Page 1

www.wackergroup.com

0201438en 002

10.2005

Gasoline powered floor saw

BFS 1350AL

Operator´s Manual

Page 2

Page 3

Important information

This machine has been equipped with an EPA certified engine.

Additional information can be found in the engine

manufacturers notes.

The engine exhaust from this product contains chemicals

known to the State of California to cause cancer, birth defects

IMPORTANT INFORMATION

WARNING

or other reproductive harm.

Caution

This engine is an EPA engine.

Adjusting the engine speed will interfere with EPA certivication and

emissions.

Only authorized personnel can make adjustments to this engine.

Please contact you nearest Motor dealer or your Wacker Dealer for more

information.

T00943GB

1

Page 4

2

Page 5

FOREWORD

Foreword

For your own safety and protection from bodily injuries, carefully read, understand and follow the safety instructions in this manual.

Please operate and maintain your Wacker machine in accordance with the instructions in this manual.

Defective machine parts are to be replaced as soon as possible.

All rights, especially the right for copying and distribution are reserved.

Copyright by Wacker Construction Equipment AG.

No part of this publication maybe reproduced in any form or byany means, electronic or mechanical, including

photocopying, without express permission in writing from Wacker Construction Equipment AG.

Any typeofreproduction,distributionorsavingondata carriers of any type or method not authorized by Wacker

represents an infringement of valid copyrights and will be prosecuted.

We expressly reserve the right to technical modifications- even without express due notice - which aim at improving our machines or their safety standards.

T00778GB

3

Page 6

TABLE OF CONTENTS

IMPORTANT INFORMATION 1

FOREWORD 3

SAFETY INSTRUCTIONS 5

General instructions 5

Operation 5

Safety checks 6

Maintenance 6

Transport 6

Maintenance checks 6

TECHNICAL DATA 7

DESCRIPTION 8

Field of applications 8

Dimensions 8

Max. admissible inclination 8

Description of function 9

General instruction for the use of diamond blades 10

8

TRANSPORT TO WORK SITE 11

OPERATION 12

Guide handle adjustment 12

Guide wheel adjustment 12

Cutting depth adjustment 13

Water tank 14

Parking brake 14

Removal of the cutting disc 15

Installation of the cutting disc 15

Right-hand, left-hand cutting conversion 16

Engine check before starting 17

Starting the engine 17

Operation the engine 18

Stopping the engine 19

MAINTENANCE 20

Maintenance schedule 20

Oil change 21

Air cleander service 21

Cleaning the fuel filter cup 22

Spark plug 22

Carburettor adjustment 22

Adjusting drive belt tension 23

Drive belt replacement 23

ELECTRIC WIRING DIAGRAM 24

LABELS 25

EC - CONFORMITY-CERTIFICATE 27

4

Page 7

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS FOR THE USE OF FLOOR SAWS

WITH COMBUSTION ENGINE

General instructions

1. Floor saws may only be operated by persons who

* are at least 18 years of age

* are physically and mentally fit for this job

* have been instructed in operating saws and proved their ability for the job to the employer

* may be expected to carry out the job they are charged with carefully.

The persons must be assigned the job of operating joint cutters by the employer.

2. Both the manufacturer’s operating instructions and these safety instructions for floor saws have to be

observed.

3. The persons charged with the operation of floor saws have to be made familiar with the necessary safety

measures relating to the machine. In case of extraordinary uses the employer shall give the necessary

additional instructions.

4. It is possible that these floor saws exceed the admissible sound level of 90 dB (A). Operators must wear

personal hearing protection if the admissible assessment sound level equals or exceeds 90 dB (A).

Operation

1. The functioning of operating levers or elements is not to be influenced or rendered ineffective.

2. Only use cutting blades suited for the circumferential (peripheral) speed or the machine’s rpm’s.

3. Always use cutting blades correctly suited for the materials to be cut.

4. Do not touch hot machine parts – danger of burns!

5. Be especially careful to observe that the cutting blade does not touch anything when starting the engine

or when lifting or putting down the machine.

6. The operator may not leave the machine while it is running.

7. The operator has to switch off the engineof thejoint cutterbefore leaving themachine. Hehas tosecure

the machine against rolling and overturning.

8. Do not smoke or handle open fire near this machine.

9. The tank lid must fit tightly. Shut fuel cock if available when stopping theengine. Forlong distancetransports of machines operated by fuel or fuel - mixtures, the fuel tank has to be drained completely.

☛ATTENTION! Leaky fuel tanks may cause explosions and must therefore be replaced

immediatelly.

10. Stop engine before filling fuel tank. When refilling fuel tank, do not allow fuel to come into contact with

the hot part of the engine or spill onto the ground.

11. Make sure that sufficient fresh air is available when operating cutters with combustion engines in enclosed areas, tunnels, adits and deep trenches.

12. Floor saws must be used in connection with water (wet cutting) in order to avoid the formation of fine

dusts which are injurious to your health. Make sure that the water supply is sufficient during wet cutting.

13. Do not operate this machine in areas where explosions may occur.

14. When working in the vicinity of inflammable materials, always have water or a fire extinguisher handy.

SV00059GB

5

Page 8

SAFETY INSTRUCTIONS

15. Always wear protective goggles, hearing protection, work gloves, protective helmet, tight-fitting clothing

and safety shoes during operations with the equipment. Shoes and pants must be closed to offer protection against flying sparks. Wear approved respiratory protection (e.g. a mask) if there is a lot of dust

in the air.

16. Avoid lateral twisting or bending of the machine during the cutting process as well as avoiding impacts,

blows or even dropping the machine as this will lead to damages of the cutting blade. Only subject the

cutting blade to radial burdens (loads).

17. Fix protective hood in lowest position before starting engine.

18. No persons are to be in the vicinity of the floor saw, i.e in front of the floor saw during operation.

19. The operator must stop the blade from turning before relocating the machine.

20. Work calmly and cautiously so as not to endanger others.

Safety checks

1. Floor power saws may only be operated if all operating and safety devices are correctly mounted. This

also includes the water tank.

2. Before starting operation, the operator has to check that all control and safety devices function properly.

3. Before starting the cutting applications check daily as follows:

* proper conditions of cutting blade.

* correct tightening of the cutting blade.

4. In case of defects of the safety devices or other defects reducing the operational safety of thefloor saw,

the supervisor has to be informed immediately.

5. In case of defects jeopardizingthe operational safety of the saw, the machine has to be switched offime

diately.

Maintenance

1. Only use original spare parts. Modifications to this machine including the adjustment of the maximum

speed set by the manufacturer are subject to the express approval of Wacker.In case of nonobservance

all liabilities shall be refused.

2. Switch off the motor and remone spark plug cap from spark plug before carrying out maintenance jobs

to avoid unintentional operation of the machine. Deviationsfrom this areonly allowedif themaintenance

jobs require a running motor.

3. Caution when checking the ignition system.The electronicignitio system produces a very hight voltage.

4. As soon as maintenance and repair jobs have been completed all safety devices have to be reinstalled.

5. Tilting the machine for maintenance works is not allowed.

6. Wash down the floor saw with fresh water after each use to avoid malfunctions.

Transport

1. Disassemble and remove the cutting blade and then place the floor saw in the lowest cutting position

before transporting the machine.

2. During transport, loading and unloading of floor saws by means of lifting devices, appropriate slinging

means or hooks have to be used on the lifting points provided for this purpose on the machine.

3. The load - carrying capacity of the loading ramps has to be sufficient and the ramps have to be secure

such that they cannot turn over. Make sure that no one be endangered by machines turning over or slipping or by moving machine parts.

4. When being transported on vehicles floor saws have to be secured against rolling, slipping or overturning.

Maintenance checks

According to the conditions and frequency of use, floor saws have to be checked for safe operation at least

once a year by skilled technicians, such as those found at Wacker-Service-Centers and have to be repaired if

necessary.

Please also observe the corresponding rules and regulations valid in your country.

SV00059GB

6

Page 9

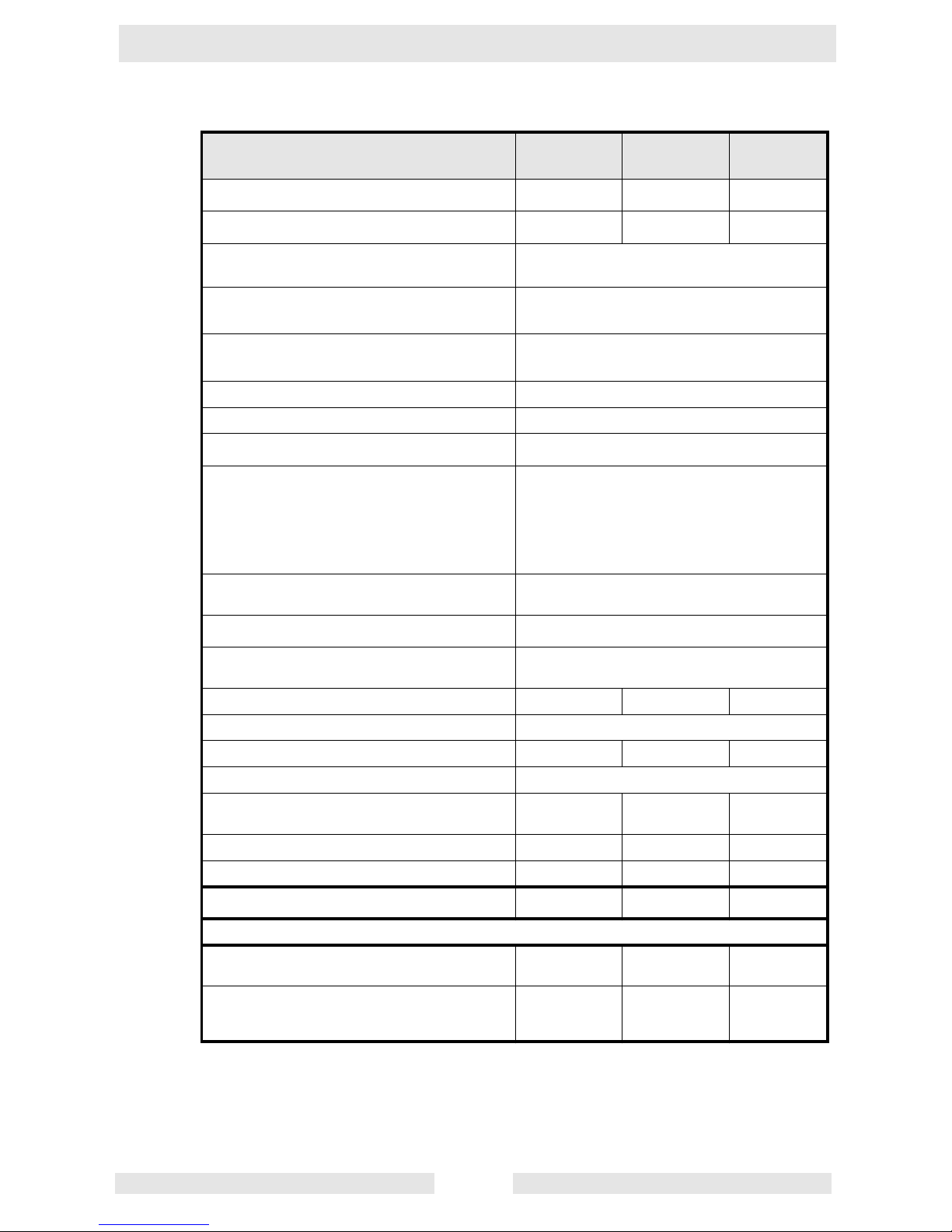

TECHNICAL DATA

BFS 1350AL BFS 1350L

Item no. 0008898 ... 0008936 ... 0008885 ...

Weight kg: 136 134 153

Power transmission From drive engine via drive belt

to cutting blade

Max. diameter of blade mm:

Min. thickness of blade mm:

Max. cutting width mm: 12

Location bore mm: 25,4

Max. cutting depth mm:

Disc’s circumferential speed

ø 350

ø 400

ø 450

ø 500

(at engine’s nominal speed)

No-load revolutions of disc

(at engine’s nominal speed)

Water tank capacity l:

in:

in:

m/s:

m/s:

m/s:

m/s:

1/min:

500

20

350

14

187,5

40,3

46,1

51,8

57,6

2200

28

BFS

1350ALS

Drive motor Air-colled single-cylinder 4 stroke

Piston displacement cm3: 389 404 389

Rated speed 1/min: 3600

Nominal output (*) kW/PS: 9,6/13 9,9/13,5 9,6/13

Fuel Normal or lead-free gasoline

Fuel consumption

(at engine’s nominal speed)

Fuel tank capacity l: 6,5 7,0 6,5

Lubricant oil capacity l: 1,1 1,2 1,1

Battery

(*) In accordance with the installed useful outlet power according to Directive 2000/14/EG.

Sound pressure level at operator’s

station

Theweighted effective acceleration

value, determined according to EN

ISO 5349

l/h: 4,3 4,2 4,3

LPA: 98 dB(A) 97 dB(A) 98 dB(A)

m/s2:

is 6,9 is 6,7 is 6,9

gasoline engine

12 V- 18 Ah

TD00673GB

7

Page 10

DESCRIPTION

Field of applications

* Cutting expansion joints in concrete and asphalt surfaces.

* Repair jobs on roads, e.g. cutting out damaged patches of either asphalt or concrete road surfaces.

* Straightening black-top and concrete surfaces.

* Demolition jobs and renovation of old dwellings.

* Cutting precast concrete elements.

* Cutting expansion joints and recesses for installations in floor toppings.

* Laying induction loops and cables in signal systems.

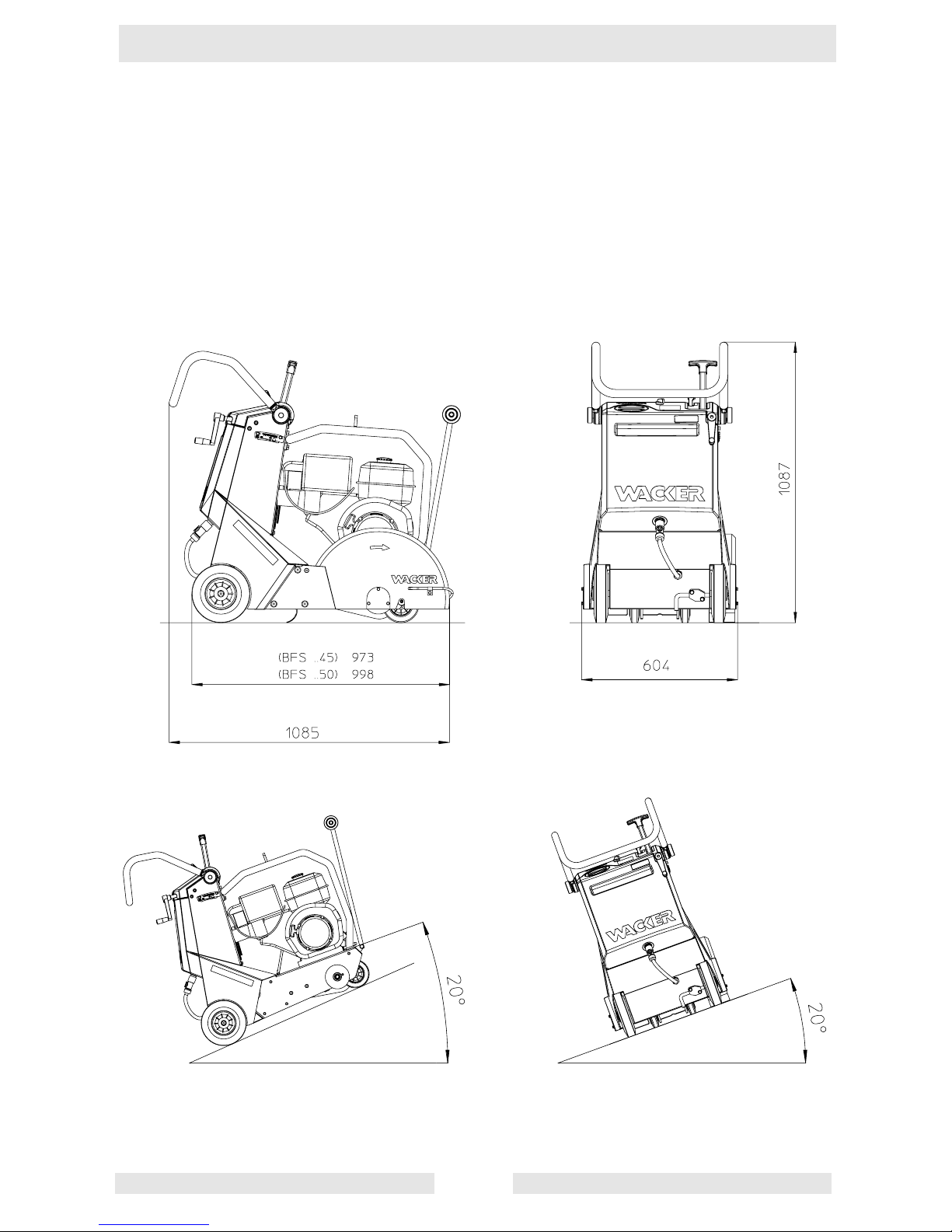

Dimensions

Max. admissible inclination

The maximum allowable tilt is related to the engine plane.

T00833GB

8

Page 11

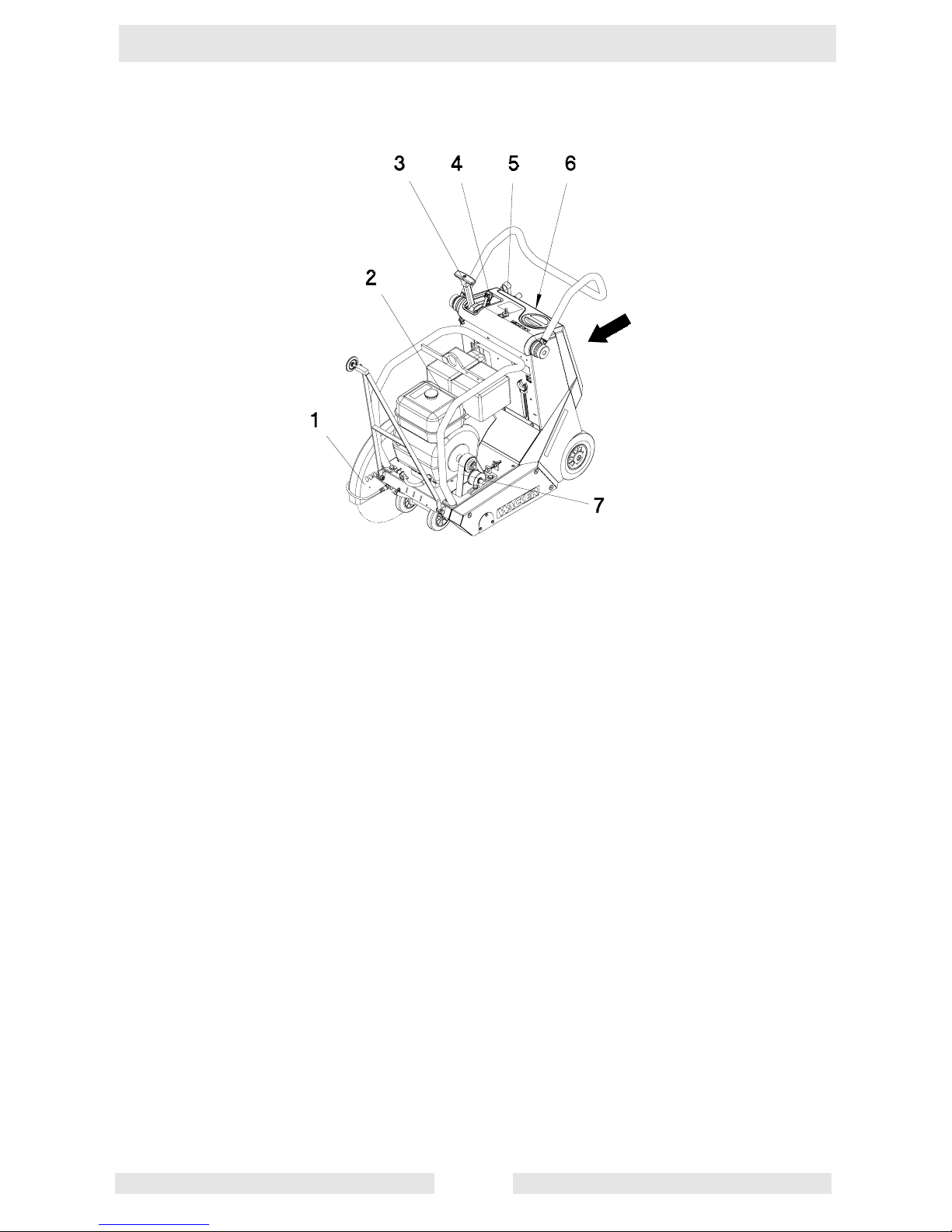

Description of function

DESCRIPTION

The floor saw should only be operated in a forward direction (see arrow).

The drive engine (2), which is fastened to the frame, drives the cutting disc by way of a drive belt (7).

A hand crank (5) is used to operate the infinitely variable height adjuster on the blade, and 1 turn = 5 mm cutting

depth adjustment. At any time it is also possible to remove or introduce the cutting disc into the material to be

cut by way of the lever (3).

The blade guard (1) can be swung away upwards for easier fixing and removing of the blade.

The blade guard is moreover linked to the water tankvia a hose and a coupling. If water is used with the blade,

this stops dust being created.

The coupling fitted to the water hose means an external water supply can be used.

A parking brake (6) has been included in the lower, right section of the console. The brake guarantees a safe

parking of the floor saw on upward or downward slopes or gradients.

The engine works according to the 4-stroke principle, is started by means of a recoil starter , takes in the air

via a dry air filter and is air colled.

The revs on the engine can be infinitely varied using the throttle control lever (4); the optimum cutting speed of

the blade is only achieved with the engine working at full load.

In order to facilitate the starting, the eingine is provieded with a choke.

T00833GB

9

Page 12

DESCRIPTION

General instruction for the use of diamond blades

* Never use a blade of a diameter larger than necessary to cut a certain depth.

* In case the blade stops operating, take it out of the cut before starting the engine anew. Check the belt ten-

sion if the cutting disc should get stuck in the cut. Check the flanged nut and make sure that it is correctly

tightened.

* Always cut in a straight line. Mark the line clearly allowing the operator to follow it easily without having to

guide it from one side to the other to come back to the line (Do not cut narrow curves).

* Sufficient drive power is essential, therefore always cut with engine at full throttle.

* Caution: Special care is required when working on slopes (lanes and surfaces). Make sure the machine is

not exerting a lateral pressure on the blade.

* Never exceed maximum speed indicated on the blade!

* Only use the appropriate cutting blade for the material you are going to cut (asphalt, concrete, ...). Wacker

has an extensive selection of diamond blades in different grades of qualities for you.

* Do not cut crushed stone or similar materials when using a diamond blade. Uneven wear may occur when

cutting road edges or two different materials. Special care is required if the material to be cut contains in-

clusions such as reinforcements, etc. as this would easily overload the blade. Proceed carefully when sta-

ring to cut, lower the blade slowly.

T00833GB

10

Page 13

TRANSPORT TO WORK SITE

Transport to work site

Conditions:

- Only use suitable lifting equipmentwith aminimum lifting capacity of 200kg forthe transport ofthe floorsaw.

- Always switch off motor during transport!

- Empty the water tank.

- Attach appropriate secure lifting devices to the central lifting point (10) provided for this purpose.

- Tie down the protection frame during transport of the floor saw on the bed of a vehicle.

- Remove the cutting disc and place the floor saw in the lowest possible cutting position before transporting

the machine.

- Turn up the guide wheel and fold the lever forwards.

- Apply the parking brake.

- Do not use the guide handle, the guide wheel or other operating devices or elements as lifting points.

Note: Also refer to the specifications in Chapter, Safety Instructions.

T00834GB

11

Page 14

OPERATION

Guide handle adjustment

The guide handle can be individually adjusted to the height of the operator.

Loosen the knurled thumb screws (11) on both sides, swivel the guide handle to the desired position and then

tighten back both knurled thumb screws.

Guide wheel adjustment

The guide wheel makes the job of cutting long straight cuts easier.

The guide wheel can be adjusted laterally to coincide exactly with the position of the cutting disc by loosening

the clamp screw (12) and then sliding the wheel in one direction or the other.

T00835GB

12

Page 15

OPERATION

Cutting depth adjustment

Place the quick-lift lever in the forward lock-in position; this will enable you to exactly adjust the cutting depth

by turning the crank (5). One turn of the crank drops the cutting disc by 5 mm (cutting depth).

It is possible to choose between two lock-in positions of the quick-lift-lever (3) at any time:

1. The forward lock-in position allows cutting with an individually set cutting depth.

2. The cutting disc isnever engaged in the material when the quick-liftlever is in the back lock-in position. The

floor saw can now be easily moved from one working area to the next.

Operation of the quick-lift lever:

1. Loosen lock with the guide handle (13) and press down T-handle.

2. Push T-handle all the way forwards or, as the case may be, backwards.

3. Let go of T-handle. The handle will lock automatically.

Each floor saw has been equipped with a metric and an inch scale; the scale is matched with the respective

standard cutting disc.

To set the scale proceed as follows:

1. Push quick-lift lever (3) fully forwards.

2. Turn the cutting depth crank (5) until the cutting disc barely starts touching the floor.

3. Loosen the screws (14) and move the arrow until it coincides with the ”0” mark of the scale.

4. Retighten the screws (14).

T00835GB

13

Page 16

OPERATION

Water tank

The floor saw has been equipped with an integrated, removable water tank (15). The filler opening (16) can be

found at top left side. The water supply can be adjusted (17) and also turned off.

To remove the water tank proceed as follows:

1. Empty the water tank completely if required. For this purpose open the metering tap (17) completely.

2. Release the hose coupling (18) once the tank has been completely drained.

3. Turn hand crank (5) to a horizontal position.

4. Apply the parking brake (6).

5. Pull the tank out by the recessed grip (20).

The adjustable hose coupling (19) can be used as a feeder point (1/2-inch) for an external hose connection.

Parking brake

To apply the parking brake (6) push bolt (21) towards the right until it locks in the spokes of the back wheel.

Always place the machine on a flat, level and non-skid surface. The maximum grade should not

exceed 10o.

T00835GB

14

Page 17

OPERATION

Removal of the cutting disc

Proceed as follows to remove a cutting disc:

1. Apply parking brake (6), stop engine (23) and stop water supply (17).

2. Move quick-lift lever (3) to position at the rear.

3. Disconnect the water hose.

4. Raise the cutting disc guard (1) all the way up.

5. Loosen the tightening nut. Hold cutting shaft with spanner at spanner surfaces.

Note: To disassemble cutting disc from right side loosen nut in clockwise direction (left-handed thread).

To disassemble cutting disc from left side loosen nut in anti-clockwise direction.

Installation of the cutting disc

Before installing check new cutting disc as follows:

* The disc type must be of the appropriate type for the material to be cut. Pay attention to the circumferential

speed, see also ”Technical Specifications”.

* The central boring of the cutting disc must fit exactly on the shaft to make sure that the disc does not run

out of center.

* The cutting disc should not be damaged.

☛ATTENTION!

Pay close attention to the correct turning direction of

the cutting disc!

In other words, check to see that the turning direction

arrow on the cutting disc coincides with the turning direction arrow on the cutting disc guard.

Proceed as follows for the installation of the cutting disc:

1. Clean the faceplates andthe locking pin and then check to

see that they are undamaged.

2. Place an intermediate layer (disc label) under each face-

plate when using bakelite-bonded cutting discs.

3. Place cutting disc and face plate on shaft.

4. Tighten the hex nut. Hold the cutting shaft with a spanner at spanner surfaces.

Note: To assemble cutting disc on right side tighten nut in anti-clockwise direction (left-handed thread).

To assemble cutting disc on left side tighten nut in clockwise direction.

5. Push cutting disc guard (1) back down.

The flange cover must be in place on the protective hood.

6. Connect the water hose.

☛ATTENTION! Only start the unit once the water hose has been plugged in (attached) and the water feed

connected.

T00835GB

15

Page 18

OPERATION

Right-hand, left-hand cutting conversion

To switch the cutting blade from one side to the other proceed as follows:

1. Disassemble the water hose fasteners and then reassemble on the opposite side in each case.

2. Loosen screws (24), remove cutting disc guard (1) and protective hood (22).

3. Loosen screws (25) and then reassemble covering plates (26) on the opposite sides.

4. Reassemble cutting disc guard (1) and protective hood (22) on the required sides.

Note: Carry out the following additional conversions if needed:

- Loosen screws (27), turn guide wheel around and then reassemble screws (27).

- Loosen screws (28), turn around dirt catcher and then reassemble screws (28).

T00835GB

16

Page 19

OPERATION

Engine check before starting

1. Oil level check

Insert dipstick in oil filter neck, butwithout screwingin. Ifoil levelis low,fill tothe topof theoil filterneck with

Fuchs Titan Unic 10W40 MC oil.

☛ATTENTION! Place machine in horizontal position before checking engine oil level.

2. Air filter system

Check to see that the air filter inserts and the cyclone housing are clean and undamaged. Cleanand replace

inserts if necessary.

3. Fuel

Use any regular grade automotive gasoline (unleaded gasoline is preferred) with a pump octane rating of

86 or higher.

Never use an oil/gasoline mixture or dirty gasoline: Avoid getting dirt, dust or water in the fuel tank.

Caution: Gasoline substitutes are not recommended, they may be harmful to the fuel system compo-

nents.

Starting the engine

☛ATTENTION! The cutting disc should not be permitted to be contact with the ground.

1. Turn the fuel valve to the ON position.

2. Move the choke lever to the CLOSE position.

Note: If the engine is warm or the air temperature is high, move the control lever away from the Choke

postion as soon as the engine starts.

T00835GB

17

Page 20

3. Push throttle lever (4) slightly forward.

4. Turn main switch (23) to position ”1”.

5. Pull starter handle out slowly until a slight resistance is felt, then pull handle with strength.

OPERATION

Caution: Do not allow the starter grip to snap back against the en-

gine. Return it dently to grevent damage to the starter.

Operation the engine

As the engine warms up, gradually move the choke lever to the OPEN position.

Set required engine speed with throttle lever (4)

Oil Alert system

The Oil Alert system is designed to prevent engine damage caused by an insufficient amount of oil in the crank-

case. Before the oil level in the crankcase. Before the oil level in the crankcase can fall below a safe limit, the

Oil Alert system will automatically shut down the engine (leave the main switch in position ”1”).

T00835GB

18

Page 21

Stopping the engine

Turn the main switch to the position ”0” to stop the engine in an emergency.

Proceed as follows under normal working conditions:

1. Pull the throttle lever (4) all the way back to the stop

position.

2. Turn the main switch to the position ”0”.

OPERATION

3. Turn the fuel valve to the OFF position.

T00835GB

19

Page 22

MAINTENANCE

Maintenance schedule

Check all external screw connections for tight fit approx. 8 hours after first operation.

Parts Maintenance jobs Maintenance interval

Air filter Check for external damage and tight daily

fit.

Check foam and filter insert clean or replace if

necessary.

Fuel Check tank lid for tightfit, replace if

necessary.

Engine oil Check oil level, top up if necessary.

Other parts Check cutting disc for damages and correct tightenning

- change and or adjust if necessary. Pay attention

to the directional arrow on the disc.

Control smooth working of the height adjustment.

Control water supply.

Belts Check tension and wear – replace if necessary. weekly

Engine oil First oil change. 20 hours

Air filter Clean. 50 hours

Ignition system Clean spark plug, check spark plug gap 0,7 mm. 100 hours

Engine oil Furhter oil changes.

Valve clearance Check, set - 0,15 mm intake valve, 0,20 mm exhaust 300 hours

valve.

T00836GB

20

Page 23

MAINTENANCE

Oil change

Drain the oil while the motor is still warm to assure rapid and complete draining.

1. Remove the oil filler cap drain plug to drain the oil.

2. Install the drain plug, and tighten it securetly.

3. Refill with the recommended oil and check oil level.

☛ATTENTION! Place machine in horizontal position before checking engine oil level.

4. Install the oil filter cap.

Motor oil capacity: 1,1 l (1,06 USqt., 1,78 lmp pt)

Take notice: Please pay attention to the corresponding environmental laws when disposing of used engine

oil. We recommend you carry the oil in a container to a central collecting point forused oils.Do

not pour used engine oil into the garbage nor into the sewer system, waste pipes or even on

the ground.

Air cleander service

A dirty air cleaner will restrict air flow to the carburetor, To prevent carburetor malfunction, service the air

cleaner regularly. Service more freqently when operating the motor in extremely dusty areas.

Warning: Never use gasoline or low flash point solvents for cleaning the air cleaner element. A fire or ex-

plosion could result.

Caution: Never run the engine without the air cleaner. Rapid engine wear will result.

1. Remove the wing nut and the air cleaner cover. Remove the elements and sparate them. Carefully check

both elements for holes or tears and replace if damaged.

2. Foam insert: Wash the insert in warm soap water, rinse and dry thoroughly. Alternatively wash the insert in

a cleaning agent with a high flashing (ignition) point and then let dry. Then impregnate the insert with clean

engine oil and press out excess oil. The engine will smoke during inial start-up if too much oil is left in the

foam.

3. Paper element: Tap the element lightly serveral times on a hard surface to remove excess dirt, or blow compressed air through the filter from the inside out. Never try to brush the dirt off; brushing will force dirt into

the fibers.

Replace the paper element if it is excessively dirt.

Cleaning the cyclone housing:

If dust has collected in the cyclone housing unscrew the three flat-head special screws and then wipe clean or

wash the parts with water. Then thoroughly dry the components and reassemble carefully.

Caution: - When reassembling the cyclonepay close attentionto seethat the tabof the airinput fitsperfectly

into the groove of the pre-filter cover.

- Assemble the air duct in the right direction.

T00836GB

21

Page 24

MAINTENANCE

Cleaning the fuel filter cup

Close the fuel tap. Remove the cup with the O-ring and clean with non-inflammable or hardly-inflammable solvent. Let dry thoroughly, then reassemble and tighten well. Turn the fuel valve on, and check for leaks.

Spark plug

Recommended spark plug: BP6ES-11, BPR6ES-11 (NGK), W20EP-U11, W20EPR-U11 (ND).

Caution: Never use a spark plug of incorrect heat range.

To ensure proper motor operation, the spark plug must be properly gapped and free of deposits.

1. Remove the spark plug cap, and use a spark plug wrench to remove the plug.

Warning: If the motor has been running, the muffler will be very hot. Be careful not to touch the muffler.

2. Visually inspect the spark plug. Discard it if the insulator is cracked or chipped. Clean the spark plug with a

wire brush if it is to be reused.

3. Measure the plug gap with a feeler gauge. The gap should be 0,7-0,8 mm (0.039-0.043 in). Correct as necessary by bending the side electrode.

4. Check that the spark plug washer is in good condition, and thread the spark plug in by hand to prevent

cross-threading.

5. After the spark plug is seated, tighten with a spark plug wrench to compress the washer.

Note: If installing a new spark plug, tighten 1/2 turn after the spark plug seats to compress the wash-

er. If reinstalling a used spark plug, tighten 1/8-1/4 turn after the spark plug seats to compress

the washer.

Caution: The spark plug must be secrely tightened. An improperly tightened spark plug can become

very hot and may damage the motor.

Carburettor adjustment

* Start the motor and allow it to warm up to normal operting temperature.

* With the motor idling, turn the pilot screw in or out to the setting that produces the highest idle rpm. The

correct setting will usually be approximately 2 1/4 turns from the fully closed position.

Caution: Do not tighten the pilot screw against its seat, this will damage the piot screw or seat. After the

pilot screw is correctly adjusted, turn the throttle stop screw to obtain the standard idle speed.

Standard idle speed: 1 400 + 150 rpm.

1. Pilot screw 2. Throttle stop screw

T00836GB

22

Page 25

MAINTENANCE

Adjusting drive belt tension

The tension of the belt should be checked at the time of the weekly engine maintenance and, if necessary,

tensioned as follows:

1. Remove V-belt guard.

2. Loosen counter nut (31).

3. Loosen the fastening screws (32) until the V-belt’s take-up

can be shifted without play.

4. Adjust drive belt tension with tensioning nut (33).

5. Tighten the fastening screws (32) and the counter nut (31).

Drive belt replacement

1. Disassemble V-belt guard (above and below) and cutting disc guard.

2. Take tension off V-belts. To do this loosen the counter nut (31), the tensioning nut (33) as well as the fastening screws (32). Only loosen the fastening screws so far that the V-belt’s take-up can be moved freely

without play.

3. Loosen the screws (34) at the oval flanges (on both sides) of the cutting shaft.

4. Replace the V-belts.

5. Reassemble cutting shaft (34).

6. Adjust drive belt tension (see „Adjusting drive belt tension“).

7. Reassemble cutting disc and V-belt guards.

T00836GB

23

Page 26

Switch

ELECTRIC WIRING DIAGRAM

yellow

brown

Ground Frame

brown

Ground

Fuel line yellow/black

Engine

SK00652GB

24

Page 27

LABELS

1 Warning sign

2 Lifting point

3 Notice sign

4 Notice sign

5 Notice sign

6 Notice sign

8 Type

9 Wacker Logo

10 Sound power level

SK00651GB

25

Page 28

26

Page 29

EC - CONFORMITY-CERTIFICATE

Wacker Construction Equipment AG , Preußenstraße 41, 80809 München

hereby certify that the construction equipment specified hereunder:

1. Category: Powered floor saw

2. Type: BFS 1345... / BFS 1350...

3. Equipment item number:

0008764 ..., 0008885 ..., 0008898 ..., 0008909 ..., 0008936 ...

4. Measured sound power level: 106 dB(A)

5. Guaranteed sound power level: 107 dB(A)

and has been manufactured in accordance with the following directives:

2000/14/EG

89/336/EG

98/37/EG

.......................................................

Dr. Sick

Board of Directors

File certificate carefully

C0003306.GB

Page 30

28

Page 31

DIN EN ISO 9001 CERTIFICATE

Page 32

Wacker Construction Equipment AG - Preußenstraße 41 - 80809München - Tel.: +49-(0)89-3 54 02-0 - Fax: +49-(0)89-3 54 02-390

WackerCorporation - P.O. Box 9007 - MenomoneeFalls,WI53052-9007 - Tel.:+1-(1)(262)-255-0500 - Fax:+1-(1)(262)-255-0550 - Tel.:(800)770-0957

Wacker Asia Pacific Operations-Skyline Tower, Suite 2303, 23/F, 39 Wang Kwong Road, Kowloon Bay, Hong Kong-Tel.: +852 2406 6032-Fax: +852 2406 6021

Page 33

Page 34

Loading...

Loading...