Wachendorff Prozesstechnik GmbH & Co. KG

Industriestr. 7, D-65366 Geisenheim, Germany

Phone: 0 67 22 / 99 65 -20

Fax: 0 67 22 / 99 65 -78

E-Mail: wp@wachendorff.de

www.wachendorff-prozesstechnik.de

ETHSW50K

Industrial Unmanaged Fast Ethernet Switch

Operating and Installation Instructions

24.05.2019

Copyright by Wachendorff Prozesstechnik GmbH & Co KG, Industriestraße 7, D-65366 Geisenheim, Germany, Tel.: +49-6722/9965-20,

Fax: -78 All information is subject to change without notice, errors excepted.

Operating and Installation Instructions

Table of contents

1. Foreword .................................................................................................................................... 3

2. Safety instructions .................................................................................................................... 3

2.1 General information ............................................................................................................. 3

2.2 Intended Use ........................................................................................................................ 3

2.3 Qualified personnel .............................................................................................................. 3

2.4 Residual hazards ................................................................................................................. 3

2.5 Liability ................................................................................................................................. 3

2.5 CE conformity ...................................................................................................................... 3

3. Device description .................................................................................................................... 4

3.1 Specifications ....................................................................................................................... 4

4. Contents of the packaging ....................................................................................................... 5

5. Installation ................................................................................................................................. 6

5.1 Mechanical Installation ......................................................................................................... 6

5.1.1 Mounting on the DIN rail ............................................................................................... 6

5.2 Electrical Installation ............................................................................................................ 7

5.2.1 Connecting the power supply ....................................................................................... 7

5.2.2 Connection of the fail safe relay ................................................................................... 8

5.2.3

6. LED status indicators ............................................................................................................... 9

7. Configuration and settings ...................................................................................................... 9

7.1 Setting the DIP switches ...................................................................................................... 9

8. PIN assignment of the network connection ......................................................................... 10

9. Dimensions of the ETHSW50K series (in mm) ..................................................................... 11

10. Copyright ................................................................................................................................. 12

11. Exclusion of liability ............................................................................................................... 12

12. Other provisions and standards ............................................................................................ 12

13. Customer service and technical support .............................................................................. 12

Connecting the network devices ................................................................................... 8

- 2 - Stand: 24.05.2019

Operating and Installation Instructions

1. Foreword

Dear customer!

We thank you for your decision to use one of our products and congratulate you on this decision. The

Unmanaged Fast Ethernet Switch ETHSW50K from Wachendorff Prozesstechnik GmbH & Co. KG

can be used for numerous different applications. In order to make optimum use of the functional

variety of this device for you, please note the following: Every person entrusted with the

commissioning or operation of this device must have read and understood the operating

instructions and in particular the safety instructions!

2. Safety instructions

2.1 General information

To ensure safe operation, the device may only be operated in accordance with the information in the

operating and installation instructions. When used, the legal and safety regulations required for the

respective application must also be observed. This also applies analogously to the use of

accessories.

2.2 Intended Use

The ETHSW50K from Wachendorff is used to expand Ethernet networks and connect Ethernetcapable terminal devices. Any use beyond this is considered improper use.

The ETHSW50K must not be used as the sole means of averting dangerous conditions on

machines and systems. Machines and systems must be designed in such a way that faulty

states cannot lead to a situation that is dangerous for the operating personnel (e.g. by independent

limit switches, mechanical interlocks, etc.).

2.3 Qualified personnel

The ETHSW50K may only be used by qualified personnel, exclusively in accordance with the

technical data. Qualified personnel are persons who are familiar with the installation, assembly,

commissioning and operation of this device and who have a qualification corresponding to their

activity.

2.4 Residual hazards

The ETHSW50K corresponds to the state of the art and is safe to operate. The unit may present

residual hazards if used and operated improperly by untrained personnel. This manual refers to

residual hazards with the following symbol:

This symbol indicates that non-observance of the safety instructions may result

in danger to persons, serious physical injury or death and/or the possibility of

damage to property.

2.5 Liability

Liability is excluded for material and legal defects in this documentation, in particular for its

correctness, freedom from errors, freedom from third-party industrial property rights and copyrights,

completeness and/or usability - except in the case of intent or fraudulent intent.

2.5 CE conformity

The declaration of conformity is available from us. You are welcome to order them. Just call us.

- 3 - Stand: 24.05.2019

Operating and Installation Instructions

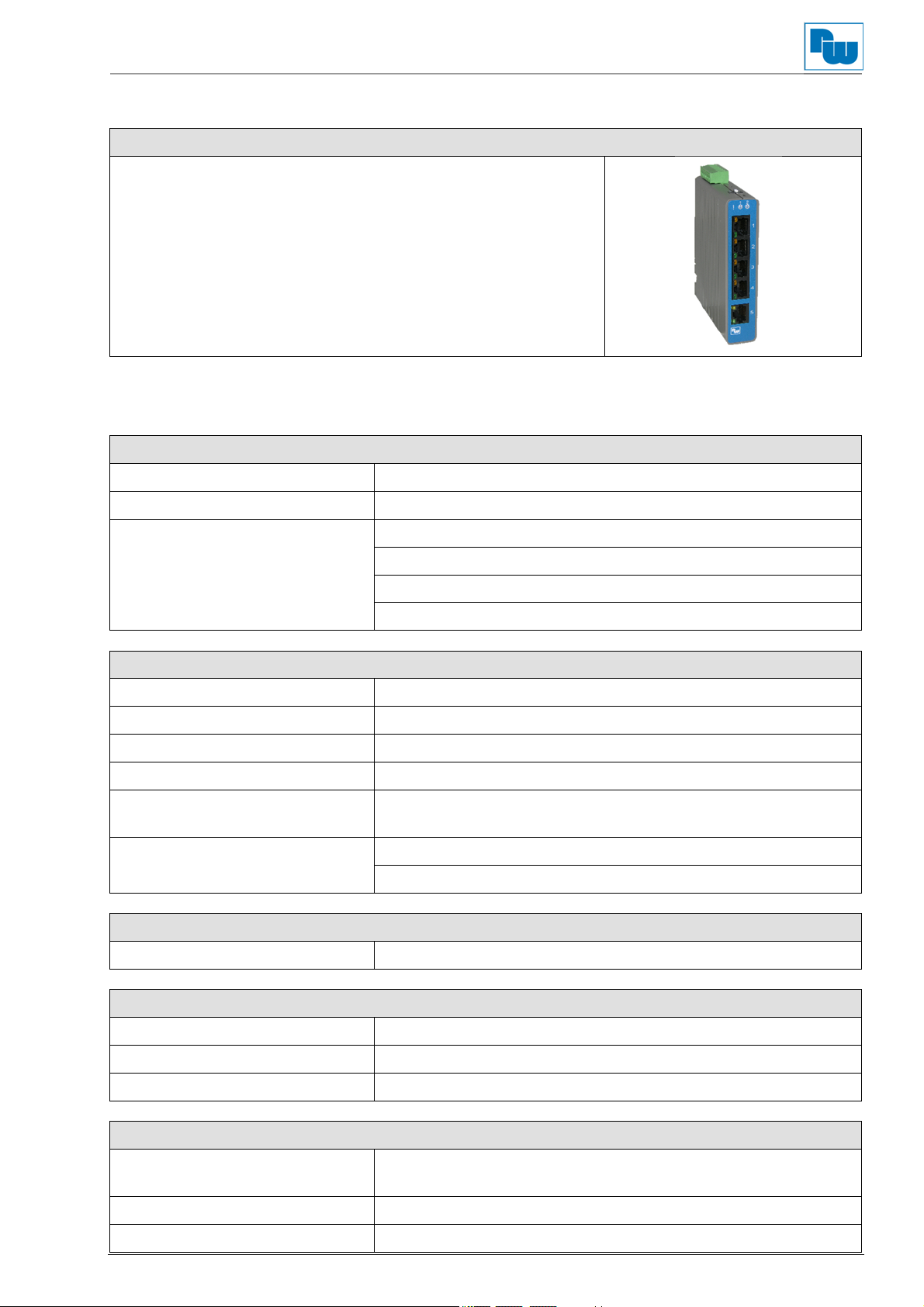

3. Device description

ETHSW50K

5 x 10/100BaseT(X)

Unmanaged / Plug and Play

IEEE 802.3, IEEE 802.3u, IEEE 802.3x

IEEE 802.3az: EEE (Energy Efficient Ethernet)

Broadcast- und Multicast-Flooding Storm Control

Redundant voltage input /

fault signal relay Output

Operating temperature -20 °C to +60 °C

Protection class IP30

3.1 Specifications

Technologies

Operating mode Store and Forward

Switching engine Wire-speed / non-blocking

Standards IEEE 802.3 (10BaseT)

IEEE 802.3u (100BaseTX)

IEEE 802.3az (EEE)

IEEE 802.3x (Full Duplex) and Back-Pressure (Half Duplex)

Interfaces

RJ45 - Ports (copper) 5x 10/100BaseT(X)

RJ45 - Speed Auto Negotiation (10/100 Mbps)

RJ45 - Duplex Half- or Full-Duplex

RJ45 - Connection MDI/MDIX Auto Crossover

Fault alarm contact Fault alarm relay for detection of power supply (normally

open, normally open, max. 1A / 24 VDC)

2 x DIP switches 1 x On/Off Power Alarm (fault signal contact) (DIP 1)

1 x On/Off Flooding Storm Control (DIP 2)

Features

MAC table size 1K

Display

1 x Alarm ALM: Power supply failure

2 x Power Status P1, P2: Power supply status

5 x Ethernet port status Link & Speed

Power supply

Execution Redundant input terminal strip plug, reverse power protection

(reverse polarity protected)

Voltage range 12 VDC to 58 VDC

Current consumption 30 mA at 48V, 25 °C, full load

- 4 - Stand: 24.05.2019

Operating and Installation Instructions

Environmental conditions

Operating temperature -20 °C to +60 °C

Storage temperature -40 °C to +85 °C

Air humidity 5 % to 95 % RH (non-condensing)

Norms and Standards

FCC/EMI FCC Part 15

CISPR 22 (EN55022), Class A

Vibration

Shock IEC60068-2-27

Free Fall IEC60068-2-32

CE (EMS) IEC61000-4-2

RoHS and WEEE RoHS (lead-free) and WEEE compliant

Housing

Degree of protection IP30

Execution

Dimensions (W x H x D) 25 mm x 113 mm x 97.38 mm

Weight 135 g

IEC60068-2-6

IEC61000-4-3

IEC61000-4-4

IEC61000-4-5

IEC61000-4-6

(Level 3)

Robust polycarbonate housing (plastic)

(with DIN rail holder)

Assembly DIN rail

4. Contents of the packaging

- Wachendorff ETHSW50K Industrial Fast Ethernet Switch unmanaged (1x)

- Terminal plug for external power supply (1x)

- Wachendorff Operating and Installation Instructions (1x)

- Device warranty card (1x)

- 5 - Stand: 24.05.2019

Operating and Installation Instructions

5. Installation

5.1 Mechanical Installation

5.1.1 Mounting on the DIN rail

The ETHSW50K is equipped with a DIN rail holder on the rear side. Please follow the steps below

for proper mounting on the DIN rail:

1. Tilt the module backwards with the top and press it onto the DIN rail. Align the

module straight.

2. Press the module down on the DIN rail until it is properly fixed on the rail. Then close

the lock on the underside by moving it upwards. The lock is correctly performed when

you hear and perceive a click.

2

Note: If the fixing clip has come loose from the holder, it must be reassembled as follows.

1

- 6 - Stand: 24.05.2019

Operating and Installation Instructions

5.2 Electrical Installation

5.2.1 Connecting the power supply

The ETHSW50K has a redundant voltage input. This ensures trouble-free operation in the event of

a power supply failure or a voltage supply failure. Please follow the steps below for proper connection:

Provide a suitable 12 to 58 VDC power source and connect it by tightening the screws

to the 6-pole terminal plug at the terminals provided for this purpose:

o P1: Primary power supply (+ / -)

o P2: Secondary power supply (+ / -)

Check the two power LEDs P1 and P2 on the device. The LEDs light up when a

connected power supply is active. The switch is ready for operation.

Warning: Before connecting the switch to the DC voltage, make sure that it complies with

the specifications.

P1

P2

Clamp P1 + P1 - P2 +

Signal

12 to 58 VDC 0 V 12 to 58 VDC

+

‐

A

L

M

+

‐

P2 -

0 V

- 7 - Stand: 24.05.2019

Operating and Installation Instructions

5.2.2 Connection of the fail safe relay

In addition to the redundant voltage input, the ETHSW50K has a fault signal relay for signalling a

fault. This ensures trouble-free operation and direct fault detection in the event of a power supply

failure or voltage supply failure. The fault signal relay is designed as a normally open contact.

For proper connection, please follow these steps:

Connect the corresponding signalling system to the connection terminals marked ALM (in the

middle of the 6-pole terminal plug, max. 1 A / 24 VDC).

Activate the fault message contact Power Alarm at PIN 1 of the DIP switch (ON).

P1

P2

+

‐

A

L

M

2

1

+

‐

Clamp ALM ALM DIP PIN 1

Connection to alarm

system

ON

Signal

Connection to alarm system

5.2.3 Connecting the network devices

The ETHSW50K has 5 x 10/100 Mbit/s ports with RJ45 connectors. At each port there are 2 LEDs

for signalling the operating mode (see chapter "6. LED status indicators"). Proceed as follows to

ensure proper functioning:

Connect your Ethernet network devices to your Fast Ethernet Switch using a

straight-through (standard patch cable) or cross-over (UTP Unshielded Twisted pair

/STP Shielded Twisted Pair) cable with RJ-45 connectors.

An LED associated with the port lights up after a successful link up depending on the

negotiated data rate.

The LED associated with the port flashes when data transmission is in progress.

- 8 - Stand: 24.05.2019

Operating and Installation Instructions

6. LED status indicators

There are three LED status indicators on the front panel of the ETHSW50K. In addition, each

RJ-45 port has 2 LED status indicators.

LED Indicator/Colour Description

P1

P2

Alarm

RJ-45 Ports

Port 1 to 5

Link/Activity

RJ-45 Ports

Port 1 to 5

Speed

On / green Primary power supply is active

Off Primary power supply not available

On / green Secondary power supply is active

Off Secondary power supply is not available

On / red Power supply failure

Off No power supply failure

On / green Ethernet link established (link up) / no data transmission

Flashing green Ethernet link established (link up) / data transmission

Off Ethernet link not established (link down)

On / yellow Ethernet link with 100 Mbit/s established

Off Ethernet link with 10 Mbit/s established or Ethernet link

7. Configuration and settings

(if power alarm is activated)

(if power alarm is activated)

not established (link down)

The ETHSW50K is an unmanaged and plug-and-play switch. The switchable Flooding Storm Control

function protects against unwanted allocation of the available transmission rate by Broad or Multicast

data frames. In addition, the ETHSW50K has a redundant voltage input and a fault relay for signalling

the fault of a power supply unit or a power supply.

7.1 Setting the DIP switches

Display

PIN 1 On Fault alarm contact Power Activate alarm

off Fault alarm contact Power Deactivate alarm

PIN 2 On Activate Flooding Storm Control

off Deactivate Flooding Storm Control

- 9 - Stand: 24.05.2019

Operating and Installation Instructions

8. PIN assignment of the network connection

RJ-45 to RJ-45, straight-through cable

PIN 1 2 3 4 5 6 7 8

Signal Tx + Tx Rx+ Rx

RJ-45, cross-over cable

PIN 1 2 3 4 5 6 7 8

Signal Rx+ Rx Tx + Tx

- 10 - Stand: 24.05.2019

Operating and Installation Instructions

9. Dimensions of the ETHSW50K series (in mm)

90,05

25,00

7,33

113,00

4,50

97,38

- 11 - Stand: 24.05.2019

Operating and Installation Instructions

10. Copyright

This document is the property of Wachendorff Prozesstechnik GmbH & Co.KG. Copying and

duplication are prohibited without prior permission. The contents of this documentation refer to the

device described therein.

11. Exclusion of liability

All technical content within this document is subject to change without notice. The content of the

document is the content of a recurring revision.

In the event of loss due to fire, earthquake, intervention by third parties or other accidents, or

intentional or accidental misuse or abuse, or use under abnormal conditions, repairs will be charged

to the user. Wachendorff Prozesstechnik is not liable for any accidental loss resulting from the use

or non-use of this product, such as loss of business profits.

Wachendorff Prozesstechnik is not liable for the consequences of improper use.

12. Other provisions and standards

FCC Conditions

This equipment has been tested and found to comply with Part 15, Class B of the FCC

Rules. Operation is subject to the following two conditions:

(1) This equipment may not cause harmful interference, which can cause harmful

interference to radio or television reception.

(2) This device must accept any interference received, including interference caused by undesired

operation.

WEEE Information

Disposal of old electrical and electronic equipment (valid in the European Union and other

European countries with separate collection system). This symbol on the product or on the

packaging means that this product must not be treated as household waste. Instead, this

product should be taken to the appropriate disposal point for recycling electrical and electronic

equipment. If the product is disposed of correctly, you help to prevent negative environmental

influences and damage to health that could be caused by improper disposal. The recycling of

materials will preserve our natural resources. For more information about recycling this product,

please contact your local Citizen Office, your household waste collection service or the store where

you purchased this product.

13. Customer service and technical support

For technical questions you can reach us under:

Industriestraße 7 - 65366 Geisenheim, Germany

Phone: +49 6722 9965-966

Fax: +49 6722 9965-78

E-mail: eea@wachendorff.de

Homepage: www.wachendorff-prozesstechnik.de

- 12 - Stand: 24.05.2019

Loading...

Loading...