Page 1

Operator's manual

Gasoline cut-off saw

BTS

930L3, 935L3, 1030L3, 1035L3, 1140L3

0109969en 008

06.2010

Page 2

Manufacturer

Wacker Neuson SE

Preußenstraße 41

80809 München

www.wackerneuson.com

Tel.: +49-(0)89-354 02-0

Fax: +49-(0)89-354 02-390

Translation of the original operator’s manual in German

Page 3

T00940en.fm 3

Important note

EPA engine

This machine is equipped with an EPA-certified engine.

Relevant details can be found in the instructions of the engine manufacturer.

Warning

The engine's exhaust fumes contain chemicals which are known to the

State of California to cause cancer, congenital defects or other reproductive anomalies.

Page 4

T00940en.fm 4

Page 5

T00965en.fm 5

Warranty for machines with EPA-certified engines (USA)

WARRANTY IN CASE OF DEFECTIVE EXHAUST MONITORING DEVICES

The engine manufacturer guarantees the first end user and every subsequent owner

that this engine was designed, built and equipped for a machine that is not to be used

on the road, that at the time of the inital purchase it met all valid EPA regulations, and

that the engine does not have any defects due to material or workmanship such that

this engine would not fulfill the requirements of the EPA regulations for the duration of

the warranty period.

For the components listed below under PARTS INCLUDED, the authorized Wacker

Neuson customer service shop will carry out all trouble-shooting, repairs or replacements necessary for the engine to meet the valid EPA regulations.

WARRANTY PERIOD IN CASE OF DEFECTIVE EXHAUST MONITORING DEVICES

The warranty period for this engine begins on the date it is purchased by the first user

and ends after 2 years.

PARTS INCLUDED

The parts included in the above warranty are listed below. Regularly scheduled maintenance is required for some of the parts listed. These parts are under warranty only

up to the first planned replacement.

Fuel batching system

Carburetor and internal parts

Fuel filter, if present

Throttle flap, if present

Choke system, if present

Air supply system

Air cleaner plate, air cleaner

Air cleaner housing, intake manifold

Ignition system

Spark plugs

Magneto flywheel

Ignition coil

Other parts of the above systems

Fuel hoses, clamps and seals

WARRANTY SERVICES

To use the services within the scope of the warranty, bring the engine to the nearest

authorized Wacker Neuson customer service shop. Present your purchase receipt,

which includes the date of purchase. The authorized Wacker Neuson customer service

shop will carry out the necessary repairs or conversion within an appropriate period of

time and will give you a copy of the repair order. All parts and accessories replaced

within the scope of this warranty become the property of Wacker Neuson.

Page 6

T00965en.fm 6

WHAT IS NOT INCLUDED?

∗ Defects due to unauthorized intervention, improper use or adjustment

(except when carried out by an authorized Wacker Neuson customer

service shop as a warranty repair), modifications, accidents, use of unsuitable fuels and oils or not carrying out prescribed maintenance

work.

∗ The replacement parts used for prescribed maintenance work.

∗ Consequential damage, e. g. loss of time, inconvenience, downtime

for engine or machine, etc.

∗ Diagnostic or testing fees if the testing reveals that a warranty claim

cannot be made.

∗ Any of the disallowed parts or breakdowns of allowable parts due to

the use of disallowed parts.

RESPONSIBILITIES OF THE OWNER WITHIN THE SCOPE OF THE WARRANTY

As the owner of the engine you are responsible for carrying out the prescribed maintenance in accordance with the operator's manual. Wacker Neuson recommends that

you retain all documents pertaining to maintenance work on your engine. However,

Wacker Neuson cannot dismiss warranty claims based only on missing documentation

or not carrying out all scheduled maintenance work. However, we draw your attention

to the fact that Wacker Neuson can dismiss warranty claims if a defect to your engine

or to a part of it was caused by improper use, negligence, improper maintenance or impermissible modifications.

You are obliged to bring your engine to the nearest authorized Wacker Neuson customer service shop as soon as a problem occurs.

If you have questions regarding your rights and responsibilities within the scope of the

warranty, please contact the Wacker Neuson CORPORATION Product Support Department (USA: 1-800-770-0957, Canada: 1-877-977-0775).

WHAT YOU SHOULD KNOW ABOUT THE WARRANTY FOR THE EXHAUST CONTROL SYSTEM:

MAINTENANCE AND REPAIRS

You are responsible for properly maintaining your engine. Retain all documents pertaining to regular maintenance work in case there are questions. Give these documents

to any subsequent owner of the engine. Wacker Neuson reserves the right to dismiss

warranty claims if the engine has not been properly maintained. However, warranty

claims will not be dismissed only because prescribed maintenance was not carried out

or maintenance documents are missing.

Page 7

T00965en.fm 7

MAINTENANCE, REPLACEMENTS OR REPAIRS OF EXHAUST GAS REGULATING

DEVICES AND SYSTEMS MAY BE CARRIED OUT BY ANY REPAIR SHOP OR PERSON. HOWEVER, WARRANTY REPAIRS MUST BE CARRIED OUT BY AN AUTHORIZED Wacker Neuson CUSTOMER SERVICE SHOP. THE USE OF PARTS THAT

ARE NOT EQUIVALENT TO ALLOWABLE PARTS IN TERMS OF PERFORMANCE

AND SERVICE LIFE CAN IMPAIR THE EFFECTIVENESS OF THE EXHAUST CONTROL SYSTEM AND VOID A WARRANTY CLAIM.

If parts other than those allowed by Wacker Neuson were used for replacements within

the scope of maintenanace or to repair components related to the exhaust control system, you are responsible for determining if a manufacturer's warranty exists for these

parts that is equivalent to that for parts allowed by Wacker Neuson in terms of performance and service life.

HOW TO MAKE A WARRANTY CLAIM

All repairs for which a warranty claim can be made within the scope of this limited warranty must be carried out by an authorized Wacker Neuson customer service shop. If

a fault is detected in a part of the exhaust control system during the warranty period,

contact the Wacker Neuson CORPORATION Product Support Department (USA: 1800-770-0957; Canada: 1-877-977-0775). They will let you know which customer service shop or which suitable service station can carry out the warranty repair.

Page 8

T00965en.fm 8

Page 9

9

Foreword

1. Foreword

For your own safety and protection from bodily injuries, carefully read,

understand and follow the safety information in this manual.

Please operate and maintain your Wacker Neuson machine in accordance with the instructions in this operator's manual. Your Wacker

Neuson machine will reward you with troublefree operation and a high

degree of availability.

Defective components must be replaced immediately.

All rights, especially the right for copying and distribution, are reserved

Copyright 2010 by Wacker Neuson SE

No part of this publication may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without express permission in writing from Wacker Neuson SE.

Any type of reproduction, distribution or saving on data carriers of any

type or method not authorized by Wacker Neuson represents an infringement of valid copyrights and will be prosecuted. We expressly reserve

the right to make technical modifications - even without special notice which aim at further improving our machines or their safety standards.

Page 10

Table of contents

10

1. Foreword 9

2. Many thanks for choosing this product! 12

2.1 Packaging ............................................................................................13

3. Scope of delivery/Symbols 14

3.1 Scope of delivery .................................................................................14

3.2 Symbols ...............................................................................................14

4. Safety information 16

4.1 Proper use ...........................................................................................16

4.2 General notes ......................................................................................16

4.3 Personal protective gear .....................................................................17

4.4 Operating fluids / Filling the tank .........................................................20

4.5 Starting up ...........................................................................................21

4.6 Cutting blades .....................................................................................22

4.7 Kickback and pulling motion ................................................................25

4.8 Work habits and methods ....................................................................26

4.9 Instructions for using synthetic resin cutting blades ............................27

4.10 Cutting metals .....................................................................................28

4.11 Cutting stone, concrete, asbestos or asphalt ......................................30

4.12 Transport and storage .........................................................................32

4.13 Maintenance ........................................................................................33

4.14 First Aid ...............................................................................................34

4.15 Disposal and environmental protection ...............................................35

5. Technical data 36

6. Part identification 39

7. Starting up 41

7.1 Attaching the cutting blade ..................................................................42

7.2 Tightening the V-belt/Checking the tension .........................................43

7.3 Operating fluids ...................................................................................44

7.4 Storing fuel ..........................................................................................45

7.5 Filling the tank .....................................................................................47

7.6 Starting the engine ..............................................................................48

7.7 Turning off the engine .........................................................................51

7.8 Readjusting the idle speed ..................................................................51

Page 11

11

Table of contents

8. Maintenance work 53

8.1 Replacing the V-belt ............................................................................54

8.2 Cleaning the protective hood ...............................................................55

8.3 Cleaning/Changing the air cleaner ......................................................55

8.4 Prefilter, air cleaner cartridge and internal filter ...................................57

8.5 Replacing the spark plug .....................................................................60

8.6 Checking the ignition spark .................................................................61

8.7 Replacing the suction head .................................................................62

8.8 Replacing the starter rope ...................................................................62

8.9 Replacing the return spring .................................................................64

8.10 Cutting attachment in the center/outer position ...................................65

8.11 Remounting the cutting attachment .....................................................66

8.12 Replacing/cleaning the spark arrester screen .....................................68

8.13 Periodic maintenance and service instructions ...................................69

8.14 Troubleshooting ...................................................................................71

9. Guide cart 72

9.1 Application ...........................................................................................72

9.2 Safety information ...............................................................................73

10. Signs 74

Page 12

Many thanks for choosing this product!

T01125en.fm 12

2. Many thanks for choosing this product!

We're pleased that you decided to purchase your new Wacker Neuson

cut-off saw. The Wacker Neuson cut-off saws are equipped with specially designed high performance engines with an excellent power to

weight ratio for better performance at a lower weight.

Other advantages of the Wacker Neuson cut-off saw include:

∗ Robust construction and high reliability.

∗ Maintenance-free electronic ignition, hermetically encapsulated to pre-

vent dust and moisture from entering.

∗ Vibration damping with a double-mass system that allows operators to

work nearly without fatigue, even with a hand-operated machine.

∗ Five stage air cleaner system for reliable operation, even when an un-

usual amount of dust is produced.

∗ Two ways to mount the cutting blade: Use the center position for opti-

mal balance with the hand-operated machine or the side position for

cutting near to walls or curbs or for horizontal cuts directly above the

ground.

∗ A comprehensive range of accessories, including synthetic resin or di-

amond-encrusted cutting blades and a guide cart, water sprayer and

angular fuel tank filler neck.

We'd like you to be happy with your purchase from Wacker Neuson.

To guarantee that your Wacker Neuson cut-off saw is always ready to

use and functions well and to ensure your personal safety, we'd like to

ask you to:

Read this operator's manual completely before using the cut-off saw

for the first time and, above all, follow the safety regulations! Not following the regulations can lead to life-threatening injuries!

Page 13

T01125en.fm 13

Many thanks for choosing this product!

2.1 Packaging

To avoid damage during transportation, your Wacker Neuson cut-off

saw was shipped in a cardboard box.

Cardboard is a renewable resource and can be used again and or recycled as waste paper.

Page 14

Scope of delivery/Symbols

T01125en.fm 14

3. Scope of delivery/Symbols

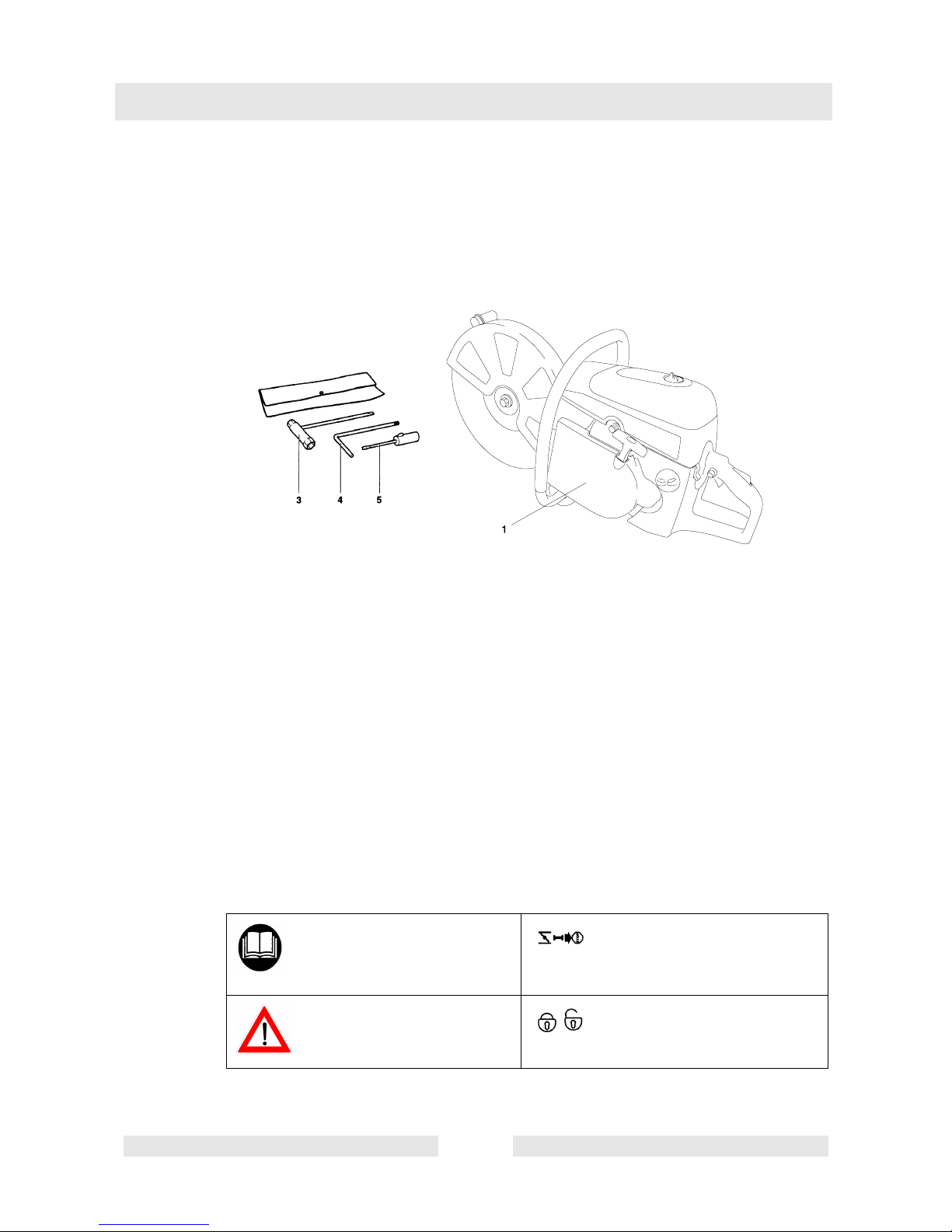

3.1 Scope of delivery

If any of the components listed here is not included with delivery,

please contact your salesperson!

3.2 Symbols

You will find the following symbols on the machine and when reading the

operator's manual:

Read the operator's manual

and observe the warnings

and safety information

Multifunction switch

Start/Stop (I/O), choke

Use extra caution! Locked / Unlocked

1. Cut-off saw

3. Combination wrench 13/19 mm

4. Offset screwdriver

5. Screwdriver for setting the carburetor

6. Operator's manual (without illustration)

Page 15

T01125en.fm 15

Scope of delivery/Symbols

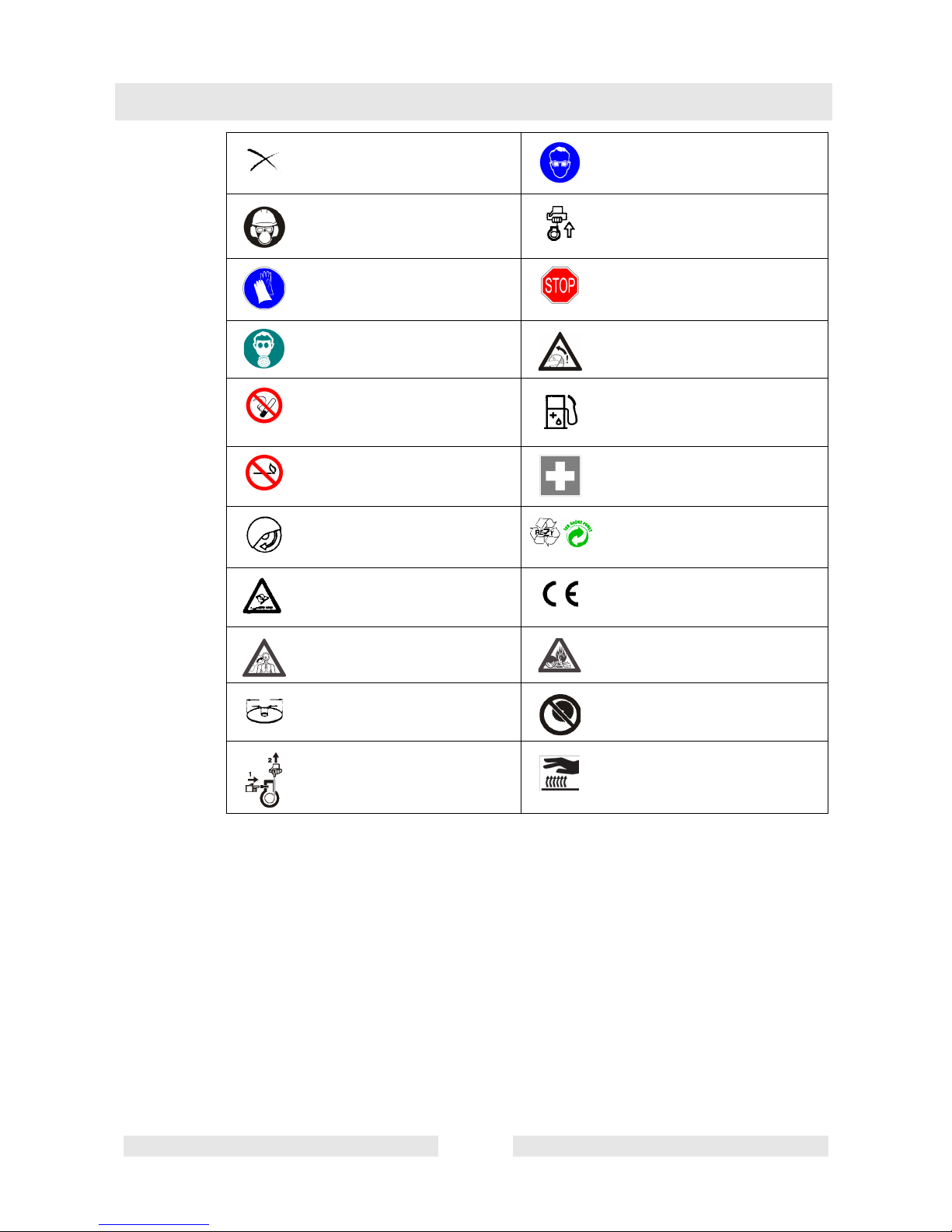

Prohibited! Wear eye protection!

Wear a helmet, eye protection, mouth protection and

ear protection!

Start the engine

Wear protective gloves! Turn off the engine!

Wear breathing protection! Caution, kickback!

No smoking! Fuel/oil mixture

No open flames! First Aid

Cutting blade's direction of

rotation!

Recycling

Maximum cutting blade peripheral speed is 80 m/s!

CE marking

Dangerous dust formation

and gas emission!

Fire hazard from flying sparks!

Cutting blade dimensions! Never use circular saw blades

Actuate the decompression

valve

Do not touch hot surfaces!

Page 16

Safety information

SV00080en.fm 16

4. Safety information

4.1 Proper use

Cut-off saw

The cut-off saw must only be used outdoors for cutting/cutting to length

suitable materials with the cutting blade approved for the unit.

Non-approved work methods:

The cutting blades of the cut-off saw must not be used as a grinding

tool (removing material with the side surface of the cutting blade). This

may cause the cutting blade to break! It is prohibited to attach saw

blades, knives or brushes to the cut-off saw.

Non-approved operators:

Persons unfamiliar with the operator's manual, children, juveniles as

well as persons under the influence of alcohol, drugs or medication

must not attempt to operate the unit.

4.2 General notes

4.2.1 To ensure safe handling, the operating person must read the op-

erator's manual (even if that person is experienced in using a cutoff saw), to become familiar with the cut-off saw. Operators can en-

danger themselves and others if they are unaware or insufficiently informed about how to properly use the unit.

4.2.2 Only lend the cut-off saw to experienced users. Give the operator's

manual to the user along with the tool.

4.2.3 First time users should receive instruction from a skilled technician regarding the characteristics of engine-driven cutting.

4.2.4 Children and juveniles under the age of 18 must not attempt to operate

the cut-off saw. Juveniles who are at least 16 years old are excepted

from this rule if they are working under the supervision of qualified personnel for educational purposes.

4.2.5 Working with the cut-off saw requires special precautions.

4.2.6 Work only if you are in good physical condition. Fatigue can lead to

carelessness. Take special precautions, particularly as you finish your

work. Carry out all work calmly and circumspectly. The operator is responsible for others in the area.

1

Page 17

SV00080en.fm 17

Safety information

4.2.7 Never operate the machine under the influence of alcohol, drugs, medication or other substances that can impair your vision, coordination

and judgment.

4.2.8 When working with highly flammable vegetation and in dry conditions

ensure that a fire extinguisher is readily available for use (danger of

fire).

4.2.9 Asbestos or materials that could discharge toxins may only be cut using the proper safety measures and after notifying the responsible authorities and under their supervision or that of persons charged with

this duty. The use of dust bonding devices is strongly recommended.

4.2.10 Some dust created by power sanding sawing, grinding, drilling, and

other construction activities contains chemicals known (to the State of

California) to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

∗ lead from lead-based paints,

∗ crystalline silica from bricks and cement and other masonry products

∗ arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies, depending on how often you do

this type of work.

To reduce your exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such as those dust

masks that are specially designed to filter out microscopic particles.

4.3 Personal protective gear

4.3.1 Wear and use the following protective equipment and devices to prevent head, eye, hand and foot injuries as well as hearing damage.

4.3.2 Clothing should be appropriate, i.e. should be close-fitting but not restrict your movement. When cutting metal, do not wear clothing in

which grains of material can be caught (pants with cuffs, jackets or

pants with open pockets, etc.).

4.3.3 Do not wear jewelry or clothing that can become entangled or distract

the operator from the cutting process.

2

Page 18

Safety information

SV00080en.fm 18

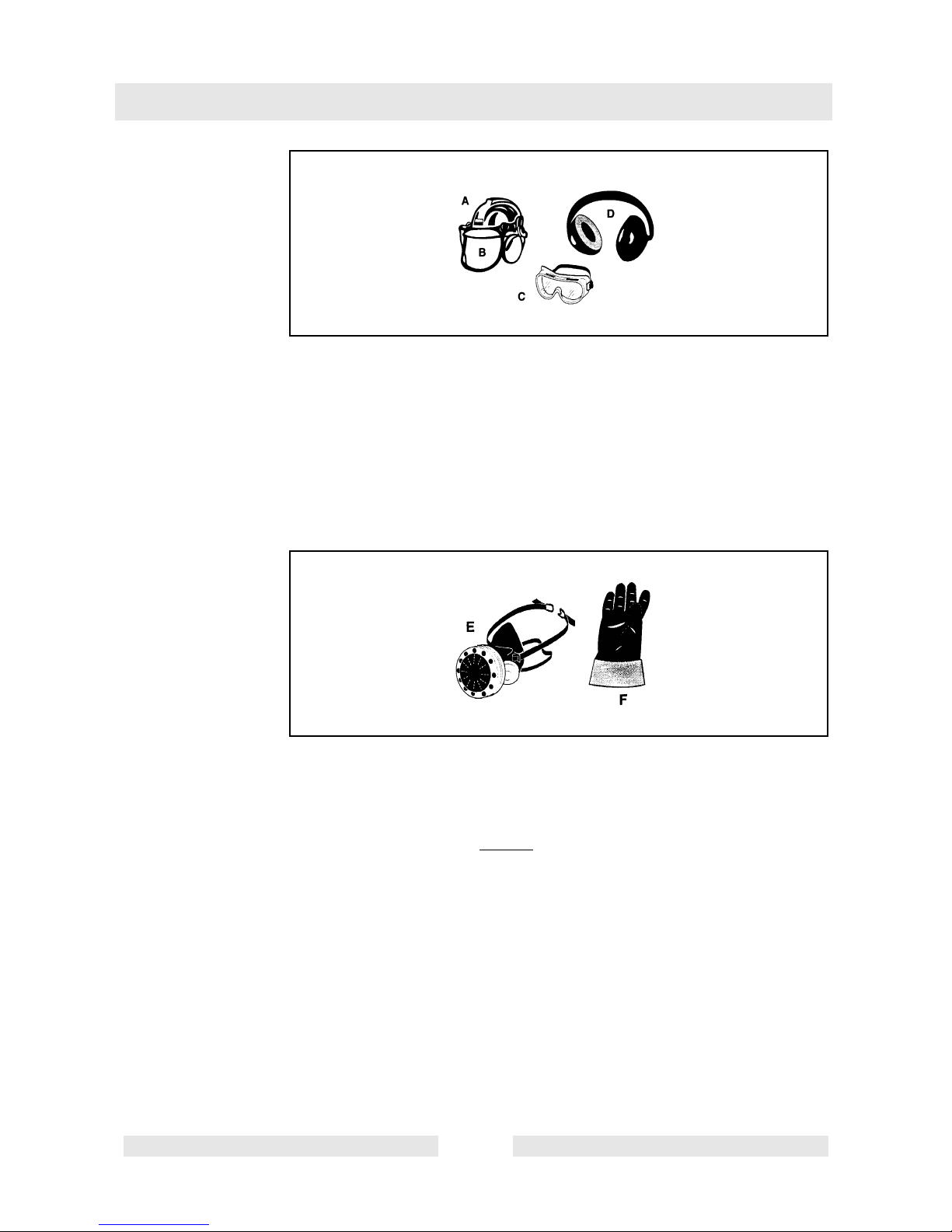

4.3.4 Always wear a hardhat (A). Regularly check the hardhat for damage

and and replace it at least every 5 years. Only use tested hardhats.

4.3.5 The hardhat face protection (B) protects the face from grinding residue and grains of material. To prevent eye and face injuries, always

wear eye protection (C) or face protection when working with the cutoff saw.

4.3.6 To prevent hearing damage always wear suitable ear protection. (Ear

protections (D), ear plugs, etc.). Octave band analysis by request.

4.3.7 When dry cutting stone materials that generate particulate matter

(stone, concrete, etc.), properly functioning breathing protection (E)

must be worn.

4.3.8 Work gloves (F) made of durable leather are part of the proper working equipment and must always be worn when working with the cut-off

saw.

3

4

Page 19

SV00080en.fm 19

Safety information

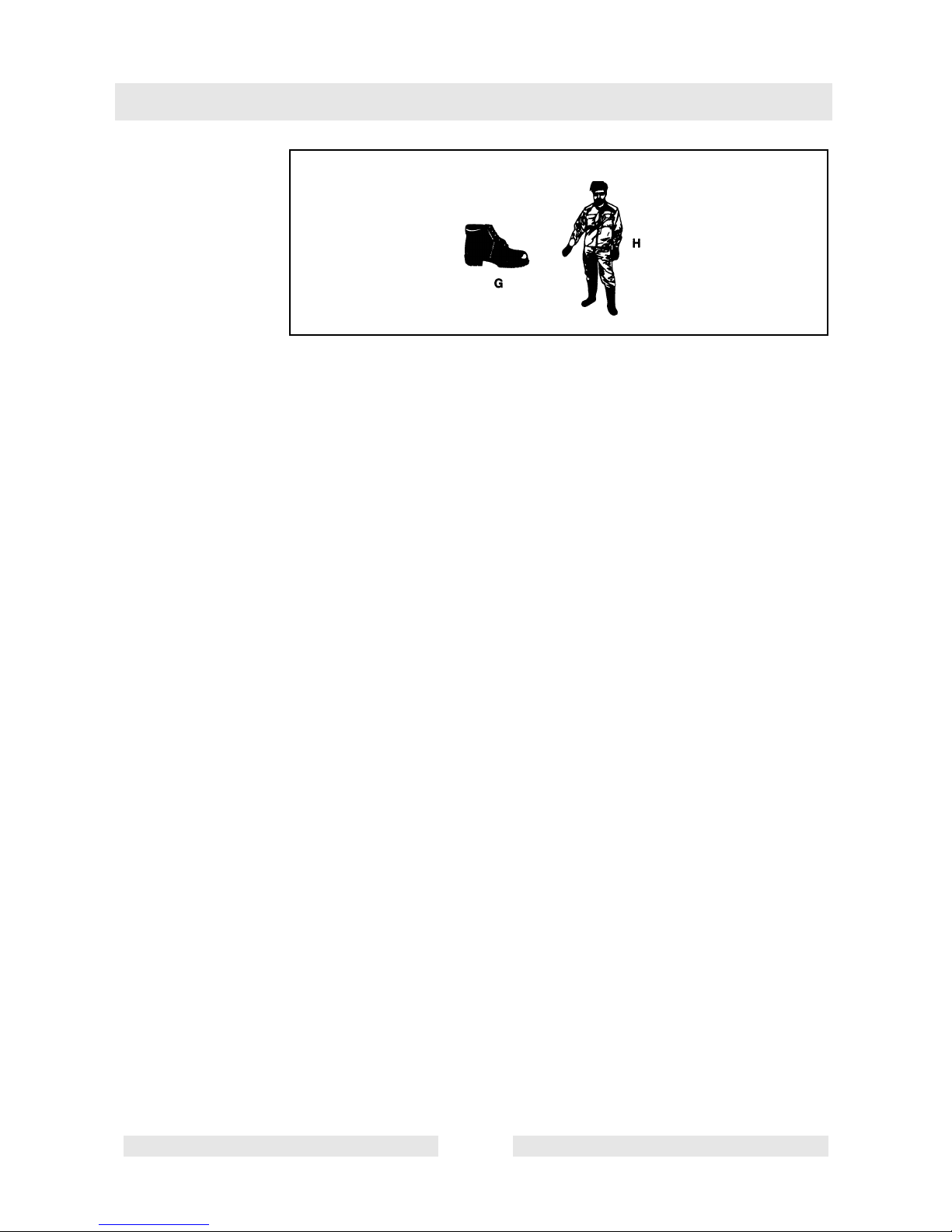

4.3.9 Wear non-skid, hard-toed shoes or boots (G) and leg protection when

working with the cut-off saw. Safety shoes with protective inlays protect feet from laceration and ensure that the operator is standing in secure position.

4.3.10 Always wear overalls (H) made of durable material that is sufficiently

fire resistant!

5

Page 20

Safety information

SV00080en.fm 20

4.4 Operating fluids / Filling the tank

4.4.1 Before you fill the tank, go to a a safe and level area. It is prohibited

to fill the tank on a scaffolding, a mound of material or similar elevated structure!

4.4.2 Turn off the engine before you fill the tank of the cut-off saw.

4.4.3 Smoking and open fires are not permitted (6).

4.4.4 Let the engine cool down before you fill the tank.

4.4.5 Fuels can contain solvent-like substances. Avoid skin and eye contact

with mineral products. When filling the tank, wear gloves (not work

gloves). Change and wash your clothing more often. Do not inhale fuel

vapors. Inhaling fuel vapors can damage your health.

4.4.6 Do not spill fuel. If you have spilled fuel, clean the cut-off saw immediately. Avoid getting fuel on your clothing. Should you spill fuel on your

clothing, change your clothes immediately.

4.4.7 Make every effort to ensure that you do not allow fuel to soak into the

ground (environmental protection). Use a suitable base.

4.4.8 Do not fill the tank in closed rooms. Fuel vapors accumulate near the

floor (danger of explosion).

4.4.9 Tightly close the screw plug on the fuel tank.

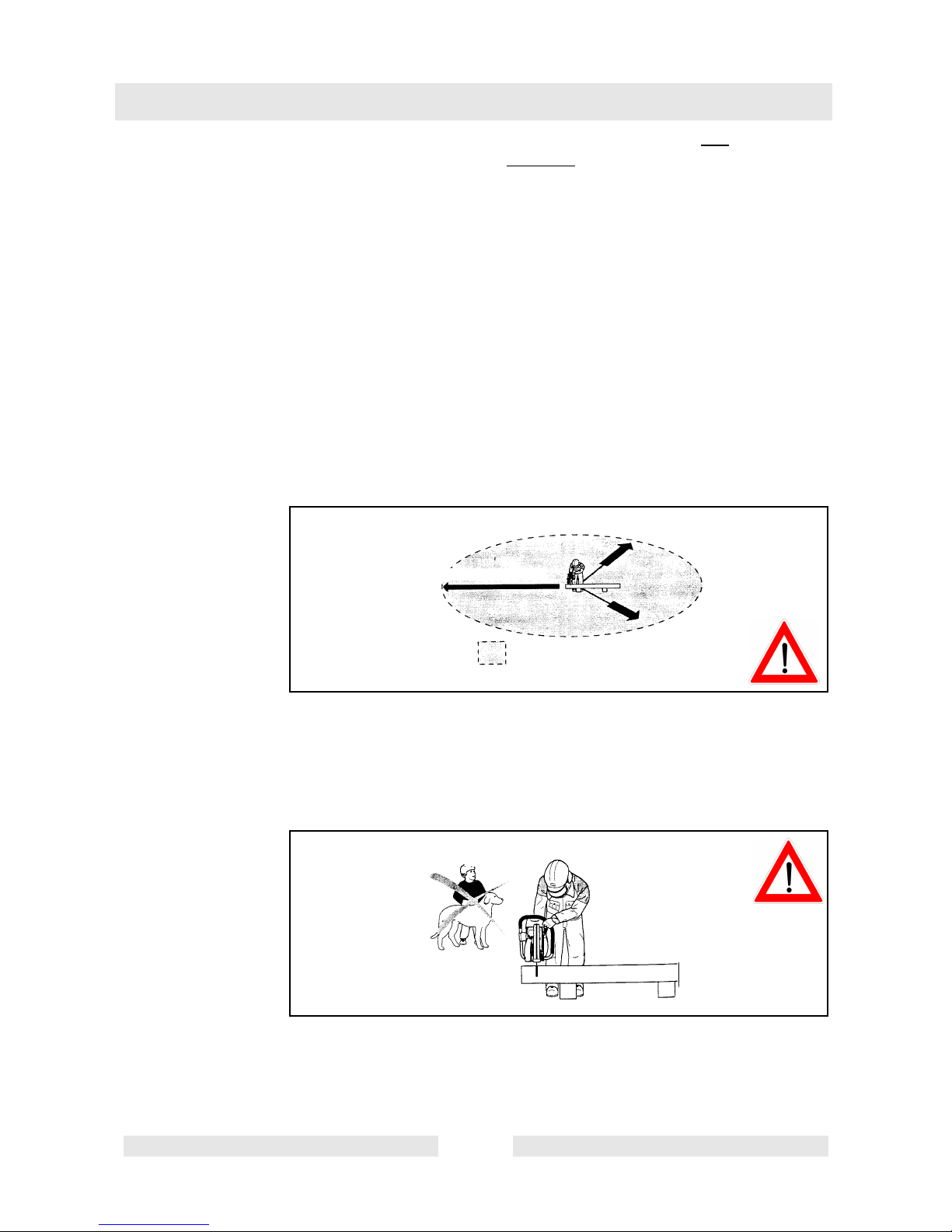

4.4.10 To start the cut-off saw, go to another location (at least 3 meters

(10 feet) away from the place where you filled the tank) (7), however

not in the extended swing area (direction of flying sparks) of the cutting

blade.

4.4.11 Fuels cannot be stored indefinitely. Purchase only enough fuel as you

can possibly use in the foreseeable future.

4.4.12 Only use fuel and oil which has been approved by Wacker Neuson,

see chapter Technical Data.

6

7

3 meters

(10 feet)

Page 21

SV00080en.fm 21

Safety information

4.4.13 When preparing the correct gasoline/oil mixing ratio, first always pour

oil into the mixing container and then the gasoline.

4.4.14 Transport and store fuel only in approved and specially marked canisters.

Do not allow children near the fuel.

4.5 Starting up

4.5.1 Do not work alone; someone must be nearby in case of an emergency (within calling distance).

4.5.2 When using cut-off saws in residential areas, please observe the local

noise regulations.

4.5.3 Never use the cut-off saw near inflammable materials or explosive gases! The cut-off saw can create sparks leading to fire or

explosion!

4.5.4 Ensure that persons (for example those assisting you) within a range

of 30 m (100 feet) also wear protective gear (see "Personal Protective

Gear") (8). Children or other persons must keep a distance of at least

30 m (100 feet) from the work area of the cut-off saw. Be aware of any

animals in the vicinity (9).

8

= Wear protective gear

30 m (100 feet)

9

Page 22

Safety information

SV00080en.fm 22

4.5.5 Before you start to work with the cut-off saw, check to see that is in

proper working order and in a safe operating condition!

In particular, check the following: Inspect the condition of the cutting

blade (replace immediately if the disc is cracked, bent or otherwise

damaged). Check that the disc is properly mounted, the protective

hood is locked in place, the belt guard is firmly attached, the V-belt is

properly tightened, the throttle lever moves unhindered and functions

correctly, the handles are clean and dry and the multifunction switch

works.

4.5.6 Do not start the cut-off saw until you have completely assembled and

tested it in operation. The cut-off saw must only be operated when it is

completely assembled!

4.6 Cutting blades

4.6.1 The protective hood must always be attached. Change the cutting

blade only when the engine has been turned off!

If you are using diamond-edged cutting blades, make sure you observe the attached rotational direction mark.

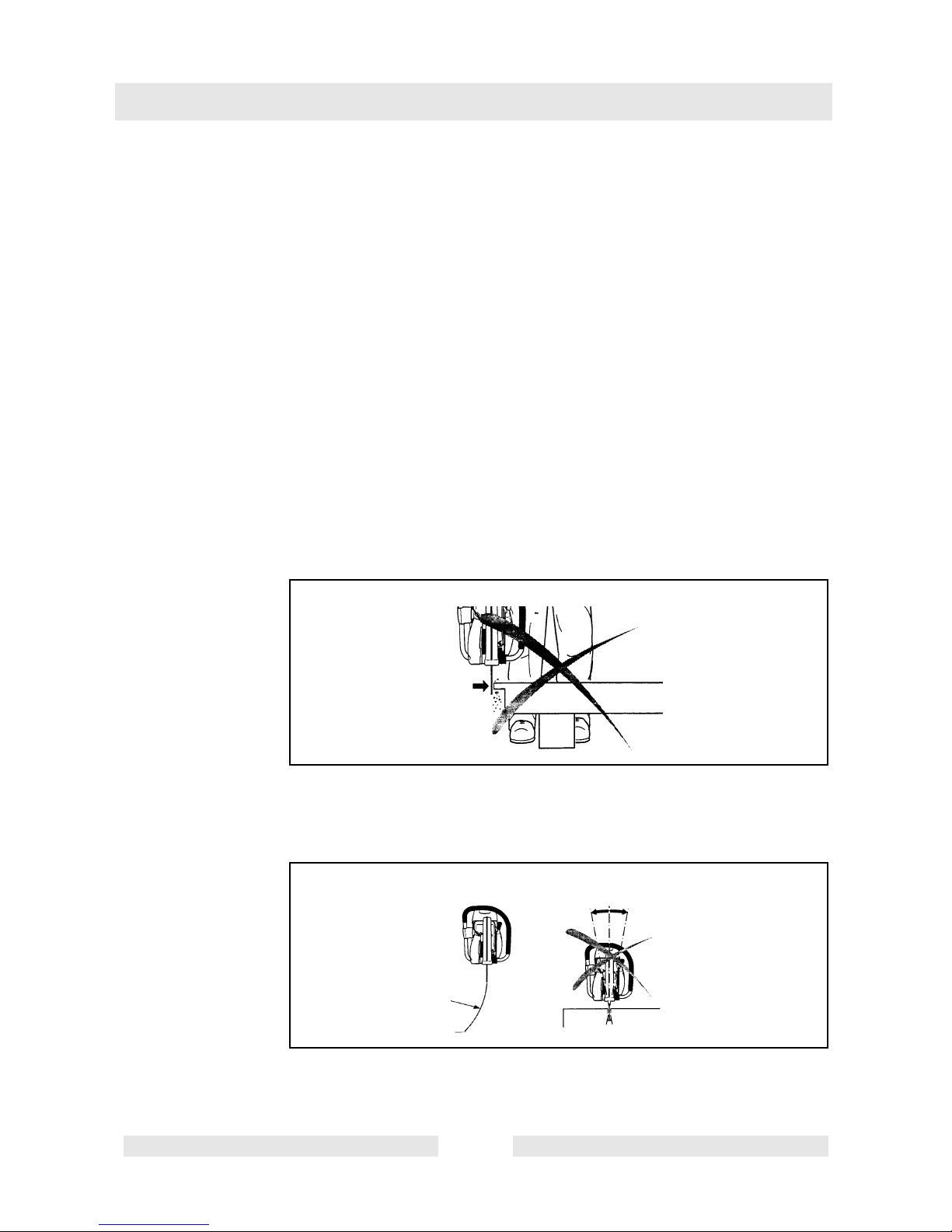

4.6.2 Cutting blades are only designed to cut materials on their edges. Never

use the side surfaces for grinding purposes as this can break the disc!

(10).

10

min. 5 m

(16 feet)

11

Page 23

SV00080en.fm 23

Safety information

NOTICE:

It is prohibited to change the direction (a radius of 5 m (16 feet) or less),

apply lateral pressure or tilt the cut-off saw while you are cutting (11)!

4.6.3 Cutting blades must only be used to cut materials they were designed

for. Depending on the material you wish to cut (metal or concrete), you

must select the proper disc type.

4.6.4 The arbor diameter of the cutting blade must precisely fit the shaft. If

the arbor diameter is larger, you must use an intermediate ring as an

adapter.

4.6.5 The cutting blade must be approved for freehand cutting with a

400 mm (16") cutting blade diameter up to 3,850 rpm or 80 m/s

(260 ft./sec), a 350 mm (14") cutting blade diameter up to 4,370 rpm or

80 m/s (260 ft./sec) or a 300 mm (12") cutting blade diameter up to

5,100 rpm or 80 m/s (260 ft./sec). Use only cutting blades that comply

with EN 12413 or EN 13236.

4.6.6 The cutting blade must be completely undamaged (12). Test it by performing a sound test with a piece of wood.

Always tighten the cutting blade to 30 Nm, otherwise you may distort

the cutting blade.

4.6.7 Before starting, the operator must stand at safe distance away from the

cut-off saw.

12

Page 24

Safety information

SV00080en.fm 24

4.6.8 Start the cut-off saw only as described in the operator's manual (13).

Always set your left foot into the handle and firmly hold the bow handle

grip handle by using your thumb. Starting the machine in any other way

is not permitted.

4.6.9 When you start up the machine, support it well and hold it firmly. The

cutting blade must be freestanding.

4.6.10 A new cutting blade must be tested before you cut with it by running it

at least 60 seconds at the specified maximum speed. Ensure that no

one is in the extended swing area of the cutting blade.

4.6.11 When operating the cut-off saw, hold it firmly with both hands.

The right hand on the rear handle, and the left hand on the bow handle

grip. Hold the grips firmly using your thumbs.

4.6.12 When you release the throttle lever, the cutting blade will contin-

ue to run briefly (afterrun).

4.6.13 Always ensure that you are standing in a secure position.

4.6.14 Hold the cut-off saw in such a way that you cannot inhale the exhaust

fumes. Do not work in closed rooms or in deep trenches (danger of poisoning through exhaust fumes).

4.6.15 If you notice any changes in the way the machine operates, turn off the

engine immediately.

4.6.16 You must turn off the engine before you check the V-belt tension,

retighten the belt, change the cutting blade, remount the cutting

attachment (outer or center position) and eliminate

malfunctions (14).

13

*

Maintenance

*

Filling the tank

*

Changing the cutting blade

*

Remounting the cutting

attachment

*

Taking a break

*

Transport

*

Shutting down

14

Page 25

SV00080en.fm 25

Safety information

4.6.17 If you hear or feel a change in the way the machine is cutting, turn off

the engine immediately and check the cutting blade.

4.6.18 During breaks and after you finish work, turn off (14) the cut-off saw

and set it down so that the cutting blade is freestanding and cannot endanger anyone.

4.6.19 Do not lay the hot cutting blade on dry grass or onto combustible objects. The muffler radiates an enormous amount of heat (danger of

fire).

4.6.20 NOTICE: After a wet cutting procedure, first shut off the stream of water and then let the cutting blade run another 30 seconds so that it can

spin off the remaining water. This prevents corrosion.

4.7 Kickback and pulling motion

4.7.1 When working with the cut-off saw, it can kick back or suddenly pull

you.

4.7.2 Kickback can occur if the upper area of the cutting blade is used for

cutting (15).

4.7.3 The cut-off saw will skid or accelerate with great force toward the operator (danger of injury!).

To prevent kickback, observe the following:

4.7.4 Never use the area illustrated in Fig. 15 for cutting!

Exercise extra caution when inserting the tool into previously made

cuts!

4.7.5 A pulling motion occurs when the cut is constricted (due to a crack or

a workpiece under tension).

4.7.6 The cut-off saw will skid or accelerate forward with great force (danger

of injury!).

To prevent this pulling motion, observe the following:

4.7.7 Always insert the tool into previously made cuts and carry out the cutting process at maximum speed.

15

Page 26

Safety information

SV00080en.fm 26

4.7.8 Always support the workpiece such that the cut is under tensile

stress (16) so that the cutting blade is not pinched as cutting progresses.

4.7.9 When starting the cutting process, always move the cutting blade carefully toward the workpiece. Avoid uncontrolled movements.

4.7.10 Never cut through several workpieces at once! When cutting, make

sure that the tool does not contact other workpieces.

4.8 Work habits and methods

4.8.1 Before starting operation, check the work area for any hazards (electrical cables, flammable materials). Clearly indicate the work area (e.g.

set up warning signs or barriers).

4.8.2 During operation, hold the cut-off saw tightly using the front and rear

handles. Never allow the cut-off saw to run unattended!

4.8.3 When possible, operate the cut-off saw with nominal spindle speed

(see "Technical data").

4.8.4 Only work in well-lit areas with good visibility. Be particularly careful regarding slippery or wet surfaces, ice and snow (slipping hazard).

4.8.5 Never work on an instable surface. Exercise caution with obstacles in

the work area that present a tripping hazard! Always ensure that you

are standing in a secure position.

4.8.6 Never cut above shoulder height (17).

16

17

Page 27

SV00080en.fm 27

Safety information

4.8.7 Never cut while standing on a ladder (17).

4.8.8 Never work with the cut-off saw on a scaffolding.

4.8.9 Do not bend too far forward when working. Always use your knees to

lift or put down the cut-off saw. Do not bend down from the waist.

4.8.10 When moving the cut-off saw, ensure that none of your body parts is

in the extended swing area of the cutting blade (18).

4.8.11 Cutting blades must only be used to cut materials they were designed

for.

4.8.12 Do not use the cut-off saw to lift or shovel workpiece scraps or other

objects out of the way.

Caution, risk of injury! Before beginning the cutting process, remove

objects such as stones, nails, etc. from the cut area. Such objects can

be flung away and cause injuries.

4.8.13 When cutting workpieces to length, use a secure support and, if necessary, secure them so they cannot slide away. Do not use your foot

to hold the workpiece down. Do not allow another person to hold the

workpiece down.

4.8.14 Round workpieces must be secured so they do not rotate during the

cutting process.

4.8.15 Guide the cut-off saw by hand only if necessary with the cutting attachment in the outer position. A cut-off saw with the cutting attachment in

the center position has a better center of gravity, which helps prevent

early fatigue.

4.9 Instructions for using synthetic resin cutting blades

NOTICE!

4.9.1 Synthetic resin cutting blades can absorb moisture. When the cutting

blade rotates quickly, the absorption of moisture causes eccentric

weight distribution. The eccentric weight can break the blade.

4.9.2 Do not cool synthetic resin cutting blades with water or another liquid.

18

Page 28

Safety information

SV00080en.fm 28

4.9.3 Do not expose synthetic resin cutting blades to high humidity or rain!

4.9.4 Only use synthetic resin cutting blades up to their expiration date! This

date (quarter/year) is engraved on the cutting blade supporting ring.

EXAMPLE: 04 / 2007

With proper use and storage, this cutting blade can be used up to and

including the 4th quarter in 2007.

4.10 Cutting metals

NOTICE!

Wear proper breathing protection!

Materials that could discharge toxins may only be cut after notifying the

responsible authorities and under their supervision or that of persons

charged with this duty.

CAUTION!

The quick rotation of the cutting blade heats and melts metals at the

contact point. As far from the cut as possible (behind it), swivel the protective hood down (19) to divert flying sparks away from the operator

(greater danger of fire!).

4.10.1 Determine and mark the cutting direction and bring the cutting blade

into contact with the material, rotating at average speed. After cutting

a guide groove you can work at full throttle and higher pressure.

4.10.2 Cut only in the vertical or horizontal direction, not at an angle, which

can break the blade.

4.10.3 The best way to achieve a square, smooth cut is to pull or reciprocate

the cut-off saw. Do not "push" the cutting blade into the material.

19

Page 29

SV00080en.fm 29

Safety information

4.10.4 Cut large rods in stages (20).

4.10.5 Thin pipes can be cut with a simple downward cut.

4.10.6 Treat large diameter pipes as large rods. To avoid canting and for better control of the cutting process, do not allow the cutting blade to cut

too deep into the material. Always make shallow cuts around the perimeter.

4.10.7 Worn cutting blades with a small diameter have a lower peripheral

speed at the same engine speed and do not cut as well.

4.10.8 Cut double T-girders or angle steel in stages. See illustration 21.

4.10.9 Cut steel strips or sheets like pipes: pull evenly and use a long cutting

surface.

20

21

Page 30

Safety information

SV00080en.fm 30

4.10.10 Always notch material that is under tension (material that is supported

or embedded in a wall) on the pressure face and then cut from the opposite side so that the cutting blade does not get pinched (22). Secure

the material that is to be cut so that it does not fall!

NOTICE!

In case of suspected tension, be prepared for the material to kick back

and make sure you can move away, should it occur.

Use extra caution in scrapyards, accident scenes or unsorted stacks

of material. Material that is under tension, slipping or cracking is unpredictable. Secure the material that is to be cut so that it does not fall

(22)! Work very carefully and only with machines that are in perfect

condition.

Observe the accident prevention regulations set forth by the professional liability insurance association.

4.11 Cutting stone, concrete, asbestos or asphalt

NOTICE!

Wear proper breathing protection!

Asbestos or materials that could discharge toxins may only be cut after

notifying the responsible authorities and under their supervision or that

of persons charged with this duty. When cutting concrete piles that are

under tension and contain metal, comply with the instructions and

norms from the respective authorities or part manufacturers. The process for cutting through reinforcing bars must be carried out in the

proper order, taking the respective safety regulations into account.

22

Page 31

SV00080en.fm 31

Safety information

NOTE!

When cut, mortar, stone or concrete generate a great deal of fine dust.

To extend the service life of the cutting blade (cooling medium), to enable a better visual inspection and to prevent excessive dust formation,

wet cutting is preferred over dry cutting. Both sides of the cutting blade

must be sprayed evenly with water. You can find the right equipment

for every wet cutting application in the Wacker Neuson product range.

4.11.1 Before beginning the cutting process, remove objects such as stones,

nails, etc. from the cut area.

Notice: Make sure that you know where the electrical cable is!

The quick rotation of the cutting blade at the contact point tears the material and throws it out of the cutting groove. As far from the cut as possible (behind it), swivel the protective hood down (23) to divert the

workpiece particles that have been cut away from the operator.

4.11.2 Mark the cutting line and grind a groove ca. 5 mm (0.2") deep along the

entire length of the workpiece at half throttle, which will guide the cutoff saw exactly during the subsequent cutting process.

NOTE:

Using a guide cart (24) is recommended for long, straight cuts. It

makes guiding the cut-off saw in a straight pass easier and doesn't require as much effort.

23

24

Page 32

Safety information

SV00080en.fm 32

4.11.3 When truing stone slabs you only need to grind one groove (to prevent

unnecessary dust formation), and then place the slab on a flat base

and knock off the overhanging piece (25).

NOTICE!

For cutting to length, prevent the cut section from pinching the cutting

blade and to avoid injuries due to falling parts, determine the direction

of the cut and the order of the steps to be carried out.

4.12 Transport and storage

4.12.1 Turn off the cut-off saw when transporting it or moving it to another location while working (26).

4.12.2 Never carry or transport the cut-off saw while the engine or the cutting

blade is running!

4.12.3 Use only the bow handle grip to carry the cut-off saw. The cutting blade

points to the rear (26). Do not touch the muffler (can cause burns).

4.12.4 For transport over a substantial distance, use a wheelbarrow or a cart.

4.12.5 When transporting by truck ensure that the cut-off saw is in a stable position so that that no fuel runs out. Always detach the cutting blade

when transporting by truck.

25

26

Page 33

SV00080en.fm 33

Safety information

4.12.6 Store the cut-off saw securely in a dry area. Do not store it outdoors.

Always detach the cutting blade. Do not allow children near the cut-off

saw.

4.12.7 Before a long storage period and before shipping the cut-off saw

make sure to follow the "Periodic maintenance and service instructions". Always empty the fuel tank and run the carburetor

empty.

4.12.8 Proceed especially carefully when storing the cutting blades:

4.12.9 Clean them and dry them well.

NOTICE:

Do not clean synthetic resin cutting blades with water or other liquids!

4.12.10 Always lay them flat to store them.

4.12.11 Avoid the risk of splintering or breakage by preventing contact with

moisture, frost, direct sunlight, high temperatures or temperature fluctuation!

4.12.12 Check the expiration date before using the synthetic resin cutting

blades again after storage (engraved on the supporting ring - quarter/

year). If the expiration date has passed, the cutting blade may not be

used.

4.12.13 Always check new cutting blades or those from storage for damage

and test them by running them at least 60 seconds at the specified

maximum speed. Ensure that no one is in the extended swing of the

cutting blade.

4.13 Maintenance

4.13.1 Before you carry out any maintenance work, always turn off the

cut-off saw (27) and pull off the spark plug connector!

4.13.2 Check that the cut-off saw is in a safe operating condition before you

start work. Make sure that the cutting blade has been attached according to instructions. Also make sure that the cutting blade is undamaged

and suited for the application at hand.

4.13.3 While operating the machine, try to produce as little noise and exhaust

fumes as possible. Check the carburetor setting.

4.13.4 Clean the cut-off saw regularly.

27

Page 34

Safety information

SV00080en.fm 34

4.13.5 Check the tank cap regularly to make sure it is on tightly.

4.13.6 Observe the accident prevention regulations set forth by the

professional liability insurance association. Never attempt to modify

the cut-off saw! Doing so will endanger your safety!

4.13.7 Service and maintenance work must only be carried out to the extent

described in these operator's manual. All other procedures must be

performed by Wacker Neuson Service.

4.13.8 Use only Wacker Neuson spare parts and accessories.

Use of spare parts, accessories and cutting blades not produced by

Wacker Neuson increases your chances of having an accident. If

accidents or damage that occurs with accessories not produced

by Wacker Neuson exempts the manufacturer from all liability.

4.14 First Aid

A first aid kit in accordance with DIN 13164 should always be available

in the working area in case an accident occurs. Immediately replace

any materials that are removed.

When requesting assistance, provide the following information:

∗ where it happened

∗ what happened

∗ how many are injured

∗ what type of injuries

∗ who is requesting assistance!

29

Page 35

SV00080en.fm 35

Safety information

NOTE!

If persons with circulatory problems are exposed too often to vibrations, the blood vessels or nervous system can be damaged.

The following symptoms can occur due to vibrations experienced in the

fingers, hands or wrists: Body parts can "go to sleep," tingling, pain,

prickling, changes in skin color or in the skin itself.

If these symptoms occur, consult a doctor.

4.15 Disposal and environmental protection

Remember our environment!

Dispose of worn out or defective cutting blades according to local

waste disposal regulations. To prevent misuse, destroy the cutting

blades that can no longer be used before disposing of them.

When the machine has reached the end of its service life, recycle it or

dispose of it in a way that does not harm the environment. If necessary,

ask your local administration for more information.

Page 36

Technical data

TD00740en.fm 36

5. Technical data

1

) Data takes the operating states idle and top speed equally into consideration.

2

) Peripheral speed at the highest engine speed.

3

) Outer diameter/centre bore/thickness.

4

) At the working area (operator's ear).

5

) Only use synthetic 2-cycle engine oil of the specification JASO FC. or ISO L-EGD!

BTS 930L3 BTS 935L3

Item no. 0008987 0008988

Engine displacement cm

3

(cu in) 64 (3.9)

Bore mm (in) 47 (1.85)

Stroke mm (in) 37 (1.46)

Max. performance kW (hp) 3.2 (4.4)

Max. torque Nm (ft.lbs.) 4.0 (3.0)

Idle speed rpm 2,500

Clutch engaging speed rpm 3,800

Limiting speed rpm 9,350

Nominal spindle speed rpm 4,300

Sound pressure level L

pA eq

according to EN 1454

1) 4)

dB(A) 97

Sound power level L

WA

109 dB(A)

Vibrational acceleration a

h,w

according to EN 1454

- Bow handle grip (idle/nominal spindle speed)

- Handle (idle/nominal spindle speed)

m/s

2

6 / 5

8 / 6

When using the guide cart FBTS:

Vibrational acceleration a

h,w

according to EN 1454

(for the guide cart)

m/s

2

2.5

Ignition system (with maximum rpm limitation) Type Electronic

Spark plug Type NGK BPMR 7A / BOSCH WSR

6F / CHAMPION RCJ 6Y

Spark plug air gap mm (in) 0.5 (.020)

Fuel consumption at max. capacity according to

ISO 8893

l/h

(US qt/h)

2.1

(2.2)

Special consumption at max. capacity according to

ISO 8893

g/kWh

(oz./hph)

500

(13)

Fuel tank capacity l (US qt) 1.1 (1.2)

Gasoline/2-cycle oil mixing ratio

5

)

50:1

Cutting blade for max. 80 m/s (260 ft/sec.)

2

)

mm (in) 300 / 20.0 / 5

3)

(12/0.787/0.2)

350 / 25.4 / 5

3)

(14/1/0.2)

Spindle diameter mm (in) 20.0 (0.787") 25.4 (1")

Weight of cut-off saw

(empty tank, without cutting blade)

kg

(lb)

10.0

(22)

10.2

(22.5)

Page 37

TD00740en.fm 37

Technical data

1

) Data takes the operating states idle and top speed equally into consideration.

2

) Peripheral speed at the highest engine speed.

3

) Outer diameter/centre bore/thickness.

4

) At the working area (operator's ear).

5

) Only use synthetic 2-cycle engine oil of the specification JASO FC. or ISO L-EGD!

BTS 1030L3 BTS 1035L3

Item no. 0008989 0008990

Engine displacement cm

3

(cu in) 73 (4.5)

Bore mm (in) 50 (1.97)

Stroke mm (in) 37 (1.46)

Max. performance kW (hp) 4.2 (5.6)

Max. torque Nm (ft.lbs.) 5.0 (3.7)

Idle speed rpm 2,500

Clutch engaging speed rpm 3,800

Limiting speed rpm 9,350

Nominal spindle speed rpm 4,300

Sound pressure level L

pA eq

according to

EN 1454

1) 4)

dB(A) 99

Sound power level L

WA

110 dB(A)

Vibrational acceleration a

h,w

according to EN 1454

- Bow handle grip (idle/nominal spindle speed)

- Handle (idle/nominal spindle speed)

m/s

2

7 / 5

8 / 7

When using the guide cart FBTS:

Vibrational acceleration a

h,w

according to EN 1454

(for the guide cart)

m/s

2

2.5

Ignition system (with maximum rpm limitation) Type Electronic

Spark plug Type NGK BPMR 7A / BOSCH WSR

6F / CHAMPION RCJ 6Y

Spark plug air gap mm (in) 0.5 (.020)

Fuel consumption at max. capacity according to

ISO 8893

l/h (US qt/h) 2.7 (2.9)

Special consumption at max. capacity according to

ISO 8893

g/kWh

(oz./hph)

500

(13)

Fuel tank capacity l (US qt) 1.1 (1.2)

Gasoline/2-cycle oil mixing ratio

5

)

50:1

Cutting blade for max. 80 m/s

2

)

mm

(in)

300/20.0/5

3)

(12/0.787/0.2)

350/25.4/5

3)

(14/1/0.2)

Spindle diameter mm (in) 20.0 (0.787") 25.4 (1")

Weight of cut-off saw

(empty tank, without cutting blade)

kg (lb) 10.0 (22) 10.2 (22.5)

Page 38

Technical data

TD00740en.fm 38

1

) Data takes the operating states idle and top speed equally into consideration.

2

) Peripheral speed at the highest engine speed.

3

) Outer diameter/centre bore/thickness.

4

) At the working area (operator's ear).

5

) Only use synthetic 2-cycle engine oil of the specification JASO FC. or ISO L-EGD!

BTS 1140L3

Item no. 0610063

Engine displacement cm

3

(cu in) 81 (4.9)

Bore mm (in) 52 (2.05)

Stroke mm (in) 38 (1.50)

Max. performance kW (hp) 4.5 (6.2)

Max. torque Nm (ft.lbs.) 5.2 (3.8)

Idle speed rpm 2,500

Clutch engaging speed rpm 3,800

Limiting speed rpm 9,350

Nominal spindle speed rpm 3,750

Sound pressure level L

pA eq

according to EN 1454

1) 4)

dB(A) 98.3

Sound power level L

WA

108 dB(A)

Vibrational acceleration a

h,w

according to EN 1454

- Bow handle grip (idle/nominal spindle speed)

- Handle (idle/nominal spindle speed)

m/s

2

5.6 / 6.3

8.8 / 6.0

When using the guide cart FBTS:

Vibrational acceleration a

h,w

according to EN 1454

(for the guide cart)

m/s

2

2.5

Ignition system (with maximum rpm limitation) Type Electronic

Spark plug Type NGK BPMR 7A

/ BOSCH

WSR 6F /

CHAMPION

RCJ 6Y

Spark plug air gap mm (in) 0.5 (.020)

Fuel consumption at max. capacity according to

ISO 8893

l/h (US qt/h) 2.9 (3.2)

Special consumption at max. capacity according to

ISO 8893

g/kWh

(oz./hph)

500

(13)

Fuel tank capacity l (US qt) 1.1 (1.2)

Gasoline/2-cycle oil mixing ratio

5

)

50:1

Cutting blade for max. 80 m/s

2

)

mm

(in)

400/25.4/5

3)

(16/1/0.2)

Spindle diameter mm (in) 25.4 (1.0")

Weight of cut-off saw

(empty tank, without cutting blade)

kg (lb) 10.6 (23.4)

Page 39

T01126en.fm 39

Part identification

6. Part identification

1 Handle

2 Filter cover for air cleaner and spark plug cap

3 Cover lock

4 Bow handle grip

5 Muffler

6 Protective hood

7 Handle for protective hood

8 Adjusting screw for tightening the V-belt

9 Fastening nuts

10 Base

11 Opening for setting the carburetor

12 Nameplate

13 Tank with hand guard

14 Decompression valve

15 Starter handle

16 Air intake port

Page 40

Part identification

T01126en.fm 40

17 Multifunction switch "Start/Stop" (I/O) choke

18 Lock button for half throttle

19 Safety switch

20 Throttle lever

21 Fuel tank seal

22 Valve housing with starting device

23 Cutting blade

24 Fastening screw for cutting blade

25 Clamping disc

26 Opening for counterholder

Page 41

T01126en.fm 41

Starting up

7. Starting up

NOTICE:

Before working on the cut-off saw, always turn off the engine, pull off the spark plug connector and wear protective

gloves!

NOTICE:

The cut-off saw must not be started until it has been completely assembled and tested!

Always use the assembly tools included in delivery for the following

procedures:

1 Combination wrench 13/19 mm

2 Offset screwdriver

3 Screwdriver for setting the carburetor

4 Adapter ring (not usually included in delivery)

NOTE: Only for the BTS 1140L3 model

No air cleaner mounted!

Before starting operation, insert the oiled foam air cleaner (prefilter) as shown in illustration 31! First remove the filter cover (see

chapter Cleaning/Changing the air cleaner).

Knead the foam air cleaner in the packaging prior insertion to ensure

distribution of the oil. Remove the packaging afterwards.

30

31

Page 42

Starting up

T01126en.fm 42

7.1 Attaching the cutting blade

Set the cut-off saw onto a sturdy base and carry out the following assembly steps:

Check the cutting blade for damage. See SAFETY INFORMATION. Unscrew the screw (9) and remove the

clamping disc (8). Set the cutting blade (5) onto the shaft (7).

NOTE: The arbor diameter of the cutting blade must precisely fit the

shaft. If the arbor diameter is larger, you must use an adapter ring (*).

NOTICE:

If you are using diamond-edged cutting blades, make sure

you observe the attached rotational direction mark!

Set the clamping disc (8) onto the shaft, screw in together with the

screw (32/9) and tighten by hand.

Turn the cutting blade slowly until you can see the locking bore of the

V-belt pulley bolt through the gear arm hole (10).

Press the offset screwdriver (2) all the way in. The shaft is now

blocked.

Firmly tighten the screw with the combination wrench (1).

NOTE: Firmly tighten the screw to 30 + 2 Nm (22 + 1.5 ft.lbs.), otherwise the cutting blade may slip while cutting.

32

33

Page 43

T01126en.fm 43

Starting up

7.2 Tightening the V-belt/Checking the tension

NOTICE:

To obtain the maximum cutting performance at the lowest fuel consumption, it is absolutely necessary to tighten the V-belt precisely. An

incorrectly tightened V-belt leads to premature wearing of the V-belt

and V-belt pulley or to damage on the clutch bearing. Retighten the

V-belt after one hour of operation!

NOTE: To tighten the V-belt and to check the tension, you must loosen

both mounting nuts (11).

To increase the tension, turn the tension screw (12) in the clockwise

direction with the combination wrench included in delivery.

The V-belt is correctly adjusted if the marking (14) is centered between

the nuts (13).

NOTICE: After tightening/testing the V-belt, make sure to

tighten the mounting nuts (11) to 30 + 2 Nm (22 + 1.5 ft.lbs.).

34

35

Page 44

Starting up

T01126en.fm 44

7.3 Operating fluids

NOTICE:

The unit uses mineral oil products (gasoline and oil)!

Take special precautions when handling gasoline.

Smoking and open fires are not permitted (danger of explosion).

Fuel mixture

The cut-off saw engine is a high-performance two-cycle engine. It is

operated with a mixture of fuel and two-cycle engine oil.

The engine is designed for use with normal unleaded gasoline with a

minimum octane rating of 91 ROZ (87 R+M)/2. If this octane is not

available, you may also use fuel of a higher octane rating. This will not

damage your engine.

For optimum engine performance and for the sake of your own health

and the environment, always use unleaded fuel! Do not use fuel that

contains alcohol.

36

Fuel 50:1

+

1,000 cm³ (1 liter) 20 cm³

5,000 cm³ (5 liters) 100 cm³

10,000 cm³ (10 liters) 200 cm³

1.0 Us-gal 2.5 floz.

2.5 Us-gal 6.4 floz.

5.0 Us-gal 12.8 floz.

Preparing the correct gasoline/oil mixing ratio:

50:1 Mix 50 parts of fuel with one part of oil.

Page 45

T01126en.fm 45

Starting up

To lubricate the engine, use a synthetic oil for two-stroke aircooled

engines (quality grade JASO FC or ISO-L-EGD), which has to be

added to the fuel.

NOTE: To prepare the fuel-oil mixture, always premix the prescribed

amount of oil volume with half of the fuel volume and then add the remaining amount of fuel. Before you fill the tank, always shake the finished mixture well.

NOTICE: Open the cap of the fuel tank carefully since there may be

pressure present!

It is not a good idea to increase the oil percentage of the two-cycle mixture for beyond the specified mixing ratio for any reason. This will increase the amount of combustion residue which pollutes the

environment and also clogs the exhaust port in the cylinder and the

muffler. Furthermore, this also increases fuel consumption and reduces engine performance.

WARNING!

FUELS WITH MORE THAN 10% ETHANOL ARE NOT APPROVED

FOR USE IN Wacker Neuson 2-STROKE ENGINES!

Use of alternative fuels, such as E-20 (20% ethanol), E-85 (85% ethanol) or any fuels not meeting Wacker Neuson requirements are not approved for use in this engine!

USE OF ALTERNATIVE FUELS CAN CAUSE THE FOLLOWING

PROBLEMS:

Poor engine performance, loss of power, overheating, fuel vapor lock,

improper clutch engagement, premature deterioration of fuel lines,

premature deterioration of gaskets, premature deterioration of carburetors.

USING ALTERNATIVE FUELS AND/OR 2-STROKE OILS NOT ACCORDING TO JASO FC OR ISO-L-EGD IN THIS 2-STROKE ENGINE

WILL VOID YOUR ENGINE WARRANTY!

7.4 Storing fuel

Fuels cannot be stored indefinitely. Fuel and fuel mixtures age due to

evaporation, particularly under the influence of high temperatures.

Fuel and fuel mixtures that have been stored for too long can lead to

problems with starting and engine damage. Purchase only enough fuel

for a few months. Mixed fuels for use at high temperatures should be

used within 6-8 weeks.

Store fuel only in approved containers in cool and secure areas!

Page 46

Starting up

T01126en.fm 46

AVOID CONTACT WITH SKIN AND EYES!

Mineral products and oils scour your skin. If used repeatedly and over

time, they will dry out your skin. This could develop into one of various

skin diseases. In addition, allergic reactions are also possible.

Oil in your eyes can cause irritations. If you get oil into your eye, rinse

it out immediately with clean water.

If irritation continues, consult a physician immediately!

37

Page 47

T01126en.fm 47

Starting up

7.5 Filling the tank

NOTICE: STRICTLY FOLLOW THE SAFETY INFORMATION!

Fuels must be handled carefully and prudently.

Only when the engine is turned off and has cooled down!

Clean the filling area so that no dirt can get into the tank.

Set the machine on its side on a flat base.

Screw off the tank cap and pour in the fuel mixture. Pour it in carefully

to avoid spilling the fuel mixture.

Tightly screw the tank cap back on.

Clean the tank cap and surrounding area after you are finished! Never

start or operate the unit at the location where you filled the tank! Should

you spill fuel on your clothing, change your clothes immediately.

Fuel mixture

38

Page 48

Starting up

T01126en.fm 48

7.6 Starting the engine

This model is fitted with a semiautomatic decompression valve (1) to

make starting easier. Press the rubber cover until you can feel it engage. This pushes in the decompression valve behind it. This in turn

reduces the compression, so that it takes less force to pull the starter

cord to accelerate the engine to its starting speed.

The high pressure in the combustion chamber after the first ignition automatically closes the decompression valve.

NOTICE:

Strictly follow the SAFETY INFORMATION.

The cut-off saw must not be started until it has been completely assembled and tested!

Take it at least 3 m (10 feet) away from the place where you filled the

tank!

39

if

required

40

3 meters

(10 feet)

Page 49

T01126en.fm 49

Starting up

Stand squarely and set the cut-off saw onto the ground so that the cutting attachment is freestanding.

Move the protective hood (3) to the best position for the application at

hand (see figure).

Grab the handle (2). The protective hood (3) can be swivelled within

the stopmounts in both arrow directions.

Notice:

Make absolutely sure that the straight edge of the stop plate (4) is parallel to the edge of the protective hood (see arrows).

If this is not the case, please take your machine to the shop.

7.6.1 Cold start

Press the multifunction switch (6) upward (choke position).

Put your hand around the handle (safety switch (8) is actuated by the

palm of your hand).

Press the throttle lever (9) all the way through and hold it.

Press the lock button (7) and release the throttle lever (9) (throttle lever

is locked in place by the lock button in the half-gas position). Press in

the start valve (5).

41

42

Page 50

Starting up

T01126en.fm 50

Put your hand around the bow handle grip and hold it firmly while you

press the cut-off saw against the ground.

Place your left foot into the rear hand guard.

Pull out the starter rope slowly until you feel resistance (the piston is

located before the top dead center).

Now continue pulling quickly with force until you hear the engine start.

43

Page 51

T01126en.fm 51

Starting up

Notice: Do not pull out the starter rope more than 50 cm (20") and let

it rewind slowly by hand, not letting it go.

Depress decompression valve (5) again.

Press the multifunction switch (42/6) to the "I" position.

Pull the starter rope again until the engine runs.

Once the engine is running, tip the throttle lever (42/9) so that the lock

button (42/7) snaps out and the engine idles.

7.6.2 Warm start

As described under cold start, however without pressing the multifunction switch (42/6) in the choke position.

7.7 Turning off the engine

Press the multifunction switch (9) down to the "Stop" position.

7.8 Readjusting the idle speed

NOTE:

The cut-off saw is equipped with a speed limiting electronic ignition. In addition, the carburetor has a fixed

nozzle that cannot be adjusted.

The idle speed has been factory set to approx. 2,500 rpm; however,

the run-in procedure of a new machine requires a slight readjustment

of the idle speed.

Adjustments to the adjusting screws (L) and (H) may only be made by

an authorised Wacker Neuson service centre. Accordingly, the holes

for the two screws are sealed shut.

44

Page 52

Starting up

T01126en.fm 52

The following steps are required to correctly set the idle speed:

Start the engine and let it warm up (approx. 3 - 5 minutes).

Set the speed for the idle position with the screwdriver that was included in delivery.

Readjust the idle speed

If the cutting blade rotates when the engine is running, screw the stop

screws (2) for the choke outward until the cutting blade no longer rotates. If the emgine stops when idling, turn the screw back in somewhat.

Turn off the engine

46

47

Page 53

T01127en.fm 53

Maintenance work

8. Maintenance work

NOTICE:

Only use spare parts from Wacker Neuson! Non-compliance will

exempt the manufacturer from all liability.

NOTICE:

When working on the cut-off saw, always turn off the engine, remove

the cutting blade, pull off the spark plug connector and wear protective

gloves!

NOTICE:

The cut-off saw must not be started until it has been completely assembled and tested!

NOTE:

For your safety, regular checks and maintenance must be carried out

at a Wacker Neuson service station because many parts not discussed

in this operator's manual are important safety devices and, like all

parts, are also subject to wear.

NOTICE:

If the cutting blade breaks during the cutting process, before

starting the machine again it must be serviced in a Wacker

Neuson shop!

48

Page 54

Maintenance work

T01127en.fm 54

8.1 Replacing the V-belt

Loosen the nuts (3).

Loosen the tension screw (1) (counterclockwise) until you see the

screw end (2) in the gap.

Release the screw (detail X, only on BTS 1140L3) and remove it.

Unscrew the nuts (3) and remove the cap (4).

Unscrew the screws (5) and (7) and take off the side brace (6).

NOTE:

Screw (5) is longer than screws (7). Observe the installation

position during assembly!

Loosen the screws (8) and take off the crankcase cover (9).

Remove the old V-belt (10) or any leftover V-belt material. Clean the

inside of the transmission with a small brush.

Insert the new V-belt.

NOTE:

Mount the crankcase cover (9), the side brace (50/6) and the cover

(50/4) in the reverse order.

Tighten the V-belt, see Chapter "Tightening the V-belt/Checking the

tension".

50

51

Page 55

T01127en.fm 55

Maintenance work

8.2 Cleaning the protective hood

With time, material deposits will form on the inside of the protective

hood (particularly when wet cutting). Under certain circumstances,

these deposits can hinder the free rotation of the cutting blade.

Detach the cutting blade and thrust washer and remove the material

deposits on the inside with a wood strip or similar tool.

Wipe off the shaft and all disassembled parts with a clean cloth.

8.3 Cleaning/Changing the air cleaner

NOTICE:

Before cleaning the air cleaner, turn off the engine! Never clean the air

cleaner with compressed air! Do not clean the prefilter or the internal

filter with fuel!

The engine's service life depends on the condition and the regular

maintenance of the filter elements. Not regularly cleaning or maintaining the engine leads to excessive wear!

Replace a damaged air cleaner immediately! Torn pieces of fabric and

large dirt particles can destroy the engine. If possible, do not work in

dusty conditions! The particulate matter generated when dry cutting

concrete and stone endangers the operator's health and shortens the

engine's service life. If possible, carry out cutting operations for concrete and stone with water to bind dust particles together.

52

NOTE: See chapter "Attaching the cutting

blade" for information on assembling the cut-

ting blade.

Page 56

Maintenance work

T01127en.fm 56

Turn the cover lock (11) to the "unlocked " position and carefully remove the filter cover (12).

Two sealing rings (54/15) are located between the filter cover (12) and

the hood (54/14).

Loosen the screws (13) and take off the hood (14).

Clean the sealing rings (15) using a small brush and check for signs of

damage.

Take the prefilter (17) out of the filter cover.

Pull the air cleaner cartridge (18) out of the hood.

Take the internal filter (16) off the suction head.

Note:

Protect the carburetor to prevent dirt from falling into it!

Put the multifunction switch in the "Choke" position or cover the carburetor with a clean cloth.

53

54

55

Page 57

T01127en.fm 57

Maintenance work

8.4 Prefilter, air cleaner cartridge and internal filter

Prefilter (dry foam) (all models except for BTS 1140L3)

Wash out the dirty prefilter (1) in warm soap water using household

dish washing detergent or filter cleaner. Do not clean the prefilter with

fuel!

Rinse away dirt under running water.

Work of filter cleaner into the prefilter foam into a good lather.

Rinse the prefilter under running water.

Dry the prefilter well.

NOTE: The prefilter must be cleaned daily; if an unusual amount of

dust is produced, several times a day. If it is not possible to clean the

prefilter on site, have a reserve prefilter ready. Renew the prefilter after

ever 25 hours of operation at the latest.

Align the prefilter with the cover holder when inserting it into the filter

cover, then press it into the filter cover (5). The prefilter must be flush

with the cover holder in all areas and pressed in tightly.

56

Page 58

Maintenance work

T01127en.fm 58

Prefilter (foam with air cleaner oil) (only BTS 1140L3)

Replacement (after cutting with excessive dust formation):

• daily

• or at least after 4 hours of operation

• or at least after filling the tank 8 times

• or at least after using 8 liters of fuel mixture

Replacement (after wet cutting/after cutting steel):

• weekly

• or at least after 25 hours of operation

• or at least after filling the tank 50 times

• or at least after using 55 liters of fuel mixture

Knead the foam air cleaner in the packaging prior insertion to ensure

distribution of the oil. Remove the packaging afterwards.

Align the prefilter with the cover holder when inserting it into the filter

cover, then press it into the filter cover (5). The prefilter must be flush

with the cover holder in all areas and pressed in tightly.

Page 59

T01127en.fm 59

Maintenance work

Internal filter (all models)

Wash out the dirty internal filter (3) in warm soap water using household dish washing detergent or filter cleaner.

Air cleaner cartridge (all models)

NOTICE:

The air cleaner cartridge (2) filters the intake air through fine paper filter lamella. Thus never wash out the cartridge or clean it with compressed air.

Clean the air cleaner cartridge once a week.

Expand the lamella of the air cleaner cartridge slightly, lay it on a clean

pad and carefully tap against it.

Replace the air cleaner cartridge after every 100 hours of operation.

Replace it immediately if you notice a drop in power, a drop in engine

speed or smoke in the exhaust fumes.

Before assembling the filter system, check whether dirt particles have

fallen into the air intake port. If necessary, remove the dirt particles.

Page 60

Maintenance work

T01127en.fm 60

8.5 Replacing the spark plug

NOTICE:

Do not touch the spark plug or spark plug connector while the engine

is running (high voltage).

Carry out maintenance work only when the engine is off.

Hot engine can cause burns. Wear protective gloves!

The spark plug must be replaced if the ceramic insulator is damaged,

or if the spark plug electrodes are severely burned, very dirty or oily.

NOTICE: Use only BOSCH WSR 6F, CHAMPION RCJ-6Y or NGK

BPMR 7A spark plugs as replacements.

Using unapproved spark plugs can damage the ignition system.

Turn the cover lock (6) to the "unlocked " position and carefully remove the filter cover (7).

Lift up the spark plug cover (8). Pull off the spark plug cap (9) from the

spark plug. Remove the spark plug with the combination wrench included in delivery.

Spark plug air gap

The spark plug air gap must be 0.5 mm (0.020").

57

Page 61

T01127en.fm 61

Maintenance work

8.6 Checking the ignition spark

Insert the combination wrench (9) between the hood and cylinder, as

shown in the figure.

NOTICE!

Do not insert the wrench into the spark plug hole; just make contact

with the cylinder (otherwise you may damage the engine).

Press the unscrewed spark plug (10), with the spark plug terminal cap

firmly attached, against the wrench using insulated pliers (away from

the spark plug hole!).

Press the multifunction switch (11) to the "I" position.

Pull out the starter rope firmly.

If the spark plug is functioning properly, you must see a spark plug between the electrodes.

58

Page 62

Maintenance work

T01127en.fm 62

8.7 Replacing the suction head

The felt filter (13) of the suction head can become clogged during operation. To ensure an unrestricted flow of fuel to the carburetor, the

suction head should be replaced about every 3 months.

Unscrew the fuel tank cap (12), pull the retainer out of the tank opening.

Empty the tank.

To change it, pull the suction head through the tank cap opening using

a wire hook.

Notice: Avoid skin and eye contact with mineral products!

8.8 Replacing the starter rope

Release the four screws (14). Remove the valve housing (15).

Unscrew the two screws (16) and carefully disconnect the air horn (17)

from the valve housing (15). Always proceed in the order

(A-B-C-D).

Remove any leftover rope (18).

59

60

Page 63

T01127en.fm 63

Maintenance work

Feed in new rope with a diameter of 4.0 mm (0.16") and a length of

1,000 mm (40"), as in the illustration (do not forget the disc (19)) and

knot both ends.

Pull the knot (20) into the rope drum (21).

Notice: Neither the knot nor the end of rope should extend beyond the

surface of the rope drum.

Pull the knot (22) into the recoil starter handle (23).

Pass the rope through the recess (24) on the rope drum and, together

with the rope, turn the rope drum twice in the direction of the arrow.

Hold the rope drum firmly with your left hand, untwist the rope with your

right hand, pull the rope taut and hold it tightly.

Carefully release the rope drum. The spring tension will cause the rope

drum to wind up the rope.

Repeat the procedure three times. Now the recoil starter handle

should now be in the upright position on the valve housing.

NOTE: When the starter rope has been fully extended, it must be possible to continue turning the rope drum at least a quarter of a turn

against the spring tension.

61

62

Page 64

Maintenance work

T01127en.fm 64

NOTICE! Danger of injury! Hold the extended recoil starter handle securely. It will recoil quickly if you accidentally let go of the rope drum.

Mount the air horn in reverse order (see Fig. 63). Make sure that the

guide (25) is positioned in the receptacle (26) on the valve housing.

When attaching the valve housing pull the recoil starter handle lightly,

if necessary, until the starting device engages.

8.9 Replacing the return spring

Remove the valve housing (see chapter "Replacing the starter rope").

Disconnect the air horn from the valve housing (see chapter "Replacing the starter rope").

Remove the retaining clip (1) (see the section on accessories for information about the pliers for external retaining clips).

Pull off the rope drum (2).

Remove the screws (3).

Pry the return spring (4) evenly off the latches by using a screwdriver

or similar tool. Exercise extra caution. The return spring is under

tension and can suddenly spring out of the cassette!

NOTICE: Danger of injury! Always wear safety glasses and wear

protective gloves when performing this procedure!

63

Page 65

T01127en.fm 65

Maintenance work

Replacement return springs are delivered already under tension in the

housing. CAUTION. The spring can snap out. A released spring can

be reinserted as in the illustration (Make sure to note the rotation di-

rection!)

Apply a light coat of multipurpose grease to the new return spring (4)

before you install it in the valve housing. Insert the return spring (4) and

press gently against it so that the tabs (5) snap into the holders. Screw

in the screw (3) and tighten only slightly. When attaching the rope

drum, turn it slightly until it you feel it snap into place. Mount the retaining clip. Wind up the starter rope (see chapter "Replacing the starter

rope"). Do not lubricate the rope drum (2) or the journals!

Attach the air horn (see chapter "Replacing the starter rope"). When attaching the valve housing pull the recoil starter handle lightly, if necessary, until the starting device engages.

8.10 Cutting attachment in the center/outer position

NOTE: The cutting attachment is mounted at the factory for operation

in the center position (1). The cutting attachment can be mounted in

the outer position (2) to maneuver around obstacles that are very close

to the cutting line (for curbs, or brick walls). Use the outer position for

guiding the cut-off saw by hand only for the work at hand. Afterwards,

mount the cutting attachment back to the center position. A cut-off saw

with the cutting attachment in the center position has a better center of

gravity, which helps prevent early fatigue.

64

Page 66

Maintenance work

T01127en.fm 66

8.11 Remounting the cutting attachment

Loosen the nuts (5).

Loosen the tension screw (3) (counterclockwise) until you see the

screw end (4) in the gap. Release the screw (detail X, only on BTS

1140L3) and remove it. Unscrew the nuts (5) and remove the cover (6).

Pry out the stop pin (8) with the combination wrench (9) far enough, as

shown in the figure, so that you are able to turn the protective hood

(11).

65