Wacker Neuson RD 12A, RD 12, 0620369, 0620059, 0620058 Repair Manual

...

Repair Manual

Roller

RD 12

EN

5000192242 02 0912

5000192242

Copyright notice

© Copyright 2012 by Wacker Neuson Production Americas LLC

All rights, including copying and distribution rights, are reserved.

This publication may be photocopied by the original purchaser of the

machine. Any other type of reproduction is prohibited without express

written permission from Wacker Neuson Production Americas LLC.

Any type of reproduction or distribution not authorized by Wacker

Neuson Production Americas LLC represents an infringement of valid

copyrights. Violators will be prosecuted.

Trademarks

Manufacturer

Original instructions

All trademarks referenced in this manual are the property of their

respective owners.

Wacker Neuson Production Americas LLC

N92W15000 Anthony Avenue

Menomonee Falls, WI 53051 U.S.A.

Tel: (262) 255-0500 · Fax: (262) 255-0550 · Tel: (800) 770-0957

www.wackerneuson.com

This Operator’s Manual presents the original instructions. The original

language of this Operator’s Manual is American English.

RD 12/RD 12A Foreword

This manual covers machines with Item Number:

0620058, 0620320, 0620369, 0620059, 0620321

Operating / Parts Information

You must be familiar with the operation of this machine before you

attempt to troubleshoot or repair it. Basic operating and maintenance

procedures are described in the Operator’s Manual supplied with the

machine. Keep a copy of the Operator’s Manual with the machine at all

times. Use the separate Parts Book supplied with the machine to order

replacement parts. If you are missing either of the documents, please

contact Wacker Neuson Corporation to order a replacement.

Damage caused by misuse or neglect of the unit should be brought to

the attention of the operator to prevent similar occurrences from

happening in the future.

This manual provides information and procedures to safely repair and

maintain the above Wacker Neuson model(s). For your own safety and

protection from injury, carefully read, understand, and observe all

instructions described in this manual. THE INFORMATION

CONTAINED IN THIS MANUAL IS BASED ON MACHINES

MANUFACTURED UP TO THE TIME OF PUBLICATION. WACKER

NEUSON CORPORATION RESERVES THE RIGHT TO CHANGE

ANY PORTION OF THIS INFORMATION WITHOUT NOTICE.

wc_tx000663gb.fm 3

Foreword RD 12/RD 12A

CALIFORNIA

Proposition 65 Warning:

Engine exhaust, some of its constituents, and certain vehicle

components, contain or emit chemicals known to the State of

WARNING

California to cause cancer and birth defects or other reproductive

harm.

All rights, especially copying and distribution rights, are reserved.

Copyright 2009 by Wacker Neuson Corporation

No part of this publication may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without

express written permission from Wacker Neuson Corporation.

Any type of reproduction or distribution not authorized by Wacker

Neuson Corporation represents an infringement of valid copyrights,

and violators will be prosecuted. We expressly reserve the right to

make technical modifications, even without due notice, which aim at

improving our machines or their safety standards.

wc_tx000663gb.fm 4

RD 12/RD 12A Table of Contents

1 Safety Information 9

1.1 Operating Safety ................................................................................ 10

1.2 Operator Safety while using Internal Combustion Engines ................ 12

1.3 Service Safety .................................................................................... 13

1.4 Label Locations .................................................................................. 15

1.5 Safety and Operating Labels .............................................................. 16

2 Operation 22

2.1 Operation and Service Locations ....................................................... 22

2.2 Control Panel ...................................................................................... 24

2.3 Vibration ............................................................................................. 26

2.4 Water Spray System .......................................................................... 27

2.5 Starting ............................................................................................... 28

2.6 Stopping/Parking ................................................................................ 30

2.7 Auxiliary Battery Positive Terminal ..................................................... 31

3 Honda Engine Starting System 32

3.1 Checking the 20A Main Fuse ............................................................. 33

3.2 Checking Wiring to the Starter Solenoid & Anti-backfire Solenoid ..... 34

3.3 Checking the Key Switch .................................................................... 36

3.4 Checking the Crank Relay .................................................................. 37

3.5 Checking the Neutral Switch .............................................................. 38

3.6 Checking the Neutral Relay ................................................................ 39

4 Wacker Neuson Engine Starting System 40

4.1 Checking the 20A Main Fuse ............................................................. 41

4.2 Checking the Wiring to the Starter Solenoid & Anti-backfire Solenoid 42

4.3 Checking the Key Switch .................................................................... 43

4.4 Checking the Crank Relay .................................................................. 44

4.5 Checking the Neutral Switch .............................................................. 45

4.6 Checking the Neutral Relay ................................................................ 46

5

Table of Contents RD 12/RD 12A

5 Drive System 48

5.1 Checking the Tow Valve ......................................................................49

5.2 Adjusting the Drive Control Cable .......................................................50

5.3 Checking the Drive System Operating Pressure .................................51

5.4 Checking the Drive System Relief Pressure .......................................52

5.5 Checking Drive Motors for Binding ......................................................53

5.6 Checking Oil Flow through the Drive Motors .......................................55

6 Vibration System and Steering 56

6.1 Checking the Engine Speed and Vibration Speed ..............................57

6.2 Troubleshooting a System that Vibrates Poorly ..................................58

6.3 Checking the Vibration Solenoid Valve ...............................................60

6.4 Checking the Vibration Switch .............................................................61

7 Steering System 62

7.1 Checking the Steering System Hydraulic Pressure .............................62

7.2 Troubleshooting the Steering System .................................................63

8 Spray System 64

8.1 Troubleshooting the Spray System .....................................................64

8.2 Checking Power to the Spray Bar Pump .............................................65

8.3 Checking the Pump Timer Module ......................................................66

8.4 Checking the Spray System Switch ....................................................67

9 Disassembly & Assembly 68

9.1 Tools Required for Disassembly/Assembly Procedures .....................68

9.2 Information Regarding Replacement Parts .........................................68

9.3 Information Regarding Reference Numbers ( ) ...................................68

9.4 Information Regarding Threadlocking Compounds .............................68

9.5 Removing the Articulating Joint ...........................................................69

9.6 Installing the Articulating Joint .............................................................70

wc_br0170797en_002TOC.fm 6

RD 12/RD 12A Table of Contents

9.7 Removing the Rear Drum ................................................................... 71

9.8 Installing the Rear Drum ..................................................................... 73

9.9 Removing the Brake and Brake Cable ............................................... 75

9.10 Installing the Brake and Brake Cable ................................................. 77

9.11 Removing Rear Drive Motor ............................................................... 79

9.12 Installing the Rear Drive Motor ........................................................... 81

9.13 Removing the Front Drum .................................................................. 83

9.14 Installing the Front Drum .................................................................... 85

9.15 Removing the Front Drive Motor ........................................................ 87

9.16 Installing the Front Drive Motor .......................................................... 88

9.17 Removing the Exciter ......................................................................... 89

9.18 Installing the Exciter ........................................................................... 91

9.19 Disassembling the Exciter Bearings ................................................... 93

9.20 Assembling the Exciter Bearings ........................................................ 95

9.21 Removing the Control Cable and Control Lever ................................. 97

9.22 Installing the Control Cable and Control Lever ................................... 99

9.23 Removing the Exciter Pump ............................................................. 100

9.24 Installing the Exciter Pump ............................................................... 101

9.25 Removing the Drive Pump ............................................................... 102

9.26 Installing the Drive Pump ................................................................. 103

9.27 Removing the Engine ....................................................................... 104

9.28 Installing the Engine ......................................................................... 106

9.29 Removing the Steering Valve ........................................................... 108

9.30 Installing the Steering Valve ............................................................. 110

9.31 Removing the Hydraulic Tank .......................................................... 112

9.32 Installing the Hydraulic Tank ............................................................ 114

9.33 Removing the Fuel Tank .................................................................. 116

9.34 Installing the Fuel Tank .................................................................... 118

10 Schematics 120

10.1 Hydraulic Schematic ......................................................................... 120

10.2 Hydraulic Schematic Components ................................................... 121

10.3 Electrical Schematic Identification—RD 12A .................................... 121

10.4 Electrical Schematic “A”—RD 12A ................................................... 122

10.5 Electrical Schematic “A” Components—RD 12A .............................. 123

10.6 Electrical Schematic “B”—RD 12A ................................................... 124

10.7 Electrical Schematic “B” Components—RD 12A .............................. 125

10.8 Electrical Schematic—RD 12 ........................................................... 126

10.9 Electrical Schematic Components—RD 12 ...................................... 127

7

Table of Contents RD 12/RD 12A

11 Technical Data 128

11.1 Engine ...............................................................................................128

11.2 Roller .................................................................................................129

11.3 Lubrication .........................................................................................129

11.4 Dimensions ........................................................................................130

11.5 Sound Measurements .......................................................................131

11.6 Measurements of Operator Exposure to Vibration ............................131

11.7 Hydraulic Pressures ..........................................................................132

wc_br0170797en_002TOC.fm 8

RD 12/RD 12A Safety Information

1 Safety Information

This manual contains DANGER, WARNING, CAUTION, NOTICE and

NOTE callouts which must be followed to reduce the possibility of

personal injury, damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

DANGER

WARNING

CAUTION

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

NOTICE: Used without the safety alert symbol, NOTICE indicates a

situation which, if not avoided, could result in property damage.

Note: Contains additional information important to a procedure.

wc_si000302gb.fm 9

Safety Information RD 12/RD 12A

1.1 Operating Safety

Notice: State Health Safety Codes and Public Resources Codes

specify that in certain locations spark arresters be used on internal

combustion engines that use hydrocarbon fuels. A spark arrester is a

device designed to prevent accidental discharge of sparks or flames

from the engine exhaust. Spark arresters are qualified and rated by

the United States Forest Service for this purpose.

In order to comply with local laws regarding spark arresters, consult

the engine distributor or the local Health and Safety Administrator.

Familiarity and proper training are required for the safe operation of the

machine. Machines operated improperly or by untrained personnel

can be hazardous. Read the operating instructions contained in this

WARNING

1.1.1 DO NOT drive over curbs or other uneven objects that will result in the

manual and the engine manual, and familiarize yourself with the

location and proper use of all controls. Inexperienced operators should

receive instruction from someone familiar with the machine before

being allowed to operate it.

machine and operator being shaken.

1.1.2 DO NOT attempt to start the machine when standing alongside it. Only

start the engine when seated in the driver's seat and with the forward/

reverse control in the neutral position.

1.1.3 Do not allow anyone to operate this equipment without proper training.

People operating this equipment must be familiar with the risks and

hazards associated with it.

1.1.4 Do not touch the engine or muffler while the engine is on or

immediately after it has been turned off. These areas get hot and may

cause burns.

1.1.5 Do not use accessories or attachments that are not recommended by

Wacker Neuson. Damage to equipment and injury to the user may

result.

1.1.6 NEVER leave the machine running unattended.

1.1.7 NEVER operate the machine with the fuel cap loose or missing.

1.1.8 NEVER carry passengers on the machine. Danger of crushing—keep

clear of the articulated steering joint between the front and rear frames.

1.1.9 NEVER use or attempt to repair damaged safety belts or ROPS.

Replace only with Wacker Neuson spare parts.

1.1.10 ALWAYS disengage and stow the locking bar for the articulated

steering joint before operating the machine. The machine cannot be

steered when the locking bar is engaged.

1.1.11 ALWAYS check that all controls are functioning properly immediately

after start-up! DO NOT operate the machine unless all controls operate

correctly.

wc_si000302gb.fm 10

RD 12/RD 12A Safety Information

1.1.12 ALWAYS remain aware of changing positions and the movement of

other equipment and personnel on the job site.

1.1.13 ALWAYS remain seated and wear the seat belt at all times while

operating the machine.

1.1.14 ALWAYS remain aware of changing surface conditions and use extra

care when operating over uneven ground, on hills, or over soft or

coarse material. The machine could shift or slide unexpectedly.

1.1.15 ALWAYS use caution when operating the machine near the edges of

pits, trenches or platforms. Check to be sure that ground surface is

stable enough to support the weight of the machine with operator and

that there is no danger of the roller sliding, falling or tipping.

1.1.16 ALWAYS wear protective clothing appropriate to the job site when

operating the machine.

1.1.17 ALWAYS keep hands, feet, and loose clothing away from moving parts

of the machine.

1.1.18 Read, understand, and follow procedures in the Operator’s Manual

before attempting to operate the machine.

1.1.19 Store the machine properly when it is not being used. The machine

should be stored in a clean, dry location out of the reach of children.

1.1.20 Always operate the machine with all safety devices and guards in

place and in working order.

1.1.21 ALWAYS be sure that all other persons are at a safe distance from the

machine. Stop the machine if people step into the working area of the

machine.

wc_si000302gb.fm 11

Safety Information RD 12/RD 12A

1.2 Operator Safety while using Internal Combustion Engines

Internal combustion engines present special hazards during operation

and fueling. Read and follow the warning instructions in the engine

owner’s manual and the safety guidelines below. Failure to follow the

WARNING

1.2.1 Do not smoke while operating the machine.

1.2.2 Do not smoke when refueling the engine.

1.2.3 Do not refuel a hot or running engine.

1.2.4 Do not refuel the engine near an open flame.

1.2.5 Do not spill fuel when refueling the engine.

1.2.6 Do not run the engine near open flames.

1.2.7 Do not run the machine indoors or in an enclosed area such as a deep

warnings and safety standards could result in severe injury or death.

trench unless adequate ventilation, through such items as exhaust

fans or hoses, is provided. Engine exhaust contains carbon monoxide.

This is a poison you cannot see or smell. Exposure to carbon

monoxide can cause loss of consciousness and CAN KILL YOU IN

MINUTES.

1.2.8 Refill the fuel tank in a well-ventilated area.

1.2.9 Replace the fuel tank cap after refueling.

1.2.10 ALWAYS keep the area around a hot exhaust pipe free of debris to

reduce the chance of an accidental fire.

1.2.11 ALWAYS check the fuel lines and the fuel tank for leaks and cracks

before starting the engine. Do not run the machine if fuel leaks are

present or the fuel lines are loose.

wc_si000302gb.fm 12

RD 12/RD 12A Safety Information

1.3 Service Safety

A poorly maintained machine can become a safety hazard! In order

for the machine to operate safely and properly over a long period of

time, periodic maintenance and occasional repairs are necessary.

WARNING

1.3.1 Some service procedures require that the machine’s battery be

disconnected. To reduce the risk of personal injury, read and

understand the service procedures before performing any service to

the machine.

1.3.2 All adjustments and repairs MUST be completed before operation. Do

not operate the machine with a known problem or deficiency! All

repairs and adjustments should be completed by a qualified

technician.

1.3.3 Do not attempt to clean or service the machine while it is running.

Rotating parts can cause severe injury.

1.3.4 Do not crank a flooded engine with the spark plug removed on

gasoline-powered engines. Fuel trapped in the cylinder will squirt out

the spark plug opening.

1.3.5 Do not test for spark on gasoline-powered engines if the engine is

flooded or the smell of gasoline is present. A stray spark could ignite

the fumes.

1.3.6 Do not use gasoline or other types of fuels or flammable solvents to

clean parts, especially in enclosed areas. Fumes from fuels and

solvents can become explosive.

1.3.7 Do not modify the machine without the express written approval of the

manufacturer.

1.3.8 DO NOT stand under the machine while it is being hoisted or moved.

1.3.9 DO NOT get onto the machine while it is being hoisted or moved.

1.3.10 DO NOT use the machine as a ladder. Use safe ladders and platforms

designed for this purpose.

1.3.11 DO NOT modify, weld, or drill safety frames (ROPS) fitted as original

equipment. DO NOT loosen or remove bolts. DO NOT weld, drill or

modify a broken safety frame.

1.3.12 DO NOT open the hydraulic lines or loosen the hydraulic connections

while the engine is running! Before dismantling the hydraulic

connectors or hoses, ensure that all pressure has been bled from the

circuit. Hydraulic fluid under pressure can penetrate the skin, cause

burns, blind, or create other personal injury hazards. Set all controls in

neutral, turn engine off, and allow the fluids to cool before loosening

hydraulic fittings or attaching test gauges.

1.3.13 ALWAYS check all external fasteners at regular intervals.

wc_si000302gb.fm 13

Safety Information RD 12/RD 12A

1.3.14 Keep the area around the muffler free of debris such as leaves, paper,

cartons, etc. A hot muffler could ignite the debris and start a fire.

1.3.15 Replace worn or damaged components with spare parts designed and

recommended by Wacker Neuson Corporation.

1.3.16 Disconnect the spark plug on machines equipped with gasoline

engines, before servicing, to avoid accidental start-up.

1.3.17 Keep the machine clean and labels legible. Replace all missing and

hard-to-read labels. Labels provide important operating instructions

and warn of dangers and hazards.

1.3.18 ALWAYS do periodic maintenance as recommended in the Operator’s

Manual.

1.3.19 ALWAYS turn the engine off before performing maintenance or making

repairs.

1.3.20 ALWAYS keep hands, feet and loose clothing away from moving parts.

1.3.21 ALWAYS make sure slings, chains, hooks, ramps, jacks and other

types of lifting devices are attached securely and have enough weightbearing capacity to lift or hold the machine safely. Always remain

aware of the location of other people in the area when lifting the

machine.

1.3.22 ALWAYS make sure hose connections have been reconnected back

to the correct fitting. Failure to do so may result in damage to the

machine and/or injury to person on or near the machine.

1.3.23 ALWAYS secure the articulated steering joint using the locking bar

before lifting, jacking, and servicing the machine. The machine halves

could swing together unexpectedly and cause a serious injury.

1.3.24 ALWAYS lock the lifting cylinders in the open position when the seat

pedestal is raised.

1.3.25 Before you start the machine, ensure that all tools have been removed

from the machine and that replacement parts and adjusters are firmly

tightened.

1.3.26 Fluid leaks from small holes are often practically invisible. DO NOT use

your bare hands to check for leaks. Check for leaks using a piece of

cardboard or wood.

wc_si000302gb.fm 14

RD 12/RD 12A Safety Information

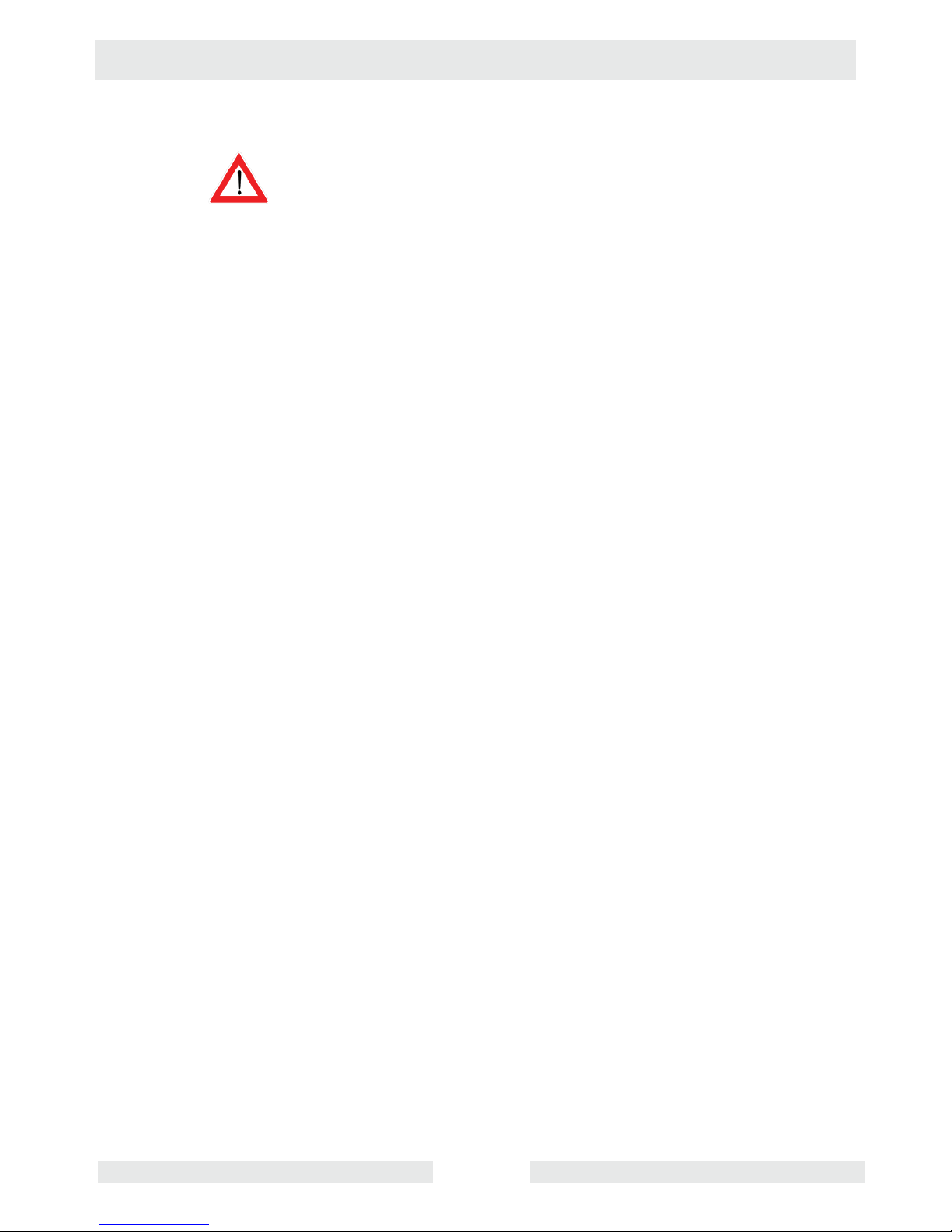

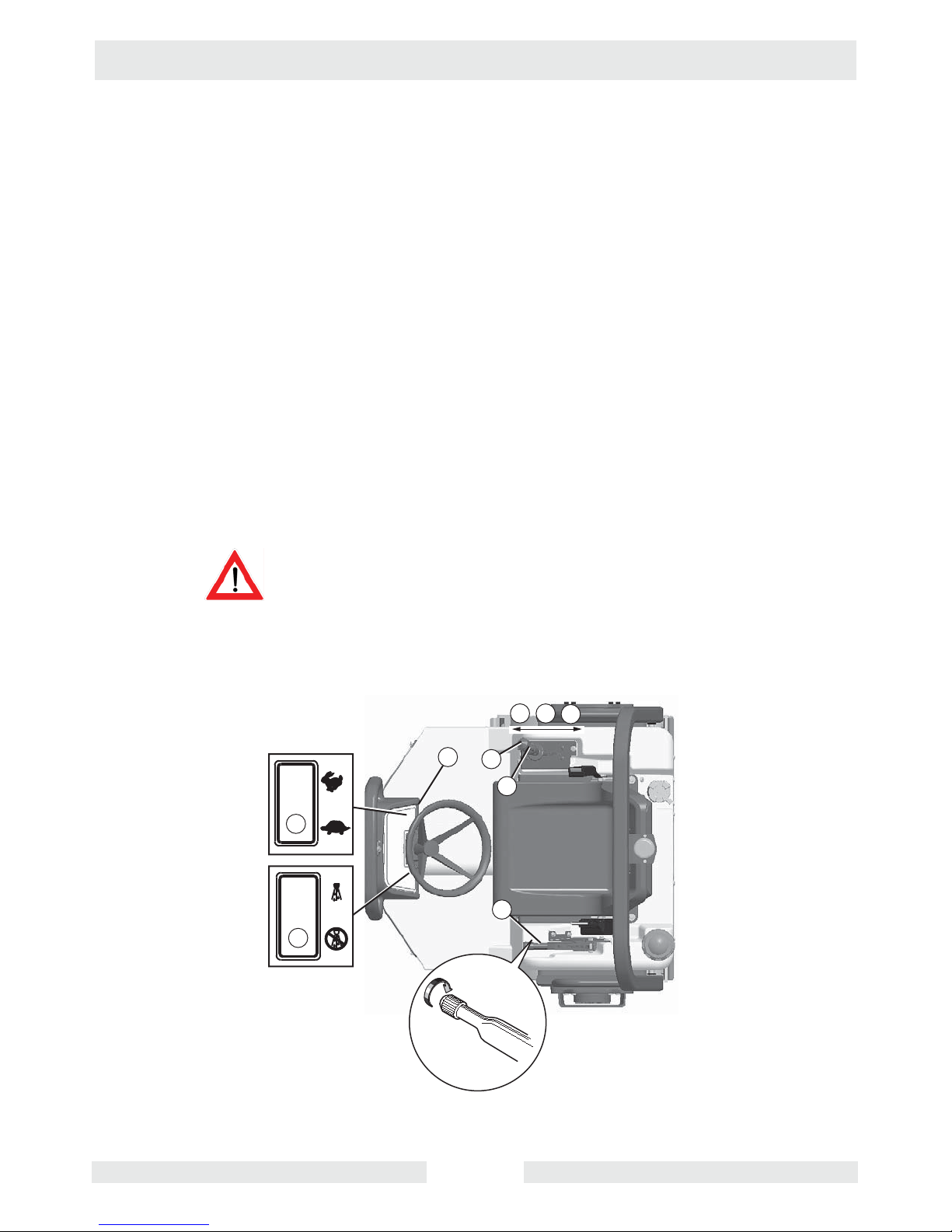

1.4 Label Locations

FF

X

wc_si000302gb.fm 15

Safety Information RD 12/RD 12A

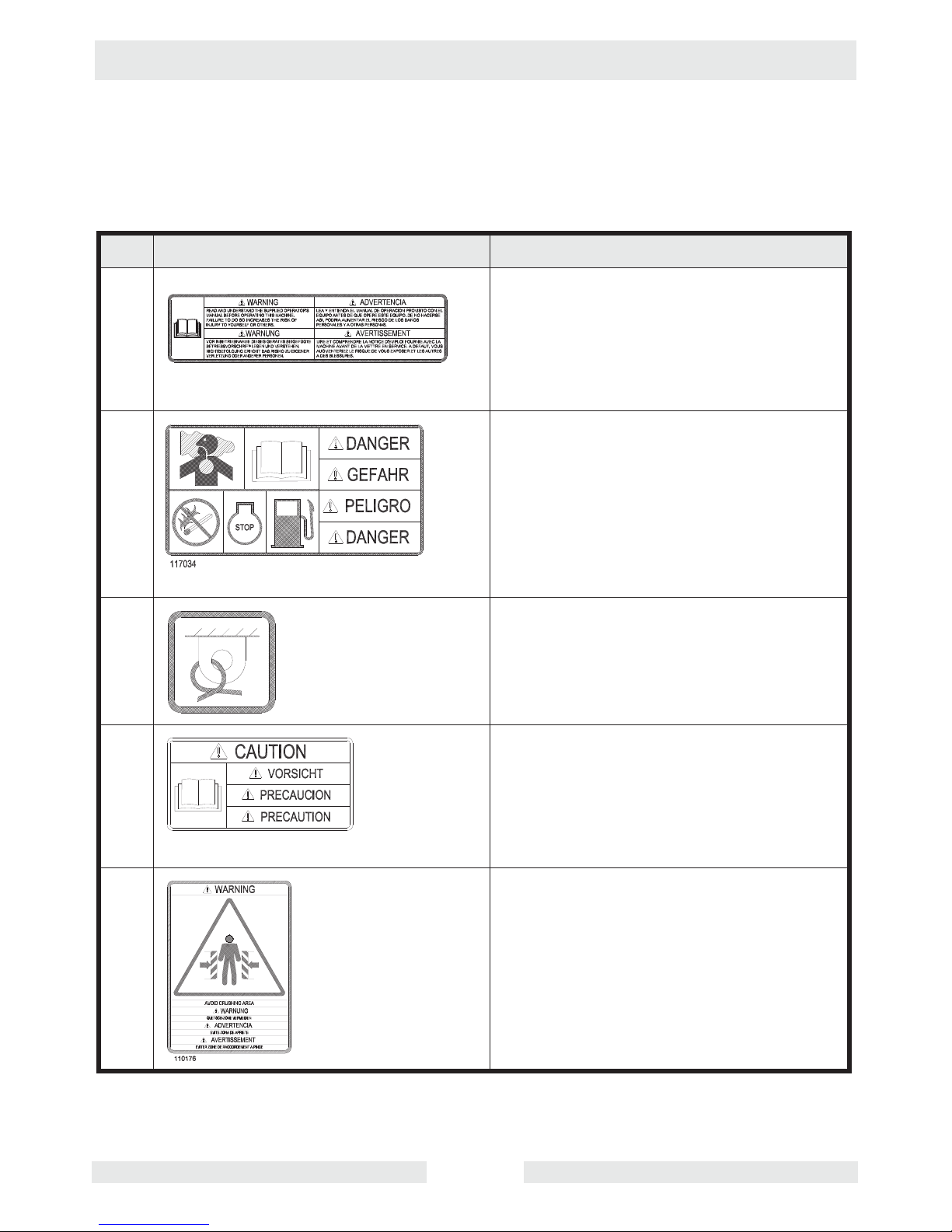

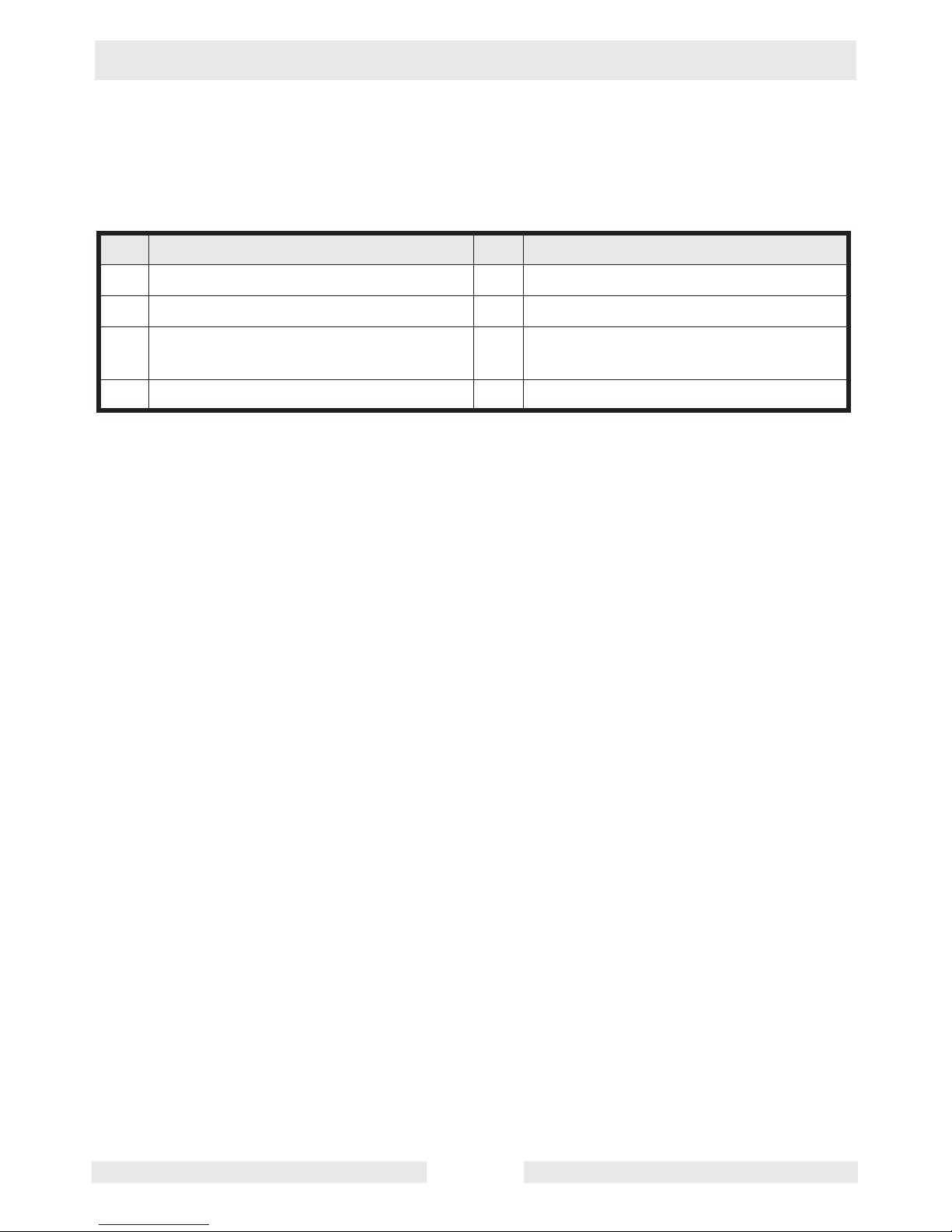

1.5 Safety and Operating Labels

Wacker Neuson machines use international pictorial labels where

needed. These labels are described below:

Ref. Label Meaning

A WARNING!

Read and understand the supplied

Operator’s Manual before operating the

machine. Failure to do so increases the

risk of injury to yourself or others.

B DANGER!

Engines emit carbon monoxide; operate

only in well-ventilated area. Read the

Operator’s Manual.

No sparks, flames, or burning objects

near the machine. Shut off the engine

before refueling.

C Tie-down point

E CAUTION!

Read and understand the supplied

Operator’s Manual before operating this

machine. Failure to do so increases the

risk of injury to yourself or others.

F WARNING!

Pinch point.

wc_si000302gb.fm 16

RD 12/RD 12A Safety Information

Ref. Label Meaning

G WARNING!

Hot surface!

H WARNING!

Hot surface!

I Hydraulic oil reservoir fill tube.

Torque nuts to 13.6-14.7 Nm (120-130

in.lbs.) maximum.

J CAUTION

Lifting point.

K WARNING!

To prevent hearing loss, wear hearing

protection when operating this machine.

M WARNING!

WARNING

Disconnect battery before servicing.

Read Repair Manual for instructions.

Battery contains caustic acid and

potentially explosive hydrogen gas.

N WARNING!

Always wear seat belt when operating

roller.

wc_si000302gb.fm 17

Safety Information RD 12/RD 12A

Ref. Label Meaning

T Choke:

0 = Open

l = Closed

U Grease points: Inspect and lubricate

every 100 hours of operation.

V WARNING!

Avoid crushing area.

Articulated steering joint locking location.

Lock the articulated steering joint before

servicing the machine.

Read Repair Manual.

W Engine will stop without operator seated.

X Guaranteed sound power level in dB(A).

wc_si000302gb.fm 18

RD 12/RD 12A Safety Information

Ref. Label Meaning

Y A nameplate listing the model number,

item number, revision number, and serial

number is attached to each unit. Please

record the information found on this plate

so it will be available should the

nameplate become lost or damaged.

When ordering parts or requesting

service information, you will always be

asked to specify the model number, item

number, revision number, and serial

number of the unit.

Z No lift point.

CC CAUTION! Electric shock hazard at

auxiliary battery positive terminal. Never

touch this terminal and a metal portion of

the machine simultaneously.

DD WARNING!

Read and understand the supplied

Operator’s Manual before operating the

machine. Failure to do so increases the

risk of injury to yourself or others.

EE Water tank

wc_si000302gb.fm 19

Safety Information RD 12/RD 12A

Ref. Label Meaning

FF This machine may be covered by one or

more patents.

wc_si000302gb.fm 20

RD 12/RD 12A Safety Information

Notes

wc_si000302gb.fm 21

Operation RD 12/RD 12A

2 Operation

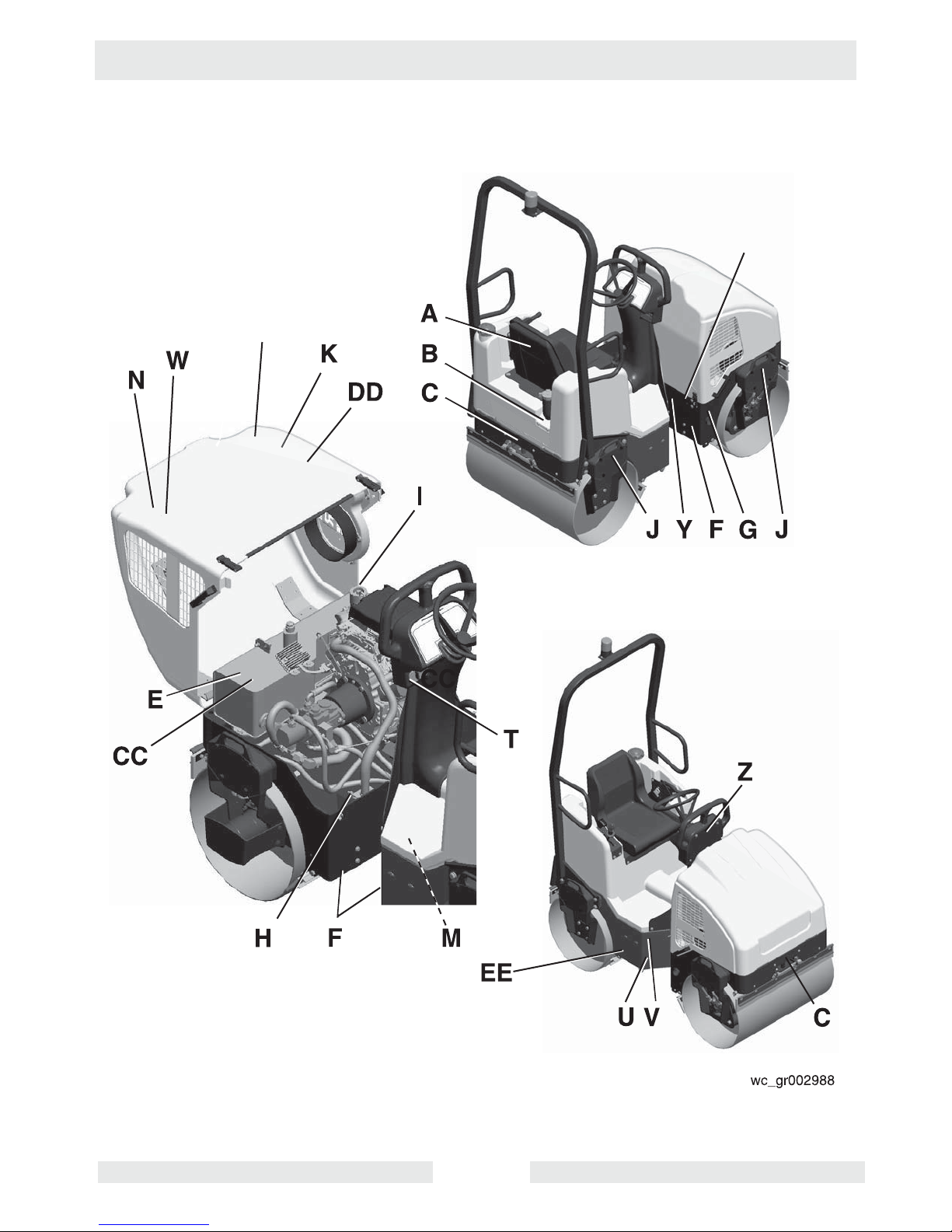

2.1 Operation and Service Locations

See Graphic: wc_gr002946

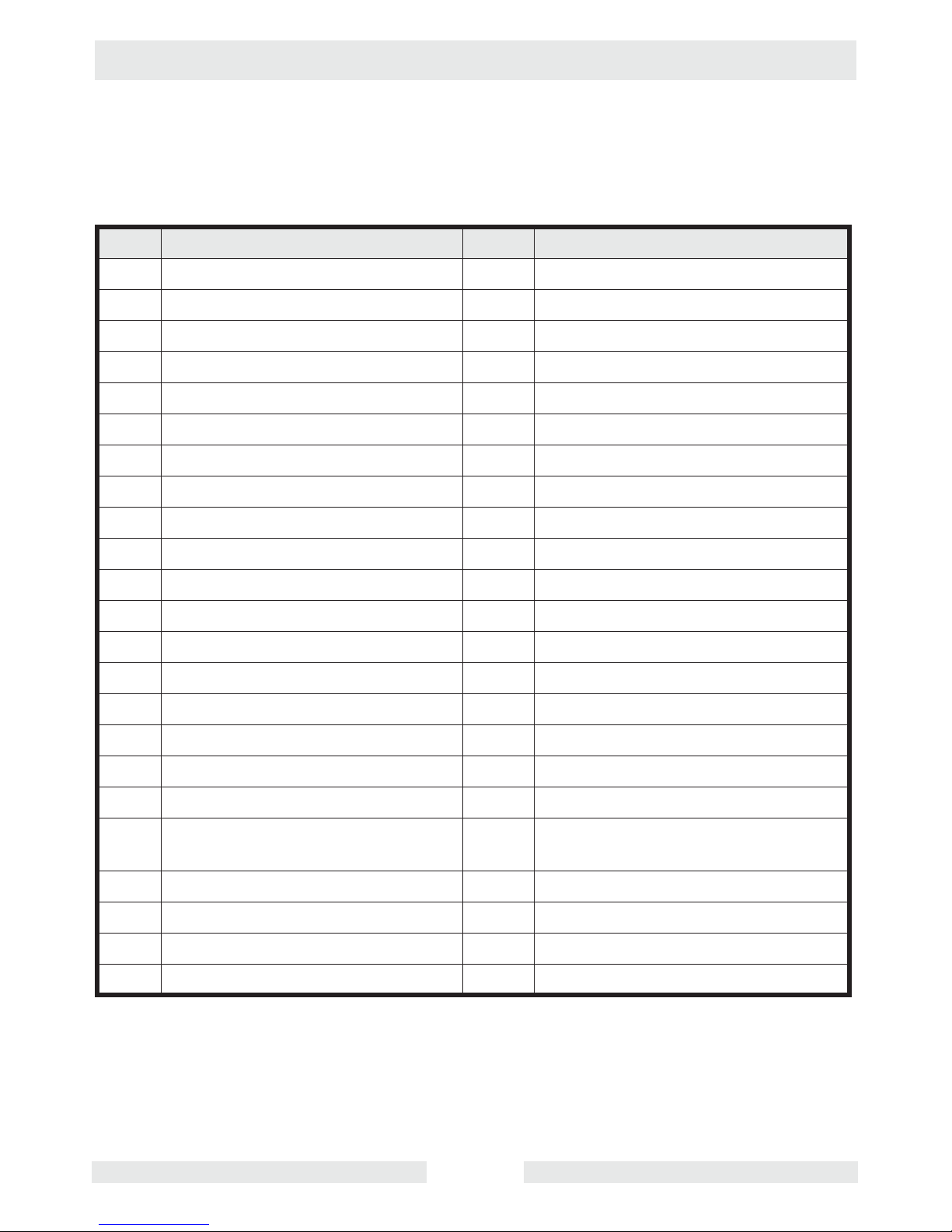

Ref. Description Ref. Description

1 Air cleaner 24 Operator’s platform

2 Articulated joint 25 Engine oil filter

3 Hand holds 26 Rear drum fill/drain plug

4 Control panel 27 Rear drum—static

5 Dipstick 28 Scraper bar (4 places)

6 Drain hose—hydraulic tank 29 Sightglass—hydraulic tank

7 Drive motor 30 Sprinkler tube (2)

8 Drive pump 31 Steering wheel

9 Engine hood 32 Steering cylinder (under floor panel)

10 Vibration control button 33 Tiedown (2 places)

11 Exciter motor 34 Beacon light (optional)

12 Exciter/Steering pump 35 Battery (under floor panel)

13 Hydraulic filter—return line 36 Hydraulic suction line

14 Hydraulic strainer—suction line 37 Grease fitting—exciter (2 places)

15 Forward / Reverse control 38 Lifting eye (4 places)

16 Front drum—vibratory 39 ROPS

17 Fuel tank fill cap 40 Seat with seatbelt

18 Fuel filter 41 Water drain

19 Grease fittings—articulated joint (4

42 Parking brake

places)

20 Hydraulic tank fill port 43 Tow valve

21 Hydraulic manifold block 44 Choke lever

22 Water tank fill cap 45 Auxiliary battery positive terminal

23 Lockarm - ---

wc_tx000865gb.fm 22

RD 12/RD 12A Operation

9

34

3

31

3

10

15

39

14

45

36

28

38

30

22

40

17

7

16

20

29

13

5

28

28

38

7

18

19

25

37

1

11

21

27

2

26

23

41

30

24

28

33

33

wc_tx000865gb.fm 23

37

12

43

6

8

44

4

32

35

42

wc_gr002946

Operation RD 12/RD 12A

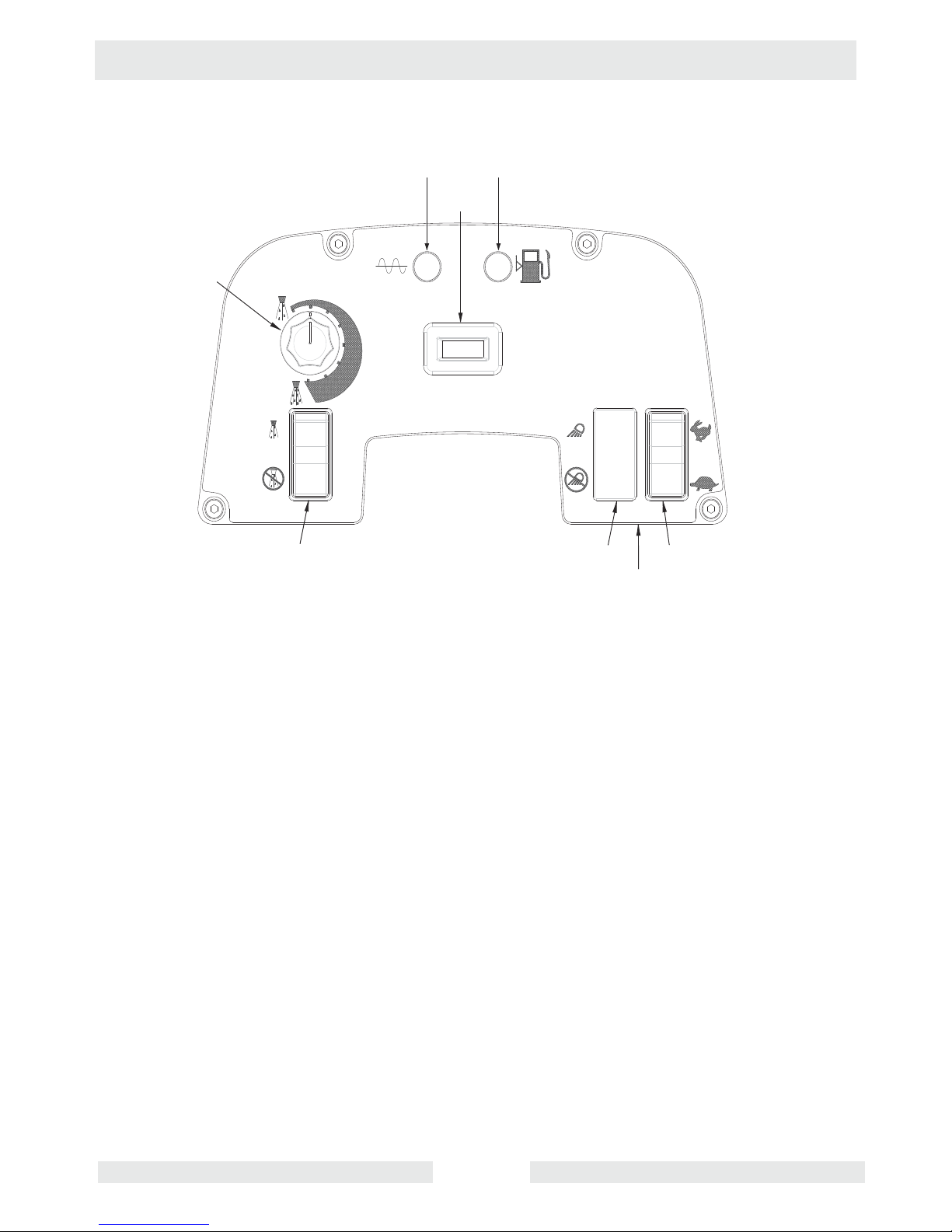

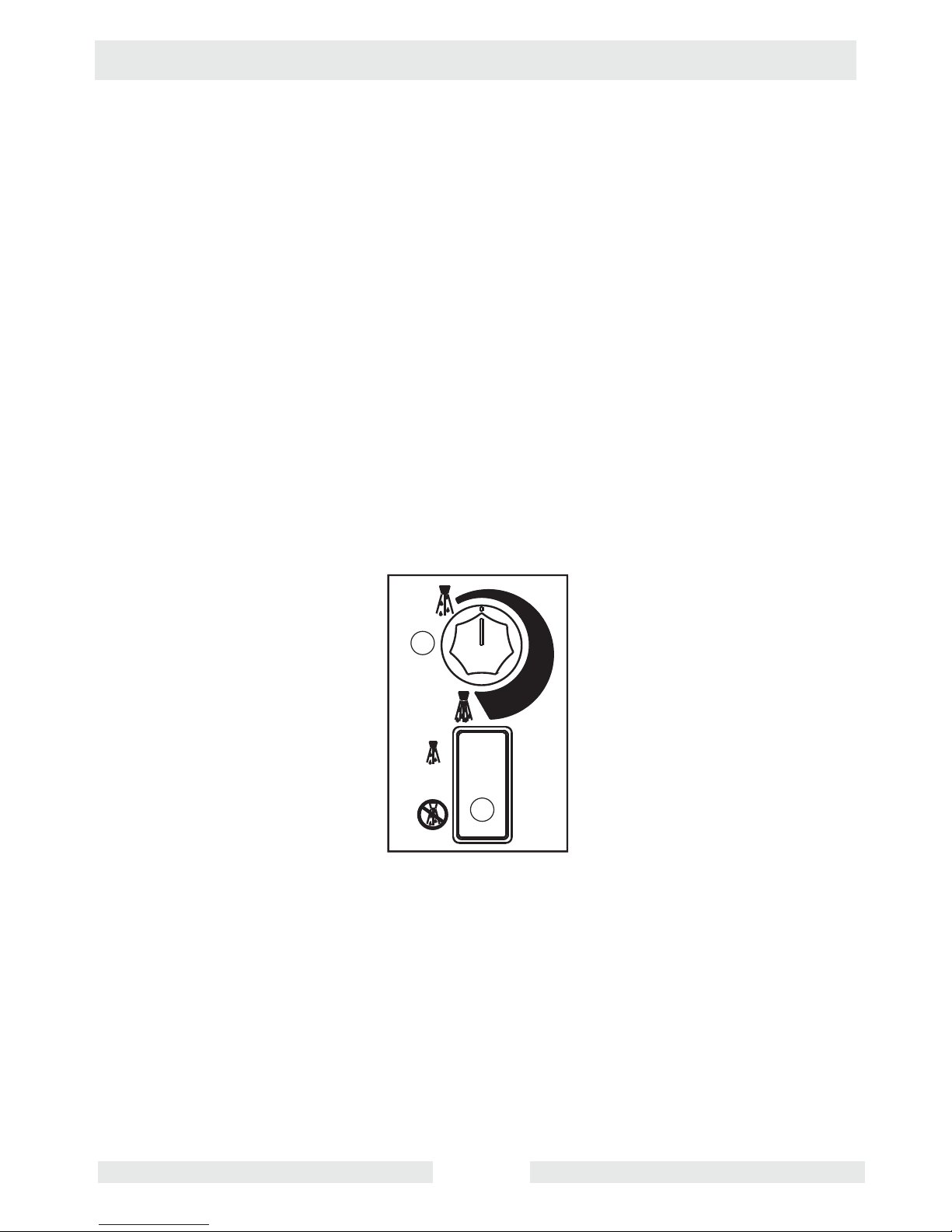

2.2 Control Panel

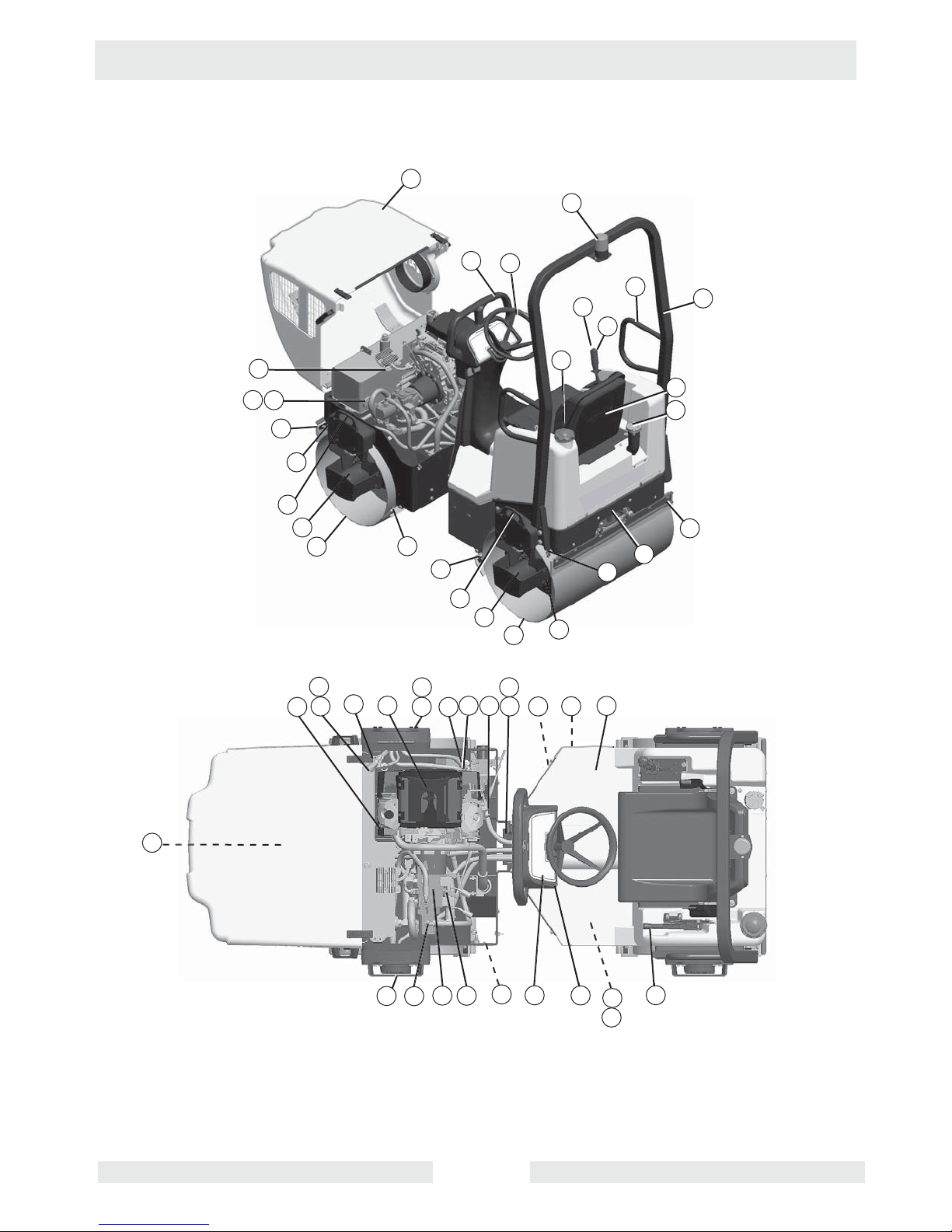

See Graphic: wc_gr004114

Ref. Description Ref. Description

47 Hour meter 55 Ignition switch

50 Vibration ON indicator 56 Low fuel indicator

53 Lights switch - ON and OFF

61 Water spray switch - ON and OFF

(if equipped)

54 Throttle switch - HIGH and LOW 62 Water spray dial

wc_tx000865gb.fm 24

RD 12/RD 12A Operation

62

61

50

47

56

53

54

55

wc_gr004114

wc_tx000865gb.fm 25

Operation RD 12/RD 12A

2.3 Vibration

See Graphic: wc_gr002955

The vibration is turned ON or OFF by a push button (10) located on the

forward/reverse control (15). Press the button to turn vibration ON;

press it again to turn it OFF. The vibration ON indicator (50) will light

when vibration is on. The vibration can be turned on while operating in

either forward or reverse and will remain on until it is turned off.

On the RD 16, select either the front drum vibration or dual drum

vibration by pressing the vibration switch (63) on the control panel.

CAUTION: If the machine has been turned off with the vibration on, the

vibration will come on as soon as the machine is restarted. Therefore,

for easier starting and to keep the surface finish smooth, be ready to

switch vibration off should it come on while cranking the engine.

Note: The vibration will remain on even when the forward/reverse

control (15) is in NEUTRAL. When operating on asphalt and in order

to keep the surface finish smooth, turn the vibration off before stopping

the roller.

50

63

10

15

wc_gr002955

N

F

R

wc_tx000865gb.fm 26

RD 12/RD 12A Operation

2.4 Water Spray System

See Graphic: wc_gr002946, wc_gr003638

Water from the tank is fed to the spray bars by an electric pump. The

flow of the water is controlled by a switch and a rotary dial.

Press the upper half of the water spray switch (61) to turn the water

pump on. Turn the water spray dial (62) clockwise to increase the

spray frequency. Turn the water spray dial counter-clockwise to

decrease the spray frequency. Press the lower half of the water spray

switch (61) to turn the water pump off.

Only use clean water. Dirty water, even when filtered, will rapidly clog

the tubes of the spraying equipment.

During winter, or when temperatures drop to below 0°C (32°F), drain

the water tank and spraying equipment. Run the water pump to

remove excess water from the system. Drain the water through the

water drain plug (41) located near the bottom of the rear frame,

through the sprayer end plugs, and the water filter. Freezing water may

cause broken hoses, filters and water pumps and may deform the

water tank.

62

61

wc_gr003638

wc_tx000865gb.fm 27

Operation RD 12/RD 12A

2.5 Starting

See Graphic: wc_gr002951

Exhaust gases are toxic. Do not start the engine in an enclosed space.

WARNING

2.5.1 Sit down in the operator’s seat and fasten the seat belt.

2.5.2 Set the forward/reverse control (15) in the neutral position.

2.5.3 If the engine is cold, move the choke lever (44) to the left into the

CLOSED position. If the engine is warm, move the choke control to the

right in the OPEN position.

Note: The roller will not start unless the forward/reverse control is in

the NEUTRAL position.

2.5.4 Check that the parking brake (42) is set. To set the brake, pull the

brake lever up until the brake pad engages the drum. To release the

brake lever, lower the lever. Always set the parking brake before

leaving the machine.

2.5.5 Turn the ignition switch (55) to start the engine. If the vibration indicator

light (50) is on, turn the vibration off by pressing the vibration control

button (10).

NOTICE: Do not crank the engine starter for more than 15 seconds at

one time. Longer cranking cycles could lead to starter damage.

Note: The ignition switch has an anti-rest art feature. If the engine does

not start, the switch will need to be turned to the OFF position before it

will allow the engine to be cranked again.

2.5.6 Gradually place the choke lever in the OPEN position as the engine

warms up. Allow the engine to warm up for a few minutes before

operating the roller.

2.5.7 Before moving the machine, release the parking brake by lowering the

brake lever.

2.5.8 Quickly press and release the upper half of the throttle switch (54) to

bring the engine to high throttle.

Prolonged exposure to high noise levels can damage your hearing.

Wear appropriate hearing protection while operating the roller.

WARNING

wc_tx000865gb.fm 28

RD 12/RD 12A Operation

N

54

44

55

F

10

15

42

R

wc_gr002951

wc_tx000865gb.fm 29

Operation RD 12/RD 12A

2.6 Stopping/Parking

See Graphic: wc_gr002953

2.6.1 Stop the machine on a flat surface with a suitable load bearing

capacity.

2.6.2 Turn the vibration off by pressing the vibration control button (10) on

the forward/reverse lever (15).

2.6.3 Press the water spray switch to the OFF position (61).

2.6.4 Set the forward/reverse control (15) to the NEUTRAL position.

2.6.5 Return the engine throttle to idle by pressing the lower half of the

throttle switch (54) and allow the engine to cool down.

2.6.6 Set the parking brake (42). To set the parking brake, pull the brake

lever up until the brake pad engages the drum. To release the brake,

lower the brake lever. Always set the parking brake before leaving the

machine.

Note: The parking brake engages the rear drum only.

2.6.7 Stop the engine by turning the ignition switch (55) to the OFF position.

If the vehicle constitutes a hazard or obstacle to traffic when parked, it

should be marked with signs, lights, and other warnings.

WARNING

If the machine must be parked on a sloping surface, chock the drums

with wedges to prevent any vehicle movement.

N

54

61

55

F

10

15

42

R

wc_tx000865gb.fm 30

wc_gr002953

Loading...

Loading...