Vulcan-Hart VFBMW Service Manual

SERVICE MANUAL

MODEL VFBMW

ELECTRIC

FLASH

BA KE

®

/ MICROWAVE

OVEN

ML 126807

- NOTICE This Manual is prepared for th e use of trained Vulcan Service

Technicians and should not be used by those not properly

qu alif ied. If yo u have attend ed a Vulcan Service School for this

product, you may be qualified to perform all the procedures

described in this man ual.

Thi s manu al i s no t i nten ded to be al l en comp assi ng . I f you have

not attende d a Vulcan S ervic e School for this produ ct , you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have th e n ecessary too ls, in strument s and skills should be

performed b y a trained Vu lcan Service Technician .

Reproduction or other use of this Manual, without the express

written consent of Vulcan-Hart, is prohibited.

A product of VULCAN-HART LOUISVILLE , KY 40201-0696

Form 24694 ( A pr il 2001)

FLASHBAKE® / MICROWAVE O VEN

TABLE OF CONTENTS

RADIATION SAFETY I NS TRUCTIONS ....................................................... 4

GENERAL............................................................................. 4

Introduction ........................................................................ 4

Electrical Specifications............................................................... 5

Installation......................................................................... 5

Operation.......................................................................... 6

Cleaning .......................................................................... 6

Tools ............................................................................. 6

REMOVAL AND REPLACEMENT OF PARTS ................................................. 7

Covers and Panels ................................................................... 7

Main Cover..................................................................... 7

Back Panel ..................................................................... 8

Bottom P anel ................................................................... 8

Front Vent Grill ..................................................................... 8

Power Cord ........................................................................ 9

Vent Fan Capaci tor .................................................................. 9

Vent Fan .......................................................................... 9

Cavity Lamp and Damper Door Assembly ................................................ 10

Damper Housing Thermal Fuse ........................................................ 10

Fuse - 20 AMP..................................................................... 11

Door............................................................................. 12

Control Panel Assembly .............................................................. 12

Control Panel .................................................................. 12

Control Board.................................................................. 13

Keypad Assembly ............................................................... 14

Display....................................................................... 14

LED Display ................................................................... 14

Relay Board....................................................................... 14

Door Switch Assembly ............................................................... 15

Upper Lamp Housing and Duct Assembly ................................................ 16

Upper Lamp Assembly ............................................................... 18

Upper Lamp Fan ................................................................... 19

Upper Lamp Housing Ducts ........................................................... 19

Right Duct .................................................................... 19

Left Duct ..................................................................... 20

Cavity Thermistor .................................................................. 20

High Volt age Transformer ............................................................ 20

Magnetron ........................................................................ 21

Magnetron Cooling Fan .............................................................. 22

Lower Lamp Housing and Duct Assembly ................................................ 23

Lower Lamp Fan ................................................................... 23

Turntable Motor .................................................................... 24

Thermal Cut Outs .................................................................. 24

Cavity, Top Left ................................................................ 24

Upper Lamps .................................................................. 25

Lower Lamp ................................................................... 26

Magnetron .................................................................... 26

Capacitor ( High Voltage) ............................................................. 26

Diode............................................................................ 27

Low Voltage Transformer ............................................................. 27

Choke Filter....................................................................... 27

Noise Filter Board .................................................................. 28

SERVICE PROCEDURES AND ADJUSTMENTS .............................................. 29

Door Latching Adjustment ............................................................ 29

Thermistor Test .................................................................... 29

Form 24694 ( A pr il 2001) Page 2 of 52

FLASHBAKE® / MICROWAVE O VEN

Door Switches - Adjustment........................................................... 29

Testing Com ponents ................................................................ 30

Transformer - High Voltage ....................................................... 30

Capacitor - High Voltage ......................................................... 30

Diode ........................................................................ 30

Low-Voltage Transformer ......................................................... 30

Keypad....................................................................... 30

Primary Interlock ............................................................... 31

Door Sensing (Secondary Interlock) ................................................. 31

Door Interlock System ........................................................... 31

Performance Test for Microwave ....................................................... 32

Performance Test for Halogen Lam ps ................................................... 32

Radiation Leak age Test .............................................................. 32

ELECTRICAL OPERATION .............................................................. 33

Component Func tion ................................................................ 33

Component Locat ion ................................................................ 34

TCO Locations, Switch Locations................................................... 35

Control Board Layout................................................................ 36

Control Board Connec tor Identificat ion ............................................... 36

Air Flow Diagrams .................................................................. 37

Combi Cook ................................................................... 37

Magnetron .................................................................... 38

Microwave .................................................................... 38

Component Wiring Diagram s .......................................................... 39

Thermal Cut Outs............................................................... 39

Door Switches ................................................................. 40

Halogen Lamps ................................................................ 41

Schematic Diagram ................................................................. 42

Wiring Diagram .................................................................... 44

Sequence of O per ation .............................................................. 46

TROUBLESHOOTING .................................................................. 47

Diagnosing Non Operating Unit ........................................................ 47

Fault Codes ....................................................................... 48

Troubleshooting Flow Chart ........................................................... 50

CONDENSED SPARE PARTS LIST ........................................................ 51

© VULCAN 2001

Form 24694 ( A pr il 2001)Page 3 of 52

FLASHBAKE® / MICROWAVE O VEN GENERAL

RADIATION SAFETY INSTRUCTIONS

PRECAUTIONS TO BE OBSERVED BEFORE

AND DURING SERVICING TO AVOID P OSSIBLE

EXPOSURE TO EXCESSIVE MICROWAVE

ENERGY.

1. Do not operate or allow the ov en to be

operated with the door open.

2. Make the f ollowing safety checks on all ovens

to be serviced before activating the magnetron

or other microwave source, and make repai r s

as necessary:

A. Interloc k operation.

B. Proper door cl osi ng.

C. Seal and sealing surfaces (arcing, wear,

and other damage).

D. Damage to or loosening of hinges and

latches.

E. Evidence of dropping or abuse.

GENERAL

INTRODUCTION

General

The combination FlashBake

cooks the outside of foods muc h like conventional

radiant heat, while also penetrating the surf ac e so

the inside cook s simultaneously. While halogen light

is the primary source of power, a “microwave boost”

is added with certain foods. Foods cook evenly and

fast, retaining their natural moisture.

®

and microwave oven

3. Before t ur ning on mi c r owave power for any

servi ce test or inspection within the microwave

generating compartm ents, check the

magnetron, wave guide or t r ansmission line

and cavity f or proper alignment, integrity, and

connections.

4. Any defective or misadj ust ed c omponent in t he

interl ock, monitor, door seal, and microwave

generation or transmission systems shall be

repaired, r eplaced, or adjusted by pr oc edur es

described in t his manual before the oven is

released to the owner.

A microwave leakage ch eck to verify

5.

compliance with the Federal Performance

Standard should be performed on each

oven prior to release to t he owner.

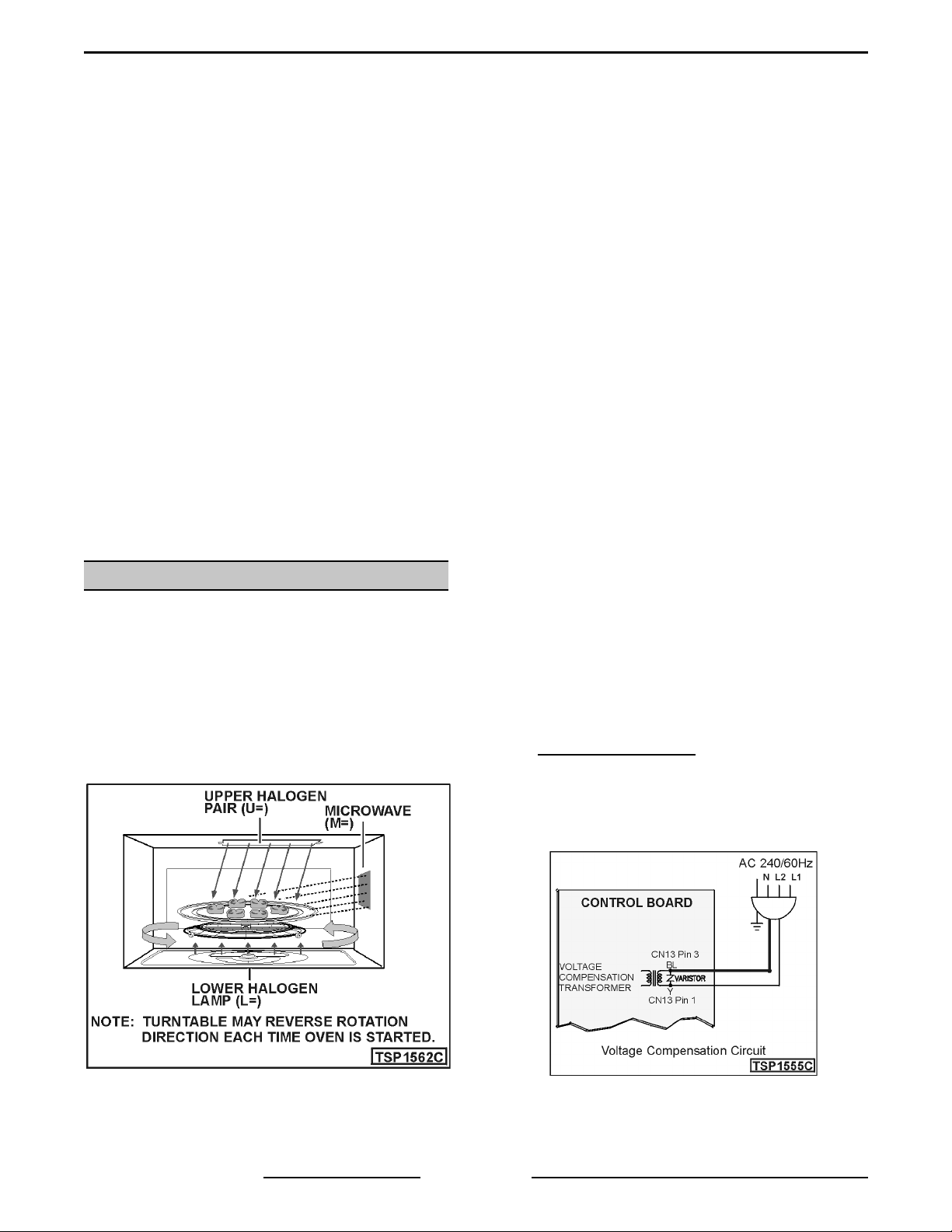

Ov en features:

• Turntable rotates to ensure even cooking.

• Halogen lamps; two 1500 watt lamps cook from

the top and one 1500 watt lamp cooks fr om the

bottom.

• Microwave “boost” is automatical ly added with

certain foods.

• Ov en c an also be used as a 950-watt

microwave oven.

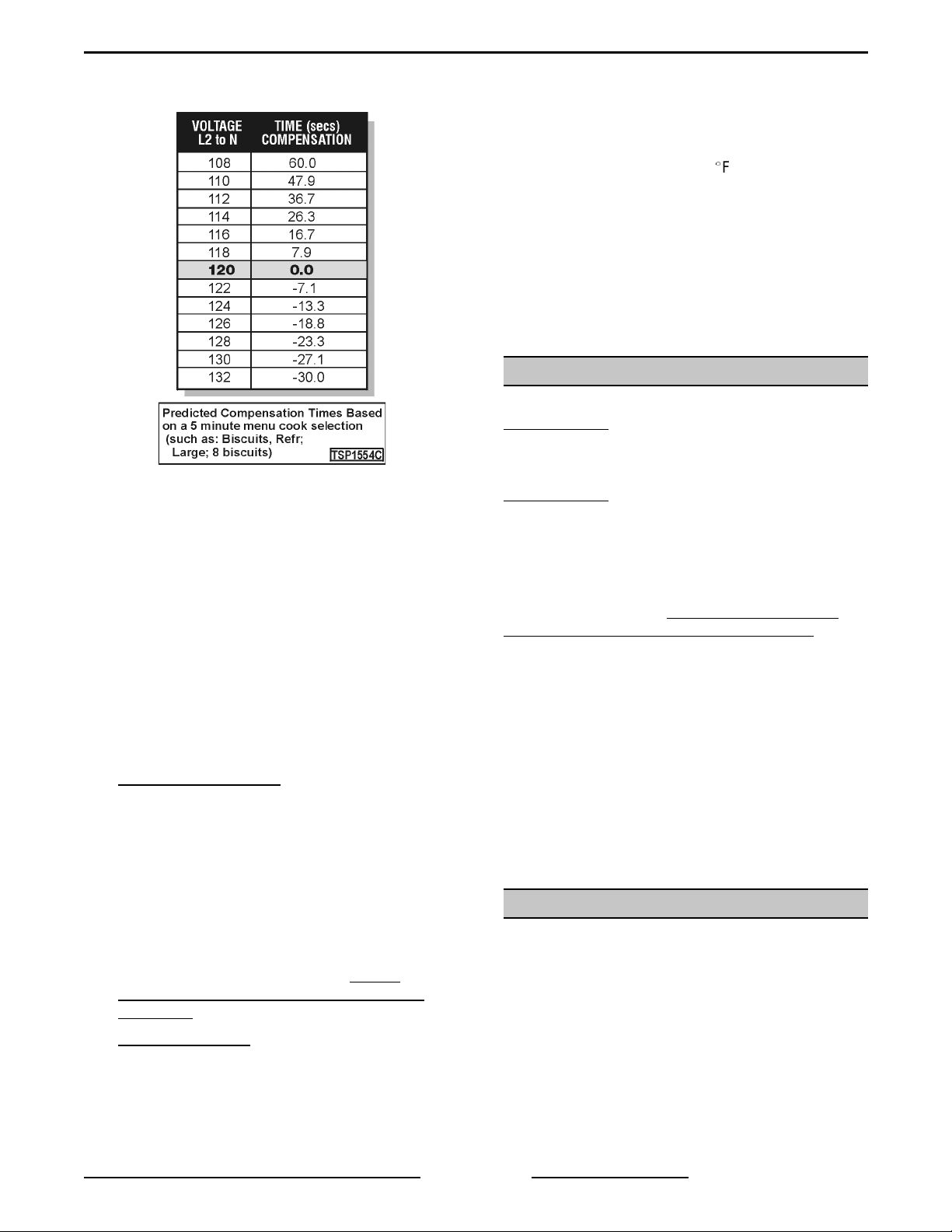

• Voltage Compensation

monit ored by the v oltage compensat ion

transformer on the contr ol board. It monitors

voltage from L2 to neutral at the start of each

menu cook selec tion and adjusts the cooking

tim e to achieve qualit y results.

: Line voltage is

Form 24694 ( A pr il 2001) Page 4 of 52

The optimal line voltage of 120VA C has no

compensation. Above 120V A C , tim e is

subtracted f rom the recipe (up to -30 sec.).

Below 120VAC, time is added to the recipe (up

FLASHBAKE® / MICROWAVE O VEN GENERAL

to +60 sec.). Compensation voltage range

is 108 to 132VAC.

Voltage compensation occurs after

approximately 5 seconds of menu cook

operation. The display will show "OPTIMIZING

COOK TIME.” The time will flash and then

display the new adjusted time, based on the

amount of voltage compensation required.

NOTE:

during menu cook operation and only occurs

once during the cooking cycle (at the initial

start of the menu cook cycle). When using

menu cook, y ou are selecting prepr ogr ammed

item s from a menu. These items require

compensation for accurate and consistent

cooking results. When c ook ing with combi

cook, voltage compensation does not occur.

• Thermal Compensation

item s consecut ively, the temperature i nsi de the

oven cavity can become very hot. The control

automatically compensates for the increased

temperat ure by adjusting t he c ook ing power

levels of both the upper and lower halogen

lamps. At the start of each new cook operation

(just pri or to voltage compensation occurring),

the cavity ther mistor reads the c avity

temperat ure and the control boar d adjusts

power levels to compensate for heat that

already ex ists in the oven cavity. It is not

possible to see the

the display.

Voltage compensation only oc c ur s

: When cooking food

adjusted

power levels in

cycle. The consumer will not notice any change

in display r eadout, however, they may notice

that the hal ogen lamps are cycling differently

than expect ed.

In the unlikely event that internal oven cavity

temperat ure exceeds 600(F, combi cook

operation will be terminated. When the control

board terminates the combi cook cycle, it

returns the displ ay to its normal off position

(with ti me of day c lock showing in display ) .

Since the t hermistor in the cavity is constantly

being monitored by the control board, when the

unit cool s, the control board r eturns oven to

normal operation.

ELECTRICAL SPECIFICATIONS

Model FBM W2 i s supplied with a cord and plug.

For cord and plug units, an NEMA 14-30R wall

receptacle is required.

Model FBM W3

NOTE:

the green and white wires crimped together . On

these units the frame i s grounded by c onnec tion of

ground lead to neutral white lead. Effective January

1, 1996, the National Elec trical Code r equires that

new construction use a (4) conductor connection

and will not permit grounding through neutral. If

used in new construction after January 1, 1996, or if

local codes do not per mit grounding through neutral

white lead, open the factory crim p c onnec tion and

connect neutral white lead to br anc h c ircuit neutral

conductor in usual manner.

120/208-240, 60 Hz, single phase, 30 amp power

supply is requir ed.

Wor k ing voltage = 208 to 264V A C.

Early hard wir ed models left the factory with

is a unit intended to be hard wired.

INSTALLATION

Refer to the INSTRUCTI ONS manual shi pped with

the ov en for installation instructi ons.

• Thermal Protection

temperat ures reach somewhere between 500

and 600 degrees, or if cook time exceeds 12

minut es of cooking at halogen power levels

greater than 7, all power levels (lamps and

microwave) will be reduced by the control

board to 7 for the remai nder of the combi cook

: If oven cavity

Form 24694 ( A pr il 2001)Page 5 of 52

FLASHBAKE® / MICROWAVE O VEN GENERAL

OPERATION

Refer to the INSTRUCTI ONS manual shi pped with

the ov en for com plete operati ng instructi ons,

precautions and utensi ls to use.

CAUTION: Do not attempt to cook with the oven

empty. If there is no l oad in the cavity to absorb

the microw ave energy, the energy will be

reflected b ack into the magnetron cau sing it to

overheat which may result in magnetron failure.

NOTE:

and off during a combi cook cycle, sometimes even

at full power levels. This is normal. The oven senses

the heat level and adjusts automati cally. What is

important to note i s t hat while the power levels have

been reduced (thermal com pensation), the power

levels which will show in the display will be the

original power lev els.

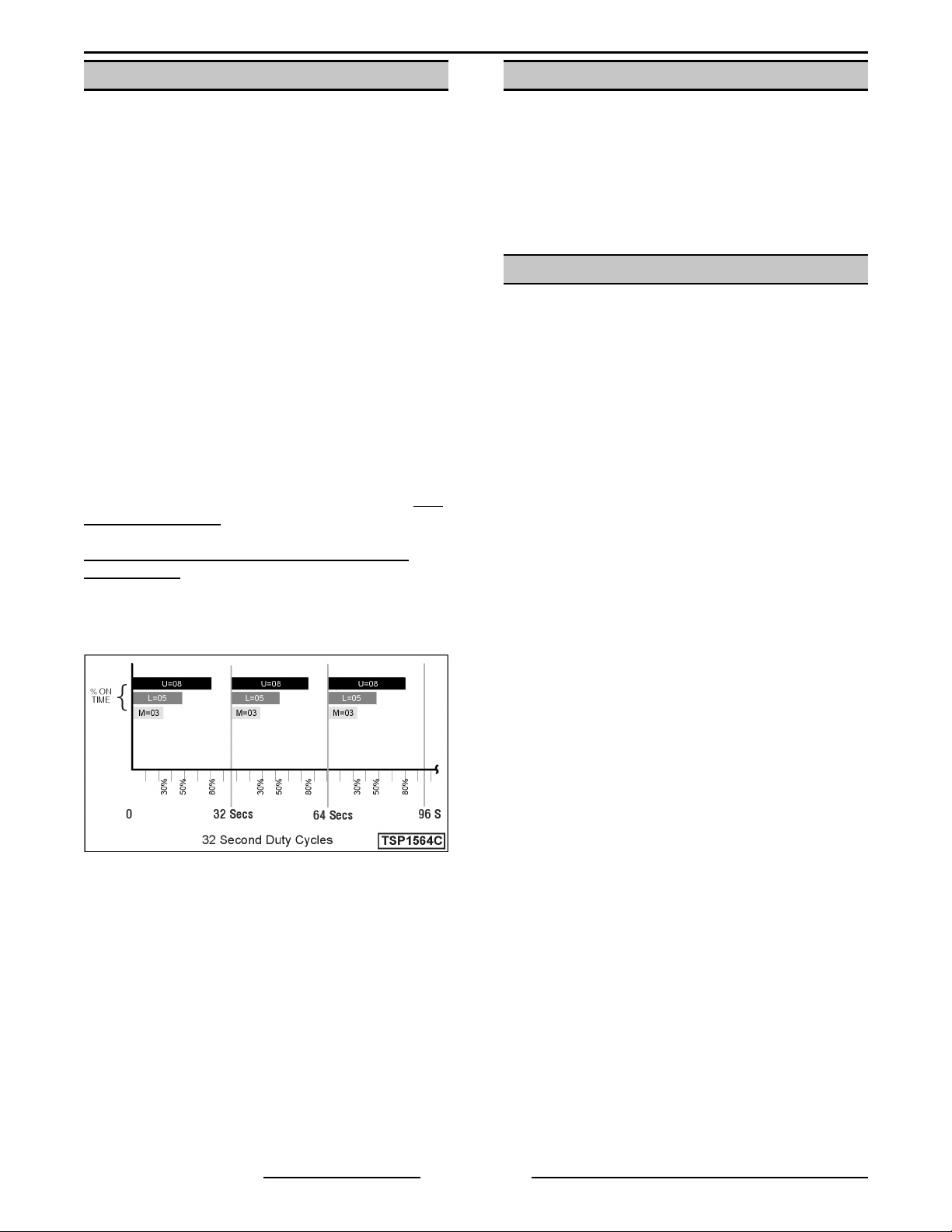

NOTE:

which control s the upper halogen lamps (U=), the

lower halogen lamp (L=), as well as the high

voltage/magnetron circuits (M=), oper ates on a duty

cycle of 32 seconds. This means the power level

you select for each component controls the

percentage of "on" time during each 32 second

period of time.

Example:

(U=08), lower halogen lamp set at 50% (L=05), and

microwave set at 30% (M=03).

The halogen lamps will dim and cycle on

The program ming on the control board

Upper halogen lamp pair set at 80%

CLEANING

CAUTION: Never use oven cleaners t o clean the

oven. Never use abrasives or sharp objects on

the oven walls or window.

Refer to the INSTRUCTI ONS manual shi pped with

the ov en for com plete cleaning instructions.

• Set of standar d hand tools

• Volt-ohm meter wi th a sensitivity of at least

20,000 ohms per volt.

• Field servic e gr ounding kit. ( TL 84919)

• 1 liter beaker (made of material suitable for

high oven temperat ur e)

• Thermometer (519928 or 538454)

• A mic rowave leak detector that has been

calibrated by the manufacture wit hin the year.

Exam ples follow:

1. Holiday: Model HI-1801

2. Simpson: Model 380-2

TOOLS

Model HI-1501

Form 24694 ( A pr il 2001) Page 6 of 52

FLASHBAKE® / MICROWAVE O VEN REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

NOTE:

NOTE:

routing of wires for proper r einstallat ion.

CAUTION: All removed screws must b e replaced to p revent possib le microwave energy leakage. Mo st of

the screws you will be removing will be of two sizes, 1/2" shank and 3/8" shank Phillips head screws.

Note their positio ns for prop er reinstallation. So me screws have machine t hreads and must be installed

in proper locations.

NOTE:

adjusted, a radiation leak test MUST be performed in the magnetron area.

NOTE:

the appropriate place before connectors can be separated. When installing connec tors, take extra care to ensure

all tabs in gang connectors are properl y aligned bef or e c onnec ting. When installing connectors, listen for click

sound and stop. If connector is seated on too far it may be diffic ult to remove. E xercise caution when removing

connectors so that components are not damaged.

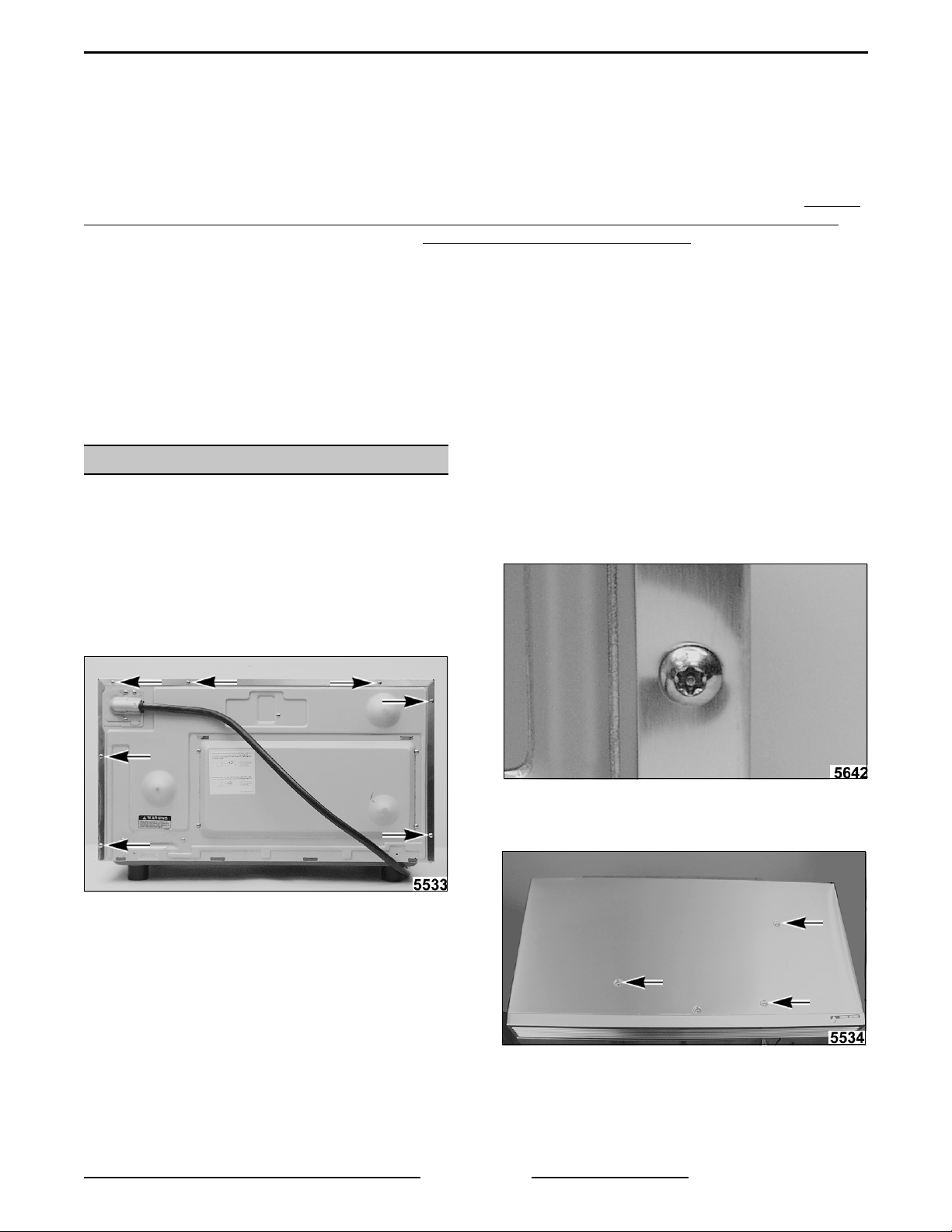

Main Cover

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

References to left and right are as viewed from the front (operator side) of unit.

Any cable ties removed in order t o service the unit should be replaced. Be sure to note t he location and

During reassembl y , before i nstalling main cover and after all necessary components are replaced and

New type connectors are used on this oven. Some have locking tabs that must be released by pressing i n

COVERS AND PANELS

DISCONNECT THE ELECTRICAL

NOTE:

screws (non remov able without special tool)

installed. If y ou encounter one of t hese units,

remove the special screws and replace them with

standard screws. Also remove the label indicating

the use of the non remov able screws.

Some earl y units had two security type

1. Remove screws securing cover at rear of unit.

MODEL FBMW2 SHOWN

2. Remove screws securing top of cover. Note

that these are silver screws.

Form 24694 ( A pr il 2001)Page 7 of 52

FLASHBAKE® / MICROWAVE O VEN REMOVAL AND REPLACEMENT OF PARTS

3. Remove two screws securing each side of

cover located underneath si de of unit.

4. Slide cover rear ward to disengage cover from

front si des of unit.

5. Carefully lift cover with vent grill off unit.

6. Reverse proc edur e to install .

Back Panel

1. Remove screws securing bottom panel.

2. Disengage bottom panel from back panel and

remove bottom panel.

3. Reverse proc edur e to install .

FRONT VENT GRILL

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove "MAIN COV E R.”

2. Remove "POWER CORD.”

3. Remove screws securing back panel.

4. Pull bot tom of bac k panel away from unit to

disengage it from bottom panel.

DISCONNECT THE ELECTRICAL

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove screw securing grill on top.

2. Remove one screw on each side of grill.

DISCONNECT THE ELECTRICAL

5. Reverse proc edur e to install .

Bottom panel

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Form 24694 ( A pr il 2001) Page 8 of 52

DISCONNECT THE ELECTRICAL

3. Pull grill out front.

4. Reverse proc edur e to install .

FLASHBAKE® / MICROWAVE O VEN REMOVAL AND REPLACEMENT OF PARTS

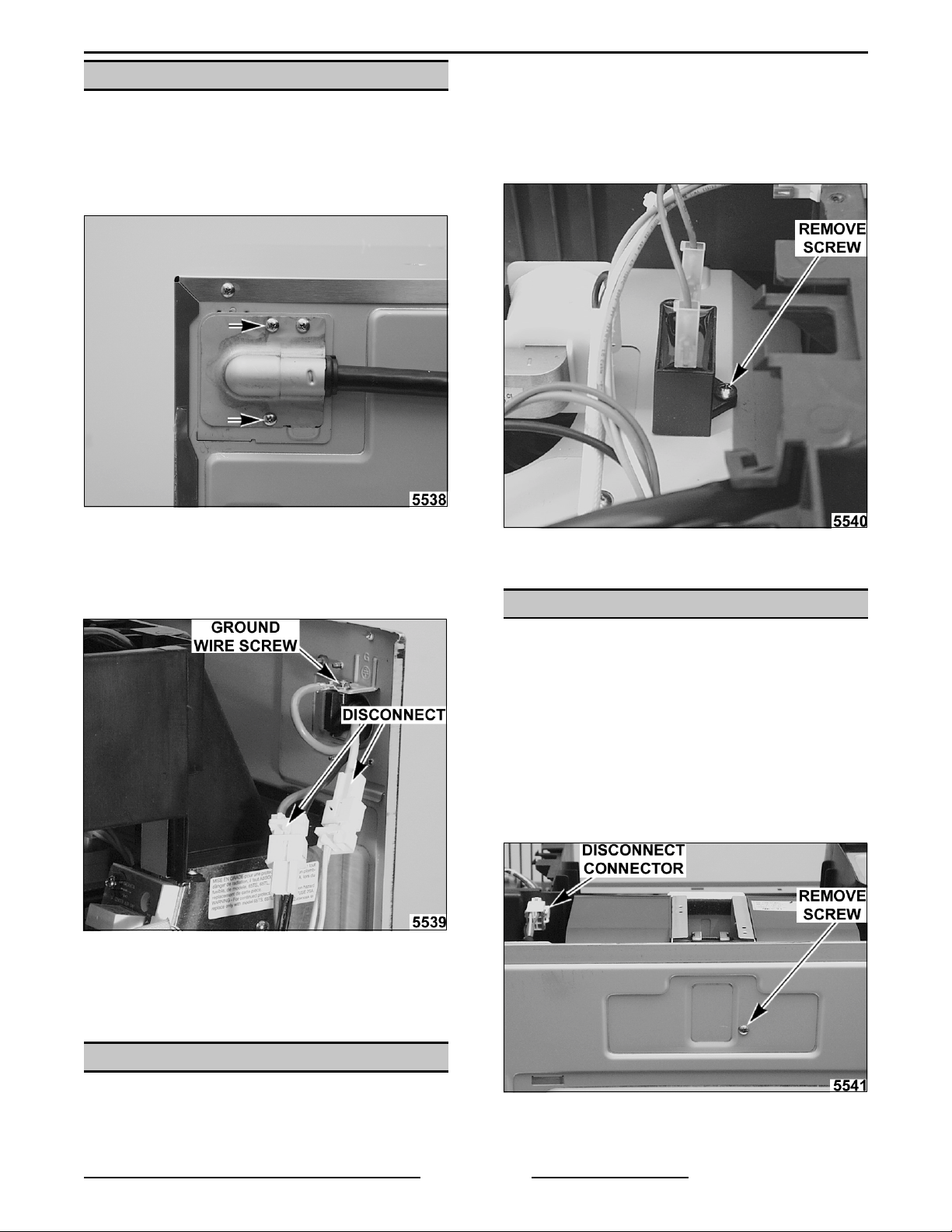

POWER CORD

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

1. Remove "MAIN COV E R.”

2. Remove two screws securing strain relief plate

and remove plate.

MODEL FBMW2 WITH MAIN COVER INSTALLED

3. Disconnect power cord connectors.

UNPLUG THE MAIN POWER CORD.

1. Remove "MAIN COV E R.”

2. Disconnect wires from capacitor.

3. Remove screw securing capacit or .

4. Reverse proc edur e to install .

4. Remove screw securing ground wire.

NOTE:

5. Remove power cord through hole in back

6. Reverse proc edur e to install .

Screw is a machine screw with fine t hr eads.

panel.

VENT FAN

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove "MAIN COV E R.”

2. Disconnect connector for fan motor.

3. Remove screw securing fan assembly to back

panel.

DISCONNECT THE ELECTRICAL

VENT FAN CAPACITOR

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

DISCONNECT THE ELECTRICAL

4. Lift fan out of unit.

5. Reverse proc edur e to install .

Form 24694 ( A pr il 2001)Page 9 of 52

FLASHBAKE® / MICROWAVE O VEN REMOVAL AND REPLACEMENT OF PARTS

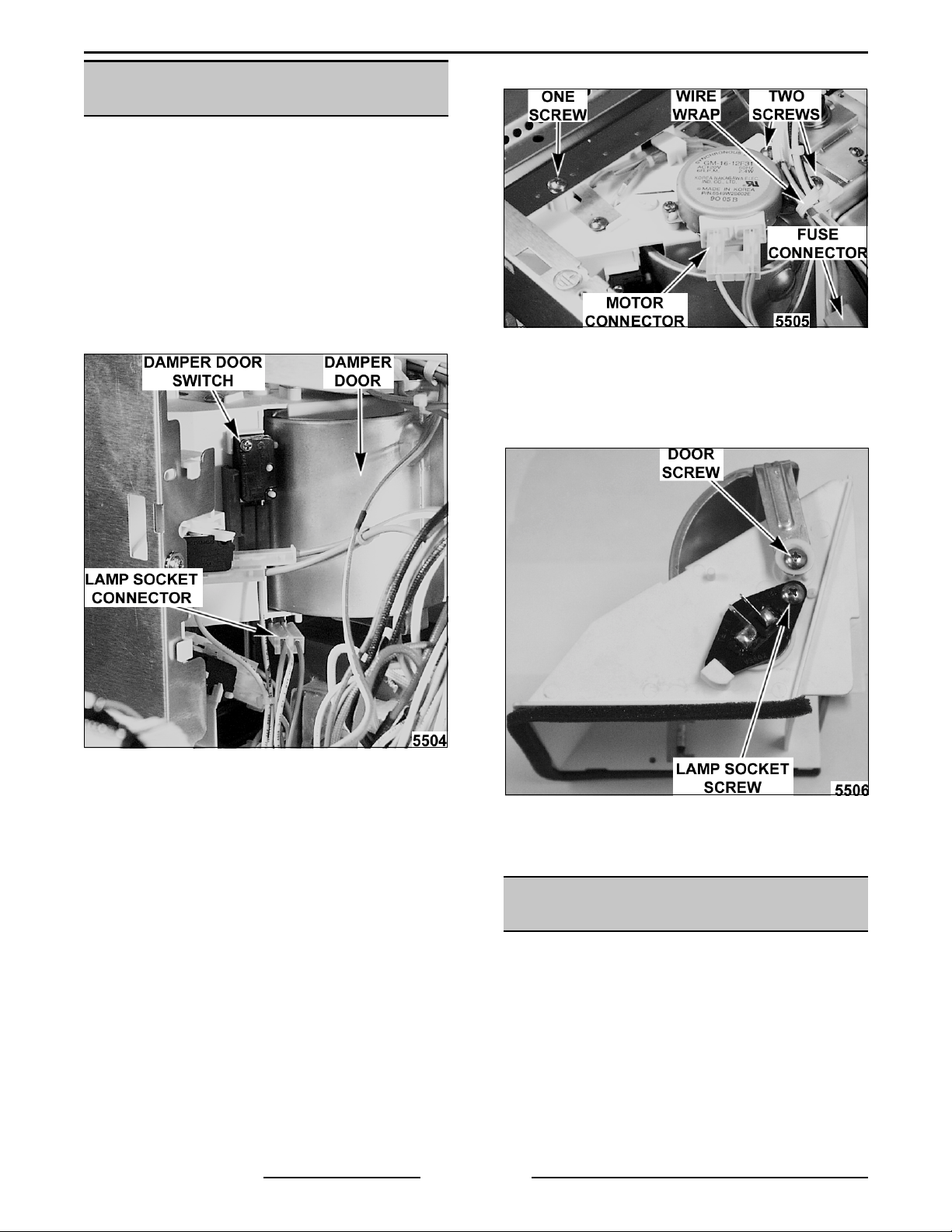

CAVITY LAMP AND DAMPER

DOOR ASSEMBLY

7. Undo wire wrap and work wires out.

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove "UPPER LAMP HOUSING AND

DUCT ASSEMBLY.”

2. Remove connector from l amp door switch.

3. Remove connector from l amp socket.

DISCONNECT THE ELECTRICAL

8. Remove sc rew secu ring lamp soc ket.

NOTE:

9. If door is to be removed, first remove motor

Lamp and socket are r eplaced as one piece.

and then remove screw securing bott om of

door.

4. Remove one screw securing assembly to top of

cavity.

5. Remove two screws securing assembly to top

of m agnetron.

NOTE:

different.

6. Disconnect motor connector and thermal fuse

Form 24694 ( A pr il 2001) Page 10 of 52

Screws removed from magnetron ar e

connector.

10. Reverse procedure to install.

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove "UPPER LAMP HOUSING AND

2. Disconnect thermal fuse connector.

3. Undo wire wrap and work wires out.

DAMPER HOUSING THERMAL

FUSE

DISCONNECT THE ELECTRICAL

DUCT ASSEMBLY.”

FLASHBAKE® / MICROWAVE O VEN REMOVAL AND REPLACEMENT OF PARTS

4. Remove screw and shield.

5. Slide fuse out of slot.

WARNING:

CARE SHOULD BE TAKEN WHEN MEASURING

AROUND THE MAGNETRON.

1. Remove "MAIN COV E R.”

2. Discharge high voltage capacitor by short ing

the term inals of the high v oltage capaci tor with

an insulated handled screwdriver or insulated

jumper wi r e.

3. Remove fuse f r om holder.

DUE TO HIGH VOLTAGE, SPECIAL

6. Reverse proc edur e to install .

FUSE - 20 AMP

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Important Note:

due to the operation of the monitor switc h, check the

following components and replace the ones found t o

be malfunctioning.

A. Door prim ary interlock switch.

B. Door secondary inter lock switch.

C. Door monitor switch.

NOTE:

cover and after al l necessary components are

replaced and adjust ed, a radiati on leak test MUST

be performed in the magnetron area.

DISCONNECT THE ELECTRICAL

When the 20 amp f use i s blown

During reassembl y , before i nstalling main

MODEL FBMW2 SHOWN

4. Reverse proc edur e to install .

Form 24694 ( A pr il 2001)Page 11 of 52

FLASHBAKE® / MICROWAVE O VEN REMOVAL AND REPLACEMENT OF PARTS

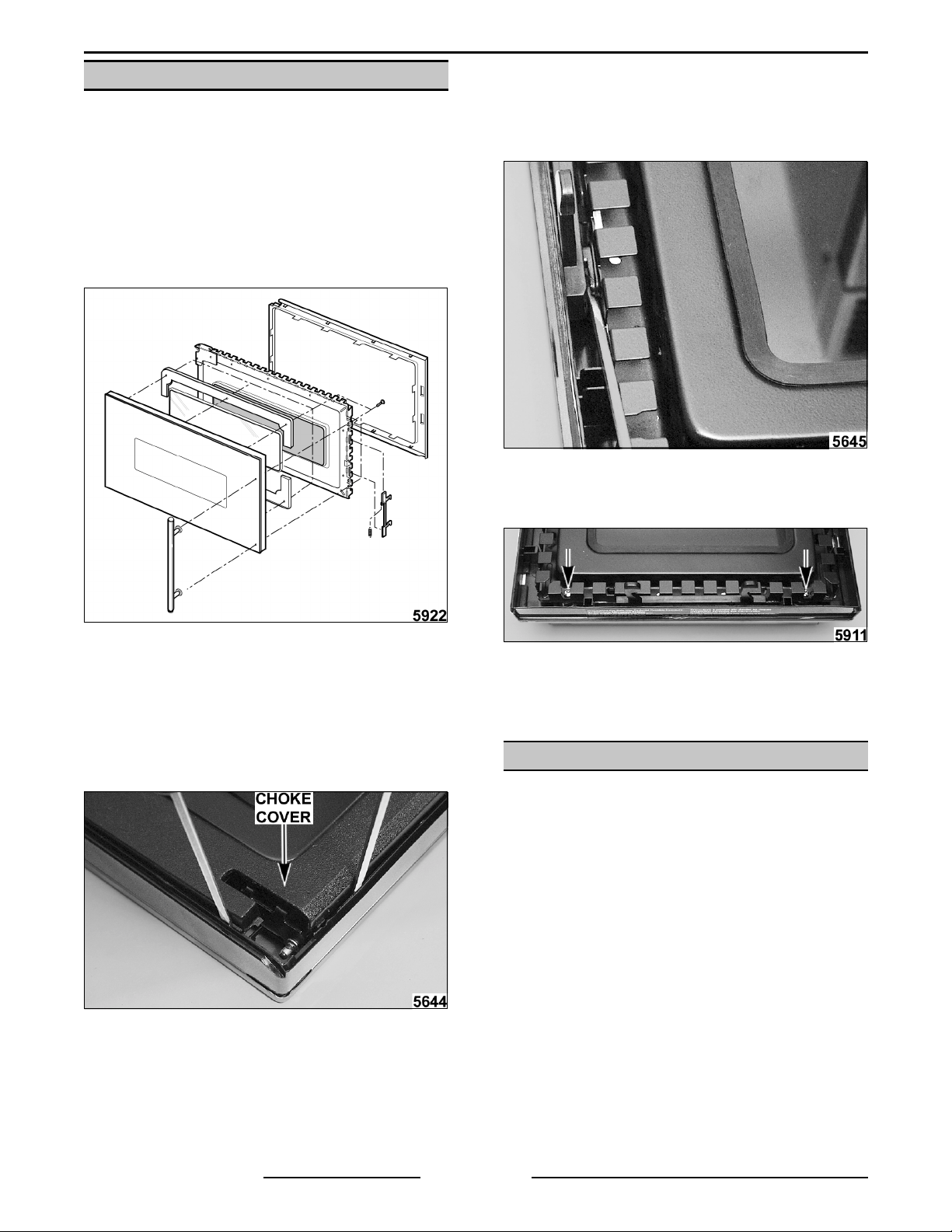

DOOR

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Open door.

2. Lift door to disengage hinge pins from holes in

hinges and remove door.

DISCONNECT THE ELECTRICAL

B. The latch c an be removed by pushing it

against spring tensi on to the end of its

travel. Then pry latch out of mounting

holes and lift it up enough to be able to

disconnect the spring.

C. Remove door handle by removing screws

securing it .

EXPLODED VIEW OF DOOR ASSEMBLY

3. To replace door handle, door lat c h:

A. Insert small flat type screwdriver into gap

between choke cover and lower right

corner of the door frame fi rst and then

around the seal plate to free engaging

parts of choke cover.

4. Reverse proc edur e to install .

5. Perform "RADIATION LEAKAGE TEST.”

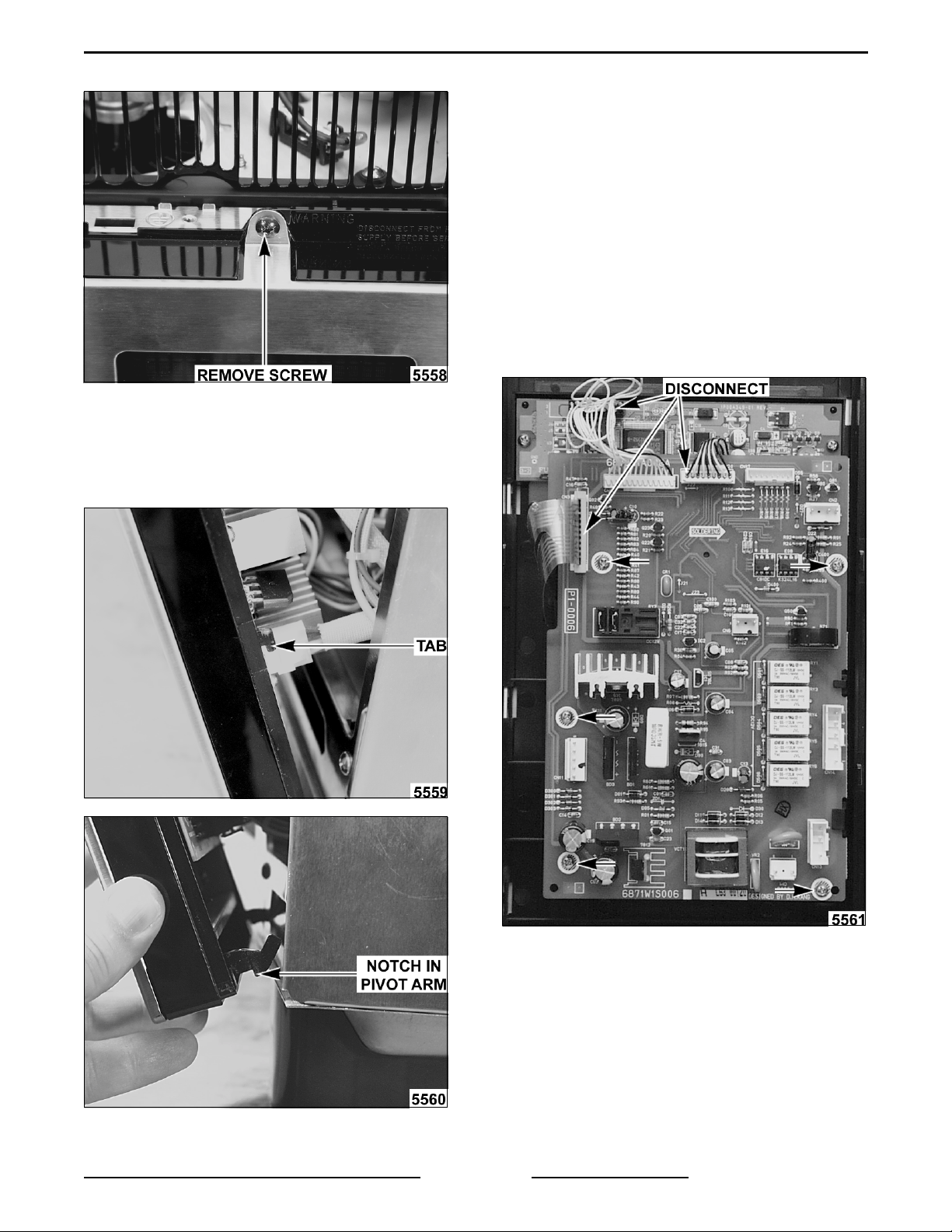

CONTROL PANEL ASSEMBLY

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

CAUTION: Certain components in this system

are subject to damage by electrostatic discharge

during field repairs. A field service grounding kit

is available to prevent damage. T he field servi ce

grounding kit must be used anytime the control

board is handled.

Control Panel

1. Remove “FRONT VENT GRILL.”

DISCONNECT THE ELECTRICAL

Form 24694 ( A pr il 2001) Page 12 of 52

FLASHBAKE® / MICROWAVE O VEN REMOVAL AND REPLACEMENT OF PARTS

2. Remove screw securing top of c ontrol panel.

3. Open ov en door .

4. Lift control panel about 1/8" to disengage tabs

at both sides of panel and notch on bottom

pivot arms.

6. Disconnect ei ght plugs from control boar d.

CAUTION: Wh en reassembling, be certain all

plugs are correctly mated. If plug is colored,

connect i t to same colo r connector o n board.

Failure to connect correctly will result in

damage to unit.

7. Lift panel and work pivot arms out of holes and

remove panel from unit.

Control Board

1. Remove "CONTROL PANEL.”

2. Disconnect connectors going to display boar d,

LED board and keyswitch board.

3. Remove fi ve screws securing control board and

remove board.

5. Allow panel to tilt forward.

Form 24694 ( A pr il 2001)Page 13 of 52

FLASHBAKE® / MICROWAVE O VEN REMOVAL AND REPLACEMENT OF PARTS

NOTE:

each side that must be released in order to

completely disconnect.

4. Reverse proc edur e to install .

The keypad connector has a locking tab on

3. Remove two screws securing LED display

assembly and remove assembly.

4. Reverse proc edur e to install .

RELAY BOARD

Keypad Assembly

1. Remove "CONTROL BOARD.”

2. Remove “DISPLAY.”

3. Remove “LED DISPLAY.”

4. Reverse proc edur e to install .

Display

1. Remove "CONTROL BOARD.”

2. Remove two screws securing display board and

remove board.

3. Reverse proc edur e to install .

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove "MAIN COV E R.”

2. Remove "CONTROL PANEL.”

3. Disconnect two blue c onnec tors on wires

coming from relay board.

4. Disconnect white c onnec tor on wires coming

from relay board.

NOTE:

removable.

DISCONNECT THE ELECTRICAL

Connector CN100 on relay board is not

LED Displ ay

1. Remove "CONTROL BOARD.”

2. Remove “DISPLAY.”

Form 24694 ( A pr il 2001) Page 14 of 52

FLASHBAKE® / MICROWAVE O VEN REMOVAL AND REPLACEMENT OF PARTS

5. Remove two screws securing relay board to

board support and work relay board out of

support.

3. Remove two screws securing assembly to unit.

6. Reverse proc edur e to install .

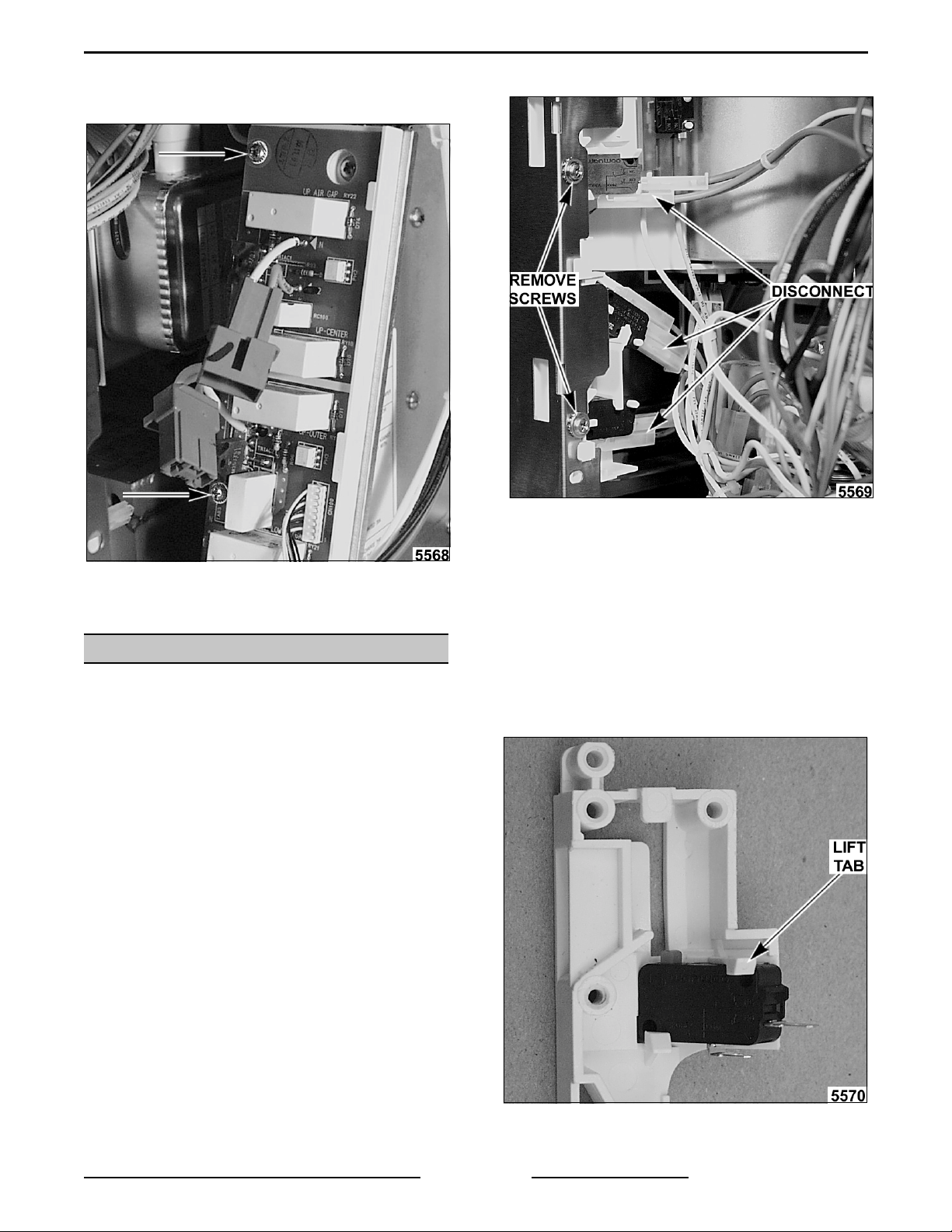

DOOR SWITCH A SSEMBLY

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove "CONTROL PANEL.”

2. Identify and disconnect connectors from the

three switches.

DISCONNECT THE ELECTRICAL

4. Careful ly slide assembly up to disengage tabs

and rotate assembl y out of unit.

5. Remove a switch by pressing appropri ate tab to

release switch.

CAUTION: Flex tabs only enough to release

switch. Excessive flexing will result in tab

breaking.

A. For top switch (primary interlock switch),

lift tab away fr om switch and slide switc h

out.

Form 24694 ( A pr il 2001)Page 15 of 52

FLASHBAKE® / MICROWAVE O VEN REMOVAL AND REPLACEMENT OF PARTS

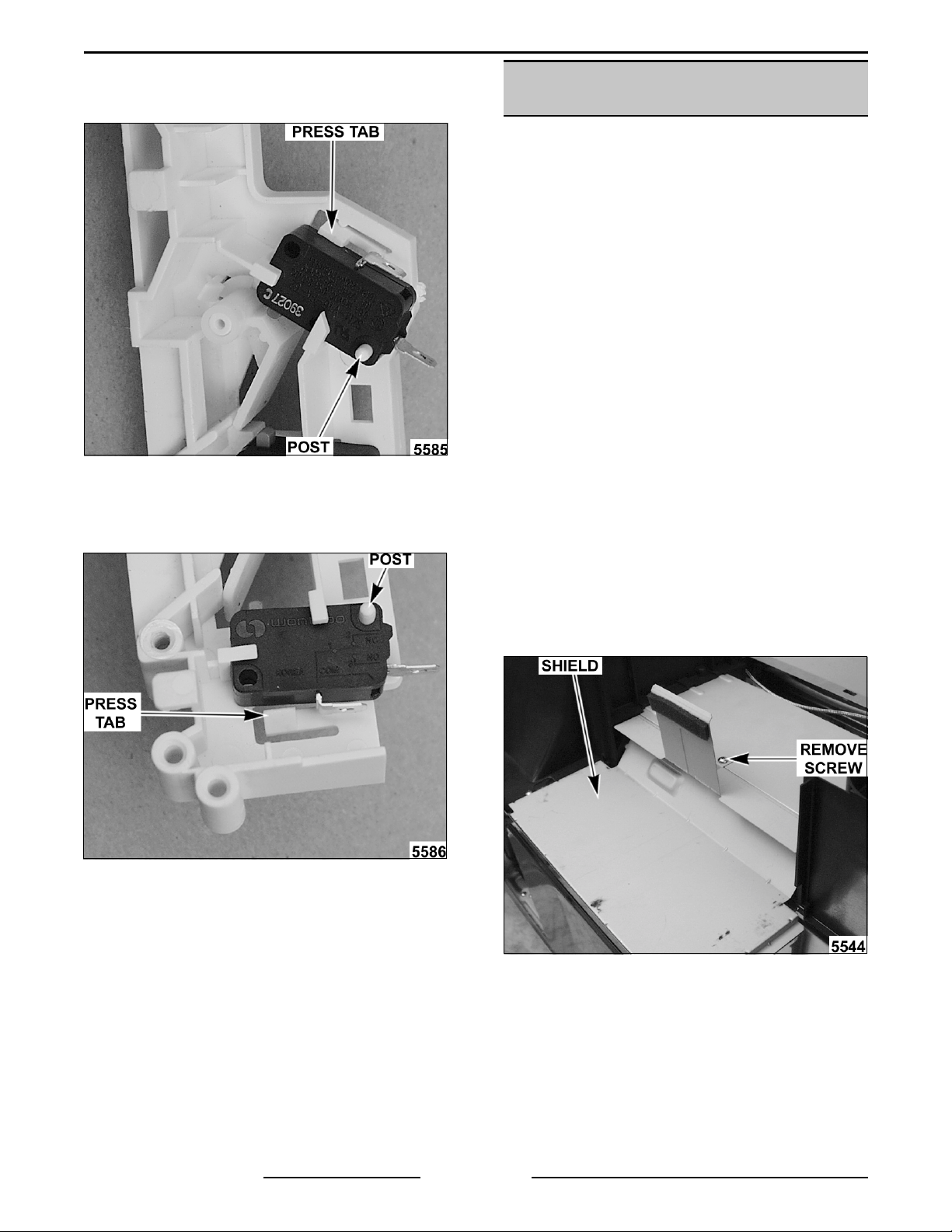

B. For middle switch (i nterlock monitor

switch), press tab downward and then

pivot switch to clear stops and lift off post.

UPPER LAMP HOUSING AND

DUCT ASSEMBLY

Parts that can be ac c essed when upper lam p

housing and duct assembly is removed:

• Cavity thermistor.

• Thermal cut out located at top of magnetron.

• Magnetron.

• Upper lamp assem bly.

• Upper lamp fan assembly.

• Damper door assembly.

• Magnetron f an assem bly.

• Lower lamp fan assembly.

• High voltage transformer.

C. For bottom switch (door sensing

secondary interlock switch), press tab

downward and then pivot switch to clear

stops and lift off post.

6. Reverse proc edur e to install .

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove "MAIN COV E R.”

2. Remove "VENT FAN.”

3. Remove "BACK PANEL.”

4. Remove screw securing shield and remove

shield.

DISCONNECT THE ELECTRICAL

7. Adjust as outlined in service procedures and

adjustment s "DOOR LATCH.”

8. Perform leakage test .

5. Discharge high voltage capacitor by short ing

Form 24694 ( A pr il 2001) Page 16 of 52

the term inals of the high v oltage capaci tor with

an insulated handled screwdriver or insulated

jumper wi r e.

Loading...

Loading...