Page 1

V SERIES FOOD HOLDING AND

TRANSPORTATION CABINETS

AND BANQUET CARTS

MODELS

INSTALLATION &

OPERATION MANUAL

VHP3 ML-126343

VHP7 ML-126344

VHP8 ML-126345

VHP15 ML-126346

VHP20 ML-126347

VBP5IML-138030

VBP7IML-126358

VBP13IML-126359

VBP15IML-126360

VBP77IML-126361

For additional information on Vulcan-Hart or to locate an authorized parts

and service provider in your area, visit our website at www.vulcanhart.com

VBS7 ML-138032

VBS15 ML-138033

VHDP5 ML-138035

VDW3 ML-138036

VB90 ML-126548

VB96 ML-126550

VB150 ML-126552

VB200 ML-138034

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

WWW.VULCANHART.COM

3600 NORTH POINT BLVD.

BALTIMORE, MD 21222

(9-07)

Page 2

V SERIES

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO

INSTALL ELECTRICAL EQUIPMENT, WHO SHOULD PERFORM THE INITIAL

FIELD START-UP AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS

MANUAL.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY

OF THIS OR ANY OTHER APPLIANCE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING

OR SERVICING THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE,

DO NOT ATTEMPT TO OPERATE THIS DEVICE.

— 2 —

Page 3

V SERIES

INSTALLATION, OPERATION AND CARE

V SERIES FOOD HOLDING AND TRANSPORTATION

CABINETS AND BANQUET CARTS

SAVE THESE INSTRUCTIONS FOR

FUTURE USE

Vulcan-Hart Holding and Transport Cabinets

and Banquet Carts are produced with quality

workmanship and material. Proper

installation, usage, and maintenance of your

cabinet will result in many years of satisfactory

performance.

It is suggested that you thoroughly read this

entire manual and carefully follow all of the

instructions provided.

The VBP series Holding and Transport

Cabinets provide an efficient means of

transporting and holding bulk prepared foods

at proper serving temperatures.

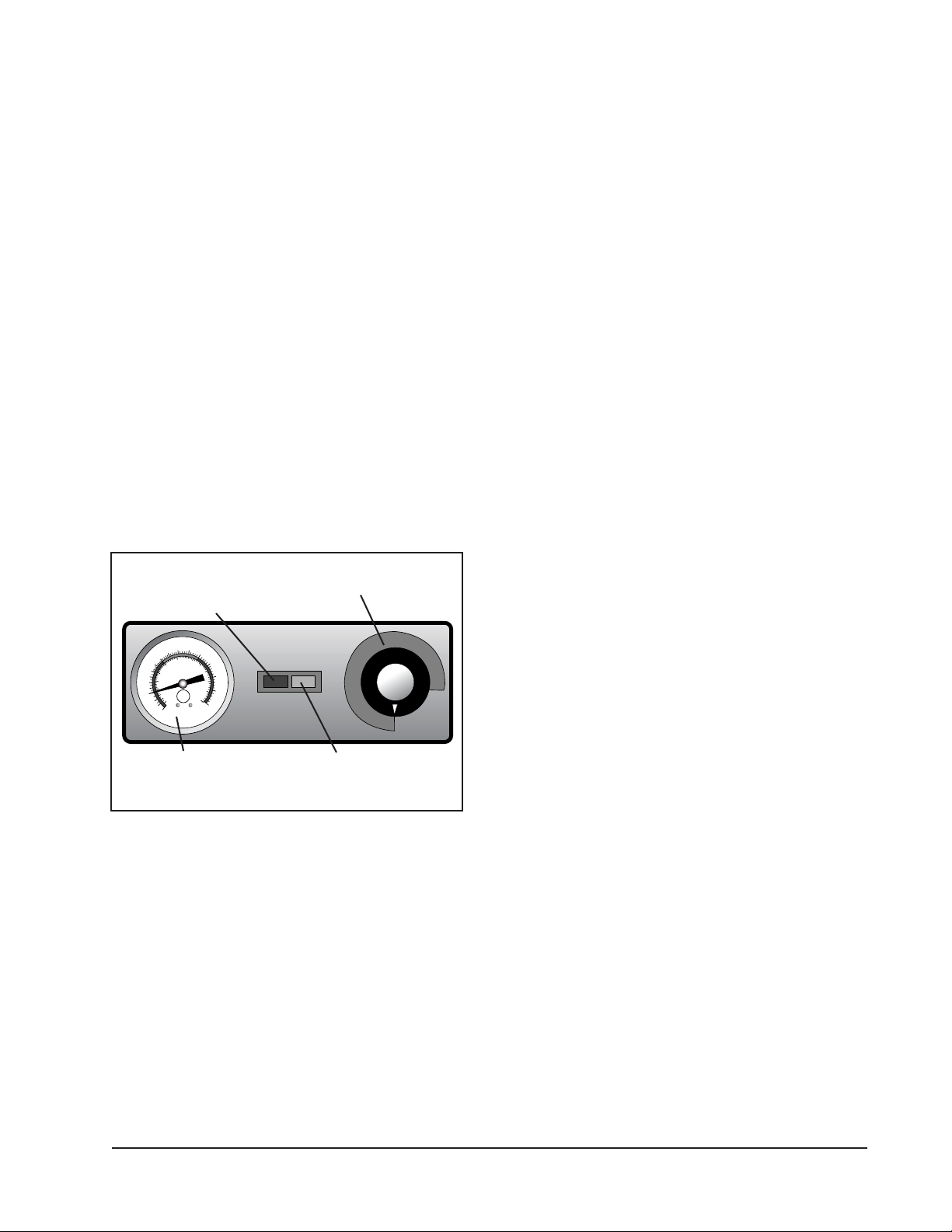

POWER

INDICATOR

LIGHT

170

160

180

150

140

120

40

100

80

60

20

190

70

80

60

50

20

0

200

90

100

210

NSF

®

105

220

°C

°F

THERMOMETER

POWER/HEAT

FULL RANGE

THERMOSTAT

3

2

1

HEAT

INDICATOR

LIGHT

5

6

4

7

8

9

10

OFF

Fig. 1

Model VBP77I cabinets have individual

controls (Fig. 1) for each of the two

compartments. The operator is able to hold

two different products at two different

temperatures in separate sections of the same

cabinet.

All VBP Model, cabinets accommodate either

a third, half, or full size steam table pans of

various depths. The cabinets will also

accommodate the 1/1 or 2/1 gastronorm pan.

Model VHP Holding and Transport Cabinets

provide an efficient means of transporting,

holding, displaying, and serving a variety of

prepared foods at proper serving

temperatures.

All VHP Model, cabinets accommodate either

a third, half, or full size steam table pans of

various depths. The cabinets will also

accommodate the 1/1 gastronorm pan.

Model VB Banquet Carts provide an efficient

and sanitary method of holding and

transporting pre-plated food products in a

banquet facility. The carts are designed to

accommodate covered or uncovered plates.

The covered plates can be used with or without

plate carriers. The uncovered plates require

the use of plate carriers. Each cart is designed

to hold 10 ½″ (27 cm) plates. If larger or

smaller plates are used the capacities increase

or decrease to fit.

— 3 —

Page 4

V SERIES

INSTALLATION

Before installing, verify the electrical service

agrees with the specifications on the rating

plate located on the lower rear of the cart. If

the electrical service does not agree with the

rating plate, do not proceed with installation.

Contact your dealer or local Vulcan-Hart

service technician immediately.

Fig. 2

UNPACKING

The APPLIANCE was inspected before leaving

the factory. The transportation company

assumes full responsibility for safe delivery

upon acceptance of the shipment.

Immediately after unpacking, check for

possible shipping damage. If the APPLIANCE

is damaged, save packing material and

contact the carrier within 15 days of delivery.

Check the delivery documentation for damage

reporting contacts and time limits.

4. On food holding and transport cabinets,

remove cardboard element cover

protector from cabinet bottom.

Remove adjustable tray slides from box.

Remove the tray slide supports and

install them in the cabinet.

a. Hook the openings in the flat flange of

the support over two vertical carriage

bolts on the interior of the cabinet.

b. Make sure all flanges on the four

supports face the door opening.

Install tray slides in the cabinet.

Make sure the hook on the end of the

tray slide is up.

LOCATION

For efficient cabinet operation, choose a

location that will provide easy loading and

unloading without interfering with the final

assembly of food orders.

1

7

0

0

6

1

5

1

0

6

5

80

4

1

40

1

7

1

3

9

7

0

0

8

0

0

60

8

2

2

1

5

0

2

9

0

0

0

0

0

40

9

1

1

HOLDING AND

8

1

0

0

0

0

2

0

1

1

0

N

S

F

2

®

1

0

5

0

6

0

TRANSPORT

P

O

W

E

0

R/

H

E

AT

2

°

C

2

20

°

F

SYSTEM

O

FF

Carefully unpack and place in a workaccessible area as near the installation

position as possible.

1. Open the door and carefully remove any

packaging materials and the retaining

straps that hold the wire plate racks

(VB) or tray slides and tray slide upright

side supports (VBP/VHP).

2. Remove all scratch protective film from

the cabinet.

3. On banquet carts, lift the plate racks

into position on the side brackets.

Leave adequate clearance

for ease of loading and unloading.

Fig. 3

The installation location must allow adequate

clearances for servicing and proper operation.

— 4 —

Page 5

V SERIES

INSTALLATION CODES AND

STANDARDS

The APPLIANCE must be installed in

accordance with:

In the United States of America:

1. State and local codes.

2. National Electrical Code, ANSI/NFPA-70

(latest edition). Copies may be obtained

from The National Fire Protection

Association, Batterymarch Park, Quincy,

MA 02269.

In Canada:

1. Local codes.

2. Canadian Electrical Code, CSA C22.1

(latest edition). Copies may be obtained

from The Canadian Standard

Association, 178 Rexdale Blvd.,

Etobicoke, Ontario, Canada M9W 1R3.

ELECTRICAL CONNECTIONS

Electrical and grounding

connections must comply with the

applicable portions ofthe National

Electrical code and/or other local electrical

codes.

The cord and plug supplied, is a suitable

durable cord with molded plug and is provided

with a proper strain relief.

Appliances equipped with

a flexible electric supply cord provided

with a three-prong grounding plug. It is

imperative that this plug be connected

into a properly grounded three-prong

receptacle. If the receptacle is not the

proper grounding type, contact an

electrician. Do Not remove the grounding

prong from this plug.

Refer to wiring diagrams in this manual.

All cabinets are equipped with an 8 ft. (2.4 m)

cord and NEMA 5-15 plug as standard

equipment.

The banquet cart series are factory wired for

either 110/120 volt or 208/240 volt, single

phase operation.

• All 208/240 volt carts are equipped

with an 8 ft. (2.4 m) cord and NEMA

6-15 plug.

— 5 —

Page 6

V SERIES

Electrical Connection

Electrical and grounding

connections must comply with the

applicable portions of the National

Electrical Code and/or other Local

Electrical Codes.

electrical power to the

machine and follow Lockout/

Tagout procedures before

cleaning.

Disconnect

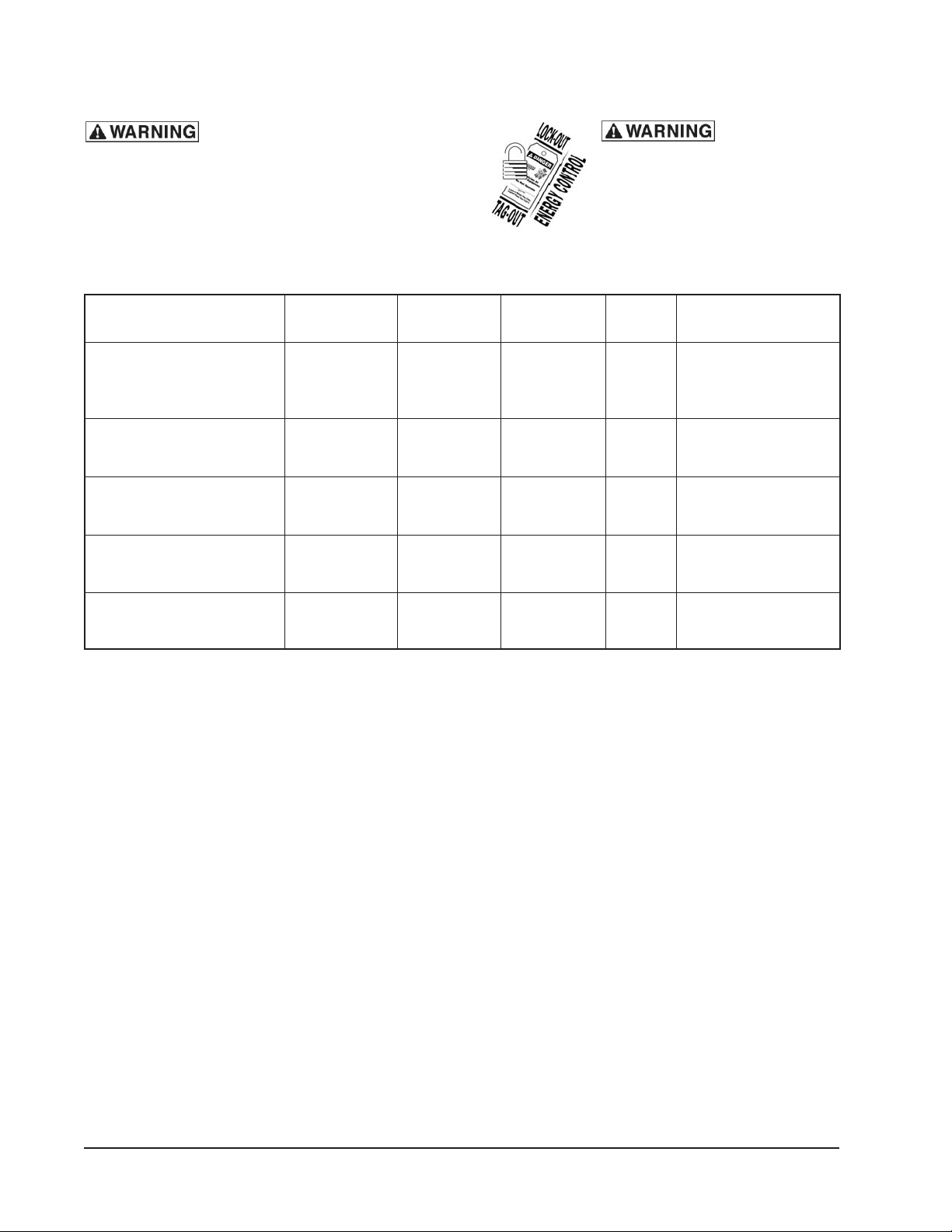

MODEL VOLTAGE AMP PHASE HZ NEMA PLUG

VBP5I, VBP7I, VBP13I, 110/120 10 1 60 5-15

VBP15I, VBS7, VBS15, 208/240 5.4 6-15

VHDP5, VDW3

VBP77I 110/120 20 1 60 5-20

208/240 10.9 6-20

VHP3, VHP7, VHP8 110/120 5 1 60 5-15

208/240 2.7 6-15

VHP15, VHP20 110/120 10 1 60 5-15

208/240 5.4 6-15

VB90, VB96, 110/120 16.6 1 60 5-20

VB150, VB200 208/240 9.0 6-20

— 6 —

Page 7

OPERATION

V SERIES

The cabinet and its parts

are hot, be very careful when operating,

cleaning or servicing the cabinet.

CONTROLS

POWER

INDICATOR

LIGHT

170

160

180

150

140

120

40

100

80

60

20

190

70

80

60

50

20

0

200

90

100

210

NSF

®

105

220

°C

°F

THERMOMETER

POWER/HEAT

FULL RANGE

THERMOSTAT

3

2

1

HEAT

INDICATOR

LIGHT

5

6

4

7

8

9

10

OFF

Fig. 4

HOLDING COMPARTMENTS

BEFORE FIRST USE

Disconnect

electrical power to the

machine and follow Lockout/

Tagout procedures before

cleaning.

POWER INDICATOR LIGHT

Lit when power is supplied to cabinet.

HEAT INDICATOR LIGHT

Lit when heat is supplied to cabinet.

FULL RANGE THERMOSTAT

Turn to desired temperature setting (1-10).

THERMOMETER

Indicates interior temperature.

Fig. 5

1. Clean appliance thoroughly.

a. Use mild soap and water solution to

clean appliance.

b. Wipe dry with a soft clean cloth.

c. Clean all accessories.

2. Operate appliance in highest

temperature setting for a period of 30-45

minutes. (See Operating Instructions).

— 7 —

Page 8

V SERIES

PO

NSF

®

°F

20

60

80

100

120

140

150

160

170

180

190

200

210

220

0

20

40

50

60

70

80

90

100

105

°C

OPERATING APPLIANCE

1. Connect electric power supply.

• Power indicator light is lit.

Fig. 6

2. Turn thermostat knob to desired setting.

• Heating elements begin heating.

Fig. 8

4. Once desired temperature is reached,

heating elements will cycle on and off.

• Heat light(s) will cycle on and off with

the heating elements.

5. Temperature in heated appliance will

fluctuate as the heating elements cycle

on and off.

6. Monitor the food product to ensure

proper temperatures.

• Heat indicator light is lit.

5

4

3

2

1

6

7

8

9

10

AT

OFF

Fig. 7

3. Thermometer will indicate the interior

temperature of the appliance.

Appliance Temperatures

The greater the thermostat setting number,

the higher the appliance temperature. The

lower the thermostat setting number, the lower

the appliance temperature.

Thermostat Setting Approximate

Temperature

1 110°F (43°C)

2 120°F (49°C)

3 130°F (54°C)

4 140°F (60°C)

5 150°F (66°C)

6 160°F (71°C)

7 170°F (77°C)

8 180°F (82°C)

9 190°F (88°C)

10 200°F (93°C)

— 8 —

Page 9

V SERIES

Shutdown

Turn full range thermostat counterclockwise

to OFF.

5

4

3

2

1

6

7

8

9

10

AT

OFF

Fig. 9

Unplug electrical power supply. Power

indicator light will go off.

CLEANING

Disconnect

electrical power to the

machine and follow Lockout/

Tagout procedures before

cleaning.

Clean appliance interior with mild soap and

water whenever a food spill occurs. Never use

harsh chemicals or abrasive pads to clean

appliance.

Daily

1. Allow appliance to cool before cleaning.

2. Remove tray slides or plate racks and

clean in a sink as you would any utensil.

3. Clean the interior of the appliance with

mild soap and water.

Fig. 10

Extended Shutdown

Unplug electrical power supply. Power

indicator light will go off.

4. Place tray slides or plate racks in the

appliance.

— 9 —

Page 10

V SERIES

TROUBLESHOOTING

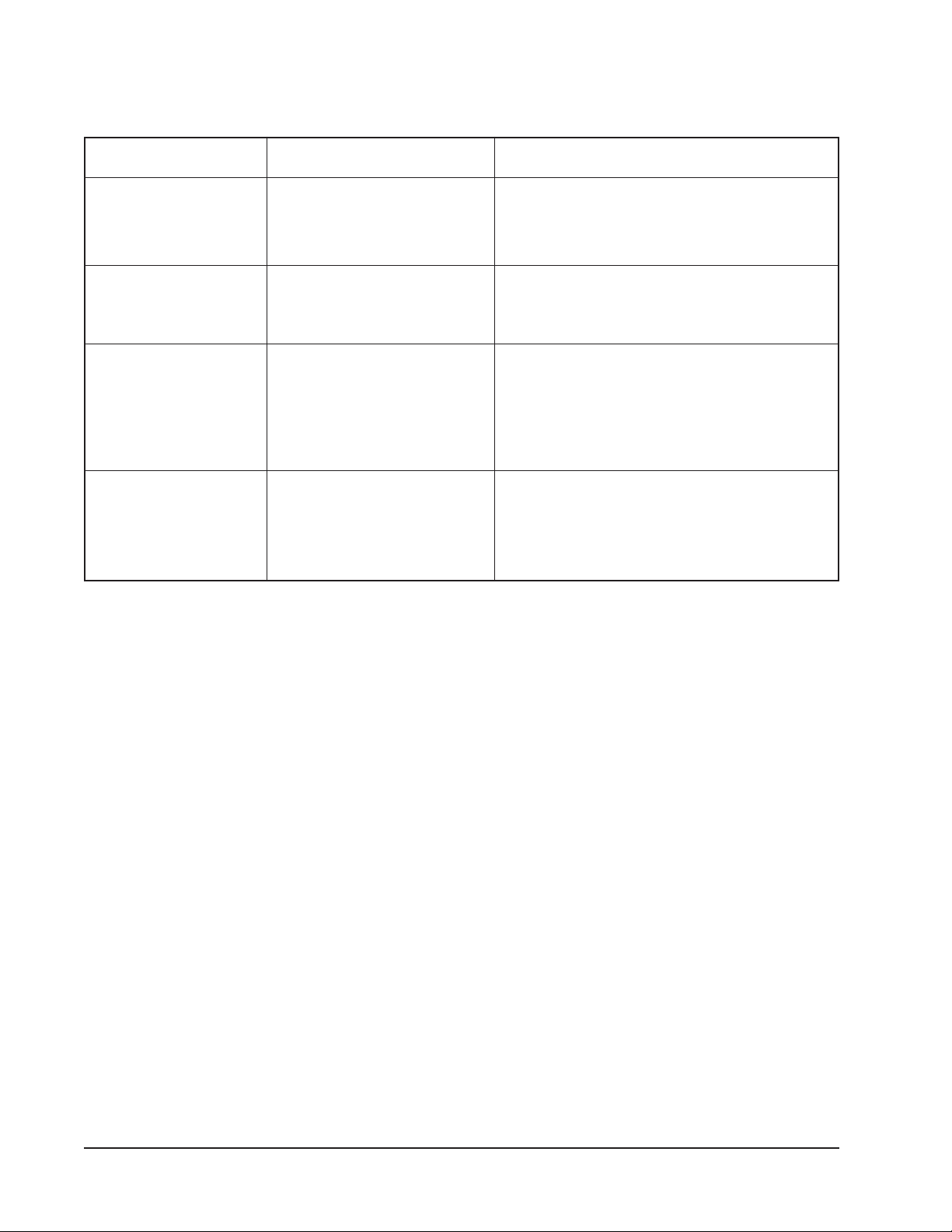

SYMPTOMS POSSIBLE CAUSES REMEDY

Temperature incorrect No main power source Check the power source or circuit breaker.

Power switch in off position Press power switch to the on position.

Door open Close door.

Door leaks Damaged door gasket Check door gasket for damage.

If adjustment is needed, contact your

Authorized Vulcan-Hart Servicer.

Compartment does Defective heating coil Contact your authorized service provider.

not heat properly

Defective thermostat or Contact your authorized service provider.

thermostat requires

adjustment

Indicator lights not lit

Power indicator light No power to appliance Check power source.

Heat indicator light No heat Check power source and thermostat

operation.

— 10 —

Page 11

WIRING DIAGRAMS

V SERIES

THERMOSTAT

BLACK

POWER

CONNECTION

120V, 1PH, 60 Hz

208/240V, 1PH, 60 Hz

BLACK

WHITE WHITE

GREEN

RED

POWER

A

A

HEATING

ELEMENT

POWER

R

HEATING

ELEMENT

VB48, VB72, VB90, VB96, VB150, VBP5I, VBP7I, VBP13I, VBP15I, VHP15, VHP20

Wiring Diagram

— 11 —

Page 12

V SERIES

POWER

CONNECTION

120V, 1PH, 60 Hz

208/240V, 1PH, 60 Hz

BLACK

WHITE

GREEN

BLACK

THERMOSTAT

HEATING

ELEMENT

BLACK

POWER

R

POWER

R

POWER

A

POWER

A

THERMOSTAT

HEATING

ELEMENT

VBP77I Wiring Diagram

— 12 —

Page 13

POWER

CONNECTION

120V, 1PH, 60 Hz

208/240V, 1PH, 60 Hz

POWER

THERMOSTAT

RED

BLACK

WHITE WHITE

GREEN

V SERIES

A

A

HEATING

ELEMENT

VHP3, VHP7, VHP8 Wiring Diagram

— 13 —

Page 14

V SERIES

VULCAN REPLACEMENT PARTS LIST

BOLT, RETAINING RACK (PACK OF 4) WP-305 851800-26

CAP, CHROME INSPECTION WP-174 851800-23

CLIP, ELEMENT WP-182 851800-14

CORD, POWER 12/3 120V. 15 AMP WP-015-1 851800-99

CORD, POWER 12/3 120V. 20 AMP WP-247 851800-148

CORD, POWER 12/3 208/240V. 15 AMP WP-015-2 851800-213

CORD, POWER 16/3 120V. WP-052 851800-6

ELEMENT, 120V – 1000W WP-105-1 851800-151

ELEMENT, 120V – 600W (1220/1826) WP-104-1 851800-11

ELEMENT, 208/240V – 600W (1220/1826) WP-104-2 851800-13

ELEMENT, 208/240V – 1000W (1826-40) WP-105-2 851800-152

GASKET, DOOR WP-302 851800-17

HANDLE, PUSH/PULL WP-117 851800-132

HANDLE, PUSH/PULL S.S. (2026 SERIES) WP-236 851800-223

HANDLE, PUSH/PULL S.S. (2-90 ONLY) WP-237 851800-375

HANDLE, PUSH/PULL S.S. (ALL EXCEPT 2-90) WP-149 851800-606

HANDLE, SIDE LIFT (1220-3, 7, 8/1826-7) WP-108 851800-134

HINGE, DOOR WP-111 851800-18

HOLDER, PROBE THERMOMETER WP-093 851800-29

HOLDER, PROBE THERMOSTAT WP-089 851800-32

KNOB, THERMOSTAT WP-242 851800-31

LATCH, DOOR WP-107 851800-8

LATCH, DOOR (MAGNETIC) WP-372 851800-626

LIGHT, INDICATOR DUAL 125V WP-106-1 851800-21

LIGHT, INDICATOR DUAL 240V WP-106-2 851800-22

PAN, HUMIDITY W/SPONGE WP-103 851800-135

PLATE, CARRIER, WIRE (COVERED) WP-126 851800-465

PLATE, CARRIER, WIRE (UNCOVERED) WP-127 851800-466

RACK, WIRE SHELF (2-150) WP-123-150 851800-408

RACK, WIRE SHELF (2-72) WP-123-72 851800-405

RACK, WIRE SHELF (2-90) WP-123-90 851800-406

RACK, WIRE SHELF (2-96) WP-123-96

SLIDES, TRAY METRIC (EACH) WP-291 851800-310

SPONGE, HUMIDITY WP-099 851800-20

STRAIN RELIEF, 12/3 POWER CORD WP-006-312 851800-229

STRAIN RELIEF, 16/3 POWER CORD WP-006-1 851800-7

THERMOMETER, DIAL WP-109 851800-28

THERMOSTAT WP-110 851800-30

851800-407

— 14 —

Page 15

NOTES

V SERIES

(9-07)

— 15 —

PRINTED IN U.S.A.

Page 16

V SERIES

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this model, contact the Vulcan-Hart Service

Agency in your area (refer to our website, www.vulcanhart.com for a complete listing of Authorized

Service and Parts depots).

When calling for service, the following information must be available: model number, serial number,

manufacture date (MD) and voltage.

— 16 —

Loading...

Loading...