Vulcan Hart VG30 Owner’s Manual

INSTALLATION &

OPERATION MANUAL

VG30, VG40, VE30 & VE40 BRAISING PANS

MODELS

VG30 ML-126847

VG40 ML-126848

VE30 ML-126849

VE40 ML-126850

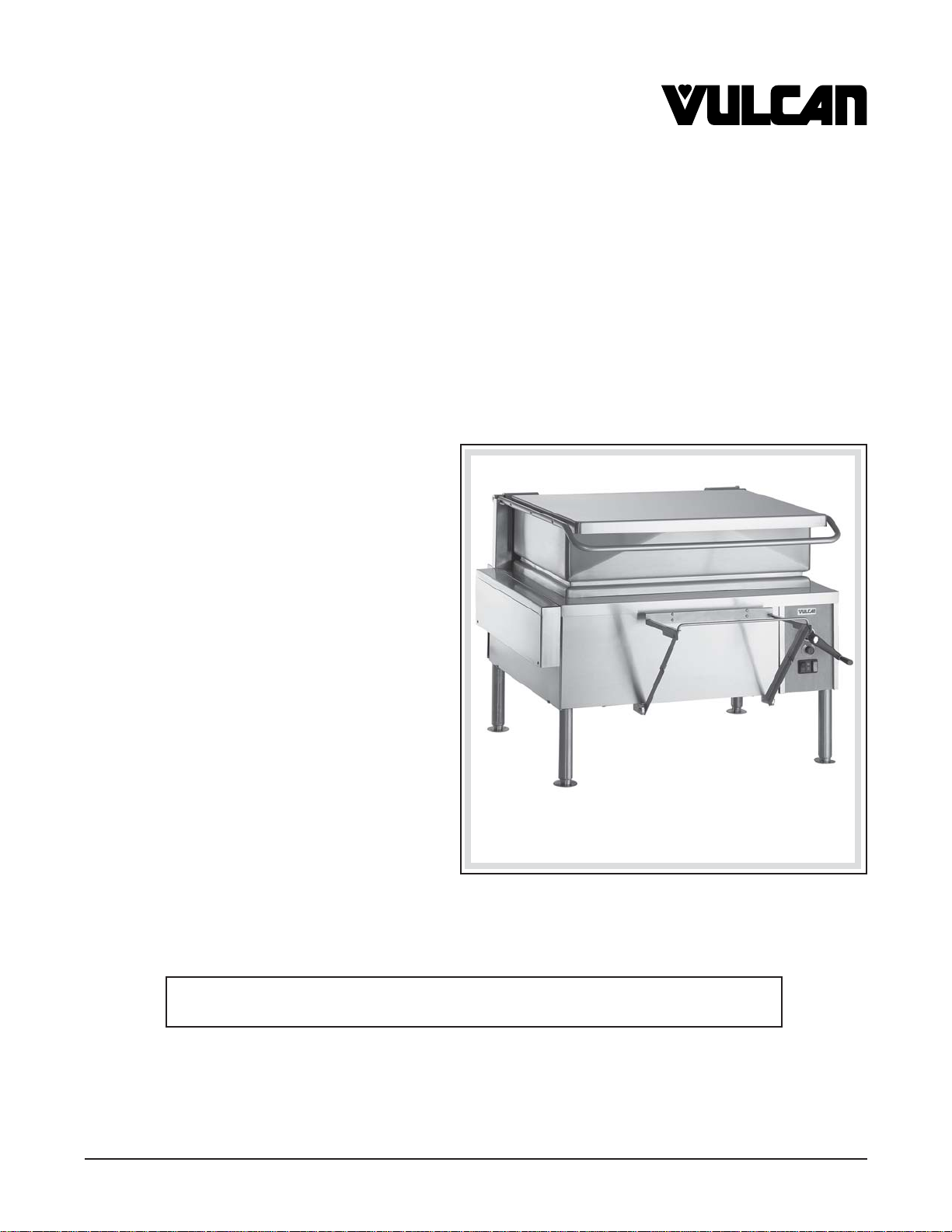

Model VE40

For additional information on Vulcan-Hart Company or to locate an authorized

parts and service provider in your area, visit our website at www.vulcanhart.com

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

WWW.VULCANHART.COM

3600 NORTH POINT BLVD.

BALTIMORE, MD 21222

FORM 31227 REV A (05-08)

VG30, VG40, VE30 & VE40 BRAISING PANS

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

Improper installation, adjustment,

alteration, service or maintenance can cause

property damage, injury or death. Read the

installation, operating and maintenance

instructions thoroughly before installing or

servicing this equipment.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

© VULCAN-HART COMPANY 2008

– 2 –

VG30, VG40, VE30 & VE40 BRAISING PANS

TABLE OF CONTENTS

GENERAL .............................................................................................................................................4

INSTALLATION ....................................................................................................................................4

Unpacking .......................................................................................................................................4

Location ...........................................................................................................................................4

Installation Codes and Standards ..................................................................................................6

Leveling and Anchoring the Tilting Braising Pan...........................................................................6

Service Connections ...................................................................................................................... 6

Testing the Gas Supply System ....................................................................................................7

Gas Connections ............................................................................................................................7

Flue Connections ............................................................................................................................7

Electrical Connections....................................................................................................................8

Installation Diagram ........................................................................................................................ 9

OPERATION...................................................................................................................................... 10

Before First Use ........................................................................................................................... 10

Gas Heat Braising Pans.............................................................................................................. 10

Electric Heat Braising Pans ........................................................................................................ 12

Operation of the Lifting System ................................................................................................... 12

Unloading Prepared Foods .......................................................................................................... 13

Steaming Inserts (Optional) ........................................................................................................ 14

Cooking Hints ............................................................................................................................... 14

Cleaning........................................................................................................................................ 15

Cooking Guidelines (Domestic Measurements) .........................................................................16

Cooking Guidelines (Metric Measurements) ...............................................................................19

MAINTENANCE................................................................................................................................. 22

Lubrication .................................................................................................................................... 22

Adjustments ..................................................................................................................................22

Vent ...............................................................................................................................................22

Service and Parts Information .................................................................................................... 22

TROUBLESHOOTING ...................................................................................................................... 23

Gas Heat Braising Pans.............................................................................................................. 23

Electric Heat Braising Pans ........................................................................................................ 23

SERVICE AND PARTS INFORMATION .......................................................................................... 24

– 3 –

VG30, VG40, VE30 & VE40 BRAISING PANS

Installation, Operation and Care of

TILTING BRAISING PANS

MODELS VG30, VG40, VE30 & VE40

SAVE THESE INSTRUCTIONS FOR FUTURE USE

GENERAL

Vulcan-Hart Tilting Braising Pans are available in two sizes. Models VG30 and VE30 have a 30-gallon

(114 L) capacity, and Models VG40 and VE40 have a 40-gallon (151 L) capacity.

The tilting braising pan is a versatile piece of equipment. It allows you to stew, simmer, pan fry, braise,

grill or saute, and all with a very uniform heat pattern.

Standard features on all models include thermostat, manual lift, drop-away food pan support and four

flanged feet.

Optional features include automatic power lift and casters.

Your Vulcan braising pan is produced with quality workmanship and material. Proper installation,

usage and maintenance will result in many years of satisfactory performance.

Vulcan-Hart suggests that you thoroughly read this entire manual and carefully follow all of the

instructions provided.

INSTALLATION

Before installing, verify that the electrical service and gas supply (natural or propane) agree with the

specifications on the rating plate located on the left front edge of the table top.

UNPACKING

This braising pan was carefully inspected before leaving the factory. The transportation company

assumes full responsibility for safe delivery upon acceptance of this shipment.

Immediately after unpacking, check for possible shipping damage. If the tilting braising pan is found

to be damaged, save the packaging material and contact the carrier within 15 days of delivery.

LOCATION

For Gas-Powered Braising Pans Only

The braising pan must be kept free and clear from combustible substances. The braising pan, when

installed, must have minimum clearance from combustible construction of 2" (5 cm)

the sides and 6" (15 cm) from the rear. Minimum clearance from noncombustible construction is 0" from

the sides and 6" (15 cm) from the rear.

– 4 –

from

VG30, VG40, VE30 & VE40 BRAISING PANS

The installation location must allow adequate clearances for servicing and proper operation.

Recommended clearances are 24" (61 cm) on the sides and back (for servicing), and 36" (91 cm) on

the front.

The braising pan must be installed so that the flow of combustion and ventilation air will not be

obstructed. Adequate clearance for air openings into the combustion chamber must be provided. Make

sure there is an adequate supply of air in the room suitable for the amount of combustion gas feeding

the braising pan burners.

Do not permit fans to blow directly at the braising pan. Wherever possible, avoid open windows next

to the braising pan. Avoid wall-type fans which create air cross currents within the room.

Gas-Powered Braising Pans Equipped with Casters (Optional)

If casters are assembled to the braising pan, the installation must be made using:

1. A connector (not supplied by Vulcan) that complies with the Standard for

Gas Appliances

, ANSI Z21.69 (latest edition) or

Connectors for Moveable Gas Appliances

Connectors for Movable

, CAN/

CGA-6.16 (latest edition).

2. A quick-disconnect device that complies with the Standard for

Use With Gas Fuel

CAN1-

6.9 (latest edition).

, ANSI Z21.41 or

Quick-Disconnect Devices for Use with Gas Fuel

Quick-Disconnect Devices for

Adequate means must be provided to limit the movement of the appliance, without depending on the

connector and/or any quick-disconnect device or its associated piping to limit braising pan movement.

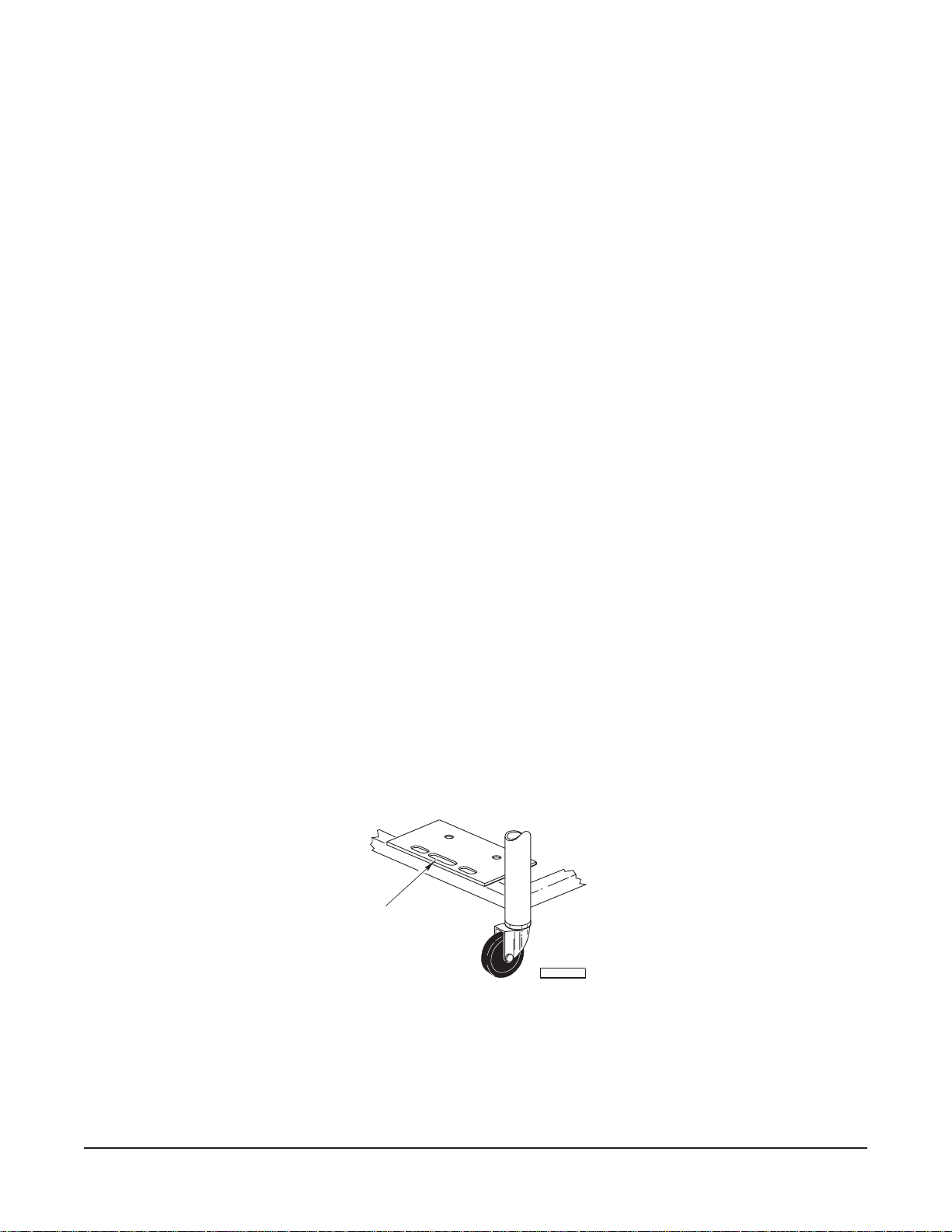

Attach the restraint at the rear of the braising pan (Fig. 1). If disconnection of the restraint is necessary,

turn off the gas supply before disconnection. Reconnect this restraint prior to turning the gas supply

on and prior to returning the braising pan to its originally installed position.

Electric-Powered Braising Pans Equipped with Casters (Optional)

If casters are assembled to the braising pan, the appliance shall be installed using flexible conduit.

Safety standards require that, when a electric Braising Pan electric supply line is properly connected

to the electrical power supply, an adequate means must be provided to limit movement of the appliance

without depending on or transmitting stress to the electrical conduit.

,

HOLES PROVIDED

FOR RESTRAINT

PL-56652

Fig. 1

If disconnection of the restraint is necessary, turn off the gas and/or electric supplies before

disconnection. Reconnect this restraint prior to turning the gas and/or electric supplies on and prior

to returning the braising pan to its originally installed position.

– 5 –

VG30, VG40, VE30 & VE40 BRAISING PANS

INSTALLATION CODES AND STANDARDS

The Vulcan braising pan must be installed in accordance with:

In the United States of America:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1/NFPA #54 (latest edition). Copies may be obtained from

The American Gas Association Accredited Standards Committee Z223, @ 400 N. Capital St. NW,

Washington, DC 20001, or the Secretary Standards Council, NFPA, 1 Batterymarch Park

Quincy, MA 02169-7471.

3. NFPA Standard # 96 Vapor Removal from Cooking Equipment, latest edition, available from

the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

4. In the Commonwealth of Massachusetts all gas appliances vented through a ventilation hood

or exhaust system equipped with a damper or with a power means of exhaust shall comply with

248 CMR.

In Canada:

1. Local codes.

2. CAN/CSA-B149.1 Natural Gas Installation (latest edition).

3. CAN/CSA-B149.2 Propane Installation Code (latest edition), available from the Canadian Gas

Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3.

LEVELING AND ANCHORING THE TILTING BRAISING PAN

1. Place the braising pan in the final installed position.

2. Place a carpenter's level on the braising pan table top and turn the adjustable feet to level the

braising pan table top side-to-side and front-to-back. Do not attempt to level the braising pan

base.

3. Mark hole locations on the floor through the anchoring holes provided in the flanged

adjustable feet.

4. Remove the tilting braising pan from the installation location and drill holes in the locations marked

on the floor. Insert proper anchoring devices (not supplied).

5. Place the tilting braising pan back in the installation location.

6. Place a carpenter's level on top of the braising pan, and re-level side-to-side and front-to-back.

7. Bolt and anchor the tilting braising pan securely to the floor.

8. Seal bolts and flanged feet with Silicon sealant or equivalent compound.

SERVICE CONNECTIONS

To access service and utility connections, remove the left side panel. To remove, hold the panel from

underneath and lift it up. While holding the panel up, swing out the lower part of the panel until it clears

the bottom flange and remove the panel. If required, the rear panel can also be removed using the same

procedure.

The gas-powered braising pan is supplied with a 120-volt power cord.

The electrical connection for the electric braising pan can be accessed from the rear or the left panel.

– 6 –

VG30, VG40, VE30 & VE40 BRAISING PANS

TESTING THE GAS SUPPLY SYSTEM

1

When test pressures exceed

/2 psig (3.45 kPa), the tilting braising pan and its individual shutoff valve

must be disconnected from the gas supply piping system.

1

When test presures are

/2 psig (3.45 kPa) or less, the tilting braising pan must be isolated from the gas

supply system by closing its individual manual shutoff valve.

GAS SUPPLY CONNECTION (See Fig. 2)

All gas supply connections and any pipe joint compound used must be resistant to the action of propane gases.

Connect a 3/4" (nominal) gas supply to the braising pan. Recommended incoming gas line pressure is

7" W.C. (Water Column) (48.3 kPa) for natural gas or 11" W.C. (75.8 kPa) for propane gas.

Gas pressure should not exceed 14" W.C., higher pressure will damage the combination valve.

Make sure the pipes are clean and free of obstructions, dirt and piping compound.

Codes require that a gas shutoff valve be installed in the gas line ahead of the tilting braising pan.

Natural gas and propane gas braising pans are equipped with fixed orifices, and gas pressure must be

verified at start up. The manifold is set at 3.7" W.C. (Water Column) (25.5 kPa) for natural gas and 10"

W.C. (68.9 kPa) for propane gas.

Prior to lighting, check all joints in the gas supply line for leaks. Use soap and

water solution. Do not use an open flame.

After piping has been checked for leaks, all piping receiving gas should be fully purged to remove air.

VENTILATION

DO NOT obstruct the flow of flue gases from the flue duct located on the rear of the tilting braising pan.

It is recommended that the flue gases be ventilated to the outside of the building through a ventilation

system installed by qualified personnel.

From the termination of the braising pan flue vent to the filters of the hood venting system,

an 18" (46

cm) minimum clearance must be maintained. The flue is not to be directly connected to the

ventilation system.

Local jurisdictions may require a ventilation system to exhaust the steam from this appliance.

Clearance of 40" is recommended for the lid to be raised without interference with the hood. A ceiling

that is too low may not allow for an installation of a hood to meet this requirement.

– 7 –

VG30, VG40, VE30 & VE40 BRAISING PANS

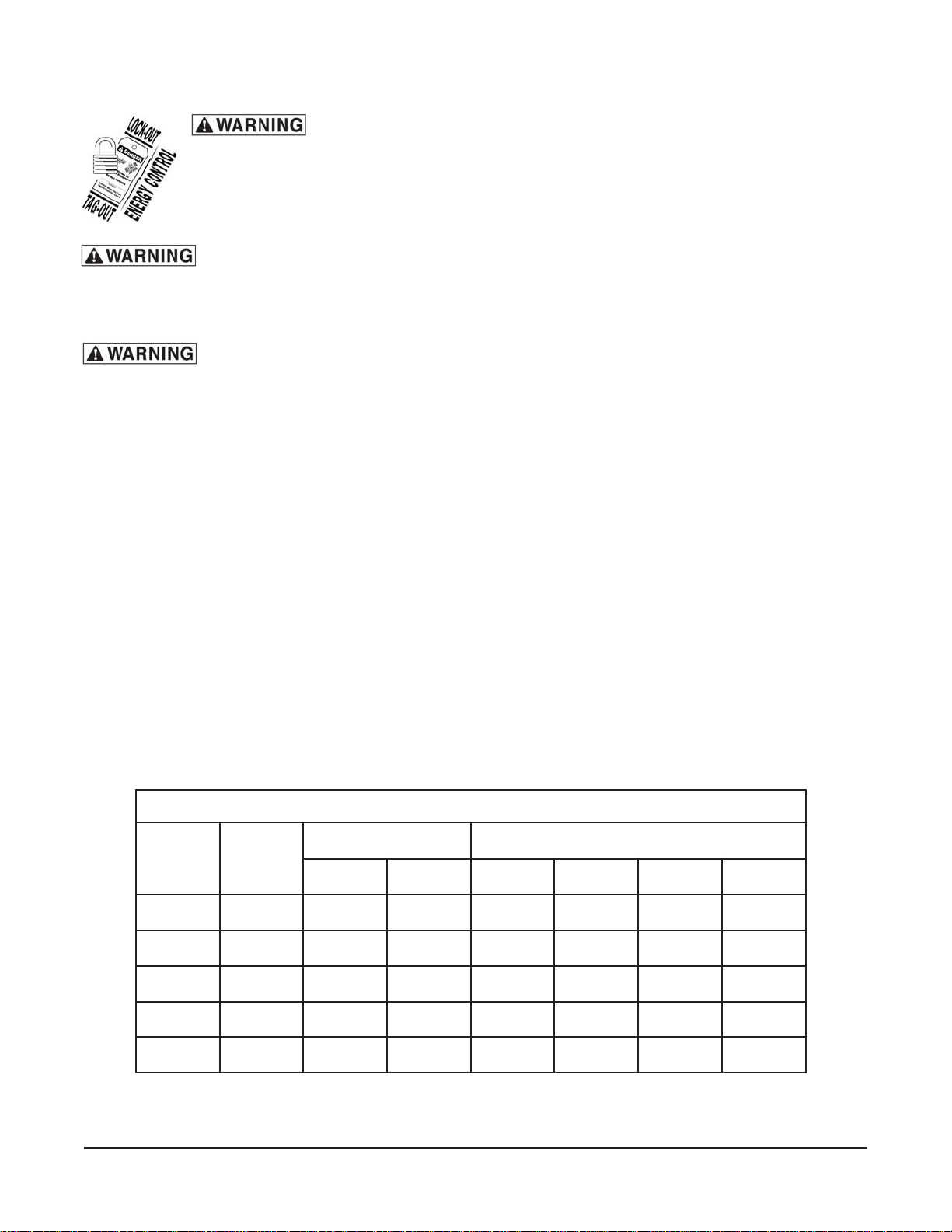

ELECTRICAL CONNECTIONS (See Fig. 2)

Disconnect the electrical power to the machine and follow

Lockout / Tagout procedures.

Appliances equipped with a flexible electric supply cord are provided with a

three-prong grounding plug. It is imperative that this plug be connected into a properly

grounded three-prong receptacle. If the receptacle is not the proper grounding type, contact an

electrician. do not remove the grounding prong from this plug.

Electrical and grounding connections must comply with the national electrical

code and/or other local codes.

The field connection box for field wire connection of Models VE30 and VE40 is located at the back of

the braising pan. A knockout hole is provided for a 1" (2.5 cm) conduit connection.

1. Remove the field connection box cover plate. Mount suitable 1" (2.5 cm) conduit fitting in the

conduit opening provided on the bottom surface.

2. Connect field wire to the terminal block as indicated on the wiring diagram. The wiring diagram

is located on the inside of the field box lid. Wire must be of the type suitable for 75°C service and

at the suitable gauge for loads shown on the data plate.

3. After making the connections, replace the control box cover plate.

4. The braising pan must be grounded by installing a properly grounded lead to the ground lug

located inside the field connection box.

5. The electronic ignition used to light the burners require proper grounding.

TRAHCATADLACIRTCELE

03EV04EV

STLOVESAHP

.W.KPMA.W.KXLYLZL

8021934218585—

04212105617676—

802395221939352

0423219261646492

0843215161323251

These values are nominal ratings. Field wire connections must be capable of withstanding anticipated

surges.

– 8 –

Loading...

Loading...