Page 1

www.wackerneuson.com

Operator's manual

Floor saw

BFS 1345

B, BZ

0203599en 006

11.2008

Page 2

Page 3

T00940en.fm 3

Important note

EPA-certified engine

This machine is equipped with an EPA-certified engine.

Relevant details can be found in the instructions of the engine manufacturer.

Warning

The engine's exhaust fumes contain chemicals which are known to the

State of California to cause cancer, congenital defects or other reproductive anomalies.

Page 4

T00940en.fm 4

Page 5

5

Foreword

1. Foreword

For your own safety and protection from bodily injuries, carefully read,

understand and follow the safety information in this manual.

Please operate and maintain your Wacker Neuson machine in accordance with the instructions in this operator's manual. Your Wacker

Neuson machine will reward you with troublefree operation and a high

degree of availability.

Defective components must be replaced immediately.

All rights, especially the right for copying and distribution, are reserved

Copyright 2008 by Wacker Construction Equipment AG

No part of this publication may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without express permission in writing from Wacker Construction Equipment AG.

Any type of reproduction, distribution or saving on data carriers of any

type or method not authorized by Wacker Neuson represents an infringement of valid copyrights and will be prosecuted. We expressly reserve

the right to make technical modifications - even without special notice which aim at further improving our machines or their safety standards.

Page 6

Table of contents

6

1. Foreword 5

2. Safety information 8

2.1 General instructions ..............................................................................8

2.2 Operation ...............................................................................................8

2.3 Safety checks ......................................................................................10

2.4 Maintenance ........................................................................................11

2.5 Transport .............................................................................................11

2.6 Maintenance checks ............................................................................11

3. Technical data 12

4. Description 13

4.1 Application ...........................................................................................13

4.2 Maximum permissible tilt .....................................................................13

4.3 Functional description .........................................................................14

4.4 General instructions for use for diamond-edged cutting blades ..........15

5. Transport to the worksite 16

6. Operation 17

6.1 Adjusting the handle ............................................................................17

6.2 Adjusting / Aligning the guide wheel ....................................................18

6.3 Cutting depth setting ...........................................................................19

6.4 Depth of cut indicator ..........................................................................19

6.5 Water tank ...........................................................................................20

6.6 Parking brake ......................................................................................21

6.7 Assembling the cutting blade ..............................................................22

6.8 Disassembling the cutting blade ..........................................................23

6.9 Checking the motor before starting .....................................................24

6.10 Starting the engine ..............................................................................25

6.11 Engine operation .................................................................................27

6.12 Switch off the engine ...........................................................................28

Page 7

Table of contents

7

7. Maintenance 29

7.1 Maintenance schedule ........................................................................29

7.2 Checking engine oil level .....................................................................30

7.3 Changing the engine oil .......................................................................30

7.4 Cleaning the air cleaner ......................................................................31

7.5 Cleaning the screws, nuts and bolts ....................................................31

7.6 Tightening the belt ...............................................................................32

7.7 Changing the belt ................................................................................33

7.8 Checking the spark plug ......................................................................34

8. Signs 35

EC Declaration of Conformity 37

DIN EN ISO 9001 Certificate 39

Page 8

Safety information

SV00075en.fm 8

2. Safety information

for floor saws with combustion engine drive

2.1 General instructions

2.1.1 Floor saws may only be operated by persons who

∗ are at least 18 years of age,

∗ are physically and mentally fit for this job,

∗ have been instructed in operating floor saws and have proved their

abilities to the employer and

∗ may be expected to carry out the job they are charged with carefully.

They must have been assigned to work on the floor saws by the company.

2.1.2 Floor saws may only be operated taking the operator's manual of the

manufacturer and this safety information into account.

2.1.3 The persons charged with the operation of floor saws must be made

familiar with the necessary safety measures relating to the machine. In

case of extraordinary uses, the employer shall give the necessary additional instructions.

2.1.4 This machine generates noise that exceeds the country-specific permissible noise levels (individual rating level). It may therefore be necessary to wear ear protection.

2.2 Operation

2.2.1 The function of operation levers or elements must not be influenced or

rendered ineffective.

2.2.2 Use only cutting blades that are suitable for the peripheral speed or the

speed of the machine.

2.2.3 Always use the correct cutting blade for the material to be cut.

2.2.4 Do not touch hot parts as they can cause burns!

2.2.5 Particularly when starting the engine you have to make sure that the

cutting blade does not come into contact with anything.

2.2.6 Never let the machine run unattended.

2.2.7 The operator must not leave the machine during operation.

2.2.8 Before the operator leaves the floor saw unattended, he must switch

off the engine and take precautions to prevent the machine from

slipping or falling over.

Page 9

Safety information

SV00075en.fm 9

2.2.9 Open flames and smoking are strictly prohibited in the immediate

vicinity of this machine.

2.2.10 The tank lid must be tightly secured. When the motor is switched off,

the fuel tap - if there is one - must be closed. When transported over

long distances, the tank of gasoline or mixed gasoline driven engines

must be completely emptied.

Leaking fuel tanks can lead to explosions and therefore must be replaced immediately.

2.2.11 The tank may only be filled when the motor is switched off and the fuel

must not make contact with hot parts or fall on the ground.

2.2.12 Safety in the work area

There may be no electric lines, gas lines, water lines or pipes in the

work area.

2.2.13 No operation in closed quarters

Do not operate the machine in closed quarters!

In partially closed rooms such as tunnels, drifts or deep trenches, ensure sufficient ventilation by, for example, providing a powerful exhaust

air fan.

Danger of poisoning! Do not inhale exhaust fumes. They contain toxic

carbon monoxide that can lead to unconsciousness or death.

2.2.14 Floor saws must be operated in wet-cutting operation to prevent

harmful particulate matter from developing. During wet-cutting

operation, a sufficient water supply must always be ensured.

2.2.15 Do not operate this machine in areas where explosions may occur.

2.2.16 Prior to working near easily combustible material, ensure that supplies

of water or a fire extinguisher are readily available for use.

2.2.17 Always wear eye protection, ear protection, working gloves, hard hat,

close-fitting clothing and hard-toed shoes during work. Shoes and leg

wear must not be open in order to protect the wearer from flying

sparks. In the case of dusty ambient air, breathing protection must also

be worn.

2.2.18 Prevent the machine from turning to the side in the case of cuts,

thrusts, blows or falls. Otherwise, the cutting blade may be damaged.

Only cut materials on the edge of the blade.

2.2.19 Prior to commissioning, fix the protective hood in protective position.

2.2.20 During work, no one is to come near the machine.

2.2.21 Prior to making adjustments, the operator must stop the cutting blade.

2.2.22 Work in a calm and composed manner. Prevent risks to others by

exercising caution.

2.2.23 Do not process loose materials (e.g. paving stones).

Page 10

Safety information

SV00075en.fm 10

2.3 Safety checks

2.3.1 Floor saws may only be operated with all safety devices installed.

2.3.2 Before starting operation, the operator has to check that all control and

safety devices are functioning properly.

2.3.3 Prior to starting the cutting operation, the following have to be checked

on a daily basis:

∗ Proper condition of the cutting blade.

∗ Tightness of the cutting blade.

∗ Damage and wear of the operating and safety equipment.

2.3.4 If defects on the safety devices or other defects impairing the

operational safety of machine are observed, the supervisor must be

informed immediately.

2.3.5 If there are defects jeopardizing operational safety, the machine has to

be switched off immediately.

Page 11

Safety information

SV00075en.fm 11

2.4 Maintenance

2.4.1 Only use original spare parts. Alterations to this machine, incl. adjustments of the maximum engine speed set by the manufacturer may only

be carried out with the express permission of Wacker Neuson. In case

of non-observance, all liability shall be refused.

2.4.2 Switch off the motor during maintenance work and remove the spark

plug terminal cap (if there is one), in order to avoid an unintentional

start. This procedure may only be waived if the work cannot be carried

out when the motor is switched off.

2.4.3 Exercise caution when checking the ignition system. The electronic

ignition creates a very high voltage.

2.4.4 As soon as maintenance and repair jobs have been completed, all

safety devices must be properly reinstalled.

2.4.5 It is not permitted to tilt the machine for maintenance work.

2.4.6 In order to prevent malfunctions, the floor saw should be cleaned using

water after each use.

2.5 Transport

2.5.1 Prior to transport, the cutting blade must be removed and the floor saw

must be put in the lowest cutting position.

2.5.2 For the loading and transportation of floor saws with hoisting gear,

suitable sling chains must be secured at the relevant fixing point.

2.5.3 Loading ramps must be able to bear the load and be in a stable

position. Make sure that no one can be endangered if the machine

slips away or tips over, or if machine parts suddenly move upward or

downward.

2.5.4 When floor saws are being transported in vehicles, precautions have

to be taken to ensure that they do not slip and fall over.

2.6 Maintenance checks

2.6.1 According to the conditions and frequency of use, floor saws must be

checked for safe operation at least once a year by skilled technicians,

such as those employed by Wacker Neuson service stations, and

repaired if necessary.

Please observe the appropriate rules and regulations valid in your country.

Page 12

Technical data

TD00737en.fm 12

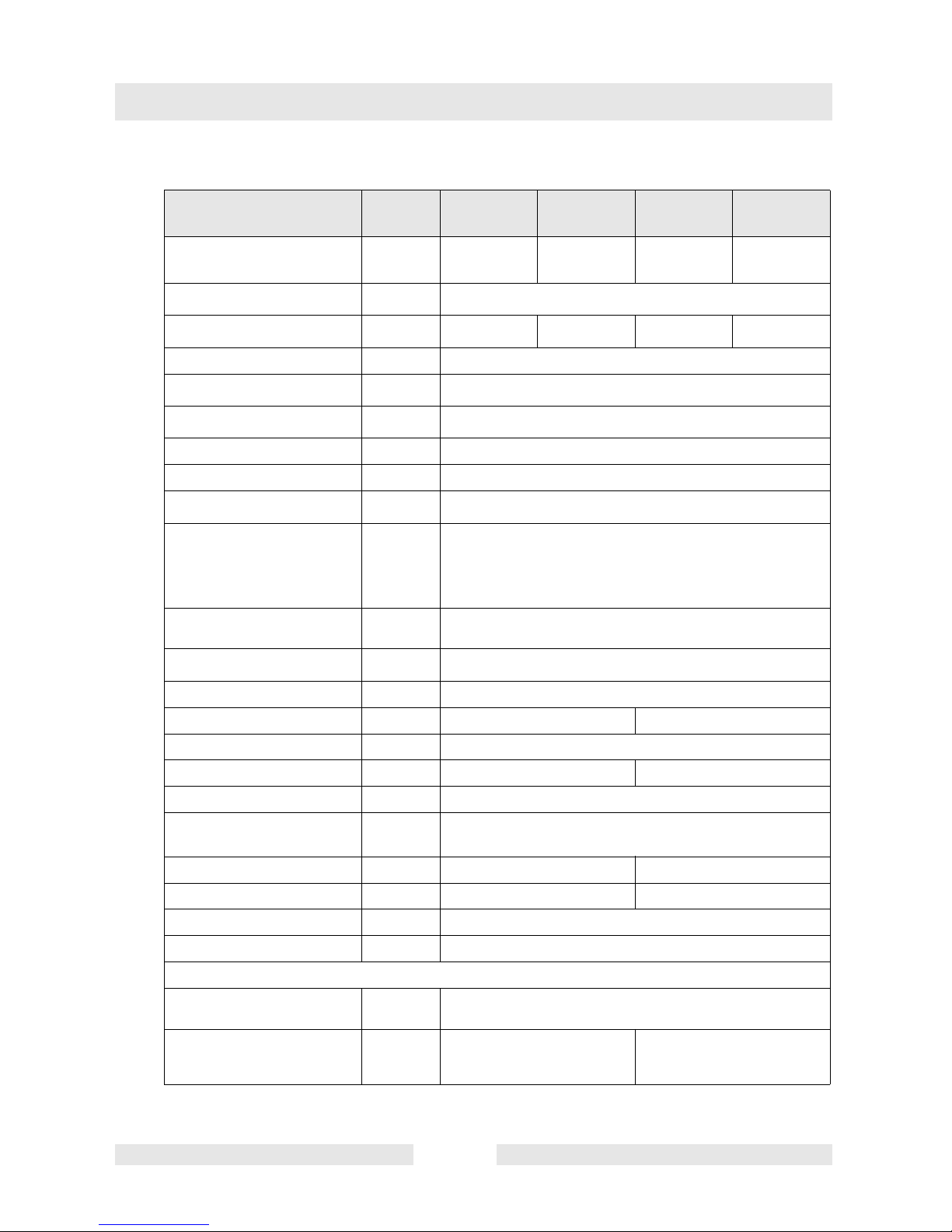

3. Technical data

BFS

1345 AB

BFS

1345 ABZ

BFS

1345 B

BFS

1345 BZ

Item no.

0008764

0610141

0610242

0008909

0610142

0610243

Length x Width x Height mm (in): 1,160 x 568 x 1,078 (45.67 x 22.36 x 42.44)

Weight kg (lb): 95 (209) 96 (212) 95 (209) 96 (212)

Powertrain From drive motor via belt to cutting blade

Max. cutting blade diameter mm (in): 450 (17.72)

Min. cutting blade diameter mm (in):

350 (13.78)

Max. cutting width mm (in): 12 (0.47)

Center bore mm (in): 25.4 (1.00)

Max. cutting depth cm (in):

17 (6.69)

Peripheral blade speed at

ø 350

ø 400

ø 450

(at rated engine speed)

m/s (ft/s):

m/s (ft/s):

m/s (ft/s):

40.3 (132)

46.1 (151)

51.8 (170)

Operating blade speed

(at rated engine speed)

rpm:

2,200

Water tank capacity l (gal):

32 (8.45)

Drive motor Air-cooled, single-cylinder, four-stroke gasoline engine

Engine displacement cm

3

(in3): 389 (23.73) 404 (24.65)

Rated speed rpm: 3,600

Rated power (*) kW/HP: 9.6/13 9.9/13.5

Fuel Normal gasoline, also unleaded

Fuel consumption

(at rated output)

l/h

(gal/h):

4.3

(1.14)

Fuel tank capacity l (gal): 6.5 (1.72) 7.0 (1.85)

Oil capacity l (gal): 1.1 (0.29) 1.2 (0.32)

Oil specification SAE 15W-40

Spark plug Type: NGK BPR6ES

(*) Corresponds to the installed effective power in accordance with Directive 2000/14/EC

Sound pressure level at

operator's station

L

PA

: 97 dB(A)

Weighted effective acceleration value according to

EN ISO 5349

m/s

2

:

6.2 7.5

Page 13

Description

T01067en.fm 13

4. Description

4.1 Application

∗ Cutting expansion joints in concrete and asphalt surfaces.

∗ Repair work on streets, e.g. cutting out damaged areas in asphalt and

concrete.

∗ Straightening blacktops and concrete surfaces.

∗ For demolition jobs and refurbishment of old buildings.

∗ Sawing off precast concrete parts.

∗ Expansion joints and installation channels in floors.

∗ Laying induction loops and cables in signal installations.

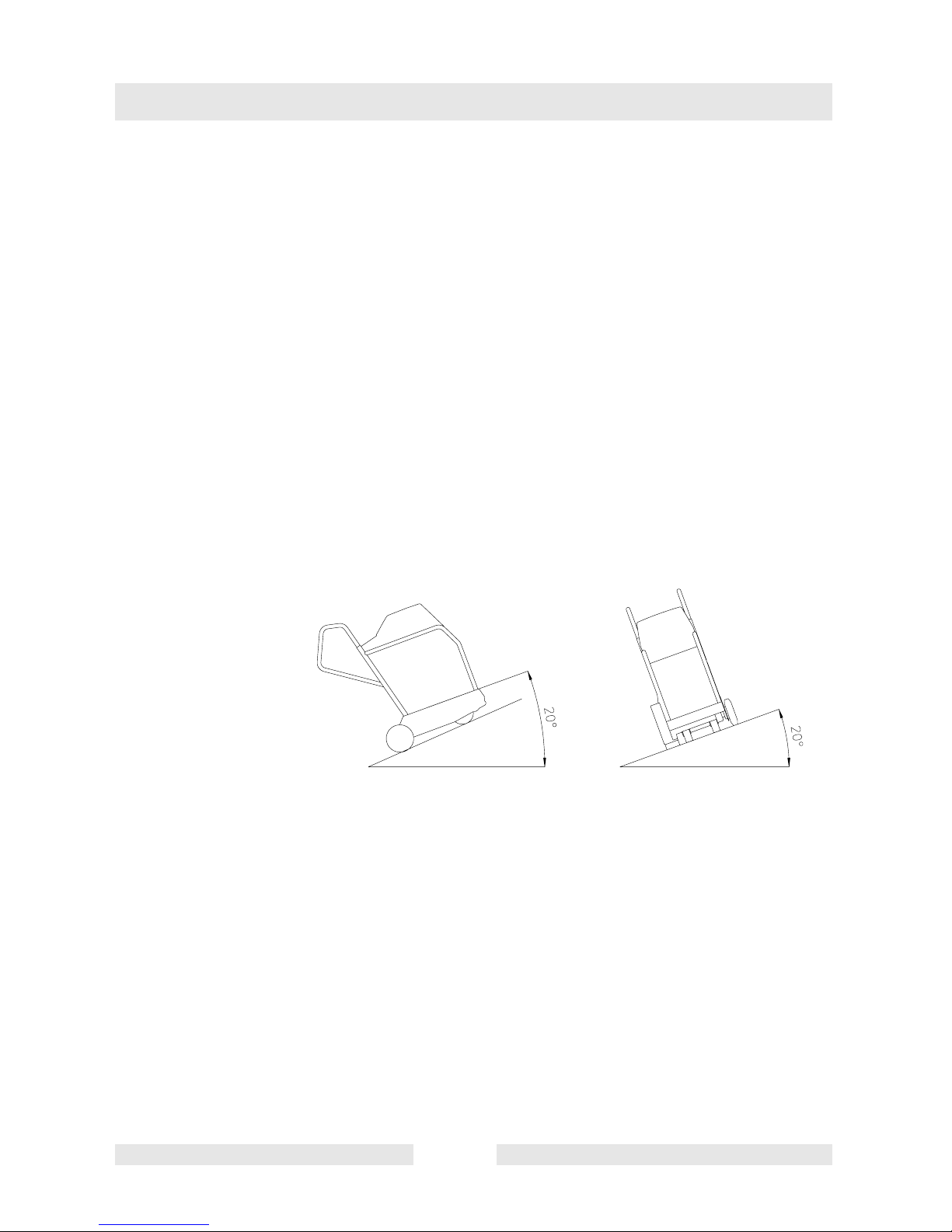

4.2 Maximum permissible tilt

The maximum permissible tilt applies to the engine level.

Page 14

Description

T01067en.fm 14

4.3 Functional description

The floor saw must only be operated in a forward direction (see arrow).

The drive motor (1) attached to the frame drives the cutting blade via

the belt (2).

The cutting blade can be infinitely adjusted by means of a crank

handle (3), 1 turn corresponds to a cutting depth adjustment of 5 mm.

The cutting blade guard (4) can be swiveled upwards to make it easier

to assemble and disassemble the cutting blade.

Furthermore, the cutting blade guard can be connected with the water

tank by means of a hose (5) and an adapter.

Wetting the cutting blade with water prevents dust from developing.

The adapter on the water hose allows the connection of an external

water supply.

The drive motor speed can be infinitely adjusted by means of the gas

throttle lever (6), whereby the optimum cutting blade speed is reached

when the drive motor is operated at full throttle.

To facilitate the starting procedure, the drive motor is equipped with a

choke.

Page 15

Description

T01067en.fm 15

4.4 General instructions for use for diamond-edged cutting blades

∗ Never use a cutting blade with a larger diameter than necessary in or-

der to cut a certain depth.

∗ If the cutting blade comes to a standstill, remove it from the cut before

starting the machine again. If the cutting blade comes to a standstill in

the cut, check whether the belt is tightened adequately. Check the tension screw and make sure that it is tightened properly.

∗ Cut in a straight line. Mark the cutting line clearly in such a way that the

operational personnel can follow it easily. This is to ensure that the

floor saw machine does not need to be redirected from one side to the

other (avoid cutting tight curves).

∗ Sufficient drive power is essential! When cutting, work at full throttle.

∗ Caution on steep tracks and levels! The machine must not exert lateral

force against the blade.

∗ Never exceed the maximum speeds (imprinted on cutting blade)!

∗ Use a suitable diamond-edged cutting blade for the material to be cut

(asphalt, concrete ...). Wacker Neuson offers an extensive range of diamond-edged cutting blades in different qualities.

∗ Do not cut into the gravel area using diamond-edged cutting blades.

When cutting on the edge of the track or when cutting two different materials (cutting in the joint area), uneven wear is possible. Check carefully for irregularities (reinforcements etc.) in the material to be

processed. These can overload the cutting blade very quickly. When

starting cutting operations, work carefully and with a low down speed.

∗ Do not process loose materials (e. g. paving stones).

Page 16

Transport to the worksite

T01111en.fm 16

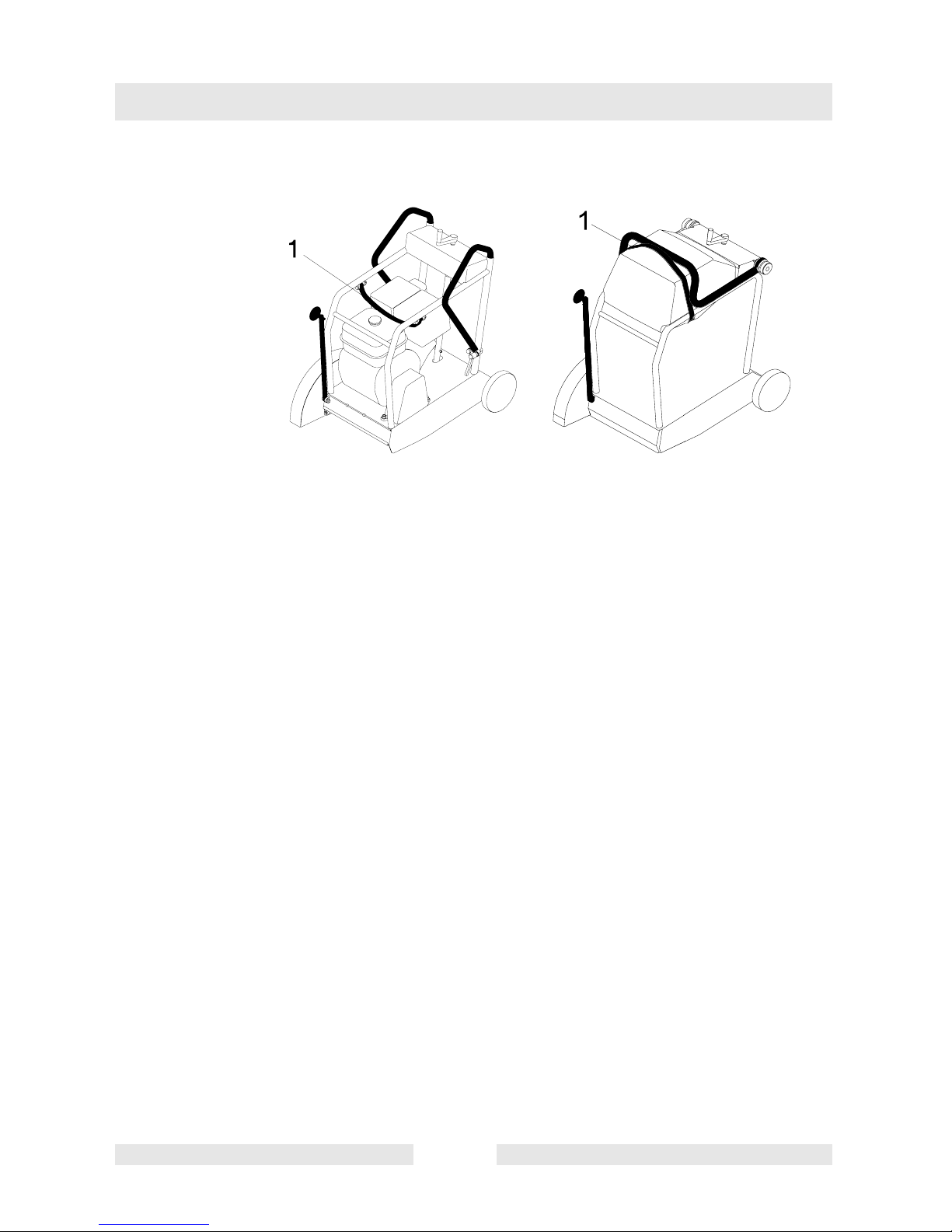

5. Transport to the worksite

Requirements:

∗ When transporting the floor saw, use only suitable hoisting gear with a

minimum load-bearing capacity of 150 kg.

∗ Always turn off the motor during transportation!

∗ Empty the water tank!

∗ Remove the cutting blade prior to transport. Set the lowest cutting po-

sition on the floor saw.

∗ Remove the water tank and attach the hoisting gear on the transport

strap (1) for lifting.

∗ If you transport the floor saw on the cargo area of a vehicle, strap it

down securely on the special safety bar.

∗ Fold the guide wheel to the top and the handles to the front (or the stir-

rup handle to the top).

∗ Handles, guide wheel and other operating controls must not be used

as attachment points.

Note: Also observe the regulations in the chapter Safety information.

Page 17

T01110en.fm 17

Operation

6. Operation

6.1 Adjusting the handle

6.1.1 Handle

The width and height of the handles can be adjusted according to the

use and the body height of the operator. To do this, release the

clamping lever (1) and apply it in the new position.

6.1.1 Stirrup handle (alternative version)

The height of the stirrup handle can be adjusted according to the use

and the body height of the operator.

Loosen the knurled screws (1) on both sides, swivel the handle to the

desired position and retighten the two knurled screws.

Page 18

Operation

T01110en.fm 18

6.2 Adjusting / Aligning the guide wheel

6.2.1 Adjusting the guide wheel

The guide wheel is designed to help the operator in making long,

straight cuts. The guide wheel can be exactly adjusted to the cutting

blade by loosening the jam nut (1) and turning the screw (2).

6.2.2 Aligning the guide wheel

To do this, make a cut of approx. 2 m length on a flat surface and with

the minimum cutting depth. Then pull back the machine without lateral

force. Then you can align the guide wheel exactly with the cut.

Page 19

T01110en.fm 19

Operation

6.3 Cutting depth setting

With the crank (1) you can set the cutting depth precisely. One turn

changes the cutting depth by exactly 5 mm. Turn the crank in the

clockwise direction to increase the cutting depth and turn it in the

counterclockwise direction to reduce the cutting depth.

Note: You can also insert the supplied tool into the receptacle (2) near

the crank and thus prevent an unintentional change of the cutting

depth.

6.4 Depth of cut indicator

You can use the indicator to check the cutting depth currently set. It

features a cm-scale and an inch-scale. You have to adjust it to the

diameter of the blade currently installed to obtain the correct value. To

do this, turn the crank (1) until the blade touches the ground, loosen

the clamp (2) and push the sleeve (3) with the scale up to the bottom

of the sleeve. Then tighten the clamp (2) again.

Page 20

Operation

T01110en.fm 20

6.5 Water tank

The floor saw features an integrated, removable water tank (1).

To fit the water tank, attach the retaining clamp (2) and tighten it with

the strap (3).

To remove the water tank or to attach an external water supply, you

can disconnect the hose on two different spots (4).

The amount of water can be regulated or stopped (5).

Note: You should remove the water tank if the machine is connected to an

external water supply.

Page 21

T01110en.fm 21

Operation

6.6 Parking brake

6.6.1 Integrated parking brake

The machine features an integrated parking brake.

The front wheels are automatically blocked in transport position

(lowest cutting position without a cutting blade) or if the maximum

cutting depth is exceeded.

6.6.2 Manual parking brake (accessories)

Press the pedal (1) down to block the right rear wheel. Push the pedal

upwards for brake release.

Check the tight fit of the parking brake and the setting of the pressure

screw (2) at regular intervals. The brake must securely block the wheel

at least on a 10° slope. Adjust the pressure screw if necessary.

Page 22

Operation

T01110en.fm 22

6.7 Assembling the cutting blade

6.7.1 Checking a new cutting blade:

∗ The blade type must be suitable for the material to be cut. Observe the

peripheral speed, refer to the "Technical data"!

∗ The arbor diameter of the cutting blade must precisely fit the shaft to

ensure smooth blade running.

∗ The cutting blade must be undamaged.

Observe the correct direction of rotation of the cutting blade! That

means the rotational direction mark on the cutting blade must

correspond with the rotational direction mark on the cutting blade

guard.

6.7.2 Proceed as follows for the assembly of the cutting blade:

1. Fold up the cutting blade guard (1).

2. Prior to the assembly of the cutting blade, clean the spring washers

and the locking pin and check them for damage.

3. Attach cutting blade and spring washer on the shaft.

4. Tighten the hexagonal bolt firmly. To do this, apply counter pressure

on the spanner surfaces of the cutting shaft.

5. Fold down the cutting blade guard.

Starting the machine is only permitted with a water hose connected

and the water supply turned on.

Page 23

T01110en.fm 23

Operation

6.8 Disassembling the cutting blade

Proceed as follows for the disassembly of the cutting blade:

1. Turn off the engine (2) and the water supply (3).

2. Turn the crank (4) in the counterclockwise direction until the blade

is clear of the ground.

3. Fold up the cutting blade guard (1).

4. Loosen the hexagonal bolt. To do this, apply counter pressure on

the spanner surfaces of the cutting shaft.

5. Remove the spring washer and the cutting blade.

6. Fold down the cutting blade guard.

Store the spring washer and the hexagonal bolt in a clean place where

they cannot become dirty. Assemble both parts for the transport of the

machine!

Page 24

Operation

T01110en.fm 24

6.9 Checking the motor before starting

6.9.1 Engine oil

Switch off the engine.

Prior to checking the engine oil level or refilling engine oil, make sure

that the engine bolting level is aligned horizontally.

∗ Remove the oil filler cap (oil level indicator).

∗ If the oil level is below the lower filling mark on the dip stick, add suit-

able engine oil until the oil reaches the edge of the filler neck.

∗ An oil change is required if the engine oil is dirty.

∗ Only use high-quality engine oil, see Technical Data.

The engine is automatically switched off when the oil level falls below

a specific level. If this is the case, the engine can only be started after

engine oil has been refilled.

6.9.2 Fuel

Do not smoke during refueling and make sure that there are no open

flames or sparks in the immediate vicinity.

∗ Turn off the engine and open the fuel tank cap.

∗ Only use leadfree fuel.

∗ Close the fuel tap before the fuel tank is filled with fuel.

∗ Always use the fuel filter when refilling fuel.

∗ Wipe off any spilled fuel before starting the engine.

Oil level

indicator

Upper level mark

Lower level mark

Page 25

T01110en.fm 25

Operation

6.10 Starting the engine

The cutting blade must not be in contact with the ground.

1. Switch the main switch (1) to "I".

2. Open the fuel tap.

.

3. Shift the throttle lever (2) to approximately 1/3 of the full throttle

position.

Close

Close

Open

Slow

Throttle lever (2)

Fast

Start position

Close

Page 26

Operation

T01110en.fm 26

4. Close the choke.

∗ If the engine is warm or at high ambient temperatures, open the choke

approximately half way or fully.

∗ If the engine is cold or at low ambient temperatures, close the choke.

5. Recoil starter

∗ Slowly pull the recoil starter handle until you can feel resistance

(compression stroke). Return the recoil starter handle to its original

position and pull with force. Do not pull out the entire length of the rope.

∗ As soon as the engine has started, rewind the starter rope by slowly

returning the recoil starter handle to its original position.

6. Choke

∗ After the engine has been started, slowly open the choke and then

leave it in the fully open position.

∗ If the engine is cold or at low ambient temperatures, never fully open

the choke immediately after the engine has been started or the engine

will stall.

Pull quickly

Open

Page 27

T01110en.fm 27

Operation

6.11 Engine operation

After the engine has started, shift the throttle lever to low (L) engine

speed and allow the engine to warm up for a few minutes.

Slowly shift the throttle lever towards the (H) position for high engine

speed in order to set the required engine speed.

Note: If no high engine speed is required, shift the throttle lever back to

operate the engine at idle speed in order to save fuel and extend the service

life of the engine.

Page 28

Operation

T01110en.fm 28

6.12 Switch off the engine

6.12.1 To turn off the engine in the event of an emergency, switch the main

switch (1) to "0". Under normal circumstances, proceed as follows:

1. Shift the throttle lever (2) to the (L) position for low engine speed and

allow the engine to operate at idle speed for a short time before

switching it off.

2. Switch the main switch (1) to "0".

3. Close the fuel tap.

4. Slowly pull the recoil starter handle until you feel resistance and

then return the recoil starter handle to its original position.

Note: This procedure is necessary in order to prevent humid ambient air

from entering the combustion chamber.

6.12.2 Switching off the engine via the fuel tap

Close the fuel tap and wait until the engine stalls. Never leave fuel in

the carburetor over a long period of time while the engine is switched

off. Otherwise, the fuel channels in the carburetor become blocked by

dirt which results in faulty operation.

2

Close

Close

Open

Recoil starter handle

Page 29

Maintenance

T01071en.fm 29

7. Maintenance

7.1 Maintenance schedule

Component Maintenance work

Maintenance

interval

Machine

Check for signs of damage and wear – change, if necessary the components.

Before operationSafety devices

Main switch

Check for proper functioning – change, if necessary.

Air cleaner

- Check for external damage and a tight fit.

- Check foam and filter element – clean or replace, if necessary.

8 hours (daily)

Fuel

- Check the tank cap for leakage – change, if necessary.

- Check the fuel level – add oil as needed.

Drive motor

Monitoring of:

- Excessive vibrations, operating noise.

- Engine oil and fuel leaks.

Engine oil Check the oil level – add oil as needed.

Miscellaneous

- Check the cutting blade for damage and tightness – replace or tighten, if necessary.

- Check the direction of rotation arrow of the cutting

blade.

- Check that the height adjustment moves freely.

- Check the water supply.

Engine oil Initial oil change. 20 hours

Air cleaner Clean – change, if necessary.

50 hours (weekly)

Belt

Check tension and wear – change, if necessary.

Spark plug Clean, set electrode gap 0.7-0.8 mm.

Engine oil Change.

Fuel filter Have this replaced by Wacker Neuson service. 200 hours

Spark plug Change.

300 hours (annually)

Valve clearance

Have this repaired by Wacker Neuson service.

Page 30

Maintenance

T01071en.fm 30

7.2 Checking engine oil level

∗ Switch off the engine.

∗ Align the engine bolting level horizontally.

∗ Remove any dirt around the oil level dipstick.

∗ Remove the oil level dipstick and wipe it with a clean, lint-free cloth.

∗ Screw the oil level dipstick all the way back in and pull it out again.

∗ Check: The motor oil level must be between the lower and upper

marks.

∗ If necessary, pour new engine oil into the opening until the upper mark

is reached on the oil level dipstick (see chapter Technical data for oil

type).

∗ Screw in the oil level dipstick and tighten it by hand.

7.3 Changing the engine oil

The work area should be covered with a waterproof sheet to protect the

floor (protection of the environment).

∗ Align the engine bolting level horizontally.

∗ Bring the engine to a hand warm temperature, either by letting it cool

down or running it until it is warm.

∗ Switch off the engine.

∗ Place a sufficiently large container under the oil drain hose to catch the

used oil.

∗ Remove oil drain hose from the holder.

∗ Remove any dirt around the locking screw.

∗ Unscrew the cap nut.

∗ Let the used oil drain out completely.

Avoid spilling oil. Remove any spilled oil immediately.

∗ Close oil drain hose with cap nut.

∗ Attach oil drain hose to the holder.

∗ Pour new engine oil (see chapter Technical data) into the opening of

the oil level dipstick until the upper mark is reached on the oil level dipstick (see Checking engine oil level).

∗ Screw in the oil level dipstick and tighten it by hand.

Dispose of the used oil in accordance with the applicable regulations.

Page 31

Maintenance

T01071en.fm 31

7.4 Cleaning the air cleaner

A dirty air cleaner causes starting difficulties, a drop in power, engine

faults and considerably reduces the service life of the engine. Always

keep the air cleaner cartridge clean.

Therefore, the air cleaner cartridge has to be cleaned regularly. During

the installation, the paper element and the polyurethane foam must be

placed on the bottom part. Make sure that the nozzle has been

installed and then tighten the filter cover with the plastic nut.

Cleaning the urethane foam:

Clean the filter element in a detergent solution and then allow it to

completely dry.

Clean the urethane foam filter element every 50 hours.

Paper element:

Clean the paper element by knocking it gently. Never use oil.

If the engine is operated in extremely dusty areas, the air cleaner

elements must be cleaned and replaced more often.

7.5 Cleaning the screws, nuts and bolts

Retighten loose screws and nuts. Check for fuel and oil leaks. Always

ensure optimum operating safety.

Plastic nut

Air cleaner cap

Urethane foam

Element

Page 32

Maintenance

T01071en.fm 32

7.6 Tightening the belt

Check the belt in the course of the weekly engine maintenance and retighten it as follows, if necessary:

1. Remove the belt guard.

2. Loosen the jam nut (1).

3. Loosen the four fastening nuts of the engine until the engine can be

moved without play.

4. Tighten the belt with the tension screw (2).

V-belt tension 700 N (vibration frequency 98 Hz).

5. If necessary, correct the parallel alignment of the engine.

As a first step, tighten a fastening nut of the engine and correct the

alignment by means of the tension screw (2).

6. Tighten all fastening nuts of the engine as well as the jam nut (1).

7. Mount the belt guard.

Note: The frame is provided with two recesses (3) which can be used to

measure the parallel alignment of the engine.

Page 33

Maintenance

T01071en.fm 33

7.7 Changing the belt

1. Remove the belt guard.

2. Loosen the jam nut (1).

3. Loosen the four fastening nuts of the engine until the engine can

be moved without play.

4. Unscrew the bearing flange (6 screws - (4)).

5. Replace the belt (5).

6. Screw on the bearing flange (6 screws - (4)).

7. Tighten the belt with the tension screw (2).

V-belt tension 700 N (vibration frequency 98 Hz).

8. If necessary, correct the parallel alignment of the engine.

As a first step, tighten a fastening nut of the engine and correct the

alignment by means of the tension screw (2).

9. Tighten all fastening nuts of the engine as well as the jam nut (1).

10. Mount the belt guard.

Note: The frame is provided with two recesses (3) which can be used to

measure the parallel alignment of the engine.

Page 34

Maintenance

T01071en.fm 34

7.8 Checking the spark plug

∗ Remove any soot deposits from the electrodes of the spark plug using a

spark plug cleaner or a wire brush.

∗ Check the spark plug gap and set it to 0.7 - 0.8 mm, if necessary.

∗ Select the correct spark plug, see chapter Technical Data.

0.7 - 0.8 mm

Page 35

Signs

SK00693en.fm 35

8. Signs

1 Cutting depth setting

2Note

- Caution, risk of injury

- Read the operator's manual.

- Wear a helmet, eye protection and ear protection!

- Machine may not be offset with the cutting blade rotating.

3 Sound power level

4 Rotational direction arrow

5 Depth of cut indicator

Page 36

Signs

SK00693en.fm 36

Page 37

www.wackerneuson.com

EC Declaration of Conformity

Manufacturer

Wacker Construction Equipment AG

Preußenstraße 41

D-80809 München

Product

Conformity assessment procedure acc. to 2000/14/EC, Appendix V.

Guidelines and standards

This is to certify that this product meets and complies with the relevant regulations and requirements of the following guidelines and standards:

98/37/EC, 2000/14/EC, 2005/88/EC, 2004/108/EC, EN 55012:2007

Munich, October 2008

Type BFS 1345 AB BFS 1345 ABZBFS 1345 B BFS 1345 BZ

Product type Floor saw

Item number 0008764

0610141

0610242 0008909

0610142

0610243

Installed power output [kW] 9.6 9.9

Measured sound

power level

dB(A) 106

Guaranteed sound

power level

dB(A) 107

Dr. Michael Fischer

Head of Research and Development

Franz Beierlein

Head of product management

Page 38

Page 39

Prüf- und Zertifizierungsinstitut

VERBAND DER ELEKTROTECHNIK

ELEKTRONIK INFORMATIONSTECHNIK e.V.

C E R T I F I C A T E

Registration-Number: 6236/QM/06.97

This is to certify that the company

Wacker Construction Equipment AG

Wacker-Werke GmbH & Co. KG

at the following locations

Head Office Munich

Preußenstraße 41

80809 Munich

Production plant Reichertshofen

Karlsfeld logistics centre

Sales regions with all branches all over Germany

has implemented and maintains a

Qality Management System for the following scope:

Machine manufacture

Construction machines

This Q System complies with the requirements of

DIN EN ISO 9001:2000

and the requirements of the German and international Road Traffic Act.

This Certificate is valid until 2009-06-05.

VDE Testing and Certification Institute

Certification

Date: 2006-05-30

63069 Offenbach, Merianstraße 28

Telefon: +49 (0) 69 83 06-0, Telefax: +49 (0) 69 83 06-555

E-Mail: vde-institut@vde.com

, http://www.vde-institut.com

The VDE Testing and Certification Institute is accredited by DAR Accreditation

Bodies according to DIN EN ISO 17020 and DIN EN ISO 45012 and notified in the EU

under ID.No. 0366.

TGA-ZM-09-92-00

KBA-ZM-A 00021-97

DIN EN ISO 9001 Certificate

Page 40

Wacker Construction Equipment AG – Preußenstraße 41 – 80809 München – Deutschland – Tel.: +49-(0)89-354 02-0 – Fax: +49-(0)89-354 02-390

Wacker Corporation – P.O. Box 9007 – Menomonee Falls, WI 53052-9007 – USA – Tel.: +1(1)262-255-0500 – Fax: +1(1)262-255-0550 – Support: 800-770-0957

Wacker Machinery (HK) Ltd.– Skyline Tower, Suite 2303, 23/F – 39 Wang Kwong Road, Kowloon Bay – Hong Kong – Tel.: +852-3188-5506, Fax: +852-2406-6021

Page 41

Page 42

Loading...

Loading...