TCE I / II

Central Electronic in

Trailers

815 000 375 3

2nd Edition

This publication is not subject to any update service.

New versions are available in INFORM at

www.wabco-auto.com

815 000 329 3

8150003293

© 2007 WABCO

Vehicle Control Systems

The right of amendment is reserved

Version 002/11.03(en)

8150100303 815 010 030 3

Table of contents

1 Objective

1.1 Concept and Implementation 4

2 General

2.1 External Communication Possibilities 5

2.2 Standards 6

3 Line connection Description

3.1 Functional overview 7

3.2 Electronics 446 122 00. 0 8

3.2.1 TCE top view with connector coding 9

3.3 System connections 10

4 Cable Overview 22

4.1 TCE connection system with connecting cable and PIN connection 15

4.1.1 Overview of plug-in connectors and corresponding cables 15

5 System Functions (acc. to terminals)

5.1 Brake lining wear indicator 37

5.2 Electrical Supply 39

5.2.1 Standardised motor vehicle plug-in connections 39

5.2.2 Supply 40

5.3 Diagnosis mode and warning light function 41

5.3.1 Gateway ISO 7638 / ISO 12098 Trailer data bus 41

5.3.2 warning light function 42

5.4 Freely programmable I/O (special modules) 42

5.4.1 Monitoring functions 42

5.5 Trailer EBS and RGE connection 42

5.5.1 Trailer EBS 42

5.5.2 RGE connection 43

5.6 Rear underdrive protection terminal 44

5.7 Ramp approach help 44

5.8 Paver brake 46

5.9 Electronically controlled air suspension (ECAS) in TCE 46

5.9.1 Components 47

5.9.2 Distance sensor(s) and trailer battery 51

5.10 Pneumatic components and installation instructions 57

6 Commissioning and Diagnosis 82

6.1 Commissioning and Diagnosis 59

6.1.1 The Calibration Process 59

7 PC - Diagnosis 23

7.1 Start- and diagnostic menu 62

7.2 Vehicle definition 63

7.2.1 Chassis & lighting 64

7.2.2 Special parameters 65

7.2.3 ECAS parameters 66

7.3 Special parameters 67

7.4 Axle load calibration 72

7.5 Switch positions / Outputs 72

7.6 Service management 73

7.7 System plate 73

7.8 End Of Line - Protocol 74

8. Annex 77

8.1 Abbreviations 78

8.2 Overview of Outline Drawings 79

2

Objective

TCE

1

In modern motor vehicles the onboard information for

drivers becomes more and more extensive. In future

drivers will be able to read information about truck and

trailer via a display on their dashboard They will get this

information via data buses, i.e. via communication

connections between different electronics having a CAN

interface. As a result the connected electronic systems

will be able to exchange, evaluate and further process

information. In future lighting on vehicles will also be

controlled via data buses and errors will be displayed in

trucks.

Trailers will be included in this exchange of information

via a 7-pin ABS/EBS plug connection acc. to ISO 7638

and in parallel via a 15-pin plug connection acc. to

ISO 12098. In both cases the data connection

corresponds to ISO 11992 part 1.

By a consequent use of the available data connections

between motor vehicle and trailer WABCO creates the

precondition for new innovative vehicle functions while

at the same time the number of the required electrical

connections is limited.

In summary the objectives are as follows:

System data bus in trailers

Integration of trailers into the motor vehicle

system

• Limitation of number of electrical connections

• Extension of the motor vehicle system functions

to trailers

Integration of trailer system functions

• Level control and lifting axle control

• Ramp approach help

• Lighting control

• Telematic connection

• Additional functions

TCE II

Modifications due to the introduction of TCE II are

marked in the following text in expanded type.

• New trailer system functions via data exchange

• More simple realisation of current system

functions

Telematics

Power 7 Pin ISO 7638

Power 15 Pin ISO 12098

IVTM - Integrated

Vehicle Tire

Monitoring system

TCE

ECAS

wear

Customer

functions

approach help

Lighting

Ramp

CAN

Trailer

Data

Diagnosis

EBS modulator

BUS

Brake lining

3

1

TCE

Objective

1.1 Concept and Realisation

As trailer central electronic TCE enables the

communication between motor vehicle and trailer res.

motor vehicle and trailer systems. Moreover TCE

supports the connection of intelligent individual systems

in trailers to a powerful system like in the towing vehicle.

TCE itself assumes the following electronic and

electrical functions:

Electrical supply of trailer systems including battery

supply and battery charging equipment. With a trailer battery diagnostic and ramp operations are possible without a motor vehicle.

Motor vehicle - trailer communication for brake and

”running gear“ systems (ISO 7638), as well as for

general vehicle systems (ISO 12098). ”Running

gear“ means components concerning the driving

safety, e.g. chassis, tires, steering and suspension.

Trailer data bus for EBS, running gear, tire systems

and vehicle systems with separate CAN connections. As a result an exchange of electrical consumers and transmission of information via data

connection is possible.

Future central diagnostic connection for TCE and

all systems connected via CAN. Future diagnosis

from the motor vehicle is provided (e.g. via an onboard display).

Brake lining wear sensing system with up to six

sensors.

In future reading and processing of analogue and

digital information will be possible.

e.g.

Programmable inputs and outputs for recording of

switch positions and analogue values, as well as for

controlling modulators and additional lighting. Individual customer modules will be created by

WABCO. These are adjustable via diagnosis.

Integrated electronic level control (ECAS) for semi-

trailers and trailers with one or two level sensors.

Integrated electronic lift axle control with automatic

functions as traction help, load dependent lowering

/ lifting and manoeuvring aid.

Ramp approaching help with automatic braking

when backing and approaching the ramp.

Electronically secured lighting control and monitor-

ing with status reports to the motor vehicle.

tire pressure recording and tire pressure monitoring

with connected IVTM system.

Service support (operating hours counter, mileage

counter, electronic notebook, battery hours counter).

ISO 7638 (5/7-pin.)

Green warning light

ISO 12098 (15/7-pin.)

Side marking and limiting lights

Diagnostic plug EBS

ABS wheel sensors

EBS

LA-Ventil

LF-Vent i l

DSENS

EBS

ABS wheel sensors

Brake lining wear sensors

DSENS2

WSENS2

WSENS1

DSENS1

Trailer battery

Brake lining wear sensors

Ultra sonic sensors

TCE

IVTM

BAT

Ultra sonic

sensor

Diagnostic

plug TCE

Remote remote control unit

4

General

)

TCE

2

The following data can be transmitted to the motor

vehicle provided the respective system is installed:

• Axle loads:

• Tire pressure values

• Status of vehicle lighting

• Distance to ramp

• Brake lining wear

• Status of ramp approach help RAH

• Lift axle status

Under same conditions as in the motor vehicle the

following data can be transmitted to a telematic system:

• Error in lighting

• Error in RAH function

• Vehicle stopped before ramp

• Service date achieved

• Vehicle overloaded

• Red /yellow/green warning light

• Axle load

• Tire pressure values

• Error in RAH function

• Vehicle hitched/unhitched

• Battery status

• Vehicle door open/closed

• Operating hours

• Mileage

• Brake lining wear

2.1 External Communication

Possibilities

When a telematic system is connected to the TCE

location of the vehicle resp. recall of vehicle specific data

is possible.

The following transmission systems can be used:

The Global Positioning System, shortly called

GPS, enables identification of the vehicle position.

The Global System for Mobile Communication

(GSM) enables wireless data transmission. Thus

remote diagnosis will also be possible in future.

The 'Short Range Communication' is only possible

in the yard near a correspond. transmitting / receiving station.

Satellite

Satellite

GPS

Global Positioning System

Short wave

Communication

(Blue Tooth, DECT, ..)

Local Server

Carrier owner

Fleet owners

Satellite

Satellite

GSM

Global System for

Mobile Communication

(D1, D2, ...)

z

h

M

0

0

9

z

h

M

0

0

8

1

z

h

M

z

3

h

3

4

M

8

6

8

Telecommunications

Company

ISDN

Internet

(TCP/IP)

Fleet Management

Carrier Park Management

Services Provider

WWW Server

Satellite Antenna

Data

5

2

TCE

General

The different systems may be used from trucks with

trailer connection or separately on trucks and on trailers

(e.g. for cooler and service information).

Thus the carrier resp. the controller can check for

instance position of the vehicle, temperature of the

cooling system and state of the vehicle. On short term

he may have the vehicle turned around and pick up

another load. In case of vehicle problems the controller

can inform a nearby repair shop in advance about the

vehicle state and can care for spare parts if required.

Telematic problems can only be corrected by the

respective telematic manufacturer in his service

repair shops.

2.2 Standards

TCE observes the following standards:

TCE II

Telematic systems in trucks and trailers can retrieve

more special information from the TCE II.

– event and profile data

– Service schedule

– Vehicle master data

Telematic systems in trailers will automatically be

informed on additional events

– Vehicle door open/closed

– Vehicle hitched/unhitched

– Tire pressure changes

– Service intervals etc.

– ISO 11992 defines data interfaces

between motor vehicles and trailers

• Part 1: Exchange of digital data between truck

and trailer

• Part 2: Application for brake and ”running gear“

of part 1

• Part 3: Application for all further systems of part

1 which were not considered in part 2

• Part 4: Diagnosis (in preparation)

– ISO 7638, 7-pin electrical truck-trailer

connection for braking and running gear

systems

• Chassis, tires and brake

• Use for lighting, superstructure control or similar

is expressly excluded.

– ISO 12098, 15-pin electrical truck-trailer

connection for lighting and superstructure

• Lighting, conventional lifting and steering axle

control

• Electrical supply and data connection for non

braking and ”running gear systems“

– Brake directive ECE-R13

• Supply of braking and running gear equipment

• Cut-off of running gear systems / Functions at

electrical overload

6

Line connection Description

3.1 Functional overview

Note:

TCE I/II is already fully operational, when except

connection to the motor vehicle only the EBS system is

connected, i.e. Ramp approaching help, ECAS, lighting,

tire pressure control and GPS/GSM do not need to be

installed resp. connected.

Bremse / Fahrwerk

Brake/running gear

Ramp approaching help

Rampenanfahrhilfe

TCE

3

Anhänger-

Trailer

+

batterie

battery

EBS

Brake lining wear sensors

Bremsbelagverschleißsensoren

ISO 7638 (7-pol.)

ISO 7638 (7-pin)

ISO 12098 (15-pol.), alternativ 24N/S

ISO 12098 (15-pin) alternative 24N/S

Diagnose

Diagnosis

IVTM

System zur Reifendrucküberwachung

TCE

TCE-

warning light

Warnlampe

(Integrated Vehicle Tire Monitor)

RGE input and output

RGE Ein- und Ausgangs-

expansion (control box)

erweiterung

RGE CAN Expansion

RGE CAN-Erweiterung

(Telematic connection)

(Telematikanschluss)

(Bedienbox)

TCE

X11

X12

X13

X14 X34X24

X31X21

X22 X42

X32

X23 X33

X41 X61

X43 X63X53

X44 X64X54

X51

X52

Pressure sensors

U

P

U

Operating

Bedienei nheit(en)

interfaces

Wegsensor(en)

Path sensors

X62

Not

occupied

Solenoid

Magnetventile

valves

Drucksensor(en)

P

Magnetventil für

Solenoid valve

Liftachssteuerung

for Lifting axle

control

Nicht

belegt

Verteiler

Lighting/superstructure systems

Beleuchtung / Aufbausysteme

Superstructure system -CAN Expansion

Aufbausystem - CAN-Erweiterung

Superstructure -additional lighting, Additional

Aufbau - Zusatzbeleuchtung, zusätzl. elektr.

Versorgung und Ein- und Ausgänge

electrical supply and Inputs and outputs

7

3

TCE

Line connection Description

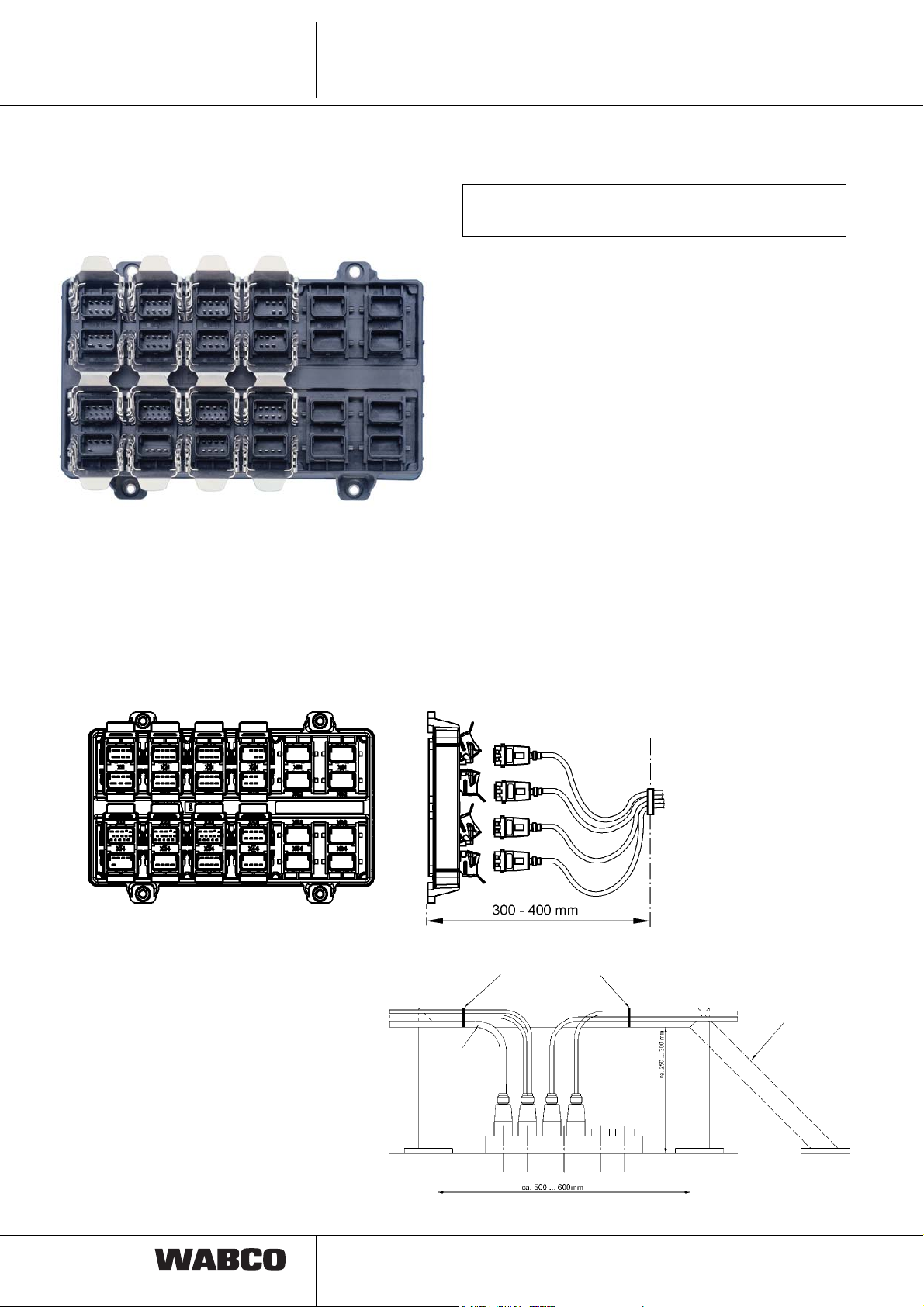

3.2 Electronic 446 122 000 0 /

446 122 001 0

Do not open the electronic remote control unit!

All terminals have to be closed.

All plug in connections are marked with an X and a

number and fitted with special locking clips. To connect

a cable, it is necessary to fold up the locking clip, push

in the plug and then close the locking clip.

Since the terminals are located very close, cables

should be plugged into the electronic in the order from

X11 to X41, X12 to X42, etc.

The front of the electronic consists of coded plug-in

terminals and thus is protected against interchange of

plugs. Unused terminals have to be closed by means of

cap 894 110 139 2.

Installation position:

Fixation to clip by means of cable binder or similar

In order to reverse the

cable back to the vehicle

frame the 45° solution

could be the better one.

Free cable

length to the

point of

fixation

approx.

300 mm

8

Line connection Description

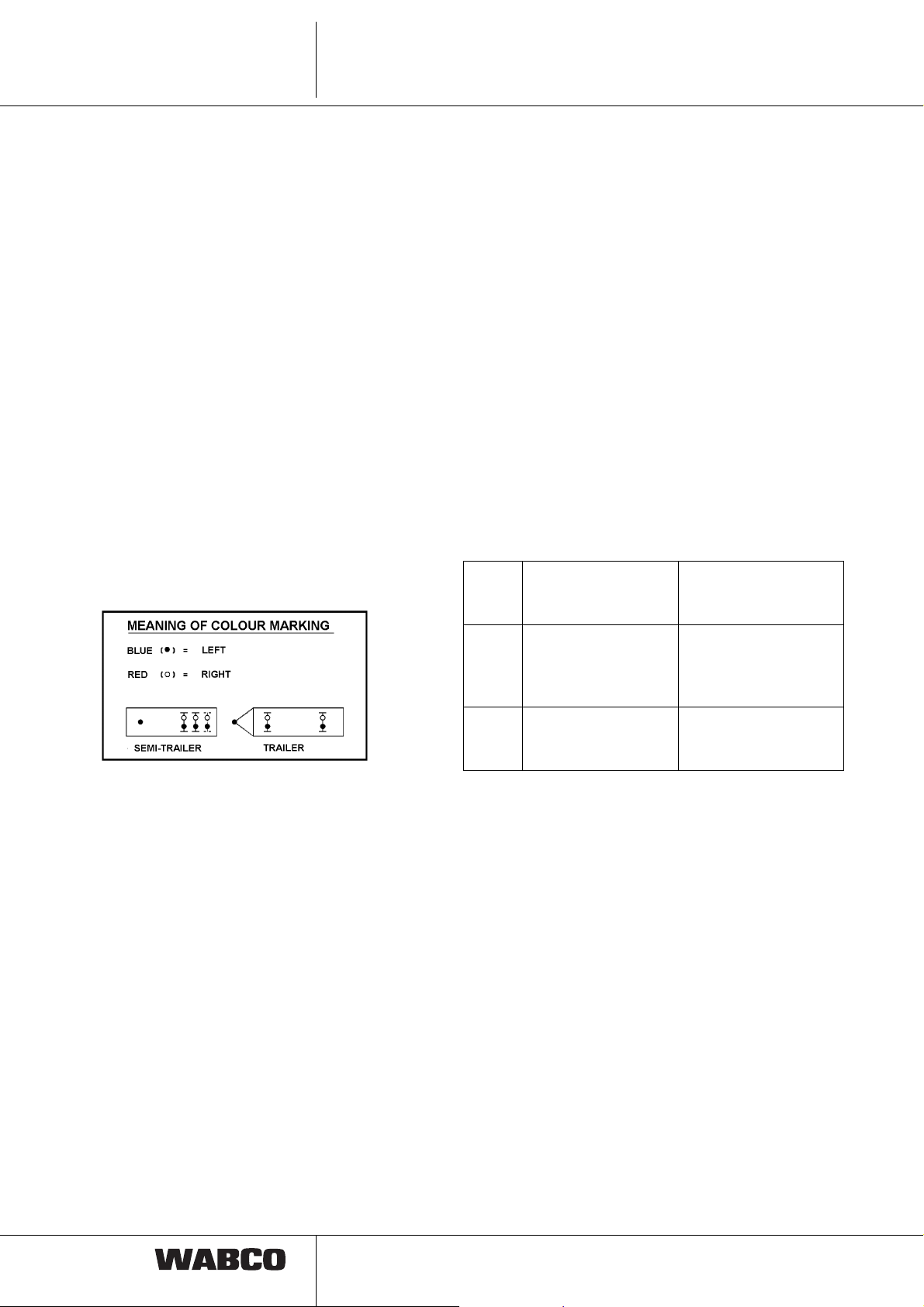

3.2.1 TCE Top View with connector coding

TCE

3

control unit

X41-Remote remote

help

X31-Ramp approaching

X21-RGE and I/O

6 5

3 2 1

Battery

X42-Height sensor

4 3 2 1

8 7 6 5

4 3 2 1

8 7 6 5

X32-IVTM and super-

structure CAN

X22-EBS and RGE CAN

4 3 2

8 7 6

4 3 2 1

8 7 6 5

4 3 2 1

8 7 6 5

X43-Solenoid valve

lighting

X33-Superstructure

X23-Lighting

4 3 2 1

8 7 6 5

1

2

12 11

13

9 7 6

4 3

1415

10 8

5

1

2

12 11

13

9 7 6

4 3

1415

10 8

5

X44-Pressure sensor

lighting

X34-Tank vehicle

X24-Side marking

8 7 6 5

4 3 2 1

8 7 6 5

8 7 6 5

X11-Brake lining wear

1

2

12 11

13

9 7 6

4 3

7 6 5

4 3 2 1

8 7 6 5

X12-ISO 7638 (7-pin)

4 3 2 1

X13-ISO 12098 (15-pin)

1415

10 8

5

2

X14-Diagnosis and

Warning lamp

3 2 14

8

9

3

TCE

Line connection Description

3.3 System connections

TCE terminals in numeric order

1. Row

Connection X11 (optional)

Brake lining wear sensors

Connection for up to six brake lining wear sensors or up

to six wear indicators (side wire). Brake lining wear

sensors measure the thickness of the brake lining only

when braking. If wear indicators are installed, thickness

of the brake lining is actualised in braked or unbraked

condition. For example, if for all indicators 0 Volt will be

measured, connector break will be identified.

The Y cable is colour marked. Below the connector there

is a red resp. blue stripe. The red marked plug belongs

to the right vehicle side, the blue marked plug to the

left side. Furthermore the axle assignment can be found

behind the plug (L1 = 1 axle on the left).

• corresponding TCE error (e.g. failure of EBS

modulator)

• Switch on of ignition (Pin)

• Interruption of ground connection

(Pin 3 and 4).

Connection X13

Motor vehicle connection acc. to ISO 12098

(15-pin)

Connection of power supply and lighting lines with data

connection acc. to ISO 12098 (15-pin). The data bus

contains information on lighting and superstructure

systems.

Plug-in pins 10, 11 and 12 are not controlled via PC

diagnosis. These can be parameterize per PC diagnosis

by means of special modules:

Pin 10

Pin 11

Pin 12

Pin 10

Pin 11

Pin 12

Pin 10,

11, 12

Brake lining sensor

not used

Axle lift

not used / steering

axle lock

Traction help

Axle lift

not controlled

according to

ISO 12098 / 1990

according to

ISO 12098 / 2000

New standard

Standard, if no trailer

or lift axle control from

the truck desired

Connection X12

Motor vehicle connection acc. to ISO 7638

Connection motor vehicle connection 7-pins (or 5-pins,

if there is no CAN-connection) acc. to ISO 7638 with

truck-trailer data connection acc. to ISO/ 11992 part 1

and 2.

Communication truck-trailer acc. to ISO 11992.

Support of the ABS module in trucks.

Monitoring of ground connections for break

Recognition of supply under or over voltage

Recognition of overload (current and voltage

measurement) and cut-off of running gear

Systems

Active control of trailer warning light (Pin 5) at:

10

Communication truck-trailer acc. to ISO 11992.

Support of trailer recognition via flashing and/or

brake light line

Maximum input impedance ≤ 2 kOhm.

Sensing/monitoring of lighting lines

Under / over voltage recognition of electrical supply

Truck-trailer data connection acc. to ISO 11992

part 1 and 3 (only with plug connection acc. to

ISO 12098)

Freely programmable inputs and outputs (special

modules; only with plug connection acc. to

ISO 12098)

Emergency supply of EBS via brake light, if

ISO 7638 interface has failed.

Line connection Description

TCE

3

Connection X14

Diagnostic connection:

Central connection for a diagnostic tool and optional

connection for a trailer warning light (green warning

light).

Diagnostic tool connection

The electrical power is supplied from ISO 7638

Pin 30 (Pin 1). Without a towing vehicle diagnosis

is enabled with a trailer battery. Raising/lowering

per remote remote control unit is also possible in

the diagnosis mode.

Connection of a warning light

An optional green warning light can be mounted to

the vehicle.

The electrical power is supplied from ISO 7638

Pin 30 (Pin 1).

Following display info is available:

Warning light status

– flashing: Display of general TCE errors

– on: trailer vehicle not within the

normal level

– off: vehicle within normal level

and without faults or ignition

switched off.

CAN communication via trailer data bus acc. to

ISO 11898 with 250 kBaud.

In case of interferences the external CAN data con-

nections can be cut off separately.

Information to connection X23/X24/X33/X34

Trailer lighting

Vehicle lighting left/right is protected separately in the

TCE.

Note:

Errors only appear when the lighting is actuated.

Connect all lights directly to the corresponding cable.

Cables must not be shortened or lengthened!

In order to avoid malfunctions during operation, the

maximum number of consumers must be observed.

Thus installation of an additional flashing light to the

underdrive protection is not allowed! At any rate the

manufacturer specifications must be observed.

Activation, control signal and electrical supply of trailer

lighting and extension for superstructure functions are

made via plug connection acc. to ISO 12098 (15-pin).

Electronic control / protection acc. to control sig-

nals via ISO 12098.

Error detection for short circuit and interruption,

when activated.

Connection X23

2. Row

Connection X21(optional)

Extension running gear / brake

Connection of 24 V-users and/or 24 V-Sensor analysis.

Power is supplied by means of motor vehicle plug

connection acc. to ISO 7638. Functional assignment is

programmable via special modules.

Note: Since the supply is made via ISO 7638, only such

systems/components may be connected, which either

belong to the vehicle brake or belong to ”running gear“

system!

The same concerns systems/components referring to

driving security, e.g. chassis, tires, steering, suspension

Connection X22

Trailer EBS & Running Gear-Systems

Connection of Trailer EBS and of an external Running

Gear Systems.

The electrical power is supplied from ISO 7638 Pin

(pin 1) with electronic overload protection.

Standard lighting rear underdrive protection

(Performance per vehicle side)

TCE I TCE II

Brake light 21 WA 2 x 21 W

Flashing light 21 WA 2 x 21 W

Rear light 30 W 30 W

(2 x10 W Rear light +

2 x 5 W Identification

light)

Reverse

light 21 W 2 x 21 W + 2 x 70 W each

Side with freely

adjustable parameters

Rear fog

light 21W 2 x 21 W per side

with parameters

adjustable

Position

lamps 2 x 10 W 2 x 10 W or LED’s

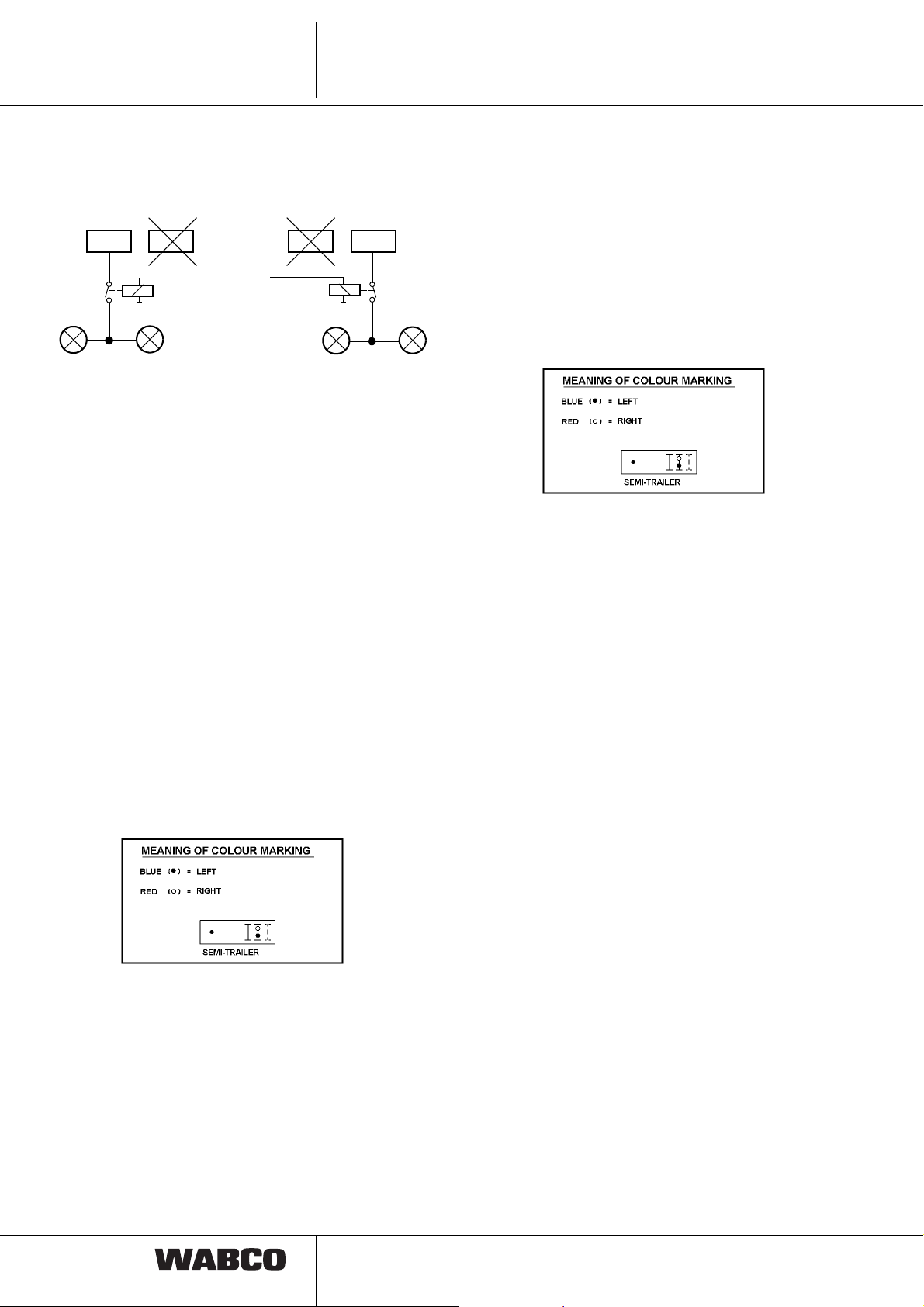

TCE I:

2 x 70 W reverse lights can be connected either to the

24 V outputs of X23 pin3 or to X33 pin 3. However, the

11

3

TCE

Line connection Description

load must only be connected to one of the plugs. A relay

is required between reverse light and the respective pin.

X23 X33 X23 X33

70 W

70 W

or

Reverse light

70 W

70 W

TCE II

Now also the connection of LED lamps to TCE II is

possible! Moreover the light failure recognition was

improved.

Via PC diagnosis the sensibility of the parameters for

cable break recognition can be set.

Standard setting: In the case of a failure of one of two

connected lights (e.g. brake light), this will not be

detected as an error.

Extended parameters: At this setting the failure of the

light with same or higher electrical power is detected.

No break recognition with light emitting diodes.

Electrical supply via separate 8 V power genera-

tion in the TCE, supplied via motor vehicle connection acc. to ISO 7638

Sending / receiving signal lines separately for each

sensor

The Y cable is colour marked. Below the connector there

is a red resp. blue stripe. The red marked plug belongs

to the right vehicle side, the blue marked plug to the

left side.

Connection X32 (optional)

Tire pressure monitoring IVTM & general vehicle

systems

Connection tire pressure monitoring and general vehicle

systems (no braking and running gear systems) with

CAN data connection.

Connection X24

Side marker lamp

The Y cable is colour marked. Below the connector there

is a red resp. blue stripe. The red marked plug belongs

to the right vehicle side, the blue marked plug to the

left side.

side marking lamps (25 W)

3. Row

Connection X31 (optional)

Ramp approaching help (RAH)

Connection of two ultrasonic sensors for measuring the

reverse distance between vehicle and ramp at backing.

General vehicle systems

Electrical supply for IVTM via ISO 7638; electrical

supply of general vehicle systems via ISO 12098

In the case of an error in the CAN communication,

it will be cut off separately (CAN connection)

Remark: Due to the electrical supply separated from

ISO 7638, the connected systems are not subject to the

overload cut-off for non braking systems.

Connection X33 (optional)

Additional lighting for superstructure like position

lamps and extensions for the superstructure

Connection of 24 V-users and/or 24 V-Sensor

analysis.

Functional assignment for freely programmable in-

puts and outputs is done via special modules of the

PC diagnosis.

12

Line connection Description

TCE

3

TCE II

Following functions may be activated via special

modules.

(Line)

normal level switch I / II PIN 7 white - green

Spring brake actuator

(ISO 11992) Pin 8 grey

Door open / closed Pin 9 white - blue

Hitched / unhitched Pin 10 white - black

normal level III / Unloading- Pin 13 red

level switch

Outputs are short circuit resp. overload protected

electrically, or by self reversion. Short circuit against

earth/power or a break is detected as error. 2 x 70 W

reverse lights can be connected either to X23 Pin 3 or

X33 Pin 3. However, the load must only be connected to

one of the plugs.

(See pict. connection X23, page 12).

Back lights (21 W)

Connection X34 (optional)

Additional lighting for tank vehicles

For high level lighting carriers with

X42: 1 or 2 level sensors (without temperature

compensation) and trailer battery

X43: Valves for 1 or 2 point control as well as lift

axle control

X44: 1 or 2 pressure sensors for axle load calcula-

tion

Connection X41

Control elements

As maximum two control elements can be connected.

By pushing button IRCU the TCE is activated (Pin 30 or

battery mode!).

For connecting two control elements a Y cable has to be

used. The Y cable is colour marked. Below the

connector there is a red resp. blue stripe. The red

marked plug leads to the second control element,

the blue marked plug to the first control element.

By means of a further plug connection between trailer

and tractor installation of a control element in the motor

vehicle is possible.

TCE I : A cable length of 25 m must not be exceeded.

TCE II : Cable lengths up to 60 m are permissible.

Brake lights (21 W)

Flashing lights (21 W)

Back lights (21 W)

The Y cable is colour marked. Below the connector there

is a red resp. blue stripe. The red marked plug belongs

to the right vehicle side, the blue marked plug to the

left side.

4. Row

Electronic level control

Electronic level control with following equipment :

X41: 1 or 2 remote control units (IRCU; Intelligent

Remote remote control unit)

Connection X42

Height sensor(s), trailer battery

A maximum of 2 height sensors can be connected to the

TCE. Here different configurations of the height sensor

arrangement are possible. This configuration is set by

means of parameters.

If only one height sensor is connected to the TCE, height

sensor 2 is active via the prefabricated cable In case of

two height sensors the plug marked with a blue

stripe is to be connected to the rear axle resp. to the

left height sensor (1

red stripe is to be connected to the front axle resp.

st

HS). The plug marked with a

13

3

TCE

Line connection Description

to the right height sensor (2nd HS). Otherwise

incorrect error display !!!

If a battery with battery box 446 156 090 0 (without

batteries), 446 156 094 0 (incl. batteries) is installed onto

the trailer, connect the prefabricated cable only.

Only lead gel accumulators may be used in the battery

box. WABCO recommend use of Panasonic LC R127R2PG lead gel accumulators, 12 V, 7,2 A.

If another box is used for the batteries, the plug of the

prefabricated cable has to be cut-off. The blue lead must

be connected to a 10 A fuse and the brown lead with the

earth pole of the battery.

Connection X43

Connection X44

Pressure sensor

TCE I:

A maximum of two pressure sensors can be connected

to the TCE. The 1

has to be connected. Among others is is used for axle

load calculation for the trailer EBS system.

st

pressure sensor (1st PS) always

TCE II

For the TCE II system it is not compulsory under certain

circumstances (dependent on the connected EBS

modulator) to connect one or two pressure sensors.

The required pressure sensor signal is directly sent from

the EBS modulator (D version) to the TCE II. If the ECAS

is to actuate a lateral or a drawbar trailer control, a

pressure sensor can be connected to the TCE.

If two pressure sensors are to be installed, the red

marked cable end is to be connected to the pressure

sensor (2

The blue marked cable end is to be connected to the

pressure sensor (1

axle.

nd

PS) to the right resp. to the front axle.

st

PS) to the left resp. to the rear

Valves 1-/2-point-control, lift axle valve

Levelling valves for semitrailers with 1- or 2- point

control (right/left), for drawbar trailers 2 point control

(front/rear). Lift axle valve(s) for one or two separately

controlled lift axle(s).

The plug marked blue leads to the lift/lower valve. The

plug marked red to the 1st lift axle valve.

14

Cable overview

4.1 The TCE plug in system with

connection cable and the

Pin assignment

Cables are supplied in different lengths. In the

following the different cable types and lengths are listed

and in column ”remark“ among others the components

to be connected. (Outline drawing see appendix).

4.1.1 Overview on terminals and the

respective cables:

Terminal X11:

Brake lining wear indicator

TCE-Electronic

TCE-Elektronik

X 11

X12 X 22 X 32 X 42 X 52 X 62

X 21 X 31 X 41 X 51 X 61

TCE

4

X 13 X 23 X 33 X 43 X 53 X 63

X 14 X 24 X 34 X 44 X 54 X 64

449 874 ...0

Used

Cable

449 874 010 0

L = 1 m

Plug

R1-2 / L1-2

R-1 „A“ +5 V 1 Brake lining

R-1 „C“ Ground 2 + 5 V

L-1 „A“ + 5 V 3 Ground

L-1 „C“ Ground 4 Brake Lining

see:

Drawing

449 874 000 0 Limit value indicator,

Assignment Plug

Remark

one axle 2x1

for PAN 17: 12480038

for PAN 19-1:

12480036 **)

Assign-

A

ment

wear R

wear L

Distributor not measurable, since with W network

**) Knorr brake to BPW axle 32480057

15

4

449 884 ... 0

TCE

Cable overview

Used

Cable

449 884 023 0

L

= 1 m

1

L

= 0.4 m

2

see:

Drawing

449 884 000 0 Limit value indicator,

Remark

two axles 2x2

for PAN 17: 12480038

for PAN 19-1:

12480036 **)

449 894 ... 0

Plug

R1-2 / L1-2

R-2 „A“ + 5 V 1 Brake lin. w. R1

R-2 „C“ Ground 5 Brake lin. w. R2

R-1 „A“ + 5 V 2 + 5 V

R-1 „C“ Ground 3 Ground

L-1 „C“ Ground 3 Ground

L-1 „A“ + 5 V 2 + 5 V

L-2 „C“ Ground 4 Brake lin. w. L1

L-2 „A“ + 5 V 8 Brake lin. w. L2

Distributor not measurable, since with W network

Used

Cable

449 894 023 0

L

= 1 m

1

L

= 0.4 m

2

449 894 043 0

L

= 1 m

1

L

= 1 m

2

Assignment PlugAAssignment

see:

Drawing

449 894 000 0 Limit value indicator,

Remark

three axles 2x3

for PAN 17: 12480038

for PAN 19-1:

12480036 **)

16

Plug

R1-3 / L1-3

R-3 „A“ + 5 V 1 Brake lin. w. R1

R-3 „C“ Ground 5 Brake lin. w. R2

R-2 „A“ + 5 V 6 Brake lin. w. R3

R-2 „C“ Ground 2 + 5 V

R-1 „A“ + 5 V 3 Ground

R-1 „C“ Ground

L-1 „A“ + 5 V

L-1 „C“ Ground 3 Ground

L-2 „A“ + 5 V 2 + 5 V

L-2 „C“ Ground 4 Brake lin. w. L1

L-3 „A“ + 5 V 8 Brake lin. w. L2

L-3 „C“ Ground 7 Brake lin. w. L3

Distributor not measurable, since with W network

Assignment PlugAAssignment

Terminal X12: Supply cable

TCE-Electronic

TCE-Elektronik

X 11

X12 X 22 X 32 X 42 X 52 X 62

X 13 X 23 X 33 X 43 X 53 X 63

X 14 X 24 X 34 X 44 X 54 X 64

X 21 X 31 X 41 X 51 X 61

449 172 ... 0

Cable overview

Used

Cable

449 172 090 0

L = 9 m

449 172 100 0

L = 10 m

449 172 120 0

L = 12 m

449 172 130 0

L = 13 m

449 172 150 0

L = 15 m

TCE

see:

Drawing

449 172 000 0 ABS/EBS

Remark

Power supply

cable

ISO 7638 (7-pin)

from

semi trailer

to motor vehicle

4

Plug A Plug B

449 272 ... 0

449 133 ... 0

Plug

A

17 red Pin 30

26black Pin 15

34yellow Ground 15

45brown Ground 30

53white Warning light

62white/green CAN H

71white/brown CAN L

Used

Cable

449 272 090 0

L = 9 m

Plug

B

see:

Drawing

449 272 000 0 ABS/EBS

Colour Assignment

Remark

Supply cable to

ISO 7638

(7-pin) from

drawbar trailer

to motor vehicle

Plug A Plug B

Used

Cable

449 133 120 0

L = 12 m

see:

Drawing

449 133 000 0 ABS/EBS

Remark

Power supply

cable with

bayonet connection

17

4

449 135 ... 0

TCE

Cable overview

Plug A Plug B

449 333 ... 0

Plug A Plug B

Used

Cable

449 135 005 0

L = 0,5 m

Plug

A

17 red Pin 30

26black Pin 15

34yellow Ground 15

45brown Ground 30

53white Warning light

62white/green CAN H

71white/brown CAN L

Used

Cable

449 333 003 0

L = 0,3 m

see:

Drawing

449 135 000 0 Power supply cable

Plug

B

see:

Drawing

449 333 000 0 Power supply cable

Remark

for semitrailer with

bayonet terminal

Colour Assignment

Remark

for semitrailer /

drawbar trailer

with bayonet

counterpart to

449 133 ... 0

449 335 ... 0

Plug A Plug B

Plug

A

11white/brown CAN L

22white/green CAN H

33white Warning light

44yellow Ground 15

55brown Ground 30

66black Pin 15

77 red Pin 30

Used

Cable

449 335 110 0

L = 11 m

449 335 140 0

L = 14 m

Plug

B

see:

Drawing

449 335 000 0 Power supply cable

Colour Assignment

Remark

for semitrailer

with bayonet

counterpart to

449 135 ... 0

18

Terminal X13: Supply

TCE-Electronic

TCE-Elektronik

X 11 X 21 X 31 X 41 X 51 X 61

X12 X 22 X 32 X 42 X 52 X 62

X 13 X 23 X 33 X 43 X 53 X 63

X 14

X 24 X 34 X 44 X 54 X 64

449 113 ... 0

Cable overview

Used

Cable

449 113 100 0

L = 10 m

449 113 120 0

L = 12 m

449 113 140 0

L = 14 m

TCE

see:

Drawing

449 113 000 0 Power supply cable

Remark

Adapter from 15 pin

to 2 x 7 pin (24 N/S)

may be used

4

Plug B Plug A

Plug

A

1 8 pink Backing light

2 3 blue Rear fog light

3 9 orange Supply Ub

4 4 white/red Ground (GND 3)

5 white Ground (GND 2)

6 15 white/brown CAN_Low

7 14 white/green CAN_High

8 10 grey Brake lining wear

9 12 white/blue Lifting Axle

10 11 white/black Pressure sensor

11 5 black Back light left

12 6 brown Back light right

13 7 red Brake light

14 2 green Turn signal right

15 1 yellow Turn signal left

Plug

B

Colour Assignment

(pin 30-2)

449 121 ... 0

Used

Cable

449 121 120 0

L = 12 m

see:

Drawing

449 121 000 0 Power supply

Remark

cable

for Aspöck

2 x 7 pin to 15 pin

Terminal

19

4

449 123 ... 0

TCE

Cable overview

449 311 ... 0

Plug B

Plug A

Used

Cable

449 123 120 0

L = 12 m

Used

Cable

449 311 120 0

L = 12 m

Plug assignment see page 19

see:

Drawing

449 123 000 0 Power supply

see:

Drawing

449 311 000 0 Power supply

Remark

cable

for

drawbar trailer

Remark

cable

for Hella

Plug adapter

20

2

Terminal X14: Diagnosis

TCE-Electronic

TCE-Elektronik

X 11 X 21 X 31 X 41 X 51 X 61

X12

X 22 X 32 X 42 X 52 X 62

Cable overview

TCE

4

X 13 X 23 X 33 X 43 X 53 X 63

X 14

449 672 ... 0

Plug B

449 644 ... 0

X 24 X 34 X 44 X 54 X 64

Plug A

Plug A

Used

Cable

449 672 030 0

see:

Drawing

449 672 000 0 Diagnostic cable

L = 3 m

449 672 040 0

L = 4 m

449 672 060 0

L = 6 m

449 672 080 0

L = 8 m

449 672 090 0

L = 9 m

Plug

A

Plug

B

14 K wire

21 Supply

37 Ground

Used

Cable

449 644 196 0

L

= 10 m

1

L

= 4 m

2

see:

Drawing

449 644 000 0 Y diagnostic cable

Remark

with terminal

for connection cable

446 300 329 2

( 6 m long ) to

Diagnostic Interface

Set 446 301 021 0

Assignment

Remark

with terminal

for connection cable

446 300 329 2

( 6 m long ) to

Diagnostic Interface

Set 446 301 021 0

and warning light

cable with green

warning light:

446 105 521 2 (cable

with plug

441 032 312 2)

Plug B

Plug

A

Plug

B

Assignment

4 Ground

8 warning light

14 K wire

21 Supply

37 Ground

2

21

4

TCE

Cable overview

Terminal X21: I/O Typ, Erweiterung

TCE-Elektronik

TCE-Electronic

X 11

X12

X 21

X 22

X 31 X 41 X 51 X 61

X 32 X 42 X 52 X 62

X 13

X 14

449 902 ... 0

X 23

X 24

X 33 X 43 X 53 X 63

X 34 X 44 X 54 X 64

Plug A

Used

Cable

449 902 050 0

L = 5 m

see:

Remark

Drawing

449 902 000 0 RGE

special functions

449 902 070 0

L = 7 m

Plug

Colour Assignment

A

1 white/green Supply 2

2 purple Digital inlet 2

3 yellow Digital inlet 1

4 green Supply 1

5 brown Ground

6 black Digital inlet 4

7 white Digital inlet 3

8 white/brown Ground

449 903 ... 0

Plug B Plug A

Used

Cable

449 903 050 0

see:

Drawing

449 903 000 0 for ECAS control box

L = 5 m

449 903 090 0

L = 9 m

Plug

A

Plug

B

24 Inlet 2

33 Inlet 1

41 Supply

52 Ground

75 Inlet 3

Remark

446 156 000 0

Assignment

22

Terminal X22: Cable to Trailer EBS

TCE-Elektronik

TCE-Electronic

X 11

X12

X 31 X 41 X 51 X 61

X 21

X 32 X 42 X 52 X 62

X 22

Cable overview

TCE

4

X 13

X 14

449 399 ... 0

Plug B Plug A

449 394 ... 0

Plug B

X 33 X 43 X 53 X 63

X 23

X 34 X 44 X 54 X 64

X 24

Plug A

Used

Cable

449 399 020 0

see:

Drawing

449 399 000 0 to EBS trailer

L = 2 m

Plug

A

Plug

B

15 Ground

27 Supply

51 CAN L

82 CAN H

Used

Cable

449 394 346 0

L

= 2 m

1

L

= 15 m

2

see:

Drawing

449 394 000 0 to EBS trailer

449 394 366 0

L

= 2 m

1

L

= 18 m

2

449 394 386 0

L

= 2 m

1

L

= 20 m

2

Remark

modulator

480 102 002 0

Assignment

Remark

modulator

480 102 002 0

and RGE with CAN

(telematic)

Plug

A

Plug

B

Colour Assignment

15 Ground

27 Supply

51 CAN L

62 CAN H

3

4 red Supply

7 blue CAN L

open

brown Ground

8 yellow CAN H

23

4

TCE

Terminal X23: Standard lighting

TCE-Elektronik

TCE-Electronic

X 11

X12

X 31 X 41 X 51 X 61

X 21

X 32 X 42 X 52 X 62

X 22

Cable overview

X 13

X 14

449 392 ... 0

Plug B

X 33 X 43 X 53 X 63

X 23

X 34 X 44 X 54 X 64

X 24

Plug A

Used

Cable

449 392 075 0

L = 7.5 m

see:

Remark

Drawing

449 392 000 0 at the underdrive

protection

(lighting carriers of

Hella, Aspöck, etc.)

PlugAPlug

Colour Assignment

B

110 pink Turn signal right

213 blue Turn signal left

315orange Supply

412white/red Ground

59 white Back light left

61white/brown Brake light right

75white/green Brake light left

811 grey Rear fog light right

93white/blue Rear fog light left

10 6 white/black Back light right

11 14 black Special modules

12 2 brown Back light right

13 7 red Position light

(Britax) right

14 8 green Position light

(Britax) left

15 4 yellow Back light left

449 391 ... 0

24

Used

Cable

449 391 120 0

L = 12 m

see:

Remark

Drawing

449 391 000 0 at the underdrive

protection

(for Aspöck lighting)

Terminal X24:

Side marking lights

TCE-Elektronik

TCE-Electronic

X 11

X12

X 21

X 22

X 31 X 41 X 51 X 61

X 32 X 42 X 52 X 62

Cable overview

TCE

4

X 13

X 14

449 904 ... 0

Plug B

X 33 X 43 X 53 X 63

X 23

X 34 X 44 X 54 X 64

X 24

Plug A

Used

Cable

449 904 190 0

L

= 4 m

1

L

= 4 m

2

449 904 253 0

L

= 6 m

1

L

= 6 m

2

see:

Remark

Drawing

449 904 000 0 with terminal (Pritax)

e.g. side marker flat

band of Hella, etc.

Plug D

Plug

A

Plug

B

PlugDColour Assignment

51 brown Side marking

lights right

62 black Ground

71black Ground

82brown Side marking

lights left

25

4

TCE

Cable overview

Terminal X31: Ultrasonic sensors

TCE-Elektronik

TCE-Electronic

X 11 X 21

X12 X 22

X 41 X 51 X 61

X 31

X 42 X 52 X 62

X 32

X 13 X 23

X 14 X 24

449 704 ... 0

Plug D

Plug B

X 43 X 53 X 63

X 33

X 44 X 54 X 64

X 34

Plug A

Used

Cable

449 704 253 0

L

= 6 m

1

L

= 6 m

2

see:

Remark

Drawing

449 704 000 0 two

ultra sonic sensors

446 122 400 0

Ram buffer

449 704 295 0

L

= 8 m

1

L

= 8 m

2

Plug

A

Plug

B

Plug

897 534 510 2

Assignment

D

14Signal inlet 2

21Supply 8 V

32Ground

53Signal outlet 2

21 Supply 8 V

32 Ground

43 Signal inlet 1

84 Signal outlet 1

26

Terminal X32:

Tire pressure monitoring IVTM and

superstructure system connection

TCE-Elektronik

TCE-Electronic

X 11 X 21

X12 X 22

X 31

X 32

X 41 X 51 X 61

X 42 X 52 X 62

Cable overview

TCE

4

X 13 X 23

X 14 X 24

449 302 ... 0

Plug B

X 33

X 34

X 43 X 53 X 63

X 44 X 54 X 64

Plug A

Used

Cable

449 302 015 0

L

= 1.5 m

1

Plug

A

see:

Drawing

449 302 000 0 IVTM

Plug

B

33 Ground

47 Supply

71 CAN L

86 CAN H

Remark

(Integrated Vehicle

Tire Monitor)

Assignment

449 301 ... 0

Used

Cable

449 301 150 0

L

= 15 m

1

see:

Remark

Drawing

449 301 000 0 superstructure

systems

CAN extension

(General vehicle

systems, e.g. chillers,

global positioning

system GPS, no

braking or running

gear systems)

Plug

Colour Assignment

A

1 brown Ground

2 red Supply

5 blue CAN L

6 yellow CAN H

27

4

449 304 ... 0

TCE

Cable overview

Used

Cable

449 304 098 0

L

= 15 m

1

L

= 1.5 m

2

see:

Drawing

449 304 000 0 Tire pressure

Remark

monitoring and

superstructure

system CAN

extension

Plug B

Plug A

Plug

A

1

2 red Supply

5 blue CAN L

6 yellow CAN H

33 Ground

47 Supply

71 CAN L

86 CAN H

Plug

B

open

Colour Assignment

brown Ground

28

Terminal X 33: Extended lighting

TCE-Elektronik

TCE-Electronic

X 11 X 21

X12 X 22

X 41 X 51 X 61

X 31

X 42 X 52 X 62

X 32

Cable overview

TCE

4

X 13 X 23

X 14 X 24

449 393 ... 0

X 43 X 53 X 63

X 33

X 44 X 54 X 64

X 34

Plug A

Used

Cable

449 393 075 0

L = 7.5 m

449 393 085 0

see:

Remark

Drawing

449 393 000 0 additional lighting

e.g. for luggage

superstructure

L = 8.5 m

449 393 100 0

L = 10 m

Plug

Colour Assignment

A

1 pink Analogue inlet 2

2 blue Analogue inlet 1

3 orange Supply

4 white/red Ground

5 white 24 V outlet

6 white/brown Analogue inlet 3

7 white/green normal level switch I/II

8 grey Spring-type brake actuator

9 white/blue Vehicle door open/closed

10 white/black Hitched / unhitched

11 black C3 Outlet

12 brown Digital inlet 6

13 red

normal level III/

Unloading Level

14 green Back light right

15 yellow Back light left

29

4

TCE

Cable overview

Terminal X 34: Additional lighting

TCE-Elektronik

TCE-Electronic

X 11 X 21

X12 X 22

X 41 X 51 X 61

X 31

X 42 X 52 X 62

X 32

X 13 X 23

X 14 X 24

449 604 ... 0

X 43 X 53 X 63

X 33

X 44 X 54 X 64

X 34

Plug A

Used

Cable

449 604 316 0

L

= 10 m

1

L

= 10 m

2

Plug

A

1

5 green Turn signal right

2 brown Ground

see:

Remark

Drawing

449 604 000 0 Additional lighting

e.g. for tank vehicles

Cable

Colour Assignment

marking

yellow Back light right

RED

6 red Brake light right

4

8 green Turn signal left

3 brown Ground

BLUE

yellow Back light left

7 red Brake light left

30

Terminal X 41: ECAS Remote remote

control unit IRCU

TCE-Electronic

TCE-Elektronik

X 11 X 21 X 31

X12 X 22 X 32

X 13 X 23 X 33

X 14 X 24 X 34

X 41

X 42

X 43

X 44

X 51 X 61

X 52 X 62

X 53 X 63

X 54 X 64

449 635 ... 0

Cable overview

Used

Cable

449 635 050 0

L = 5 m

449 635 070 0

L = 7 m

TCE

see:

Drawing

449 635 000 0 one ECAS remote

Remark

remote control unit

IRCU

(Intelligent Remote

remote control unit)

446 056 202 0

4

Plug B

449 634 ... 0

Plug D

Plug A

Plug

A

Plug

B

Colour Assignment

13yellow Clock

21 red Supply

32brown Ground

54green Data 2

Used

Cable

449 634 232 0

L

= 5 m

1

L

= 5 m

2

449 634 239 0

L

= 18 m

1

L

= 5 m

2

see:

Remark

Drawing

449 634 000 0 two ECAS remote

remote control

units IRCU

(Intelligent Remote

remote control unit)

446 056 202 0

449 634 278 0

L

= 15 m

1

L

= 7 m

2

449 634 316 0

L

= 10 m

1

L

= 10 m

2

Plug B

Plug A

Plug

A

Plug

B

PlugDColour Assignment

13yellow Clock

21red Supply

32brown Ground

54green Data 2

13 yellow Clock

21 red Supply

32 brown Ground

64 green Data 1

31

4

449 654 ... 0

Plug D

TCE

Cable overview

Used

Cable

449 654 232 0

L

= 5 m

1

L

= 5 m

2

449 654 252 0

L

= 5 m

1

L

= 6 m

2

see:

Drawing

449 654 000 0 one ECAS remote

Remark

remote control unit

IRCU

and

one ECAS control

box

Plug B

449 655 ... 0

Plug A

Plug

A

13yellow Clock

21red Supply

32brown Ground

54green Data 2

13 yellow Clock

21 red Supply

32 brown Ground

64 green Data 1

26 Pin 15

Used

Cable

449 655 050 0

L = 5 m

Plug

B

PlugDColour Assignment

see:

Drawing

449 655 000 0 one ECAS control

Remark

box

32

Plug APlug B

Plug

A

13yellow Clock

21 red Supply

32brown Ground

54green Data 2

26 Pin 15

Plug

B

Colour Assignment

Terminal X42:

Height sensor and battery box

TCE-Elektronik

TCE-Electronic

X 11 X 21 X 31

X12 X 22 X 32

X 41

X 42

X 51 X 61

X 52 X 62

Cable overview

TCE

4

X 13 X 23 X 33

X 14 X 24 X 34

449 814 ... 0

Plug D

Plug B

X 43

X 44

X 53 X 63

X 54 X 64

Plug A

Used

Cable

449 814 228 0

L

= 3 m

1

L

= 5 m

2

449 814 272 0

L

= 5 m

1

L

= 7 m

2

449 814 292 0

L

= 5 m

1

L

= 9 m

2

Plug

A

see:

Remark

Drawing

449 814 000 0 one height sensor

441 050 012 0 and

battery box:

446 156 090 0

without 7.2 AH lead

gel battery.

446 156 094 0 with

batteries

Plug

PlugDColour Assignment

B

21 height sensor

32 Ground

61blue battery switch

72brown Ground

449 804 ... 0

Plug D

Plug B

Plug E

Plug A

Used

Cable

449 804 228 0

L

= 3 m

1

L

= 5 m

2

see:

Remark

Drawing

449 804 000 0 two height sensors

441 050 012 0 and

one battery box

446 156 090 0 without

7,2 AH lead gel

battery.

446 156 094 0 with

batteries

Plug

Assignment PlugAColourAssignme

B, D, E

D 1 Height

Sensor 2

2 Height

Sensor 2

D 2 Ground 3 Ground

B 1 Height

Sensor 1

4 Height

Sensor 1

B 2 Ground 3 Ground

E 1 Battery 6 blue Battery

E 2 Ground 7 brown Ground

nt

33

4

TCE

Terminal X 43:

Solenoid valve, 1-/2 point control

TCE-Elektronik

TCE-Electronic

X 11 X 21 X 31

X12 X 22 X 32

X 41

X 42

X 51 X 61

X 52 X 62

Cable overview

X 13 X 23 X 33

X 14 X 24 X 34

449 483 ... 0

X 43

X 44

X 53 X 63

X 54 X 64

Plug APlug B

Used

Cable

449 483 015 0

L = 1.5 m

449 483 025 0

L = 2.5 m

Plug

A

see:

Remark

Drawing

449 483 000 0 Solenoid valve,

472 900 053 0

472 900 055 0

472 880 030 0

Plug

Assignment

B

81 Pressurizing

44 Supply

72Rear axle right

33 Rear axle left

449 484 ... 0

Plug D

Plug B

Plug A

Used

Cable

449 484 085 0

L

= 1.5 m

1

L

= 1.5 m

2

449 484 127 0

L

= 2.5 m

1

L

= 2.5 m

2

see:

Remark

Drawing

449 484 000 0 Solenoid valve,

with

lifting axle control

472 905 114 0 with

transverse throttle

or

472 905 111 0

without transverse

throttle

Plug

A

Plug

B, D

Assignment

3D 1 Rear axle left

4D 4 Supply

7D 2Rear axle right

8D 3 Pressurizing

4B 4 Supply

5B 3lifting axle raise

6B 1Lifting axle lower

34

449 485 ... 0

Plug B

Cable overview

Used

Cable

449 485 106 0

L

= 1.5 m

1

L

= 1.5 m

2

Plug A

TCE

see:

Drawing

449 485 000 0 Solenoid valve,

Remark

Raising/Lowering

Valve

472 900 055 0

Spring returned

lifting axle valve

463 084 030 0

4

Plug C

449 494 ... 0

Plug D

Plug A

Plug

A

3B 3 Rear axle left

4

5C 1lifting axle raise

7B 2Rear axle right

8B 1 Pressurizing

Used

Cable

449 494 025 0

L

= 1.5 m

1

L

= 0.4 m

2

Plug

B, C

B 4 Supply

C 2 Supply

see:

Drawing

449 494 000 0 Solenoid valve,

Assignment

Remark

with 2 separate

lifting axles

472 905 114/111 0

and second lifting

axle solenoid valve

463 084 010 0

Plug E

Plug B

Plug

B, D, E

D 2 Lifting Axle 2 H 1 Lifting axle 2 raise

D 1 Supply

E 1 Rear axle left Supply

E 4 Supply Supply

E 2 Rear axle right 5 Lifting axle 1 raise

E 3 Pressurizing 6 Lifting axle 1 lower

B 4 Supply 3 Rear axle left

B 3 Lifting axle 1

B 1 Lifting axle 1

Assignment Plug

A

4

7 Rear axle right

raise

8 Pressurizing

lower

Assignment

Supply

35

4

TCE

Terminal X 44: Pressure sensor

TCE-Elektronik

TCE-Electronic

X 11 X 21 X 31 X 41 X 51 X 61

X12 X 22 X 32

X 42

X 52 X 62

Cable overview

X 13 X 23 X 33

X 14 X 24 X 34 X 44 X 54 X 64

449 823 ... 0

449 824 ... 0

X 43

X 53 X 63

Plug APlug B

Used

Cable

449 823 020 0

L

= 2 m

1

* with seal

Plug

A

53Pressure sensor

61 Supply

72 Ground

see:

Drawing

449 823 000 0 one pressure

Plug

B

Remark

sensor

441 040 007 0 (old)

441 040 015 0 (new)*

441 040 013 0 (new)

Assignment

Plug D

Plug B

Plug A

Used

Cable

449 824 108 0

L

= 3 m

1

L

= 2 m

2

* with seal

Plug

A

5B 3Pressure sensor 2

6B 1 Supply

7B 2 Ground

6D 1 Supply

7D 2 Ground

8D 3Pressure sensor 1

see:

Drawing

449 824 000 0 two

Plug

B, D

Remark

Pressure sensors

441 040 007 0 (old)

441 040 015 0 (new)*

441 040 013 0 (new)

Assignment

36

System functions

5.1 Brake lining wear indicator

-> Limit value indicator

Terminal X11

Advantages:

Retrofittable and not expensive

High degree of lining utilisation due to:

1. Skew wear compensation

2. Separate sensoring of both lining sides (no safety

allowance required for differential and disc wear)

3. On signal the residual thickness of lining is 2 mm.

TCE

Brake lining wear sensor

5

Schematic Z section through the brake

(PAN 19-1)

Installed brake lining wear sensor

Slide wire

Brake disc

Residual lining 2 mm

19 mm

Wear dimension

Report point

Cable abraded

Residual lining 2 mm

37

5

TCE

System functions

A maximum of up to six final value indicators (a wire

integrated in the brake lining) can be connected to TCE

for monitoring the state of wear of the disc brakes. The

driver is warned via the ABS warning light shortly before

and when the wear limit value is achieved.

When at a limit value indicator the wire is abraded in

braked mode, there will occur a short circuit to the

ground (ground connection between brake and frame

required) and warning level 1 is activated. At the first

warning level the ABS warning light flashes 4 times

(1 cycle) when the ignition is switched on.

WARNING SIGNAL SEQUENCE WARNING LEVEL 1

ON

OFF

Ignition

ON

When at a limit value indicator the wire is abraded for a

certain time, warning level 2 is activated. At the second

warning level the ABS warning light flashes 4 times 4

TIME

cycles (total of 16 flashes), when the ignition is switched

on.

WARNING SIGNAL SEQUENCE WARNING LEVEL 2

ON

OFF

Ignition

ON

The warning is interrupted when the vehicle's speed

exceeds 7 km/h. In case of system faults the ABS

warning light is activated continuously!

At the same time, the corresponding information is

transmitted via the motor vehicle/trailer interface and

can be shown on the display there.

The system automatically detects when new limit value

indicators are fitted after replacement of the brake lining.

All warning levels are deactivated after a time of 2

minutes (switch on the ignition for at least 2 minutes).

The warning light extinguishes not earlier than the next

ignition ON.

TIME

Wear indicators are available for following axles

Axle manufacturer SAF BPW

Brake type WABCO

PAN 19-1

PAN 19-1 plus

TDB-/

Test protocol No.

The TDB Test protocol No. can

be found on the reference plate

of the axle

Per axle

one set is required

Wear indicators are always packed

axlewise

TDB 0678

TDB 0749

12 999 755 VT 12 999 797 12 999 792 12 999 792

WABCO

PAN 22- 1

361-094-02

361-106-02

361-107-02

Knorr

SB 6-7

TDB 0605

TDB 0606

TDB 0590

TDB 0591

Knorr

SB 6-7

TDB 0568

TDB 0568

TDB 0632

38

System functions

I

N

N

TCE

5

5.2 Electrical supply

The table delivers an overview of the plug connections

acc. to their application, the second shows the contact

5.2.1 Standardized motor vehicle plug in

assignment.

connections

Terminals X12 and X13

Designation Standard Remark

ABS/EBS

Plug connection

ISO 7638 Supply and data communication

Trailer EBS, Running Gear Systems

1)

15 pin connection ISO 12098 Lighting, trailer supply, special functions

and data connection

1)

24 N ISO 1185 Alternatively to ISO 12098, lighting and

trailer supply

24 S ISO 3731 Alternatively to ISO 12098, lighting, special functions

and trailer supply

1)

Data connection acc. to ISO 11992

Figure: Standard motor vehicle-trailer - plug in connections

Terminal X12 Terminal X13

ISO 7638 (ABS 7-pin)

SO 7836 (ABS 7-polig)

Solenoid control valve +

Magnetregelventile +

Electronic supply +

Elektronikversorgung +

Electronic supply -

Elektronikversorgung -

Solenoid control valve -

Magnetregelventile -

Warning device

Warneinrichtung

CAN High 1)

CAN High 1)

CAN Low 1)

CAN Low 1)

1) Data connection acc. to ISO/DIS 11992

1) Datenverbindung nach ISO/DIS11992

Terminal X13

can be connected via an adapter 15 pin to 2 x 7 pin. However, then no

1

2

3

4

5

6

7

then CAN connection between motor vehicle and trailer as well as axle lifting and

traction help function.

ISO 1185 (24N)

Masse

Ground

Schlußlicht links

Rear light left

Fahrtrichtungs anzeiger links

Turn signal left

Br e ms l e u c h t e

Brake light

Fahrtrichtungs anzeiger rechts

Turn signal right

Schlußlicht rechts

Rear light right

Steuerung Anhängerbremsung

Control trailer brake valve

1

2

3

4

5

6

7

31/1

58L/2

L/3

54/4

R/5

58R/6

54g/7

ISO/DIS 12098 (15-polig)

Fahrtrichtungsanzeiger links

Turn signal left

Fahrtrichtungsanzeiger rechts

Turn signal right

ebelschlußleuchte

Fog rear light

M asse

Ground

Sch luß licht links

Rear light left

Sch luß licht rech ts

Rear light right

Bremsleuchte

Brake light

Rückfahrleuchte

Backing light

Stromversorgung (Kl. 30)

Power supply (pin 30)

Bremsbelagverschleißsensor

Brake lining wear sensor

Drucksensor Federspeicher

Pressure sensor spring b. actuator

Liftachsposition

Lifting axle position

M asse Datenleitungen

Ground data line

Datenleitung #1

Data line #1

Datenleitung #2

Data line #2

(15-pin)

ISO 3731 (24S)

Masse

Ground

nicht belegt

not connected

Rückfahr leucht e

Backing light

Stromversorgung (Kl. 30)

Power supply (pin 30)

Steuerung über Masse

Control via ground

Stromversorgung (Kl. 15)

Power supply (pin 15)

ebe ls chl ußl euc hte

Fog rear light

(1994)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

(2001)

Steering axle lock

traction help

Axle lift

CAN High

CAN Low

1

2

3

4

5

6

7

31/1

58L/2

L/3

54/4

R/5

58R/6

54g/7

39

5

TCE

System functions

5.2.2 Supply

Three types of supply are supported:

• Standard supply ISO 7638 (X12) with Pin 30

(Pin 1), Pin 15 (Pin 2) for Braking and Running

Gear Systems, ISO 12098 (X13) with Pin 30

(Pin 9) for all other systems.

• Battery supply – Ramp operation:

only TCE level control function

• Battery supply - diagnostic mode:

only braking and RG systems

Central load dump protection for all TCE compo-

nents and connected external systems.

Table: TCE functional conditions

No. Designation Supply voltage Functional condition

Below range of service

1

voltage

Below

2

under voltage threshold

3 Service voltage range 18 V ≤ U

Over voltage threshold

4

exceeded

U

< 16 V Restricted functionality, if necessary, cut off

B

16 V ≤ U

U

> 32V Restricted functionality, if necessary, cut off

B

1)

< 18 V No control of levelling and lift axle valves, no

B

≤ 32 V All system functions active

B

Control of TCE battery supply as well as of con-

nected trailer systems (incl. diagnostic tool) for diagnostic and ramp operations (electronic levelling).

Moreover a connected tire pressure monitoring

(terminal X32) is permanently supplied via the trailer battery if a motor vehicle supply is missing.

Charging equipment with electronic protection for

trailer batteries up to 10Ah approx.

Sensoring of electrical motor vehicle supply lines.

Emergency supply of EBS via ISO 12098 brake

light and ground.

Dependent on the supply voltage the functional

conditions are complied acc. to the following table.

of certain switching parts

electrical supply of RGE systems

of certain switching parts.

1. Remark: The functional conditions of systems connected may be different.

5.2.2.1 Standard supply

The TCE is supplied via the plug connections acc. to

ISO 7638 (X12) Pin 30 (Pin 1) and Pin 15 (Pin 2). The

respective ground connections GND15 (Pin 3) and

GND30 (Pin 4) are monitored for breaks.

In case of a failure of ground lines GND15 or GND30 the

trailer warning light is activated.

TCE is switched on via

• cut in ISO 7638 Pin 15 (Pin 2)

• Data transfer from motor vehicle via ISO 7638 or

ISO 12098

• Operation of remote control unit (IRCU) for level

control

• Signal at special plug pins

• Connection of a diagnostic tool to connection X14.

Here activation of the TCE can follow via one or

several points at the same time.

The service voltage is measured and monitored for

falling below resp. exceeding the under resp.

overvoltage threshold. In case ISO 7638 (X12) Pin 15

(Pin 2) is cut in without ISO 7638 Pin 30 (Pin 1), this is

detected as failure and the trailer warning light

(ISO 7638, Pin 5) in the motor vehicle is activated.

5.2.2.2 Emergency supply of EBS

In case of a failure of supply ISO 7638, the TEBS is

additionally controlled via the brake light supply

ISO 12098. The TEBS is supplied only as long as the

brake is operated. This function is designed for

emergency cases only. At any rate the ISO 7638

connection has to be plugged.

40

System functions

TCE

5

5.3 Diagnostic mode and warning

light function; connection X14

If a communication is initialised from a connected test

device via the K line, EBS and all other modules with

connected consumers are switched on. To prevent an

overload, the supply mode ”battery supply - diagnostic

mode“ is communicated via the trailer data bus to the

modules and systems supplied. Functions which are not

actually to be checked shall be cut off from the systems

during this type of supply. This kind of operation is

automatically terminated if there is no communication

between test device and TCE or if the diagnostic mode

is explicitly closed by the test device.

5.3.1 Gateway ISO 7638 / ISO 12098

Trailer data bus

The TCE represents a bidirectional gateway between

data connection of ISO 7638 resp. ISO 12098 and the

CAN trailer data bus. Messages received will be filtered

complying with a programmed table and be transmitted

to the connected trailer systems / components. The

messages will be processed in dependence of event

and time. Messages from the motor vehicle which are to

be transmitted to the trailer data bus and messages from

the trailer bus which are to be transmitted to the motor

vehicle, will be processed event controlled. Messages to

be sent from TCE to the motor vehicle or on the trailer

data bus are processed simultaneously.

When messages on both data interfaces are received at

the same time the interface to the motor vehicle has

priority. Messages to send are respectively queued up

on both data connections according to their priorities.

responses, the TCE is responsible.

5.3.1.2 TCE Diagnosis

For parameter settings and system start-up incl.

calibrating a WABCO training is obligatory! For

registration and training schedule please phone to

+ 49 511 922 2971.

Diagnosis of TCE and systems connected is effected via

the diagnostic tool connection X14. The TCE diagnostic

functions correspond to the VDA recommendation and

the WABCO directive for KWP2000. They include the

following tasks:

– Parameter settings, system start-up

– Fault storage and access to fault storage

– System check / Service

Diagnosis is possible only by means of a PC. This

applies to end line tests at the vehicle manufacturer as

well as for troubleshooting in the workshop.

A diagnosis can be performed, when the TCE is

supplied via the 7 pin + 15 pin plug connection to the

trailer. Performance of the diagnosis is also possible

during the battery mode. However, in this battery mode

the connection to the diagnostic tool will be interrupted

5 minutes after the last query in order to save battery

power. A renewed diagnosis is enabled by connecting/

disconnecting the diagnostic plug to the vehicle.

During the diagnostic mode the vehicle can be raised

resp. lowered by means of the service unit. Only in the

calibrating mode this is impossible.

System requirement

– Remarkbook/Laptop or PC

5.3.1.1 Gateway diagnostic tool Trailer data

bus

The TCE represents a bidirectional gateway between

data connection of ISO 14230 resp. ISO 12098 and the

CAN trailer data bus. Messages received will be filtered

complying with a programmed table and be transmitted

to the connected trailer systems / components. The

messages are processed in dependence of events.

When messages on both data interfaces are received at

the same time, the interface to the motor vehicle has

priority. Messages to send are respectively queued up

on both data connections according to their priorities.

For maintaining the communication with the test device

resp. for keeping the timing especially in case of delayed

– Pentium processor

– 32 MB main memory, colour display 800x600

– approx. 10 MB free hard disc memory

3 ½" floppy disc drive

– COM interface (9-pin connection) for the

WABCO Diagnostic Interface

– Windows 95/98, Windows NT

Software order No.

446 301 680 0 German

In addition a diagnostic interface and a diagnostic

connector cable are required for the connection between

electronic and computer.

41

5

TCE

System functions

446 301 021 0 Diagnostic Interface Set (incl. a

diagnostic interface + diagnostic cable

to the PC)

446 300 329 2 trailer diagnostic cable, length 6 m

(Connecting cable between diagnostic

interface + external round diagnostic

plug terminal).

5.3.2 Warning Light Functions

A green system warning light can be connected to the

TCE. It indicates the following states:

Warning light status

– flashing: Display of general TCE errors

– on: trailer vehicle not within the

normal level

– off: vehicle within normal level

and without faults or ignition

switched off.

5.4 Freely programmable I/O

(Special modules) terminal X21

and X33

Implementation of vehicle and equipment specific

functions.

TCE II

At terminal X33 various ”special modules“, whose

parameters are to be set via the PC diagnosis, can be

released.

• Reading of analogue and digital information

• Control of electrical equipment

• Transfer and transmission of information via CAN

data connections

• Receiving and processing of CAN control data

After a reset all inputs / outputs are highly resistive. All

inputs / outputs are resistant to short circuits due to

supply voltage and ground.

Operating voltage monitoring

The operating voltage is measured and in case of being

above or below the operating voltage range, the change

to the respective mode will be effected.

Overload monitoring / cutting-off

In accordance with the directives to ECE-R 13 power

and operating voltage are monitored via plug connection

ISO 7638 and in case of an overload, electrical non

braking systems / consumers are cut off.

5.5 Trailer EBS and RGE

Connection Terminal X22

5.5.1 Trailer EBS

The Trailer EBS works independently from the TCE and

disposes of an own PC diagnostic tool which is operated

via the diagnostic connection. For more information

please see our brochure ”Trailer EBS - electronically

controlled brake system in trailer vehicles“,

Wabco print 815 010 019 3 and 815 010 020 3.

Important

TCE I:

In this connection the trailer modules 480 102 002/005 0

have to be used.

TCE II

Using TCE II the EBS axle modulator 480 102 015 0 (D)

should be connected. However, TCE II also works in

connection with previous modulators 480 102 002/005

0. In this case special requirements of the pressure

sensor connection have to be observed.

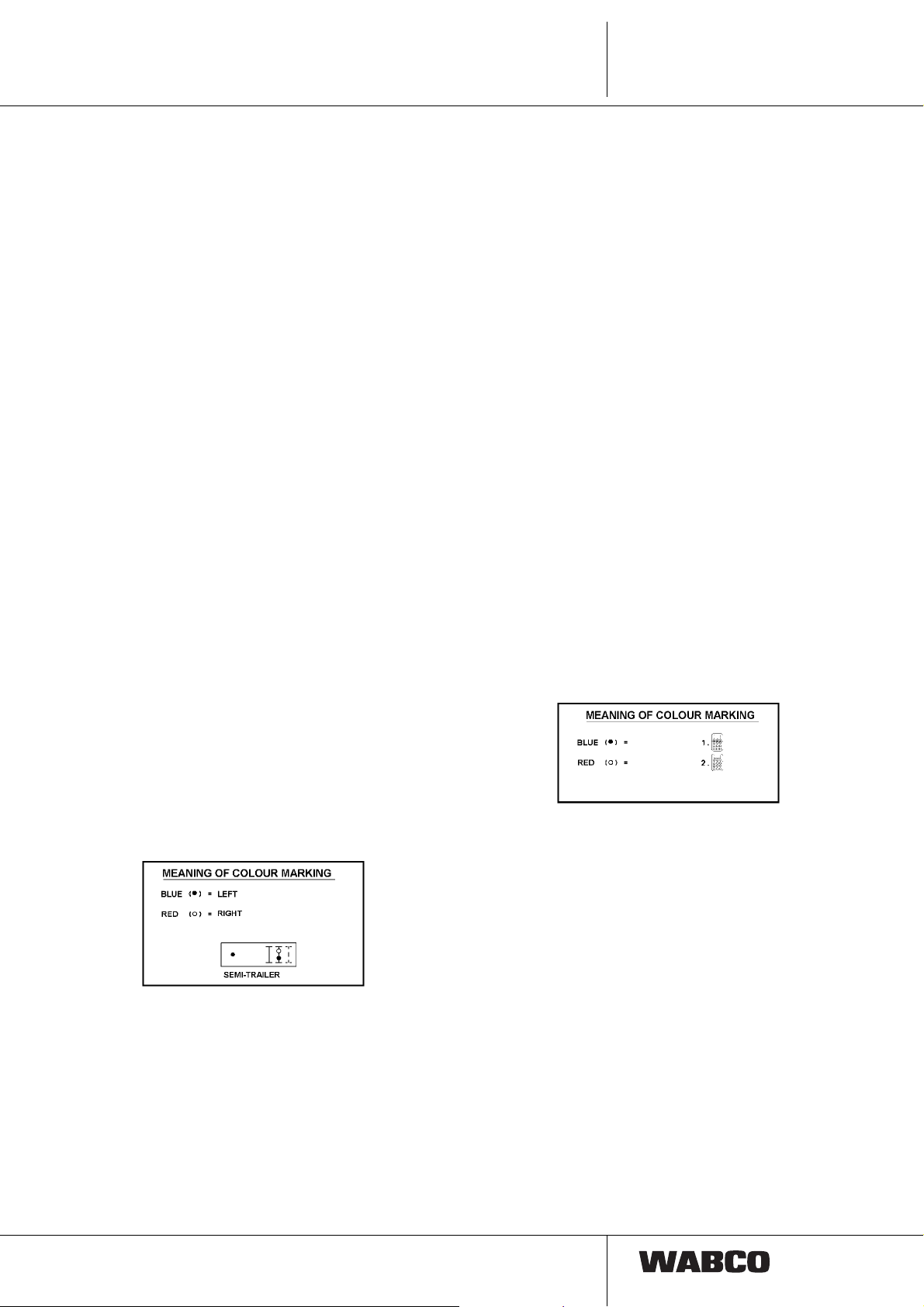

P

U

EBS modulator

480 102 002/005 0

P

U

P

U

P

U

Air bellows pressure

connection 5

EBS modulator

480 102 015 0

Air bellows pressure

connection 5

5.4.1 Monitoring functions

Watchdog (program running time monitoring )

Function of the micro controller resp. software

processing is monitored by an external watchdog.

Memory test

Parameter memory and ROM memory are cyclically

tested during operation.

42

EBS modulator

480 102 002/005 0

EBS modulator

480 102 015 0

If another EBS trailer modulator is used, this will be

reported as error on the TCE when the system is started.

System functions

TCE

5

Reason: The values of the pressure or axle load sensors

and of the brake lining wear sensors are already

supplied from the TCE electronic.

Remarks for the system start up

EBS modulator

• Modifications resp. differences between TCE I and

TCE II:

EBS-Modulator to be used for TCE I

480 102 002 0 (C)

480 102 005 0 (C+RSS)

EBS-Modulator to be used for TCE II

480 102 015 0 (D0).

• Voltage supply cable to be connected to TCE ECU.

• Create new set of parameters for modulator. Here

”electr. switch output 1+2“ has to be clicked as ”not

available“. The brake lining wear indicator as ”not

existing“.

EBS

• The sequence for system start up must be first EBS

and then TCE.

5.5.2 RGE Connection

When in the diagnostic mode the connection ”additional

function“ is activated, the trailer data bus and the voltage

supply are released.

The connection may be used for activation of a telematic

system or of a brake or chassis related system. The

electrical power is supplied via the TCE.

43

5