Page 1

SERVICE MANUAL

VC3ED FULL SIZE ELECTRIC

CONVECTION OVEN

VC3ED ML-137013

- NOTICE -

This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qualified.

This manual is not intended to be all encompassing. If you have

not attended a Vulcan Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Vulcan Service Technician.

The reproduction, transfer, sale or other use of this Manual,

without the express written consent of Vulcan, is prohibited.

This manual has been provided to you by ITW Food Equipment

Group LLC ("ITW FEG") without charge and remains the property

of ITW FEG, and by accepting this manual you agree that you will

return it to ITW FEG promptly upon its request for such return at

any time in the future.

A product of Vulcan-Hart 3600 North Point Blvd Baltimore, MD 21222

F45534 (0415)

Page 2

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN

TABLE OF CONTENTS

GENERAL .................................................................................................. 3

INTRODUCTION ....................................................................................... 3

INSTALLATION ........................................................................................ 3

OPERATION ........................................................................................... 3

CLEANING ............................................................................................. 3

LUBRICATION ......................................................................................... 3

TOOLS ................................................................................................. 3

SPECIFICATIONS ...................................................................................... 3

REMOVAL AND REPLACEMENT PARTS ................................................................... 5

COVERS AND PANELS ................................................................................ 5

CONTROL PANEL COMPONENTS ..................................................................... 7

COMPONENT PANEL COMPONENTS ................................................................. 7

TEMPERATURE PROBE ............................................................................... 7

HEATING ELEMENTS .................................................................................. 8

BLOWER AND MOTOR ................................................................................ 9

DOOR SWITCH ....................................................................................... 10

ROLLER LATCH ASSEMBLY (INDEPENDENT DOORS) ............................................... 11

DOOR REMOVAL ..................................................................................... 11

HIGH LIMIT THERMOSTAT ........................................................................... 11

INTERIOR LIGHTS .................................................................................... 12

COOLING FAN ........................................................................................ 12

SERVICE PROCEDURES AND ADJUSTMENTS ........................................................... 14

SOLID STATE TEMPERATURE CONTROL TEST ..................................................... 14

TEMPERATURE PROBE TEST (SOLID STATE CONTROL) ........................................... 15

SOLID STATE TEMPERATURE CONTROL CALIBRATION ............................................ 15

HEATING ELEMENT TEST ............................................................................ 17

BLOWER ADJUSTMENT .............................................................................. 17

DOOR STRIKE ADJUSTMENT INDEPENDENT DOORS) .............................................. 18

ELECTRICAL OPERATION ................................................................................ 19

COMPONENT FUNCTION ............................................................................ 19

COMPONENT LOCATION ............................................................................. 20

SEQUENCE OF OPERATION ......................................................................... 22

SCHEMATICS AND WIRING DIAGRAMS .............................................................. 24

TROUBLESHOOTING ..................................................................................... 30

VC3ED ................................................................................................ 30

© VULCAN 2015

F45534 (0415) Page 2 of 31

Page 3

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - GENERAL

GENERAL

INTRODUCTION

FEATURES

MODEL CAVITY DEPTH

VC3ED 26.5" Solid State Independent 1-Hour Dial

NOTE: Stainless steel doors with window (standard)

INSTALLATION

TEMPERATURE

CONTROL

• HUSKEY™ TF-1000 grease or equivalent high

DOORS (50/50) COOK TIMER

temperature non-stick grease.

Refer to OPERATORS MANUAL for procedures

related to Installation, Operation and Cleaning.

OPERATION

Refer to OPERATORS MANUAL for procedures

related to Installation, Operation and Cleaning.

CLEANING

Refer to OPERATORS MANUAL for procedures

related to Installation, Operation and Cleaning.

LUBRICATION

• Cavity blower motor has sealed bearings and

requires no additional lubrication.

Standard

• Standard set of hand tools

• VOM with ability to measure micro amp current.

VOM with minimum of NFPA-70E CAT III 600V,

UL/CSA/TUV listed. Sensitivity of at least 20,000

ohms per volt. Meter leads must also be rated at

CAT III 600V.

• Gear Puller to remove blower

• Temperature tester (thermocouple type)

• Manometer

• RTV sealant, 736 DOW silicone high temp (P/N

542133) or equivalent

TOOLS

SPECIFICATIONS

AMPERAGE - 3 PHASE/ 60HZ

TOTAL

MODEL

VC3ED 12.5 35 33 15 45 40 20

NOTES:

POWER

(KW)

1

Amperage values in the table are nominal. Tolerance is +5/-10%.

2

Complied in accordance with National Electric Code, ANSI/NFPA 70, latest edition

208V 240V 480V 208V 240V 480V

PER LINE

1

RECOMMENDED CIRCUIT

PROTECTION

2

Page 3 of 31 F45534 (0415)

Page 4

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - GENERAL

AMPERAGE - 1 PHASE/ 60HZ

RECOMMENDED CIRCUIT

PROTECTION

MODEL

TOTAL

POWER

(KW)

PER LINE

1

208V 240V 480V 208V 240V 480V

VC3ED 12.5 60 52 26 80 70 35

1

NOTES:

Amperage values in the table are nominal. Tolerance is +5/-10%.

2

Complied in accordance with National Electric Code, ANSI/NFPA 70, latest edition.

SPECIFICATION SHEET

2

F45534 (0415) Page 4 of 31

Page 5

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - REMOVAL AND REPLACEMENT PARTS

REMOVAL AND REPLACEMENT PARTS

COVERS AND PANELS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

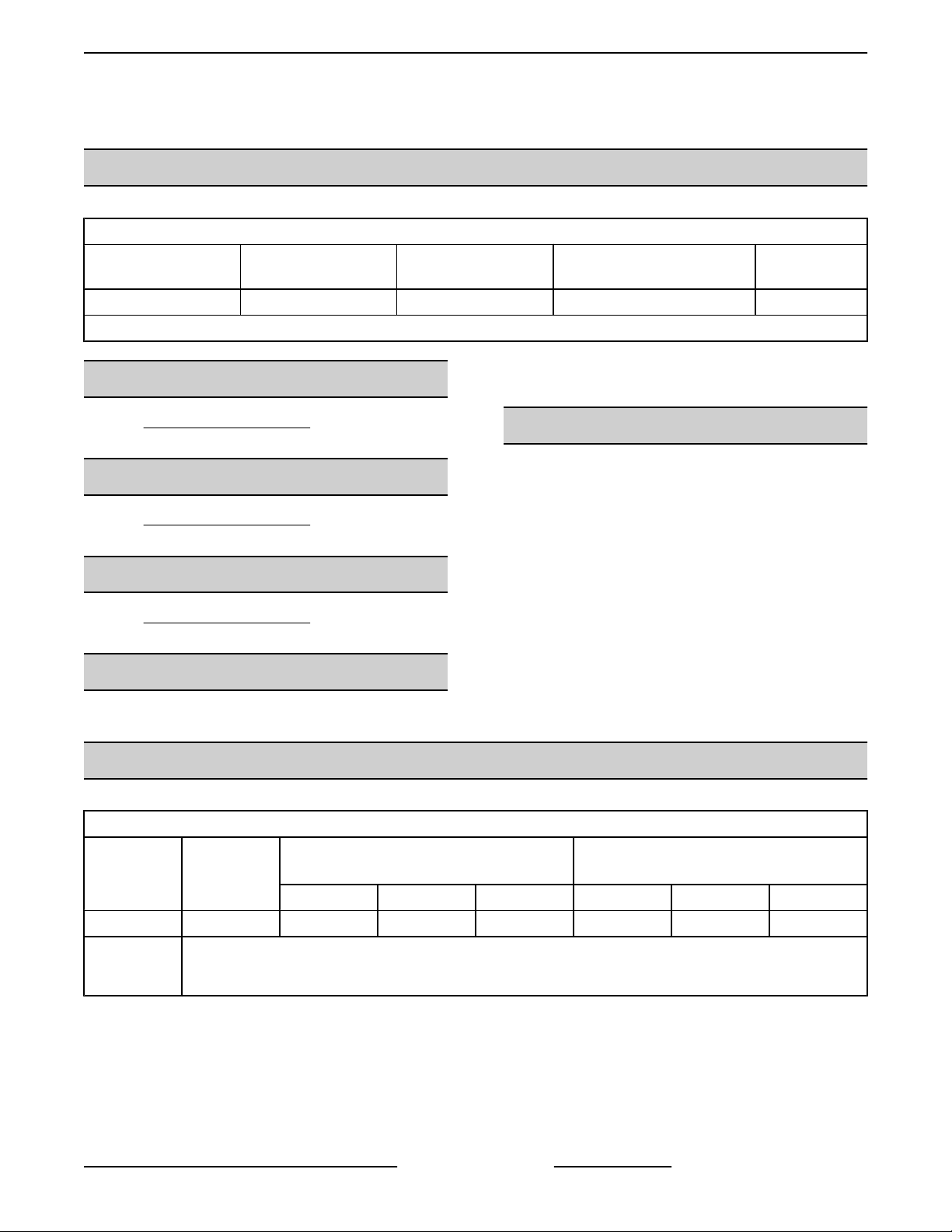

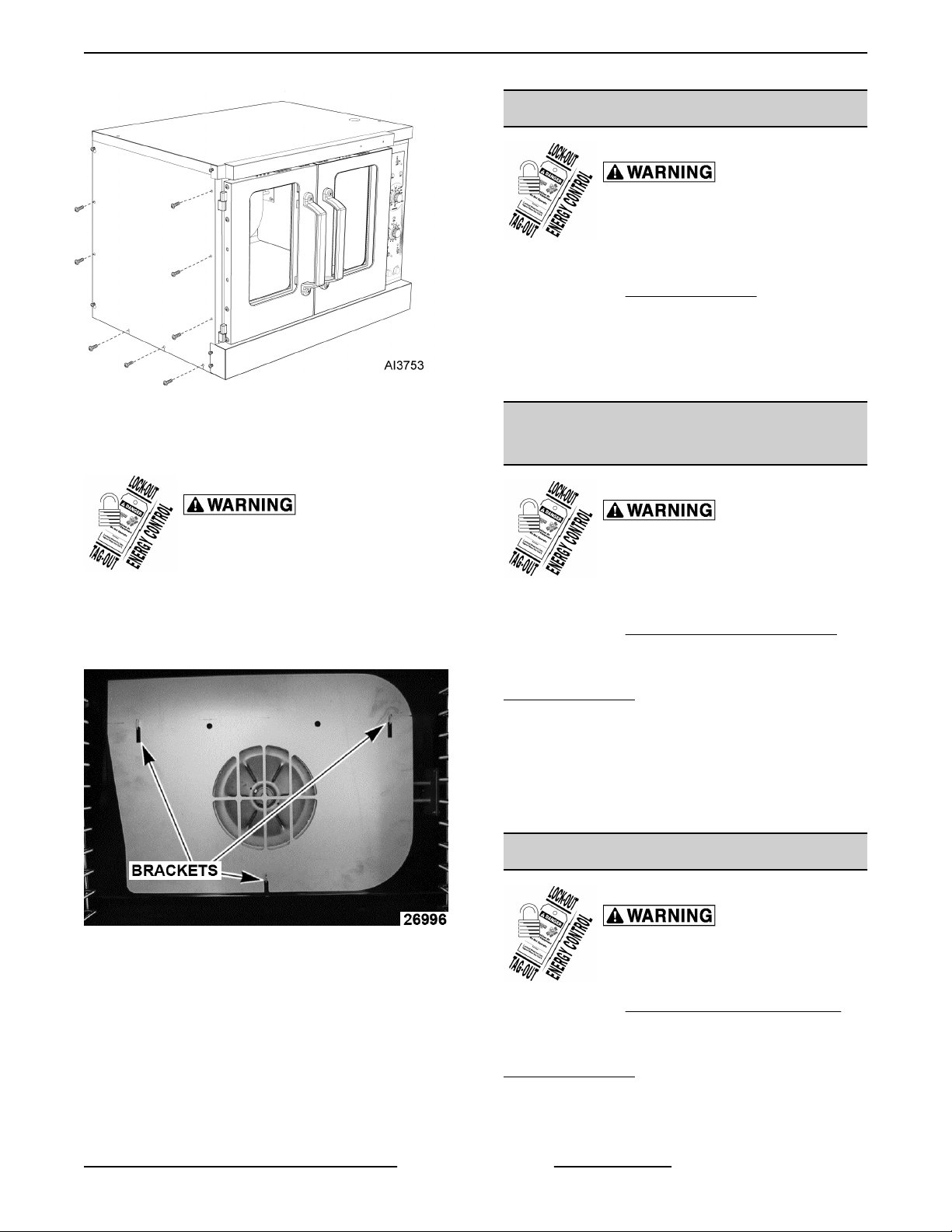

Bottom Front Cover

1. The bottom front cover is secured with four (4)

screws, two on each side of cover. Remove these

screws then remove cover from oven.

Fig. 1

2. Reverse procedure to install. Verify bottom cover

is seated under front plate.

Fig. 2

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

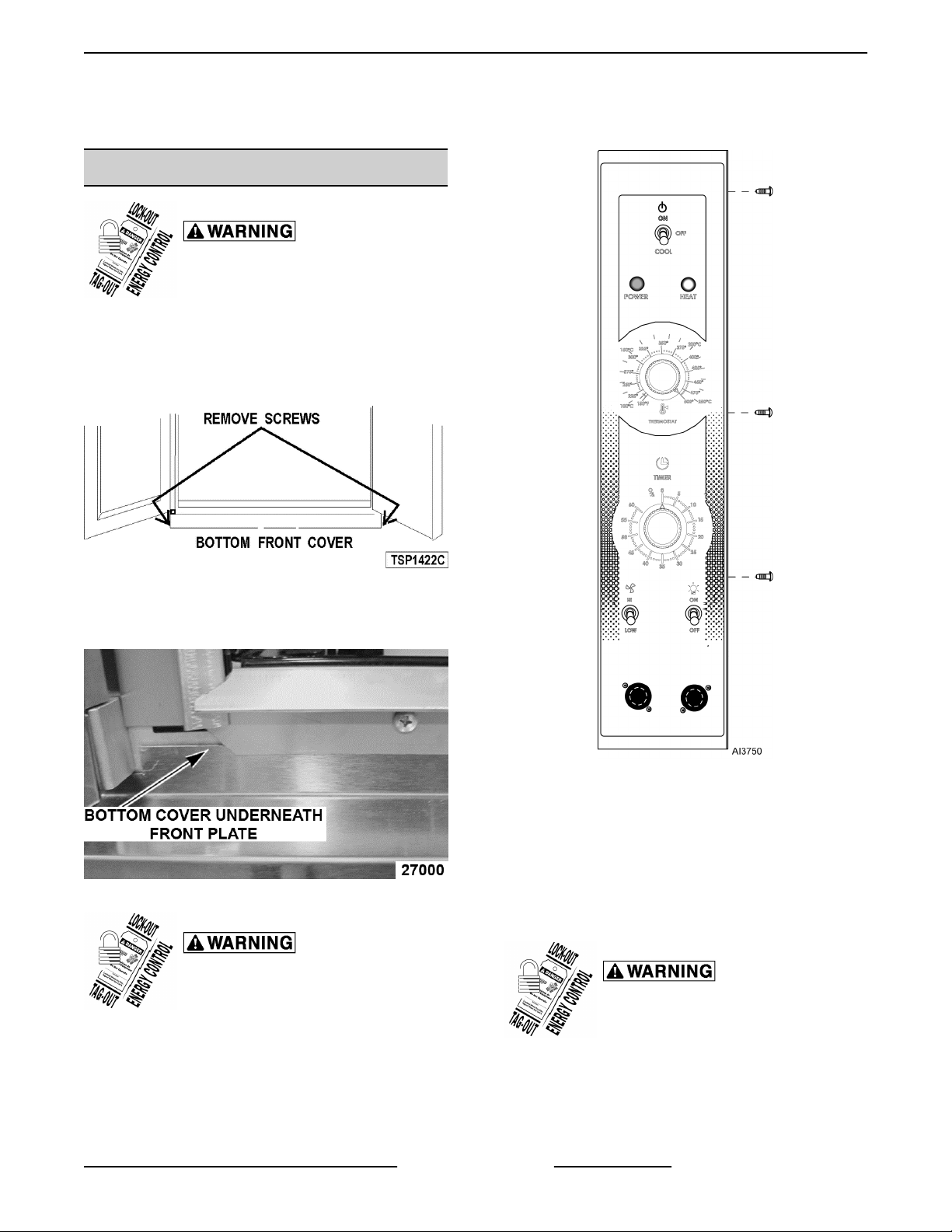

Control Panel

Control Panel Cover

2. Disconnect temperature probe leads from solid

state temperature control.

3. Disconnect fuse wires.

4. Unplug wire harness connector to control panel

components.

5. Reverse procedure to install.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove three (3) screws on the right side which

secure the control panel then left up and pull

away.

Page 5 of 31 F45534 (0415)

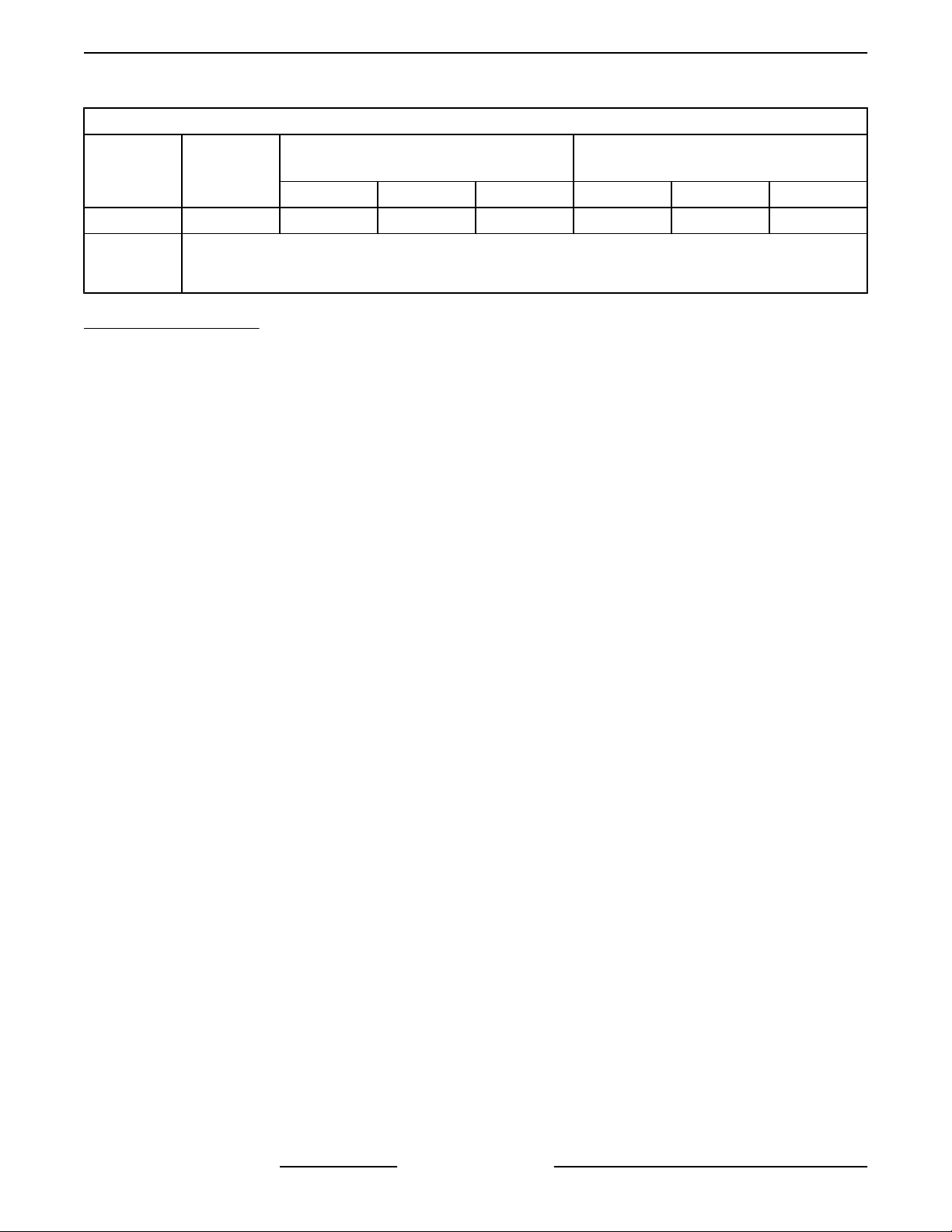

Right Side - Front Panel

1. Loosen two screws near front of oven, which

secure bottom front cover.

Page 6

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - REMOVAL AND REPLACEMENT PARTS

2. Loosen screws on left side of front panel and top

cover screw.

3. Remove screws along right side and bottom of

front panel.

Fig. 4

4. Slide right side front panel out.

5. Reverse procedure to install.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Right Side - Rear Panel

1. Remove two middle screws along right side of

rear panel.

2. Remove screws along left side of rear panel.

3. Remove bottom screws on rear panel.

4. Loosen top and bottom screw along right side of

rear panel.

Fig. 5

5. Slide right side rear panel up and to the right to

remove.

6. Reverse procedure to install.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

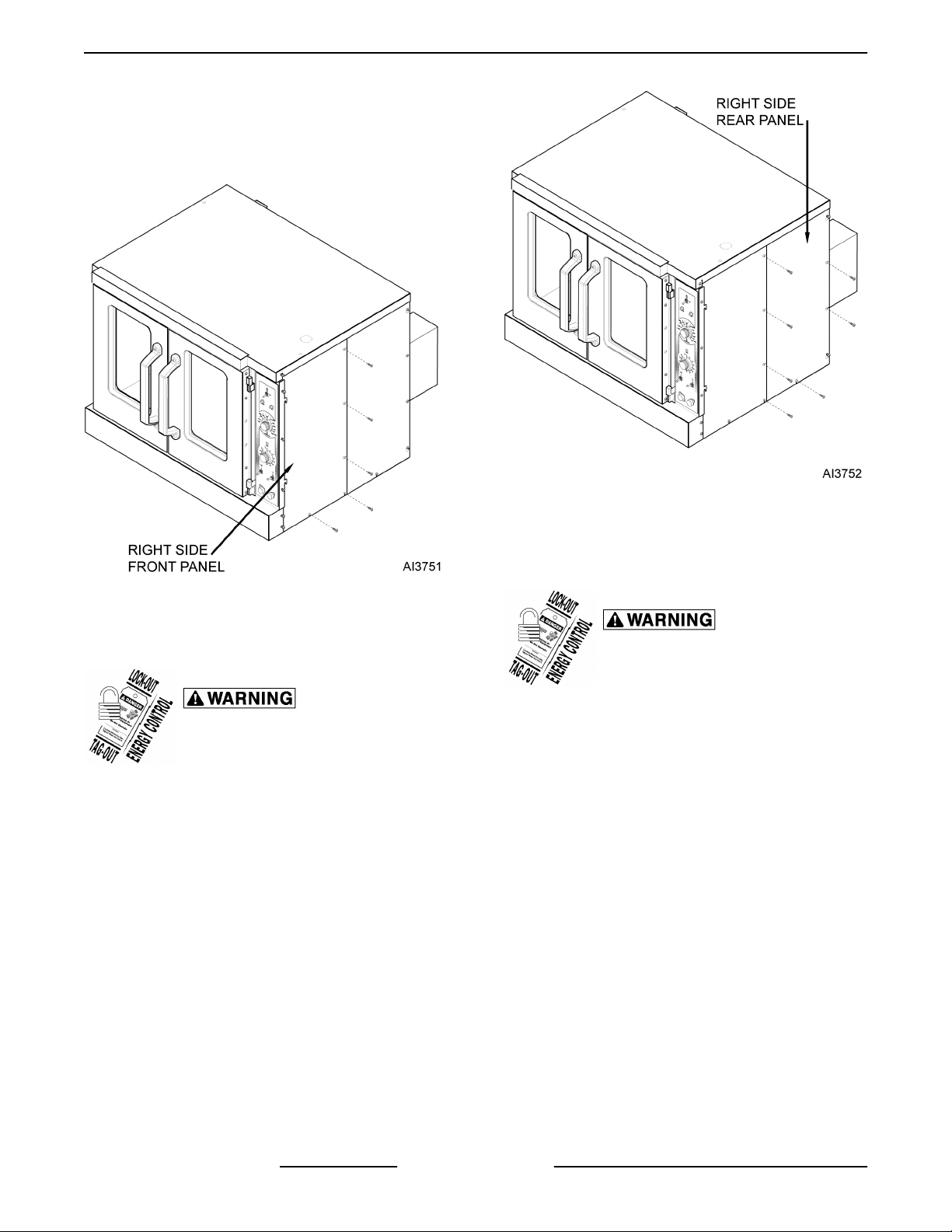

Left Side Panel

1. Remove screws along right side, middle left side,

and bottom on left side panel.

2. Loosen screws on top and bottom on left side of

panel.

3. Loosen two screws near front of oven, which

secure bottom front cover.

F45534 (0415) Page 6 of 31

Page 7

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - REMOVAL AND REPLACEMENT PARTS

Fig. 6

4. Lift up and pull away to remove.

5. Reverse procedure to install.

CONTROL PANEL COMPONENTS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Removable Components

1. Remove the CONTROL PANEL.

2. Remove the component being replaced.

3. Reverse the procedure to install the replacement

component, then check oven for proper

operation.

COMPONENT PANEL

COMPONENTS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Fan Cover

1. Remove racks.

2. Lift fan cover up and out of oven.

Fan Cover Removal

3. Reverse procedure to install.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Removable Components

1. Remove the RIGHT SIDE - FRONT PANEL.

NOTE: If right side panel is not accessible, this

component can be serviced by removing the

CONTROL PANEL.

2. Disconnect the wire leads to the component

being replaced.

3. Remove the component.

4. Reverse the procedure to install the replacement

component and check oven for proper operation.

TEMPERATURE PROBE

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the RIGHT SIDE - FRONT PANEL.

NOTE: If right side - front panel is not accessible, this

component can be serviced by removing the

CONTROL PANEL.

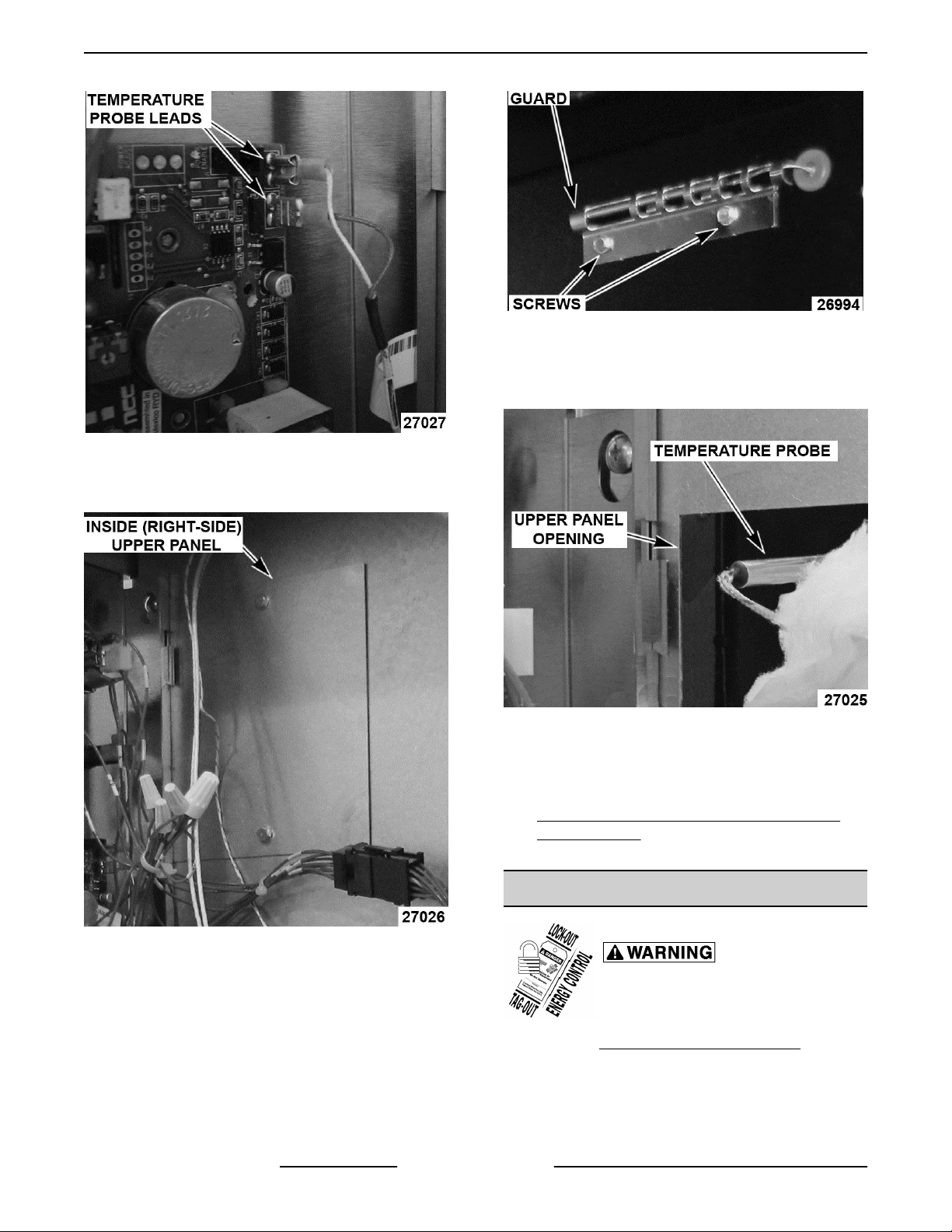

Disconnect the probe leads from the solid state

temperature control.

Page 7 of 31 F45534 (0415)

Page 8

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - REMOVAL AND REPLACEMENT PARTS

Fig. 8

2. Remove upper panel and pull out insulation cutaway.

Fig. 10

5. Remove probe by pushing it through the oven

wall and down through upper panel into the

control panel area.

6. Reverse the procedure to install the replacement

7. Adjust the temperature control as outlined under

Fig. 9

3. Remove the racks from inside cavity.

4. Remove the probe guard.

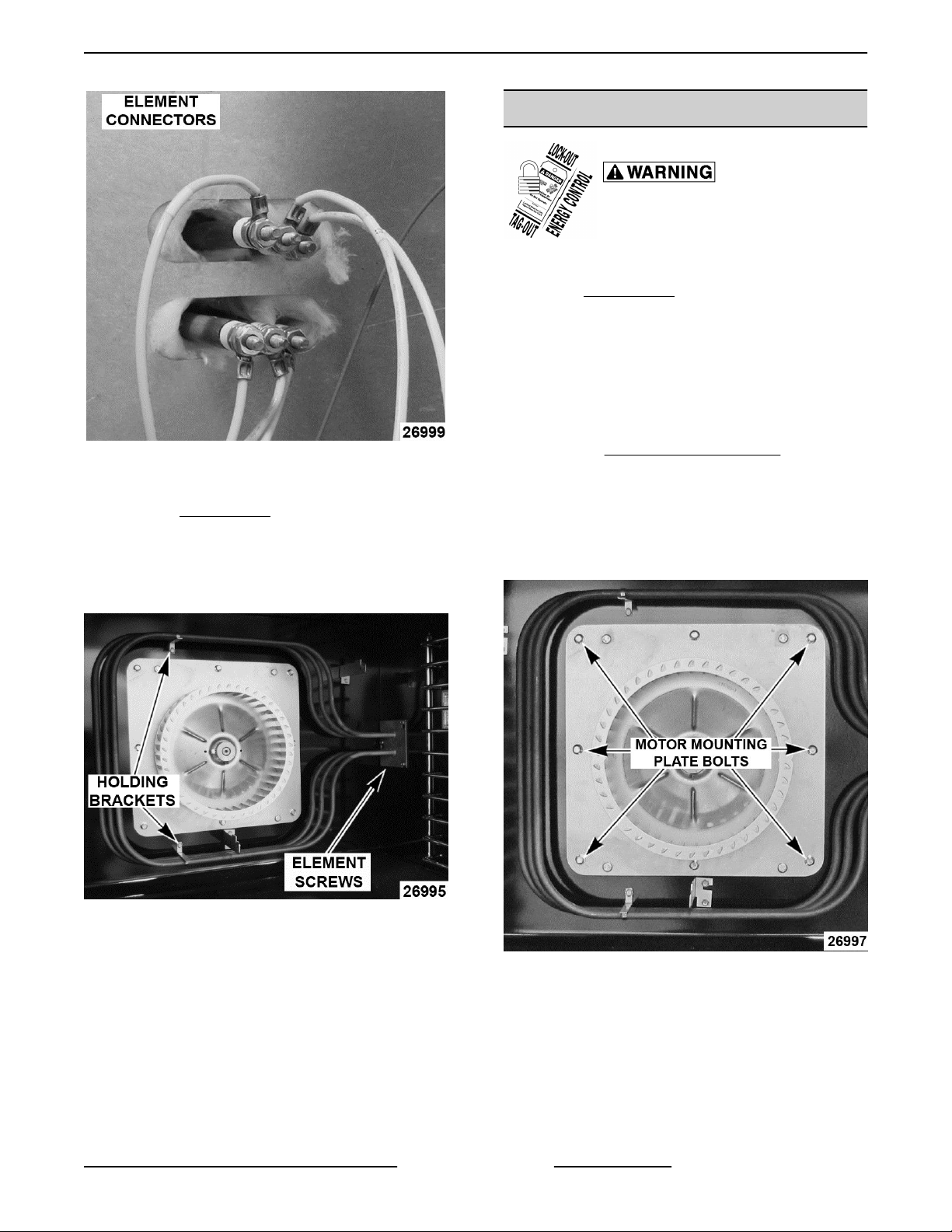

1. Remove RIGHT SIDE - REAR PANEL.

2. Disconnect element wire connectors.

F45534 (0415) Page 8 of 31

Fig. 11

probe.

SOLID STATE TEMPERATURE CONTROL

CALIBRATION under Service Procedures and

Adjustments.

HEATING ELEMENTS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Page 9

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - REMOVAL AND REPLACEMENT PARTS

Fig. 12

3. Remove racks from cavity.

4. Remove FAN COVER.

Loosen element screws on side wall.

5. Remove screws on back wall holding brackets.

BLOWER AND MOTOR

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Take out the racks and rack supports.

2. Lift off FAN COVER.

3. If replacing:

A. Blower Only - Loosen bolts on blower hub

and using a bearing puller, remove blower

from motor shaft.

1) Reverse procedure to install and adjust

blower position as outlined under

BLOWER ADJUSTMENT under

Service Procedures and Adjustments.

B. Motor - perform step 3A and continue

procedure.

4. Remove bolts that secure the motor mounting

plate to the rear wall.

6. Pull elements forward, then away from right wall.

Heating Element

7. Reverse the procedure to install the replacement

heating element.

Fig. 14

5. Place a piece of cardboard on the bottom of the

oven cavity to protect its surface from any

damage during motor assembly removal.

6. Pull the motor assembly into the oven cavity and

place it on the cardboard.

7. Remove the junction box cover from the motor,

disconnect lead wires and remove the conduit.

Page 9 of 31 F45534 (0415)

Page 10

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - REMOVAL AND REPLACEMENT PARTS

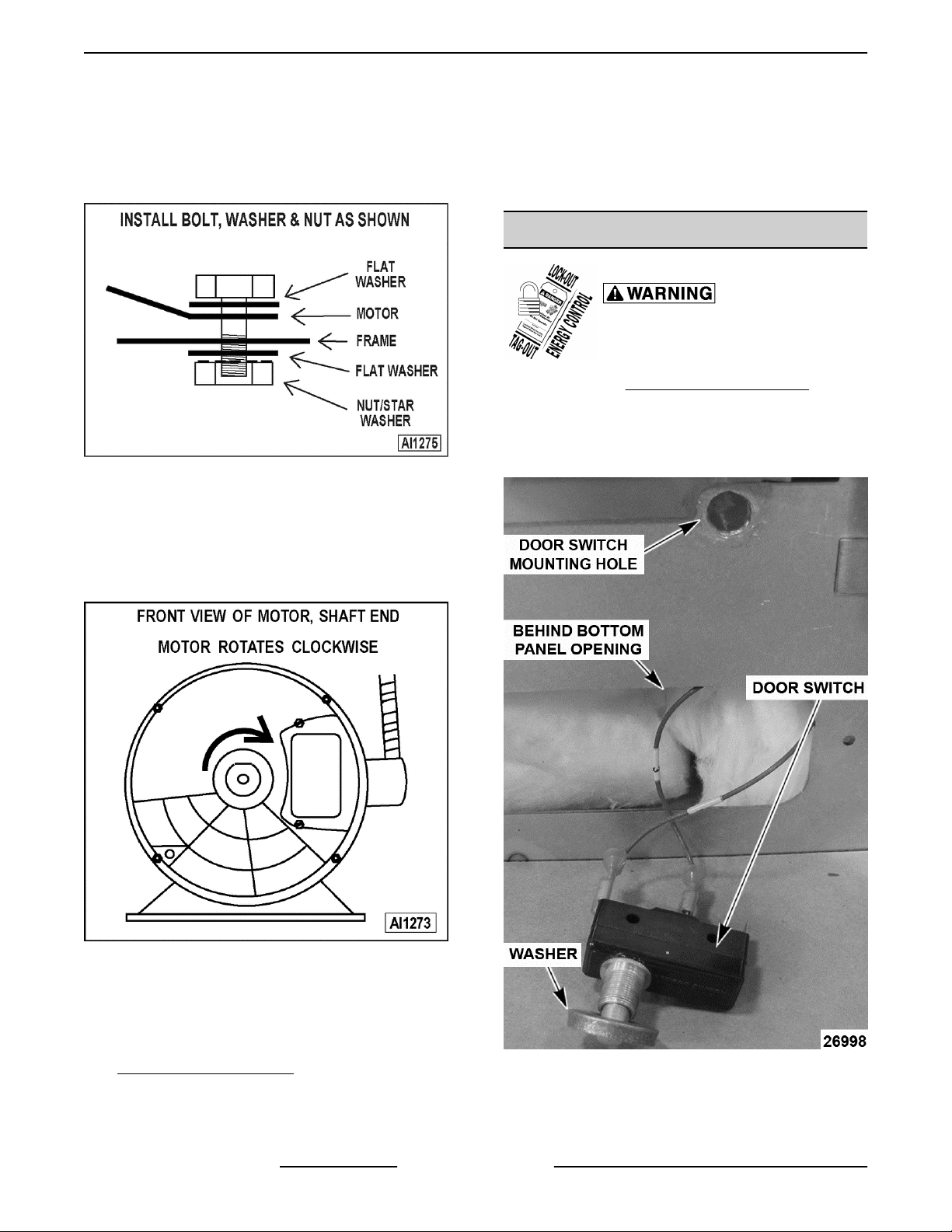

8. Remove motor mounting bolts and flat washers

then lift the motor from the mounting plate.

9. Position the replacement motor on the motor

mounting plate and install mounting bolts and

washers. Hand tighten mounting bolts only.

Fig. 15

10. Reconnect lead wires at the motor, replace

conduit and junction box cover.

NOTE: Check data plate on motor for wiring

schematic. The motor must rotate clockwise when

viewed from the shaft end.

14. Replace the baffle panel.

15. Remove cardboard from the bottom of the oven

cavity.

16. Check oven for proper operation then replace

rack guides and racks.

DOOR SWITCH

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the BOTTOM FRONT COVER.

2. Unscrew nut holding door switch.

3. Pull door switch and washer out through bottom

panel opening.

Fig. 16

11. Slide blower onto motor shaft until hub is flush

with end of shaft then tighten bolts.

12. Adjust motor position until blower is parallel to

motor mounting plate as outlined under

BLOWER ADJUSTMENT under Service

Procedures and Adjustments.

13. Position motor mounting plate on the rear wall

and secure with screws and washers.

F45534 (0415) Page 10 of 31

4. Disconnect the lead wires to the door switch.

5. Reverse procedure to install the replacement

Fig. 17

switch.

Page 11

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - REMOVAL AND REPLACEMENT PARTS

ROLLER LATCH ASSEMBLY

(INDEPENDENT DOORS)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the screws that attach roller latch

assembly to door.

3. Reverse the procedure to install the replacement

door and check oven for proper operation.

HIGH LIMIT THERMOSTAT

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Take out racks from the oven.

2. Remove the high limit thermostat cover/mounting

plate from inside the oven cavity at the top.

Fig. 18

2. Reverse procedure to install.

DOOR REMOVAL

1. Open door to a 90° angle.

2. Lift door up off hinges to remove.

Fig. 20

3. Disconnect lead wires from high limit thermostat.

NOTE: Remove the old RTV sealer from the cover

and mating surfaces inside the oven cavity and apply

new high temperature RTV sealer before installing.

4. Reverse procedure to install.

Fig. 19

Page 11 of 31 F45534 (0415)

Page 12

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - REMOVAL AND REPLACEMENT PARTS

INTERIOR LIGHTS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Do not touch the Halogen lamp with bare

hands. If lamp is exposed to oil from the skin, the life

will be reduced. Ensure lamp is free from oil and dirt

before replacing.

Bulb Replacement

1. Pull lamp cover off.

2. Grasp lamp using a clean cloth and remove from

lamp assembly.

Fig. 21

3. Reverse procedure to install new bulb.

Lamp Assembly Replacement

1. Remove racks in cavity.

2. Pull lamp cover off.

3. Remove RIGHT SIDE - REAR PANEL.

Fig. 22

4. Disconnect wires.

5. Reverse procedure to install new lamp assembly.

COOLING FAN

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the

NOTE: If right side - front panel is not accessible, this

component can be serviced by removing the

CONTROL PANEL.

2. Remove wire nuts from fan wire connections.

RIGHT SIDE - FRONT PANEL.

Insert screw driver and push lamp assembly out

into cavity.

F45534 (0415) Page 12 of 31

Page 13

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - REMOVAL AND REPLACEMENT PARTS

Fig. 23

3. Loosen the tab screw holding the fan to the

component panel. Rotate the tab so that the fan

will clear and remove the fan.

4. Reverse the procedure to install the replacement

fan and check for proper operation.

NOTE: The fan must be installed so air is pulled from

outside the rear of the oven and blown into the control

area. The arrow on the fan body indicates "air flow"

direction and should be pointing toward the controls.

Page 13 of 31 F45534 (0415)

Page 14

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

SOLID STATE TEMPERATURE

CONTROL TEST

Certain procedures in

this section require electrical test or

measurements while power is applied

to the machine. Exercise extreme

caution at all times and follow Arc Flash

procedures. If test points are not easily

accessible, disconnect power and

follow Lockout/Tagout procedures,

attach test equipment and reapply

power to test.

1. Remove the

NOTE: If right side panel is not accessible, this

component can be serviced by removing CONTROL

PANEL.

2. Place a thermocouple in the geometric center of

the oven cavity.

NOTE: Oven temperature must be below 450°F.

NOTE: If oven is equipped with "Cook and Hold"

option, set to Cook (normal cooking) before

continuing.

3. Set the temperature control to the maximum

setting.

4. Check machine data plate for correct voltage to

oven. Refer to diagram below for proper terminal

locations and voltages before checking the

control. Use the correct terminals for the

corresponding voltage.

5. Turn the power switch to ON.

RIGHT SIDE - FRONT PANEL.

Fig. 24

6. Check for proper voltage across terminals COM

AC to 120VAC or COM AC to 208-240VAC for

power to the control.

A. If correct, proceed to step 7.

B. If incorrect, problem is not with the

temperature control. See

TROUBLESHOOTING.

7. Check relay voltages on the board:

A. For 120VAC controls - check across

OUTPUT RELAY terminal (left side) to 120

VAC terminal for input to the internal relay.

Check across OUTPUT RELAY terminal

(right side) to 120 VAC for output from the

internal relay.

B. For 208-240VAC controls - check across

OUTPUT RELAY terminal (left side) to

208-240 VAC terminal for input to the

internal relay. Check across OUTPUT

RELAY terminal (right side) to 208-240 VAC

for output from the internal relay.

F45534 (0415) Page 14 of 31

1) If input voltage to the internal relay is

correct, proceed to step 8. If input

voltage to the internal relay is not

present, problem is not with the

temperature control. See

TROUBLESHOOTING.

Page 15

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - SERVICE PROCEDURES AND ADJUSTMENTS

2) If output voltage from the internal relay

is correct proceed to step 8. If output

voltage from the internal relay is not

correct, check temperature probe as

outlined under TEMPERATURE

PROBE TEST (SOLID STATE

CONTROL).

8. Set the temperature control to the minimum

setting.

NOTE: Oven temperature must be above 300°F.

9. Check for zero (0) volts AC across terminals

OUTPUT RELAY terminal (right side) to 120 VAC

or OUTPUT RELAY terminal (right side) to

208-240 VAC for no output from the internal

relay.

A. If correct, temperature control is functioning

properly.

B. If incorrect, check temperature probe as

outlined under TEMPERATURE PROBE

TEST (SOLID STATE CONTROL).

1) If temperature probe is OK:

a. Turn the power switch OFF.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

b. Replace the temperature control

and check calibration as outlined

SOLID STATE

under

TEMPERATURE CONTROL

CALIBRATION.

NOTE: If right side panel is not accessible, this

component can be serviced by removing CONTROL

PANEL.

2. Place a shielded thermocouple in the geometric

center of the oven cavity and determine the

temperature in the oven cavity.

3. Remove the probe lead wires from the solid state

temperature control.

4. Test the probe with an multimeter.

A. If the measured resistance values are inside

the given tolerance then the probe is

functioning properly.

B. If the measured resistance values are

outside the given tolerance then replace the

probe and retest.

1) Check oven for proper operation.

5. Reverse procedure to install.

TEMP (°F) OHMS * TEMP (°F) OHMS *

77 90,000 360 822

240 4,077 380 656

260 3,016 400 529

280 2,266 425 424

300 1,726 450 334

320 1,332 475 266

340 1,041

* Resistance in ohms ± 10%

SOLID STATE TEMPERATURE

CONTROL CALIBRATION

TEMPERATURE PROBE TEST

(SOLID STATE CONTROL)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

NOTE: The temperature probe used in conjunction

with the Solid State Temperature control is an RTD

(resistance temperature detector) of the Thermistor

type. As temperature increases the resistance value

decreases.

1. Remove the RIGHT SIDE - FRONT PANEL.

Page 15 of 31 F45534 (0415)

Calibration Steps

1. Place a thermocouple in the geometric center of

the oven cavity.

2. Set the ON / OFF / OVEN COOL switch to ON.

3. Set the temperature controller dial to 350°F.

4. Allow the oven temperature to stabilize

(minimum three heating cycles).

5. Record the temperature at which the Heat lamp

comes ON (heating starts) and goes OFF

(heating stops). This is the control differential.

Heat lamp OFF temp - Heat lamp ON temp =

Control Differential.

6. The nominal control differential should be less

than 20°F.

Page 16

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - SERVICE PROCEDURES AND ADJUSTMENTS

A. If the control differential is less than 20°F,

the temperature control circuit is functioning

properly. Proceed to step 7.

B. If the control differential is more than 20°F,

check the temperature probe as outlined

under Temperature Probe Test.

C. If the control differential is more than 20°F

and the probe passes the test parameters,

then temperature controller is

malfunctioning. Install a new temperature

controller and run calibration steps again.

7. Calculate the average oven temperature by

adding the actual minimum temperature to the

actual maximum temperature and dividing by 2.

EXAMPLE:

Oven set to 350°F.

Actual minimum oven temperature = 335°F

Control turns on at 334°F

Actual maximum oven temperature = 347°F

Control turns off at 340°F

335 + 347 = 682

9. Monitor the internal oven temperature and

determine at what temperature the control should

turn on to give you the required minimum

temperature (Example: 350-341=9; 334+9=341.

341°F is the temperature at which you would wish

the controller to turn on).

Fig. 25

682/ 2 = 341 (the control is 9°F out of calibration)

340 - 334 = 6°F Control Differential

347 - 335 = 12°F Oven Temperature Differential.

A. If the average oven temperature is within +/-

5°F from the dial setting, no calibration is

necessary.

B. If the average oven temperature is not within

+/- 5°F, calibration is recommended.

8. Loosen the set screw on the temperature

controller and carefully remove the knob from the

shaft, without rotating the shaft. This will expose

the calibration adjustment control access hole in

the front panel.

10. After allowing the oven to operate through

several cycles (minimum 3 cycles), monitor the

temperature as it falls to the desired turn on point.

Using a small screw driver, adjust the calibration

adjustment until the controller turns on at the

desired turn on temperature.

11. The calibration control is adjusted clockwise in

order to increase the set temperature and

counter clockwise to decrease the set

temperature.

12. The controller has only +/- 25°F of adjustment.

1/4 turn of the calibration adjustment represents

approximately 20°F shift in calibration.

F45534 (0415) Page 16 of 31

Page 17

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - SERVICE PROCEDURES AND ADJUSTMENTS

HEATING ELEMENT TEST

Certain procedures in

this section require electrical test or

measurements while power is applied

to the machine. Exercise extreme

caution at all times and follow Arc Flash

procedures. If test points are not easily

accessible, disconnect power and

follow Lockout/Tagout procedures,

attach test equipment and reapply

power to test.

1. Turn the power switch ON and set the oven

temperature control to the highest setting.

2. Measure the voltage at the heating element

terminals and verify it against the data plate

voltage.

A. If voltage is incorrect, find the source of the

problem.

B. If voltage is correct, check current draw

(amps) through the heating element lead

wires.

NOTE: This method is preferred over a resistance

check when a clamp on type amp meter is available.

1) If current draw is correct then heating

element is functioning properly. See

Heating Element Values table.

2) If current draw is not correct, turn the

power switch OFF and disconnect the

electrical supply to the oven.

a. Replace heating element, then

proceed to step 3.

C. If unable to check current draw, a resistance

check may indicate a malfunctioning

element.

1) Turn the power switch OFF and

disconnect the electrical supply to the

oven.

HEATING ELEMENT VALUES

VOLT.

208 4 19 19 10

240 4 16.5 16.5 14.5

480 4 8 8 57

NOTES:

KW PER

ELEMENT

1. Values in the table are nominal.

Tolerance is +5/-10%.

2. Voltage values are @ 60HZ.

3. Resistance values (ohms) are @

room temperature.

AMPS PER

ELEMENT

1 PH 3 PH

OHMS PER

ELEMENT

BLOWER ADJUSTMENT

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove the blower motor and mounting

assembly by following steps 1 through 7 as

outlined under

Removal and Replacement of Parts.

2. Loosen the motor mounting bolts.

3. Adjust the motor position until the blower is

parallel to and 1/4 inch away from the motor

mounting plate. Check for squareness of the

blower to the motor mounting plate at the top,

bottom, left and right of the blower.

A. If the blower is square then tighten motor

mounting bolts and proceed to step 4.

B. If the blower is not square continue

adjusting until proper spacing is achieved

then tighten motor mounting bolts.

NOTE: If necessary, place shims between motor and

frame.

BLOWER AND MOTOR under

2) Remove the lead wires from the

heating element and check resistance

(ohms). See Heating Elements

Values table.

3. Check for proper operation.

Page 17 of 31 F45534 (0415)

Page 18

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - SERVICE PROCEDURES AND ADJUSTMENTS

Fig. 26

Fig. 28

2. Open and close the doors several times while

observing the roller latch and strike plate

operation.

A. Replace roller latch if malfunctioning as

outlined under ROLLER LATCH

ASSEMBLY (INDEPENDENT DOORS)

and adjust as outlined in this procedure.

Fig. 27

4. Reverse the procedure to install.

DOOR STRIKE ADJUSTMENT

INDEPENDENT DOORS)

1. Open the doors and inspect door strike for proper

shape.

A. Bend strike plate.

3. Each oven door should open with a force of 8 to

25 pounds when pulled at the handle. The

adjustments must allow the doors to remain

closed during normal operation and allow

opening without exertion by the user.

F45534 (0415) Page 18 of 31

Page 19

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - ELECTRICAL OPERATION

ELECTRICAL OPERATION

COMPONENT FUNCTION

Power Switch (S1) .... Determines the mode of operation; ON, OFF, or COOL down.

Oven Light Switch

(S3) ...................

Fan Speed Switch

(S2) ...................

Alarm/Buzzer ......... Signals the end of a "Cook" cycle when cooking time expires.

Cook Timer ........... Counts the "Cook" time of the product and signals the buzzer at the end of the cycle.

Door Switch .......... Allows the oven to operate when the doors are closed but stops the oven from operating

Blower Motor ......... Operates the oven cavity blower (convection fan).

Transformer .......... Provides 240VAC power to the oven control circuit and blower motor (480VAC models

Solid State

Temperature

Control ...............

High Limit

Thermostat ...........

1C .................... Provides power to heating elements when energized. 1C is energized by the temperature

Power ON Light ....... Lit whenever the power switch (S1) is turned to ON or Cool Down mode.

Controls the oven cavity lights.

Controls blower motor speed between High and Low settings.

when the doors are opened.

only).

Monitors temperature sensor and regulates the oven cavity temperature by controlling

1CON to energize the heating elements when the control calls for heat.

Protects the oven from temperatures above 550°F by removing power from the heating

circuit. Auto resets at 500°F.

control when a call for heat is made.

Heat Light ............ Lit whenever temperature control is calling for heat.

Temperature Probe ... Senses the oven temperature for the solid state temperature control or computer control.

On oven models using the solid state control, converts the temperature into a resistance

valve which is monitored by the temperature control board. The probe is an RTD

(resistance temperature detector) of the Thermistor type. As temperature increases the

resistance value decreases.

Cooling Fan .......... Circulates cooler air from outside the oven to cool components in the control area.

Fuses ................. Protect control circuit.

Page 19 of 31 F45534 (0415)

Page 20

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - ELECTRICAL OPERATION

COMPONENT LOCATION

Fig. 29

F45534 (0415) Page 20 of 31

Page 21

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - ELECTRICAL OPERATION

Fig. 30

Page 21 of 31 F45534 (0415)

Page 22

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - ELECTRICAL OPERATION

Fig. 31

SEQUENCE OF OPERATION

Cook Cycle

1. Conditions.

A. Oven connected to correct voltage and is

properly grounded.

B. Power switch (S1) OFF.

C. Temperature dial set to lowest temperature

(fully CCW).

D. High limit thermostat CLOSED.

F45534 (0415) Page 22 of 31

2. Power switch (S1) turned ON.

E. Oven doors closed (door switch contacts

CLOSED).

F. Oven cavity temperature below 140°F.

A. Power ON light (Amber) comes ON.

B. Solid state temperature control energized.

1) Heating elements powered and

heating starts.

2) 1C coil energized.

3) Heat light (Clear) comes on.

Page 23

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - ELECTRICAL OPERATION

C. Blower motor energized.

NOTE: Motor speed (Hi/Low) depends on position of

fan speed switch (S2).

D. Component cooling fan energized.

E. Power to oven cavity light switch (S3) wire

#1. Turns cavity lights ON/OFF; does not

affect "Cook" cycle.

3. Set temperature dial to desired "Cook"

temperature.

4. Oven reaches set temperature.

A. Temperature control de-energizes internal

relay and the normally open (N.O.) contacts

OPEN.

1) Heat light goes out.

2) 1C coil de-energized.

a. Power removed from heating

elements and heating stops.

5. The oven will continue to cycle on the

temperature control until the doors are opened or

power switch (S1) is turned to the OFF or COOL

down position.

B. Contacts 1 & 4 close.

1) Buzzer energized and sounds.

NOTE: The buzzer continues to sound until the timer

dial is set to the OFF position or additional time is set.

Cool Down Cycle

1. Conditions.

A. Oven is ON.

B. Oven cavity temperature needs to be

lowered.

C. Doors are open (door switch contacts

OPEN).

D. Fan speed switch (S2) set to "Hi".

2. Power Switch (S1) turned to COOL DOWN.

A. Power ON light (Amber) goes out.

B. Convection fan motor energized.

3. If doors are CLOSED (door switch contacts

CLOSED):

A. Power ON light (Amber) comes ON.

B. Component cooling fan energized.

Timer Cycle, Cooking

NOTE: The "Cook" timer operates independently of

the heating cycle. Additional time can be set or the

timer can be turned OFF throughout the cooking cycle.

1. With the power switch turned ON, power is

supplied to "Cook" timer terminal 1.

2. Set "Cook" timer to desired time.

A. Contacts 1 & 3 close, timer motor is

energized and timing "down" begins.

3. Time expires on "Cook" timer.

A. Contacts 1 & 3 open, timer motor is de-

energized and timing stops.

C. Power is supplied to:

1) "Cook" timer terminal 1. If a time is

dialed, timer will operate and buzzer

will sound when timer reaches zero.

2) Oven cavity light switch (S3) wire #1.

Turns cavity lights ON/OFF; does not

affect Cool down cycle.

4. The oven will remain in this condition until the

power switch (S1).

Page 23 of 31 F45534 (0415)

Page 24

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - ELECTRICAL OPERATION

SCHEMATICS AND WIRING DIAGRAMS

VC3ED 208-240V Wire Diagram

F45534 (0415) Page 24 of 31

Page 25

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - ELECTRICAL OPERATION

VC3ED 208-240V WIRE DIAGRAM TABLE

ITEM DESCRIPTION

A SWITCH, TOGGLE S.P.S.T

B FAN SWITCH, TOGGLE D.P.D.T

C LIGHT, 250V, CLEAR

C1 LIGHT, 250V, CLEAR

D WIRE SET, LIMIT SWITCH

E TEMP. CONTROL - NCC

F TIMER, 230 VOLT (1-HR, 60 HZ.) (5-HR, 60 HZ.)

G BUZZER 230 VOLT

H DOOR SWITCH, 2HP

J BLOCK,PORCELIAN ASSEMBLY

K LIMIT CONTROL 550F

L ELEMENT ASSY, 12.5 KW (240 VOLT) (208 VOLT)

P PROBE,THERMISTOR

R FUSE & HOLDER 15A

S TERMINAL BLOCK 3 POLE

T CONTACTOR 40A 3 POLE

V MOTOR 1/2 HP. 2 SPEED G.E.

X SWITCH, TOGGLE D.P.D.T. (CO)

Y OVEN LAMP, 40W, 230V

AB WIRE NUT BLUE

Page 25 of 31 F45534 (0415)

Page 26

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - ELECTRICAL OPERATION

VC3ED 208-240V SCHEMATIC

F45534 (0415) Page 26 of 31

Page 27

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - ELECTRICAL OPERATION

VC3ED 480V Wire Diagram

VC3ED 480V WIRE DIAGRAM TABLE

ITEM DESCRIPTION

A SWITCH, TOGGLE S.P.S.T

B FAN SWITCH, TOGGLE D.P.D.T

C LIGHT, 250V, CLEAR

C1 LIGHT, 250V, CLEAR

Page 27 of 31 F45534 (0415)

Page 28

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - ELECTRICAL OPERATION

VC3ED 480V WIRE DIAGRAM TABLE

ITEM DESCRIPTION

E TEMP. CONTROL - NCC

F TIMER, 230 VOLT (1-HR, 60 HZ.) (5-HR, 60 HZ.)

G BUZZER 230 VOLT

H DOOR SWITCH, 2HP

J BLOCK,PORCELIAN ASSEMBLY

K LIMIT CONTROL 550F

L LCOE ELEMENT ASSY, 12.5 KW (208 VOLT) (240 VOLT)

P PROBE,THERMISTOR

R FUSE & HOLDER 15A

S TERMINAL BLOCK 3 POLE

T CONTACTOR 40A 3 POLE

V MOTOR 1/2 HP. 2 SPEED G.E.

X SWITCH, TOGGLE D.P.D.T. (CO)

Y OVEN LAMP, 40W, 230V

AB WIRE NUT BLUE

AC WIRE SET, LIMIT SWITCH

AD TRANSFORMER, 480 TO 240V

F45534 (0415) Page 28 of 31

Page 29

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - ELECTRICAL OPERATION

VC3ED 480V SCHEMATIC

Page 29 of 31 F45534 (0415)

Page 30

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - TROUBLESHOOTING

TROUBLESHOOTING

Certain procedures in this section require electrical test or measurements while

power is applied to the machine. Exercise extreme caution at all times and follow Arc Flash

procedures. If test points are not easily accessible, disconnect power and follow Lockout/Tagout

procedures, attach test equipment and reapply power to test.

VC3ED

SYMPTOMS POSSIBLE CAUSES

1. Line voltage incorrect.

2. Fuse.

Blower motor doesn’t run with power switch in "ON"

"COOL DOWN" or position.

Blower motor doesn’t run with power switch "ON", but

oven heats.

Blower motor doesn’t run in "Cool Down", but runs OK in

"ON" position.

Excessive Heat in oven.

Low heat in oven.

3. Power switch (S1) malfunction.

4. Fan speed switch (S2) malfunction.

5. Interconnecting wiring malfunction.

6. Motor inoperative.

1. Door switch malfunction.

2. Fan speed switch (S2) malfunction.

3. Interconnecting wiring malfunction.

4. Motor inoperative.

1. Power switch (S1) malfunction.

2. Interconnecting wiring malfunction.

1. Temperature probe malfunction.

2. Temperature control not calibrated.

3. Contactor malfunction.

4. Heating element(s) malfunction.

1. Line voltage incorrect.

2. High limit thermostat OPEN.

3. Contactor malfunction.

4. Heating element(s) malfunction.

5. Temperature probe malfunction.

6. Temperature calibration.

Timer inoperative or not functioning properly.

Component cooling Fan does not run.

F45534 (0415) Page 30 of 31

1. Interconnecting wiring malfunction.

2. Timer malfunction.

1. Interconnecting wiring malfunction.

2. Fan motor inoperable.

Page 31

VC3ED FULL SIZE ELECTRIC CONVECTION OVEN - TROUBLESHOOTING

SYMPTOMS POSSIBLE CAUSES

1. Convection Fan motor speed/direction.

2. Air flow Baffles missing or damaged.

3. Line voltage incorrect.

4. High limit thermostat malfunction.

Uneven Cooking.

Intermittent operation problems.

Oven will not turn on.

No heat, convection fan motor runs.

No power to temperature control.

5. Contactor malfunction.

6. Heating element(s) malfunction.

7. Doors out of adjustment.

8. Door roller out of adjustment or broken.

9. Door seals damaged.

1. Cooling fan malfunction.

2. Wiring connections loose.

3. High ambient temperatures.

1. Line voltage incorrect.

2. Control circuit fuses OPEN.

3. Power switch (S1) inoperative.

4. Transformer inoperative (480V only).

1. High limit thermostat OPEN.

2. Temperature probe malfunction.

3. Heating element malfunction.

4. Contactor malfunction.

5. Temperature control malfunction.

1. Power switch (S1) in "Cool Down".

2. Door switch malfunction.

1. Doors out of adjustment.

Door does not seal or shut properly

2. Door catch roller out of adjustment or broken

(independent doors).

3. Door seals damaged.

Page 31 of 31 F45534 (0415)

Loading...

Loading...