Page 1

SERVICE MANUAL

V Series Heated Holding

Insulated Cabinets

VBP5 ML-138030

VBP7 ML-126358

VBP13 ML-126359

VBP15 ML-126360

VBP18

VHP7 ML-126344

VHP15 ML-126346

VPT7

VPT13

VPT15

VPT18

- NOTICE -

This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qualified.

This manual is not intended to be all encompassing. If you have

not attended a Vulcan Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Vulcan Service Technician.

The reproduction, transfer, sale or other use of this Manual,

without the express written consent of Vulcan, is prohibited.

This manual has been provided to you by ITW Food Equipment

Group LLC ("ITW FEG") without charge and remains the property

of ITW FEG, and by accepting this manual you agree that you will

return it to ITW FEG promptly upon its request for such return at

any time in the future.

A product of Vulcan-Hart 3600 North Point Blvd Baltimore, MD 21222

F45748 (0219)

Page 2

V Series Heated Holding Insulated Cabinets

TABLE OF CONTENTS

SERVICE UPDATES ....................................................................................... 3

SERVICE UPDATES ................................................................................... 3

TIS DOCUMENT LIST - V SERIES HEATED HOLDING INSULATED CABINETS ......................... 3

GENERAL .................................................................................................. 4

INTRODUCTION ....................................................................................... 4

INSTALLATION, OPERATION AND CLEANING ......................................................... 4

TOOLS ................................................................................................. 4

SPECIFICATIONS ...................................................................................... 4

DATA PLATE LOCATIONS ............................................................................. 4

REMOVAL AND REPLACEMENT OF PARTS ............................................................... 5

TOP COVER ........................................................................................... 5

FOOD COMPARTMENT FAN ........................................................................... 5

HEATING ELEMENTS .................................................................................. 6

POWER CORD ......................................................................................... 7

HIGH LIMIT SWITCH ................................................................................... 8

TERMINAL BLOCK ..................................................................................... 8

TEMPERATURE PROBE ............................................................................... 8

COMPONENT COOLING FAN .......................................................................... 9

CONTROL BOARD ..................................................................................... 9

DOOR GASKET ....................................................................................... 11

DOOR ASSEMBLY .................................................................................... 11

DOOR LATCH (MAGNETIC) ........................................................................... 12

SERVICE PROCEDURES AND ADJUSTMENTS ........................................................... 14

TEMPERATURE VERIFICATION ...................................................................... 14

HEATER ELEMENT TEST ............................................................................. 14

ELECTRICAL OPERATION ................................................................................ 15

COMPONENT DESCRIPTIONS ....................................................................... 15

WIRING DIAGRAM .................................................................................... 16

SEQUENCE OF OPERATION ......................................................................... 16

TROUBLESHOOTING ................................................................................. 17

© VULCAN 2019

F45748 (0219) Page 2 of 17

Page 3

V Series Heated Holding Insulated Cabinets - SERVICE UPDATES

SERVICE UPDATES

SERVICE UPDATES

JANUARY 2019

• New service manual release.

TIS DOCUMENT LIST - V SERIES HEATED HOLDING INSULATED CABINETS

SERVICE TAB

Document Title Document Type

V Series Heated Holding Transportation Cabinets Service Manual

SERVICE MULTIMEDIA TAB

Document Title Document Type

V Series Heated Holding Transportation Cabinets Installation &

Operation

V Series Heated Holding Transportation Cabinets Specifications Specification

Operators Manual

PARTS TAB

Document Title Document Type

V Series Heated Holding Transportation Cabinets Parts Catalog

Page 3 of 17 F45748 (0219)

Page 4

V Series Heated Holding Insulated Cabinets - GENERAL

GENERAL

INTRODUCTION

This manual is applicable only to models listed on the

cover page. Procedures in this manual will apply to all

models unless specified. Pictures and illustrations can

be of any model unless they need to be model specific.

INSTALLATION, OPERATION AND

CLEANING

For detailed installation, operation and cleaning

instructions, refer to the Installation & Operation

Manual sent with each unit. The manual is also

available online at www.vulcanequipment.com.

TOOLS

Standard

• Standard set of hand tools.

• VOM with minimum of NFPA-70E CATIII 600V,

UL/CSA/TUV listed. Sensitivity of at least 20,000

ohms per volt and the ability to measure DC

micro amps. Meter leads must also be rated at

CAT III 600V.

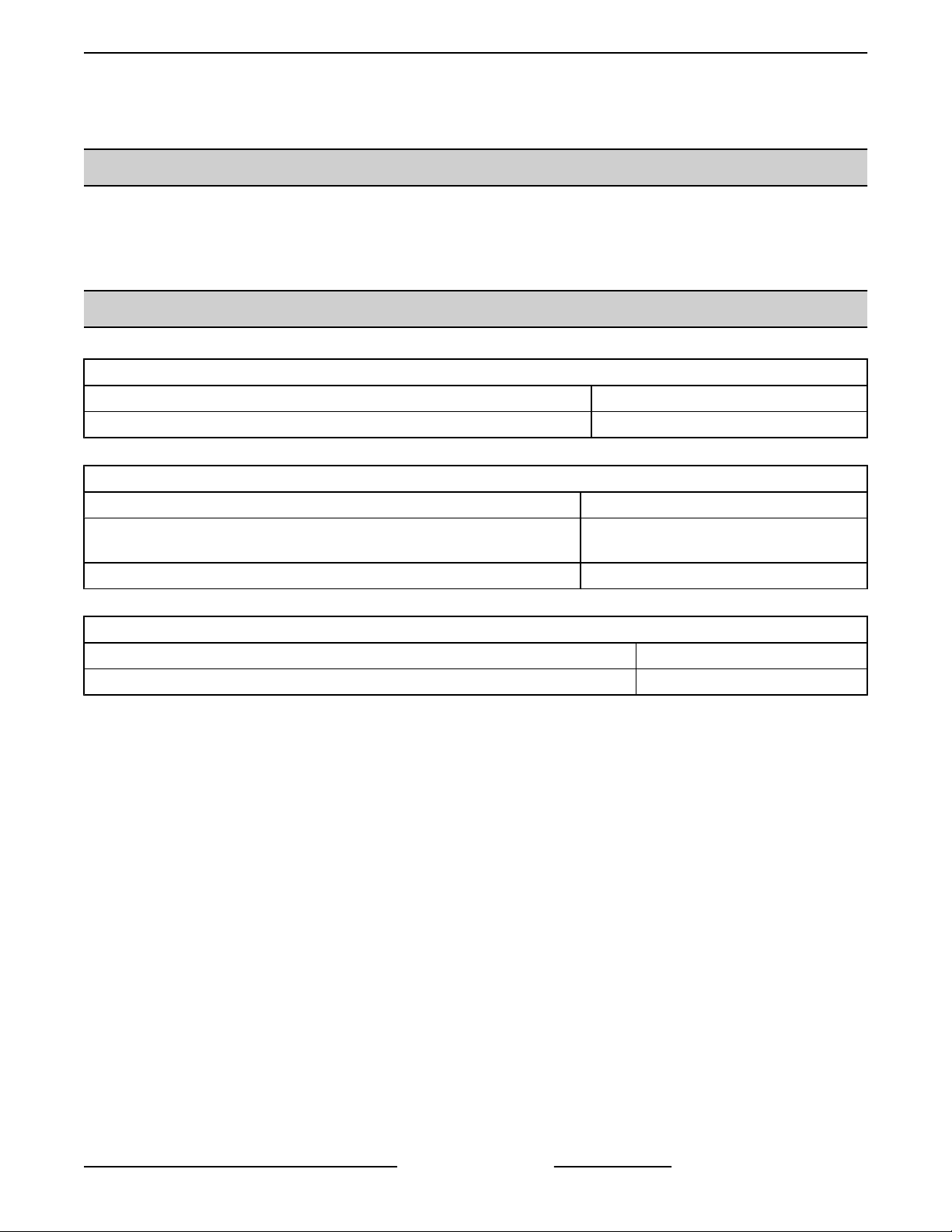

DATA PLATE LOCATIONS

DATA PLATE LOCATED ON BACK PANEL

• Clamp on type amp meter with minimum of

NFPA-70E CAT III 600V,UL/CSA/TUV listed.

• Temperature tester (thermocouple type).

• ESD (Electrostatic discharge) Protection Kit.

Special

• Handheld, digital temperature and humidity

sensor Grainger No. 3LYH7 or equivalent.

SPECIFICATIONS

MODELS VOLTS WATTS AMPS

VBP and

VPT

120V 1,500 12.5

240V 1,500 6.25

INSIDE DATA PLATE

F45748 (0219) Page 4 of 17

Page 5

V Series Heated Holding Insulated Cabinets - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

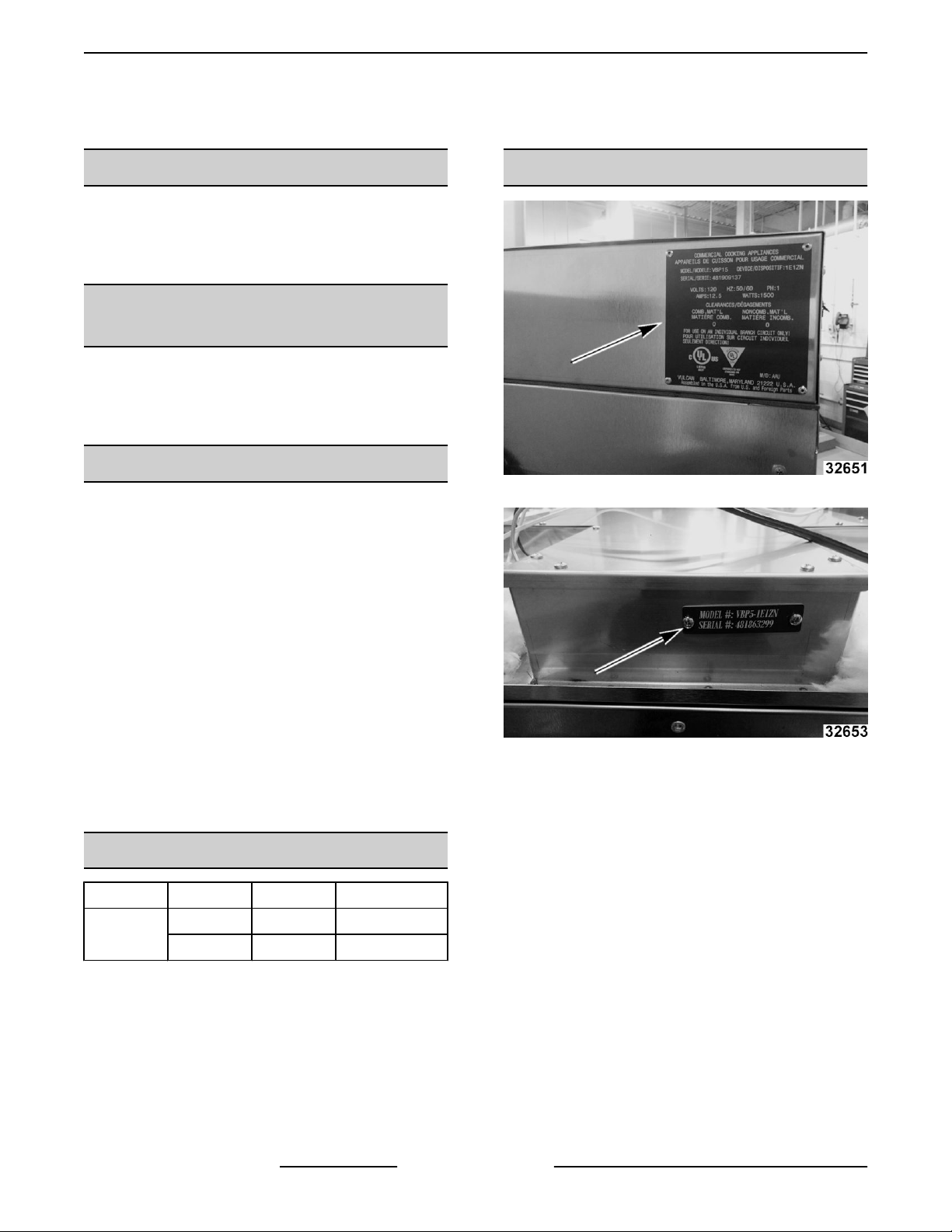

TOP COVER

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

NOTE: Remove top cover to access power cord,

cooling fan, and control board.

1. Remove screws from top and side of top cover.

2. Remove insulation (1, Fig. 5).

Fig. 5

3. Note and disconnect wiring from terminal block

and control board.

4. Remove inside access cover (1, Fig. 6).

Fig. 3

Fig. 4

2. Lift cover off cabinet.

3. Reverse procedure to install.

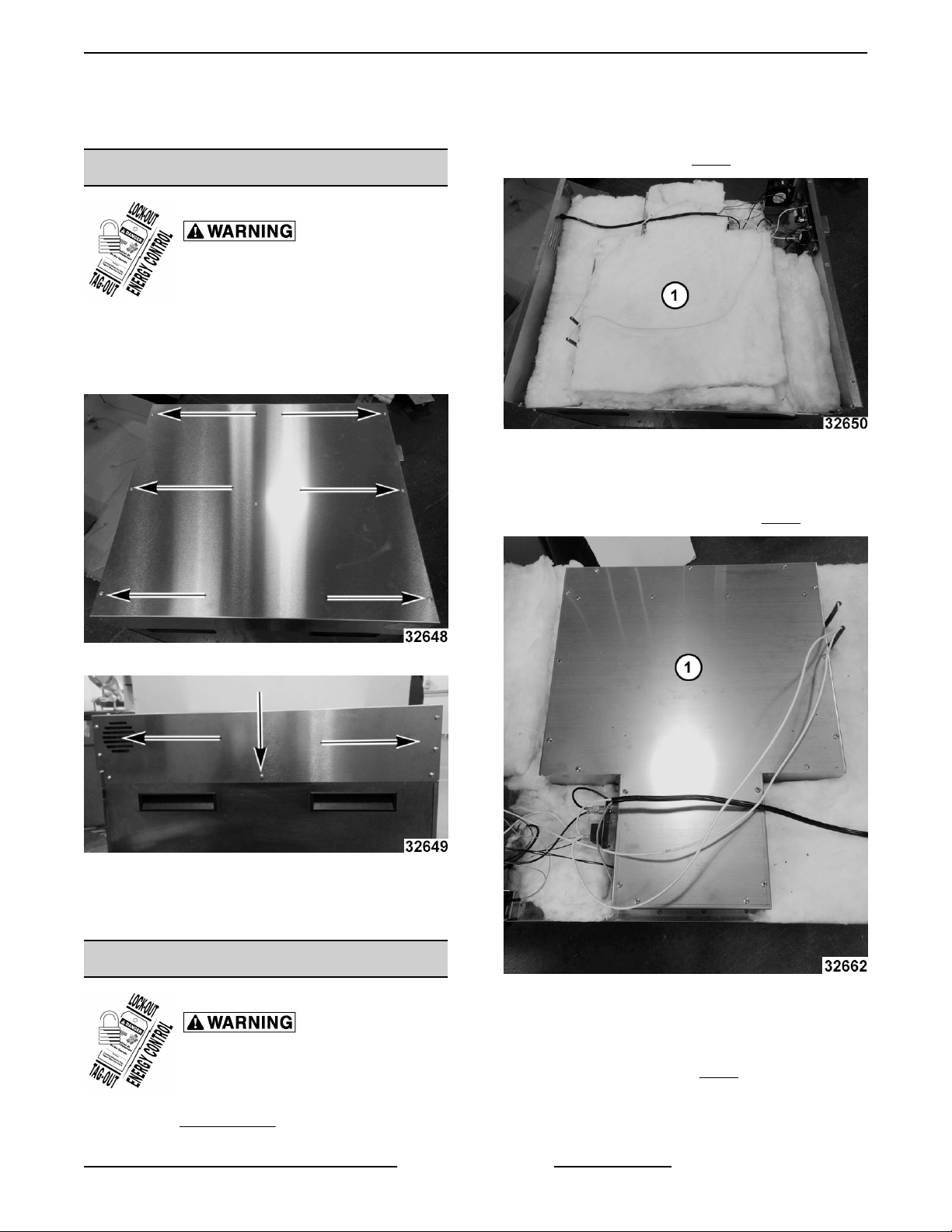

FOOD COMPARTMENT FAN

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

Fig. 6

5. Remove fan mounting bracket.

6. Remove screws from fan.

7. Install fan with label (1, Fig. 7) up.

1. Remove TOP COVER .

Page 5 of 17 F45748 (0219)

Page 6

V Series Heated Holding Insulated Cabinets - REMOVAL AND REPLACEMENT OF PARTS

Fig. 7

8. Reverse procedure to install.

Verify air flow direction in cavity.

When installing inside access cover, verify edge

inserts into slot without catching.

Fig. 9

HEATING ELEMENTS

Fig. 8

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

1. Remove TOP COVER .

2. Remove insulation (1, Fig. 10).

Fig. 10

3. Note and disconnect wires from terminal block

and control board.

4. Remove inside access cover (1, Fig. 11).

F45748 (0219) Page 6 of 17

Page 7

V Series Heated Holding Insulated Cabinets - REMOVAL AND REPLACEMENT OF PARTS

When installing inside access cover, verify edge

inserts into slot without catching.

Fig. 13

POWER CORD

Fig. 11

5. Remove heating element mounting screws.

Fig. 12

6. Reverse procedure to install.

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

1. Remove TOP COVER .

2. Note and disconnect wiring from terminal block

and high limit.

3. Squeeze cord grip to remove from panel.

Fig. 14

4. Reverse procedure to install.

Page 7 of 17 F45748 (0219)

Page 8

V Series Heated Holding Insulated Cabinets - REMOVAL AND REPLACEMENT OF PARTS

HIGH LIMIT SWITCH

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

1. Remove TOP COVER .

2. Note and disconnect wiring.

3. Remove mounting screws for high limit switch (1,

Fig. 15).

Fig. 16

4. Reverse procedure to install.

TEMPERATURE PROBE

Fig. 15

4. Reverse procedure to install.

TERMINAL BLOCK

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

1. Remove TOP COVER .

2. Note and disconnect wiring.

3. Remove terminal block (1, Fig. 16) mounting

screws.

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

1. Remove TOP COVER .

2. Disconnect temperature probe at control board

connection.

3. Open door.

4. Pull temperature probe out from holder on cavity

ceiling.

5. Pull probe (1, Fig. 18) up through grommet in top

F45748 (0219) Page 8 of 17

Fig. 17

of cabinet.

Page 9

V Series Heated Holding Insulated Cabinets - REMOVAL AND REPLACEMENT OF PARTS

Fig. 18

6. Reverse procedure to install.

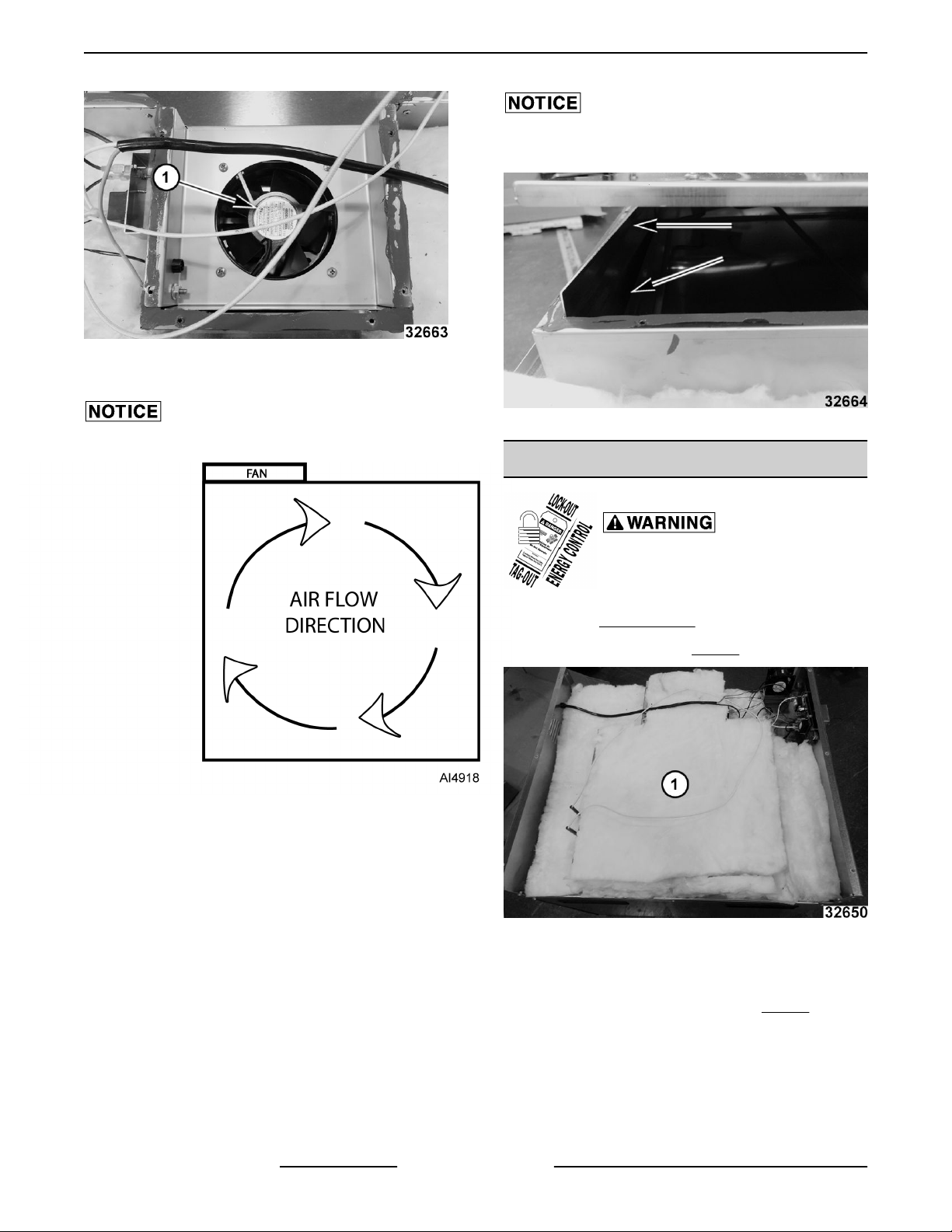

COMPONENT COOLING FAN

Note air flow direction on fan when replacing fan. (1,

Rotation

Fig. 20) (2, Air Flow Fig. 20)

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

1. Remove TOP COVER .

2. Note and disconnect fan wiring to terminal block

and control board.

3. Remove fan mounting screws.

Fig. 19

Fig. 20

4. Reverse procedure to install.

CONTROL BOARD

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

Certain components in this system are subject to

damage by electrostatic discharge (ESD) during field

repairs. An ESD kit is required to prevent damage. The

ESD kit must be used anytime the circuit board is

handled.

1. Remove TOP COVER .

2. Note and disconnect board connectors and

wires.

Page 9 of 17 F45748 (0219)

Page 10

V Series Heated Holding Insulated Cabinets - REMOVAL AND REPLACEMENT OF PARTS

Fig. 21

3. Remove "optional" knob cover if applicable

(VBP5 and VBP7).

Fig. 22

4. Remove retaining screw in knob.

Fig. 24

5. Remove potentiometer retaining nut.

Fig. 25

6. Remove control board mounting nuts.

Fig. 23

F45748 (0219) Page 10 of 17

7. Remove board.

8. Reverse procedure to install.

Fig. 26

Page 11

V Series Heated Holding Insulated Cabinets - REMOVAL AND REPLACEMENT OF PARTS

DOOR GASKET

NOTE: Measure gasket before ordering replacement.

Gasket is a separate component from retainer and

should be ordered separately from retainer.

1. Open door.

2. Unscrew gasket retainers.

Fig. 29

5. Install retainer with flat side against cavity wall

and channel toward inside of cabinet.

DOOR ASSEMBLY

1. Remove door hinge covers (1, Fig. 30) from lower

and upper door hinge.

Fig. 27

3. Remove gasket (1, Fig. 28) from retainer (2, Fig.

28).

Fig. 28

4. Press gasket on retainer while aligning channel.

Page 11 of 17 F45748 (0219)

Fig. 30

Remain in control of door when removing hinges.

2. Remove door hinge inside mounting screws

from lower door hinge first.

Page 12

V Series Heated Holding Insulated Cabinets - REMOVAL AND REPLACEMENT OF PARTS

Fig. 31

3. Remove door hinge inside mounting screws from

upper door hinge while supporting door weight.

4. Lift door assembly from cabinet.

5. Reverse procedure to install.

6. Check for proper operation.

DOOR LATCH (MAGNETIC)

NOTE: Note orientation of door handle before

removal.

Fig. 32

F45748 (0219) Page 12 of 17

Page 13

V Series Heated Holding Insulated Cabinets - REMOVAL AND REPLACEMENT OF PARTS

Install handle in the same orientation it was removed.

4. Check for proper operation.

Fig. 33

1. Open door.

2. Remove screws securing door latch to door

assembly.

Fig. 34

3. Reverse procedure to install.

Page 13 of 17 F45748 (0219)

Page 14

V Series Heated Holding Insulated Cabinets - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

TEMPERATURE VERIFICATION

The warmer and its parts are hot. Use care when

operating, cleaning or servicing the oven.

NOTE: Units prior to 1/1/15 can be calibrated, counter

clockwise to increase and clockwise to decrease.

Screw is located inside stem on the mechanical

thermostat. quarter turn is five degrees. Units after

1/1/15 can not be calibrated.

1. Check room temperature.

2. Place temperature probe at the center of the

cabinet.

3. Set unit temperature to 145°F.

4. Wait 45 minutes.

5. The temperature setting should be between 138

- 152F°.

VERIFY

• When using cabinet, frequently opening the

door will affect average internal

temperature. Modify set temperature as

necessary to ensure product is held above

appropriate food safe temperature.

Heating Elements

Model Wattage Voltage Resistance

all VBP

NOTE: If numbers do not match, replace HEATER

ELEMENTS.

1500 240 38.4 +/- 10 %

HEATER ELEMENT TEST

Certain procedures in this section

require electrical test or

measurements while power is

applied to the machine. Exercise

extreme caution at all times and

follow Arc Flash procedures. If test

points are not easily accessible,

disconnect power and follow

Lockout/Tagout procedures, attach

test equipment and reapply power to

test.

1. Access the heater element being tested. Refer

to: HEATER ELEMENTS.

2. Check resistance.

Heating Elements

Model Wattage Voltage Resistance

all VPT 1500 120 9.6 +/- 10 %

F45748 (0219) Page 14 of 17

Page 15

V Series Heated Holding Insulated Cabinets - ELECTRICAL OPERATION

ELECTRICAL OPERATION

COMPONENT DESCRIPTIONS

ITEM DESCRIPTION

Food Compartment Fan Circulates air inside the cabinet. Moisture resistant with metal fan blades.

Controller Board Controls the temperature, humidity and fan inside the cabinet.

Heating Element - Dry Heats the air to keep prepared food at the proper serving temperatures.

Component Cooling Fan Circulates air in the electrical component area.

High Limit High Limit opens at 375°F.

Page 15 of 17 F45748 (0219)

Page 16

V Series Heated Holding Insulated Cabinets - ELECTRICAL OPERATION

WIRING DIAGRAM

Fig. 35

SEQUENCE OF OPERATION

1. Conditions.

A.

Unit connected to correct voltage and is

properly grounded.

B. Power switch is off.

2. Power switch turned on.

A. Relays K1 and K2 are de-energized

(contacts N.O.).

B. Controller board performs diagnostic test

and verifies temperature input signal is

present.

F45748 (0219) Page 16 of 17

3. Fan relay K2 is energized, K2 contacts close and

4. Based on temperature and humidity settings, the

5. Adjust temperature to desired level.

6. Turning power switch off stops heating cycle.

power the fans.

board determines whether K1 relay will be

energized to power element.

Page 17

V Series Heated Holding Insulated Cabinets - ELECTRICAL OPERATION

TROUBLESHOOTING

Symptom Possible Cause

Cabinet not operating.

Ground Fault Circuit Indicator (GFCI)

tripped.

Cabinet connected to power, switch is

ON, circuit breaker is ON but cabinet not

heating.

1. Cabinet not connected to power source or circuit breaker tripped.

2. Cabinet lighted power switch not ON or malfunctioning.

1. Shorted heating element.

2. Pinched/damaged wiring (heating elements or fan).

3. Damaged power cord.

1. Heating element malfunction.

2. Temperature probe malfunction.

1. Element wires disconnected from element. Replace wire assembly

and element.

Cabinet not heating properly.

Fan not operating.

Moisture present at the top of the cabinet

near the control board.

Corrosion present inside cabinet.

2. FOOD COMPARTMENT FAN not circulating air or malfunction.

3. Door not sealing properly.

4. Temperature probe malfunction.

1. Power not being supplied to fan (malfunction).

2. Fan wiring not connected or malfunction.

3. Fan not circulating air or malfunction.

1. COMPONENT COOLING FAN malfunction.

1. Periodic cleaning needed. Refer to Operations manual.

2. Hardware has rusted. Replace rusted hardware with 18-8 stainless

steel components and replace FOOD COMPARTMENT FAN.

Page 17 of 17 F45748 (0219)

Loading...

Loading...