Page 1

Operator’s Manual

5000192669

Wet Screed

P35A

Type P35A

Document 5000192669

Date 0818

Revision 06

Language EN

Page 2

Copyright notice

© Copyright 2018 by Wacker Neuson Production Americas LLC

All rights, including copying and distribution rights, are reserved.

This publication may be photocopied by the original purchaser of the

machine. Any other type of reproduction is prohibited without express

written permission from Wacker Neuson Production Americas LLC.

Any type of reproduction or distribution not authorized by Wacker

Neuson Production Americas LLC represents an infringement of valid

copyrights. Violators will be prosecuted.

Trademarks

Manufacturer

Original instructions

All trademarks referenced in this manual are the property of their

respective owners.

Wacker Neuson Production Americas LLC

N92W15000 Anthony Avenue

Menomonee Falls, WI 53051 U.S.A.

Tel: (262) 255-0500 · Fax: (262) 255-0550 · Tel: (800) 770-0957

www.wackerneuson.com

This Operator’s Manual presents the original instructions. The original

language of this Operator’s Manual is American English.

Page 3

CALIFORNIA Proposition 65 Warning

CALIFORNIA Proposition 65 Warning

WARNING

The engine exhaust from this product contains chemicals known to the State of

California to cause cancer, birth defects, or other reproductive harm.

WARNING

Diesel engine exhaust and some of its constituents are known to the State of

California to cause cancer, birth defects, and other reproductive harm.

WARNING

Cancer and Reproductive Harm www.P65Warnings.ca.gov.

WARNING

Batteries, battery posts, terminals and related accessories contain lead and lead

compounds, and other chemicals known to the State of California to cause cancer

and birth defects or other reproductive harm. WASH HANDS AFTER HANDLING.

wc_tx004643en.fm

3

Page 4

CALIFORNIA Proposition 65 Warning

Notes

4

wc_tx004643en.fm

Page 5

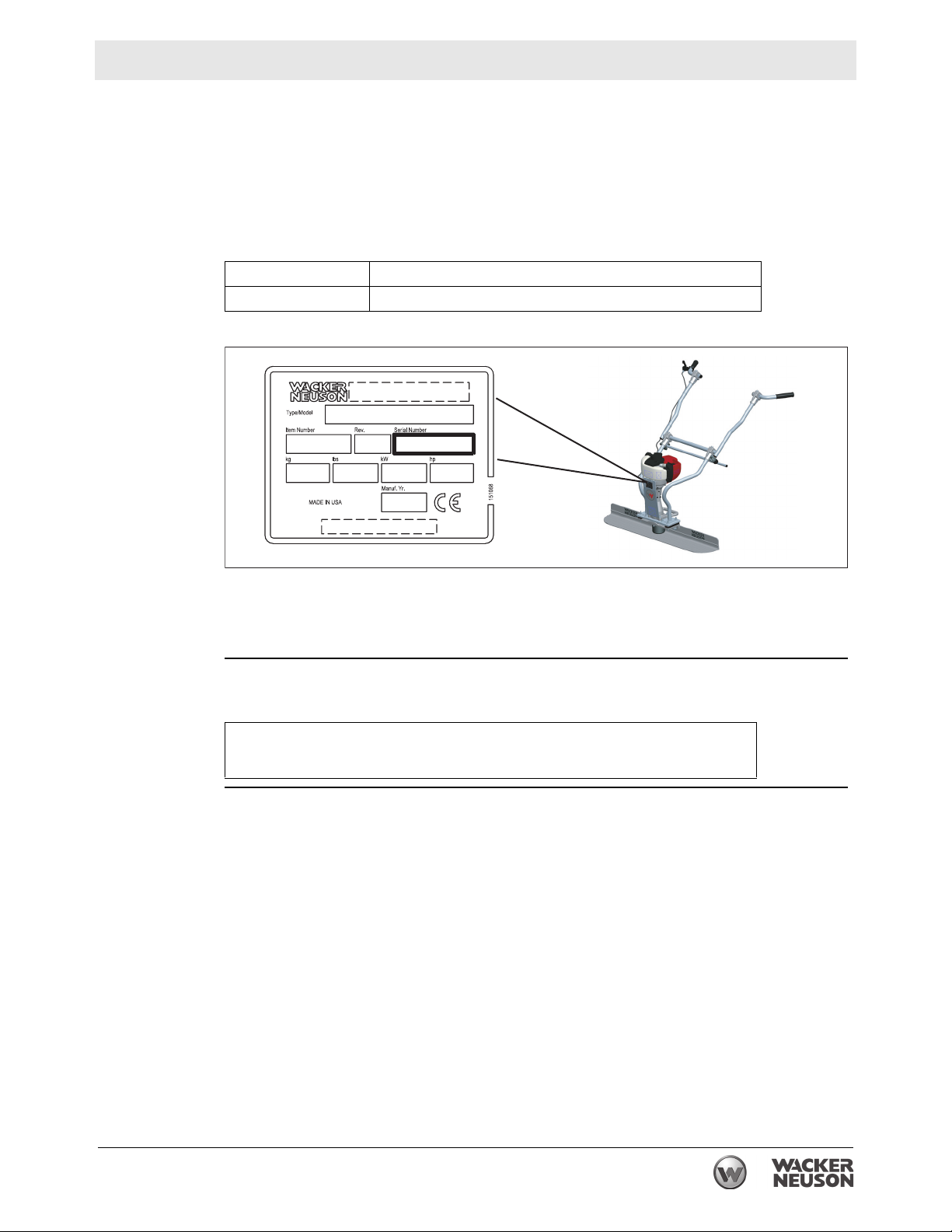

P 35A Foreword

wc_gr010231

Foreword

SAVE THESE INSTRUCTIONS—This manual contains important instructions for

the machine models below. These instructions have been written expressly by

Wacker Neuson Production Americas LLC and must be followed during installation,

operation, and maintenance of the machines.

Machines

covered in

this manual

Machine

identification

Serial number

(S/N)

Machine Item Number

P 35A 0620956, 0620957, 0620958

A nameplate listing the model number, item number, revision number, and serial

number is attached to this machine. The location of the nameplate is shown above.

For future reference, record the serial number in the space provided below. You will

need the serial number when requesting parts or service for this machine.

Machine

■ From this point forward in this documentation, Wacker Neuson Production

documentation

■ Keep a copy of the Operator’s Manual with the machine at all times.

■ For spare parts information, please see your Wacker Neuson Dealer, or visit the

■ When ordering parts or requesting service information, be prepared to provide

wc_tx003251gb_FM10.fm

Serial Number:

Americas LLC will be referred to as Wacker Neuson.

Wacker Neuson website at http://www.wackerneuson.com/.

the machine model number, item number, revision number, and serial number.

5

Page 6

Foreword P 35A

Expectations

for

information in

this manual

CALIFORNIA

Proposition

65 Warning

Laws

pertaining to

spark

arresters

■ This manual provides information and procedures to safely operate and

maintain the above Wacker Neuson model(s). For your own safety and to

reduce the risk of injury, carefully read, understand, and observe all instructions

described in this manual.

■ Wacker Neuson expressly reserves the right to make technical modifications,

even without notice, which improve the performance or safety standards of its

machines.

■ The information contained in this manual is based on machines manufactured

up until the time of publication. Wacker Neuson reserves the right to change any

portion of this information without notice.

■ The illustrations, parts, and procedures in this manual refer to Wacker Neuson

factory-installed components. Your machine may vary depending on the

requirements of your specific region.

Combustion exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to the State of California to cause cancer and

birth defects or other reproductive harm.

NOTICE: State Health Safety Codes and Public Resources Codes specify that in

certain locations spark arresters be used on internal combustion engines that use

hydrocarbon fuels. A spark arrester is a device designed to prevent accidental

discharge of sparks or flames from the engine exhaust. Spark arresters are

qualified and rated by the United States Forest Service for this purpose. In order to

comply with local laws regarding spark arresters, consult the engine distributor or

the local Health and Safety Administrator.

Manufacturer’s

approval

This manual contains references to approved parts, attachments, and

modifications. The following definitions apply:

■ Approved parts or attachments are those either manufactured or provided by

Wacker Neuson.

■ Approved modifications are those performed by an authorized Wacker

Neuson service center according to written instructions published by Wacker

Neuson.

■ Unapproved parts, attachments, and modifications are those that do not

meet the approved criteria.

Unapproved parts, attachments, or modifications may have the following

consequences:

■ Serious injury hazards to the operator and persons in the work area

■ Permanent damage to the machine which will not be covered under warranty

Contact your Wacker Neuson dealer immediately if you have questions about

approved or unapproved parts, attachments, or modifications.

6

wc_tx003251gb_FM10.fm

Page 7

EC Declaration of Conformity

Manufacturer

Wacker Neuson Production Americas LLC, N92W15000 Anthony Avenue,

Menomonee Falls, Wisconsin 53051 USA

Product

Product

Product category

Product function

Item number

P35A

Vibratory Concrete Screed

To level freshly poured concrete

5000620956, 5000620957, 5000620958

Directives and Standards

We hereby declare that this product meets and complies with the relevant regulations and

requirements of the following directives and standards:

2006/42/EC, 2014/30/EU, EN 12649

Authorized Person for Technical Documents

Robert Raethsel, Wacker Neuson Produktion GmbH & Co. KG, Wackerstrasse 6, 85084

Reichertshofen, Germany

Menomonee Falls, WI, USA, 09.05.16

Keith Herr

Vice President and Managing Director

For Wacker Neuson

2016-CE-P35A_en_FM10.fm

Jeff Volden

Director, Product Engineering

For Wacker Neuson

Scott Grahl

Manager, Product Engineering

For Wacker Neuson

Original Declaration of Conformity

Page 8

Page 9

P35A

Table of Contents

CALIFORNIA Proposition 65 Warning 3

Foreword 5

EC Declaration of Conformity 7

1 Safety Information 11

1.1 Signal Words Used in this Manual ..................................................... 11

1.2 Machine Description and Intended Use ............................................. 12

1.3 Operating Safety ................................................................................ 13

1.4 Service Safety .................................................................................... 15

1.5 Operator Safety while Using Internal Combustion Engines ............... 17

2 Labels 18

2.1 Label Locations .................................................................................. 18

2.2 Label Meanings .................................................................................. 19

3 Lifting and Transporting 21

4 Operation 22

4.1 Control / Component Locations .......................................................... 22

4.2 Preparing the Machine for First Use ................................................... 23

4.3 Position of the Operator ..................................................................... 23

4.4 Recommended Fuel ........................................................................... 24

4.5 Before Starting ................................................................................... 24

4.6 Starting ............................................................................................... 25

4.7 Stopping ............................................................................................. 25

4.8 Operation ............................................................................................ 26

4.9 Exciter Adjustment ............................................................................. 28

4.10 Adjusting the Handle Height ............................................................... 29

4.11 Kickstand ............................................................................................ 29

4.12 Emergency Shutdown Procedure ....................................................... 29

5 Maintenance 30

5.1 Maintaining the Emission Control System .......................................... 30

5.2 Periodic Maintenance Schedule ......................................................... 30

5.3 Engine Oil ........................................................................................... 31

wc_bo5000192669_06TOC.fm

9

Page 10

Table of Contents

5.4 Air Cleaner ..........................................................................................32

5.5 Spark Plug (Wacker Neuson/Honda) ..................................................33

5.6 Cleaning the Machine ..........................................................................34

5.7 Long-Term Storage .............................................................................34

5.8 Troubleshooting ...................................................................................34

P35A

6 Technical Data 35

6.1 Engine .................................................................................................35

6.2 Blades .................................................................................................36

6.3 Dimensions ..........................................................................................36

6.4 Sound and Vibration Specifications .....................................................37

7 Emission Control Systems Information

and Warranty 38

7.1 Emission Control Systems Warranty Statement .................................38

10

wc_bo5000192669_06TOC.fm

Page 11

P 35A Safety Information

1 Safety Information

1.1 Signal Words Used in this Manual

This manual contains DANGER, WARNING, CAUTION, NOTICE, and NOTE

signal words which must be followed to reduce the possibility of personal injury,

damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential personal hazards.

► Obey all safety messages that follow this symbol.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

► To avoid death or serious injury from this type of hazard, obey all safety

messages that follow this signal word.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

► To avoid possible death or serious injury from this type of hazard, obey all safety

messages that follow this signal word.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

► To avoid possible minor or moderate injury from this type of hazard, obey all

safety messages that follow this signal word.

NOTICE: Used without the safety alert symbol, NOTICE indicates a situation

which, if not avoided, could result in property damage.

Note: A Note contains additional information important to a procedure.

wc_si000748gb_FM10.fm

11

Page 12

Safety Information P 35A

1.2 Machine Description and Intended Use

This machine is a vibratory concrete screed. The Wacker Neuson Wet Screed

consists of a gasoline engine, a fuel tank, a metal blade, an eccentric weight

positioned at the center of the metal blade, and a control handle. The gasoline

engine spins the eccentric weight through a drive shaft, producing vibrations that

travel the length of the metal blade. The operator uses the control handle to pull the

machine across uncured concrete.

This machine is intended to be used for striking off uncured concrete slabs with or

without the support of grade stakes or forms.

This machine has been designed and built strictly for the intended use described

above. Using the machine for any other purpose could permanently damage the

machine or seriously injure the operator or other persons in the area. Machine

damage caused by misuse is not covered under warranty.

The following are some examples of misuse:

■ Using the machine as a ladder, support, or work surface

■ Using the machine to carry or transport passengers or equipment

■ Engaging the screed when not on uncured concrete

■ Operating the machine on non-compactable surfaces, such as asphalt or cured

concrete

■ Operating the machine outside of factory specifications

■ Operating the machine in a manner inconsistent with all warnings found on the

machine and in the Operator’s Manual

This machine has been designed and built in accordance with the latest global

safety standards. It has been carefully engineered to eliminate hazards as far as

practicable and to increase operator safety through protective guards and labeling.

However, some risks may remain even after protective measures have been taken.

They are called residual risks. On this machine, they may include exposure to:

■ Heat, noise, exhaust, and carbon monoxide from the engine

■ Chemical burns from the curing concrete

■ Fire hazards from improper refueling techniques

■ Fuel and its fumes, fuel spillage from improper lifting technique

■ Personal injury from improper lifting techniques or operating techniques

■ Excessive vibration by holding the blade

To protect yourself and others, make sure you thoroughly read and understand the

safety information presented in this manual before operating the machine.

12

wc_si000748gb_FM10.fm

Page 13

P 35A Safety Information

1.3 Operating Safety

Operator

training

Operator

qualifications

Application

area

Before operating the machine:

■ Read and understand the operating instructions contained in all manuals

delivered with the machine.

■ Familiarize yourself with the location and proper use of all controls and safety

devices.

■ Contact Wacker Neuson for additional training if necessary.

When operating this machine:

■ Do not allow improperly trained people to operate the machine. People

operating the machine must be familiar with the potential risks and hazards

associated with it.

Only trained personnel are permitted to start, operate, and shut down the machine.

They also must meet the following qualifications:

■ Have received instruction on how to properly use the machine

■ Are familiar with required safety devices

The machine must not be accessed or operated by:

■ Children

■ People impaired by alcohol, drugs, or prescription drugs

Be aware of the application area.

■ Keep unauthorized personnel, children, and pets away from the machine.

■ Remain aware of changing positions and the movement of other equipment and

personnel in the application area/job site.

■ Identify whether special hazards exist in the application area, such as toxic

gases or unstable ground conditions, and take appropriate action to eliminate

the special hazards before using the machine.

■ Do not operate the machine in areas that contain flammable objects, fuels, or

products that produce flammable vapors.

Safety

devices,

controls, and

attachments

Only operate the machine when:

■ All safety devices and guards are in place and in working order.

■ All controls operate correctly.

■ The machine is set up correctly according to the instructions in the Operator’s

■ The machine is clean.

■ The machine’s labels are legible.

To ensure safe operation of the machine:

■ Do not operate the machine if any safety devices or guards are missing or

■ Do not modify or defeat the safety devices.

■ Only use accessories or attachments that are approved by Wacker Neuson.

wc_si000748gb_FM10.fm

Manual.

inoperative.

13

Page 14

Safety Information P 35A

Safe

operating

practices

Personal

Protective

Equipment

(PPE)

After use

When operating this machine:

■ Remain aware of the machine’s moving parts. Keep hands, feet, and loose

clothing away from the machine’s moving parts.

■ Do not operate a machine in need of repair.

Wear the following personal protective equipment (PPE) while operating this

machine:

■ Close-fitting work clothes that do not hinder movement

■ Safety glasses with side shields

■ Hearing protection

■ Safety-toed footwear

■ Stop the engine when the machine is not being operated.

■ Close the fuel valve on engines equipped with one when the machine is not

being operated.

■ Ensure that the machine will not tip over, roll, slide, or fall when not being

operated.

■ Store the machine properly when it is not being used. The machine should be

stored in a clean location out of the reach of children.

14

wc_si000748gb_FM10.fm

Page 15

P 35A Safety Information

1.4 Service Safety

Service

training

Precautions

Before servicing or maintaining the machine:

■ Read and understand the instructions contained in all manuals delivered with

the machine.

■ Familiarize yourself with the location and proper use of all controls and

protective devices.

■ Only trained personnel shall troubleshoot or repair problems occurring with the

machine.

■ Contact Wacker Neuson for additional training if necessary.

When servicing or maintaining this machine:

■ Do not allow untrained or improperly trained people to service or maintain the

machine. Personnel servicing or maintaining the machine must be familiar with

the associated potential risks and hazards.

Follow the precautions below when servicing or maintaining the machine.

■ Read and understand the service procedures before performing any service to

the machine.

■ All adjustments and repairs must be completed before operation. Do not

operate the machine with a known problem or deficiency.

■ All repairs and adjustments shall be completed by a qualified technician.

■ Turn off the machine before performing maintenance or making repairs.

Machine

modifications

Replacing

parts and

labels

Cleaning

When servicing or maintaining the machine:

■ Use only accessories/attachments that are approved by Wacker Neuson.

■ Do not defeat safety devices.

■ Do not modify the machine without the express written approval of Wacker

Neuson.

■ Replace worn or damaged components.

■ Replace all missing and hard-to-read labels.

■ When replacing electrical components, use components that are identical in

rating and performance to the original components.

■ When replacement parts are required for this machine, use only Wacker

Neuson replacement parts or those parts equivalent to the original in all types of

specifications, such as physical dimensions, type, strength, and material.

When cleaning and servicing the machine:

■ Keep machine clean and free of debris such as leaves, paper, cartons, etc.

■ Keep labels legible.

When cleaning the machine:

■ Do not clean the machine while it is running.

■ Never use gasoline or other types of fuels or flammable solvents to clean the

machine. Fumes from fuels and solvents can become explosive.

wc_si000748gb_FM10.fm

15

Page 16

Safety Information P 35A

Personal

protective

equipment

(PPE)

Safe service

practices

Wear the following Personal Protective Equipment (PPE) while servicing or

maintaining this machine:

■ Close-fitting work clothes that do not hinder movement

■ Safety glasses with side shields

■ Hearing protection

■ Safety-toed footwear

In addition, before servicing or maintaining the machine:

■ Tie back long hair.

■ Remove all jewelry (including rings).

■ Do not crank a flooded engine with the spark plug removed on gasoline-

powered engines. Fuel trapped in the cylinder will squirt out the spark plug

opening.

■ Do not test for spark on gasoline-powered engines if the engine is flooded or the

smell of gasoline is present. A stray spark could ignite the fumes.

■ Handle blades carefully. The blades can develop sharp edges which can cause

serious cuts.

16

wc_si000748gb_FM10.fm

Page 17

P 35A Safety Information

1.5 Operator Safety while Using Internal Combustion Engines

WARNING

Internal combustion engines present special hazards during operation and fueling.

Failure to follow the warnings and safety standards could result in severe injury or

death.

► Read and follow the warning instructions in the engine owner’s manual and the

safety guidelines below.

DANGER

Exhaust gas from the engine contains carbon monoxide, a deadly poison.

Exposure to carbon monoxide can kill you in minutes.

► NEVER operate the machine inside an enclosed area, such as a tunnel, unless

adequate ventilation is provided through such items as exhaust fans or hoses.

Operating

safety

Refueling

safety

When running the engine:

■ Keep the area around the exhaust pipe free of flammable materials.

■ Check the fuel lines and the fuel tank for leaks and cracks before starting the

engine. Do not run the machine if fuel leaks are present or the fuel lines are

loose.

■ Do not smoke while operating the machine.

■ Do not run the engine near sparks or open flames.

■ Do not touch the engine or muffler while the engine is running or immediately

after it has been turned off.

■ Do not operate a machine when its fuel cap is loose or missing.

■ Do not start the engine if fuel has spilled or a fuel odor is present. Move the

machine away from the spill and wipe the machine dry before starting.

When refueling the engine:

■ Clean up any spilled fuel immediately.

■ Refill the fuel tank in a well-ventilated area.

■ Reinstall the fuel tank cap after refueling.

■ Do not smoke.

■ Do not refuel a hot or running engine.

■ Do not refuel the engine near sparks or open flames.

■ Use suitable tools for refueling (for example, a fuel hose or a funnel).

■ Do not refuel if the machine is positioned in a truck fitted with a plastic bed liner.

Static electricity can ignite the fuel or fuel vapors.

wc_si000748gb_FM10.fm

17

Page 18

Labels P35A

2 Labels

2.1 Label Locations

F

B

C

D

A

E

wc_gr008018

18

wc_si000749gb_FM10.fm

Page 19

P35A Labels

178745

STOP

178715

2.2 Label Meanings

A WARNING

To reduce the risk of hearing loss and

eye injury, always wear hearing

protection and eye protection when

operating this machine.

178745

B WARNING

Hot surface

C DANGER

Asphyxiation hazard

Engines emit carbon monoxide.

Do not run the machine indoors or in an

enclosed area unless adequate ventilation, through such items as exhaust

fans or hoses, is provided.

Read the Operator’s Manual.

No sparks, flames, or burning objects

near the machine.

STOP

178715

Stop the engine before refueling.

D This machine may be covered by one or

more patents.

wc_si000749gb_FM10.fm

19

Page 20

Labels P35A

E WARNING

Rotating machinery! Do not reach inside

machine when the engine is running.

F California Proposition 65 Warning

WARNING

Cancer and Reproductive Harm

www.P65Warnings.ca.gov

Cancer and Reproductive Harm www.P65Warnings.ca.gov.

ADVERTENCIA

Cáncer y daño reproductivo

www.P65Warnings.ca.gov

AVERTISSEMENT

Cancer ou malformations

congénitales

www.P65Warnings.ca.gov

5100045462

20

wc_si000749gb_FM10.fm

Page 21

P35A Lifting and Transporting

3 Lifting and Transporting

To lift and transport the machine:

1. Loosen the screws (a) and fold down the upper guide handle (b). Tighten the

screws to hold the upper guide handle in position.

a

b

c

wc_gr010850

2. Use the lifting handle (c) at the base to lift and transport the machine.

wc_tx003252gb_FM10.fm

21

Page 22

Operation P 35A

wc_gr008019

5

4

1

7

6

2

3

4 Operation

4.1 Control / Component Locations

Ref Description Ref Description

1 Adjustable handle 5 Kickstand

2 Adjustable handle grips 6 Lifting handle

3 Throttle control 7 Blade

4 Fuel tank — —

wc_tx003253gb_FM10.fm

22

Page 23

P 35A Operation

4.2 Preparing the Machine for First Use

1. Make sure all loose packaging materials have been removed from the machine.

2. Check the machine and its components for damage. If there is visible damage,

do not operate the machine! Contact your Wacker Neuson dealer immediately

for assistance.

3. Take inventory of all items included with the machine and verify that all loose

components and fasteners are accounted for.

4. Add fluids as needed and applicable, including fuel, engine oil, hydraulic oil,

retardant, and battery acid.

5. Move the machine to its operating location.

6. Connect component parts not already attached.

4.3 Position of the Operator

Safe and efficient use of this machine is the operator’s responsibility. Full control of

the machine is not possible unless the operator maintains the proper working

position at all times.

While operating this machine, the operator must:

■ stand between the handles, facing the engine

■ grasp the adjustable handle grips with both hands, using the fingers of the right

hand to squeeze the throttle control

■ walk backwards while pulling the screed across the wet concrete

wc_tx003253gb_FM10.fm

23

Page 24

Operation P 35A

4.4 Recommended Fuel

The engine requires regular grade unleaded gasoline. Use only fresh, clean

gasoline. Gasoline containing water or dirt will damage the fuel system. Consult the

engine owner’s manual for complete fuel specifications.

Use of

oxygenated

fuels

Some conventional gasolines are blended with alcohol. These gasolines are

collectively referred to as oxygenated fuels. If you use an oxygenated fuel, be sure

it is unleaded and meets the minimum octane rating requirement.

Before using an oxygenated fuel, confirm the fuel’s contents. Some states and

provinces require this information to be posted on the fuel pump.

The following is the Wacker Neuson approved percentage of oxygenates:

ETHANOL - (ethyl or grain alcohol) 10% by volume. You may use gasoline

containing up to 10% ethanol by volume (commonly referred to as E10). Gasoline

containing more than 10% ethanol (such as E15, E20, or E85) may not be used

because it could damage the engine.

If you notice any undesirable operating symptoms, try another service station, or

switch to another brand of gasoline.

Fuel system damage or performance problems resulting from the use of an

oxygenated fuel containing more than the percentages of oxygenates mentioned

above are not covered under warranty.

4.5 Before Starting

Read and understand safety and operating instructions at beginning of this manual.

Check:

■ Oil level in engine

■ Fuel level

■ Condition of air cleaner

■ Tightness of external fasteners

■ Condition of fuel lines

Adjust handles for operator’s comfort

CAUTION

Pinch hazard.

► Make sure all hardware is tightened before use and be aware of pinch points

during handle adjustments.

24

wc_tx003253gb_FM10.fm

Page 25

P 35A Operation

4.6 Starting

1. Move the choke lever to the closed position (a1).

Note: If engine is hot, set choke to open position (a2 ).

2. Turn engine switch to “ON”.

3. Press the priming bulb (b) repeatedly until fuel can be seen in the clear plastic

fuel-return tube (c).

4. Pull the starter grip (d).

5. Open choke as engine warms (a2).

6. Open throttle to operate.

4.7 Stopping

1. Reduce engine RPM to idle.

2. Turn engine switch to “OFF”.

a1

a2

c

b

d

wc_gr010245

wc_tx003253gb_FM10.fm

25

Page 26

Operation P 35A

wc_gr07996

a

a

c

4.8 Operation

Procedure

Perform the procedure below to perform a typical screeding of concrete.

1. Establish wet pads for wet screed guidance. Place wet pads (a) in strips no less

than 0.6m (2.0 ft) wide.

d

Note: Hand tools such as magnesium floats are used in conjunction with a laser

receiver, transit level, or grade stakes to establish the proper elevation of the pads.

2. Use a float to strike off or build up the level of the fresh concrete to the desired

grade. This is usually marked with an “X” (b) to signal the screed operator that

grade has been established. A minimum of two areas should be marked per

length of screed blade used to strike the entire pad.

3. Place the blade on the pad and strike-off perpendicular to the strip axis (c). Use

the marked pads as elevation guides.

4. Place concrete between the strips (d) and use them as “wet forms” for the rest

of the placement. Strike-off at this point will be parallel to the axis of the initial

wet pads of concrete.

This procedure continues on the next page.

26

wc_tx003253gb_FM10.fm

Page 27

P 35A Operation

Continued from the previous page.

Note: Screeding MUST be complete before any excess moisture or bleed water is

present on the surface, and before the strips have taken an initial set.

5. Start the engine and move the throttle forward one-half to three-quarters. This

increases the engine speed to approximately 6000–7000 rpm which is

appropriate for most screeding applications.

6. Pull the screed across the concrete to perform the strike-off. A creamy liquid

should form around the edges of the screed blade as the concrete is leveled.

NOTICE: Operating the screed at continuous full throttle is not recommended.

Prolonged operation of the engine at high speed creates excessive vibration that

cannot be absorbed by the concrete. This can result in:

■ increased machine vibration

■ increased handle vibration

■ premature failure of the power unit

■ premature failure of the exciter

■ accelerated drive shaft wear

To prolong screed life, use the lowest possible throttle and exciter settings that

produce an acceptable surface finish. The proper engine speed for a given exciter

setting will produce a smooth concrete surface and limit vibration transmitted to the

machine and handles.

Troubleshooting

Follow the recommendations below if a creamy liquid does not appear while

striking off the concrete.

■ Increase engine speed slightly.

■ Increase the exciter setting one position at a time to properly vibrate the

concrete. See Exciter Adjustment.

wc_tx003253gb_FM10.fm

27

Page 28

Operation P 35A

wc_gr007997

a b

c

d

c

e

wc_gr007998

1 2 3

+–

4.9 Exciter Adjustment

Overview

Procedure

Proper operation of the screed produces a creamy liquid around the blade during

strike-off. If a creamy liquid does not form at the standard throttle range of one-half

to three-quarters speed (6000–7000 rpm), or with slight speed increases, then

adjust the exciter.

Perform the procedure below to adjust the exciter.

1. Remove the 4 screws (a) mounting the blade to the power unit.

2. Remove the 3 screws mounting the eccentric housing (b).

3. Using a 1/4-inch Allen wrench, loosen the screw (c) holding the adjustable

eccentric weight in place.

4. The screed eccentric is preset at the factory to Position 2 as shown. Rotate the

exciter to the right for less vibration, or to the left for more vibration.

Note: The maximum vibration exciter setting is Position 1. The minimum exciter

vibration setting is Position 3.

5. Reassemble components and tighten all hardware.

wc_tx003253gb_FM10.fm

28

Page 29

P 35A Operation

wc_gr008023

a

4.10 Adjusting the Handle Height

For maximum comfort and user control of the wet screed during operation, the

handlebar (a) can be rotated up or down to suit the operator’s preference. Loosen

the screws (b) and raise or lower the handlebar as desired. Tighten the screws

when the handles are in the desired position.

4.11 Kickstand

The kickstand (a) props up the screed when it is not in use.

a

b

wc_gr008022

4.12 Emergency Shutdown Procedure

Procedure

wc_tx003253gb_FM10.fm

If a breakdown or accident occurs while the machine is operating, follow the

procedure below:

1. Stop the engine.

2. Close the fuel valve.

3. Remove the machine from the job site using correct lifting techniques.

4. Clean concrete from the blade and the machine.

5. Contact the rental yard or machine owner for further instructions.

29

Page 30

Maintenance P35A

5 Maintenance

5.1 Maintaining the Emission Control System

For machines sold in North America:

Normal maintenance, replacement, or repair of emission control devices and

systems may be performed by any repair establishment or individual; however,

warranty repairs must be performed by a dealer/service center authorized by

Wacker Neuson. The use of service parts that are not equivalent in performance

and durability to authorized parts may impair the effectiveness of the emission

control system and may have a bearing on the outcome of a warranty claim.

5.2 Periodic Maintenance Schedule

The table below lists basic engine maintenance. Tasks designated with check

marks may be performed by the operator. Tasks designated with square bullet

points require special training and equipment.

Refer to the engine manufacturer’s owner’s manual for additional information.

Check fuel level.

Check engine oil level.

Inspect air filter. Replace as needed.

Change engine oil.

Clean air cleaner.

Clean sediment cup.

Check and clean spark plug.

Daily

before

starting

After

first

10 hours

Every

50

hours

Every

100

hours

30

wc_tx003254gb_FM10.fm

Page 31

P35A Maintenance

wc_gr008291

b

d

a

c

5.3 Engine Oil

1. Drain oil while the engine is still warm.

2. Turn the engine 90° so the fuel tank is facing downward. Check that the fuel

tank cap (a) is tightened.

3. Remove the oil fill plug (b) and drain the oil into a container by tipping the engine

toward the oil filler neck (c).

Note: In the interests of environmental protection, place a plastic sheet and a

container under the machine to collect any liquid which drains off. Dispose of this

liquid in accordance with environmental protection legislation.

4. Fill the engine crankcase with recommended oil up to the level of the plug

opening (d). See Technical Data for oil quantity and type.

5. Install the oil filler plug (b).

WARNING

Most used oil contains small amounts of materials that can cause cancer and other

health problems if inhaled, ingested, or left in contact with skin for prolonged

periods of time.

► Take steps to avoid inhaling or ingesting used engine oil.

► Wash skin thoroughly after exposure to used engine oil.

wc_tx003254gb_FM10.fm

31

Page 32

Maintenance P35A

wc_gr010247

b

c

5.4 Air Cleaner

The engine is equipped with a single element air cleaner. Service air cleaner

frequently to prevent carburetor malfunction.

NOTICE: Do not run engine without air cleaner. Severe engine damage will occur.

WARNING

Fire and explosion hazard.

► Do not use gasoline or other types of low flash point solvents for cleaning the

air cleaner. A fire or explosion could result.

To serv ic e :

1. Press the latch (a) on the side of the air cleaner cover (b), and remove the

cover.

2. Check the filter (c) to be sure it is in good condition. Replace damaged filters.

3. Wash filter element (c) in solution of mild detergent and warm water. Rinse

thoroughly in clean water. Allow element to dry thoroughly. Soak element in

clean engine oil and squeeze out excess oil.

4. Re-install the filter (c) and air cleaner cover (b).

wc_tx003254gb_FM10.fm

32

Page 33

P35A Maintenance

wc_gr008043

a

a

5.5 Spark Plug (Wacker Neuson/Honda)

Clean or replace the spark plug as needed to ensure proper operation. Refer to

your engine owner’s manual.

WARNING

Hot surface hazard. The muffler becomes very hot during operation and remains

hot for a while after stopping the engine.

► Do not touch the muffler while it is hot.

Note: Refer to section “Technical Data” for the recommended spark plug type and

the electrode gap setting.

1. Remove the spark plug and inspect it.

2. Replace the spark plug if the insulator is cracked or chipped.

3. Clean the spark plug electrodes with a wire brush.

4. Set the electrode gap (a).

5. Tighten the spark plug securely.

NOTICE: A loose spark plug can become very hot and may cause engine damage.

wc_tx003254gb_FM10.fm

33

Page 34

Maintenance P35A

5.6 Cleaning the Machine

1. Remove any excess concrete with a high pressure washer. Be sure to remove

any concrete buildup on the underside of the blades.

Note: When pressure washing the machine, avoid using harsh chemicals and only

use moderate water pressure (500–1000 psi).

2. Avoid direct pressure to the following components:

■ Engine

■ Hoses

■ Labels

NOTICE: Do not use a hammer or wire brush to remove concrete from the screed.

5.7 Long-Term Storage

Prepare the machine for long-term storage if you intend to take it out of service for

more than 30 days.

.

1. Change engine oil, drain fuel, and follow procedures described in the engine

owner’s manual for engine storage.

WARNING

Fire/burn hazards. Gasoline is flammable and can ignite or explode.

► Keep all open flames, sparks, and cigarettes away from the machine while

draining fuel.

► Do not drain fuel while the engine is running or hot.

Note:

protection regulations.

2. Clean the entire power unit and engine.

3. Check the machine for loose or missing fasteners. Tighten or replace as

4. Cover the entire machine and store in a clean, dry area.

Dispose of dr

needed.

5.8 Troubleshooting

If engine doesn’t start, check that the:

■ Engine switch is in the “ON” position.

■ Fuel tank has fuel.

■ Choke lever is in correct position. Choke should be closed when starting a cold

engine.

■ Spark plug is in good condition.

■ Spark plug cap is tight.

■ Engine oil level is adequate.

ained fuel and oil in accordance with current environmental

wc_tx003254gb_FM10.fm

34

Page 35

P 35A Technical Data

6 Technical Data

6.1 Engine

Engine Power Rating

Net power rating per SAE J1349. Actual power output may vary due to conditions

of specific use.

P 35A

0620956, 0620957

Engine

Engine type 4-stroke, overhead camshaft,

single cylinder

Engine make Honda

Engine model GX35

Max. rated power @ rated

speed

Displacement cm³ (in³) 35.8 (2.18)

Spark plug NGK CM5H

Electrode gap mm

Operating speed (max.) rpm 8000

Engine speed (idle) rpm 3100

Air cleaner type Foam element

kW (hp) 1.0 (1.3)

@ 7000 rpm

or NGK CMR5H

0.60–0.70

(in.)

(0.024–0.028)

P 35A

0620958

wc_td000549gb_FM10.fm

Engine lubrication oil grade SAE 10W-30, API SJ or SL

Engine oil capacity ml (oz.) 100 (3.38)

Fuel type Regular unleaded Australian ULP

Fuel tank capacity L (gal) 0.63 (0.166)

35

Page 36

Technical Data P 35A

933 mm

(36.7 in.)

933 mm

(36.7 in.)

wc_gr008044

903 mm

6.2 Blades

Blade Models

SB 15M 1.5 (4-11") 0.12 (4.88) 4.3 (9.5)

SB 20M 2.0 (6-7") 0.12 (4.88) 5.6 (12.4)

SB 10F 3.0 (10) 0.12 (4.88) 9.4 (19.0)

SB 12F 3.7 (12) 0.12 (4.88) 10.3 (22.8)

SB 14F 4.3 (14) 0.12 (4.88) 13 (28.5)

SB 16F 4.9 (16) 0.12 (4.88) 14 (30.4)

6.3 Dimensions

Length

m (ft)

SB 4F 1.2 (4) 0.12 (4.88) 3.4 (7.6)

SB 6F 1.8 (6) 0.12 (4.88) 5.2 (11.4)

SB 8F 2.4 (8) 0.12 (4.88) 7.5 (15.2)

Width

m (in.)

Weight

kg (lb)

36

wc_td000549gb_FM10.fm

Page 37

P 35A Technical Data

6.4 Sound and Vibration Specifications

Sound

specifications

Vibration

specifications

The required sound specification, Paragraph 1.7.4.2.u of 2006/42/EC Machinery

Directive, is:

the sound pressure level at operator’s location (L

the guaranteed sound power level (L

): 97 dB(A)

WA

): 85 dB(A)

pA

These sound values were determined according to ISO 3744 for the sound power

level (L

) and ISO 6081 for the sound pressure level (LpA) at the operator’s

WA

location. Data was collected from a technically comparable machine under

laboratory conditions.

The operator of this machine should expect to be exposed to vibration when using

the machine within its normally intended function.

ISO 5349 Part 1 Annex F states, “The vibration characteristics of a vibrating tool

can be highly variable. It is therefore important that the range of vibration

conditions associated with different workpieces, materials, working conditions,

methods of use of the tool, and exposure duration patterns be reported.”

The average hand and arm vibration (HAV) value obtained for the entire

operating rpm range is 4.7 m/s

The maximum hand and arm vibration value obtained within the entire operating

rpm range is 6.1 m/s

The minimum hand and arm vibration value obtained within the entire operating

rpm range is 3.5 m/s

Operating the machine in the recommended RPM range of 6000 to 7000 rpm

2

.

2

.

yields an HAV range of 3.5 to 4.7 m/s

2

.

2

.

HAV

Uncertainties

Products are tested for hand/arm vibration level in accordance with ISO 5349 Part

1 and ISO 8662 Part 1. The results are in compliance with the limit and action

vibration values (hand/arm and whole body) as specified in European directive

2002/44/EC.

Hand-transmitted vibration was measured per ISO 5349-1. This measurement

includes an uncertainty of 1.5 m/s

2

.

wc_td000549gb_FM10.fm

37

Page 38

Emission Control Systems Information and Warranty

7 Emission Control Systems Information

and Warranty

The Emission Control Warranty and associated information is valid only for the

U.S.A., its territories, and Canada.

7.1 Emission Control Systems Warranty Statement

See the supplied engine owner’s manual for the applicable exhaust and

evaporative emission warranty statement.

38 wc_tx001753gb_FM10.fm

Page 39

Important: For spare parts information, please see your Wacker Neuson Dealer, or visit the

Wacker Neuson website at http://www.wackerneuson.com/.

Wichtig! Informationen über Ersatzteile erhalten Sie von Ihrem Wacker Neuson Händler oder

besuchen Sie die Wacker Neuson Website unter http://www.wackerneuson.com/.

Important : Pour des informations sur les pièces détachées, merci de consulter votre

distributeur Wacker Neuson, ou de visiter le site Internet de Wacker Neuson sur

http://www.wackerneuson.com/.

Importante : Para saber más sobre las piezas de repuesto, póngase en contacto con su

distribuidor de Wacker Neuson o acceda al sitio web de Wacker Neuson en

http://www.wackerneuson.com/.

Importante : Per informazioni sui pezzi di ricambio, contattare il rivenditore Wacker Neuson o

visitare il sito di Wacker Neuson all’indirizzo www.wackerneuson.com.

Viktigt : För information om reservdelar, kontakta din Wacker Neuson-leverantör eller besök

Wacker Neusons webbplats på http://www.wackerneuson.com/.

Tärkeää : Pyydä varaosatietoja Wacker Neusonin jälleenmyyjältä tai vieraile Wacker Neusonin

web-sivustolla osoitteessa http://www.wackerneuson.com/

Viktig : For informasjon om reservedeler, vennligst kontakt din Wacker Neuson-forhandler, eller

besøk Wacker Neusons nettside på http://www.wackerneuson.com/.

Vigtigt : Hvis du ønsker oplysninger om reservedele, bedes du kontakte din Wacker Neuson

forhandler eller besøg Wacker Neuson websiden på http://www.wackerneuson.com/.

Belangrijk! Neem contact op met uw Wacker Neuson dealer of bezoek de website van Wacker

Neuson op http://www.wackerneuson.com/ voor meer informatie over reserveonderdelen.

Importante : Para obter informações sobre as peças sobresselentes, consulte o seu

fornecedor da Wacker Neuson ou aceda ao site Web da Wacker Neuson em

http://www.wackerneuson.com

Ważne : W celu uzyskania informacji na temat części zamiennych skontaktuj się z

przedstawicielem firmy Wacker Neuson lub skorzystaj z witryny internetowej

http://wackerneuson.com/.

Důležité upozornění! Pro informace o náhradních dílech, prosím, kontaktujte svého Wacker

Neuson dealera, nebo navštivte webové stránky http://www.wackerneuson.com/.

FONTOS: A pótalkatrészekre vonatkozó információkért kérjük, forduljon Wacker Neuson

kereskedőjéhez vagy látogasson el a Wacker Neuson weboldalára a következő címen:

http://www.wackerneuson.com/.

Важно! Для ознакомления с информацией о запасных частях, пожалуйста, обратитесь к

местному торговому представителю компании Wacker Neuson или посетите веб-сайт

http://www.wackerneuson.com/.

Σημαντικό : Για πληροφορίες σχετικά με τα ανταλλακτικά, μιλήστε με τον αντιπρόσωπό σας της

Wacker Neuson, ή επισκεφθείτε τον ιστότοπο http://www.wackerneuson.com/.

Važno : Za rezervne dijelove obratite se svom Wacker Neuson prodavaču ili posjetite mrežne

stranice tvrtke Wacker Neuson: http://www.wackerneuson.com/.

Önemli : Yedek parça bilgileri için Wacker Neuson Bayinize bakın veya Wacker Neuson web

sitesini ziyaret edin. http://www.wackerneuson.com/

重要 交換部品の情報については、ワッカーノイソンディーラーにお問い合わせ頂くか、ワッ

カーノイソンウェブサイト http://www.wackerneuson.com/ をご覧ください。

重要 有关备件信息,请咨询您的威克诺森经销商或访问威克诺森网站:

http://www.wackerneuson.com/。

Important : Pentru informaţii referitoare la piesele de schimb, vă rugăm să vă adresaţi

distribuitorului Wacker Neuson sau să vizitaţi site-ul web Wacker Neuson la adresa

http://www.wackerneuson.com/.

Важно : За информация относно резервни части, моля, обърнете се към местния дилър

на Wacker Neuson или посетете уебсайта на Wacker Neuson на адрес

http://www.wackerneuson.com/.

Wacker Neuson Produktion GmbH & Co. KG, Preußenstraße 41, D-80809 München,

Wacker Neuson Production Americas LLC, N92W15000 Anthony Ave., Menomonee Falls, WI. 53051

Wacker Neuson Limited - Room 1701–03 & 1717–20, 17/F. Tower 1, Grand Century Place, 193 Prince Edward

Road West, Mongkok, Kowloon, Hongkong. Tel: (852) 3605 5360, Fax: (852) 2758 0032

Tel.: +49-(0)89-3 54 02-0 Fax: +49 - (0)89-3 54 02-390

Tel.: (262) 255-0500 Fax: (262) 255-0550 Tel.: (800) 770-0957

Page 40

Loading...

Loading...