Page 1

Air dehumidifier

AD ...

0211675en 001

10.2006

Operator's manual

Page 2

Page 3

3

Contents

1. Foreword 5

2. Control panel 6

3. Description 7

4. Operation 9

4.1 Installation .............................................................................................9

4.2 Using the machine .................................................................................9

5. Transport 11

6. Maintenance 12

7. Disposal 13

8. Malfunctions, causes and remedies 15

9. Electric wiring diagram 16

10. Technical data 18

EC Declaration of Conformity 19

Page 4

Contents

4

Page 5

5

Foreword

1. Foreword

This operator's manual contains information and procedures for the

safe operation and maintenance of your Wacker machine. In the interest of your own safety and to prevent accidents, you should carefully

read through the safety information, familiarize yourself with it and observe it at all times.

This operator's manual is not a manual for extensive maintenance and

repair work. Such work should be carried out by Wacker Service or authorized specialists.

The safety of the operator was one of the most important aspects taken into consideration when this machine was designed. Nevertheless,

improper use or incorrect maintenance can pose a risk. Please operate

and maintain your Wacker machine in accordance with the instructions

in this operator's manual. Your reward will be troublefree operation and

a high degree of availability.

Defective components should be replaced immediately!

Please contact your Wacker representative if you have any questions

concerning operation or maintenance.

All rights reserved, especially reproduction and distribution rights.

Copyright 2006 Wacker Construction Equipment AG

No part of this publication may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without the

expressed written permission of Wacker.

Any type of reproduction, distribution or storage on data media of any

type and form not authorized by Wacker represents an infringement of

copyright and will be prosecuted.

We expressly reserve the right to make technical modifications – even

without special notice – which aim at further improving our machines

or their safety standards.

Page 6

Control panel AD ...

wagtx5700000039en.fm 6

2. Control panel

a Main switch d Rotary control moisture meter

b Control lamp e Operating hour meter

c Control lamp "Water collecting

pan full" (not for AD 80)

Page 7

wagtx5700000011en.fm 7

AD ... Description

3. Description

The air dehumidifiers of the AD series are designed for use in rooms

and at locations that can be quickly dried or in which the relative humidity must not increase in an unregulated manner.

The air dehumidifiers of the AD series consist of a cooling circuit and

a fan and condense the water vapor present in the air. This reduces

the relative humidity.

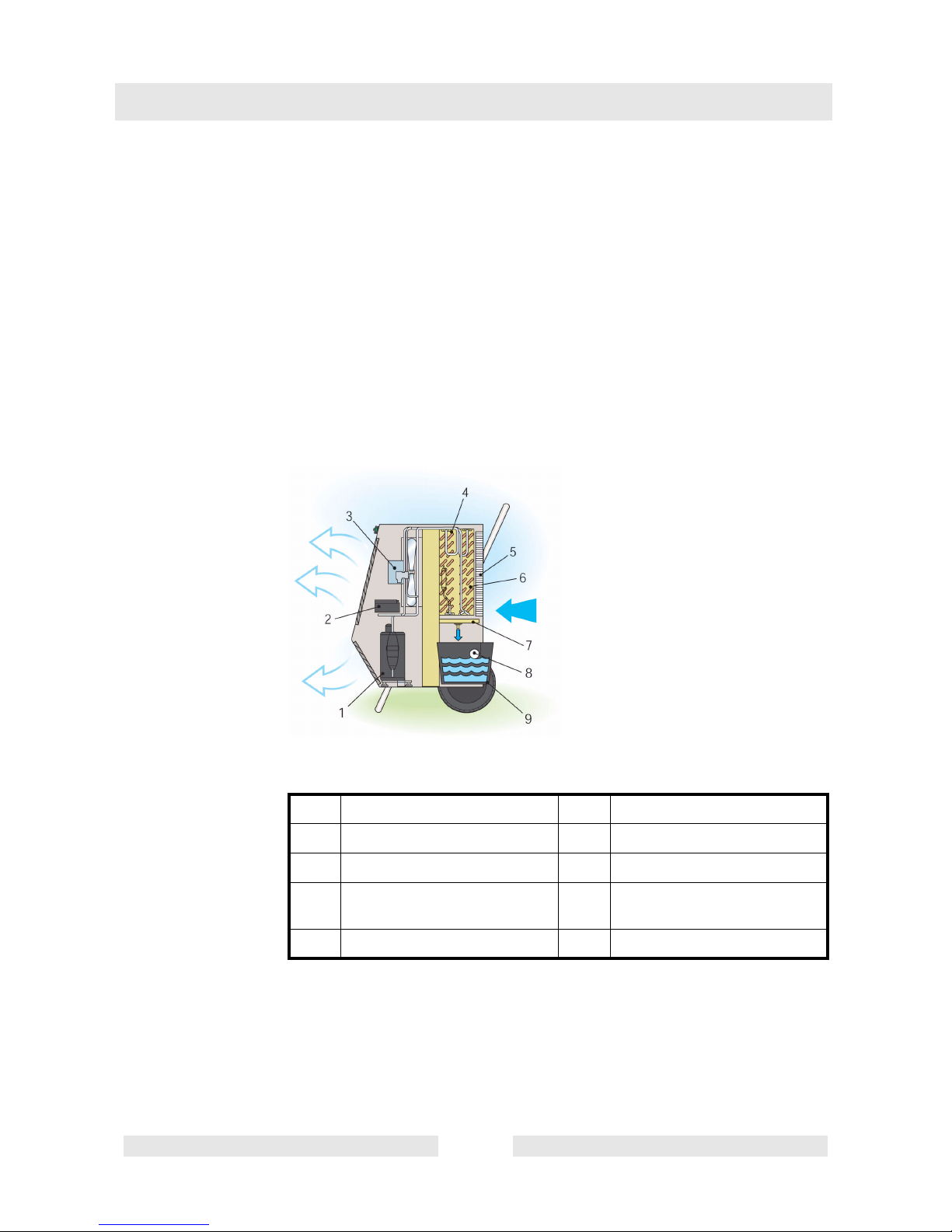

Figure 1 schematically illustrates the function of the machine. The air

drawn in by the fan (3) flows through the air filter (5) and against the

cold walls of the evaporator (6). This cools the air to a temperature that

is under the condensation point. A part of the vapor is condensed and

is collected in the water collection pan (9). Afterwards, the air flows

through the condenser (4) and is heated to a temperature that is slightly higher than the room temperature.

Figure 1: Function diagram

1 Hermetic compressor 6 Evaporator

2 Control unit 7 Condensate outlet

3 Fan 8 Float

4 Condenser 9 Water collecting pan (not for

AD 80)

5 Air filter

Page 8

Description AD ...

wagtx5700000011en.fm 8

For the most efficient and reliable operation, the humidity should be

between 40 % and 100 % and the temperature between 3 °C and

40 °C.

The moisture meter turns the air dehumidifier on automatically and

turns it automatically back off when the set limit value has been

reached. The control unit (2) turns the defrosting unit automatically on

and off if the operating conditions change. In addition, the machine is

turned off (fan and compressor switch off, control lamp (b) is lit) if a

malfunction occurs or if the machine overheats in a room that is too hot

(Tmax = 40 °C).

Caution

If the room temperature falls below the minimum level (3 °C), the air

dehumidifier does not function. The control lamp (b) will blink.

Page 9

wagtx5700000016en.fm 9

AD ... Operation

4. Operation

4.1 Installation

Caution

The mains for supplying power to the machine (230 V, single phase,

50 Hz) must be grounded and equipped with a fault current protective

switch.

Set up the air dehumidifier in the middle of the room to be dehumidified. The air suction side and the air discharge side must not be obstructed. The minimum distance from the walls should be 20 - 30 cm.

Do not set up the machine near heat sources (for example radiators,

ovens, heat outlets etc.) or near doors or openings. Doors and windows in the room must remain closed while the air dehumidifier is in

operation.

Caution

Do not place any rags or cloths on the air dehumidifier.

If required, you can conduct the water formed by dehumidification directly to a drain. To do this, remove the water collecting pan (9) and

connect a rubber hose to the condensate outlet (7).

4.2 Using the machine

4.2.1 Turning the machine on and off

Caution

Always keep the air dehumidifier in the vertical position (during operation, storage and, with model AD 22, during transport).

To turn on the air dehumidifier, proceed as follows:

* Turn the rotary control (d) of the moisture meter in the clockwise di-

rection to the marking "20 %".

* Set the green main switch (a) to the "ON" position. The fan and com-

pressor are turned on. The control lamp in the switch is lit.

Page 10

Operation AD ...

wagtx5700000016en.fm 10

Caution

The air dehumidifier is equipped with an automatic safety device. This

is why the compressor is turned on only 1 minute after you have

pressed the main switch (a).

* Turn the rotary control (d) of the moisture meter in the counterclock-

wise direction until you obtain the desired humidity.

To turn off the machine, set the green main switch (a) to the "OFF" position.

Caution

If the room temperature falls below the permissible level (3 °C), the air

dehumidifier will not function. The control lamp (b) will blink.

4.2.2 Water collecting pan (not for AD 80)

If the water collecting pan (9) is full, the air dehumidifier will switch off.

The control lamp (c) is lit. After you empty the pan, you can restart the

air dehumidifier.

Caution

Before you remove the water collecting pan, disconnect the machine

from the electric power supply. Set the main switch to the "OFF" position and pull the power plug from the electrical socket.

Caution

Carefully slide the water collecting pan back into the machine. This

helps prevent damage or inadvertent actuation of the switch connected

to the float.

Page 11

wagtx5700000020en.fm 11

AD ... Transport

5. Transport

Caution

Disconnect the machine from the electric power supply prior to transport. Set the main switch to the "OFF" position and pull the power plug

from the electrical socket.

During transport, do not store the air dehumidifier in the horizontal position.

Wind up the cable, take hold of the machine at the top handle and

transport on the wheels. Tilt the machine slightly and do not lift the machine.

Transporting the machine on stairs or on a steep incline is easier if you

hold the machine as shown in the figure:

Page 12

Maintenance AD ...

wagtx5700000023en.fm 12

6. Maintenance

Caution

Before you start maintenance procedures, disconnect the machine

from the electric power supply. Set the main switch to the "OFF" position and pull the power plug from the electrical socket.

To ensure trouble-free operation, clean the air filter and the internal

parts of the air dehumidifier on a regular basis. Blow out the air filter

with compressed air or wash it with a lukewarm soap solution. To clean

the internal parts, first disassemble the housing completely. Remove

the screws that connect the outer plates to the frame of the air dehumidifier. Clean the internal parts with a vacuum cleaner. In particular,

vacuum off the cooling fins of the condenser and evaporator.

Page 13

wagtx5700000007en.fm 13

AD ... Disposal

7. Disposal

The air dehumidifier has coolant R407C in the cooling circuit that is under pressure and oil in the compressor. When the machine has

reached the end of its service life, it must be disassembled and/or recycled or scrapped.

Caution

Only qualified personnel are permitted to carry out the steps described

in this section.

Do not allow the liquid coolants to escape in the atmosphere. To recycle the R407C, have the following on hand:

* Refilling unit (condenser unit)

* Pressure vessel

* Punch pliers

To recycle the R407C, proceed as follows:

* Connect the pressure vessel to the refilling unit and the refilling unit

to the punch pliers.

* Using the punch pliers, punch the outlet hose of the compressor.

* Open the valve on the refilling unit, turn on the refilling unit and drain

the cooling circuit.

* Turn off the refilling unit, close the suction and purging cocks of the

refilling unit as well as the cock of the pressure vessel.

* Remove the punch pliers.

* If the container is full with R407C: Bring it to a recycling point for

waste liquids.

Page 14

Disposal AD ...

wagtx5700000007en.fm 14

Remove the welded-on connectors of the purging and suction hoses

and loosen the fastening screws. Lift the compressor, drill a hole in the

bottom side of the housing and tip the machine to empty the oil into a

container or a barrel. Bring the container or the barrel to a recycling

point or waste disposal site for waste oil.

The remaining metallic parts contain copper, aluminum, and steel and

thus can be scrapped.

Page 15

wagtx5700000028en.fm 15

AD ... Malfunctions, causes and remedies

8. Malfunctions, causes and remedies

Malfunction Cause Remedy

The machine does not start

No electric power

Check the function and position

of the main switch

Check the ratings of the electrical power line (230 V 1 ~

50 Hz)

The moisture meter is incorrectly set

Set the moisture meter so that

the value is smaller than the

current value of the relative

humidity in the room

The machine does not start

Water collecting pan is full

(control lamp (c) is lit)

Empty the water collecting pan

Fan and compressor are in

operation but there is no formation of water and ice on the

evaporator

Insufficient air supply

Check if there are objects

obstructing the suction and discharge side

Check if there are any deposits

or incrustations on the filter or

on the cooling fins of the condenser or evaporator

Values for the temperature and

relative humidity are too low

Check if the temperature is

between 0 °C and 40 °C and if

the relative humidity is between

40 % and 100 %

The cooling circuit does not

function properly

Contact the Technical Customer Service

The machine has switched off,

and the control lamp (c) is lit

Water collecting pan is full Empty the water collecting pan

The machine has switched off

and the control lamp (b) is lit

(the cooling fins of the condenser have overheated)

Air flow path is obstructed Remove any obstructions and

turn the machine back on

Room temperature is over

40 °C

Do not start the machine until

the temperature has fallen

below 40 °C

The fan motor is defective Contact the Technical Cus-

tomer Service

The cooling circuit does not

function properly

Contact the Technical Customer Service

The machine has switched off,

and the control lamp (b) is lit

Temperature is below 3 °C Place the air dehumidifier in a

room that has a temperature of

3°C

Page 16

Electric wiring diagram AD ...

wagtx5700000033en.fm 16

9. Electric wiring diagram

MV Fan motor S1 Defrost probe S2 Overheating probe

S3 Sensor for the room tem-

perature

CP Compressor CO Condenser

FU Fuse (500 mA) IA Switch "Water collecting

pan full"

TI Operating hour meter

IG Main switch SA Control lamp "Water col-

lecting pan full"

SB Control lamp "Malfunc-

tion"

UM Moisture meter ST Control lamp "Voltage" EV Solenoid valve

AP Control unit TC Compressor thermostat RC Compressor relay

Page 17

wagtx5700000033en.fm 17

AD ... Electric wiring diagram

MV Fan motor S1 Defrost probe S2 Overheating probe

S3 Sensor for the room tem-

perature

CP Compressor CO Condenser

FU Fuse (500 mA) TI Operating hour meter IG Main switch

SA Control lamp "Water col-

lecting pan full"

SB Control lamp "Malfunc-

tion"

UM Moisture meter

ST Control lamp "Voltage" EV Solenoid valve AP Control unit

TC Compressor thermostat

Page 18

Technical data AD ...

wagtd5700000006en.fm 18

10. Technical data

Unit AD 22 AD 52 AD 80

Item number 0610130 0610131

0610139

0610132

0610140

Relative humidity

1

1. Work area

[%] 40 – 100

Temperature

1

[°C] 3 – 40

Air flow performance [m³/h] 250 650 900

Dehumidifying perfor-

mance

2

2. T = 30 °C; UR = 80 %

[l/24h] 22 52 80

Coolant R407C

Amount of coolant [g] 300 525 1600

Voltage [V] 230 1~

Frequency [Hz] 50

Current consumption

2

[W] 550 1000 1350

Noise level, SPL [dBA] 59 65 64

Tank capacity [l] 5 11 —

Dimensions, L x B x H [mm] 540 x 585 x 775 650 x 615 x 958 761 x 776 x 1048

Weight [kg] 39 52 76

Page 19

EC Declaration of Conformity

Wacker Construction Equipment AG, Preußenstraße 41, 80809 München

certifies that the construction machine:

Type:

Air dehumidifier

fulfill the requirements of the directive 89/392/EC with amendments 91/368, 93/44,

93/68 and 98/37.

The machine was constructed in accordance with the following directives:

89/336/EC

92/31/EC

73/23/EC

Type AD 22 AD 52 AD 80

Machine type number 0610130 0610131

0610139

0610132

0610140

Installed electrical output [W] 550 1000 1350

Dr. Stenzel

Head of Research and Development

Please keep this document in a safe place

Page 20

Wacker Construction Equipment AG - Preußenstraße 41 - 80809 München - Tel.: +49-(0)89-3 54 02-0 - Fax: +49-(0)89-3 54 02-390

Wacker Corporation - P.O. Box 9007 - Menomonee Falls, WI 53052-9007 - Tel.: +1 (1) 262-255-0500 - Fax: +1 (1) 262-255-0550 - Tel.: 800-770-0957

Wacker Machinery Ltd.- Skyline Tower, Suite 2303, 23/F, 39 Wang Kwong Road, Kowloon Bay, Hong Kong -Tel.: +852 2406 6032 -Fax: +852 2406 6021

Page 21

Page 22

Loading...

Loading...