idéal pour l’aplanissement, la construction générale, la préparation

de site, et les autres applications de nivellement.

2.2 Calibrage

Il est important de vérifier que le calibrage de votre laser est correct. Le laser

est un instrument de précision et il est important de le maintenir calibré et en

bonne condition. La précision de votre travail relève entièrement de votre

responsabilité et vous devriez vérifier votre instrument avant de démarrer

chaque projet, surtout à la suite d’un impact important ou d’une chute de

l’instrument, ou lorsque la température subit des écarts de plus de 28 °C. Voir

« Maintenance » pour les procédures de calibrage.

2.3 Emplacements de configuration et de fonctionnement

Réf. Description Réf. Description

1 Tête rotative 5 Indicateur de niveau

2 Port de calibrage de l’axe X 6 Indicateur de batterie

3 Port de calibrage de l’axe Y 7 Bloc-batterie

4 Commutateur On / Off

(Marche / Arrêt)

2

3

7

1

6

5

wc_gr004579

4

Page 47

PAL 450 Fonctionnement

wc_tx000804fr.fm FR-7

2.4 Utilisation du Laser

Voir le graphique : wc_gr004579

Configuration :

Le laser s’installe sur n’importe quel trépied 5/8 po x 11 (tête plate ou

de dôme) ou peut s’appuyer sur n’importe quelle surface stable

(plancher, briques, etc.). Placer le trépied, attacher le laser, puis

ajuster le trépied jusqu’à ce qu’il soit plus ou moins à niveau

(en dedans de ± 4° la plage d’autonivellement).

Allumer le laser :

Appuyer sur la touche ON / OFF (MARCHE / ARRÊT) (4) pour allumer

le laser. Le système d’auto-diagnostique de l’unité démarre

automatiquement. Les deux DELs (5 et 6) clignoteront pour avertir

d’un malfonctionnement pendant la procédure d’auto-diagnostique. La

DEL des batteries devrat être verte. Si les batteries sont faibles, la DEL

des batteries sera rouge et les deux DELs clignoteront.

Nivellement :

En allumant le laser, la DEL indicatrice de niveau (5) clignote en rouge

jusqu’à ce que l’appareil soit à niveau. Si le laser ne réussit pas à

s’autoniveler en dedans de 90 secondes, la DEL s’allumera et

demeurera allumée. Réajuster le trépied afin de ramener le laser dans

la plage d’autonivellement. Une fois l’appareil nivelé, la tête rotative

commencera à tourner à 600 tr/min.

Alerte de niveau :

Si le laser est dérangé, le système d’alerte de niveau arrêtera la

rotation de la tête. Le laser s’autonivellera et retournera à l’opération

automatique à moins qu’il ne soit dérangé de nouveau pendant qu’il

est dans la plage d’auto-nivellement (± 4°). Toujours revérifier la

hauteur du faisceau contre une référence lorsqu’une remise à niveau

est requise.

Sources d’alimentation :

Le laser peut fonctionner avec un bloc de batteries alcalines (4 batteries

grosseur D) ou un bloc optionnel de batteries NiCd rechargeables.

Charger complètement le bloc de batteries NiCd avant la première

utilisation. Le bloc de batteries NiCd peut aussi être chargé pendant

l’opération du laser. Si l’électricité est disponible sur le chantier,

simplement brancher le chargeur et continuer à travailler.

Page 48

PAL 450 Fonctionnement

wc_tx000804fr.fm FR-8

2.5 Détecteur laser

Votre transmetteur est équipé d’un détecteur de laser qui est utilisé sur

une perche de nivellement ou pour les applications à main.

Voir le graphique : wc_gr004586

Réf. Description Réf. Description

1 Fiole de niveau 8 ON / OFF (MARCHE / ARRÊT)

2 Écran LCD (devant) 9 Tourner pour attacher la pince

au détecteur

3 Fenêtre de détection 10 Tourner pour resserrer or retirer la

pince de la perche de nivellement.

4 Pince de perche 11 Compartiment de batteries 9V

(Suivre les instructions sur la

polarité à l’intérieur)

5 Coche d’alignement sur-pente 12 Fiole en bulle pour mettre la perche

d’aplomb

6 Choix de niveau de son 13 Écran LCD (arrière)

7 Choix de précision

Page 49

PAL 450 Fonctionnement

wc_tx000804fr.fm FR-9

wc_gr004586

1

2

3

4

5

6

7

8

9

10

13

12

11

LCD Display

Page 50

PAL 450 Fonctionnement

wc_tx000804fr.fm FR-10

Voir le graphique : wc_gr004586 et wc_gr004588

Utilisation du détecteur :

2.5.1 Appuyer sur la touche ON / OFF (MARCHE / ARRÊT) (8) pour allumer

le détecteur.

2.5.2 Appuyer sur la touche du milieu (7) pour sélectionner la précision

(zone morte).

2.5.3 Appuyer sur la touche supérieure (6) pour sélectionner le niveau de son.

2.5.4 Tourner la fenêtre de détection (3) dans la direction du laser, puis

déplacer le détecteur vers le haut ou le bas selon l’information fournie

sur l’écran LCD (2). Il y a cinq canaux d’information, ou indicateurs

de pente.

2.5.5 Une flèche vers le bas indique que vous devez déplacer le détecteur

vers le bas pour atteindre la référence du laser ; et la flèche vers le

haut indique que vous devez le déplacer vers le haut. Lorsqu’une ligne

horizontale apparaît sur l’écran, le détecteur est au même niveau que

le faisceau laser.

2.5.6 Appuyer sur la touche ON / OFF (MARCHE / ARRÊT) pour éteindre le

détecteur. Il émettra automatiquement un bip d’avertissement et

s’éteindra après 10 minutes d’inactivité.

2.5.7 Maintenez la propreté de la fenêtre de détection, utilisant un chiffon

doux et un nettoyeur pour vitres.

2.6 Autres accessoires

Contacter votre concessionnaire Wacker Neuson pour plus de

renseignements concernant les accessoires disponibles.

Page 51

Maintenance PAL 450

wc_tx000807fr.fm FR-11

3. Maintenance

3.1 Survol du calibrage

CETTE SECTION EST TRÈS IMPORTANTE : on y retrouve des

instructions simples pour vérifier le calibrage de votre laser. Le laser

est un instrument de précision et il est important de le maintenir calibré

et en bonne condition. La précision de votre travail relève entièrement

de votre responsabilité et vous devriez vérifier votre instrument avant

de démarrer chaque projet, surtout à la suite d’un impact important ou

d’une chute de l’instrument, ou lorsque la température subit des écarts

de plus de 28 °C.

Le calibrage devrait être vérifié régulièrement. Il est commode d’établir

un champ de mire pour rendre les vérifications routinières plus

rapides. Votre concessionnaire Wacker Neuson peut vous aider à

mettre un tel champ de mire en place. Permettre au laser de se

réchauffer pendant au-moins 15 minutes avant de procéder à la

vérification ou l’ajustement du calibrage.

3.2 Vérification du calibrage

3.2.1 Choisir un champ de mire à niveau d’au moins 30 m de long. Installer

le laser sur une surface plane ou sur un trépied. À une distance

d’environ 30 m, ériger une perche ou une tige verticale.

3.2.2 Placer le laser de façon à ce qu’un des axes soit aligné vers la perche

à l’extrémité du champ de mire.

3.2.3 Allumer le laser et permettre qu’il s’autonivelle.

3.2.4 À l’aide d’un détecteur, marquer l’élévation du faisceau sur la perche.

Celle-ci est la marque « A ».

3.2.5 Tourner le laser par 180° de façon à ce que l’axe soit de nouveau

aligné avec la perche, mais dans la direction opposée. Utiliser le

détecteur de nouveau pour marquer l’élévation du faisceau à la

perche. Celle-ci sera la marque « B ».

3.2.6 Si les marques « A » et « B » sont en dedans de 3 mm l’une de l’autre,

le calibrage est correct.

3.2.7 Répéter cette procédure pour l’autre axe. Si les marques sont

séparées par plus de 2,5 mm, procéder à « Ajustement du calibrage ».

Page 52

PAL 450 Maintenance

wc_tx000807fr.fm FR-12

3.3 Ajustement du calibrage

Voir le graphique : wc_gr004603 et wc_gr004804

3.3.1 Effectuer de nouvelles marques « A » et « B » tel que proposé dans

la consigne « Vérifier le calibrage ». Placer une troisième marque à

mi-chemin entre les nouvelles marques A et B. Appeler celle-ci « C ».

Celle-ci est le centre correct pour le faisceau.

3.3.2 Le port de calibrage pour chaque axe se situe sur le dessus en avant

du laser. Choisir le port de l’axe X (2) ou le port de l’axe Y (3) au

besoin. Ouvrir un seul couvercle à la fois afin d’éviter d’ajuster le

mauvais axe.

3.3.3 À l’aide d’un petit tournevis, tourner délicatement la vis du port

d’ajustement de calibrage vers la gauche ou la droite jusqu’à ce que le

faisceau soit centré sur la marque C. Effectuer les changements par

petits incréments. Après chaque ajustement, vérifier le déplacement

du faisceau sur la perche.

3.3.4 Contre-vérifier l’axe. Pivoter le laser par 180° et vérifier le faisceau de

nouveau. Le faisceau devrait rencontrer la marque C en-dedans de

1,5 mm. Sinon, répéter les étapes 1 à 3, ajuster au besoin jusqu’à ce

que l’axe soit calibré.

3.3.5 Vérifier et ajuster le calibrage de l’autre axe. Le calibrage est terminé

lorsque la marque C est la même pour les deux axes.

2

3

wc_gr004604

wc_gr004603

FRONT

X Axis

Top View

Y Axis

Page 53

Maintenance PAL 450

wc_tx000807fr.fm FR-13

3.4 Bloc-batterie

Voir le graphique : wc_gr004602

Pour remplacer les batteries alcalines, ou pour charger un bloc-batterie

NiCd, retirer en premier le bloc-batterie. Le bloc-batterie NiCd doit être

chargé avant la première utilisation.

Dépose du bloc-batterie

3.4.1 Appuyer sur le bouton de déverrouillage -- voir (1) dans le graphique

ci-dessous.

3.4.2 Tout en supportant la batterie, appuyer sur la relâche de batterie (2)

pour la déposer.

A) Remplacement de la batterie

3.4.1 Soulever la relâche du couvercle pour retirer le couvercle de la batterie.

3.4.2 Insérer 4 batteries D. La direction d’insertion des batteries est indiquée

sur le porte batteries.

3.4.3 Fixer le couvercle de batteries, insérant les lèvres de guidage dans les

rainure de guidage.

B) Recharger (bloc-batterie NiCd optionnel)

3.4.1 Retirer le connecteur de charge sur le bloc-batterie et brancher

le chargeur.

wc_gr004602

Page 54

PAL 450 Maintenance

wc_tx000807fr.fm FR-14

3.4.2 Brancher le chargeur dans une prise secteur. Un voyant rouge sur le

chargeur indique qu’il effectue la charge.

3.4.3 Lorsque le voyant rouge clignote (voyant allumé pendant 6 secondes,

éteint pendant 20 secondes), la charge est complétée. Le temps

requis pour la charge est environ 7,5 heures. L’unité peut être chargée

tout en étant utilisée. Pour atteindre une durée de vie optimale de la

batterie, recharger la batterie après l’avoir complètement déchargée.

Pour assurer une longue vie à la batterie, ne pas charger pendant plus

de 20 heures.

C) Installer le bloc-batterie

3.4.1 Installer la colonne de guidage dans la rainure de guidage du laser.

3.4.2 Attacher la batterie au laser en appuyant le dessus de la batterie

contre le laser jusqu’à ce que vous entendiez un clic.

Page 55

Dépannage PAL 450

wc_tx000807fr.fm FR-15

3.5 Entretien et manipulation

L’utilisation de commandes ou des ajustements, ou l’exécution de

procédures autres que celles spécifiées dans ce document pourrait

résulter en une exposition dangereuse à de la radiation.

3.5.1 Le laser est un instrument de précision qui doit être manipulé avec

soin. Éviter les chocs et les vibrations. Toujours ranger et transporter

le laser et ses accessoires dans son étui de transport.

3.5.2 Même si le laser est résistant à l’eau, assurez-vous de le nettoyer et

de le sécher avec un chiffon doux après chaque usage. Ceci

augmentera aussi la vie utile de la batterie.

3.5.3 Ne pas ranger le laser à des températures sous -20 °C ou au-dessus

de 80 °C parce certains composants électroniques pourraient être

endommagés.

3.5.4 Pour éviter la condensation d’eau à l’intérieur, ne pas ranger celui-ci

dans son étui si l’instrument ou l’étui sont mouillés.

3.5.5 Afin de maintenir la précision du laser, vérifier et calibrer le faisceau

régulièrement.

3.5.6 Maintenir le boîtier de verre autour de la tête rotative sec et propre.

Utiliser un chiffon doux et un nettoyeur de verre pour le nettoyer.

3.5.7 Charger les batteries régulièrement. Par contre, les charger uniquement

lorsqu’elles sont presque ou complètement déchargées. Recharger les

batteries qui sont encore utilisables raccourcira leur vie utile.

4. Dépannage

Pour réparer un laser, le calibrer, ou effectuer des réparations sous

garantie, veuillez contacter ÉQUIPRO à 1-866-378-4776.

PRÉCAUTION

Page 56

PAL 450 Caractéristiques techniques

wc_td000246fr.fm FR-16

5. Caractéristiques techniques

5.1 Niveau laser PAL 450

Article

PAL 450

0620408

Niveau laser

Plage opérationnelle

m

450

diamètre

Plage d’autonivellement ± 4° (± 7 %)

Précision supérieure à ± 4 mm / 100 m

± 8 secondes d’arc

Vitesse de rotation

tr/min

600

Type de faisceau / sortie Diode infrarouge ; 785 nm ; 1,0 mW,

classe 1

Sources d’alimentation (1) bloc de 4 batteries « D »

alcalines

(2) option bloc de batteries

NiCd rechargeables

(3) option Chargeur CA avec

bloc-batterie NiCd

Vie utile des batteries

heures

environ 100 (alcaline)

40 (NiCd)

Base d’installation 1,6 cm x 18 plate ou en dôme

Écologique Étanchéité, IP55

Température opérationnelle °C –10 to 50

Température de rangement °C –20 à 60

Dimensions et poids

cm

kg

20 x 16 x 15

2,3

Page 57

Caractéristiques techniques PAL 450

wc_td000246fr.fm FR-17

5.2 Détecteur laser

Article

Détecteur laser

0147101

Détecteur laser

Distance

m

225

Précision

mm

Fine : ± 1

Standard : ± 2,5

Indication de niveau LCD et tons audibles

Vie utile des batteries

heures

50

Source d’alimentation 9V alcaline

Écologique Étanchéité (IP 66+)

Dimensions et poids

cm

kg

15 x 8 x 3,5

0,2

Page 58

Wacker Neuson SE · Preußenstraße 41 · D-80809 München · Tel.: +49-(0)89-3 54 02-0 · Fax: +49 - (0)89-3 54 02-390

Wacker Neuson Corporation · P.O. Box 9007 · Menomonee Falls, WI 53052-9007 · Tel. : (262) 255-0500 · Fax: (262) 255-0550 · Tel. : (800) 770-0957

Wacker Neuson Limited - Room 1701–03 & 1717–20, 17/F. Tower 1, Grand Century Place, 193 Prince Edward Road West, Mongkok, Kowloon, Hongkong.

Tel: (852) 3605 5360, Fax: (852) 2758 0032

AM 1040-05/09

Loading...

Loading...