Page 1

Service Manual

/

Track excavator

Machine model 803

Edition 2.4

Order no. 1000164843

Language en

Page 2

Documentation

Title Language Order no.

Operator’s manual de 1000161345

Service manual en 1000164843

Spare parts list de/en/fr 1000161641

de/it/es 1000161643

Legend

Edition Issued

1.0 09/2006

1.1 10/2007

2.0 02/2011

2.1. 08/2012

2.2 06/2013

2.3 02/2014

2.4 04/2015

Copyright – 2015 Wacker Neuson Linz GmbH, Hörsching

Printed in Austria

All rights reserved, in particular the copyright, the right of reproduction and the right of distribution applicable worldwide.

No part of this publication may be reproduced, translated or used in any form or by any means – graphic, electronic or mechanical

including photocopying, recording, taping or information storage or retrieval systems – without prior permission in writing from the

manufacturer.

No reproduction or translation of this publication, in whole or part, without the written consent of Wacker Neuson Linz GmbH.

Violations of legal regulations, in particular of the copyright protection, shall be subject to civil and criminal prosecution.

Wacker Neuson Linz GmbH keep abreast of the latest technical developments and constantly improve their products. For this rea-

son, we may from time to time need to make changes to figures and descriptions in this documentation which do not reflect products

that have already been delivered and that will not be implemented on these machines.

Technical data, dimensions and weights are only given as an indication. Responsibility for errors or omissions not accepted.

The cover features the machine with possible optional equipment.

The Operator’s Manual and any amendments to it must always be available at the place of use of the machine. Possible amend-

ments are included at the end of the Operator’s Manual.

Refer to the Operator’s Manual of the machine for information on labels.

Wacker Neuson Linz GmbH

Flughafenstr. 7

A-4063 Hörsching

+43 (0) 7221 63000

Phone

E-mail: office.linz@wackerneuson.com

www.wackerneuson.com

Document: SHB 803 en

Order no.: 1000164843

Edition: 2.4

Page 3

Table of contents

Table of contents

Table of contents

Operation

Information on this service manual .......................................................................... 1-2

Identification of warnings and dangers .................................................................... 1-3

Designated use and exemption from liability ........................................................... 1-4

Labels ...................................................................................................................... 1-5

Machine overview (up to serial no. AI00966) ........................................................... 1-7

Machine overview (from serial no. AI00967) ........................................................... 1-8

Control stand overview (up to serial no. AI00814) ................................................... 1-9

Control stand overview (from serial no. AI00815) .................................................. 1-11

Display elements (overview) .................................................................................. 1-12

Engine compartment overview (up to serial no. AI00814) ..................................... 1-13

Engine compartment overview (from serial no. AI00815) ...................................... 1-14

Technical data

Chassis .................................................................................................................... 2-2

Engine ...................................................................................................................... 2-2

Fuel injection pump ........................................................................................... 2-4

Engine capacities .............................................................................................. 2-4

Engine tightening torques .................................................................................. 2-4

Hydraulic system ..................................................................................................... 2-4

Auxiliary hydraulics oil flow ................................................................................ 2-5

Travel gear and swivel unit ...................................................................................... 2-5

Stabilizer blade ........................................................................................................ 2-5

Screwable hose burst valve ............................................................................... 2-5

Electrical system ...................................................................................................... 2-6

Fuses behind the right-hand trim ....................................................................... 2-6

Relays behind the right-hand trim ...................................................................... 2-7

Fuses and relays with Dual Power option ......................................................... 2-7

Noise levels ............................................................................................................. 2-8

Vibration ................................................................................................................... 2-8

Coolant compound table .......................................................................................... 2-8

Model-specific tightening torques ............................................................................ 2-9

General tightening torques ...................................................................................... 2-9

Tightening torques for hydraulic threaded fittings (dry assembly) ..................... 2-9

Tightening torques for high-resistance threaded fittings .................................. 2-11

Dimensions model 803 (up to serial no. AI00966) ................................................. 2-12

Dimensions model 803 with ROPS rollbar (from serial no. AI00967) .................... 2-13

Dimensions model 803 without ROPS rollbar (from serial no. AI00967) ............... 2-14

Lift capacity table 803 RD ...................................................................................... 2-15

Kinematics ............................................................................................................. 2-15

Maintenance

Fluids and lubricants ................................................................................................ 3-2

Additional oil change and filter replacement (hydraulic system) ........................ 3-3

Maintenance label .................................................................................................... 3-5

Explanation of symbols on the maintenance label ........................................... 3-5

Maintenance label (up to serial number AF02412) ............................................ 3-6

Maintenance label (from serial number AF02413) ............................................ 3-7

Maintenance plan (overview) ................................................................................... 3-8

Service package .................................................................................................... 3-12

Introduction ............................................................................................................ 3-12

Safety-relevant parts .............................................................................................. 3-12

Fuel system ........................................................................................................... 3-13

Specific safety instructions .............................................................................. 3-13

Refueling ......................................................................................................... 3-13

Stationary fuel pumps ...................................................................................... 3-14

SHB 803 en – Edition 2.4 * 803s20IVZ.fm I-1

Page 4

Table of contents

Diesel fuel specification ................................................................................... 3-14

Bleeding the fuel system .................................................................................. 3-15

Fuel prefilter with water separator ................................................................... 3-15

Replacing the fuel filter .................................................................................... 3-17

Engine lubrication system ...................................................................................... 3-18

Checking the oil level ....................................................................................... 3-18

Adding engine oil ............................................................................................. 3-19

Changing engine oil ......................................................................................... 3-20

Replacing the engine-oil filter cartridge ........................................................... 3-21

Cooling system ...................................................................................................... 3-22

Specific safety instructions .............................................................................. 3-22

Checking the coolant level/adding coolant ...................................................... 3-23

Draining coolant ............................................................................................... 3-25

Air filter (up to serial no. AI00875) ......................................................................... 3-26

Replacing air filter elements ............................................................................ 3-27

Air filter (from serial no. AI00876) .......................................................................... 3-27

Replacing air filter elements ............................................................................ 3-28

V-belt ...................................................................................................................... 3-30

Checking V-belt tension ................................................................................... 3-30

Retensioning the V-belt ................................................................................... 3-31

Pressure check ...................................................................................................... 3-32

General ............................................................................................................ 3-32

Pressure check of gear pump P2 .................................................................... 3-32

Pressure check of gear pump P1 .................................................................... 3-33

Test report .............................................................................................................. 3-34

Hydraulic system .................................................................................................... 3-36

Specific safety instructions .............................................................................. 3-36

Checking the hydraulic oil level ....................................................................... 3-36

Adding hydraulic oil .......................................................................................... 3-38

Changing hydraulic oil ..................................................................................... 3-39

Replacing the filter cartridge ............................................................................ 3-39

Checking hydraulic pressure lines ................................................................... 3-40

Tracks .................................................................................................................... 3-41

Checking track tension .................................................................................... 3-41

Setting the tracks ............................................................................................. 3-42

Lubrication points on boom (up to serial number AI00966) ................................... 3-43

Lubrication strip ............................................................................................... 3-44

Overview of lubrication points (from serial no. AI00967) ....................................... 3-45

Parking the machine ........................................................................................ 3-46

Lubrication points on the stabilizer blade and stabilizer blade cylinder ........... 3-47

Lubrication points on swiveling console ........................................................... 3-47

Swiveling cylinder lubrication points ................................................................ 3-47

Lubrication points on live ring (ball bearing) .................................................... 3-48

Lubrication points of live ring teeth .................................................................. 3-49

Ball sockets (ISO/SAE changeover option) ..................................................... 3-50

Maintenance of attachments ............................................................................ 3-50

Electrical system .................................................................................................... 3-51

Specific safety instructions .............................................................................. 3-51

Servicing and maintenance at regular intervals ............................................... 3-51

Instructions concerning specific components .................................................. 3-52

Alternator ......................................................................................................... 3-52

Battery ............................................................................................................. 3-53

General maintenance ............................................................................................. 3-54

Cleaning ........................................................................................................... 3-54

General instructions for all areas of the machine ............................................ 3-54

Control stand ................................................................................................... 3-54

Exterior of the machine .................................................................................... 3-55

I-2 SHB 803 en – Edition 2.4 * 803s20IVZ.fm

Page 5

Table of contents

Engine compartment ....................................................................................... 3-55

Threaded fittings and attachments .................................................................. 3-55

Pivots and hinges ............................................................................................ 3-55

Preparatory work before taking out of service ....................................................... 3-56

Maintenance if the machine is out of service for a longer period of time ............... 3-56

Putting into operation again ............................................................................. 3-56

Engine

Overview of engine 3TNV70-VNS (Tier IV final up to 2012) .................................... 4-2

Fuel system ............................................................................................................. 4-3

Checking and adjusting valve clearance ................................................................. 4-5

Tightening order for cylinder head bolts .................................................................. 4-6

Checking the injection nozzles ................................................................................ 4-7

Pressure check .................................................................................................. 4-7

Checking the nozzle jet ............................................................................................ 4-7

Injection time ............................................................................................................ 4-8

Checking and adjusting injection time ............................................................... 4-8

Replacement of fuel injection pump .................................................................. 4-9

Adjusting engine speed ......................................................................................... 4-10

Compression .......................................................................................................... 4-10

Checking the coolant thermostat ........................................................................... 4-10

Checking the thermal switch .................................................................................. 4-11

Oil pressure switch ................................................................................................ 4-11

Checking the coolant circuit ................................................................................... 4-12

Engine trouble ........................................................................................................ 4-13

Overview of engine 3TNV74F-SNNS (Tier IV final from 2012) .............................. 4-15

Fuel system ........................................................................................................... 4-17

Cooling system ...................................................................................................... 4-18

Altitude-dependent output reduction ...................................................................... 4-19

Checking and adjusting valve clearance ............................................................... 4-20

Tightening order for cylinder head bolts ................................................................ 4-22

Order for removing the cylinder-head bolts: .................................................... 4-22

Order for installing the cylinder-head bolts: ..................................................... 4-22

Checking the injection nozzles .............................................................................. 4-23

Pressure check ................................................................................................ 4-23

Checking the nozzle jet .......................................................................................... 4-24

Injection time .......................................................................................................... 4-24

Checking injection time .................................................................................... 4-24

Setting injection time ....................................................................................... 4-26

Removing and installing the injection pump .......................................................... 4-27

Removing the injection pump .......................................................................... 4-27

Fitting the fuel injection pump .......................................................................... 4-28

Measuring and adjusting the engine speed ........................................................... 4-30

Compression .......................................................................................................... 4-30

Checking the coolant thermostat ........................................................................... 4-31

Checking the temperature sensor .......................................................................... 4-31

Oil pressure switch ................................................................................................ 4-32

Checking the coolant circuit ................................................................................... 4-32

Cleaning the cooling water channels ..................................................................... 4-32

Coolant and fuel hoses .......................................................................................... 4-33

Crankcase vent ...................................................................................................... 4-33

Replacing the glow plugs ....................................................................................... 4-33

Engine trouble ........................................................................................................ 4-34

Hydraulic system

Hydraulic pump PGP505B0050CA1H2NJ7J5C-505A00 (Tier IV final up to 2012) . 5-2

SHB 803 en – Edition 2.4 * 803s20IVZ.fm I-3

Page 6

Table of contents

Pump unit: exploded view .................................................................................. 5-3

Hydraulic pump PGP505B0040CA1H2NJ7J5C-505A0040XB1J5B1B1 (Tier IV final

from 2012) ................................................................................................................ 5-4

Pump unit: exploded view .................................................................................. 5-5

Main valve block ...................................................................................................... 5-6

Connections ....................................................................................................... 5-6

Legend ............................................................................................................... 5-7

Main valve block diagram .................................................................................. 5-8

Pressure limiting valves ..................................................................................... 5-9

Pump assignment ............................................................................................ 5-10

Traveling drive ....................................................................................................... 5-11

Function ........................................................................................................... 5-12

Swivel unit .............................................................................................................. 5-14

Swivel unit ........................................................................................................ 5-15

Swivel joint ............................................................................................................. 5-16

Sealing ............................................................................................................. 5-16

Mechanical control ................................................................................................. 5-17

Control levers (up to serial no. AI00814) ......................................................... 5-17

Drive levers (up to serial no. AI00814) ............................................................ 5-18

Control levers (from serial number AI00815) ................................................... 5-19

Drive levers (from serial number AI00815) ...................................................... 5-20

Lock lever (from serial number AI00815) ......................................................... 5-21

Troubleshooting in the hydraulic system ................................................................ 5-22

Plastic trims ............................................................................................................ 5-22

Hydraulics diagram (legend) .................................................................................. 5-24

Hydraulics diagram ................................................................................................ 5-25

Hydraulics diagram (Dual Power option) ............................................................... 5-26

Main valve block diagram ...................................................................................... 5-27

Electrical system

Ohm’s Law (current, voltage, resistance); power ..................................................... 6-2

Measuring equipment, measuring methods ............................................................. 6-2

Cable color coding ................................................................................................... 6-3

Relays ...................................................................................................................... 6-3

Use, mode of function ........................................................................................ 6-3

Electrical system ...................................................................................................... 6-4

Fuses behind the right-hand trim ....................................................................... 6-4

Relays behind the right-hand trim ...................................................................... 6-5

Fuses and relays with Dual Power option .......................................................... 6-5

Control lever push button ......................................................................................... 6-6

I-4 SHB 803 en – Edition 2.4 * 803s20IVZ.fm

Page 7

Table of contents

Right handle ...................................................................................................... 6-6

Working light ............................................................................................................ 6-6

Dynamo ................................................................................................................... 6-7

Rectifier .................................................................................................................... 6-7

Starter ...................................................................................................................... 6-7

Engine wiring harness legend (Tier IV final up to 2012) .......................................... 6-9

Engine wiring harness (Tier IV final up to 2012) .................................................... 6-10

Engine wiring harness legend (Tier IV final from 2012) ......................................... 6-11

Engine wiring harness (Tier IV final from 2012) ..................................................... 6-12

Wiring harness for indicators (up to serial number WNCE0801TPAL00923) ........ 6-13

Wiring harness for indicators (from serial number WNCE0801PPAL00924) ......... 6-14

Traveling signal wiring harness (option) ................................................................ 6-15

Horn wiring harness ............................................................................................... 6-16

Battery lead ............................................................................................................ 6-17

Indicating instrument wiring harness (Dual Power option) ..................................... 6-18

Engine/chassis wiring harness (Dual Power option) .............................................. 6-19

Seat console wiring harness .................................................................................. 6-20

Wiring diagram ....................................................................................................... 6-22

Wiring diagram Tier IV (Yanmar) ........................................................................... 6-23

Wiring diagram (Dual Power option) ...................................................................... 6-24

Options

Rollbar ..................................................................................................................... 7-2

TOPS rollbar up to serial number AF01416 ...................................................... 7-2

Lowerable ROPS rollbar (from serial no. AF01417 to serial no. AI00966) ........ 7-3

Raising/lowering the rollbar: .............................................................................. 7-3

Lowering and raising the rollbar ........................................................................ 7-4

Lowerable ROPS rollbar from serial no. AI00967 .............................................. 7-4

Raising/lowering the rollbar: .............................................................................. 7-5

ISO/SAE changeover (option) ................................................................................. 7-6

Traveling signal (option) .......................................................................................... 7-7

Telematic ................................................................................................................. 7-8

Connections ....................................................................................................... 7-8

Functional check/diode ...................................................................................... 7-8

Zero-emission Dual Power drive .............................................................................. 7-9

Overview ............................................................................................................ 7-9

SHB 803 en – Edition 2.4 * 803s20IVZ.fm I-5

Page 8

Table of contents

I-6 SHB 803 en – Edition 2.4 * 803s20IVZ.fm

Page 9

Operation

Page 10

Operation

Operation

1 Operation

1.1 Information on this service manual

This service manual contains important information on how to work safely, correctly and

economically with the machine. Therefore, it aims not only at new personnel, but it also

serves as a reference for experienced personnel. It helps to avoid hazardous situations

and reduce repair costs and downtimes.

Furthermore, the reliability and the service life of the machine will be increased by following the instructions in the service manual.

Careful and prudent working is the best way to avoid accidents!

Operational safety and readiness of the machine do not only depend on your skill, but also

on maintenance and servicing of the machine. This is why regular maintenance and servicing is absolutely necessary.

Extensive maintenance and repair work must always be performed by a Wacker Neuson

service center. Use only original spare parts for repairs. This ensures operational safety

and readiness of your machine, and maintains its value.

• We reserve the right to improve the technical standard of our machines without

adapting the service manual.

• Modifying Wacker Neuson products and fitting them with additional equipment and

attachments not included in our delivery program requires Wacker Neuson’s written

authorization, otherwise warranty and product liability for possible damage caused by

these modifications shall not be applicable.

• Subject to modifications and printing errors.

Your Wacker Neuson dealer will be happy to answer any further questions regarding the

machine or the service manual.

Abbreviations/symbols

• Identifies a list

• Subdivision within lists or an activity. Follow the steps in the recommended order

☞Identifies an activity

➥Description of the effects or results of an activity

n. s. = not shown

“Opt” = option

Stated whenever controls or other components of the machine are installed as an option.

A combination of digits, or a combination of digits and letters, for example 40/18 or 40/A

used for identifying the control elements, means:

Figure no. 40/control element no. 18 or position A in figure no. 40

Figures carry no numbers if they are placed to the left of the text.

1-2 SHB 803 en – Edition 2.4 * 803s110.fm

Page 11

1.2 Identification of warnings and dangers

Danger!

Caution!

Notice!

Environment!

Important indications regarding the safety of the personnel and the machine are identified

in this Operator’s Manual with the following terms and symbols:

Failure to observe the instructions identified by this symbol can cause injury or

death for the operator or other persons.

☞Measures for avoiding danger

Failure to observe the instructions identified by this symbol can cause damage

to the machine.

☞Measures for avoiding danger for the machine

This symbol identifies instructions for a more efficient and economical use of

the machine.

Operation

Failure to observe the instructions identified by this symbol can cause damage

to the environment. The environment is in danger if environmentally hazardous

material (for example waste oil) is not subject to proper use or disposal.

SHB 803 en – Edition 2.4 * 803s110.fm 1-3

Page 12

Operation

1.3 Designated use and exemption from liability

• The machine is intended for:

• Moving earth, gravel or rubble, and for hammer operation

• See chapter 1.5 “Fields of application, attachments” in the Operator’s Manual for

more information on the use of attachments.

• Every other application is regarded as not designated for the use of the machine.

Wacker Neuson will not be liable for damage resulting from use other than mentioned

above. The user alone will bear the risk.

• Designated use also includes observing the instructions set forth in the Operator’s

Manual and observing the maintenance and service conditions.

• The safety of the machine can be negatively affected by performing machine modifications without proper authority and by using spare parts, equipment, attachments and

optional equipment that have not been checked and released by Wacker Neuson.

Wacker Neuson will not be liable for damage resulting from this.

• Wacker Neuson Linz GmbH shall not be liable for personal injury and/or damage to

property caused by failure to observe the safety instructions and the Operator’s

Manual, and by the negligence of the duty to exercise due care when:

• handling

• operating

• servicing and performing maintenance and

• repairing the machine. This is also applicable in those cases in which special

attention has not been drawn to the duty to exercise due care, in the safety instructions, the Operator’s Manuals and maintenance manuals (machine/engine).

• Read and understand the Operator’s Manual before starting up, servicing or repairing

the machine. Observe all safety instructions!

• The machine may not be used for transport jobs on public roads!

• Hammer operation is only allowed in specified areas.

1-4 SHB 803 en – Edition 2.4 * 803s110.fm

Page 13

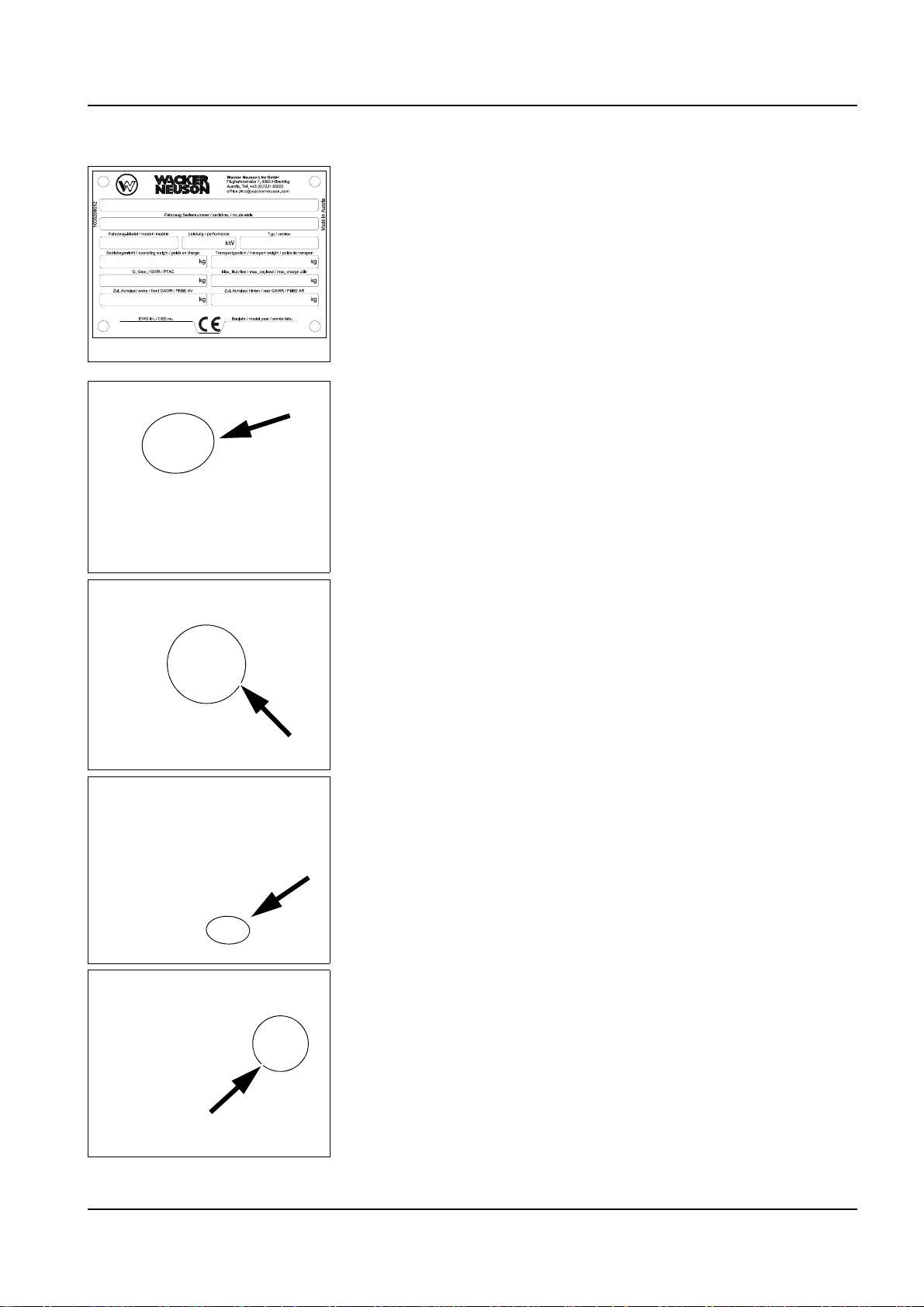

1.4 Labels

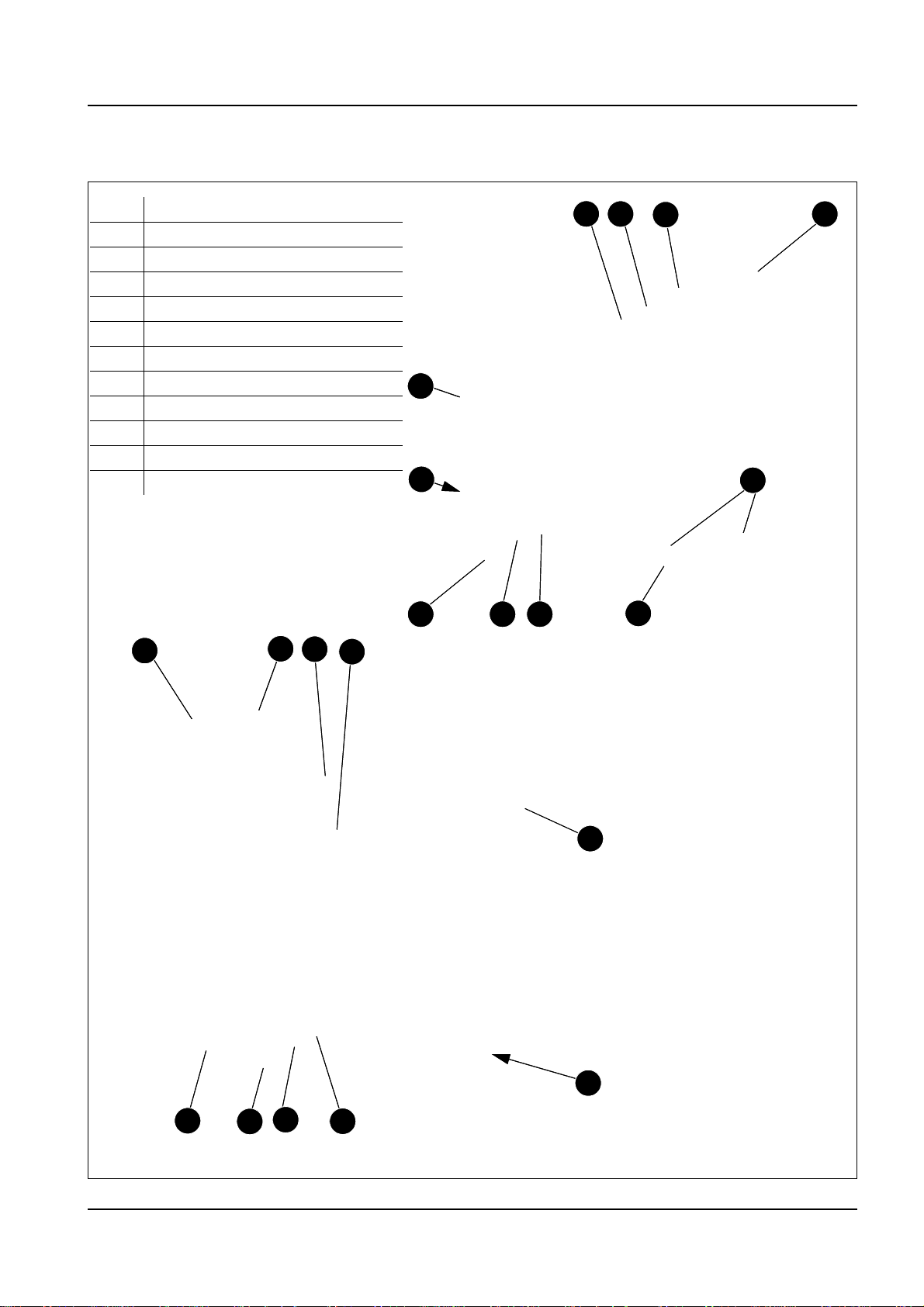

Fig. 1: Type label (symbolic representation)

Fig. 2: Diesel engine type label

Fig. 3: Hydraulic pump type label

Fig. 4: Main valve block type label

Fig. 5: Traveling drive type label

Operation

Serial number

The serial number is located on the type label.

The serial number is also stamped on the machine chassis.

Refer to the Operator’s Manual of the machine for more information.

Diesel engine type label

The type label (arrow) is located on the cylinder-head cover (engine).

Hydraulic pump type label

The type label (arrow) is located on the hydraulic pump housing.

Main valve block type label

The type label (arrow) is located on the lower side of the main valve block.

Traveling drive type label

The type label (arrow) is located on the traveling drive.

SHB 803 en – Edition 2.4 * 803s110.fm 1-5

Page 14

Operation

Fig. 6: Swivel unit type label

Swivel unit type label

The type label (arrow) is located on the swivel unit.

1-6 SHB 803 en – Edition 2.4 * 803s110.fm

Page 15

1.5 Machine overview (up to serial no. AI00966)

Fig. 7: Machine outside views

1 Boom light

2 Boom

3Stick

4Track

5 Travel gear

6 Stabilizer blade

7 Handhold

8 Lifting eye for loading/tying down the machine

9 Engine cover

10 Storage bin for Operator’s Manual

11 Lock lever

12 Track tensioner

1

2

7

3

9

8

6

54

8

2

4

5

6

8

7

11

10

12

12

3

Operation

SHB 803 en – Edition 2.4 * 803s110.fm 1-7

Page 16

Operation

2

3

1

4 5

6

8

9

11

7

13

14

12

Fig. 8: Machine outside views

1 Boom light

2 Boom

3Stick

4Track

5 Travel gear

6 Stabilizer blade

7 Handhold

8

Lifting eye for loading/tying down the

machine

9 Engine cover

10 Storage bin for Operator’s Manual

11 Lock lever

12 Track tensioner

13 ROPS rollbar (option)

14 Shatter protection (option)

8

4

5

6

10

11

14

7

2

3

8

12

1.6 Machine overview (from serial no. AI00967)

1-8 SHB 803 en – Edition 2.4 * 803s110.fm

Page 17

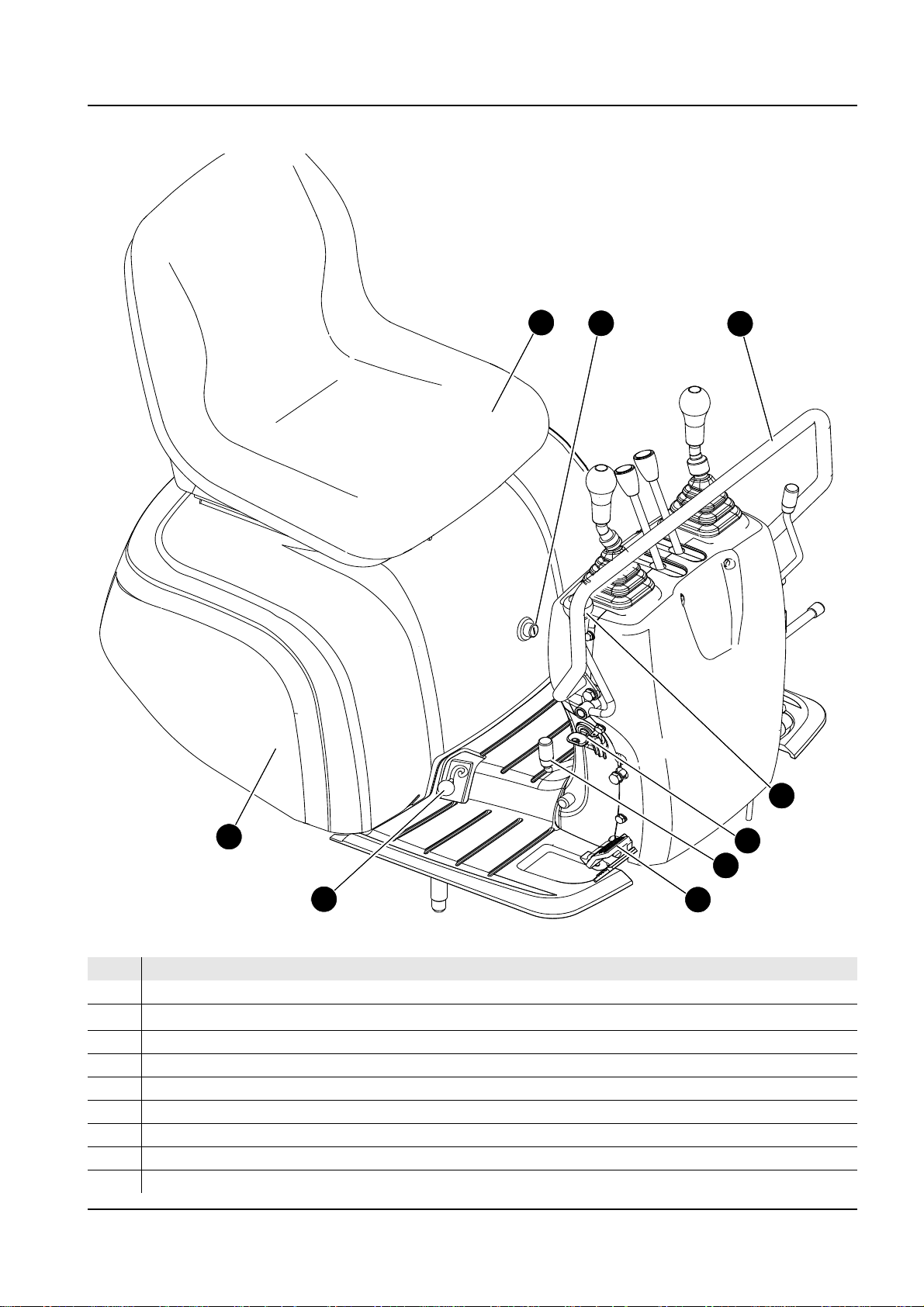

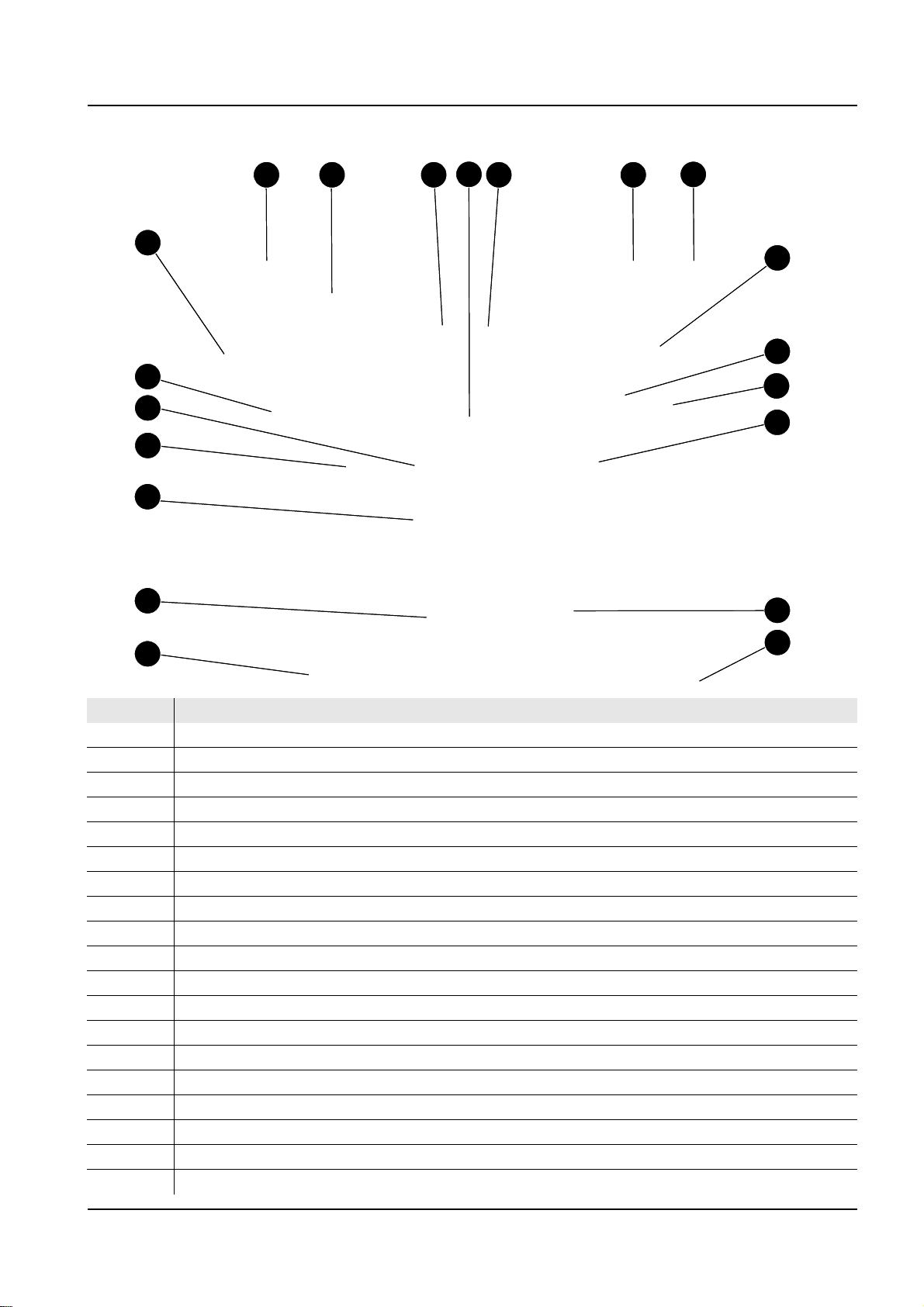

1.7 Control stand overview (up to serial no. AI00814)

1

3

9

8

2

7

6

4

5

Operation

Pos.

Designation

1

Operator seat

2

Upper carriage lock

3

Engine cover lock

4

Preheating start switch

5

Stabilizer blade/telescopic undercarriage lever

6

Stabilizer blade/telescopic travel gear changeover lever

7

Auxiliary hydraulics

8

Engine cover

9

Handhold

SHB 803 en – Edition 2.4 * 803s110.fm 1-9

Page 18

Operation

10

11

12

13

14

15

17

16

18

Pos. Designation

10

Boom swivel/auxiliary hydraulics pedal

11

Footrest

12

Control lever lock

13

Throttle

14

Control lever (left)

15

Drive lever (left)

16

Drive lever (right)

17

Control lever (right)

18

Indicators

1-10 SHB 803 en – Edition 2.4 * 803s110.fm

Page 19

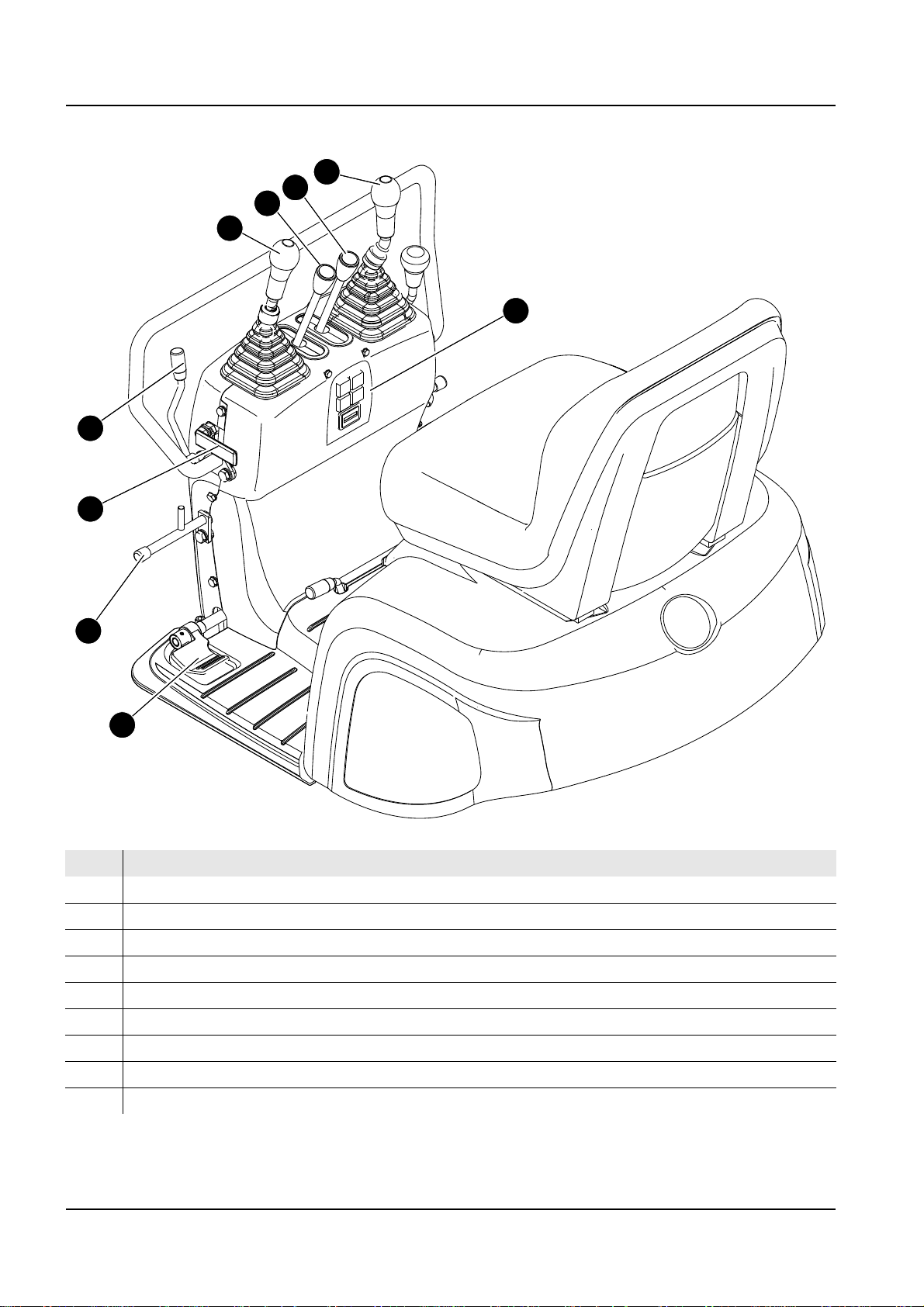

1.8 Control stand overview (from serial no. AI00815)

4

6

1

2

3

5

7

8

10

11

11

12

1314 15 16 17

9

18

19

Operation

Pos. Designation

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Operator seat

Upper carriage lock

Engine cover lock

Starter

Stabilizer blade/telescopic travel gear lever

Stabilizer blade/telescopic travel gear changeover lever

Boom swivel pedal

Engine cover

Handhold

Auxiliary hydraulics pedal

Footrest

Lock lever

Throttle

Control lever (left)

Drive lever (left)

Drive lever (right)

Control lever (right)

Display element

Lever for switching over hammer/grab operation (option)

SHB 803 en – Edition 2.4 * 803s110.fm 1-11

Page 20

Operation

22

20

24

21

23

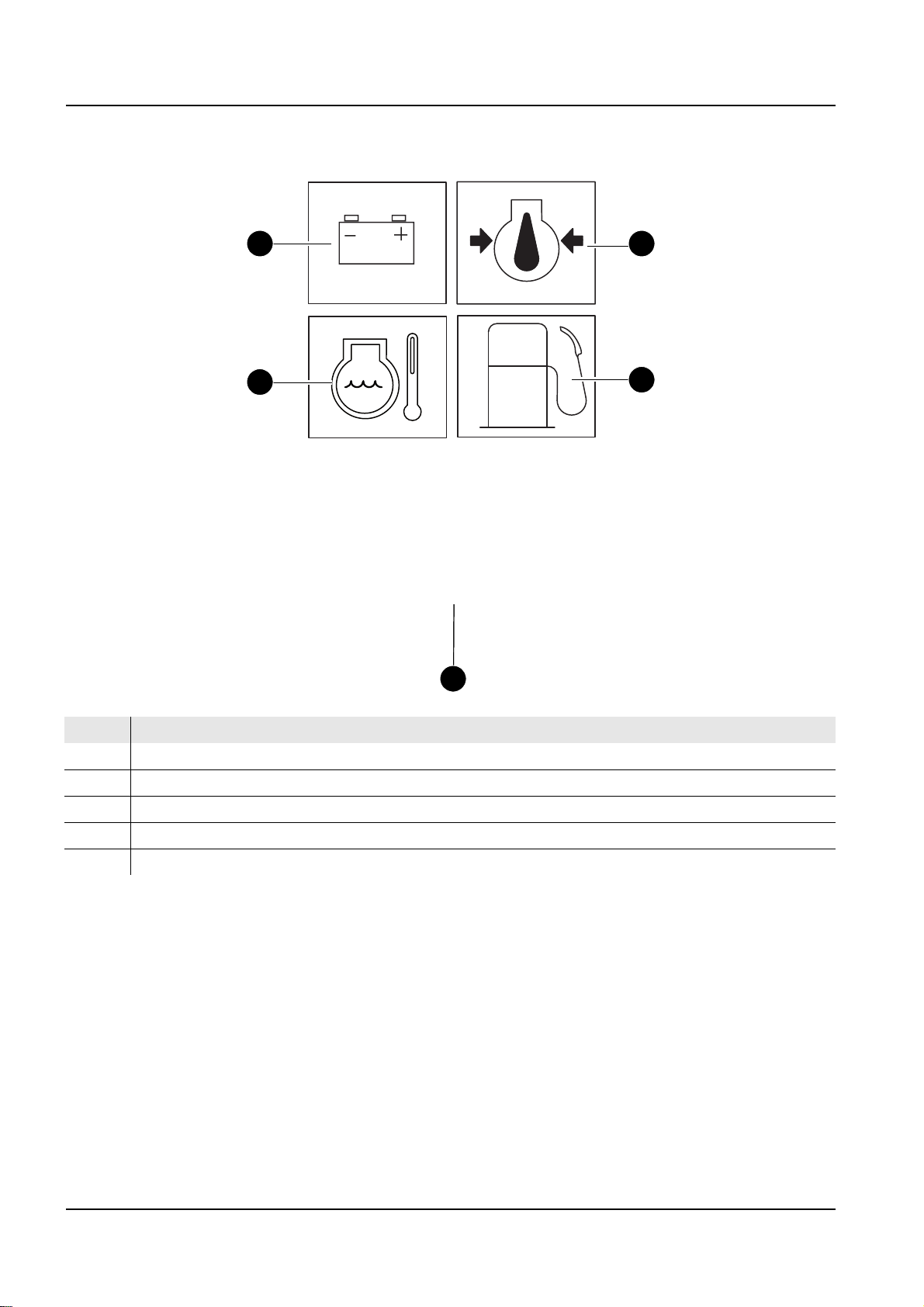

1.9 Display elements (overview)

Pos. Designation

20

Indicator light (red) – alternator charge function

21

Indicator light (red) – engine oil pressure

22

Indicator light (red) – coolant temperature

23

Indicator light (yellow) – fuel gage

24

Hour meter

1-12 SHB 803 en – Edition 2.4 * 803s110.fm

Page 21

1.10 Engine compartment overview (up to serial no. AI00814)

29

31

30

25

27

26

32

28

Operation

Pos. Designation

25

Air filter

26

Throttle cable

27

Fuel filter

28

Swivel unit

29

Thermostat

30

Filler neck

31

Coolant filler inlet

32

Coolant reservoir

SHB 803 en – Edition 2.4 * 803s110.fm 1-13

Page 22

Operation

37

39

38

33

34

35

40

36

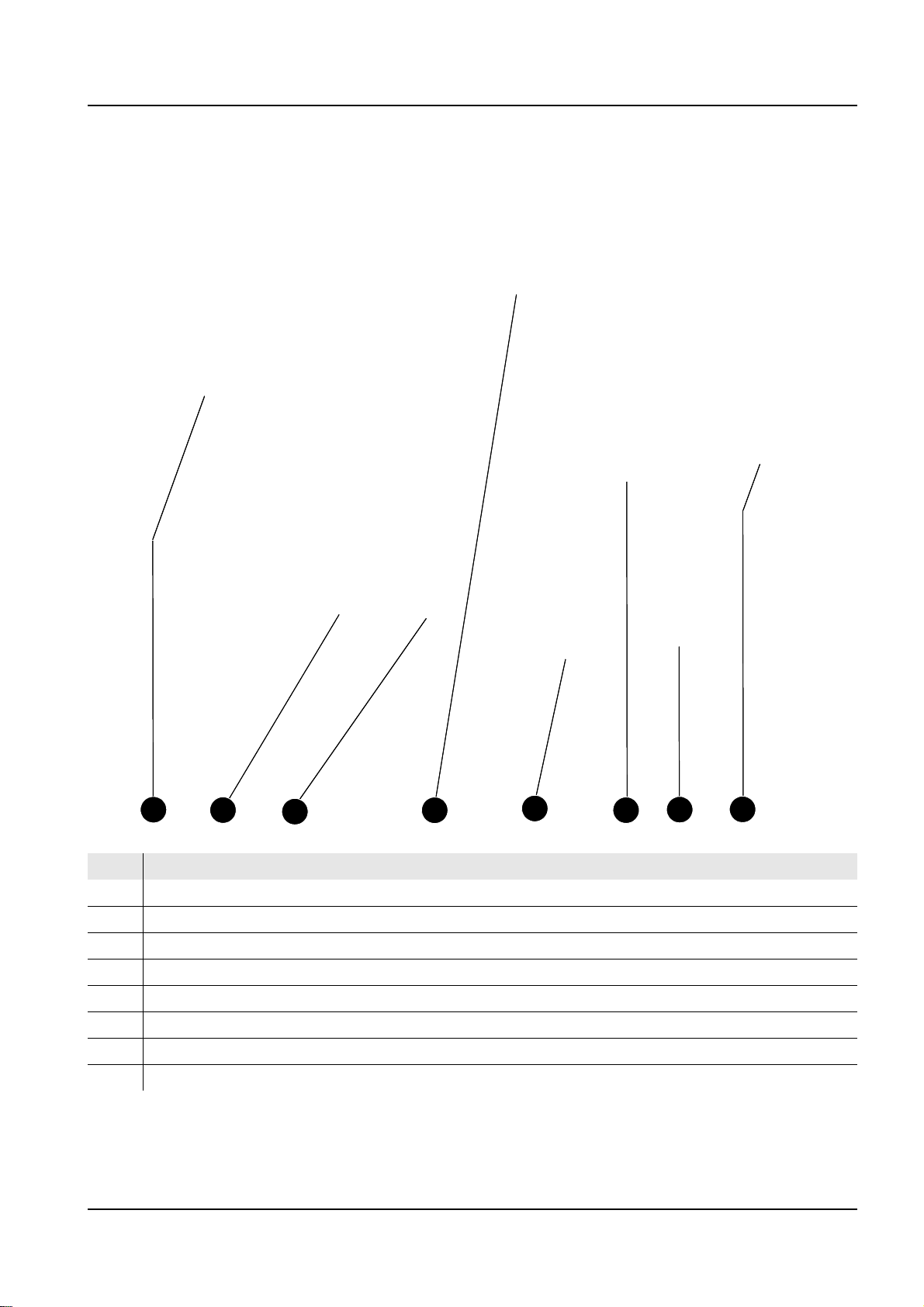

1.11 Engine compartment overview (from serial no. AI00815)

Pos. Designation

33

Air filter

34

Fuel filter

35

Throttle cable

36

Swivel unit

37

Thermostat

38

Filler neck

39

Coolant filler inlet

40

Coolant reservoir

1-14 SHB 803 en – Edition 2.4 * 803s110.fm

Page 23

Technical data

Page 24

Technical data

Technical data

2 Technical data

2.1 Chassis

2.2 Engine

Sturdy steel sheet chassis, rubber-mounted engine

Engine Model 803

Product Yanmar diesel engine

Type 3TNV70-VNS

Design Water-cooled 4 stroke diesel engine

Number of cylinders 3

Fuel injection system Indirect injection

Aspiration Natural aspiration

Cooling system Water-cooled/blowing fan

Lubrication system Force-feed lubrication with trochoidal pump

Displacement 854 cm³ (52.1 in³)

Nominal bore and stroke 70 x 74 mm (2.75 x 2.91")

Output 9.6 kW (12.9 hp) at 2100 rpm

Max. torque 51.5 Nm (38 ft lbs) at 1500 rpm

Max. engine speed without load 2270 +/− 25 rpm

Idling speed 1300 +/− 25 rpm

Valve clearance (intake = outlet) 0.15 – 0.25 mm/(0.006 – 0.01") cold

Compression 32.4 +/− 1 bar (469.9 +/− 15 psi) at 250 rpm

Engine oil pressure 2.9 – 4.4 bar (42 – 64 psi) at rated output

Pressure switch for engine oil pump 0.5 +/− 0.1 bar (7.25 +/− 1.45 psi)

Thermostat opening temperature 69.5 – 72.5 °C (157 – 163 °F)

Thermal switch 107 – 113 °C (225 – 235 °F)

Firing order 1 – 3 – 2 – 1

Direction of rotation

Starting aid Glow plugs (preheating time 4 seconds)

Specific fuel consumption 272 g/kWh (lb/hph)

Max. engine droop

(all 2 pumps under full load)

Anticlockwise

(as seen from the flywheel)

By about 90 rpm

Exhaust values according to EPA TIER IV final (up to 2012)

2-2 SHB 803 en – Edition 2.4 * 803s210.fm

Page 25

Technical data

Engine Model 803

Product Yanmar diesel engine

Type 3TNV74F-SNNS

Design Water-cooled 4 stroke diesel engine

Number of cylinders 3

Fuel injection system Indirect injection

Aspiration Natural aspiration

Cooling system Water-cooled/blowing fan

Lubrication system Force-feed lubrication with trochoidal pump

3

Displacement 993 cm³ (60.6 in

Nominal bore and stroke 74 x 77 mm (2.9 x 3.0 in)

Output

Max. torque

Max. engine speed without load

Idling speed

11.5 kW at 2500 rpm

(15.4 hp/2,500 rpm)

53 Nm at 1800 rpm

(39 ft.lbs/1800 rpm)

2675 +/− 25 rpm

(2,675 +/− 25 rpm)

1300 +/− 25 rpm

(1,300 +/− 25 rpm)

Valve clearance (intake = outlet) 0.15 – 0.25 mm/(0.006 – 0.01") cold

)

Compression 32.4 +/− 1 bar (469.9 +/− 15 psi) at 250 rpm

Engine oil pressure 3 – 4.5 bar (43.5 – 65.3 psi) at rated output

Pressure switch for engine oil

pump

0.5 +/− 0.1 bar (7.25 +/− 1.45 psi)

Thermostat opening temperature 71 °C (160 °F)

Thermal switch 107 °C (230 °F)

Firing order 1 – 3 – 2 – 1

Direction of rotation

Anticlockwise

(as seen from the flywheel)

Starting aid Glow plugs (preheating time 4 seconds)

Specific fuel consumption 279 g/kWh (lb/hph)

Max. engine droop (all 2 pumps

under full load)

By about 110 rpm

Exhaust values according to EPA TIER IV final (from 2012)

SHB 803 en – Edition 2.4 * 803s210.fm 2-3

Page 26

Technical data

Fuel injection pump

Engine capacities

Engine tightening torques

Type

Design In-line pump

Injection pressure 118 – 128 bar (1711 – 1856 psi)

Engine speed control Mechanical

Lubrication system Force-feed engine oil lubrication

Capacities Model 803

Fuel tank 7 l (1.85 gal)

Engine oil (max./effect.) 2.8 l/1.3 l (0.74/0.34 gal)

Coolant (with radiator) 2.9 l (0.77 gal)

Coolant reservoir 1.1 l (0.29 gal)

Overview of capacities – see Fluids and lubricants on page 3-2

Tightening torques Model 803

Cylinder-head bolt

1

Connecting rod bearing screw

1

54 – 58 Nm (M9x1.25) (40 − 43 ft lbs)

22.6 − 27.5 Nm (M7x1.0) (16.6 − 20.3 ft lbs)

2.3 Hydraulic system

Main bearing screw 75.5 – 81.5 Nm (M10x1.25) (55.7 – 60 ft lbs)

Flywheel screw 80.4 – 86.4 Nm (M10x1.25) (59.3 – 63.7 ft lbs)

1. Screws must be oiled!

Hydraulics Model 803

Pump (Tier IV final up to 2012) Twin gear pump 2 x 5 cm³ (2 x 0.3 in³/rev)

Flow rate (Tier IV final up to 2012)

2 x 11.35 l/min at 2270 rpm

(2 x 3 gal/min at 2270 rpm)

Pump (Tier IV final from 2012) Twin gear pump 2 x 4 cm³ (2 x 0.24 in³/rev)

Flow rate (Tier IV final from 2012)

2 x 10.7 l/min at 2675 rpm

(2 x 2.8 gal/min at 2675 rpm)

Control valve 9 sections

Main pressure limiting valve for pumps

P1, P2

Secondary pressure limiting valve

for swivel unit

Secondary pressure limiting valve, stick 250 +/−5 bar (3625.9 +/−72.5

170 +/− 3 bar (2465.64 +/− 44 psi)

70

-0/+0.5

bar (1015.3

-0/+7 psi

gal/min)

) at 11.5 l/min (3

psi)

Hydraulic reservoir capacity 13.8 l (3.6 gal)

2-4 SHB 803 en – Edition 2.4 * 803s210.fm

Page 27

Auxiliary hydraulics oil flow

Notice!

2.4 Travel gear and swivel unit

Travel gear/swivel unit Model 803

Travel speeds 1.82 kph (1.13 mph)

Technical data

Pressure (bar/psi) P1 + P2 (l/min / gal/min)

12.5/181.3 22/5.8

37.8/548.2 20.8/5.5

50/725.2 20.4/5.4

79/1145.8 19.7/5.2

140/2030.5 18.5/4.8

160/2320.6 10.5/2.7

168/2436.6 5/1.3

Output indications for auxiliary hydraulics with unpressurized return line

2.5 Stabilizer blade

Screwable hose burst valve

Hill climbing ability

(no longer than 3 minutes)

Track width 180 mm (7.09'')

No. of track rollers on either side 2

Ground clearance 132 mm (5.2'')

Ground pressure 0.24 kg/cm² (3.4 psi)

Upper carriage swivel speed 8 rpm

Stabilizer blade Model 803

Width (folded in/out) 700/860 mm (27.55"/33.85")

Height 198 mm (7.8'')

Max. lift over/under subgrade 197/174 mm (7.76"/6.85")

Location Thread Gap dimension

Stabilizer blade 3/8" 0.3 mm (0.012'')

30°/58 %

SHB 803 en – Edition 2.4 * 803s210.fm 2-5

Page 28

Technical data

F1

F2F3

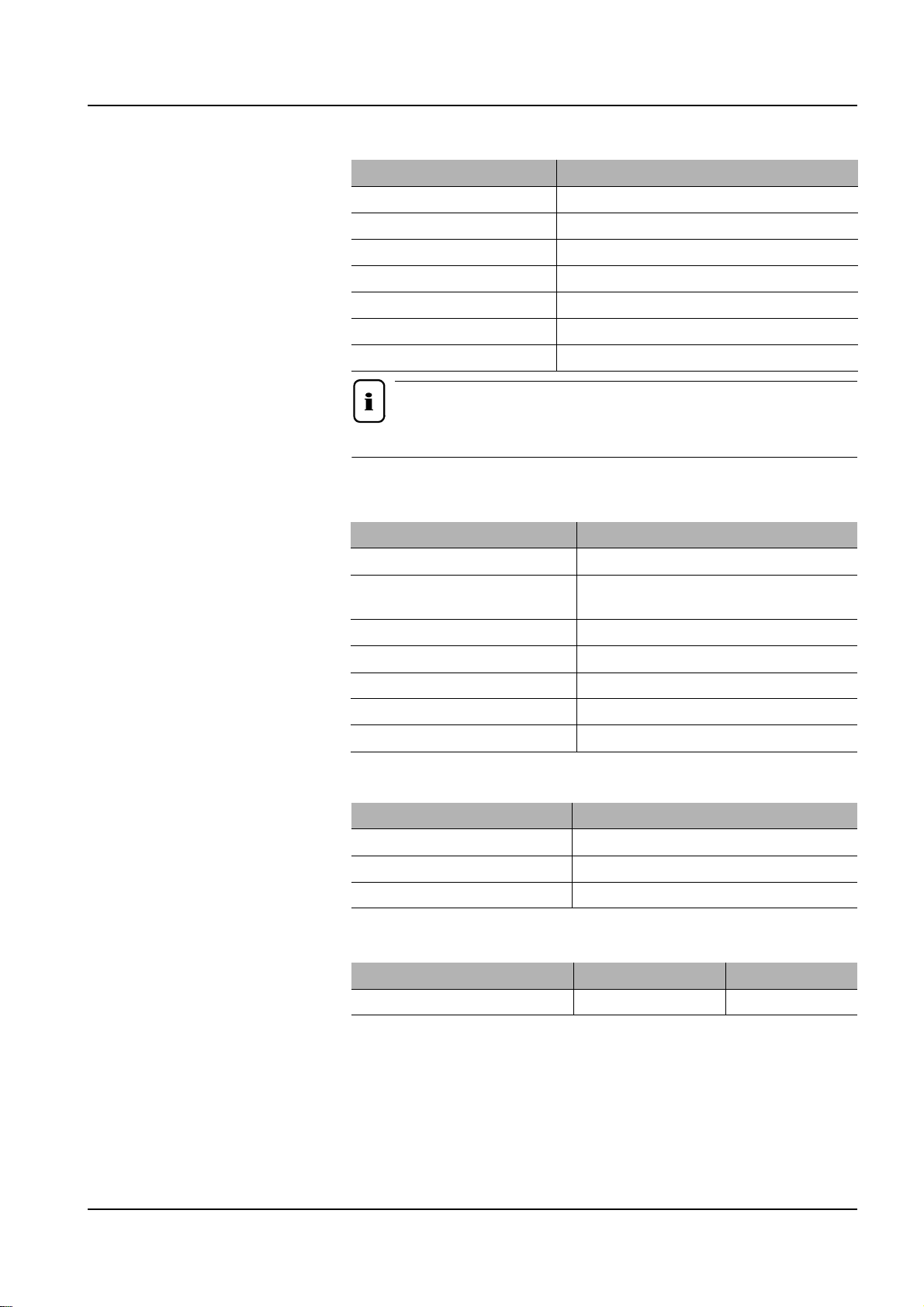

Fig. 9: Fuses (up to serial number

WNCE0801CPAL0050)

F1

F2F3

Fig. 10: Fuses (from serial number WNCE0801TPAL0051)

F4

2.6 Electrical system

Fuses behind the right-hand trim

Electrical system

Dynamo 12 V 20 A

Starter 12 V 1.1 kW (1.5 hp)

Battery 12 V 30 Ah

Socket For 12 V power outlet, for example; 15 A max.

Fuse no. Rated current (A) Protected circuit

F1 40 A

F2 10 A

F3 10 A

F4 10 A

Main fuse: air-pressure sensor/output adaptation

(Yanmar 3TNV74F-SNNS)

Fuse: relay, indicator, cutoff solenoid

Fuse: horn, working light 12 V power outlet (up to

serial number WNCE0801CPAL0050, travel signal

(option)

12 V power outlet (from serial number

WNCE0801TPAL0051)

2-6 SHB 803 en – Edition 2.4 * 803s210.fm

Page 29

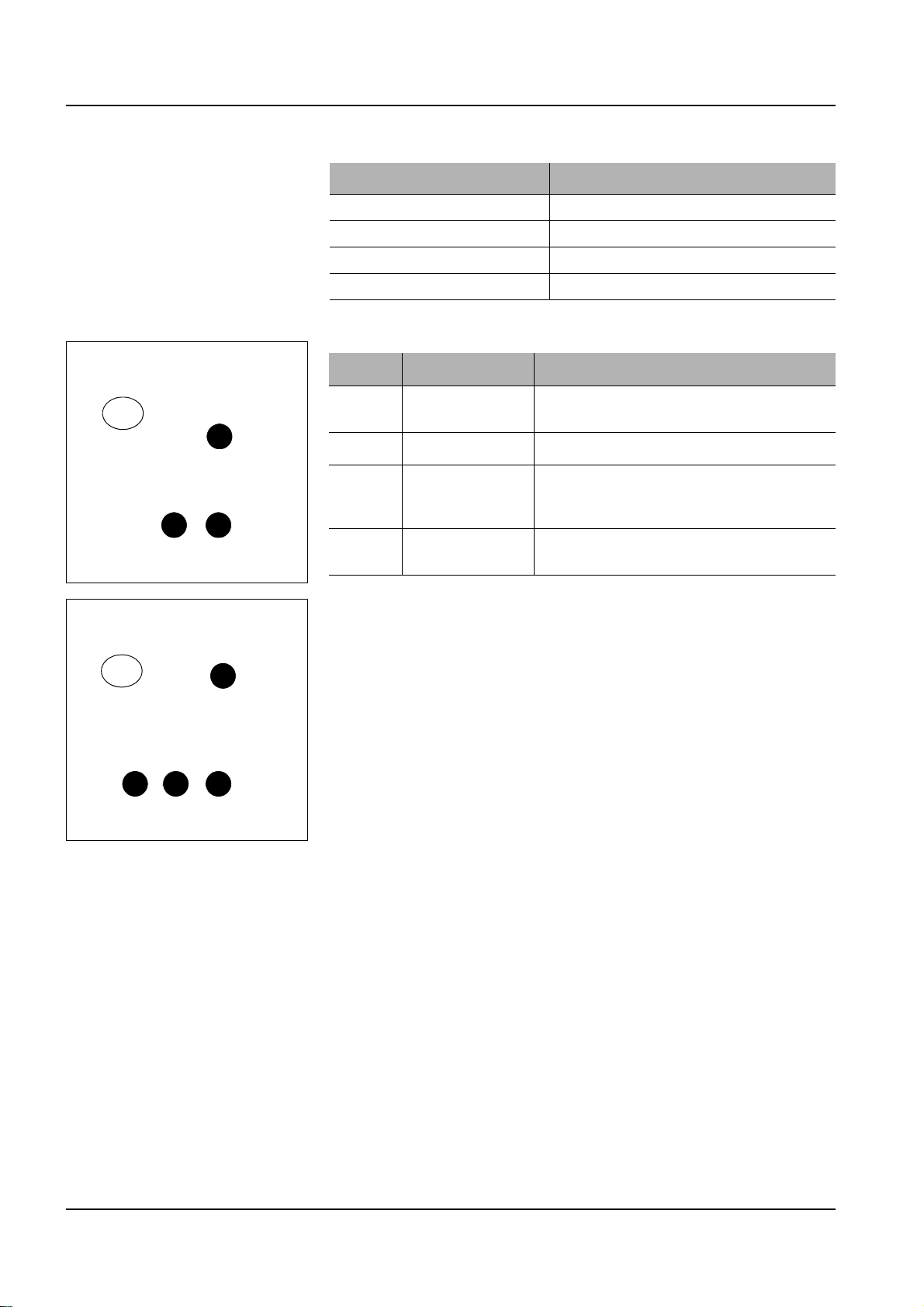

Relays behind the right-hand trim

K8

K9

K7

Fig. 11: Relays

Fig. 12: Fuses and relays with Dual Power option

F1

F4

F2

F3

K7K9

Fig. 13: Relay K8

K8

Technical data

Relay no. Protected circuit

K 7 Starting relay

K 8 Cutoff solenoid time lag relay 1s

K 9 Cutoff solenoid switching relay

Fuses and relays with Dual Power option

If the machine is equipped with the Dual Power option, the fuses and relays are located

under the base plate.

Fuse no. Rated current (A) Protected circuit

F1 40 A

F2 10 A

Main fuse: air-pressure sensor/output adaptation

(Yanmar 3TNV74F-SNNS)

Fuse: relay, indicator, cutoff solenoid

Fuse: horn, working light 12 V power outlet (up to

F3 10 A

serial number WNCE0801CPAL0050, travel signal

(option), battery control (Dual Power option)

F4 10 A

12 V power outlet (from serial number

WNCE0801TPAL0051)

Relay no. Protected circuit

K 7 Starting relay

K 8 Cutoff solenoid time lag relay 1s

K 9 Cutoff solenoid switching relay

K 116 Battery control

SHB 803 en – Edition 2.4 * 803s210.fm 2-7

Page 30

Technical data

Notice!

2.7 Noise levels

2.8 Vibration

Sound power level Model 803

1

Sound power level (L

Operator-perceived sound pressure level (L

Uncertainty (K

1. ISO 6395 (EC Directives 2000/14/EC and 2005/88/EC)

2. EN ISO 4871 (EC Directives 2000/14/EC and 2005/88/EC)

3. ISO 6394 (EC Directives 84/532/EEC, 89/514/EEC, 95/27/EEC)

PA

)

WA

PA

3

)

2

)

93 dB (A)

77 dB (A)

1.2 dB (A)

Measurements performed on asphalted surface.

Vibration

2.9 Coolant compound table

Effective acceleration value for the upper extremities of the

body (hand-arm vibration)

< Trigger value

< 2.5 m/s

Effective acceleration value for the body (whole-body vibration) < 0.5 m/s

Vibration values indicated in m/s².

Coolant

Outside temperature

Water Anticorrosion agent Antifreeze agent

Up to °C (°F)

% by

volume

cm³/l / (in3/gal) % by volume % by volume

-37 (-34.6) 50 10 (2.6) 1 50

Use the 1:1 concentration for warm outside temperatures, too:

Protection against corrosion, cavitation and deposits

Do not mix the coolant with other coolants.

Machine filled at the factory with Eurolub SF D12 coolant (ethylene glycol basis).

2

2

2-8 SHB 803 en – Edition 2.4 * 803s210.fm

Page 31

2.10 Model-specific tightening torques

Technical data

Model 803 Thread

Live ring M12x1.25 10.9 130 (95.9)*

Track roller M10 10.9 65 (47.9)*

Drive pinion M10 10.9 65 (47.9)*

Traveling drive M10 10.9 65 (47.9)*

Gear motor M12 10.9 110 (81.1)*

Angled engine bracket M10 8.8 45 (33.2)

Engine bearing M10 8.8 45 (33.2)

Pump base M10 8.8 45 (33.2)

Pump M10 8.8 45 (33.2)

Swivel joint M10 10.9 64 (47.2)*

Bumper M14 12.9 230 (169.6)*

*) All connections with an * must be glued with Loctite S2420 or VaryBond 12-43.

2.11 General tightening torques

Tightening torques for hydraulic threaded fittings (dry assembly)

Metric hose fittings for hydraulic applications (light execution, DKOL)

Nominal Ø Outer Ø Thread Wrench size

05 6L M12X1.5 WS 14 15 (11)

06 8L M14X1.5 WS 17 20 (14.7)

08 10L M16X1.5 WS 19 40 (29.5)

10 12L M18X1.5 WS 22 50 (36.8)

12 15L M22X1.5 WS 27 75 (55.3)

16 18L M26X1.5 WS 32 85 (62.7)

20 22L M30X2 WS 36 100 (73.75)

25 28L M36X2 WS 41 180 (132.7)

32 35L M45X2 WS 55 220 (162.3)

Galvanized and dry surface (O-ring slightly oiled). Torque tolerance: −10 %

Values determined empirically and to be applied as approximate figures.

Torque

Nm (ft lbs)

Torque

Nm (ft lbs)

Metric hose fittings for hydraulic applications (heavy execution, DKOL)

Nominal Ø Outer Ø Thread Wrench size

Torque

Nm (ft lbs)

05 8S M16X1.5 WS 19 40 (29.5)

06 10S M18X1.5 WS 22 50 (36.8)

08 12S M20X1.5 WS 24 60 (44.3)

10 14S M22X1.5 WS 27 75 (55.3)

12 16S M24X1.5 WS 30 90 (66.4)

16 20S M30X2 WS 36 100 (73.8)

20 25S M36X2 WS 41 180 (132.8)

25 30S M42X2 WS 50 270 (199.1)

32 38S M52X2 WS 60 400 (295)

Galvanized and dry surface (O-ring slightly oiled). Torque tolerance: −10 %

Values determined empirically and to be applied as approximate figures.

SHB 803 en – Edition 2.4 * 803s210.fm 2-9

Page 32

Technical data

Threaded fittings with various seals for hydraulic applications (light execution)

Thread

Straight pipe fitting with thread and

screwed plug

Sealing

washer

Elastic seal O-ring

Non-return

valve with

elastic seal

Identification aid

outside Ø

Nm (ft lbs) Nm (ft lbs) Nm (ft lbs) Nm (ft lbs) mm (")

M10X1.0 9 (7) 18 (13) 15 (11) 18 (13) 10 (0.4)

M12X1.5 20 (15) 25 (18) 25 (18) 25 (18) 12 (0.5)

M14X1.5 35 (26) 45 (33) 35 (26) 35 (26) 14 (0.55)

M16X1.5 45 (33) 55 (41) 40 (30) 50 (37) 16 (0.6)

M18X1.5 55 (41) 70 (52) 45 (33) 70 (52) 18 (0.7)

M22X1.5 65 (48) 125 (92) 60 (44) 125 (92) 22 (0.9)

M27X2.0 90 (66) 180 (133) 100 (74) 145 (107) 27 (1.0)

M33X2.0 150 (111) 310 (229) 160 (118) 210 (155) 33 (1.3)

M42X2.0 240 (177) 450 (332) 210 (155) 360 (266) 42 (1.7)

M48X2.0 290 (214) 540 (398) 260 (192) 540 (398) 48 (1.9)

G1/8A 9 (7) 18 (13) 15 (11) 18 (13) 9.73 (0.38)

G1/4A 35 (26) 35 (26) 30 (22) 35 (26) 13.16 (0.52)

G3/8A 45 (33) 70 (52) 45 (33) 50 (37) 16.66 (0.66)

G1/2A 65 (48) 90 (66) 55 (41) 65 (48) 20.96 (0.83)

G3/4A 90 (66) 180 (133) 100(74) 140 (103) 26.44 (1.04)

G1A 150 (111) 310 (229) 160 (118) 190 (140) 33.25 (1.31)

G1 1/4A 240 (177) 450 (332) 210 (155) 360 (266) 41.91 (1.65)

G1 1/2A 290 (214) 540 (398) 260 (192) 540 (398) 47.80 (1.88)

Torque tolerance: −10 %; countermaterial: steel/aluminum

Threaded fittings with various seals for hydraulic applications (heavy execution)

Thread

Straight pipe fitting with thread and

screwed plug

Sealing

washer

Elastic seal O-ring

Non-return

valve with

elastic seal

Identification aid

outside Ø

Nm (ft lbs) Nm (ft lbs) Nm (ft lbs) Nm (ft lbs) mm (")

M12X1.5 20 (15) 35 (26) 35 (26) 35 (26) 12 (0.5)

M14X1.5 35 (26) 55 (41) 45 (33) 45 (33) 14 (0.55)

M16X1.5 45 (33) 70 (52) 55 (41) 55 (41) 16 (0.6)

M18X1.5 55 (41) 90 (66) 70 (52) 70 (52) 18 (0.7)

M20X1.5 55 (41) 125 (92) 80 (59) 100 (74) 22 (0.9)

M22X1.5 65 (48) 135 (100) 100 (74) 125 (92) 27 (1.0)

M27X2.0 90 (66) 180 (133) 170 (126) 135 (100) 12 (0.5)

M33X2.0 150 (111) 310 (229) 310 (229) 210 (155) 33 (1.3)

M42X2.0 240 (177) 450 (332) 330 (243) 360 (266) 42 (1.7)

M48X2.0 290 (214) 540 (398) 420 (310) 540 (398) 48 (1.9)

G1/8A 35 (26) 55 (41) 45 (33) 45 (33) 13.16 (0.52)

G1/4A 45 (33) 80 (59) 60 (44) 60 (44) 16.66 (0.66)

G3/8A 65 (48) 115 (85) 75 (55) 100 (74) 20.96 (0.83)

G1/2A 90 (66) 180 (133) 170 (125) 145 (107) 26.44 (1.04)

G3/4A 150 (111) 310 (229) 310 (229) 260 (192) 33.25 (1.31)

G1A 240 (177) 450 (332) 330 (243) 360 (266) 41.91 (1.65)

G1 1/4A 290 (214) 540 (398) 420 (310) 540 (398) 47.80 (1.88)

Torque tolerance: –10 %; countermaterial: steel/aluminum

2-10 SHB 803 en – Edition 2.4 * 803s210.fm

Page 33

Tightening torques for high-resistance threaded fittings

Thread

M5 5.5 (4) 8 (6) 10 (7) 5 (4) 7 (5)

M6 10 (7) 14 (10) 17 (13) 8.5 (6) 12 (9)

M8 25 (18) 35 (26) 42 (31) 20 (15) 30 (22)

M10 45 (33) 65 (48) 80 (59) 40 (30) 59 (44)

M12 87 (64) 110 (81) 147 (108) 69 (51) 100 (74)

M14 135 (100) 180 (133) 230 (170) 110 (81) 160 (118)

M16 210 (155) 275 (203) 350 (258) 170 (125) 250 (184)

M18 280 (207) 410 (302) 480 (354) 245 (181) 345 (254)

M20 410 (302) 570 (420) 690 (509) 340 (251) 490 (361)

M22 550 (406) 780 (575) 930 (686) 460 (339) 660 (487)

M24 710 (524) 1000 (738) 1190 (878) 590 (435) 840 (620)

M27 1040 (767) 1480 (1092) 1770 (1305) 870 (642) 1250 (922)

M30 1420 (1047) 2010 (1482) 2400 (1770) 1200 (885) 1700 (1254)

DIN 912 – hexagon socket head cap screw; DIN 931/DIN 933 – hexagon head screw with/without shaft;

DIN 7984 – hexagon socket head cap screw with short head

All values subject to a friction coefficient of µ = 0.12 and are to be used as approximate figures.

Technical data

With coarse-pitch thread

Screws according to DIN 912, DIN 931,

DIN 933, etc.

8.8 10.9 12.9 8.8 10.9

Nm (ft lbs) Nm (ft lbs) Nm (ft lbs) Nm (ft lbs) Nm (ft lbs)

Screws according to DIN 7984

With fine-pitch thread

Thread

Screws according to DIN 912, DIN 931,

DIN 933, etc.

8.8 10.9 12.9 8.8 10.9

Screws according to DIN 7984

Nm (ft lbs) Nm (ft lbs) Nm (ft lbs) Nm (ft lbs) Nm (ft lbs)

M8X1.0 25 (18) 37 (28) 43 (32) 22 (16) 32 (24)

M10X1.0 50 (37) 75 (55) 88 (65) 43 (32) 65 (48)

M10X1.25 49 (36) 71 (52) 83 (61) 42 (31) 62 (46)

M12X1.25 87 (64) 130 (96) 150 (111) 75 (55) 110 (81)

M12X1.5 83 (61) 125 (92) 145 (107) 72 (53) 105 (77)

M14X1.5 135 (100) 200 (148) 235 (173) 120 (89) 175 (129)

M16X1.5 210 (155) 310 (229) 360 (266) 180 (133) 265 (195)

M18X1.5 315 (232) 450 (332) 530 (391) 270 (199) 385 (284)

M20X1.5 440 (325) 630 (465) 730 (538) 375 (277) 530 (391)

M22X1.5 590 (435) 840 (620) 980 (723) 500 (369) 710 (524)

M24X2.0 740 (546) 1070 (789) 1250 (922) 630 (465) 900 (664)

M27X2.0 1100 (811) 1550 (1143) 1800 (1328) 920 (679) 1300 (959)

M30X2.0 1500 (1106) 2150 (1586) 2500 (1844) 1300 (959) 1850 (1364)

DIN 912 – hexagon socket head cap screw; DIN 931/DIN 933 – hexagon head screw with/without shaft;

DIN 7984 – hexagon socket head cap screw with short head

All values subject to a friction coefficient of µ = 0.12 and are to be used as approximate figures.

SHB 803 en – Edition 2.4 * 803s210.fm 2-11

Page 34

Technical data

787 (31 in)

1294 (51 in)

1220 (48 in)

500 (20 in)

897 (35 in)

747 (29 in)

1906 (75 in)

323 (13 in)

1198 (47 in)

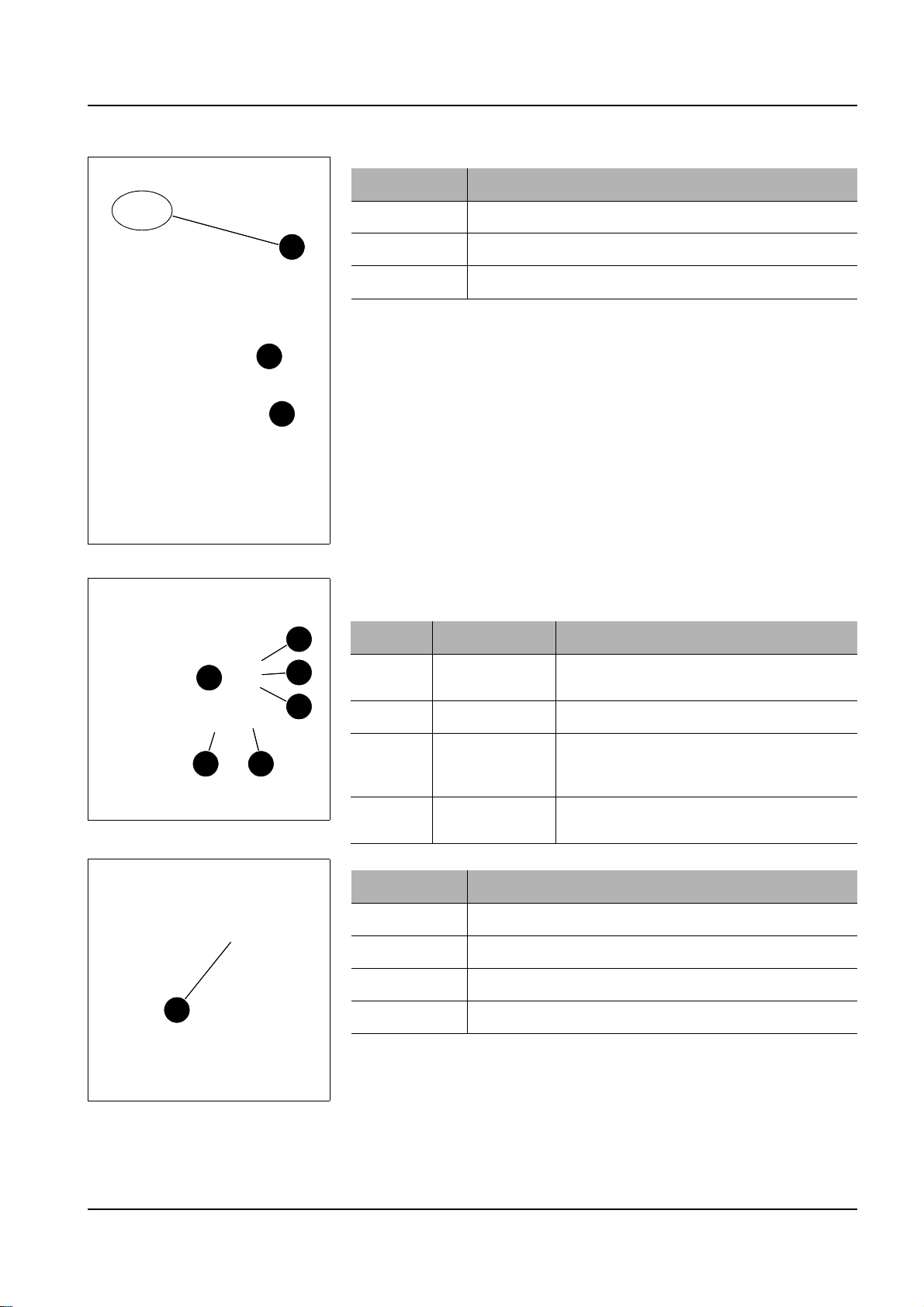

Fig. 14: Machine dimensions (model 803)

198

1507

700/860

180

180

340

700/860

730

2.12 Dimensions model 803 (up to serial no. AI00966)

Main data Model 803

Operating weight 935 kg (2061 lbs.)

Height (transport position) 1507 mm (4'-11")

Upper carriage width 730 mm (2'-5'')

Width of telescopic travel gear (retracted/extended) 700/860 mm (2'-4"/2'-10")

Width of stabilizer blade (folded in/out) 700/860 mm (2'-4"/2'-10")

Transport length 2747 mm (9')

Max. digging depth 1731 mm (5'-8")

Stick length 890 mm (2'-11'')

Max. vertical digging depth 1349 mm (4'-5")

Max. digging height 2863 mm (9'-5")

Max. tilt-out height 2035 mm (6'-8")

Max. digging radius 3074 mm (10'-1")

Max. reach at ground level 3028 mm (9'-11")

Max. breakout force at bucket tooth 8.99 kN (2021 lbf)

Max. tearout force 4.51 kN (1014 lbf)

Min. tail end slewing radius 747 mm (2'-5'')

Max. tail end lateral projection (90° rotation of upper carriage)

Telescopic travel gear retracted/extended

Stabilizer blade folded in/out

397/317 mm (1'-4"/1")

397/317 mm (1'-4"/1")

Max. boom displacement to bucket center (right side) 287 mm (0' 11")

Max. boom displacement to bucket center (left side) 242 mm (0'-10")

2-12 SHB 803 en – Edition 2.4 * 803s210.fm

Page 35

2.13 Dimensions model 803 with ROPS rollbar (from serial no. AI00967)

Fig. 15: Machine dimensions (model 803)

Technical data

Main data Model 803

Operating weight

Transport weight

Height (transport position)

1087 kg ( 2396 lbs)

990 kg (2182 lbs)

2248 mm (7'-5")

Upper carriage width 730 mm (2'-5'')

Width of telescopic travel gear (retracted/extended) 700/860 mm (2'-4"/2'-10")

Width of stabilizer blade (folded in/out) 700/860 mm (2'-4"/2'-10")

Transport length

Max. digging depth

Stick length

Max. vertical digging depth

Max. digging height

Max. tilt-out height

Max. digging radius

Max. reach at ground level

Max. breakout force at bucket tooth

Max. tearout force

Min. tail end slewing radius

Max. tail end lateral projection (90° rotation of upper carriage)

Retracted/extended telescopic travel gear

Stabilizer blade folded in/out

Max. boom displacement to bucket center (right side)

Max. boom displacement to bucket center (left side)

2747 mm (9')

1766 mm (5'-10")

890 mm (2'-11'')

1320 mm (4'-4")

2853 mm (9'-4")

2008 mm (6'-7")

3092 mm (10'-2")

3046 mm (10")

8.99 kN (2021 lbf)

4.51 kN (1014 lbf)

747 mm (2'-5'')

397/317 mm (1'-4"/1')

397/317 mm (1'-4"/1')

287 mm (0' 11")

242 mm (0'-10")

SHB 803 en – Edition 2.4 * 803s210.fm 2-13

Page 36

Technical data

730 (29 in)

R747 (29 in)

R1039(41 in)

180 (7 in)

1436 (57 in)

178

(7 in)

194

(8 in)

1220 (48 in)

3092 (10'-2'')

1320 (52 in)

1766 (70 in)

2008 (79 in)

2853 (9'-4'')

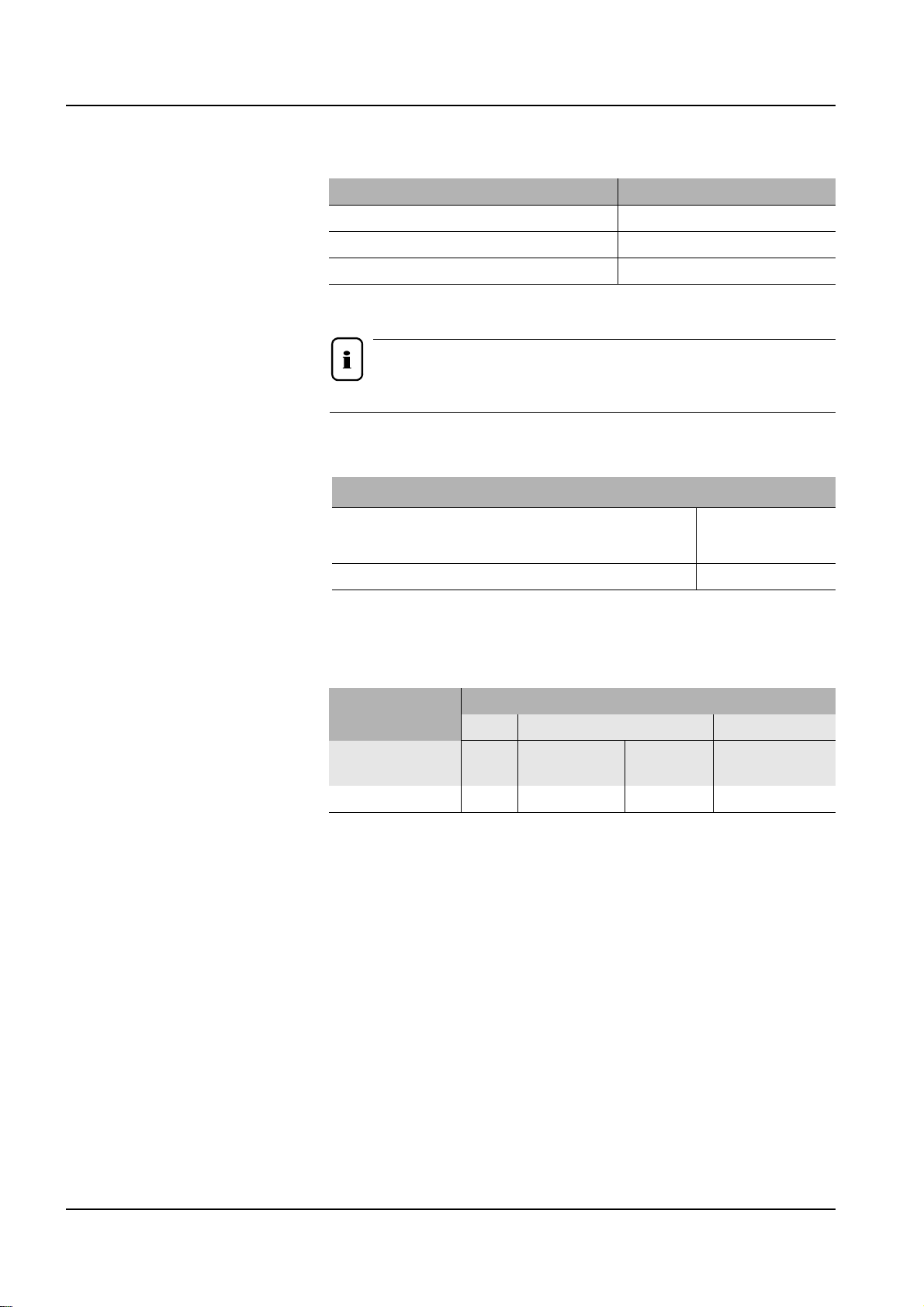

Fig. 16: Machine dimensions (model 803)

2.14 Dimensions model 803 without ROPS rollbar (from serial no. AI00967)

Main data

Operating weight

Transport weight

Height (transport position)

Model 803

1029 kg ( 2268 lbs)

932 kg (2055 lbs)

1436 mm (4'-9")

Upper carriage width 730 mm (2'-5'')

Width of telescopic travel gear (retracted/extended)

Width of stabilizer blade (folded in/out)

Transport length

Max. digging depth

Stick length

Max. vertical digging depth

Max. digging height

Max. tilt-out height

Max. digging radius

Max. reach at ground level

Max. breakout force at bucket tooth

Max. tearout force

Min. tail end slewing radius

Max. tail end lateral projection (90° rotation of upper carriage)

Retracted/extended telescopic travel gear

Stabilizer blade folded in/out

Max. boom displacement to bucket center (right side)

Max. boom displacement to bucket center (left side)

700/860 mm (2'-4"/2'-10")

700/860 mm (2'-4"/2'-10")

2747 mm (9')

1763 mm (5'-9'')

890 mm (2'-11'')

1320 mm (4'-4")

2853 mm (9'-4")

2008 mm (6'-7")

3090 mm (10'-2")

3046 mm (10")

8.99 kN (2021 lbf)

4.51 kN (1014 lbf)

747 mm (2'-5'')

397/317 mm (1'-3"/1')

397/317 mm (1'-3"/1')

(0'-11")

287 mm

(0'-10")

242 mm

2-14 SHB 803 en – Edition 2.4 * 803s210.fm

Page 37

2.15 Lift capacity table 803 RD

E Pin diameter 25 mm (0.98'')

F Stick width 100 mm (3.9'')

L

Pin distance from

bucket mount

165 mm (6.5'')

Bucket

Stick

Refer to the Operator’s Manual of the machine for specific data.

2.16 Kinematics

Technical data

SHB 803 en – Edition 2.4 * 803s210.fm 2-15

Page 38

Technical data

2-16 SHB 803 en – Edition 2.4 * 803s210.fm

Page 39

Maintenance

Page 40

Maintenance

Maintenance

3 Maintenance

3.1 Fluids and lubricants

Component/appli-

cation

Fluid/lubricant Specification Season/temperature Capacities

API: CG-4/CH-4/CI-4

Diesel engine Engine oil

ACEA: E3, E4, E5

ACEA E3, E4, E5 (SAE10 W 40)

3

5

Hydraulic oil

reservoir

Hydraulic oil

Biodegradable oil

HVLP46

HVLP46

6

PANOLIN HLP Synth 46

BP BIOHYD SE-46

Roller and friction bearings

Grease

Live ring gears

Live ring (ball bearing race)

KPF2N-20

7

Grease zerks

Battery terminals

Acid-proof grease

8

FINA Marson L2

2-D ASTM D975 – 94 (USA)

1-D ASTM D975 – 94 (USA)

Fuel tank Diesel fuel

EN 590 : 96 (EU)

ISO 8217 DMX (International)

BS 2869 – A1 (GB)

BS 2869 – A2 (GB)

Distilled water and antifreeze ASTM

Engine cooling

system

Coolant

D4985 (reddish)

Distilled water and antifreeze ASTM

D6210 (violet)

Ball socket ISO/

SAE controls

1. The capacities indicated are approximate values; the oil level check alone is relevant for the correct oil level

Capacities indicated are no system fills

2. According to DIN 51511

3. According to DIN 51524 section 3

4. Depending on local conditions – see Hydraulics oil grade on page 3-4

5. According to DIN 51524 section 3

6. Hydraulic ester oils (HEES)

7. KP2N-20 according to DIN 51502 EP multipurpose calcium sulphonate complex grease

8. Standard acid-proof grease

9. Up to serial number WNCE0801EPAL00899

10. From serial no. WNCE0801VPAL00900

Lubricant Gleitmo 800

9

10

1

−15 °C (5 °F)

2

+40 °C (104 °F)

Year-round

4

2.5 l (0.66 gal)

13.8 l (3.64 gal)

Year-round As required

Year-round As required

Depending on outside

temperatures

Summer or winter diesel

7 l (1.85 gal)

fuel

Year-round

2.9 l (0.77 gal)

Year-round As required

3-2 SHB 803 en – Edition 2.4 * 803s310.fm

Page 41

Oil grades for the diesel engine, depending on temperature

Caution!

Notice!

Engine oil grade Ambient temperature (°C/°F)

-20-15-10-5 0 5 10152025303540

°C

SAE 10W

SAE 20W

SAE 10W-30

SAE 10W-40

API: CG-4/CH-4/

CI-4

ACEA: E3, E4, E5

SAE 15W-40

SAE 20

Maintenance

SAE 30

-4 514233241505968778695104

°F

Additional oil change and filter replacement (hydraulic system)

An additional oil change and filter replacement can be required depending on

how the machine is used. Failure to observe these replacement intervals can

cause damage to hydraulic components.

☞Observe the following intervals

Application Hydraulic oil Hydraulic oil filter insert

Normal work (excavation work)

20% Every 800 o/h

40% Every 400 o/h

Percentage of hammer work

60% Every 300 o/h

Over 80 % Every 200 o/h

Replace the first time after 500

o/h, then every 1000 o/h

Replace the first time after 50 o/h, then every 500 o/h

SAE 40

300 o/h

100 o/h

Please refer to the maintenance plan on page 3-8 for additional maintenance.

SHB 803 en – Edition 2.4 * 803s310.fm 3-3

Page 42

Maintenance

Hydrau-

lics oil

grade

°C

Oil grades for the hydraulic system, depending on temperature

Ambient temperature (°C/°F)

-20-15-10-5 0 5 1015202530354050

ISO VG32

1

HVLP

-4 5 14233241505968778695104

°F

1. According to DIN 51524 section 3

ISO VG46

ISO VG68

122

3-4 SHB 803 en – Edition 2.4 * 803s310.fm

Page 43

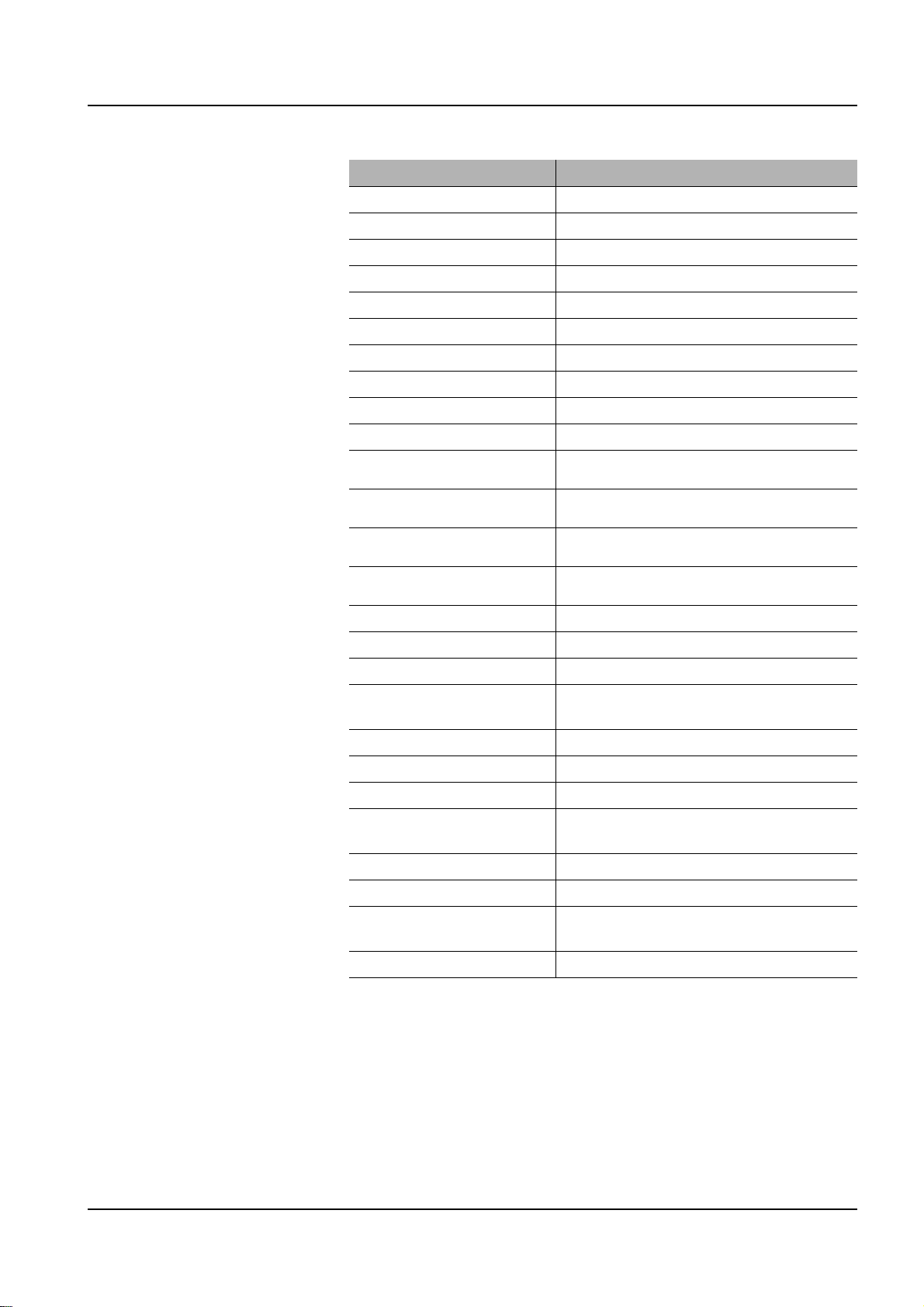

3.2 Maintenance label

Explanation of symbols on the maintenance label

Symbol Assembly Explanation

General Visual check

General Grease instructions

Fuel system Drain condensation water

Fuel system Replace the fuel filter, clean the fuel prefilter

Radiator Check the coolant level

Radiator Drain and add new coolant

Maintenance

Engine Check valve clearance. Adjust if necessary

Engine Check the engine oil level

Engine Change the engine oil

Engine Replace the oil filter

Engine Check the V-belt tension

Travel gear Check track tension

Hydraulic system Check oil level

Hydraulic system Change the hydraulic oil

Hydraulic system Replace the hydraulic oil filter, replace the breather filter

Radiator fins Clean

SHB 803 en – Edition 2.4 * 803s310.fm 3-5

Page 44

Maintenance

Maintenance label (up to serial number AF02412)

3-6 SHB 803 en – Edition 2.4 * 803s310.fm

Page 45

Maintenance label (from serial number AF02413)

Maintenance

SHB 803 en – Edition 2.4 * 803s310.fm 3-7

Page 46

Maintenance

Authorized

service center

Customer

Every 2000 o/h

Every 1000 o/h

once a year

Every 500 o/h

Every 250 o/h

Every 50 o/h

Maintenance

(once a day)

Maintenance plan/operating hours (o/h)

●● ●

●● ●

●● ●

●● ●

●● ●

●●

●●

●●

●●

●●

●●

●●

6

4

2

1

Maintenance

3.3 Maintenance plan (overview)

Work description

For servicing and maintenance on the attachment, please refer to the operation and maintenance manual of

the attachment manufacturer.

Fluid and filter changes ( ):

Perform the following oil and filter changes (check oil levels after test run):

3

• Engine oil

• Engine oil filter

• Fuel filter

• Water separator ●●

5

• Engine oil

• Engine coolant ●●

• Fuel ●●

• Coolant ●●

• Hydraulic oil filter insert

• Hydraulic oil

• Drain condensation water from the hydraulic oil reservoir (from serial no. AH02272) ●●

• Air filter element (up to serial no. AI00875) ●●

• Air filter element according to dirt indicator (from serial no. AI00876)

Inspection work ( ):

Check the following material. Refill if necessary:

• Hydraulic oil ●●

Check the function of the pedals (up to serial no. AI00975)

• Clean, lubricate or repair the pedals

Check the function of the pedals, they must flip back automatically (from serial no. AI00976)

7

• Clean, lubricate or repair the pedals, check the torsion springs

Clean water ducts

Check radiator for engine and hydraulic oil for dirt. Clean if necessary

Check cooling systems and hoses for leaks and pressure (visual check)

3-8 SHB 803 en – Edition 2.4 * 803s311.fm

Page 47

Authorized

service center

Customer

Every 2000 o/h

Maintenance

●

Every 1000 o/h

once a year

Every 500 o/h

Every 250 o/h

Every 50 o/h

Maintenance

(once a day)

Maintenance plan/operating hours (o/h)

●●

●●

●●

●●

●●

●●

●●

●●

●●

●●

●●

●

●●

●●

●● ●

●●●

●●

●●

●●

●●

●●

●●

10

8

9

• Clean ●●

Air filter (damage)

Remove dust from dust valve

3.3 Maintenance plan (overview)

Work description

For servicing and maintenance on the attachment, please refer to the operation and maintenance manual of

the attachment manufacturer.

SHB 803 en – Edition 2.4 * 803s311.fm 3-9

Prefilter with water separator: drain water

Check V-belt condition and tension

Replace the V-belt

Check the exhaust system for damage and condition

Check the rollbar for damage

Check valve clearance. Adjust if necessary

Clean and adjust the fuel injection pump

Check and adjust the injection pressure of the injection nozzles, clean the injection needles/nozzles

Check and adjust injection time

Empty the fuel tank and check for dirt

Check battery electrolyte. Add distilled water if necessary

Check alternator, starter and electric connections, bearing play and function

Check preheating system and electric connections

Pressure check of primary pressure limiting valves

Check tracks for cracks and cuts

Check track tension. Retighten if necessary

Check bearing play of tread rollers, track carrier rollers, front idlers

Check piston rods for damage

Check the threaded fittings of the safety devices (for example rollbar, etc.) for tightness

Check the threaded fittings for tightness

Page 48

Maintenance

Authorized

service center

Customer

Every 2000 o/h

Every 1000 o/h

once a year

Every 500 o/h

Every 250 o/h

Every 50 o/h

Maintenance

(once a day)

Maintenance plan/operating hours (o/h)

●●

●●

●●

●● ●

●●

●●

●●

●●

●●

●●

11

12

3.3 Maintenance plan (overview)

Work description

For servicing and maintenance on the attachment, please refer to the operation and maintenance manual of

Check pin lock

Check line fixtures

Check indicator lights for correct function

Couplings, dirt pile-up on hydraulic system dust caps

the attachment manufacturer.

Check insulating mats in engine compartment for damage/condition

• Stabilizer blade

Check labels and Operator’s Manual for completeness and condition

Lights and acoustic warning system

Check lubricant on live ring

Lubrication service ( ):

Check gearing of swivel unit pinion ●●

Lubricate the following assemblies/components – see Maintenance label on page 3-5:

• Swiveling console ●●

• Swiveling cylinder ●●

• Boom ●●

•Stick ●●

• Attachments ●●

• Teeth of live ring ●●

• Live ring (ball bearing) ●●

• Ball sockets (ISO/SAE changeover option) ●●

Functional check ( ):

• Lights and acoustic warning system

• Check pedal function ●●

Check the function of the following assemblies/components. Rectify if necessary:

3-10 SHB 803 en – Edition 2.4 * 803s311.fm

Page 49

Authorized

service center

Customer

Every 2000 o/h

Every 1000 o/h

once a year

Every 500 o/h

Every 250 o/h

Every 50 o/h

Maintenance

Maintenance

(once a day)

Maintenance plan/operating hours (o/h)

●●

• Visual check

☞Engine, hydraulic system and hydraulic components ●●

☞Cooling circuit ●●

Leakage check ( ):

3.3 Maintenance plan (overview)

Work description

For servicing and maintenance on the attachment, please refer to the operation and maintenance manual of

the attachment manufacturer.

SHB 803 en – Edition 2.4 * 803s311.fm 3-11

Check for tightness, leaks and chafing: pipes, flexible lines and threaded fittings of the following assemblies and components. Rectify if necessary:

☞Traveling drive ●●

1. Drain engine oil the first time after 50 o/h, then every 250 o/h

2. Replace the engine oil filter the first time after 50 o/h, then every 250 o/h

3. Replace the fuel filter the first time after 50 o/h, then every 500 o/h

4. Replace the hydraulic oil filter insert the first time after 50 o/h, then every 500 o/h

5. Replace the hydraulic oil the first time after 500 o/h, after 1000 o/h the second time, then every 1000 o/h

6. According to the dirt indicator, every 1000 o/h or once a year at the latest. (Replace after 50 o/h when in extensive use in environments with acidic air, such as acid production facilities, steel and aluminum mills, chemical plants and other nonferrous-metal plants)

7. Clean the water ducts every other 1000 o/h servicing

8. Clean and adjust the fuel injection pump every other 1000 o/h servicing

9. Check and adjust injection time every other 1000 o/h servicing

10. Check the first time after 50 o/h, then every 500 o/h

11. Check once a week

12. Check the first time after 50 o/h, then every 500 o/h

Page 50

Notice!

Maintenance

Maintenance

3.4 Service package

3.5 Introduction

3.6 Safety-relevant parts

Please refer to the 803 spare parts catalogue for the article numbers of the 2 available service packages (for 50 and 500 operating hours).

Operational readiness and the service life of ma chines are h eavily depen dent on maintenan ce.

It is therefore in the interest of the machine owner to perform the mandatory maintenance.

Bear in mind the following points before performing servicing and maintenance:

• Chapter 2 “SAFETY INSTRUCTIONS” in the Operator’s Manual

• The Operator’s Manuals of the attachments.

Perform the prescribed inspections and rectify any disorders before putting the machine

into operation.

Secure the open engine cover and other open covers appropriately. Do not open the

engine cover and other covers on slopes or in strong wind.

When using compressed air, dirt and debris can be blown into your face. Therefore, wear

safety glasses, protective masks and clothing when using compressed air.

Daily servicing and maintenance, and maintenance according to maintenance plan “A”

must be performed by a specifically trained person. All other maintenance must be performed by trained and qualified personnel only.