Page 1

INSTALLATION & OPERATION MANUAL

GAS CHARBROILERS

MODELS

VACB25

VACB36

VACB47

VACB60

VACB72

ACB25

ACB36

ACB47

ACB60

ACB72

VACB36

©ITW Food Equipment Group, LLC

3600 North Point Blvd.

Baltimore, MD 21222

ACB36

RETAIN THIS MANUAL FOR FUTURE USE

FORM F38328 (3-13)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO

INSTALL GAS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD

START-UP AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS

MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN

THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE

OBTAINED FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

adjustment, alteration, service or maintenance

can cause property damage, injury, or death.

Read the installation, operating and maintenance

instructions thoroughly before installing or

servicing this equipment.

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO OPERATE THIS DEVICE.

Improper installation,

-

2 -

Page 3

INSTALLATION, OPERATION AND CARE OF

GAS COUNTERTOP CHARBROILERS

GENERAL

Vulcan/Wolf Gas Countertop Charbroilers are designed for commercial use only and

feature fast, efficient gas heat. Each burner is controlled by an adjustable gas valve.

Cast radiants are located directly above each burner to maintain uniform temperature.

Radiants are easily removed for cleaning when cool.

Heavy-duty cast iron top grates are reversible to allow all or part of the cooking grid

surface to be level or sloped. A crumb tray is provided to collect fat run-off and debris;

it opens to the front for inspection or cleaning.

Model Number of Burners

VACB25 / ACB25 4

VACB36 / ACB36 6

VACB48 / ACB48 8

VACB60 / ACB60 11

VACB72 / ACB72 13

Natural Gas BTU/hr

Input Rating

68,000 64,000

102,000 96,000

136,000 128,000

187,000 176,000

221,000 208,000

LP Gas BTU/hr

Input Rating

INSTALLATION

UNPACKING

Immediately after unpacking, check for possible shipping damage. If the broiler is found

to be damaged, save the packaging material and contact the carrier within 15 days of

delivery.

Carefully unpack your charbroiler and make sure that no parts are discarded with

packaging material. A pressure regulator designed to operate with the broiler has been

supplied and must be installed before the charbroiler is placed into service (Refer to GAS

PRESSURE REGULATOR INSTALLATION in this manual).

Before installing, verify that the type of gas (natural or propane) and the clearance

dimensions agree with the specifications on the rating plate which is located on the lower

front corner on the right side.

-

3 -

Page 4

LOCATION

The installation location must be kept free and clear of combustibles. Do not obstruct the

flow of combustion and ventilation air. DO NOT install the charbroiler adjacent to open

burners or fryers.

Sufficient air should be allowed to enter the room to compensate for the amount of air

removed by any ventilating system and for combustion of the gas burners. Do not

obstruct the air flow into and around the appliance. Do not obstruct the flow of flue gases

through and above the broiler's top grate. Position the broiler in its final location. Check

that there are sufficient clearances to service the broiler and to make the required gas

supply connection(s). Provide 24" clearance at the front for cleaning, maintenance,

service and proper operation.

This broiler is for use in non-combustible locations only.

Minimum clearances to non-combustible walls are 3" to the rear and 3" to the sides.

INSTALLATION CODES AND STANDARDS

The Charbroiler must be installed in accordance with:

In the United States of America:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1/NFPA #54 (latest edition). This shall include but

not be limited to: NFPA #54 Section 10.3.5.2 for Venting. Copies may be obtained

from The American Gas Association Accredited Standards Committee Z223, @ 400

N. Capital St. NW, Washington, DC 20001 or the Secretary Standards Council, NFPA,

1 Batterymarch Park Quincy, MA 02169-7471

NOTE: In the Commonwealth of Massachusetts

All gas appliances vented through a ventilation hood or exhaust system equipped with

a damper or with a power means of exhaust shall comply with 248 CMR.

3. NFPA Standard # 96 Vapor Removal from Cooking Equipment, latest edition, available

from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada:

1. Local codes.

2. CAN/CSA-B149.1 Natural Gas Installation (latest edition)

3. CAN/CSA-B149.2 Propane Installation Code (latest edition), available from the

Canadian Gas Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3

-

4 -

Page 5

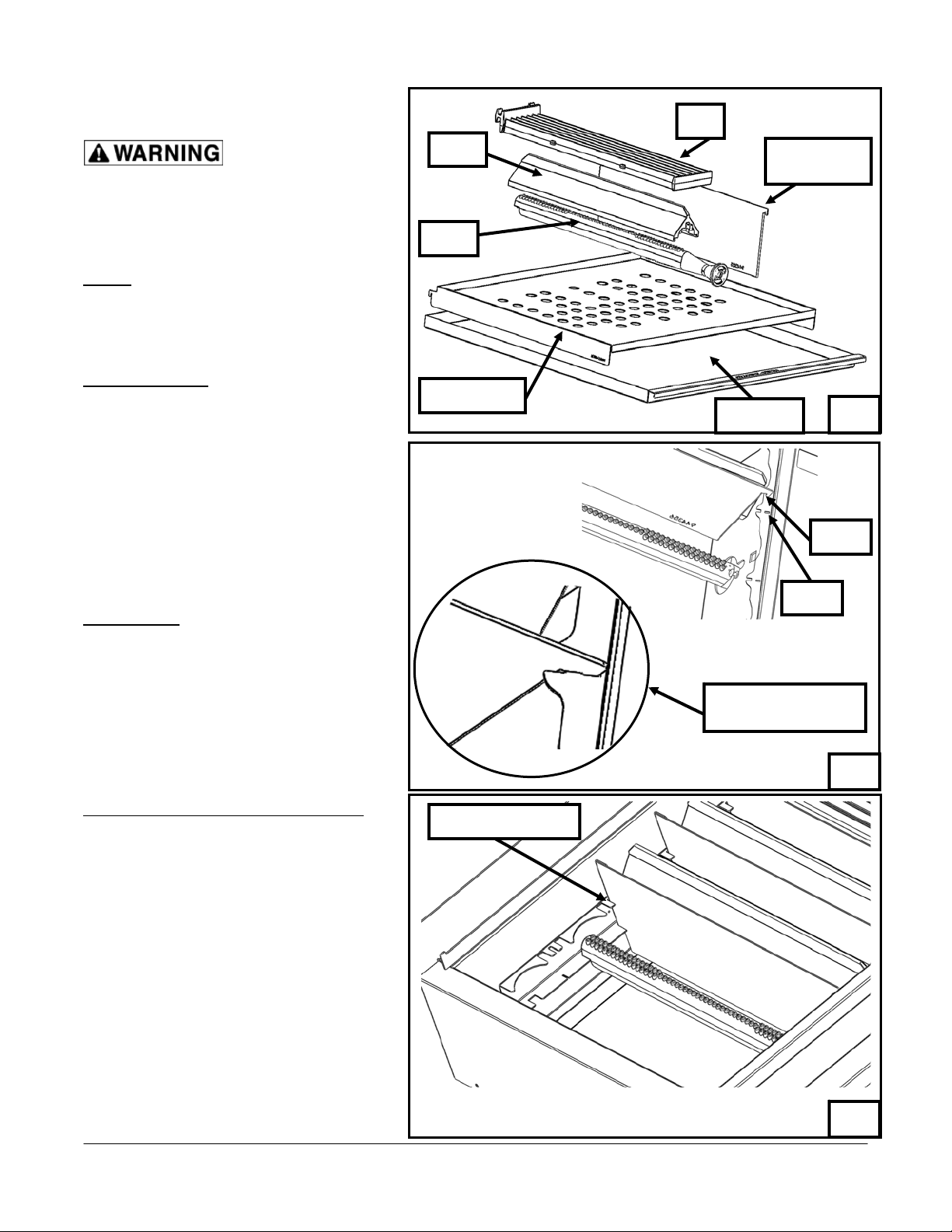

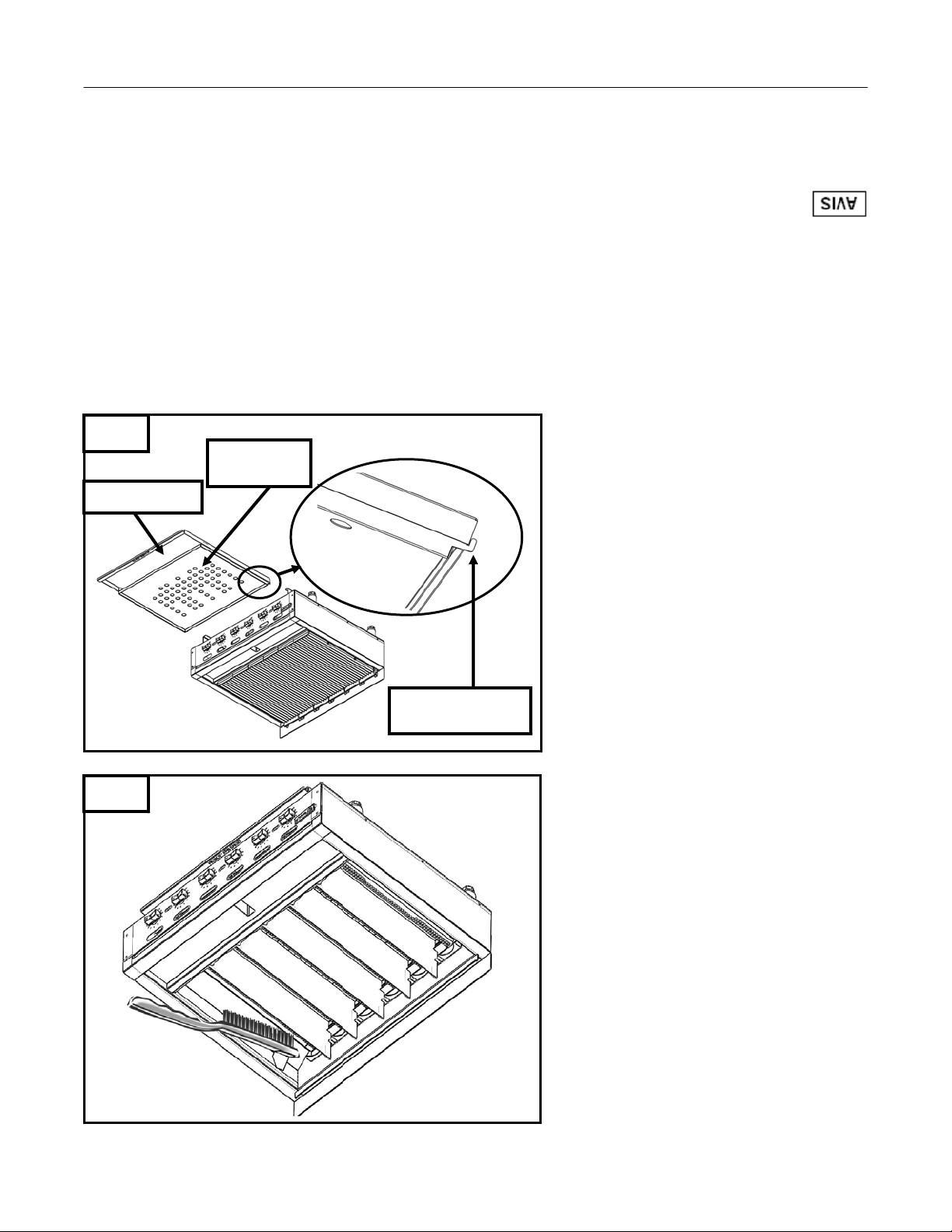

KEY COMPONENTS

r

r

The charbroiler

and its parts are hot. Use care

when operating, cleaning or

servicing the charbroiler.

Grate

flat or sloped for operational

– The grates can be utilized

flexibility.

Deflector Tray

is the removable pan with holes in

– The deflector tray

it. The deflector tray deflects heat

back toward the cooking surface

while allowing debris to pass

through the holes and into the

crumb tray below. The deflector

tray should always be in place

above the crumb tray when

operating.

Crumb tray

removable pan without holes in it.

– The crumb tray is the

The crumb tray catches any debris

that passes thru the deflector tray

and should always be installed

beneath the deflector tray. (Fig. 1).

Radiant

Burner

Deflector Tray

Grate

Super Charge

Burner Divide

Crumb Tray

Enlarged View of Hook

Engaged In Slot

Fig. 1

Hook

Slot

Supercharger Burner Divider

These act as dividers between

cooking zones to offer flexibility in

cooking and help direct heat

upwards to provide for a even

heating pattern. You may remove

some or all of the supercharger

burner dividers at your discretion if

you find your production method

works better without them. The

super charger burner dividers are

installed by inserting the hooks

thru corresponding slots at the

front (Fig. 2) and the back rests in

the super charger guide to the

rear. (Fig. 3).

Supercharger Guide

-

5 -

Fig. 2

Fig. 3

Page 6

Radiant – The charbroiler must

never be operated without the

radiants in place. They protect the

burner from food drippings and

heat up to provide an even heating

pattern. The radiants are installed

by inserting the tab thru the

corresponding slot in the heat

shield to the front (Fig. 4-A) and

the back of the radiants set on the

radiant rest to the rear (Fig. 5-A).

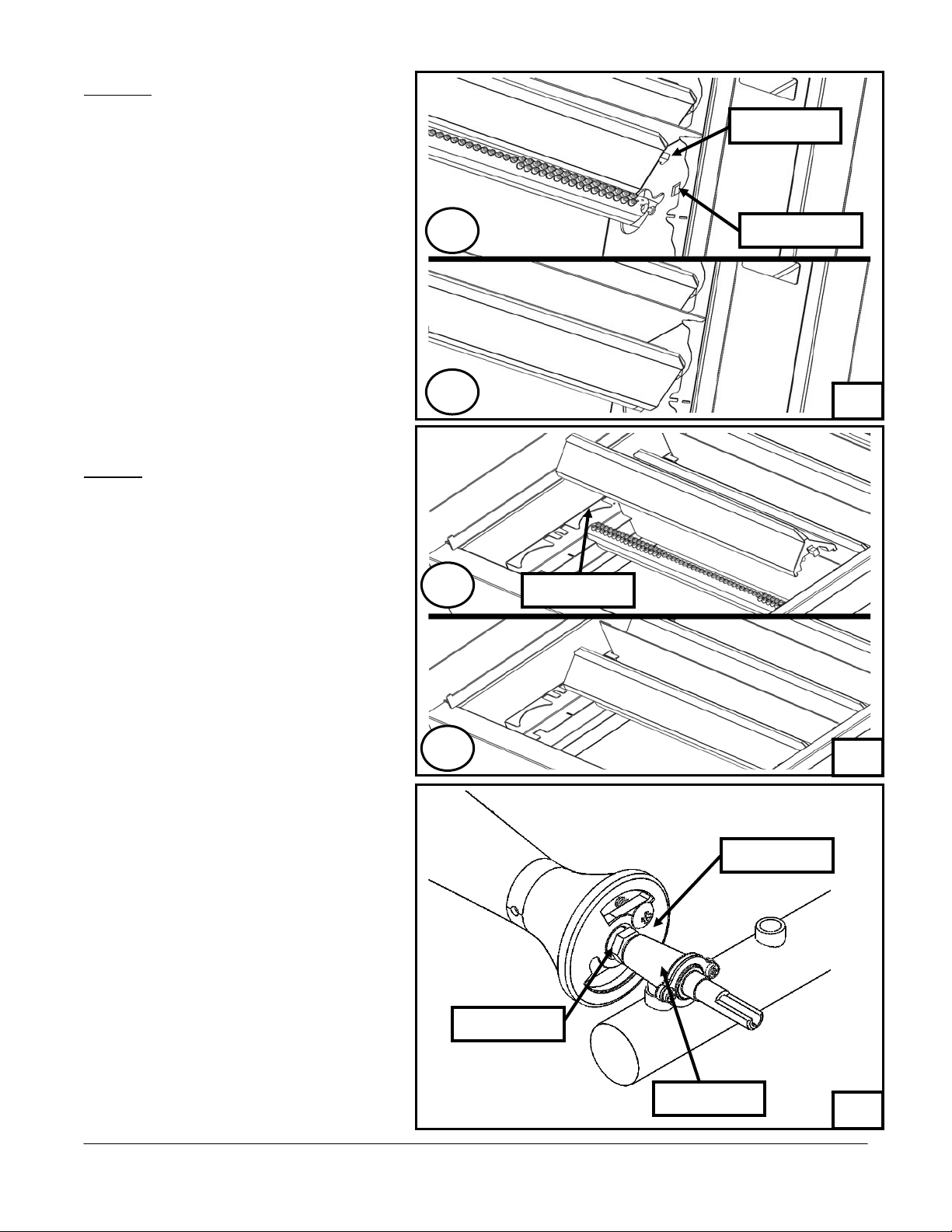

A

B

Radiant Tab

Heat Shield Slot

Fig. 4

Burner

– The burner shutter

should engage the orifice to the

front (Fig. 6) and rest in the

burner slot to the rear of the unit.

Proper burner shutter adjustment

is important for optimal charbroiler

performance. The burner shutters

should only be adjusted with all

radiants in place. The shutter will

typically be about 50% open for

natural gas and 80 to 100% open

for LP. A properly adjusted burner

should exhibit solid blue flames

that are touching the burner. All

traces of yellow should be

adjusted out of the burner flame

for natural gas and only a slight

yellow tipping should be observed

on LP gas. Large, yellow tipped

flames typically indicate not

enough air and the burner shutters

should be opened slightly.

Floating flames (not touching the

burner) typically indicate too much

air and the shutter should be

closed slightly.

A

B

-

6 -

Orifice

Radiant Rest

Burner Shutter

Burner Valve

Fig. 5

Fig. 6

Page 7

LEVELING

It is important that the charbroiler is level front to back and left to right. Areas of uneven

heat distribution will occur on an unlevel unit. The charbroiler is equipped with adjustable

legs. Turn the feet at the bottom of the legs to adjust to level. The unit should be

rechecked for level anytime it has been moved.

VENTILATION HOOD

The broiler must be installed under a suitable ventilation hood. For safe operation and

proper ventilation, keep the space between the charbroiler and vent hood free from any

obstructions.

GAS CONNECTION

The data plate on the lower right side of the charbroiler indicates the type of gas your unit

is equipped to burn. DO NOT connect to any other gas type.

All gas supply connections and any joint compound must be

resistant to the action of propane gases.

Purge the supply line to clean out any dust, dirt, or any foreign matter before connecting

the line to the unit.

Codes require that a gas shut-off valve be installed in the gas line ahead of the

charbroiler. The gas supply line must be at least the equivalent of ¾” iron pipe.

60” and 72” models have a gas inlet at each end of the unit. The unit will arrive from the

factory with a metal cap on one end and a plastic dust cover on the other. You may move

the metal cap to the other end and use which ever connection point is most convenient to

the available supply outlet. The plastic dust cover must be replaced with a metal pipe cap

if you do not use that location as the gas inlet. Do not connect both of the available

charbroiler gas inlets to the gas supply.

A pressure regulator is supplied and must be installed outside of the broiler when making

the gas supply connection. Standard orifices are set for 5"WC (Water Column) for

Natural Gas — 10"WC (Water Column) for Propane. Use the

1

/8” pipe tap on the burner

manifold for checking pressure. Make sure the gas piping is clean and free of

obstructions, dirt, and piping compound.

An adequate gas supply is necessary. Undersized or low pressure lines will restrict the

volume of gas required for satisfactory performance. A minimum supply pressure of 7"

W.C. for natural gas and 11" W.C. for propane gas is recommended. With all units

operating simultaneously, the manifold pressure on all units should not show any

appreciable drop.

When testing the gas supply piping system, if test pressures exceed ½ psig (3.45 kPa),

the charbroiler and its individual shutoff valve must be disconnected from the gas supply

piping system. When test pressures are ½ psig (3.45 kPa) or less, the charbroiler must

-

7 -

Page 8

be isolated from the gas supply piping system by closing its individual manual shut-off

valve during any pressure testing of the system.

Prior to lighting, check all joints in the gas supply line for leaks.

Use soap and water solution. Do not use an open flame.

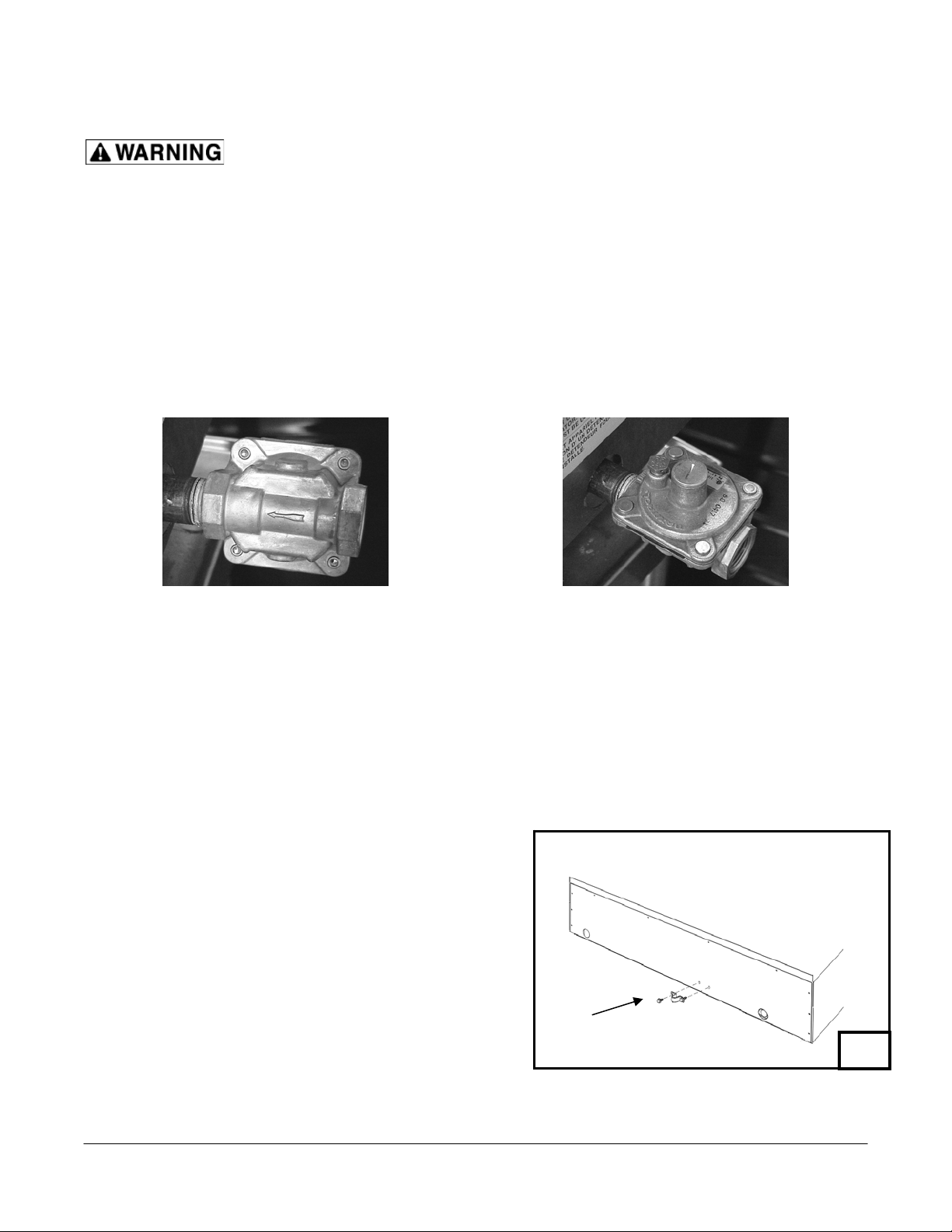

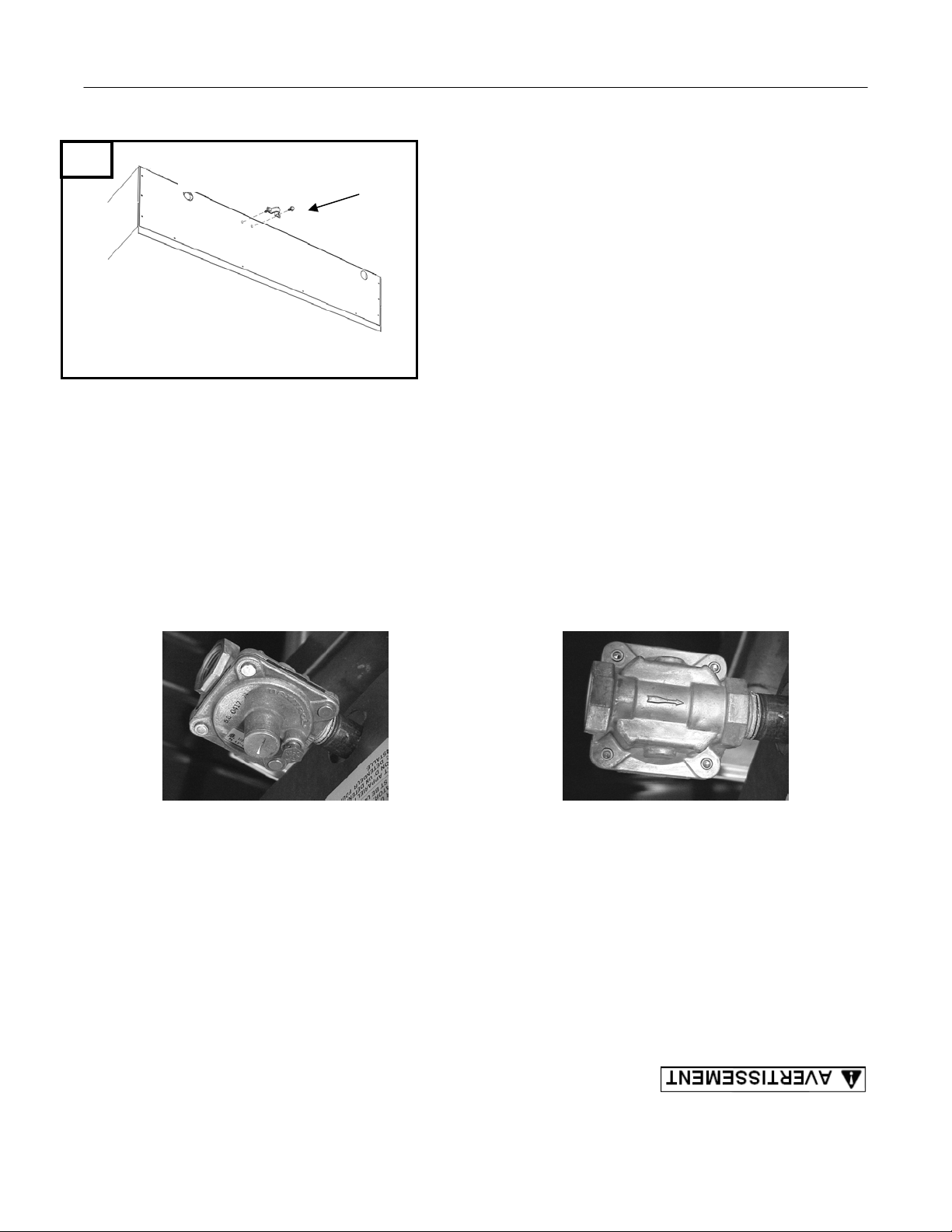

GAS PRESSURE REGULATOR INSTALLATION

Gas regulator pressure is preset at 5” Water Column (W.C.) for natural gas, and 10” W.C.

for propane gas. Minor adjustments may be required based on site specific gas pressure.

Install the regulator as close to the broiler on the gas supply line as possible. Make sure

that the arrow on the underside of the regulator is oriented in the direction of gas flow to

the broiler (Fig. 7) and the regulator is positioned with the vent plug and adjustment

screw upright (Fig. 8).

Fig. 7

The supply pressure (upstream of the regulator) should be 7-9” W.C. for natural gas and

11-12” W.C. for propane gas. At no time should the charbroiler be connected to supply

pressure greater than ½ psig (3.45 kPa) or 14” W.C.

CASTER EQUIPPED CHARBROILERS

Charbroilers mounted on stands with casters

Charbroilers mounted on stands with casters must use a

must use a flexible connector (not supplied) that

flexible connector (not supplied) that complies with the

complies with the Standard for Connectors for

Standard for Connectors for Movable Gas Appliances,

Movable Gas Appliances, ANSI Z21.69 • CSA

ANSI Z21.69 • CSA 6.16 and a quick-disconnect device

6.16 and a quick-disconnect device that complies

that complies with the Standard for Quick-Disconnect

with the Standard for Quick-Disconnect Devices

Devices for use With Gas Fuel, ANSI-Z21.41 • CSA 6.9.

for use With Gas Fuel, ANSI-Z21.41 • CSA 6.9.

In addition, adequate means must be provided to limit

In addition, adequate means must be provided to

movement of the broiler without depending on the

limit movement of the broiler without depending

connector and the quick-disconnect device or its

on the connector and the quick-disconnect device

associated piping to limit broiler movement. Attach the

or its associated piping to limit broiler movement.

restraining device at the rear of the charbroiler. If

Attach the restraining device at the rear of the

charbroiler. If disconnection of the restraint is

disconnection of the restraint is necessary, turn off the

necessary, turn off the gas supply before

gas supply before disconnection. Reconnect the restraint

disconnection. Reconnect the restraint prior to

prior to turning the gas supply on and return the

turning the gas supply on and return the

charbroiler to its installation position.

charbroiler to its installation position.

Connect Gas Line

Strain Relief Here

Fig. 8

Fig. 9

-

8 -

Page 9

OPERATION

The charbroiler and its parts are hot. Use care when operating,

cleaning or servicing the charbroiler.

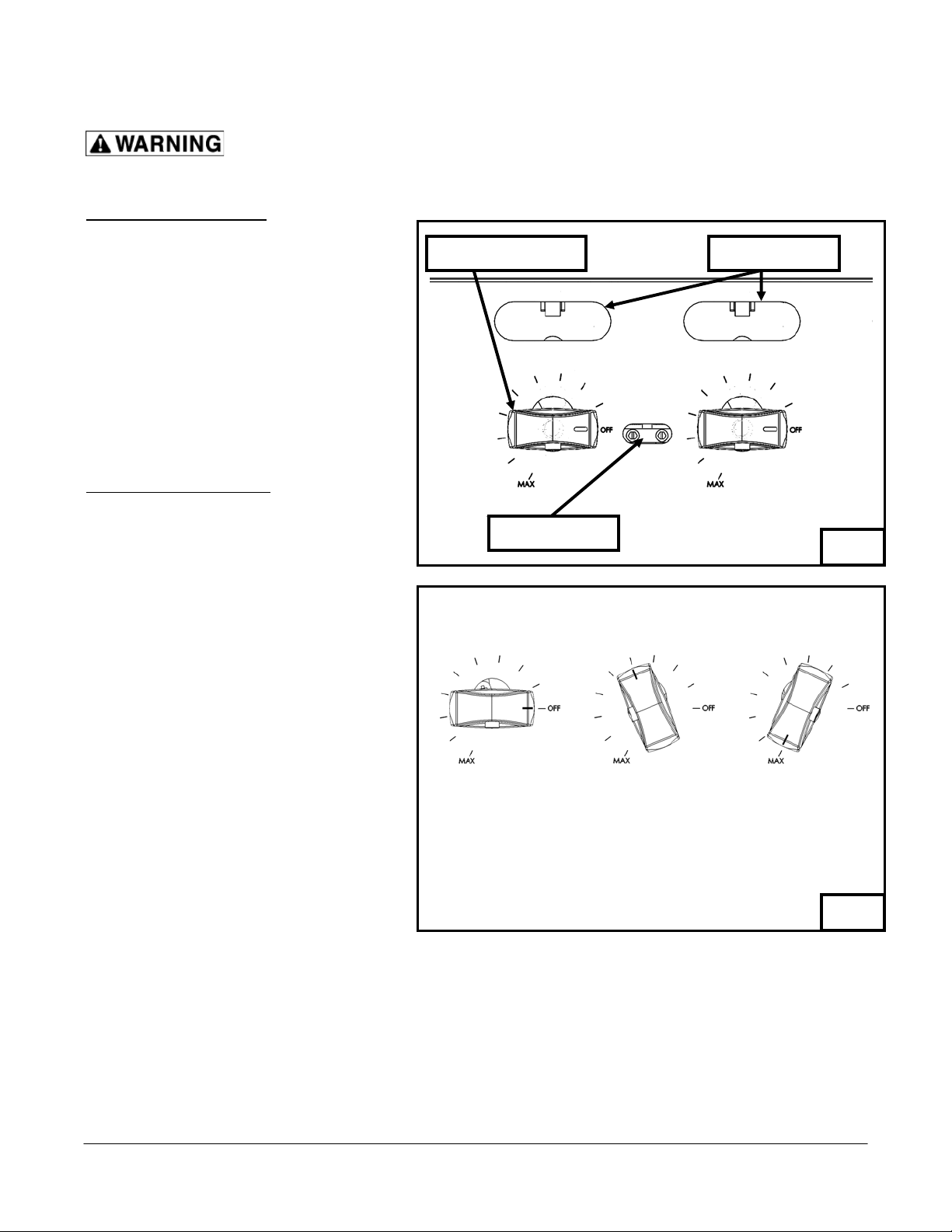

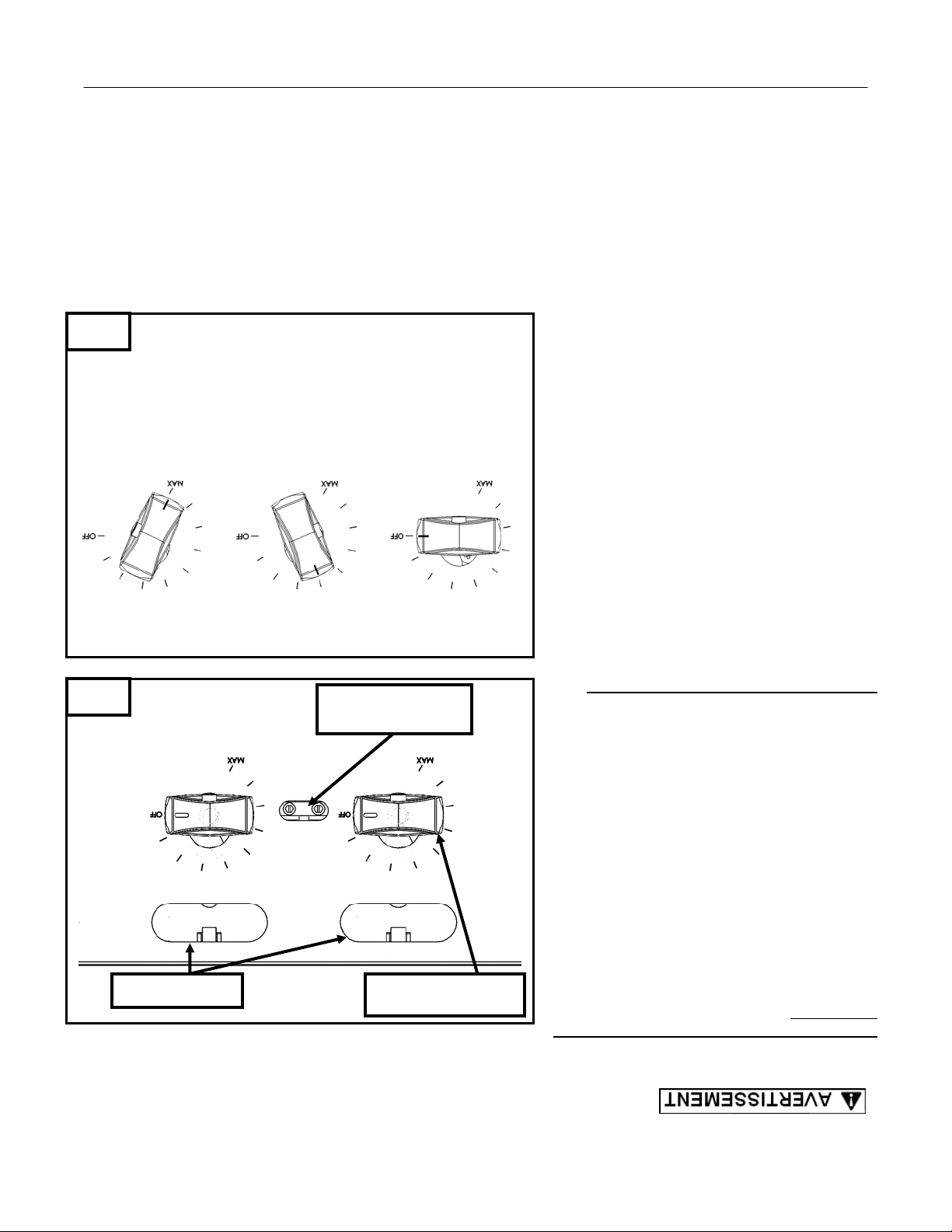

Pilot Control Valves – The pilot

control valves are located between

the burner control knobs and

CONTROLS

accessed thru slots in the front panel

(Fig. 10). There is one pilot and

corresponding adjustment screw for

every burner.

Using a flathead screwdriver, turn the

slotted, hex-head pilot adjustment

screw clockwise to decrease the

flame and counter clockwise to

increase the flame. Standing pilots

should be adjusted to provide a slight

yellow tip on the flame.

Burner Control Valves

valve for each burner. To initially

light the burners, the knobs should

be turned to the “MAX” setting then

adjusted to the desire setting as

needed.

The burners will be off when the

control knob is turned all the way to

the right and pointing to “OFF”. The

burners will be at maximum setting

when turned all the way to the left

and pointing to “MAX”. A medium

burner setting can be achieved by

adjusting the knob approximately half

way between the “OFF” and “MAX”

marks. See Fig. 11.

The charbroiler is a free vented

appliance. All products of

combustion and the heat generated

by the burners passes through the

grates. When food products are

placed on the grates, this blocks the

venting and causes a temperature

build-up.

– There is one

Burner Control Valve

Pilot Control Valve

OFF MEDIUM MAXIMUM

Pilot Sight Holes

Fig. 10

Fig. 11

TO COMPLETELY SHUTDOWN THE BURNERS AND PILOT LIGHTS

For complete shutdown: Turn the main gas supply valve OFF. Make sure all individual

burner valves are OFF.

PREHEATING THE CHARBROILER

Allow the charbroiler to preheat for 30 minutes. Rub grates with cooking oil before using.

-

9 -

Page 10

LIGHTING THE GAS PILOT

1. Turn the main gas shut-off valve

and the individual burner gas

valves OFF. Wait 5 minutes.

2. Turn the main gas shut-off valve

ON.

3. Light each pilot using an outside

ignition source. Pass the ignition

source through the pilot access

hole in the front panel and ignite

the pilot (Fig. 12). The end of the

ignition source will need to be at

least 7” long so it can extend pass

the front panel to reach the pilot

inside.

4. While viewing through the pilot

access hole, adjust the

corresponding pilot valve screw

until the pilot has a slight yellow

tip

Fig. 10

Pilot

Pilot Valve

Pilot Access Hole

Fig. 12

5. Repeat steps 3-4 until all pilots

are lit.

6. To light the burners, turn the

individual burners valves ON (MAX

setting) after all pilots are lit. (Fig.

13). If the burners fail to light, turn

all burner valves and the main gas

shut-off valve to the OFF position

and contact an authorized service

agency.

CLEANING

and its parts are hot. Use care

when operating, cleaning or

servicing the charbroiler.

Scrape top grates during broiling

with a wire brush to keep the

grates clean. Do not allow debris

to accumulate on the grates. (Fig.

14)

The charbroiler

-

10 -

Fig. 13

Fig. 14

Page 11

Top grates may be immersed in

strong commercial cleaning

compound overnight. In the

morning, rinse with hot water to

remove any residues of cleaning

compound. Thoroughly dry and

apply cooking oil to prevent

rusting.

Stainless steel surfaces may be

cleaned using damp cloth with

mild detergent and water solution.

Daily, when cool, remove top

grates and radiants to clean

places where fat, grease, or food

can accumulate. (Fig. 15)

Deflector trays and crumb trays

should be emptied and cleaned

regularly when cool. Ensure that

the rear hooks of the deflector tray

are over the back edge of the

crumb tray as shown in Fig. 16

when reassembled.

Deflector Tray Hook

Deflector Tray

Fig. 15

Crumb Tray

Fig. 16

Never cover the surface of the charbroiler with pans or other objects in attempt

to “burn off” or clean debris from unit. This will cause a buildup of heat that can

potentially damage and warp components of the charbroiler.

-

11 -

Page 12

MAINTENANCE

The charbroiler and its parts are hot. Use care when operating,

cleaning or servicing the charbroiler.

VENT SYSTEM

At least twice a year the exhaust hood (venting system) must be examined and cleaned.

LUBRICATION

All valves, at the first sign of sticking, should be lubricated by a trained technician using

high temperature grease.

SERVICE

Contact your local Service Agency for any repairs or adjustments needed on this

equipment. For a complete listing of service and parts depots refer to

www.vulcanequipment.com

available from the appliance identification plate: Model Number and Serial Number.

. When calling for service, the following information should be

TROUBLE SHOOTING

Uneven heating, sides burning A. Burner valves improperly adjusted

B. Fluctuating gas pressure

C. Improperly adjusted burner

Too much top heat A. Burner valves adjusted too high

B. Faulty ventilation

C. Overrated gas pressure

D. Improperly adjusted burner

Uneven heat side to side A. Burner valves improperly adjusted

B. Appliance is not level side to side

C. Improperly adjusted burner

D. Deflector tray and/or crumb tray improperly maintained

or not installed correctly.

Uneven heat front to back A. Appliance is not level front to back

B. Faulty ventilation

C. Improperly adjusted burner

D. Deflector tray and/or crumb tray improperly maintained

or not installed correctly.

Pilot outage A. Pilot flame is set too low. Adjust pilot to allow more gas

flow.

B. Obstruction in pilot orifice

C. Low gas pressure

Yellow burner flames A. Open burners shutters until flames are blue and touching

burner

Lifting burner flames A. Close burner shutters until flames touch burner and are

not yellow.

Fluctuating gas pressure A. Checked for clogged vent on regulator

-

12 -

Page 13

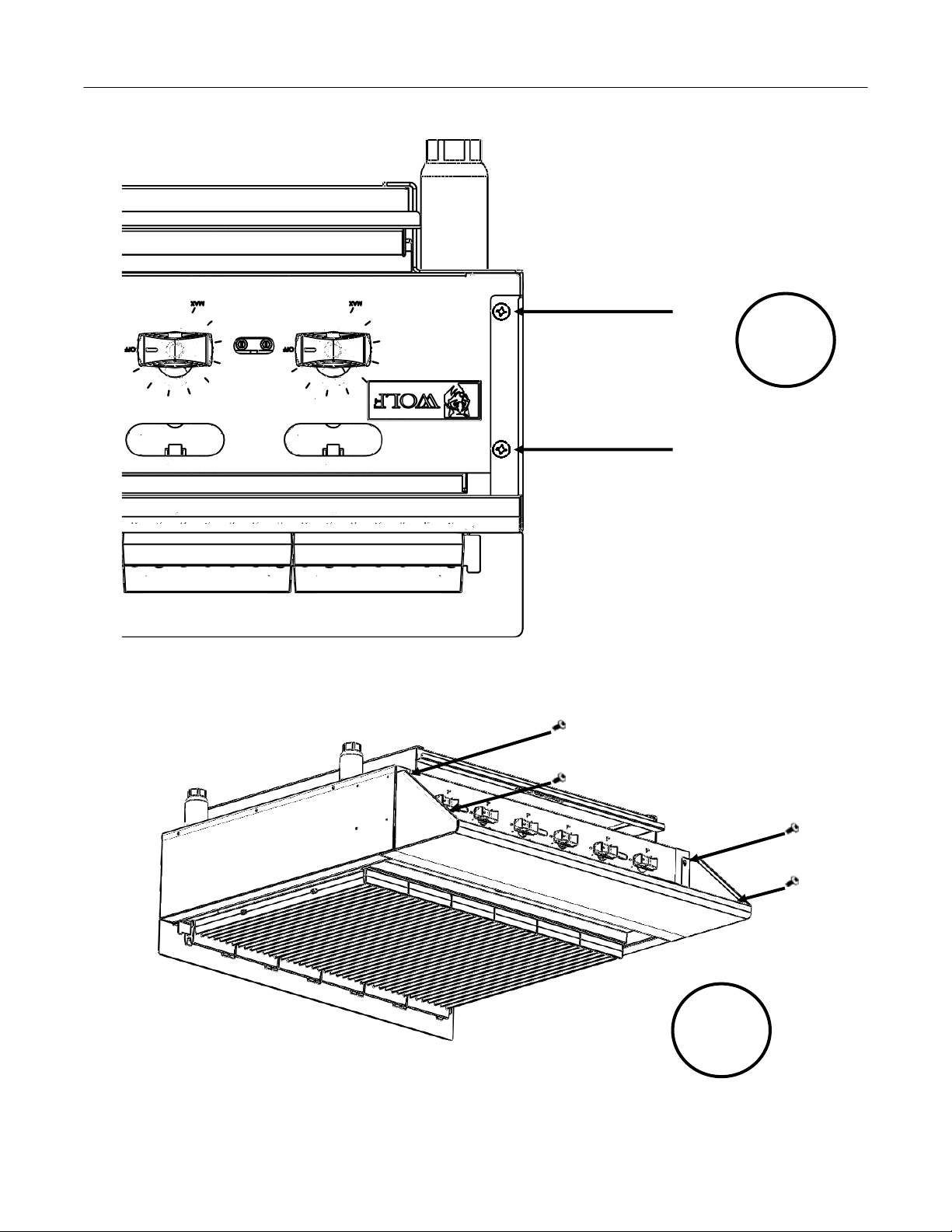

ACCESSORY INSTALLATION

The charbroiler and its parts are hot. Use care when operating,

cleaning or servicing the charbroiler.

1

2

SIDEVIEW

-

13 -

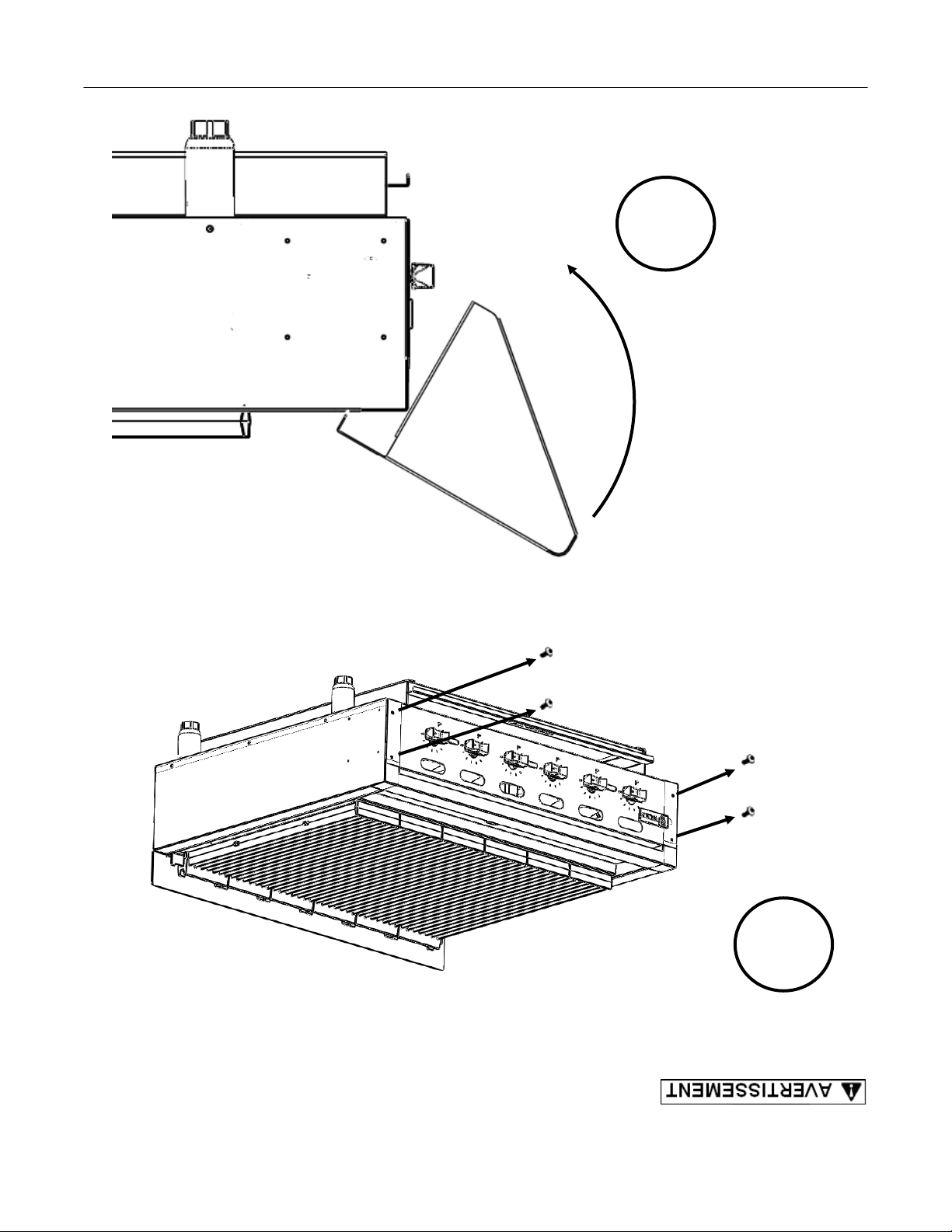

Page 14

3

4

FRONTVIEW

-

14 -

Page 15

14 -

-

VUEDEDEVANT

4

3

Page 16

13 -

-

VUEDECÔTÉ

2

1

de le faire fonctionner, de le nettoyer ou de l'entretenir.

Le gril et ses pièces sont chauds. Faites attention au moment

INSTALLATION DES ACCESSOIRES

Page 17

12 -

-

gaz

A. Vérifiez si la prise d'air du régulateur est bouchée

flammes touchent le brûleur et ne soient plus jaunes.

flammes redeviennent bleues et touchent le brûleur

A. Ouvrez les obturateurs des brûleurs jusqu'à ce que les

C. La pression du gaz est basse.

B. L’orifice de la veilleuse d’allumage est obstrué

plus de gaz.

veilleuse d’allumage pour permettre la circulation de

A. La veilleuse d’allumage est réglée trop bas. Réglez la

entretenus ou mal installés

D. Le plateau déflecteur et le ramasse-miettes sont mal

C. Le brûleur est mal réglé

B. La ventilation est défectueuse

A. L’appareil n’est pas de niveau de l’avant vers l’arrière

entretenus ou mal installés

D. Le plateau déflecteur et le ramasse-miettes sont mal

C. Le brûleur est mal réglé

B. L’appareil n’est pas de niveau d’un côté à l’autre

A. Les soupapes des brûleurs sont mal réglées

D. Le brûleur est mal réglé

C. La pression du gaz est surestimée

B. La ventilation est défectueuse

C. Le brûleur est mal réglé

B. La pression du gaz varie

Variation de la pression du

Flammes trop élevées A. Fermez les obturateurs des brûleurs jusqu’à ce que les

jaunes

Flammes des brûleurs

d’allumage

Panne de la veilleuse

vers l’arrière

Chaleur inégale de l’avant

l’autre

Chaleur inégale d’un côté à

Trop de chaleur sur le dessus A. Les soupapes des brûleurs sont réglées trop haut

Chaleur inégale, côtés brûlés A. Les soupapes des brûleurs sont mal réglées

DÉPANNAGE

. Lorsque vous appelez pour obtenir du service,

Le gril et ses pièces sont chauds. Faites attention au moment

ENTRETIEN

l'appareil : le numéro du modèle et le numéro de série.

veuillez fournir l'information suivante, disponible sur la plaque d'identification de

consultez www.vulcanequipment.com

nécessaire sur cet équipement. Pour une liste des bureaux des services et des pièces,

Communiquez avec votre service à la clientèle local pour toute réparation ou tout réglage

SERVICE

résistant aux températures élevées dès le premier signe de coincement.

Toutes les soupapes devraient être lubrifiées par un technicien qualifié avec une huile

LUBRIFICATION

moins deux fois par année.

La hotte à évacuation (système de ventilation) devrait être examinée et nettoyée au

SYSTÈME DE VENTILATION

de le faire fonctionner, de le nettoyer ou de l'entretenir.

Page 18

11 -

r

-

augmentation de la chaleur qui peut endommager ou déformer les composants du gril.

essayer de « brûler » ou de nettoyer les débris de l’élément. Cela provoquera une

Ne couvrez jamais la surface du gril avec une casserole ou d'autres objets pour

Fig. 16

déflecteur

Ramasse-miettes

Plateau

déflecteu

Crochet du plateau

Fig. 15

(Fig. 16).

miettes quand ils sont assemblés

par-dessus le bord du ramasseplateau déflecteur sont passés

vous que les crochets arrière du

lorsqu'ils sont froids. Assurezvidés et nettoyés régulièrement

ramasse-miettes doivent être

Les plateaux déflecteurs et les

s'accumuler. (Fig. 15).

graisse et les aliments peuvent

nettoyer tous les endroits où la

les éléments radiants pour

refroidies, enlevez les grilles et

Chaque jour, une fois qu'elles sont

solution d’eau et d’un savon doux.

d’un linge humide et d’une

peuvent être nettoyées à l’aide

Les surfaces en acier inoxydable

cuisson afin de prévenir la rouille.

fond et mettez de l’huile de

tout résidu du détersif. Rincez à

avec de l'eau chaude pour enlever

toute la nuit. Au matin, rincez-les

un puissant détersif commercial

Les grilles peuvent tremper dans

Page 19

10 -

V

g

-

Fig. 14

Le gril et

s'accumuler sur les grilles. (Fig. 14).

propres. Empêchez les débris de

brosse métallique afin de les garder

durant la cuisson au grill avec une

Grattez les grilles supérieures

nettoyez ou entretenez ce gril.

attention lorsque vous employez,

ses pièces sont chauds. Faites

NETTOYAGE

agence de service autorisée.

« OFF » et communiquez avec une

soupape principale de gaz sur

Fig. 13

toutes les soupapes ainsi que la

Si le brûleur ne s'allume pas, mettez

veilleuses sont allumées. (Fig. 13).

(MAX) une fois que toutes les

sa soupape en position « ON »

6. Pour allumer un brûleur, mettez

Fig. 12

allumées.

ce que toutes les veilleuses soient

5. Répétez les étapes 3 et 4 jusqu'à

bout jaune.

que sa flamme présente un petit

veilleuse correspondante jusqu'à ce

Fig. 10

réglez la vis de l'obturateur de la

4. Tout en regardant par le trou,

l'intérieur du trou.

façon à atteindre le pilote à

la veilleuse

Soupape de

doit avoir au moins 7 po de long de

L'extrémité de la source d'ignition

gril et allumez la veilleuse (Fig. 12).

trou d'accès au pilote à l'avant du

Passez la source d'ignition par le

d'une source d'ignition externe.

3. Allumez chaque veilleuse à l'aide

du gaz.

2. Ouvrez le robinet d’arrêt principal

sur « OFF ». Attendez 5 minutes.

e

Trou du regard

d’alluma

eilleuse

et les valves de tous les brûleurs

1. Mettez la valve principale de gaz

ALLUMAGE DE LA VEILLEUSE DU GAZ

Page 20

9 -

du brûleur

-

avant de l'utiliser.

Préchauffez le gril pendant 30 minutes. Frottez les grilles avec de l’huile de cuisson

PRÉCHAUFFAGE DU GRIL

Assurez-vous que toutes les soupapes individuelles des brûleurs sont fermées.

Pour fermer complètement : mettez le robinet d'alimentation en gaz sur « OFF ».

VEILLEUSES

POUR FERMER COMPLÈTEMENT LES FLAMMES DES BRÛLEURS ET DES

une augmentation de la température.

Fig. 11

ARRÊT MOYEN MAXIMUM

Fig. 10

de la veilleuse

Soupape de contrôle

– Il

Trou du regard

Soupape de contrôle

cela bloque la ventilation et provoque

des aliments sont placés sur les grilles,

passent à travers les grilles. Lorsque

de la chaleur générés par les brûleurs

Tous les produits de la combustion et

Le gril est un appareil sans évacuation.

« OFF » et « MAX » (Fig. 11).

environ à mi-chemin entre les marques

intermédiaire, le bouton doit se trouver

position « MAX ». Pour tout réglage

complètement tourné vers la gauche, en

quand leur bouton de commande est

« OFF ». Les brûleurs sont au maximum

tourné vers la droite, en position

bouton de commande est complètement

Les brûleurs sont éteints quand leur

puis placé au réglage souhaité.

le bouton doit être tourné sur « MAX »

allumer pour la première fois un brûleur,

y a une soupape par brûleur. Pour

Soupapes de contrôle des brûleurs

jaune sur la flamme.

réglées afin d'offrir une légère pointe

veilleuses permanentes devraient être

pour augmenter la flamme. Les

contraire des aiguilles d'une montre

pour diminuer la flamme et dans le sens

dans le sens des aiguilles d'une montre

de réglage de la veilleuse d’allumage

tournez la vis à tête hexagonale fendue

À l’aide d’un tournevis à tête plate,

chaque brûleur.

une veilleuse et une vis de réglage pour

fentes du panneau avant (Fig. 10). Il y a

brûleurs et sont accessibles par les

entre les boutons de commande des

des veilleuses d'allumage sont situées

d'allumage – Les soupapes de contrôle

Soupapes de contrôle des veilleuses

vous employez, nettoyez ou entretenez ce gril.

Le gril et ses pièces sont chauds. Faites attention lorsque

EMPLOI

Page 21

du

uyau

e

atio

c

Fig. 9

8 -

-

gril à l'endroit où il doit être installé.

avant d’ouvrir l’alimentation en gaz et replacez le

t

nt

n i

i

d'alim

Fixez le dispositif de serrage

avant le débranchement. Rebranchez le dispositif

est nécessaire, fermez l’alimentation en gaz

l’arrière du gril. Si le débranchement du dispositif

associées. Attachez le dispositif de retenue à

à démontage rapide ou de leurs conduites

dépendre du connecteur et du dispositif de prise

apportées pour limiter le mouvement du gril sans

De plus, des mesures appropriées doivent être

for use With Gas Fuel, ANSI-Z21.41 • CSA 6.9.

conforme à la norme Quick-Disconnect Devices

dispositif de prise à démontage rapide qui est

Gas Appliances, ANSI Z21.69 • CSA 6.16 et un

conforme à la norme Connectors for Movable

employer un raccord flexible (non fourni) qui est

Les grils sur supports avec roulettes doivent

GRILS MUNIS DE ROULETTES

36 cm CE.

moment être connecté à une pression d’alimentation supérieure à ½ psi (3,45 kPa) ou

le gaz naturel et de 28 à 30 cm CE pour le gaz propane. Le gril ne devrait à aucun

La pression d'alimentation (en amont du régulateur) devrait être de 18 à 23 cm CE pour

Fig. 8

Fig. 7

bouchon d’aération ainsi que la vis d’ajustement vers le haut (Fig. 8).

direction de la circulation du gaz du brûleur (Fig. 7) et que le régulateur est placé avec le

en gaz. Assurez-vous que la flèche au-dessous du régulateur est orientée dans la

Installez le régulateur aussi près que possible du brûleur sur la conduite d’alimentation

pression des gaz spécifique au site.

CE pour le propane. Certains réglages mineurs peuvent être nécessaires selon la

Le régulateur de pression de gaz est préréglé à 25 cm CE pour le gaz naturel et à 28 cm

INSTALLATION DU RÉGULATEUR DE PRESSION DE GAZ

N’utilisez pas une flamme nue.

d’alimentation en gaz pour les fuites. Utilisez une solution d’eau et savon.

Avant l’allumage, vérifiez tous les joints dans la conduite

les obturateurs individuels manuels pendant tout test de pression du système.

(3,45 kPa) ou moins, le grill doit être isolé du système d'alimentation en gaz en fermant

Page 22

7 -

-

déconnectés de la tuyauterie de l’alimentation en gaz. Si la pression est de 1/2 psi

excèdent ½ psi (3,45 kPa), le gril et son robinet d’arrêt individuel doivent être

Lorsque vous évaluez la tuyauterie de l’alimentation en gaz, si les pressions d’essai

baisse notable.

même temps, la pression d’admission sur tous les éléments ne devrait pas démontrer une

gaz naturel et de 28 cm CE pour le gaz propane. Avec tous les éléments fonctionnant en

satisfaisante. On recommande une pression d'alimentation minimum de 18 cm CE pour le

ou à basse pression limiteront le volume de gaz nécessaire pour une performance

Une alimentation adéquate en gaz est requise. Des conduites de dimension insuffisante

saleté et de toute pâte à tuyauterie.

Assurez-vous que les conduites de gaz soient propres et exemptes d'obstructions, de

propane. Utilisez le taraud de 0,3 cm sur la rampe de brûleurs pour vérifier la pression.

10 cm CE (colonne d’eau) pour le gaz naturel – 25 cm CE (colonne d’eau) pour le

effectuez la connexion d’alimentation en gaz. Les orifices en mince paroi sont établis à

Un régulateur de pression est fourni et doit être installé à l’extérieur du gril lorsque vous

disponibles du gril à l’alimentation en gaz.

métallique si vous n'utilisez pas cette entrée. Ne branchez pas les deux arrivées de gaz

d’alimentation. Le capuchon antipoussière peut être remplacé par un bouchon de tuyau

l’autre extrémité et utiliser le point de raccordement étant le plus pratique pour la sortie

un capuchon antipoussière sur l’autre. Vous pouvez déplacer le capuchon métallique sur

l’unité. L’unité arrivera de l’usine avec un capuchon métallique à l’une des extrémités et

Les modèles de 60 et de 72 po sont équipés d’une arrivée de gaz à chaque extrémité de

2 cm.

gril. La conduite d’alimentation en gaz doit être au moins l’équivalent d’un tuyau en fer de

Les codes exigent que la soupape d’arrêt du gaz soit installée dans la conduite de gaz du

corps étranger avant de la connecter à l’appareil.

Videz la conduite d’alimentation pour la nettoyer de toute poussière, saleté ou tout autre

pâtes à joints doivent résister à l’action du gaz propane.

Toutes les connexions d’alimentation en gaz et toutes les

utilisable par ce brûleur. NE branchez PAS un autre type de gaz.

La plaque signalétique placée sur le côté inférieur droit du grill indique le type de gaz

CONNEXION DU GAZ

évacuation libre de toute obstruction.

sécuritaire et une ventilation adéquate, laissez un espace entre le gril et la hotte à

Le gril devrait être installé sous une hotte de ventilation appropriée. Pour un emploi

HOTTE DE VENTILATION

qu'il est déplacé.

régler le niveau. Vous devriez vérifier le niveau de cet appareil à nouveau chaque fois

niveau. Le gril est muni de pattes réglables. Tournez le pied au bout des pattes pour

la droite. La distribution de la chaleur sera inégale dans un appareil qui n'est pas mis de

Il est important que le gril soit mis de niveau de l'avant vers l'arrière et de la gauche vers

MISE DE NIVEAU

Page 23

Fig. 6

q

r

Fig. 5

brûleu

Obturateur du

6 -

-

brûleur

Soupape du

un peu plus fermé.

d'air et que l'obturateur doit être

Orifice

brûleur) indiquent qu'il y a trop

flottantes (qui ne touchent pas le

plus ouvert. Les flammes

que l'obturateur doit être un peu

signe qu'il n'y a pas assez d'air et

l'extrémité jaune constituent le

propane. De longues flammes à

petit bout de jaune avec le

naturel. Il ne doit y avoir qu'un

être éliminée de la flamme au gaz

brûleur. Toute trace de jaune doit

flamme bleue compacte touche le

Lorsqu'ils sont bien ajustés, une

et de 80 à 100 % pour le propane.

B

ouverts à 50 % pour le gaz naturel

place. En général, ils doivent être

tous les éléments radiants en

gril. Ils doivent être ajustés avec

essentiel pour la performance du

obturateurs du brûleur est

L'ajustement correct des

Fig. 4

ue

thermi

Fente de l'écran

radiant

l'élément

Attache de

l'élément radiant

Support de

A

B

A

de l'unité.

dans la fente du brûleur à l'arrière

situé à l'avant (Fig. 6) et repose

doit être enfoncé dans l'orifice

– L'obturateur du brûleur

Brûleur

radiants à l'arrière (Fig. 5-A).

repose sur le support à éléments

A), l'arrière des éléments radiants

l'écran thermique à l'avant (Fig. 4correspondante découpée dans

l'attache dans la fente

radiants s'installent en insérant

cuisson uniforme. Les éléments

chauffent de façon à procurer une

des éclaboussures d'aliments et

en place. Ils protègent le brûleur

que les éléments radiants soient

devrait jamais être utilisé sans

Éléments radiants – Le gril ne

Page 24

5 -

V

-

Fig. 3

(Fig. 3).

les guides prévus à cet effet.

l'avant (Fig. 2), l'arrière repose sur

dans les fentes correspondantes à

s'installent en insérant les crochets

diviseurs de brûleur suralimenté

fonctionne mieux sans eux. Les

méthode de production qui

suralimenté si vous trouvez une

tous les diviseurs de brûleur

Vous pouvez retirer certains ou

répartition uniforme de la chaleur.

chaleur vers le haut pour une

de cuisson et aide à diriger la

Guide du diviseur

– Il

Fig. 2

la fente

crochet enfoncé dans

ue agrandie du

– Le ramasse-

Fente

cuisson pour offrir de la flexibilité

agit en diviseur entre les zones de

Diviseur de brûleur suralimenté

(Fig. 1).

installé sous le plateau déflecteur

déflecteur et doit toujours être

qui passent à travers le plateau

miettes récupère tous les débris

avec des trous. Le ramassemiettes est le panneau amovible

Ramasse-miettes

fonctionne.

ramasse-miettes quand il

Crochet

être en place au-dessus du

Le plateau déflecteur doit toujours

ramasse-miettes situé en dessous.

par les trous et de tomber dans le

permettant aux débris de passer

la surface de cuisson tout en

Fig. 1

Ramasse-miettes

déflecteur

Plateau

– Le plateau

déflecteur renvoie la chaleur vers

avec des trous. Le panneau

déflecteur est le panneau amovible

Plateau déflecteur

plus de flexibilité.

utilisées à plat ou inclinées pour

– Les grilles peuvent être

Grille

Brûleur

brûleur

Diviseur de

Grille

radiant

Élément

Le gril et

l'entretenir.

fonctionner, de le nettoyer ou de

attention au moment de le faire

ses pièces sont chauds. Faites

PRINCIPALES COMPOSANTES

Page 25

4 -

-

M9W 1R3

de l’Association Canadienne du Gaz, 178 boul. Rexdale, Etobicoke, Ontario, Canada

3. Code d'installation du propane CAN/CSA-B149.2 (dernière édition), disponible auprès

2. Code d'installation du gaz naturel CAN/CSA-B149.1 (dernière édition)

1. Codes locaux.

Au Canada :

Quincy, MA 02269.

disponible auprès de la National Fire Protection Association, Batterymarch Park,

3. La norme NFPA n° 96 Vapor Removal from Cooking Equipment, dernière édition,

d’échappement qui doivent être conformes à 248 CMR.

système d’échappement muni d’une clef de réglage ou avec une moyenne potentielle

Tous les appareils d’utilisation du gaz aérés grâce à une hotte de ventilation ou à un

REMARQUE : dans l’État du Massachusetts

Secretary Standards Council, NFPA, 1 Batterymarch Park Quincy, MA 02169-7471

Standards Committee Z223, à 400 N. Capital St. NW, Washington, DC 20001 ou le

pouvez obtenir des copies auprès de l’American Gas Association Accredited

comprendre sans être limité à : NFPA N° 54 Section 10.3.5.2 pour la ventilation. Vous

2. National Fuel Gas Code, ANSI-Z223.1/NFPA N° 54 (dernière édition). Cela doit

1. Codes locaux et d’état.

Aux États-Unis d'Amérique :

L'installation du gril doit être conforme :

CODES ET NORMES D'INSTALLATION

8 cm de chaque côté.

Les espaces minimums pour les parois non combustibles sont de 8 cm à l’arrière et de

Ce brûleur ne doit être utilisé que dans des endroits incombustibles.

espace libre de 61 cm à l’avant pour le nettoyage, l’entretien et l’emploi adéquat.

le gril et effectuer la (les) connexion(s) nécessaire(s) d’alimentation en gaz. Prévoyez un

emplacement définitif. Assurez-vous qu’il y a suffisamment d’espace libre pour entretenir

gaz de combustion et le dessus de la grille supérieure du gril. Placez le gril dans son

la circulation de l’air à l’intérieur et autour de l’appareil. N'obstruez pas la circulation des

par tout système de ventilation et par la combustion des brûleurs de gaz. N'obstruez pas

Suffisamment d’air devrait entrer dans la pièce afin de compenser la quantité d'air enlevé

N'installez PAS le gril près de friteuses ou de brûleurs ouverts.

N’obstruez pas la circulation de l'air de combustion ainsi que l’air de ventilation.

L'emplacement où sera installé le gril doit être dégagé et exempt de combustibles.

EMPLACEMENT

Page 26

3 -

-

sur le côté inférieur droit.

le dégagement correspondent aux spécifications de la plaque signalétique, qui est située

Avant d’effectuer l’installation, vérifiez que le type de gaz (naturel ou propane) ainsi que

DU RÉGULATEUR DE PRESSION DU GAZ dans ce manuel).

fourni et doit être installé avant que le gril soit mis en service (consultez INSTALLATION

l’emballage. Un régulateur de pression conçu pour fonctionner avec le brûleur a été

Déballez soigneusement votre gril et assurez-vous qu’aucune pièce n’a été jetée avec

le transporteur dans les 15 jours suivant la livraison.

vous découvrez que le gril est endommagé, conservez l’emballage et communiquez avec

Immédiatement après avoir déballé, vérifiez s’il y a des dommages dus à la livraison. Si

DÉBALLAGE

INSTALLATION

221 000 208 000

187 000 176 000

136 000 128 000

102 000 96 000

68 000 64 000

GPL BTU/h

Consommation de

gaz naturel BTU/h

Consommation de

VACB72 / ACB72 13

VACB60 / ACB60 11

VACB48 / ACB48 8

VACB36 / ACB36 6

VACB25 / ACB25 4

Modèle Nombre de brûleurs

l'avant pour inspection ou nettoyage.

miettes est fourni pour recueillir les écoulements et les débris de graisse; il s'ouvre par

la grille de cuisson d'être mise à plat ou inclinée en totalité ou en partie. Un ramasseLes grilles supérieures en fonte résistante sont réversibles pour permettre à la surface de

s’enlèvent facilement pour le nettoyage lorsqu’ils sont refroidis.

chaque brûleur afin de maintenir une température uniforme. Les éléments radiants

soupape à gaz réglable. Les éléments radiants moulés sont situés directement sous

et offrent une chaleur au gaz rapide et efficace. Chaque brûleur est contrôlé par une

Les grils au gaz de comptoir Vulcan/Wolf sont conçus à des fins commerciales seulement

GÉNÉRAL

DES GRILS POUR COMPTOIR AU GAZ

INSTALLATION, FONCTIONNEMENT ET ENTRETIEN

Page 27

2 -

-

APPAREIL.

EN CAS DE PANNE DE COURANT, NE TENTEZ PAS DE FAIRE FONCTIONNER CET

vous servir de cet équipement.

d’emploi et d’entretien avant d’installer ou de

minutieusement les instructions d’installation,

matériels, une blessure ou la mort. Lisez

entretien inapproprié peut causer des dommages

ajustement, une modification, un service ou un

Une installation, un

DE TOUT AUTRE APPAREIL.

INFLAMMABLES À PROXIMITÉ DE CET APPAREIL OU

L’ESSENCE OU D'AUTRES VAPEURS OU LIQUIDES

N'ENTREPOSEZ PAS ET N'UTILISEZ PAS DE

POUR VOTRE SÉCURITÉ

GAZ LOCAL AFIN D’OBTENIR DU SERVICE.

COMPAGNIE DE GAZ OU VOTRE FOURNISSEUR DE

APPAREILS ET COMMUNIQUEZ AVEC VOTRE

FERMEZ LE ROBINET D’ARRÊT PRINCIPAL DES

AU CAS OÙ UNE ODEUR DE GAZ SERAIT DÉTECTÉE,

IMPORTANT

DEMANDER CES RENSEIGNEMENTS AU FOURNISSEUR DE GAZ LOCAL.

SUIVIES AU CAS OÙ UNE ODEUR DE GAZ SERAIT DÉTECTÉE. VOUS POUVEZ

PLACEZ DANS UN ENDROIT IMPORTANT LES INSTRUCTIONS QUI DOIVENT ÊTRE

RÉGLAGES INITIAUX DE L’ÉQUIPEMENT DONT IL S’AGIT DANS CE MANUEL.

ÉQUIPEMENT AU GAZ, QUI DOIT EFFECTUER LA MISE EN MARCHE ET LES

CE MANUEL A ÉTÉ CONÇU POUR LE PERSONNEL APTE À INSTALLER UN

IMPORTANT POUR VOTRE SÉCURITÉ

Page 28

FORMULAIRE F38328 (3-13)

UTILISATION FUTURE

GARDER CE MANUEL POUR UNE

ACB36

ACB72

ACB60

ACB47

ACB36

ACB25

VACB36

VACB72

VACB60

VACB47

VACB36

VACB25

MODÈLES

Baltimore, MD 21222

3600, North Point Boulevard

©ITW Food Equipment Group, LLC

GRILS AU GAZ

FONCTIONNEMENT

MANUEL D'INSTALLATION ET DE

Loading...

Loading...