Page 1

OPERATION MANUAL

VC SERIES

GAS CONVECTION OVENS

MODELS

VC4GD ML-126611

VC4GC ML-136494

VC6GD ML-126613

VC6GC ML-136495

INSTALLATION &

STACKED MODELS

VC44GD ML-126611

VC44GC ML-136494

VC66GD ML-126613

VC66GC ML-136495

For additional information on Vulcan-Hart or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanhart.com

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

MODEL VC4GD

P.O. BOX 696

LOUISVILLE, KY 40201-0696

WWW.VULCANHART.COM

FORM 31123 Rev. G (10-06)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN

UNITS AT MAIN SHUTOFF VALVE AND CONTACT THE

LOCAL GAS COMPANY OR GAS SUPPLIER FOR

SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING

OR SERVICING THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT

TO OPERATE THIS DEVICE.

© VULCAN-HART, 2005, 2006

– 2 –

Page 3

Installation, Operation and Care of

VC SERIES

GAS CONVECTION OVENS

KEEP THIS MANUAL FOR FUTURE REFERENCE

GENERAL

Models VC4GD and VC6GD feature a solid state temperature control. Models VC4GC and VC6GC

feature a programmable oven controller. One hour dial timer is standard; five hour timer is optional.

Two-speed

additional oven racks are available. The burner input rating for each oven is 44,000 BTU/hr.

Porcelain interior is standard on all models.

Model VC6GD and VC6GC has a 4 inches (102 mm) deeper oven cavity.

Standard ovens are 120 V, 60 Hz, 1 PH and include cord and plug. Optional electrical specifications

of 208/240 V are available and require hard wire connection.

1

/2 HP (0.37 kw) electric motor is standard equipment. Each oven is furnished with 5 racks;

Independently opening doors are standard; simultaneous door opening is optional.

Other options include: an open stand with lower storage rack, roast and hold, and a stacking kit for

mounting one oven on top of another.

Vulcan VC Series Gas Convection Ovens are produced with quality workmanship and material. Proper

installation, usage and maintenance of your oven will result in many years of satisfactory performance.

It is suggested that you thoroughly read this entire manual and carefully follow all of the instructions

provided.

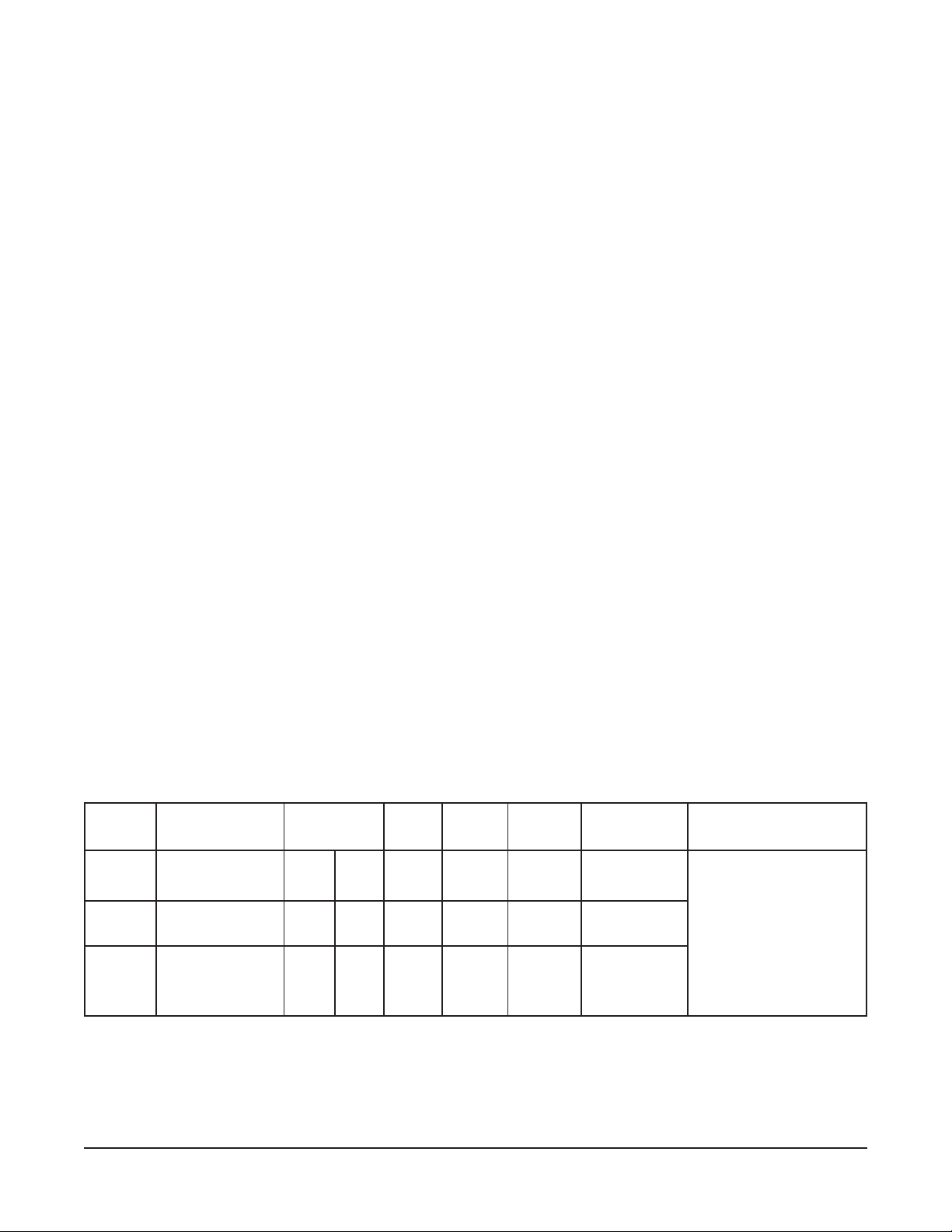

FEATURES AND OPTIONS

Model Thermostat Timer

VC4GD

VC6GD Std. Opt. (654 mm)

VC4GC

VC6GC (654 mm)

Stacked 8"

Ovens (203 mm)

Solid State

Programmable N/A N/A Std. Std.

1 Hr. 5 Hr.

Oven Roast &

Lights Hold Storage Rack

Std. Opt.

Legs

3

25

253/4

/4

Stand with

Opt.

Opt.

Voltage

120/60/1 Std.

208/60/1 Opt.

240/60/1 Opt.

240/50/1 Opt.

220/380 (3W)/50/3 Opt.

220/380 (4W)/50/3 Opt.

240/415 (4W)/50/3 Opt.

– 3 –

Page 4

INSTALLATION

Before installing, verify that the electrical service and type of gas supply (natural or L.P.) agree with

the specifications on the rating plate, located behind the top trim panel on the front of the oven. If the

supply and equipment requirements do not agree, do not proceed with the installation. Contact your

dealer or Vulcan-Hart Company immediately.

UNPACKING

This oven was inspected before leaving the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of the shipment. Immediately after unpacking, check

for possible shipping damage. If the oven is found to be damaged, save the packaging material and

contact the carrier within 15 days of delivery.

Carefully unpack the oven and place it in a work-accessible area near to its final installed position.

Do not use the doors or their handles to lift the oven.

LOCATION

The equipment area must be kept free and clear of combustible substances.

When installed, minimum clearance from combustible construction must be 1 inch (25 mm) at the left

side, 4 inches (102 mm) at the right side and 6 inches (152 mm) at the rear. Minimum clearance from

noncombustible construction must be 0 inch (0 mm) at the left side, 4 inches (102 mm) at the right side

and 6 inches (152 mm) at the rear. The oven may be installed on combustible floors.

The installation location must allow adequate clearances for servicing and proper operation. For solid

state and digital control models, there must be 18 inches (457 mm) of clearance on the right side of

the oven from any open flame.

The oven must be installed so that the flow of combustion and ventilation air will not be obstructed.

Adequate clearance for air openings into the combustion chamber must be provided. Make sure there

is an adequate supply of air in the room to allow for combustion of gas at the oven burners.

Do not permit fans to blow directly at the oven. Wherever possible, avoid open windows next to the oven.

Avoid wall-type fans which create air cross currents within the room.

INSTALLATION CODES AND STANDARDS

In the United States of America:

1. State and local codes.

2. National Fuel Gas Code, ANSI/Z223.1/NFPA #54 (latest edition). Copies may be obtained from The

American Gas Association, Inc., Accredited Standards Committee Z223 @ 400 N. Capital St. NW,

Washington, DC 20001 or the Secretary Standards Council, NFPA, 1 Batterymarch Park, Quincy,

MA 02169-7471.

NOTE: In the Commonwealth of Massachusetts,

All gas appliances vented through a ventilation hood or exhaust system equipped with a damper or

with a power means of exhaust shall comply with 248 CMR.

– 4 –

Page 5

3. Vapor Removal From Cooking Equipment

, NFPA-96 (latest edition). Copies may be obtained from

The National Fire Protection Association, Batterymarch Park, Quincy, MA 02169-7471.

4.

National Electrical Code, ANSI/NFPA-70 (latest edition). Copies may be obtained from The

National Fire Protection Association, Batterymarch Park, Quincy, MA 02169-7471.

In Canada:

1. Local codes.

2. CSA B149.1 Natural Gas and Propane Installation Code.

3. CSA C22.1 Canadian Electric Code (latest edition).

The above are available from the Canadian Standard Association, 5060 Spectrum Way, Suite 100,

Mississauga, Ontario, Canada L4W 5N6.

INSTALLING BASIC OVEN

The basic oven must be installed on legs or be mounted on a

modular stand. Installations on concrete bases or other supports

restricting air circulation underneath the oven is not advisable

and may void the warranty.

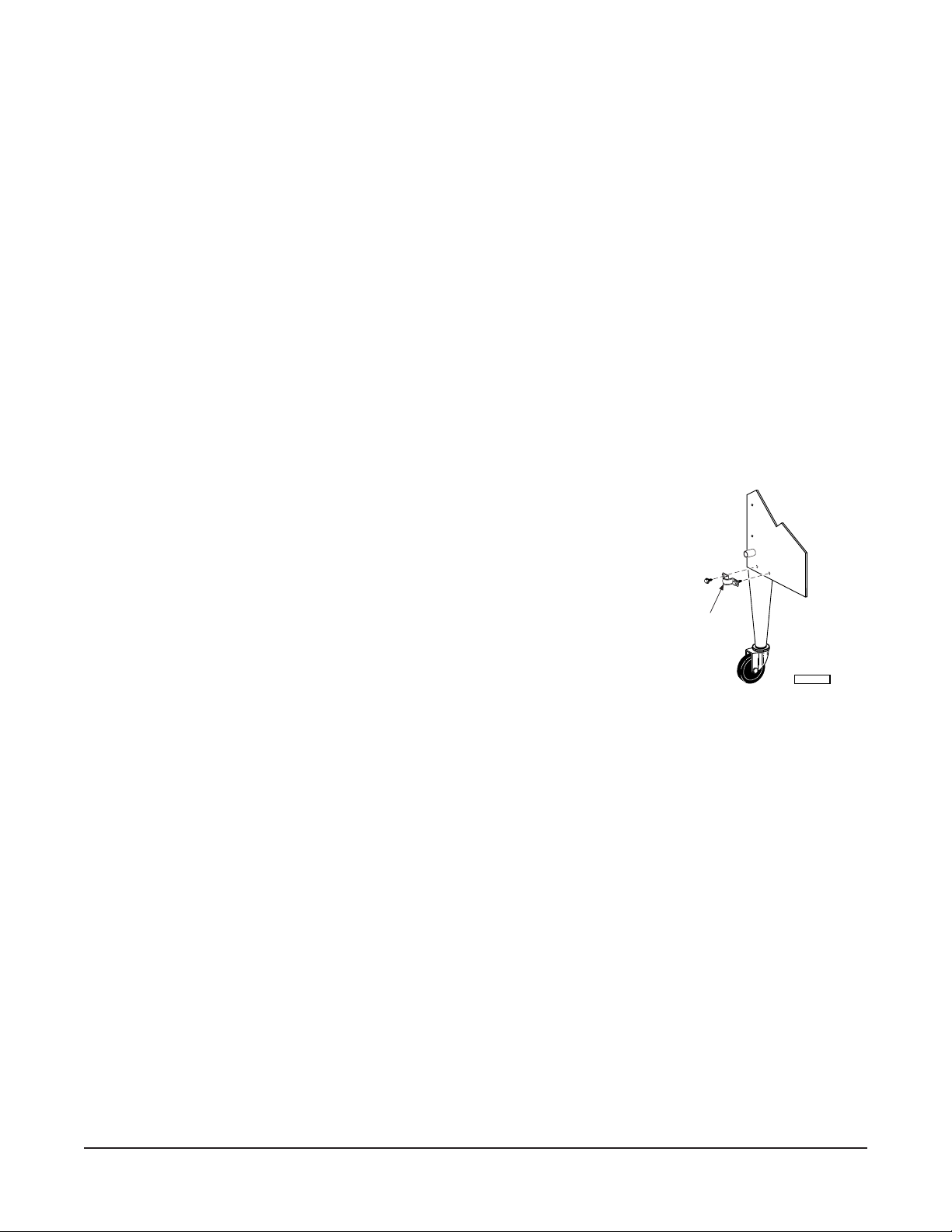

Ovens Mounted on Casters

Ovens mounted on casters must use a flexible connector (not

supplied by Vulcan) that complies with the Standard for

Connectors for Movable Gas Appliances, ANSI Z21.69 • CSA

6.16 and a quick-disconnect device that complies with the

Standard for Quick-Disconnect Devices for Use With Gas

CONNECT

GAS LINE

STRAIN RELIEF

HERE

PL-53563

Fuel, ANSI-Z21.41 • CSA 6.9. In addition, adequate means

must be provided to limit movement of the appliance without

depending on the connector and the quick-disconnect device

Fig. 1

or its associated piping to limit appliance movement. Attach the

restraining device at the rear of the oven as shown in Fig. 1.

Remove two screws from the rear of the oven and install the tie-down strap shipped with the casters

using these screws (Fig. 1). Attach the gas line strain relief to the tie-down strap at the rear of the oven

(Fig. 1).

If disconnection of the restraint is necessary, turn off the gas supply before disconnection. Reconnect

this restraint prior to turning the gas supply on and returning the oven to its installation position.

Separate instructions for installing casters to the oven are included with the casters.

Note: If the oven is installed on casters and is moved for any reason, it is recommended that the oven

be releveled front to back and side to side.

– 5 –

Page 6

Assembling the Legs to the Oven

The legs must be installed on the bottom of the oven. Gently

position the oven on its side, taking care not to scratch or damage

it.

Attach each of the four leg assemblies to the bottom of the oven

with the 24 bolts and lockwashers (six per leg). Carefully raise the

oven to its normal position.

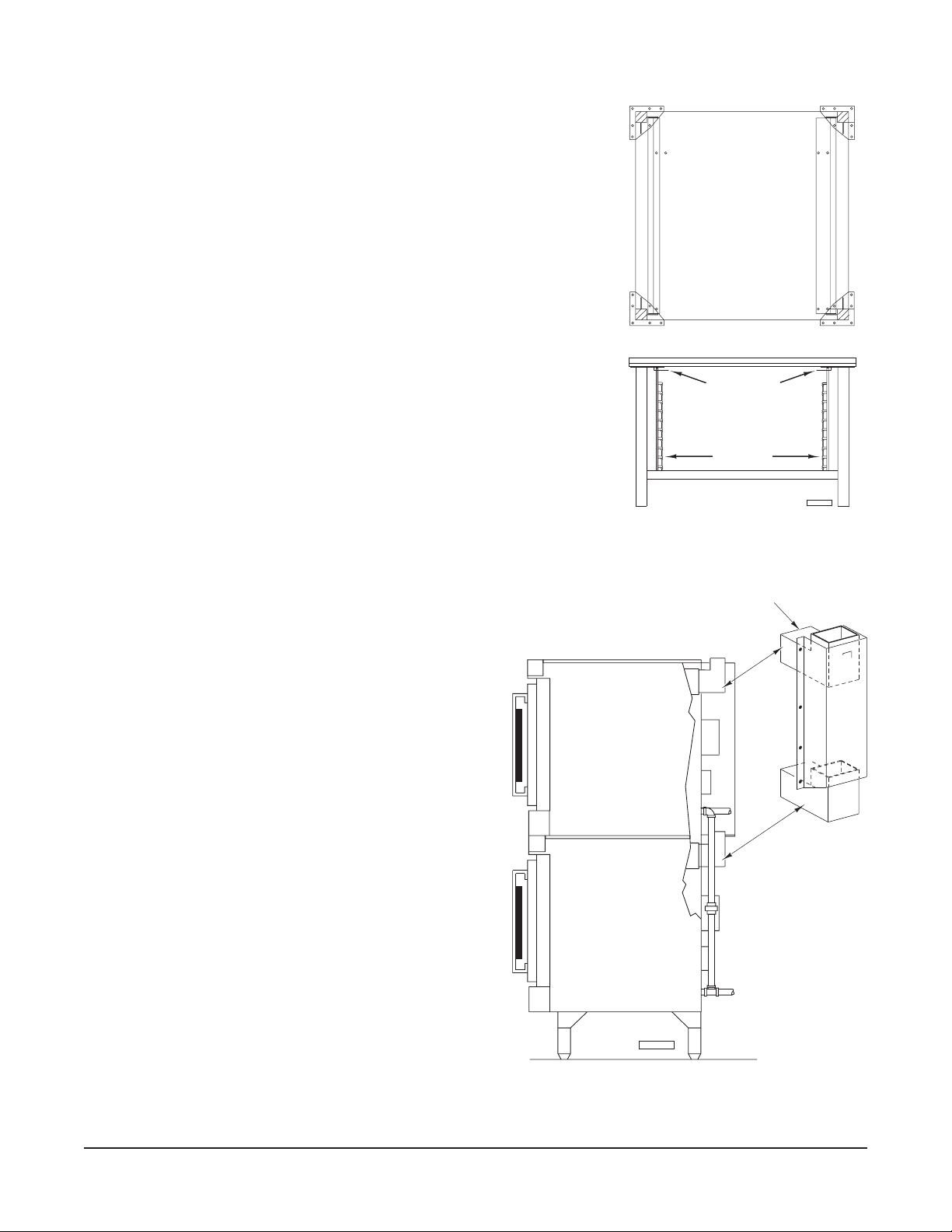

ASSEMBLING THE STAND TO THE OVEN

Attach each of the four leg assemblies to the bottom of the oven

with the 24 bolts and lockwashers (six per leg). Carefully raise the

oven to its normal position.

Attach the undershelf to the legs with eight bolts and lockwashers

(two per leg).

Install the rack guides into the undershelf at desired locations (for

pan or flat rack), then attach the rack supports to the top end of the

rack guides. Attach rack supports to the leg assembly by removing

one middle bolt and reattaching back through the end holes in the

rack support (Fig. 2).

BACK

FRONT

RACK SUPPORT

RACK GUIDE

PL-56178

Fig. 2

ASSEMBLING STACKED OVENS

Unpack the ovens and stack kit. Position the

oven to be used as the bottom oven on its back

for access to the oven bottom, taking care not to

scratch or damage it. The gas pipe protrudes

beyond the back; provide for this when the oven

is tipped back by resting it on suitable spacers

(2 x 4" [51 x 102 mm], etc.). Attach the four leg

assemblies with the 24 bolts and lockwashers

(six per leg).

Place the lower oven (with legs) on the floor and

7

remove two

/16 inch (11 mm) diameter knockouts

on each side of the top cover. Remove vent

guard and discard it.

Move the oven with legs to the installed position

and place upper oven on top of lower oven using

the locating studs.

Install the stacking flue (Fig. 3) with the four

screws provided.

STACKING FLUE

Connect the piping between the top oven and

bottom oven. For all gas supply connections,

pipe joint compound must be resistant to the

action of propane gases.

PL-53564

Fig. 3

– 6 –

Page 7

LEVELING

Make sure that the oven racks are level in the final installed position. If the oven is installed on legs,

turn the adjustable feet in or out to level the oven front-to-back and side-to-side. If the oven is installed

on casters, loosen set screws and turn casters in or out to level the oven front-to-back and side-to-side.

Retighten set screws after leveling.

GAS CONNECTION

SAGATAD

GNITARTUPNIERUSSERPDLOFINAM

VC4GD

VC6GD

VC4GC

VC6GC

LEDOM

larutaN

DG4CV

DG6CV

rh/UTB000,44rh/UTB000,44

sesaG.P.L

)enaporP(

larutaN

.C.W"5.3

)aPk9.0(

sesaG.P.L

)enaporP(

.C.W"01

)aPk5.2(

Gas supply connections and any pipe joint compound must be resistant to the action of propane gases.

Location of the gas inlet is at the rear of the oven. Codes require that a gas shutoff valve must be

installed in the gas line ahead of the oven.

Connect gas supply after leveling the oven. The gas supply line must be at least the equivalent of

3

/4 inch (19 mm) iron pipe. Make sure the pipes are clean and free of obstructions, dirt or pipe joint

compound.

The ovens are equipped with fixed burner orifices which coincide with installation elevation.

The oven is provided with a regulator integral to the gas solenoid valve and requires no external

regulator.

CAUTION: The gas pressure regulator provided with this appliance must be used. This regulator is set

for an outlet pressure of 3.5” W.C. (0.9 kPa) natural gas and 10” W.C. (2.5 kPa) propane gas.

WARNING: PRIOR TO LIGHTING, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR LEAKS.

USE SOAP AND WATER SOLUTION. DO NOT USE AN OPEN FLAME.

A. CHECK ALL JOINTS PRIOR TO THE GAS VALVE (SOLENOID) BEFORE LIGHTING UNIT.

B. CHECK ALL JOINTS BEYOND GAS VALVE (SOLENOID) AFTER UNIT IS LIT.

After piping has been checked for leaks, all piping receiving gas should be fully purged to remove air.

TESTING THE GAS SUPPLY SYSTEM

When gas supply pressure exceeds

1

/2 psig (3.45 kPa), the oven and its individual shutoff valve must

be disconnected from the gas supply piping system.

When gas supply pressure is

1

/2 psig (3.45 kPa) or less, the oven should be isolated from the gas supply

system by closing its individual manual shutoff valve.

– 7 –

Page 8

BURNER AIR ADJUSTMENT

Although main burner air is adjusted before shipment, it should be checked at the time of installation.

Excessive air will cause flames to lift off a burner when cold or may cause flash-back during normal

cycling of oven, particularly when propane gas is used.

Insufficient air will cause flames to burn with a yellow tip and result in carbon accumulation in the flame

chamber and heat exchanger tubes.

Contact your local Vulcan-Hart servicer if required.

VENT SYSTEM

DO NOT obstruct the flow of flue gases from the flue located on the rear of the oven. It is recommended

that the flue gases be ventilated to the outside of the building through a ventilation system installed by

qualified personnel.

Ovens may use an optional down-draft diverter flue method. This optional down-draft diverter must be

purchased from the oven manufacturer and vented to the outside; otherwise, the installation of any

such device will void all oven certifications and warranties. This oven is suitable for connection to

Type B Gas Vent when used with the draft hood provided.

From the termination of the flue to the filters of the hood venting system, a minimum clearance of

18 inches (457 mm) must be maintained.

Information on the construction and installation of ventilating hoods may be obtained from

Removal from Cooking Equipment

, NFPA Standard No. 96 (latest edition), available from the National

Vapor

Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW

LOCKOUT / TAGOUT PROCEDURES.

WARNING: APPLIANCES EQUIPPED WITH A FLEXIBLE ELECTRIC SUPPLY CORD ARE

PROVIDED WITH A THREE-PRONG GROUNDING PLUG. IT IS IMPERATIVE THAT THIS PLUG

BE CONNECTED INTO A PROPERLY GROUNDED THREE-PRONG RECEPTACLE. IF THE

RECEPTACLE IS NOT THE PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN. DO

NOT REMOVE THE GROUNDING PRONG FROM THIS PLUG.

VC series ovens with 120 V/60 Hz/1 PH electrical specification are equipped with a cord and plug as

standard equipment.

A wiring diagram is located on the inside of the control housing.

– 8 –

Page 9

sledoMHP/zH/V

ATADLACIRTCELE

yticapmAtiucriCmuminiM

eciveDevitcetorPmumixaM

SPMA

VC4GD

VC6GD

VC4GC

VC6GC

1/06/021

1/06/802

DG4CV

DG6CV

1/06/042

1/05/042

3/05/)W3(083/022

3/05/)W4(083/022

3/05/)W4(514/042

.)noitidetsetal(07-APFN,edoClacirtcelElanoitaNehthtiwecnadroccanidelipmoC

51

51

51

51

51

51

51

– 9 –

Page 10

OPERATION

WARNING: THE APPLIANCE AND ITS PARTS ARE HOT. USE CARE WHEN OPERATING,

CLEANING OR PERFORMING ANY MAINTENANCE.

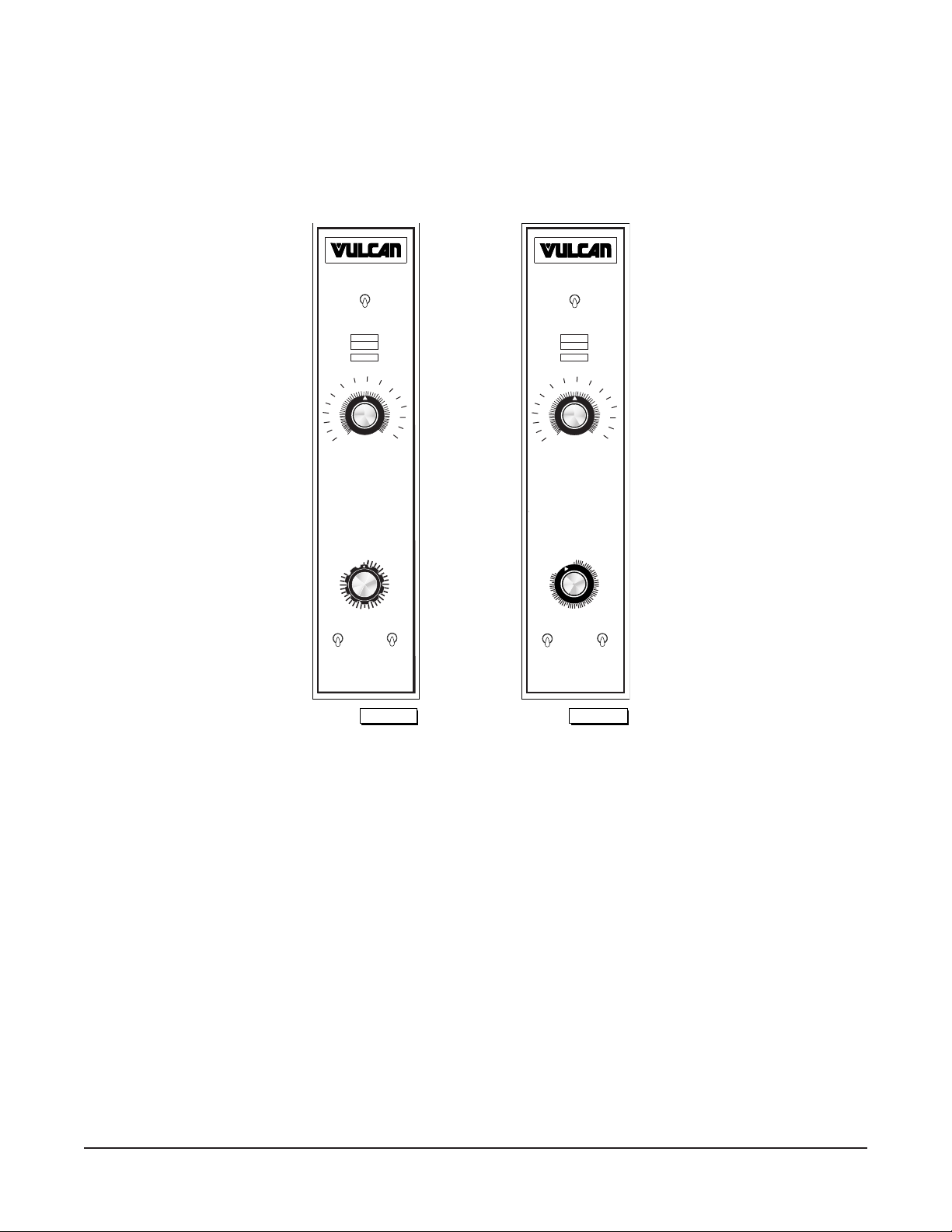

CONTROLS (Models VC4GD and VC6GD Without Roast & Hold)

MASTER SWITCH

ON

OFF

OVEN COOL

ON

HEAT

IGNITION

THERMOSTAT

150

300

275

250

225

150

C

100

LIGHTING INSTRUCTIONS

PUSH MASTER SWITCH "ON"

IF BURNER FAILS TO LIGHT

WAIT 5 MINUTES FOR RETRIAL

SHUTDOWN INSTRUCTIONS

TURN GAS AND MASTER SWITCH "OFF"

5

4

FAN SPEED

HI

LO

LO

350

325

F

TURN GAS "ON"

TURN GAS "OFF"

TIMER

OFF

0

3

375

500

LIGHTS

OFF

200

400

425

450

475

250

1

2

ON

PL-53547

MASTER SWITCH

ON

OFF

OVEN COOL

ON

HEAT

IGNITION

THERMOSTAT

325

150

300

275

250

225

150

C

100

LIGHTING INSTRUCTIONS

PUSH MASTER SWITCH "ON"

IF BURNER FAILS TO LIGHT

WAIT 5 MINUTES FOR RETRIAL

SHUTDOWN INSTRUCTIONS

TURN GAS AND MASTER SWITCH "OFF"

60

55

50

45

FAN SPEED

HI

LO

LO

350

F

TURN GAS "ON"

TURN GAS "OFF"

TIMER

0

OFF

40

35

375

500

5

10

30

LIGHTS

ON

OFF

200

400

425

450

475

250

15

20

25

PL-53562

Master Switch ON — Turns oven control circuits on.

OFF — Turns oven control circuits off.

OVEN COOL — Allows the fan motor to run with the doors ajar to speed ovencooling.

On Light (Amber) — Lit when Master Switch is ON.

Heat Light (White) — Comes on and goes off when the burner cycles on and off.

Ignition Light (Red) — Comes on if burner fails to ignite. When lighting the oven, the IGNITION

light flashes.

Thermostat — Controls oven temperature during cooking operation.

Timer (1 Hr. or 5 Hr.) — Sets the bake time. Buzzer sounds continuously after timer counts down

to 0. Oven does not turn off. Turn Timer to OFF to stop buzzer. When oven

is not in use, keep Timer at OFF position.

Fan Speed Switch — Allows you to select HI or LO Fan Speed.

Lights Switch — Turns the lights in the oven ON or OFF.

– 10 –

Page 11

CONTROLS (Models VC4GD and VC6GD With Roast & Hold)

MASTER SWITCH

ON

OVEN COOL

ON

HEAT

IGNITION

THERMOSTAT

350

325

150

300

275

250

225

F

150

C

100

OFF

0

5

4

3

R & H TIMER

TIMER

0

OFF

60

55

50

45

40

35

NORMAL

FUNCTION

R & H

OFF

375

5

500

30

LIGHTS

MASTER SWITCH

ON

OFF

OVEN COOL

ON

HEAT

IGNITION

THERMOSTAT

200

400

425

450

475

250

1

2

325

150

300

275

250

225

150

C

100

5

4

R & H TIMER

10

15

20

25

ON

OFF

5

4

NORMAL

FUNCTION

R & H

F

OFF

OFF

TIMER

200

350

375

400

425

450

475

500

250

0

1

2

3

0

1

2

3

LIGHTS

ON

OFF

PL-53551

PL-53550

Master Switch ON — Turns oven control circuits on.

OFF — Turns oven control circuits off.

OVEN COOL — Allows the fan motor to run with the doors ajar to speed ovencooling.

On Light (Amber) — Lit when Master Switch is ON.

Heat Light (White) — Comes on and goes off when the burner cycles on and off.

Ignition Light (Red) — Comes on if burner fails to ignite. When lighting the oven, the IGNITION

light flashes.

Thermostat — Controls oven temperature when Function switch is on NORMAL or during

the first stage of Roast & Hold.

R & H Timer — Sets the first stage cooking time in Roast & Hold.

Timer (1 Hr. or 5 Hr.) — Sets the bake time when Function switch is on NORMAL. Buzzer sounds

continuously after timer counts down to 0. Oven does not turn off at end

of cycle. Turn Timer to OFF to stop buzzer. When oven is not in use, keep

timer at OFF position.

Function Switch — Allows you to select Normal or Roast & Hold (R & H).

Normal: Uses the regular timer and high fan speed.

R & H: Uses the R & H Timer for the first stage of roasting at the

thermostat setting, selects a hold temperature of 160°F (71°C) during

second stage roasting. Uses low fan speed when burners are on.

Lights Switch — Turns the lights in the oven ON or OFF.

– 11 –

Page 12

BEFORE FIRST USE

Before using the oven for the first time, it must be "burned in" to release any odors that might result from

heating the new surfaces in the chamber.

1. Using a clean, damp cloth, wipe the inside of the oven including the racks.

2. Close the oven doors.

3. Push the Master Switch to ON.

4. Turn the Thermostat to 300°F (149°C) and allow the oven to cycle for 2 hours or until no odor is

detected before pushing the Master Switch to OFF.

LIGHTING MODEL VC4GD AND VC6GD OVENS

1. Turn the main gas supply ON.

2. Push the Master Switch to ON.

3. If the burner fails to light, push Master Switch OFF. Wait 5 minutes for retrial.

If the oven does not light after three trials, turn off the main gas valve and call a qualified servicer.

SHUTDOWN INSTRUCTIONS

1. Turn Master Switch to OFF.

EXTENDED SHUTDOWN

1. Push Power Switch to OFF.

2. Turn gas and electrical power supplies OFF.

USING MODEL VC4GD AND VC6GD OVENS

Preheating

1. Select the proper rack arrangement for the product to be cooked. Refer to RACK ARRANGEMENTS,

page 15.

2. Make sure the doors are closed.

3. Push Master Switch to ON. The amber ON light will come on, indicating that power to the oven

is on.

4. Set the two-speed FAN SWITCH to the desired setting (without Roast & Hold models).

5. Set thermostat as desired. The HEAT light will come on and remain on until the oven reaches set

temperature (approximately 10 to 15 minutes for settings from 300 to 400°F (149 to 204°C)).

Refer to SUGGESTED COOKING GUIDELINES for temperatures and times for various products.

If the burner fails to light, the red IGNITION light will come on and remain on.

6. Prepare product and place in suitable pans. When the white HEAT light goes off, the oven has

reached the desired preheat temperature.

– 12 –

Page 13

Cooking

1. Open doors and load the product into the oven. Place pans in the center of the racks. Close doors.

2. Set the Timer. After the preset time lapses, turn Timer to OFF position to stop alarm.

3. When product is done, open doors and carefully remove cooked product from the oven. Care

should be taken when wiping up spills, as oven is still hot.

Roast & Hold (When Equipped)

1. Turn the oven ON.

2. Set the Thermostat to the desired setting.

3. Position the Function switch to R & H.

4. Set the R & H TIMER to the desired roasting time.

• The oven will roast the product for the chosen set time and temperature. The oven controller

will automatically switch from the roasting thermostat to the holding thermostat at the end of

the preset roasting time. In holding mode the oven will maintain a temperature of 160°F (71°C)

until the oven is turned off. The blower fan will run while the burner is on and the unit is

operating in R & H.

5. To turn Cook & Hold off, flip the Function switch to the NORMAL position. The oven temperature

will return to the thermostat setting.

End of Day

1. Turn Thermostat to OFF setting.

2. Push Master Switch to OVEN COOL. Leave door ajar while the fan is on to cool the oven.

3. When oven has cooled sufficiently, flip Master Switch to OFF.

4. Turn gas valve to OFF and clean oven.

Extended Shutdown

Repeat Steps 1 through 3 of End of Day. Unplug oven and shut off manual gas valve.

CONSERVING ENERGY— ALL MODELS

• Turn off unused equipment.

• Adjust menu patterns and cooking/baking schedules for optimum equipment use.

• Reduce thermostat settings in slack periods since gas equipment heats up and recovers quickly.

• Preheat only to required cooking temperature for specific food — not higher.

• Do not open the oven door unless absolutely necessary.

• Keep area around the oven door clean and free of food particles.

• Any obstruction that prevents the door from closing completely will adversely affect oven efficiency.

– 13 –

Page 14

ROAST & HOLD OPERATION — (When Equipped)

Roast & Hold cooks the product in two stages. During first-stage cooking, the oven temperature is

regulated by the temperature setpoint and the R & H Timer setting. After the time counts down to 00:00,

second-stage cooking begins. During second-stage cooking, the heat is off as the temperature in the

oven declines to the hold temperature. The doors should remain closed during second-stage cooking.

When the hold temperature is reached, the oven temperature will be maintained at the hold temperature

until the oven is turned off.

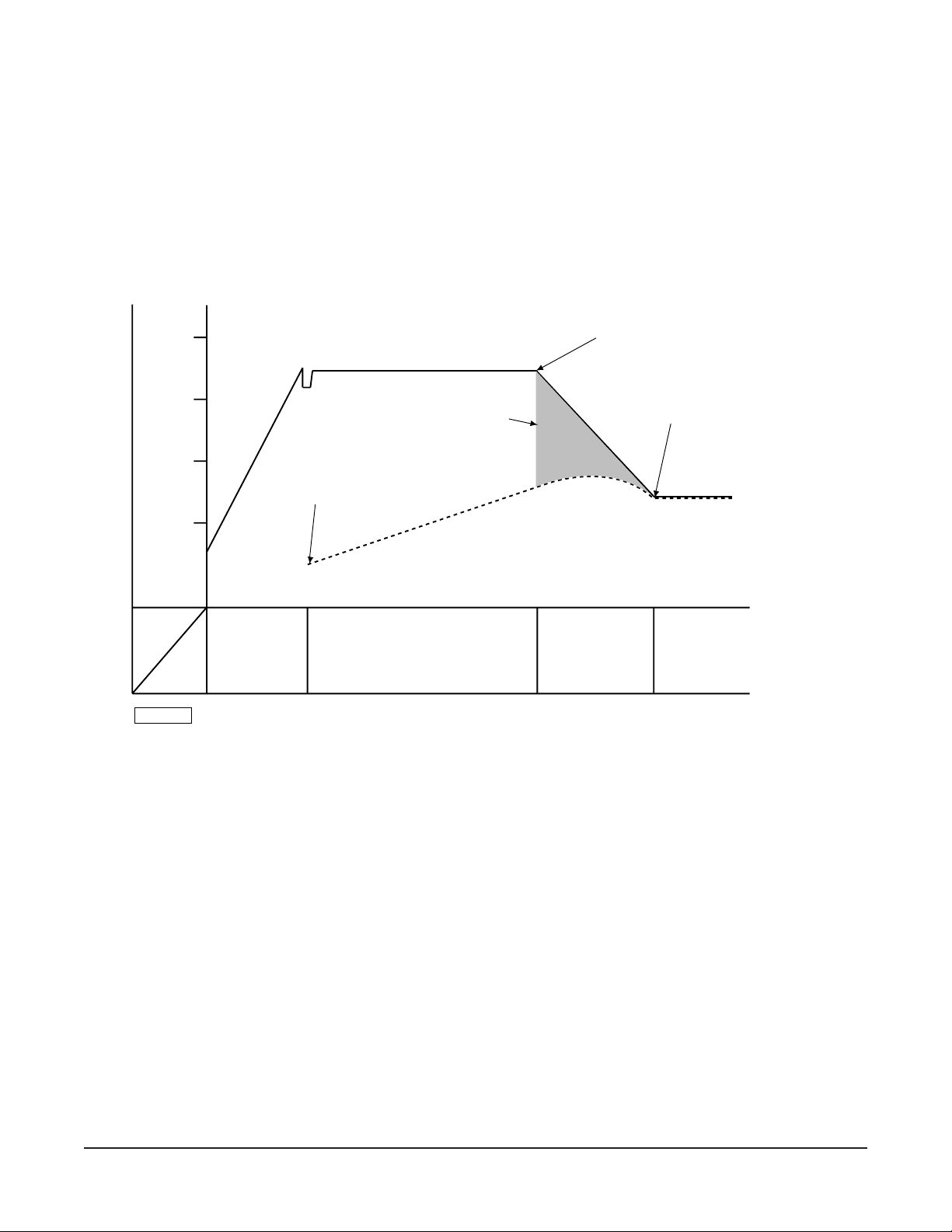

ROAST AND HOLD DIAGRAM - Time vs. Temperature

400ºF

204°C

300ºF

149°C

200ºF

93°C

100ºF

38°C

TEMP.

TIME

PL-56291

PREHEAT FIRST-STAGE COOKING SECOND-STAGE

PROPER UTENSILS

OVEN TEMPERATURE

TIMER DISPLAY COUNTS DOWN.

COOKING FROM

STORED HEAT

LOAD PRODUCT

INTO OVEN

PRODUCT TEMPERATURE

SHORT BEEP.

TIMER DISPLAYS "HOLD."

ROAST THERMOSTAT OFF.

HEATERS OFF UNTIL HOLD

TEMPERATURE IS REACHED.

HEATERS MAINTAIN

HOLD TEMPERATURE.

TIMER DISPLAY FLASHES

"HOLD."

HOLDING

COOKING

(DO NOT OPEN

DOORS)

The use of proper utensils can enhance oven operation. Medium and light weight pans allow the

product to warm faster. Roast meats in shallow pans deep enough to hold all juices yet allow free air

circulation.

OPERATING HINTS

When using the convection oven for the first time with a particular food, check the degree of doneness

periodically before the suggested time has elapsed. This will ensure the desired doneness is achieved.

Record your temperature and time settings for various products. The convection oven can provide

consistent and repeatable results.

The convection oven is faster than conventional deck-type ovens; temperature settings are lower and

cook times are shorter. Since recipes and foods are subject to many variations and tastes, the

guidelines regarding times and temperatures in this manual are SUGGESTIONS ONLY. Experiment

with your food products to determine the cooking temperatures and times that give you the best results.

– 14 –

Page 15

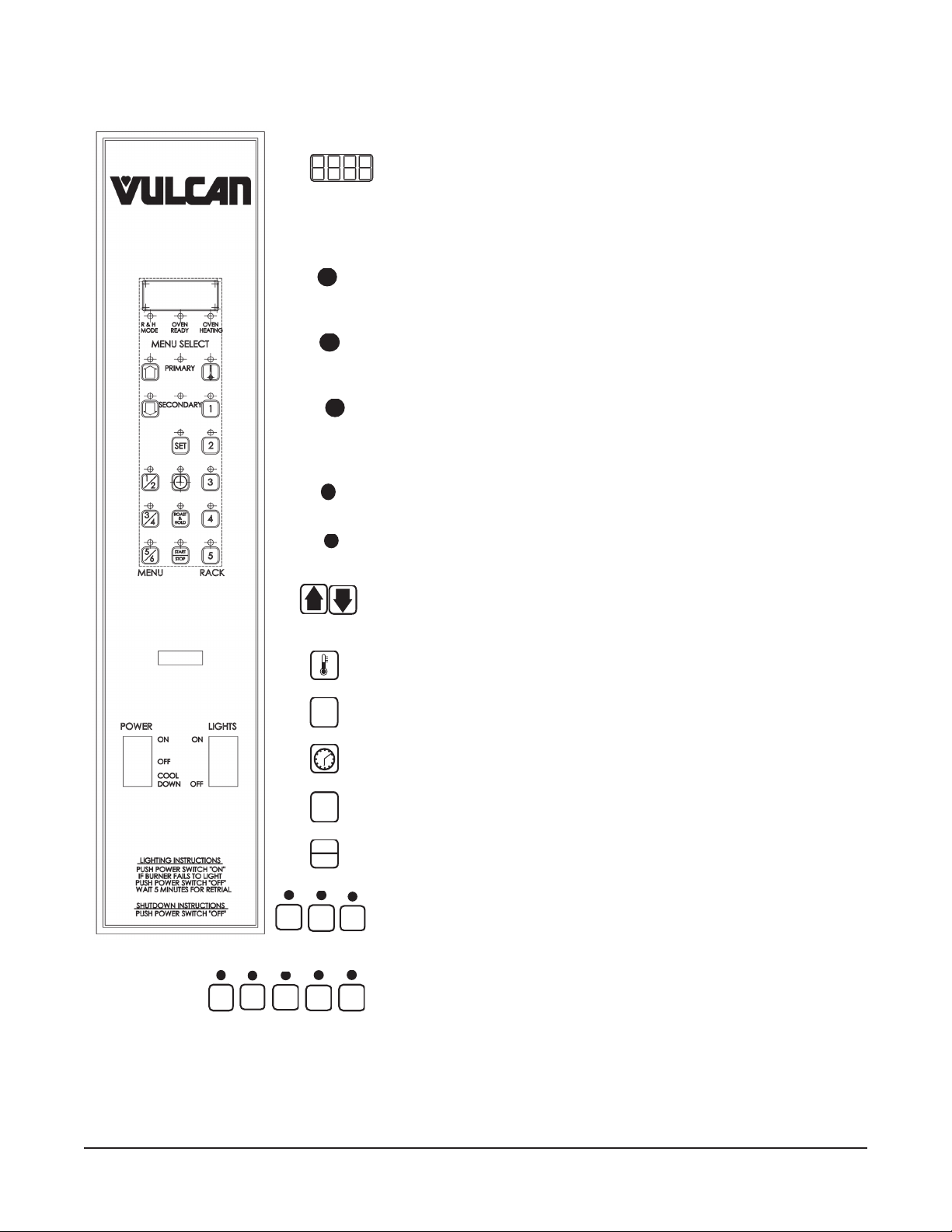

PROGRAMMABLE CONTROLS (Models VC4GC AND VC6GC)

Y

Y

Always displays [HR:Min] when setting the time.

Displays [HR:Min] if the countdown time is more than 1 hour.

Displays [Min:Sec] if the countdown time is less than 1 hour.

Displays temperature in °F.

R & H

MODE

OVEN

READ

OVEN

HEATING

PRIMARY

SECONDAR

SET

Indicates the oven is in the Roast & Hold Mode.

Indicates the oven is preheated and ready for cooking.

Indicates the oven is preheating or burners have cycled on to

maintain temperature setting.

Primary indicates menu items 1, 3 or 5.

Secondary indicates menu items 2, 4 or 6.

Up arrow increases and Down arrow decreases a displayed

time or temperature value (if arrow keys are lit).

TEMPERATURE: Use with SET to set the oven temperature.

SET: Use with time or temperature.

1/2

2 3 4

1

TIME: Use with SET to manually set the cooking time.

ROAST

&

HOLD

START

STOP

3/4

Selects Roast & Hold mode; also selects low fan speed.

Press once to start; press a second time to stop.

Select Menu Cook Times. Press once for primary (1, 3 or 5).

5/6

Press a second time for secondary (2, 4 or 6). See next page.

Rack Buttons select individual Menu/Rack Number Cook

5

Times — once programmed.

– 15 –

Page 16

MANUALLY SETTING THE TEMPERATURE AND COOK TIME

To Set the Temperature

StPt

1. Press the SET button. Press the TEMPERATURE button;

displays to indicate Setpoint.

2. Use the Up and Down arrow keys to increase or decrease the displayed temperature value.

3. Press the SET button again to save the temperature setpoint in the computer.

To Set the Cook Time

Tine

1. Press the SET button. Press the TIME button.

displays to indicate time.

2. Use the Up and Down arrow keys to increase or decrease the displayed cook time (HR:Min).

3. Press the SET button again to save the time setting in the computer.

To Start Cooking

1. Press the START/STOP button.

2. The manual Cook Time counts down to 00:00. Displays [HR:Min] above 1 hour; [Min:Sec] below.

3. The buzzer will sound. To silence the buzzer, press the START/STOP button again.

The control retains the manual settings for temperature and time.

4.

TO PROGRAM MENU ITEM AND RACK NUMBER COOK TIMES

Factory-Preset and Programmable Cook Times are shown in the table, below:

UNEM

NOITCELES

yramirP2/11.nim01

yradnoceS2/12.nim51

yramirP4/33.nim02

yradnoceS4/34.nim52

yramirP6/55.nim03

yradnoceS6/56.nim53

UNEM

METI

TESERP-YROTCAF

METIUNEM

EMITKOOC

METIUNEM

EMITKOOC

1KCAR

EMITKOOC

2KCAR

EMITKOOC

SEULAVELBAMMARGORP

3KCAR

EMITKOOC

4KCAR

EMITKOOC

5KCAR

EMITKOOC

The PRIMARY indicator light with MENU 1/2 selects Menu Item 1 (Factory-Preset Cook

Time = 10 minutes). The SECONDARY indicator light with Menu 1/2 selects menu item 2 (Factory-Preset

Cook Time = 15 minutes). This is similar for MENU Buttons 3/4 or 5/6. Any menu item cook time can

be changed using the procedure below. Rack number cook times may be programmed if desired but

are not required.

To Change the Time Setting for any Menu Item (1 – 6)

1. To enter program mode, press and hold the Up and Down arrow buttons until PrOG displays.

Tine

2. Select the menu item to be programmed (1 – 6).

displays to indicate time. Use the Up and

Down arrow buttons to increase or decrease the Menu Item's COOK TIME. Repeat this step for

any other menu items.

3. Press the START/STOP button; LOC displays. Press the START/STOP button a second time

to save the Menu Item(s)' COOK TIME(s).

4. Press the START/STOP button once to begin cooking (with the Menu Item's Cook Time). To exit,

press the START/STOP button a second time.

To Program Individual Rack Number Cook Times for a Menu Item

1. To enter program mode, press and hold the Up and Down arrow buttons until PrOG displays.

Tine

2. Select the Menu Item to be programmed (1 – 6);

t 1

3. Then select the rack number (1 – 5). [

] indicates rack 1; [

displays to indicate time.

t 2

] indicates rack 2 and so on. Use

the Up and Down arrows to increase or decrease the cook time for any rack number.

NOTE: All rack times can be preprogrammed before pressing the START/STOP button to lock.

LOC

4. Press the START/STOP button;

displays. Press the START/STOP button a second time

to save the Menu/Rack Number's COOK TIME(s).

5. To exit program mode, press START/STOP twice.

– 16 –

Page 17

Always Set the Temperature Before Setting the Time

door

1. Open the door;

2. Place the desired product on any of the five racks.

3. Close the door. The display should return to the set temperature or the

4. Press the MENU key once for primary or twice for secondary to select a menu item cook time.

5. Press the START/STOP button.

will display.

GROWING BAR

Pressing the START/STOP button after making a menu

selection will time all racks for the selected menu time.

6. The timer will count down the time remaining for the Menu Item Cook Time.

7. When the time has counted down to 00:00, the buzzer will sound and all Rack Buttons will flash.

8. To silence the buzzer, press the START/STOP button.

Starting a Timed Cycle Using Programmed Individual Menu/Rack Number Cook Time(s)

door

1. After the set temperature is reached, open the door;

2. Close the door. The display returns to the set temperature or the

3. Select the menu item (once for primary or twice for secondary) and the Rack Number to select

the Menu/Rack Number Cook Time. If using simultaneous cook times, select the other Menu/

Rack Numbers.

4. The timer selects the rack number with the shortest cook time and counts down to 00:00.

5. The buzzer sounds and the rack number flashes. To silence the buzzer, press the flashing Rack

Number.

door

6. Open the door;

7. The next shortest cook time displays, its rack number flashes and the time counts down to 00:00.

8. The buzzer sounds. Press the flashing Rack Number. Open the door;

product and close the door.

9. Repeat steps 7 and 8 until all rack numbers are done.

To Display the Actual Oven Temperature

displays. Remove the finished product and close the door.

displays. Place product(s) in oven.

GROWING BAR

door

displays. Remove the

.

.

1. Press and hold the TEMPERATURE button for 3 seconds to display actual oven temp until

released.

To End a Cooking Cycle

At the end of a cooking cycle, the buzzer will sound. To silence the buzzer and end a menu item cooking

cycle, press START/STOP. To silence the buzzer and end a rack number cooking cycle, press the

Rack Number.

To cancel a cooking cycle which might have been started in error, press and hold the Rack Number

button to be terminated and press START/STOP at the same time.

Door and Timing

Opening the door while loading additional product will interrupt all timing functions until the door is closed

and the timer resumes. For example, if a product time had diminished to 1 minute and the door was

opened for 30 seconds and then closed, the timer would still show 1 minute.

– 17 –

Page 18

PL-52806

#1

RACK POSITION

#2

#3

#4

#5

#6

#7

#8

#9

#10

#11

SETTING THE OVEN FOR ROAST & HOLD

1. Press the ROAST & HOLD button to select roast & hold.

2. Set the first stage temperature and the cook time as described in MANUALLY SETTING THE

TEMPERATURE AND COOK TIME. Press START/STOP to begin cooking.

The roast temperature is preset by the computer control at 150°F (66°C).

3.

4.

The low fan speed is present during Roast & Hold. Use Roast & Hold to select low fan speed.

ROAST & HOLD OPERATION — (When Equipped)

Roast & Hold roasts the product in two stages. During first-stage cooking, the oven temperature is

regulated by the temperature setpoint and the time setting. After the time counts down to 00:00,

second-stage cooking begins. During second-stage cooking, the heat is off as the temperature in the

oven declines to the hold temperature. The doors should remain closed during second-stage cooking.

When the Hold temperature is reached, the display flashes HOLD (on ovens equipped with Programmable

Controls only). Temperature in the oven will be maintained at the hold temperature until the oven is

turned off.

RACK ARRANGEMENTS

All models are supplied with five racks and have a maximum operating capacity of six racks per oven.

The 11-position rack supports provide for maximum flexibility and proper rack spacing.

The following arrangements are recommended. The position

numbers are in numerical sequence starting at the bottom

(Fig. 4).

Arrangement #1 — Five racks in positions #2, #4, #6, #8

and #10 for cookies or reconstitution of frozen lunches at

maximum capacity. Also recommended position for general

1

baking in sheet pans with products not over 2

/2 inches

(64 mm) high.

Arrangement #2 — Four racks in positions #1, #4, #7 and

#10 for general baking in sheet pans, muffin pans, pie or

1

cake tins and pudding pans 3

/2 inches (89 mm) high with

products not over 4 inches (102 mm) high. This arrangement

can also be used for casseroles or meat dishes in #200

1

series food service pans 12 x 20 x 2

/2" (305 x 508 x 64 mm).

Fig. 4

Arrangement #3 — Three racks in positions #1, #5 and #9 for baking breads or cakes in loaf or tube

pans and high meringue pies. This arrangement can also be used for casseroles, meat dishes or

1

roasting in pans up to 5

Arrangement #4 — Two racks in positions #1 and #6 for roasting turkeys and other roasts up to 7 inches

(178 mm) high.

With the rack in position #1, there is limited space for a water pan (see cooking chart in this manual).

When mixed loads or partial loading is regular practice, some users have developed other rack

arrangements to suit their particular needs.

/2 inches (140 mm) deep with products up to 6 inches (152 mm) high.

– 18 –

Page 19

SPECIAL PROCEDURES FOR BAKING

When baking yeast breads, cooking starts immediately in the convection oven. Yeast breads do not

usually rise as much in a convection oven as in a conventional oven. Therefore it is usually necessary

1

to allow fuller proof, 2

/2 to 3 times increase in volume, for best results.

When baking pies in your convection oven, three or four pies should be put on an 18 x 26" (457 x 660 mm)

sheet or bun pan. This procedure helps the bottom crust to bake, makes handling easier and reduces

the possibility of boilover spoiling the appearance of the pies on the lower racks.

HIGH LIMIT SWITCH

All ovens are equipped with a high limit switch, which senses the temperature of the oven to prevent

overheating. The high limit switch operates independently and will automatically shut the oven down

should the primary control fail. If this situation occurs, DO NOT attempt to bypass the high limit. Shut

the oven down and contact your local Vulcan authorized service agency.

– 19 –

Page 20

RECOMMENDED TEMPERATURES AND TIMES FOR ROASTING

Meat roasting is most satisfactory at temperatures of 225 to 325°F (107 to 163°C) for beef, lamb, poultry

and ham; 325°F (163°C) for fresh pork as recommended by USDA and American Meat Institute.

A pan, approximately 12 x 20 x 1" (305 x 508 x 25 mm) full of water, may be placed in the oven bottom.

This water supplies humidity to reduce shrinkage. Water should be added if necessary during roasting.

Roasting pans should be no deeper than necessary to hold drippings (usually 2 to 2

1

/2" (51 to 64 mm).

Cooking time and shrinkage may vary with roasting temperature, cut, grade of meat and degree of

doneness. Smaller cuts will generally show greater time savings than larger cuts at a given

temperature.

ROASTING TEMPERATURE CHART

TEMP

PRODUCT °F (°C) APPROXIMATE TIMES

Standing Rib Roast — Oven Ready 250 (121) 3 to 4 Hrs. — Rare

Rolled Rib Roasts — 20 to 22 lb (9.1 to 10 kg) 275 (135) 4 Hrs. — Med.

Veal Roast — 15 lb (6.8 kg) 300 (149) 3 Hrs. — Med. Well

Turkeys — 15 to 20 lb (6.8 to 9.1 kg) 300 (149) 3 Hrs.

Meat Loaf — 8 to 10 lb (3.6 to 4.5 kg) 350 (177) 45 to 60 Minutes

4 to 4

1

/2 Hrs. — Med.

COOKING HINTS

Forced air convection cooking is faster than conventional oven cooking, and therefore overcooking is

more common. Do not cook products faster than is practical for the best results. Since forced air

convection supplies heat to the surface of the product, the thicker or more massive a product is for its

type, the longer it will take to absorb enough heat to cook.

The oven will cook or bake full or partial loads at standard recipe temperatures. As with any oven, you

may wish to use a temperature of up to 25 F° (-4 C°) higher or lower than the recipe for the particular

product result that you prefer.

When established, convection oven times and control settings should be noted on your recipe.

SUGGESTED COOKING GUIDELINES

Recommended temperatures, times and number of racks are intended as a guide only. Adjustments

must be made to compensate for variations in recipes, ingredients, preparation and personal

preference in product appearance.

The oven does not require special recipes. Excellent results can be obtained from any good

commercial recipe with reduced cooking times.

– 20 –

Page 21

RECOMMENDED TEMPERATURES, TIMES AND NUMBER OF RACKS FOR BAKING

TEMPERATURE TIME IN NO. OF

PRODUCT °F (°C) MINUTES RACKS

Cakes

Sheet Cakes

18 x 26 x 1" (457 x 660 x 25 mm) pan

Scaled 4

Scaled 6 to 71/2 lb (2.7 to 3.4 kg)/pan

Sheet Cakes

18 x 26 x 2" (457 x 660 x 51 mm) pan 300-325 (149-163) 25 to 35 4

Scaled 10 to 12 lb (4.5 to 5.4 kg)/pan 300-325 (149-163) 25 to 35 3

Or, two 12 x 18 x 2" (305 x 457 x 51 mm) pans

Scaled 5 to 6 lb (2.3 to 2.7 kg)/pan

Angel or Sponge Cakes

Sheet Pans 18 x 26 x 1" (457 x 660 x 25 mm)

Scaled 5 to 6 lb (2.3 to 2.7 kg)/pan

Loaf or Tube Pans 315-340 (157-171) 20 to 30 3 – 4

Cupcakes 350-400 (177-204) 6 to 12 4

Frozen Fruit Pies 350-375 (177-191) 30 to 45 3 – 4

Pumpkin or Custard Pies 300-350 (149-177) 30 to 45 3 – 4

Cobblers

12 x 18 x 2" (305 x 457 x 51 mm) or

12 x 20 x 21/2" (305 x 508 x 64 mm)

Meringue Pies 350-425 (177-218) 6 to 10 2 – 4

Fruit Turnovers

18 x 26 x 1" (457 x 660 x 25 mm) pans 350-375 (177-191) 15 to 25 3 – 5

NOTE: Pies and cobblers; fruit, custard

and pumpkin pies in pie pans should be

placed on 18 x 26 x 1" (457 x 660 x 25 mm)

pans for baking.

Cookies

Rolled or Pressed 350-400 (177-204) 6 to 12 3 – 5

Drop 350-400 (177-204) 6 to 15 3 – 5

Brownies 350 (177) 12 to 20 4 – 5

Yeast Breads NOTE: Yeast breads should

be fully proofed for best results.

Rolls — 1 oz (28 g) 350-400 (177-204) 5 to 10 3 – 4

1

1

/2 to 21/2 oz (43 to 71 g) 350-400 (177-204) 8 to 15 3 – 4

Loaf Bread — 1 lb (453.4 g) 325-375 (163-191) 20 to 40 3(30) Pans

Sweet Rolls & Danish Pastry 325-375 (163-191) 5 to 15 3 – 4

Biscuits — Rolled

Muffins 325-375 (163-191) 6 to 18 3 – 4

18 x 26 x 1" (457 x 660 x 25 mm) pan, 335-400 (168-204) 10 to 20 4

5 to 7 lb (2.3 to 3.2 kg)/pan

18 x 26 x 2" (457 x 660 x 51 mm) pan, 335-400 (168-204) 15 to 25 4

8 to 20 lb (3.6 to 9 kg) per pan

Corn Muffins 335-385 (168-196) 10 to 20 3 – 4

1

/2 to 6 lb (2 to 2.7 kg)/pan 325-360 (163-182) 20 to 23 5

335-350 (168-177) 22 to 25 4

300-325 (149-163) 15 to 20 4

350-400 (177-204) 30 to 45 3 – 4

2(20) Pans

1

/2" (13 mm) Thick 350-400 (177-204) 5 to 15 3 – 4

– 21 –

Page 22

REHEATING PREPARED FOODS

TEMPERATURE TIME IN NO. OF

PRODUCT °F (°C) MINUTES RACKS

Frozen French Fries 400-450 (204-232) 6 to 8 4

2 to 3

Frozen TV Dinners 350-400 (177-204) 10 to 12 2 – 5

Frozen Entrees 300-350 (149-177) 10 to 20 2 – 5

3

/4 to 1" (19 to 25 mm) thick

Frozen Meals, 8 oz (226 g) Foil Pkg. 350-400 (177-204) 20 to 30 2 – 5

Fish Sticks & Portions

Frozen Breaded, 1 oz (28 g) 350-400 (177-204) 6 to 10 2 – 4

1

2

/2 to 3 oz (71 to 85 g) 350-375 (177-191) 8 to 15 2 – 4

Chicken Pieces

Broiled or Oven Fried

Lobsters — 1 to 1

Lobster Tails — Frozen

Hamburger Patties

1

2 to 2

/2 lb (0.9 to 1.1 kg)/bird 375-425 (191-218) 8 to 15 2 – 5

1

2

/2 to 3 lb (1.1 to 1.4 kg)/bird 350-400 (177-204) 15 to 25 2 – 4

1

/2 lb (0.45 to 0.7 kg) 400-450 (204-232) 8 to 14 2 – 4

1

/2 to 3/4 lb (0.2 to 0.3 kg) 350-400 (177-204) 10 to 15 2 – 4

8 per lb (0.45 kg), med. to well done 400-450 (204-232) 5 to 6 2 – 6

6 per lb (0.45 kg) 400-450 (204-232) 7 to 10 2 – 6

4 per lb (0.45 kg) 375-450 (191-232) 8 to 12 2 – 6

CASSEROLES

Food Service Pans

2 to 3" (51 to 76 mm) deep 325-375 (162-191) 15 to 25

3 to 4" (76 to 102 mm) deep 325-375 (162-191) 20 to 35 2 – 4

Ramekins or Foil Pans 350-400 (177-204) 5 to 6 4 – 5

1

Up to 1

/2" (38 mm) deep 2 – 4

Frozen 10 to 15

MISCELLANEOUS PRODUCTS

Baked Potatoes

120 count per 50 lb (22.7 kg) 400-450 (204-232) 20 to 25 2 – 5

100 count per 50 lb (22.7 kg) 400-450 (204-232) 25 to 40 2 – 5

80 count per 50 lb (22.7 kg) 400-425 (204-218) 30 to 45 2 – 5

Pizzas — Frozen or With

Prebaked Crust 425-475 (218-247) 5 to 10 2 – 4

Grilled Cheese Sandwiches 400-425 (204-218) 8 to 10 2 – 4

– 22 –

Page 23

CLEANING

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW

LOCKOUT / TAGOUT PROCEDURES.

Allow the oven to cool before cleaning.

Snorkel

The snorkel (heat circulation tube), located in the back of oven cavity, should never be blocked. The

snorkel should be kept clean at all times for proper operation of the oven. Clean with standard oven

cleaner at least once a week. Be sure to thoroughly clean all cleansing solution off before using the oven

again. It is also recommended that the oven be run at 400°F (204°C) for 20 minutes before using to burn

off any cleaning solution that was not thoroughly rinsed from the snorkel.

Daily

Exterior stainless steel oven panels should be cleaned with a damp cloth. Stubborn soil may be

removed with detergent. (DO NOT USE "DAWN".) Rinse thoroughly and wipe dry with a soft, clean

cloth.

Clean porcelain oven interior daily with soap or detergent and water. Rinse thoroughly and wipe dry

with a soft, clean cloth.

Nickel-plated racks and rack supports are dishwasher-safe and may be removed for cleaning.

For exterior burned-on foods and grease which resist simple soap and water cleaning, an abrasive

cleanser (scouring powder) mixed into a paste may be used. Apply with stainless steel wool or sponge,

always rubbing with the "grain." This treatment is equally effective for "heat tint" (slightly darkened

areas caused by oxidation). Again, remember to rub in the direction of the polish lines. Rinse with clear

water and dry with a soft cloth.

Do not use scouring powder on the glass window; it will scratch and fog the glass.

After processing some foods at low temperatures, odors may linger in the oven. These odors may be

cleared by setting the thermostat to 500°F (260°C) and allowing the oven to run unloaded for 30 to 45

minutes.

GUIDELINES FOR MAINTAINING STAINLESS STEEL SURFACES

There are three basic things that can break down the surface layer of stainless steel and allow corrosion

to develop: 1) Abrasion; 2) Deposits and water and 3) Chlorides.

Avoid abrasion from rubbing with steel pads, wire brushes or scrapers that can leave iron deposits on

stainless steel; instead, use plastic scouring pads or soft cloths. For stubborn stains, use products such

as Cameo, Talc or Zud First Impression. Always rub parallel to the polish lines or with the grain.

Hard water can leave deposits that promote rust on stainless steel. Treated water from softeners or

certain filters can eliminate these mineral deposits. Deposits from food must be properly removed

by cleaning. Use mild detergent and nonchloride cleaners. Rinse thoroughly. Wipe dry. If using

chloride-containing cleaners or sanitizers,

rinse repeatedly

to avoid stainless steel corrosion. Where

appropriate, apply a polish recommended for stainless steel (such as Benefit or Super Sheen) for

extra protection and lustre.

– 23 –

Page 24

MAINTENANCE

WARNING: THE APPLIANCE AND ITS PARTS ARE HOT. USE CARE WHEN OPERATING,

CLEANING OR SERVICING THE OVEN.

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW

LOCKOUT / TAGOUT PROCEDURES.

LUBRICATION

The fan motor comes with sealed bearings and requires no lubrication.

VENT

Periodically check the flue, when the oven is cool, to be sure it is free of obstructions.

REPLACING LAMPS

1. Allow oven to cool.

2. Remove all racks by pulling forward, lifting up and out.

3. Unscrew glass dome from light body.

4. Replace the bulb.

5. Reassemble glass dome and racks.

TROUBLESHOOTING

melborPesuaCelbissoPnoitcAevitcerroCdetsegguS

gninworbnevenU

.1

dekoocrevoro

.segde

ronapfoegde

.gnillips

evissecxE

.egaknirhs

thgilnoitingI

.slairt3retfa

.2

otgnilluptcudorP

.1

.2

.1

.nevoni

.2

.hgihoot

eromroftilsniamer

sdnoces02naht

.tohootsinevO

.desuskcarynamooT

.leveltonsinevO

.deprawerasnapteehS

retawniatniamoteruliaF

erutarepmetgnitsaoR

.ylppussagoN•

.1

.2

.1

front from front to back.

.2

.1

(305 x 508 x 25 mm).

.2

•

.kcabottnorf

.)senilediuGgnikooCotrefer(gnitteserutarepmetecudeR

.noitalucricrettebwollaotskcarrewefesU

1

(3 mm) low at the

/

8

otleveldnaedisotedislevelebdluohs

.puorggnikabehtmorf

.)mc5.2x15x5.03(

.erutarepmetecudeR

kcarehT.kcabottnorfdnaedisotedis-skcarnevoleveL

morftnorfehttawol"

larenegmorfetarapesrettabgnikabrofdesusnappeeK

tievomer,prawotycnednetaswohsnapynafI.snapesoprup

"1x02x21gnirusaemnevofomottobniretawfonapecalP

.thgilerotgnitpmettaerofebseunim5rofffonevonruT

.nepoerayehterusebotsevlavylppussagkcehC

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this model, contact the Vulcan-Hart Service

Agency in your area (refer to our website, www.vulcanhart.com for a complete listing of Authorized

Service and Parts depots).

When calling for service, the following information must be available: model number, serial number,

manufacture date (MD) and voltage.

FORM 31123 Rev. G (10-06) PRINTED IN U.S.A.

– 24 –

Page 25

– 24 –

trop élevée.

2. Température de rôtissage 2. Réduire la température.

Si une plaque a tendance à gauchir, ne plus l’utiliser.

2. Séparer les plaques à pâtisserie des plaques tout usage.

circulation.

FORM 31123 Rév. G (10-06) IMPRIMÉ AUX É.-U.

de série, la date de fabrication, le type de gaz et d’alimentation électrique.

Lors d’une demande de service, fournir les renseignements suivants : le numéro de modèle, le numéro

pièces autorisées, visiter notre site Web à l’adresse : www.vulcanhart.com.

Vulcan-Hart le plus près. Pour une liste complète de nos succursales de service de l’entretien et de

Pour tout renseignement sur l’entretien ou les pièces de ce four, communiquer avec le service de l’entretien

SERVICE DE L’ENTRETIEN ET PIÈCES DE RECHANGE

de 20 secondes.

allumée pendant plus

Allumage demeure Aucune alimentation en gaz. • S'assurer que les robinets de gaz sont ouverts.

tentatives, le voyant tentative d'allumage.

Après trois • Éteindre le four pendant 5 minutes avant une autre

excessif. dans le bas du four.

Flétrissement 1. Manque d'eau dans le four. 1. Placer un bac d'eau de 305 x 508 x 25 mm (12 x 20 x 1 po)

ou qui renversent. 2. Tôles gauchies. l'autre et 3 mm (1/8 po) plus basses à l'avant qu'à l'arrière.

d'un côté de la plaque Celles-ci doivent être parfaitement droites d'un côté à

Aliments qui inclinent 1. Four dénivelé. 1. Niveler les grilles du four latéralement et de l'avant vers l'arrière.

bord des plaques. 2. Trop grand nombre de grilles. 2. Réduire le nombre de grilles pour permettre une meilleure

cuisson excessive au au Guide de cuisson).

Brunissage inégal ou 1. Le four est trop chaud. 1. Réduire le réglage du commutateur de puissance (se reporter

Problème Cause possible Correction suggérée

DÉPANNAGE

5. Remettre le dôme et les grilles en place.

4. Remplacer l’ampoule.

3. Dévisser le dôme de la lampe.

2. Enlever toutes les grilles en les tirant vers soi et en les soulevant.

1. Laisser refroidir le four.

REMPLACEMENT DES LAMPES :

obstrué.

Une fois l’an, vérifier le conduit d’évacuation lorsqu’il est froid pour s’assurer qu’il n’est pas

VENTILATION :

Le moteur du ventilateur est pourvu de roulements scellés ne nécessitant aucune lubrification.

LUBRIFICATION :

LES PROCÉDURES DE VERROUILLAGE ET D’ÉTIQUETAGE.

AVERTISSEMENT : COUPER L’ALIMENTATION ÉLECTRIQUE DE L’APPAREIL ET SUIVRE

PRUDENCE LORS DE L’EXPLOITATION, LE NETTOYAGE ET L’ENTRETIEN DE CET APPAREIL.

AVERTISSEMENT : LE FOUR ET SES COMPOSANTS SONT CHAUDS. EXERCER UNE EXTRÊME

ENTRETIEN

Page 26

– 23 –

(tel que Benefit ou Super Sheen) pour une protection additionnelle et un lustre plus éclatant.

la corrosion de l’acier inoxydable. Si nécessaire, appliquer un poli recommandé pour l’acier inoxydable

utiliser des nettoyants contenant de la chlorure ou des désinfectants, rincer plusieurs fois pour éviter

et des nettoyants ne contenant pas de chlorure. Rincer soigneusement et essuyer. Si vous devez

minéraux. Nettoyer soigneusement les dépôts d’aliments en les lavant. Utiliser un détergent doux

Des adoucisseurs pour le traitement de l’eau ou certains filtres peuvent aider à éliminer ces dépôts

L’eau dure peut laisser des dépôts qui peuvent accélérer le processus de la rouille sur l’acier inoxydable.

Talc ou Zud First Impression. Toujours frotter parallèlement dans le sens du “grain”.

tampons à récurer en plastique. Pour les taches rebelles, utiliser des produits tels que Cameo,

racloirs qui pourraient laisser des dépôts de fer sur l’acier inoxydable; il est préférable d’utiliser des

Pour éviter l’abrasion, ne pas frotter avec des tampons en acier, des brosses métalliques ou des

1) l’abrasion; 2) les dépôts et l’eau; et 3) les chlorures.

Les trois causes pouvant altérer la surface en acier inoxydable et causer la corrosion sont les suivantes :

GUIDE POUR PRÉSERVER LES SURFACES EN ACIER INOXYDABLE

sans rien mettre dedans.

Pour les enrayer, régler le thermostat à 260 °C (500 °F) et faire fonctionner le four de 30 à 45 minutes

Après la cuisson d’aliments à des basses températures, il peut se dégager des odeurs dans le four.

Ne pas utiliser de poudre à récurer sur le hublot; elle pourrait égratigner et voiler la vitre.

claire et essuyer au moyen d’un chiffon doux.

noircies par l’oxygène). Toujours frotter dans le sens des lignes de revêtement. Rincer à l’eau

du “grain”. Ce traitement est tout aussi efficace pour les taches de décoloration (zones légèrement

d’un tampon en acier inoxydable ou d’une éponge en prenant soin de toujours frotter dans le sens

nécessaire d’utiliser une pâte de nettoyant abrasif (poudre à récurer). Appliquer cette pâte au moyen

Dans le cas de taches rebelles de recuit ou de graisse qui résistent à l’eau et au savon, il peut s’avérer

pour le nettoyage.

Les grilles nickelées et les supports à grilles sont lavables au lave-vaisselle et doivent être enlevées

et essuyer au moyen d’un chiffon doux et propre.

Nettoyer l’intérieur du four en porcelaine quotidiennement avec de l’eau savonneuse. Rincer soigneusement

et essuyer au moyen d’un chiffon doux et propre.

au moyen d’un détergent. (NE PAS UTILISER LE DÉTERGENT “DAWN”.) Rincer soigneusement

Nettoyer les panneaux en inox extérieurs au moyen d’un chiffon humide. Enlever les taches rebelles

Nettoyage quotidien

qui n’aurait pas été soigneusement rincée sur le tube de circulation de chaleur.

le four à 204 °C (400 °F) pendant 20 minutes avant de l’utiliser pour brûler toute solution de nettoyage

aucune solution de nettoyage avant de s’en servir à nouveau. Il est aussi conseillé de faire fonctionner

d’un nettoyant à four standard au moins une fois par semaine Bien rincer le four pour qu’il ne reste

bloqué. Il doit toujours demeurer propre pour un bon fonctionnement du four. Le nettoyer à l’aide

Le tube de circulation de chaleur (Snorkel) situé à l’arrière de la cavité du four ne doit jamais être

Snorkel

Laisser refroidir le four avant le nettoyage.

AU DISJONCTEUR POUR INDIQUER QU’UN TECHNICIEN TRAVAILLE SUR LE CIRCUIT.

AVERTISSEMENT : COUPER L’ALIMENTATION ÉLECTRIQUE ET APPOSER UNE ÉTIQUETTE

NETTOYAGE

Page 27

– 22 –

Sandwiches au fromage fondant 204 à 218 (400 à 425) 8 à 10 2 à 4

218 à 247 (425 à 475) 5 à 10 2 à 4

Pizzas

– Surgelés ou pâte précuite

204 à 218 (400 à 425) 30 à 45 2 à 5

204 à 232 (400 à 450) 25 à 40 2 à 5

204 à 232 (400 à 450) 20 à 25 2 à 5

80 par 22,7 kg (50 lb)

100 par 22,7 kg (50 lb)

120 par 22,7 kg (50 lb)

Pommes de terre au four

ALIMENTS DIVERS

Si surgelés

10 à 15 2 à 4

177 à 204 (350 à 400) 5 à 6 4 à 5

162 à 191 (325 à 375) 20 à 35 2 à 4

162 à 191 (325 à 375) 15 à 25

Jusqu’à 38 mm (1 1/2 po) de profondeur

Ramequins ou plats en aluminium

76 à 102 mm (3 à 4 po) de profondeur

51 à 76 mm (2 à 3 po) de profondeur

Plats de service

CASSEROLES

191 à 232 (375 à 450) 8 à 12 2 à 6

204 à 232 (400 à 450) 7 à 10 2 à 6

204 à 232 (400 à 450) 5 à 6 2 à 6

177 à 204 (350 à 400) 10 à 15 2 à 4

– Surgelées

4 par 0,45 kg (1 lb)

6 par 0,45 kg (1 lb)

8 par 0,45 kg (l lb) à point à bien cuit

Fricadelles de boeuf

0,2 à 0,3 kg (1/2 à 3/4 lb)

Queues de homard

2 à 3

204 à 232 (400 à 450) 8 à 14 2 à 4

177 à 204 (350 à 400) 15 à 25 2 à 4

191-218 (375-425) 8 à 15 2 à 5

177 à 191 (350 à 375) 8 à 15 2 à 4

177 à 204 (350 à 400) 6 à 10 2 à 4

177 à 204 (350 à 400) 20 à 30 2 à 5

149 à 177 (300 à 350) 10 à 20 2 à 5

177 à 204 (350 à 400) 10 à 12 2 à 5

204 à 232 (400 à 450) 6 à 8 4

°C (°F) EN MINUTES GRILLES

– 0,45 à 0,7 kg (1 à 1 1/2 lb)

226 g (8 oz). Enveloppés dans l’aluminium

Homards

1,1 à 1,4 kg (2 1/2 à 3 lb)

0,9 à 1,1 kg (2 à 2 1/2 lb)

Cuits sur le gril ou au four

Morceaux de poulet

71 à 85 g (2 1/2 à 3 oz)

Panés et congelés, 28 g (1 oz)

Bâtonnets et portions de poisson

Repas congelés,

19 à 25 mm (3/4 à 1 po) d’épaisseur

Entrées surgelées

Repas rapides surgelés (TV Dinners)

Pommes de terre congelées

PRODUIT TEMPÉRATURE TEMPS DE CUISSON NOMBRE DE

RÉCHAUFFAGE D’ALIMENTS PRÉPARÉS

Page 28

– 21 –

à

4

à

4

à

4

à

4

2(20) plaques

à

4

à

4

à

5

à

5

à

5

à

5

168 à 196 (335 à 385) 10 à 20 3

163 à 191 (325 à 375) 6 à 18 3

Roulés de 13 mm (1/2 po) d’épaisseur 177 à 204 (350 à 400) 5 à 15 3

163 à 191 (325 à 375) 5 à 15 3

453.4 g (l lb) 163 à 191 (325 à 375) 20 à 40 3(30) plaques

– 28 g (1 oz) 177 à 204 (350 à 400) 5 à 10 3

(Bien fermenter la pâte pour de

177 (350) 12 à 20 4

Tartes et tourtes aux fruit : cuire les garnitures

Pain de maïs

3,6 à 9 kg (8 à 20 lb) par plaque

457 x 660 x 51 mm (18 x 26 x 2 po) 168 à 204 (335 à 400) 15 à 25 4

Poids de 2,3 à 3,2 kg (5 à 7 lb) par plaque

Plaque de 457 x 660 x 25 mm (18 x 26 x 1 po) 168 à 204 (335 à 400) 10 à 20 4

Muffins

Biscuits –

Brioches et pâtisseries danoises

Miche de pain –

43 à 71 g (1 1/2 à 2 1/2 oz) 177 à 204 (350 à 400) 8 à 15 3

Petits pains

meilleurs résultats)

Pain au levain

Carrés au chocolat

Bonbons 177 à 204 (350 à 400) 6 à 15 3

Roulés ou aplatis 177 à 204 (350 à 400) 6 à 12 3

Biscuits

plaques de 457 x 660 x 25 mm (18 x 26 x 1 po)

en conserve pour tartes à la crème et à la citrouille dans des

NOTA :

Plaque de 457 x 660 x 25 mm (18 x 26 x 1 po) 177 à 191 (350 à 375) 15 à 25 3

Chaussons aux fruits

à

4

à

4

à

4

à

4

à

4

177 à 218 (350 à 425) 6 à 10 2

149 à 177 (300 à 350) 30 à 45 3

177 à 191 (350 à 375) 30 à 45 3

177 à 204 (350 à 400) 6 à 12 4

157 à 171 (315 à 340) 20 à 30 3

°C (°F) EN MINUTES GRILLES

Tartes meringuées

305 x 508 x 64 mm (12 x 20 x 2 1/2 po)

305 x 457 x 51 mm (12 x 18 x 2 po) ou 177 à 204 (350 à 400) 30 à 45 3

Tourtes aux fruits

Tartes à la crème ou à la citrouille

Tartes aux fruits congelés

Petits gâteaux

Moules tubulaires ou à pain

Poids de 2,3 à 2,7 kg (5 à 6 lb) par plaque 149 à 163 (300 à 325) 15 à 20 4

Plaques de 457 x 660 x 25 mm (18 x 26 x 1 po)

Gâteaux des anges ou de Savoie

Poids de 2,3 à 2,7 kg (5 à 6 lb) par plaque

Ou 2 plaques de 305 x 457 x 51 mm (12 x 18 x 2 po)

Poids de 4,5 à 5,4 kg (10 à 12 lb) par plaque 149 à 163 (300 à 325) 25 à 35 3

457 x 660 x 51 mm (18 x 26 x 2 po) 149 à 163 (300 à 325) 25 à 35 4

Plaque à gâteaux

Poids de 2,7 à 3,4 kg (6 à 7 1/2 lb) par plaque 168 à 177 (335 à 350) 22 à 25 4

Poids de 2 À 2,7 kg (4 1/2 à 6 lb) par plaque 163 à 182 (325 à 360) 20 à 23 5

Plaque à gâteau de 457 x 660 x 25 mm (18 x 26 x 1 po)

Gâteau

PRODUIT TEMPÉRATURE TEMPS DE CUISSON NOMBRE DE

TEMPÉRATURES, TEMPS DE CUISSON ET NOMBRE DE GRILLES RECOMMANDÉS POUR LA CUISSON

Page 29

– 20 –

bonne recette commerciale avec des temps de cuisson réduits.

Le four ne requiert pas de recettes spéciales. Vous pouvez obtenir d’excellent résultats pour toute

Les adapter aux recettes, aux ingrédients, à l’installation et aux goûts personnels.

Les températures, le temps de cuisson, le nombre de grilles sont suggérés à titre d’exemple seulement.

GUIDE DE CUISSON SUGGÉRÉ

être noter sur votre recette.

Lorsque ceci sera établi, les temps de cuisson à air pulsé et les réglages de commandes devraient

que la recette destinée à un produit en particulier que vous préférez.

vous voudrez peut-être utiliser une température jusqu’à – 4 °C (25 °F) plus élevée ou plus basse

Le four cuira des charges entières ou partielles à des températures standard. Comme tout autre four,

absorber assez de chaleur pour la cuisson.

surface du produit, si le produit est plus épais ou plus massif, il prendra plus de temps pour

produits plus rapidement qu’il ne le faut. Comme la circulation d’air forcé fournit de la chaleur à la

conséquent, la surcuisson est plus commune. Pour obtenir de bons résultats, ne pas cuire les

La cuisson à circulation d’air forcé est plus rapide que la cuisson dans un four traditionnel, par

4 à 4 h 30 (à point)

CONSEILS D’UTILISATION

Pain de viande – 3,6 à 4,5 kg (8 à 10 lb) 177 (350) 45 à 60 min

Dindes – 6,8 à 9,1 kg (15 à 20 lb) 149 (300) 3 h

Rôti de veau – 6,8 kg (15 lb) 149 (300) 3 h (à point à bien cuit)

Côtes de bœuf désossées – 9,1 À 10 kg (20 à 22 lb) 135 (275) 4 h (à point)

Côtes de bœuf – Prêtes à aller au four 121 (250) 3 à 4 h (saignant)

°C (°F) APPROXIMATIF

PRODUIT TEMPERATURE TEMPS DE CUISSON

TEMPÉRATURE DE RÔTISSAGE

cuisent en général plus rapidement que les gros morceaux.

de viande ainsi que le degré de cuisson. À une même température, les petits morceaux de viande

Le temps de cuisson et le flétrissement varient selon la température de rôtissage, la coupe et la catégorie

64 mm (2 à 2 1/2 po) en général.

Les plats à rôtir ne doivent pas excéder la profondeur requise pour contenir la graisse, soit de 51 à

de l’humidité et réduit le flétrissement. En ajouter pendant le rôtissage, au besoin.

Placer un plat rempli d’eau (environ 305 x 508 x 25 mm [12 x 20 x 1 po]) dans le four. L’eau dégage

volaille et le jambon et à 163 °C (325 °F) pour le porc.

rôtissage doivent varier idéalement entre 107 et 163 °C (225 et 325 °F) pour le bœuf, l’agneau, la

Selon le ministère de l’Agriculture des États-Unis et l’American Meat Institute, les températures de

TEMPÉRATURES ET TEMPS DE CUISSON RECOMMANDÉS POUR LE RÔTISSAGE

Page 30

– 19 –

Éteindre le four et communiquer avec le service de l’entretien Vulcan.

primaires venaient à faire défaut. Si cela se produisait, NE PAS tenter de court-circuiter le thermostat.

qu’il ne surchauffe. Il fonctionne indépendamment et assure l’arrêt automatique du four si les commandes

Tous les fours sont pourvus d’un thermostat de sécurité qui capte la température du four pour empêcher

THERMOSTAT DE SÉCURITÉ

des grilles inférieures s‘en trouvent réduits et les produits conservent leur apparence savoureuse.

cuisent mieux, les tartes sont plus faciles à manipuler, les risques de débordement sur les tartes

des tôles de 457 x 660 mm (18 x 26 po) ou dans des moules à brioches. Ainsi, les fonds de tarte

Pour la cuisson des tartes dans un four à air pulsé, les mettre par groupe de trois ou quatre dans

résultats.

traditionnel. Il faut donc laisser la pâte atteindre 2 1/2 à 3 fois sont volume pour de meilleurs

Habituellement, le pain au levain ne lève pas autant dans un four à air pulsé que dans un four

Pour la cuisson de pain au levain, la cuisson commence immédiatement dans le four à air pulsé.

PROCÉDURES SPÉCIALES POUR LA CUISSON

Page 31

Fig. 4

POSITION DES GRILLES

– 18 –

utilisateurs développent d’autres façons de disposer les grilles pour satisfaire à leurs propres besoins.

Lorsque les chargements mixtes ou les chargements partiels sont choses courantes, quelques

de l’eau (se référer au Guide de cuisson de ce manuel).

En positionnant la grille en position #1, il y a suffisamment d’espace pour un récipient contenant

jusqu’à 178 mm (7 po) de hauteur.

Arrangement #4 – Deux grilles en positions #1 et #6 pour le rôtissage de dindes et autres rôtis allant

jusqu’à 140 mm (5 1/2 po) de profondeur pour des produits jusqu’à 152 mm (6 po) de hauteur.

utiliser cet arrangement pour les casseroles, assiettes à viande ou plats à rôtir dans des bacs allant

des moules rectangulaires ou en tube et aussi pour les tartes avec de la meringue. On peut aussi

Arrangement #3 – Trois grilles en positions #1, #5 et #9 pour la cuisson de pains ou gâteaux dans

(12 x 20 x 2 1/2 po).

la restauration de la série #200 de 305 x 508 x 64 mm

casseroles ou des assiettes de viande dans des bacs pour

dépasser 102 mm (4 po). On peut aussi y déposer des

89 mm (3 1/2 po) de hauteur et les produits ne doivent pas

moules à muffins ou à gâteaux et moules à pouding de

#7 et #10 pour la cuisson en général dans des tôles,

Arrangement # 2 – Quatre grilles en positions #1, #4,

pas 64 cm (2 1/2 po) de hauteur.

général dans des tôles pour des produits ne dépassant

recommandons aussi cette position pour la cuisson en

collations congelées à une capacité maximale. Nous

#8 et #10 pour les biscuits ou la reconstitution de

Arrangement #1 – Cinq grilles en positions #2, #4, #6,

numériques en commençant par le bas (Fig. 4).

suivante. Les chiffres de position sont en séquences

Il est recommandé de disposer les grilles de la façon

et un bon espace pour les grilles.

de six grilles par four. Les supports pour grilles à 11 positions fournissent une flexibilité maximale

Tous les modèles de fours sont pourvus de cinq grilles et leur capacité d’opération maximale est

ARRANGEMENT DES GRILLES

Garde-au-chaud est maintenue jusqu’à ce que l’on éteigne le four.

clignote (sur les fours munis de commandes programmables seulement). La température de

Lorsque la température de Garde-au-chaud est atteinte, le message HOLD (Garde-au-chaud)

pendant cette deuxième partie du cycle.

de l’enceinte diminue jusqu’à la température de Garde-au-chaud. Laisser les portes fermées

du cycle de cuisson s’amorce. Au cours de cette partie, les brûleurs sont éteints et la température

réglé. Lorsque ce temps est écoulé, c’est-à-dire que l’affichage indique 00 :00, la deuxième partie

cours de la première partie, la température est régulée par la température de consigne et le temps

En mode Roast & Hold (Rôtissage et Garde-au-chaud), la cuisson s’effectue en deux parties. Au

MODE ROAST & HOLD (Rôtissage et Garde-au-chaud (si équipé)

Garde-au-chaud). Utiliser ce mode pour sélectionner la vitesse du ventilateur.

4. La basse vitesse du ventilateur est utilisée pendant le cycle Roast & Hold (Rôtissage et

3. La commande de l’ordinateur règle à l’avance la température de rôtissage à 66 °C (150 °F).

la cuisson, appuyer sur la touche START / STOP (marche/arrêt).

RÉGLAGE MANUEL DE LA TEMPÉRATURE ET DU TEMPS DE CUISSON. Pour commencer

2. Régler la première étape de température et de temps de cuisson apparaissant sous le titre :

1. Pour sélectionner le mode Rôtissage et Garde-au-chaud, appuyer sur le bouton ROAST & HOLD.

RÉGLAGE DU FOUR EN MODE RÔTISSAGE ET GARDE-AU-CHAUD

Page 32

– 17 –

indique encore 1 minute.

est réduit d’une minute et que la porte est ouverte pendant 30 secondes puis refermée, la minuterie

jusqu’à la fermeture de la porte et au redémarrage de la minuterie. Par exemple, si un temps de produit

L’ouverture de la porte pour ajouter un autre produit interrompt toutes les fonctions de minutage

Porte et minuterie

touche de grille à annuler, tout en appuyant sur la touche START / STOP (marche-arrêt).

Pour annuler un cycle de cuisson qui aurait démarré par erreur, appuyer et maintenir enfoncée la

et terminer un cycle de cuisson d’un numéro de grille, appuyer sur la touche du numéro de grille.

d’articles de menu, appuyer sur la touche START / STOP (marche-arrêt). Pour éteindre l’avertisseur

À la fin d’un cycle de cuisson, l’avertisseur retentit. Pour l’éteindre et terminer un cycle de cuisson

Fin d’un cycle de cuisson

température réelle du four.

1. Appuyer et maintenir la touche TEMPÉRATURE enfoncée pendant 3 secondes pour afficher la

Affichage de la température réelle du four

9. Répéter les étapes 7 et 8 jusqu’à ce que tous les numéros de grilles aient été sélectionnés.

indique door (porte). Enlever le produit et fermer la porte.

8. L’avertisseur retentit. Appuyer sur le numéro de grille qui clignote. Ouvrir la porte, l’afficheur

rebours indique 00:00.

7. Le prochain temps de cuisson le plus court s’affiche, le numéro de grille clignote et le compte à

6. Ouvrir la porte; l’afficheur indique door (porte). Enlever le produit cuit et fermer la porte.

numéro de grille qui clignote.

5. L’avertisseur retentit et le numéro de grille clignote. Pour éteindre l’avertisseur, appuyer sur le

compte à rebours indique 00:00.

4. La minuterie sélectionne le numéro de grille dont le temps de cuisson est le plus court et le

simultanément les temps de cuisson, sélectionner un autre menu de numéros de grilles.

de grille pour sélectionner le menu de temps de cuisson d’un numéro de grille. Pour utiliser

3. Sélectionner l’article de menu (une fois pour Primaire ou deux fois pour Secondaire) et le numéro

2. Fermer la porte. L’affichage retourne à la température réglée ou à GROWING BAR (barre croissante).

le ou les produits dans le four.

1. Lorsque la température réglée est atteinte, ouvrir la porte; l’afficheur indique door (porte). Placer

cuisson pour chaque numéro de grille

Démarrage d’un cycle minuté en utilisant un menu individuel programmé pour le temps de

8. Pour éteindre l’avertisseur, appuyer sur la touche START / STOP (marche/arrêt).

grilles clignotent.

7. Lorsque le compte à rebours du temps est à 00:00, l’avertisseur retentit et toutes les touches de

6. La minuterie compte à rebours le temps de cuisson restant pour un article de menu.

fait une sélection de menus permettra de minuter toutes les grilles pour le temps de menu choisi.

5. Appuyer sur la touche START / STOP (marche/arrêt). Le fait d’appuyer sur ce bouton après avoir

MENU pour primaire ou deux fois pour secondaire.

4. Pour sélectionner un temps de cuisson d’un article de menu, appuyer une fois sur la touche

3. Fermer la porte. L’affichage retourne à la température réglée ou à GROWING BAR (barre croissante).

2. Placer le produit désiré sur l’une des cinq grilles.

1. Ouvrir la porte; l’affichage indique door (porte).

Toujours régler la température avant de régler le temps

Page 33

– 16 –

5. Pour quitter le mode Programmation, appuyer deux fois sur la touche START / STOP (marche-arrêt).

un numéro de grille.

START / STOP (marche-arrêt) une seconde fois pour sauvegarder le menu TEMPS DE CUISSON pour

4. Appuyer sur la touche START / STOP (marche-arrêt); l’afficheur indique LOC. Appuyer sur la touche

START / STOP (marche/arrêt) pour verrouiller.

NOTA : Tous les temps de cuisson pour grille peuvent être programmés à l’avance avant d’appuyer sur le bouton

touches avec flèches pour augmenter ou diminuer le TEMPS DE CUISSON pour tout numéro de grille.

3. Puis sélectionner le numéro de grille (1 à 5). [t 1] indique la grille #1; [t 2] la grille #2, etc. Se servir des

2. Sélectionner l’article de menu à programmer (1 à 6); l’afficheur indique Tine pour le temps.

l’afficheur indique PrOG.

1. Pour entrer en mode Programmation, appuyer et maintenir les touches avec flèches jusqu’à ce que

Programmation du temps de cuisson d’un numéro de grille individuel pour un article de menu

de l’article de menu). Pour quitter, appuyer sur la touche START / STOP (marche-arrêt) une seconde fois.

4. Appuyer une fois sur la touche START / STOP (marche-arrêt) pour commencer la cuisson (avec le temps de cuisson

STOP (marche – arrêt) une seconde fois pour sauvegarder le TEMPS DE CUISSON de l’article de menu.

3. Appuyer sur la touche START / STOP (marche-arrêt); l’afficheur indique LOC. Appuyer sur la touche START /

cette étape pour tous les autres articles de menu.

touches avec flèches pour augmenter ou diminuer le TEMPS DE CUISSON de l’article de menu. Répéter

2. Sélectionner l’article de menu à programmer (1 à 6). L’afficheur indique Tine pour le temps. Se servir des

l’afficheur indique PrOG .

1. Pour entrer en mode Programmation, appuyer et maintenir les touches avec flèches jusqu’à ce que

Changement du réglage du temps de cuisson pour tout article de menu (1 à 6)

des grilles (1 à 5) peuvent être programmés si on le désire, mais ne sont pas requis.

cuisson pour tout article de menu peut être changé en utilisant la procédure ci-dessous. Les temps de cuisson

de cuisson préréglé en usine = 15 minutes). Même chose pour les touches de menu 3/4 ou 5/6. Le temps de

usine = 10 minutes). Le voyant SECONDARY (secondaire) pour le menu 1/2 sélectionne Articles de menu 2 (Temps

Le voyant PRIMARY (primaire) pour le menu 1/2 sélectionne Articles de menu 1 (Temps de cuisson préréglé en

CUISSON CUISSON CUISSON CUISSON CUISSON CUISSON

TEMPS DE TEMPS DE TEMPS DE TEMPS DE TEMPS DE TEMPS DE

ARTICLES DE MENU GRILLE 1 GRILLE 2 GRILLE 3 GRILLE 4 GRILLE 5

VALEURS PROGRAMMABLES

TEMPS DE CUISSON

ARTICLES DE MENU

PRÉGLAGE EN USINE

DE MENU

ARTICLES

5/6 Secondaire 6 35 min

5/6 Primaire 5 30 min

3/4 Secondaire 4 25 min

3/4 Primaire 3 20 min

1/2 Secondaire 2 15 min

1/2 Primaire 1 10 min.

DE MENU

SÉLECTION