Page 1

INSTALLATION &

OPERATION MANUAL

HEAVY DUTY ELECTRIC BROILER SERIES

MODELS

VB 21 ML-052312

VB 21C ML-052312

VB 25 ML-052313

VB 73 ML-052249

VB 221 ML-052315

VB 221C ML-052315

VB 225 ML-052316

VTMB 221 ML-052314

VTMB 221C ML-052314

VTMB22

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201-0696, TEL. (502) 778-2791

FORM 31065 (5-98)

Page 2

TABLE OF CONTENTS

GENERAL ......................................................................................................................................... 3

INSTALLATION .................................................................................................................................. 4

Unpacking ..................................................................................................................................... 4

Installation Codes and Standards ................................................................................................. 4

Location ......................................................................................................................................... 4

Electrical Connections ................................................................................................................... 4-5

Electrical Data Chart ..................................................................................................................... 5

Electrical Tests ............................................................................................................................... 6

Leveling ......................................................................................................................................... 6

OPERATION ....................................................................................................................................... 7

Controls ......................................................................................................................................... 7

Before First Use ............................................................................................................................ 8

Using the Broiler ............................................................................................................................ 8

Using the Oven .............................................................................................................................. 8-9

Time, Temperature & Switch Chart for Baking............................................................................... 10

Cleaning ........................................................................................................................................ 11

MAINTENANCE ................................................................................................................................. 12

Service and Parts Information ....................................................................................................... 12

– 2 –

Page 3

Installation, Operation and Care of

MODELS VTMB22, VTMB2, VB2S & VB21

HEAVY DUTY ELECTRIC BROILERS

KEEP THESE INSTRUCTIONS FOR FUTURE USE

GENERAL

Your Vulcan-Hart Heavy Duty Electric Broiler is produced with quality workmanship and material.

Proper installation, usage and maintenance of your broiler will result in many years of satisfactory

performance.

Vulcan-Hart Company suggests that you thoroughly read this entire manual and carefully follow all of

the instructions provided.

Model VB Ovens are provided with one rack as standard equipment.

MODEL DESCRIPTION

VB 21 Single section broiler with standard oven below

VB 25 Single section broiler with storage space below

VB 225 Double section broilers with storage space below

VTMB 2 Modular single section broiler

VTMB 22 Modular double section broiler

VB 73 Backshelf broiler for mounting over a 3-ft. (91 cm) range

VB 21C Single section broiler with convection oven below

VB 221 Double section broiler with standard oven below

VB 221C Double section broilers with convection oven below

– 3 –

Page 4

INSTALLATION

UNPACKING

Immediately after unpacking, check for possible shipping damage. If the broiler is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery.

Remove all shipping wire, wood blocking, and accessories.

Before installing, verify that the electrical service agrees with the specifications on the rating plate

located as follows: VTMB units - on the control panel front; VB21 - behind the oven door on the breaker

box cover; and VB2S - behind the door panel of the storage cabinet base. If the supply and equipment

requirements do not agree, contact your dealer or Vulcan-Hart immediately.

INSTALLATION CODES AND STANDARDS

Your Vulcan broiler must be installed in accordance with:

1. State and local codes, or in the absence of local codes, with:

2. National Electrical Code ANSI/NFPA-70 (latest edition).

LOCATION

Position the broiler in its installation position. The area around the broiler should be kept free and clear

of all combustible materials.

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT THE ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH TO INDICATE THAT YOU ARE WORKING ON THE CIRCUIT.

Bring conduit containing the proper supply wire (size and type in accordance with latest edition of the

National Electrical Code ANSI/NFPA-70) to the broiler. Use wire suitable for 167°F ( 75°C) on broilers

carrying more than 80 amps. On Models VB2S, VB22S, VB21 and VB221, the conduit enters into the

broiler through the 2" (51mm) hole located in the bottom of the broiler. On Models VTMB2 and

VTMB22, the conduit enters through the clearance hole provided in the back and is terminated on the

vertical panel behind the terminal block.

Connect the supply leads to the terminal block and the green grounding lead to the labeled ground lug.

Broilers designed for 220/380 or 240/415 volts require voltage supplies with grounded neutral

(3 phase, 4 wire; or 1-phase, 3-wire).

– 4 –

Page 5

Broilers wired for 3-phase service may be changed to 1-phase (or vice versa) by simply relocating two

of the four broiler leads on the terminal block as shown in the wiring diagram. (1-phase not available

on 480 volt models.)

All required broiler wiring diagrams are packaged separately in a clear plastic ziplock bag and shipped

with the broiler.

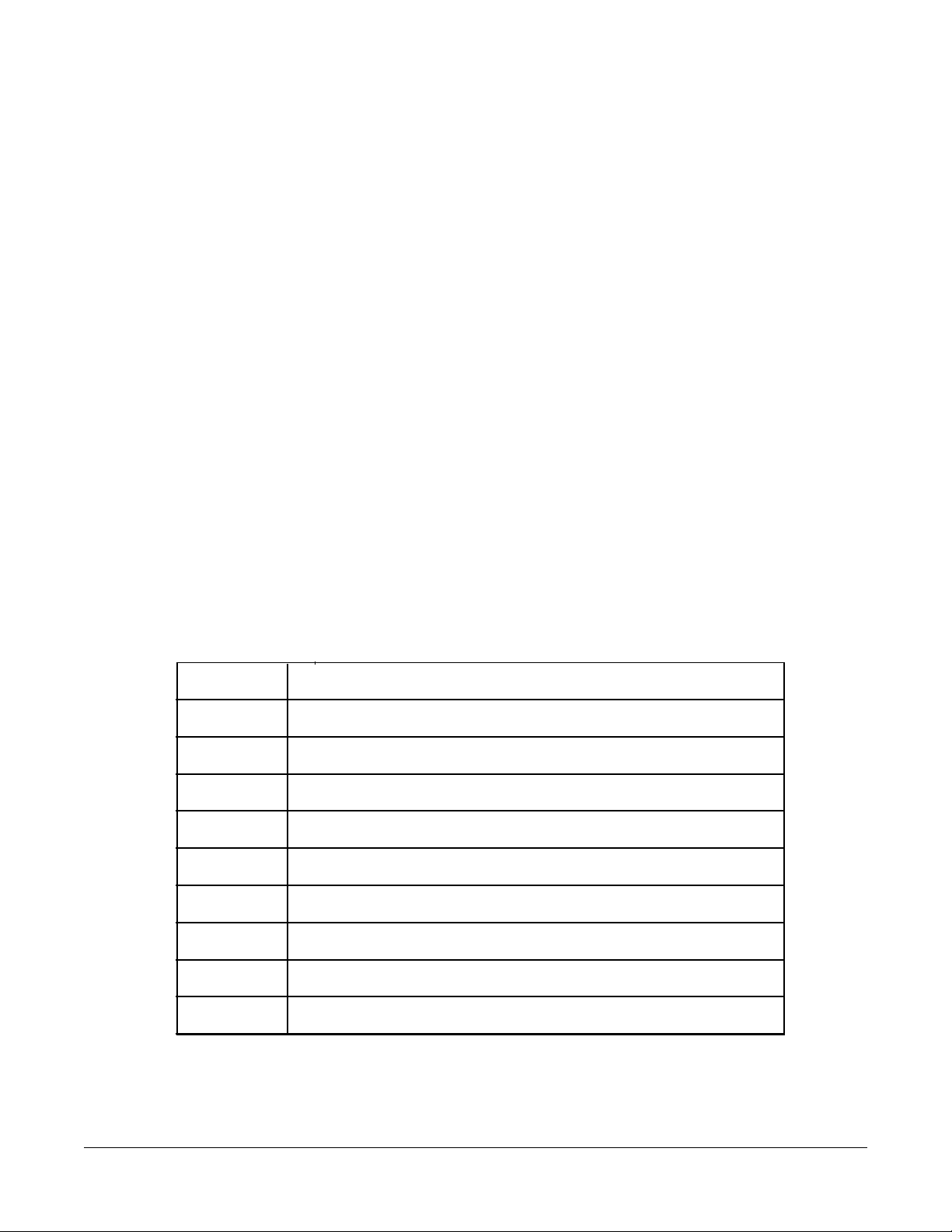

ELECTRICAL DATA CHART

STANDARD VOLTAGES - 208 VOLTS OR 240 VOLTS 60 Hz 1 PHASE - 480 VOLTS 60 Hz 3 PHASE ONLY

VOLTS KW KW PER PHASE 208V 240V 208V 240V 480V

TOTAL LOADING 1-PHASE 3-PHASE

MODEL DESCRIPTION 60 Hz CON. X-Y Y-Z X-Z X Y Z X Y Z X Y Z

VB2S Broiler w/Storage Base 208-240-480 12.0 3 6 3 58 50 25 37 37 22 32 32 16 11 16

VB21 Broiler w/Oven 208-240-480 18.7 6 6 6.7 90 78 53 50 53 45 43 45 23 21.5 23

VB22S Dbl.Broiler w/Storage 208-240-480 24.0 9 9 6 115 100 62 74 62 54 65 54 32 27 27

VB221 Dbl.Broiler w/Oven 208-240-480 30.7 12 10 8.7 148 128 86 91 78 74 79 67 40 37 34

STANDARD VOLTAGES - 208 VOLTS OR 240 VOLTS 60 Hz 1 PHASE OR 3 PHASE - 480 VOLTS 60 Hz 3 PHASE ONLY

TOTAL LOADING 1-PHASE 3-PHASE

VOLTS KW KW PER PHASE 208V 240V 208V 240V 480V

MODEL DESCRIPTION 60 Hz CON. X-Y Y-Z X-Z X Y Z X Y Z X Y Z

VTMB2 Single Broiler 480 12.0 3 3 6 — — ——————161116

VTMB2 Single Broiler 208-240 12.0 3 6 3 58 50 25 37 37 22 32 32 — — —

VTMB22 Double Broiler 480 24.0 9 6 9 — — ——————322727

VTMB22 Double Broiler 208-240 24.0 9 9 6 115 100 62 74 62 54 65 54 — — —

3-PHASE NOMINAL AMPS PER LINE

3-PHASE NOMINAL AMPS PER LINE

BROILERS WITH CONVECTION OVENS

”N/A” BROILERS NOT AVAILABLE IN 480V 1 PHASE

3-PHASE LOAD 3-PHASE LOAD NOMINAL AMPS PER LINE WIRE

KW PER PHASE KW PER PHASE 3 PHASE 1 PHASE

TOTAL

KW

MODEL CONN. X-Y Y-Z X-Z X-Y Y-Z X-Z X Y Z X Y Z X Y Z XYZ XYZ XYZ

VB21C 19.0 4.2 7.2 7.6 7.2 7.2 4.6 65 53 54 43 41 53 21 26 21 91 79 40

VB221C 31.0 10.2 10.2 10.6 7.2 13.2 10.6 87 85 87 75 74 75 32 337 43 149 129 N/A

208 & 240V 480V 208V 240V 480V 208V 240V 480V

– 5 –

Page 6

ELECTRICAL TESTS

Turn each switch from LOW through HIGH and verify that it controls the heating elements correctly.

Free Standing Models - 208V & 240V

Left switch controls front element, LOW-HIGH

Right switch controls rear element, LOW-HIGH

Free Standing Models - 480V

Left switch controls two front elements

Right switch controls two rear elements:

LOW = 2 elements on LOW

MED = 1 element on HIGH and 1 element OFF

HIGH = 2 elements on HIGH

Model VB73 - 208V & 240V

Top switch controls left element, LOW-HIGH

Bottom switch controls right element, LOW-HIGH

Model VB73 - 480V

One switch controls 2 elements:

LOW = left and right elements on LOW

MED = left element OFF, right element on HIGH

HIGH = left and right elements on HIGH

LEVELING

Using a carpenter's level placed on top of the broiler, adjust the feet of the broiler so that the broiler

is level front-to-back and side-to-side.

– 6 –

Page 7

OPERATION

WARNING: THE BROILER AND ITS PARTS ARE HOT. BE CAREFUL WHEN OPERATING,

CLEANING OR SERVICING THE BROILER.

CONTROLS

Broiler

Infinite Load Switches — Two switches independently control the front and rear heating elements

in 208 and 240 volt models. The switch located on the left-hand side

of the switch panel controls the percent on-time of the two front

elements, and the switch located on the right-hand side of the switch

panel controls the two rear elements. The percent on-time of the

infinite load control varies from approximately 10% in the VERY LOW

position to 100% in the HIGH position.

3-Heat, 4-Position Switch —

Grid Handle — The distance of the grid surface from the elements is controlled by the

The operator can, by independent setting of each switch, provide a wide range of broiler temperatures

depending on the type and location of the broiling product.

Oven

3-Heat Switches — Two switches (located on the right side of the switch panel, on each

On 480 volt models, each of the two non-cycling 3-heat, 4-position

switches control independently the front and rear sections of the

broiler.

elements

on) to LO

pull-and-release grid handle at the right of the broiler. This grid handle

locks in 13 positions over the 6" (152 mm) grid travel.

side of the thermostat) independently control the top and bottom

heating elements. At HIGH position, the maximum element power

is utilized (elements connected in parallel); at MED position, only one

of the two elements is on (about 1/2 power); at LO position, the two

elements are connected in series (about 1/4 power); at the

position, both elements are completely turned off.

Input varies from full power at the HIGH position (both

connected in parallel) to MED position (one element only

position (both elements connected in series).

OFF

Thermostat — Controls the temperature of the oven from 175°F to 550°F (79°C to

288°C).

Indicator Light — (Mounted next to the thermostat.) When lit, the thermostat is calling

for heat, and when off, indicates the desired temperature is

reached.

– 7 –

Page 8

When the thermostat is turned on, it provides power to the two 3-heat switches, which in turn, according

to their setting, independently turn the top and bottom heating elements on and off. Thus, while the

thermostat controls and maintains the oven temperature around the desired set temperature, the

3-heat switches control the rate of temperature build-up.

BEFORE FIRST USE

Before using for the first time, clean the broiler or oven with detergent and water. Rinse thoroughly and

wipe dry with a soft clean cloth.

Seasoning (Oven Models Only)

Lightly, but thoroughly, coat the oven steel deck with cooking oil and allow it to season in the oven at

450°F (232°C) for 30 minutes to 1 hour. This seasoning will lessen sticking of spillage and inhibit rust.

USING THE BROILER

Preheating

At full input, the elements will heat to broiling radiance in approximately 5 minutes. The broiler will

saturate for full loading in 10 to 15 minutes at full input.

Grid

The grid is the V bar type, which permits easy scraping with a steak turner during operation. Drippings

from the broiling food go through the grid onto the drip shield and into the grease collector.

Grease Collector

The grease collector collects grease and waste which is diverted by the tilt of the drip shield. DO NOT

allow the grease collector to overflow. The grease collector should be emptied when three-quarters

full to reduce the possibility of spillage.

USING THE OVEN

Preheating

Set top and bottom 3-heat switches to HIGH. Set thermostat to desired baking temperature. The

indicator light will light and remain lit until the oven reaches temperature. The oven may be loaded

when the indicator light goes off the first time; however, it is desirable to allow the indicator light to go

on and off at least twice so the oven is thoroughly heated and will brown baked products evenly. After

the first cycle (oven indicator light on and off), set the 3-heat switches as desired for baking. (Refer

to TIME, TEMPERATURE & SWITCH SETTING CHART FOR BAKING.)

– 8 –

Page 9

While it is recommended that you set the 3-heat switches to the HIGH position in order to preheat the

oven to the desired temperature, it is necessary for some baking products to turn the 3-heat switch

controlling the top elements to the MED or LO position in order to reduce the amount of radiant heat

applied to the particular product. This will eliminate burning of the top portion of the product.

Loading

Load the oven as rapidly as possible to prevent excessive heat loss. Place pans directly on the deck

and in rows back to front, beginning on the right, then the next row, etc., until oven deck is full. Do not

place pans closer to the door than 3" (76 mm). Do not let the pans touch the sides or back of the oven

or each other.

Baking

Approximate cooking times are given in recipe directions or are shown on the TIME, TEMPERATURE

& SWITCH SETTING CHART FOR BAKING shown below. When baking on the rack, it may be

necessary to set the bottom switch at HIGH.

Meat Roasting

Meat roasting is best performed in a balanced oven. Switch positions of HIGH and HIGH are

suggested, with the temperature control setting at the low temperature recommended by the American

Meat Institute and the Department of Agriculture. Top heat results in a well colored or carmelized finish

to meats. When roasting fowl and a heavily browned appearance is not desired, the top oven switch

should be set at MED or LO. The use of a meat thermometer is strongly recommended for all meat

roasting operations.

– 9 –

Page 10

TIME, TEMPERATURE & SWITCH SETTING CHART FOR BAKING

This baking chart is a guide only. Recipes, mixing procedures, utensils and individual standards of

doneness, browning, etc., can result in variations in the precise time, temperature and switch settings

necessary to produce a satisfactory product.

High product quality can be obtained and maintained only if all phases of the baking operation are

properly performed. Variation in ingredients, under or overmixing, holding time before baking, etc., can

affect the texture, consistency and the basic quality of the product.

TEMPERATURE TIME SWITCH SETTINGS

PRODUCT (F°) (C°) (MIN.) TOP BOTTOM

Bread 375 – 425 191 – 218 35 – 50 MED MED

Rolls 375 – 425 191 – 218 20 – 30 MED MED

Cake, Layer 350 – 375 177 – 191 20 – 30 MED MED

Cup Cakes 375 – 400 190 – 204 15 – 20 MED MED

Cake, Loaf 350 – 375 177 – 191 20 – 30 MED MED

Angel Cake 300 – 335 149 – 168 35 – 50 MED MED

Corn Bread 400 – 425 204 – 218 25 – 30 HI MED

Fruit Pies 400 – 425 204 – 218 40 – 60 MED MED

Meringue Pies 425 – 450 218 – 232 5 – 8 HI OFF

Browning Biscuits 400 – 425 204 – 218 12 – 18 MED MED

– 10 –

Page 11

CLEANING

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY BEFORE CLEANING.

Do not use Dawn dish detergent to clean the interior or exterior of the unit.

Stainless steel oven fronts may be cleaned with a damp cloth. Stubborn soil may be removed with a

detergent and water. Rinse thoroughly and wipe dry with a soft clean cloth.

Porcelain oven linings and door linings may be cleaned with a cloth dampened with detergent or oven

cleaners.

Empty the grease collector and clean in a sink.

Silvertone surfaces may be cleaned with a cloth dampened with a detergent solution. An occasional

application of silicone base auto polish will help to maintain a "like new" appearance.

Steel decks may be removed and scoured at the sink. After scouring, the steel decks should be

reseasoned (see BEFORE FIRST USE in this manual).

– 11 –

Page 12

MAINTENANCE

WARNING: THE BROILER AND ITS PARTS ARE HOT. BE CAREFUL WHEN OPERATING,

CLEANING OR SERVICING THE BROILER.

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning these broilers, contact the Vulcan-Hart Service

Depot in your area (refer to listing supplied with the broiler), or Vulcan-Hart Company Service

Department at the address or phone number shown on the front cover of this manual.

FORM 31065 (5-98) PRINTED IN U.S.A.

– 12 –

Loading...

Loading...