Page 1

SERVICE MANUAL

HEG / RRE / WEG Series Griddle

VULCAN HEG24E

HEG36E

HEG48E

HEG60E

HEG72E

RRE24E

RRE36E

RRE48E

WOLF WEG24E

WEG36E

WEG48E

WEG60E

WEG72E

This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qualifi ed.

This manual is not intended to be all encompassing. If you have

not attended a Vulcan Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you

do not have the necessary tools, instruments and skills should

be performed by a trained Vulcan Service Technician.

The reproduction, transfer, sale or other use of this Manual,

without the express written consent of Vulcan, is prohibited.

This manual has been provided to you by ITW Food Equipment

Group LLC (“ITW FEG”) without charge and remains the property

of ITW FEG, and by accepting this manual you agree that you will

return it to ITW FEG promptly upon its request for such return

at any time in the future.

For additional information on Vulcan-Hart Company or to locate an authorized

parts and service provider in your area, visit our website at www.vulcanequipment.com

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

www.vulcanequipment.com

BALTIMORE, MD 21222

F45490 Rev. A (0315)

Page 2

HEG / WEG / RRE Series Griddle

TABLE OF CONTENTS

GENERAL .................................................................................................. 3

INTRODUCTION ....................................................................................... 3

MODELS COVERED ................................................................................... 3

INSTALLATION ........................................................................................ 3

CLEANING PROCEDURES ............................................................................. 3

TOOLS AND TEST EQUIPMENT ....................................................................... 3

LUBRICATION ......................................................................................... 3

OPERATING CONTROLS .............................................................................. 3

THERMOSTAT ..................................................................................... 3

INDICATOR LIGHT ................................................................................. 3

REMOVAL AND REPLACEMENT OF PARTS ............................................................... 4

GRIDDLE SERVICE POSITION ......................................................................... 4

HEATING ELEMENT REPLACEMENT .................................................................. 4

THERMOSTAT REPLACEMENT ........................................................................ 6

SERVICE PROCEDURES AND ADJUSTMENTS ............................................................ 8

THERMOSTAT CALIBRATION PROCEDURES ......................................................... 8

TESTING VOLTAGE TO HEATER(S) ................................................................... 9

ELECTRICAL OPERATION ................................................................................ 10

PROCEDURE OF OPERATION ....................................................................... 10

24" WIRING DIAGRAM ................................................................................ 11

24" SCHEMATIC ...................................................................................... 12

1 & 3 PHASE ...................................................................................... 12

2 PHASE, 3 WIRE ................................................................................. 12

36" WIRING DIAGRAM ................................................................................ 14

36" SCHEMATIC ...................................................................................... 14

1 & 3 PHASE ...................................................................................... 14

2 PHASE, 3 WIRE ................................................................................. 15

48" WIRING DIAGRAM ................................................................................ 17

48" SCHEMATIC ...................................................................................... 17

1 & 3 PHASE ...................................................................................... 17

3 PHASE, 4 WIRE ................................................................................. 18

60" WIRING DIAGRAM ................................................................................ 19

60" SCHEMATIC ...................................................................................... 20

1 & 3 PHASE ...................................................................................... 20

2 PHASE, 3 WIRE ................................................................................. 21

72" WIRING DIAGRAM ................................................................................ 22

72" SCHEMATIC ...................................................................................... 23

1 & 3 PHASE ...................................................................................... 23

2 PHASE, 3 WIRE ................................................................................. 24

TROUBLESHOOTING ..................................................................................... 26

TROUBLESHOOTING ................................................................................. 26

© HOBART SERVICE 2015

F45490 Rev. A (0315) Page 2 of 27

Page 3

HEG / WEG / RRE Series Griddle - GENERAL

GENERAL

INTRODUCTION

This manual is applicable to the models and ML

numbers on the cover page. Procedures apply to all

models unless specified otherwise.

MODELS COVERED

Vulcan Brand

Models Length Depth

HEG24E 24" 24"

HEG36E 36" 24"

HEG48E 48" 24"

HEG60E 60" 24"

HEG72E 72" 24"

Vulcan Brand

Models Length Depth

RRE24E 24" 24"

RRE36E 36" 24"

RRE48E 48" 24"

Wolf Brand

Models Length Depth

WEG24E 24" 24"

WEG36E 36" 24"

WEG48E 48" 24"

WEG60E 60" 24"

WEG72E 72" 24"

INSTALLATION

TOOLS AND TEST EQUIPMENT

Tools Required

• Standard set of hand tools.

• VOM with AC current tester.

NOTE: VOM sensitive of at least 20,000 ohms/volt

can be used.

Special

• Thermocouple type, griddle or surface mount,

temperature tester.

• 2 each, 8 inch long 4 x 4 wooden blocks.

LUBRICATION

1. Anti seezing coumpound

2. Penetrating oil

3. Finger Nail Polish

OPERATING CONTROLS

Thermostat

With the dial set to the desired setting, the temperature

of the griddle section is maintained. When the

operator turns the thermostat dial to OFF, electrical

power is removed from the heating unit. Each

thermostat controls a 12 inch wide section of the

griddle surface.

Indicator Light

A red light will energize automatically for each section

of the griddle when the thermostat is set, and will deenergize when the section has reached the thermostat

setting. The light will energize and de-energize during

the cooking operation to show that current

temperature is being maintained.

Generally, all installation are made by the dealer or

others contracted by the dealer or owner. Detailed

installation instructions are included in the "Installation

and Owners Manual" for the appropriate model.

CLEANING PROCEDURES

Detailed cleaning procedures are included in the

"Installation and Owners Manual" for the appropriate

model.

Page 3 of 27 F45490 Rev. A (0315)

Page 4

HEG / WEG / RRE Series Griddle - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

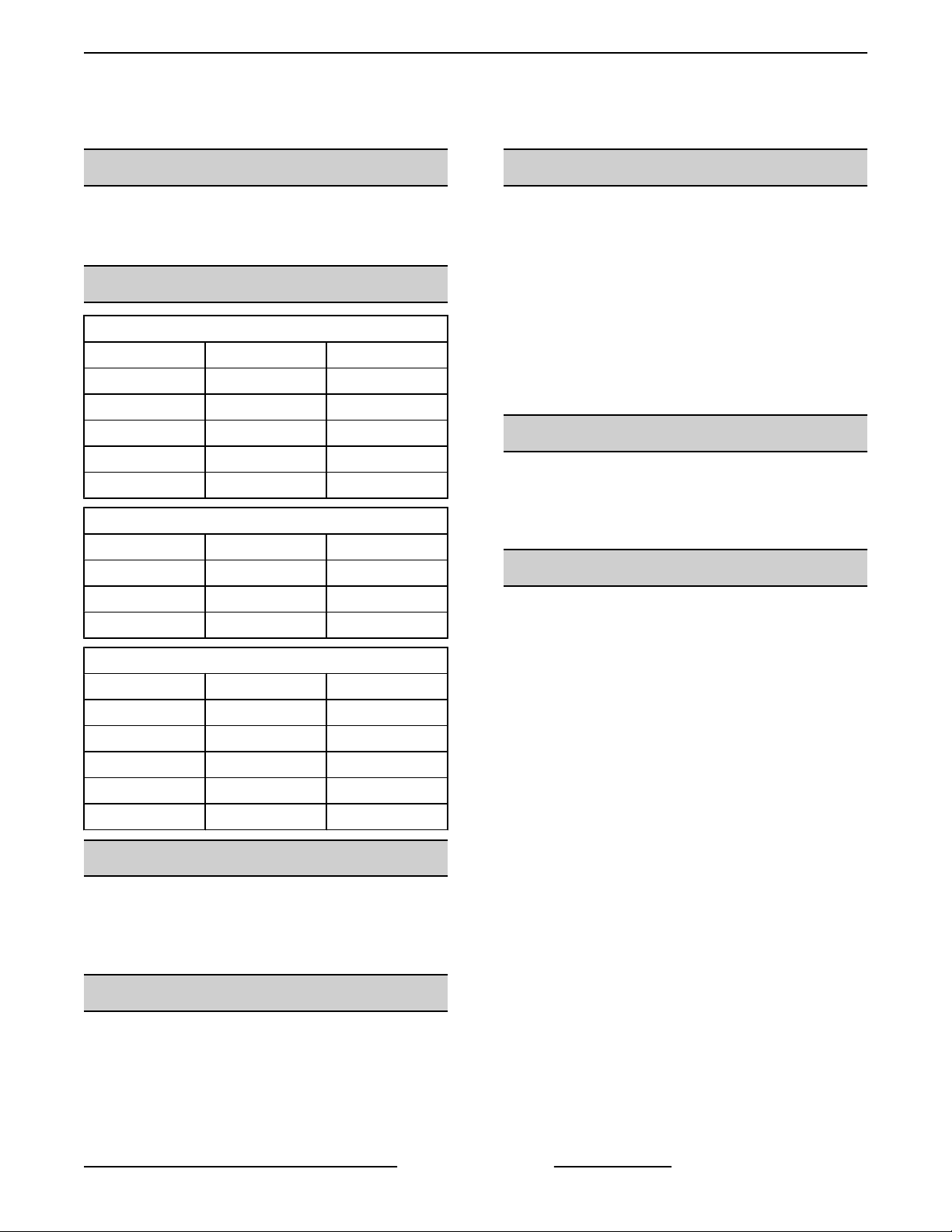

GRIDDLE SERVICE POSITION

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Griddle plate might be hot.

Griddle Service Position

1. Remove thermostat knobs.

2. Remove front trim panel screws and remove front

trim panel.

Do not damage indicator lights when

removing front trim panel.

4. Lift griddle plate up, to add two 4 x 4 blocks

between the griddle plate and left and right sides

of unit, approximately 6 to 7 inches.

Fig. 3

Verify Grease Chute does not raise past

the heater element panel. This helps prevent the top

from sliding to the rear.

Use 4 x 4, or greater, blocks to

support griddle top. Do NOT use 2 x 4 blocks as they

can tip over and lower griddle plate.

Fig. 1

3. Remove griddle plate assembly mounting bolts,

left and right side.

Fig. 2

HEATING ELEMENT

REPLACEMENT

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Griddle plate might be hot.

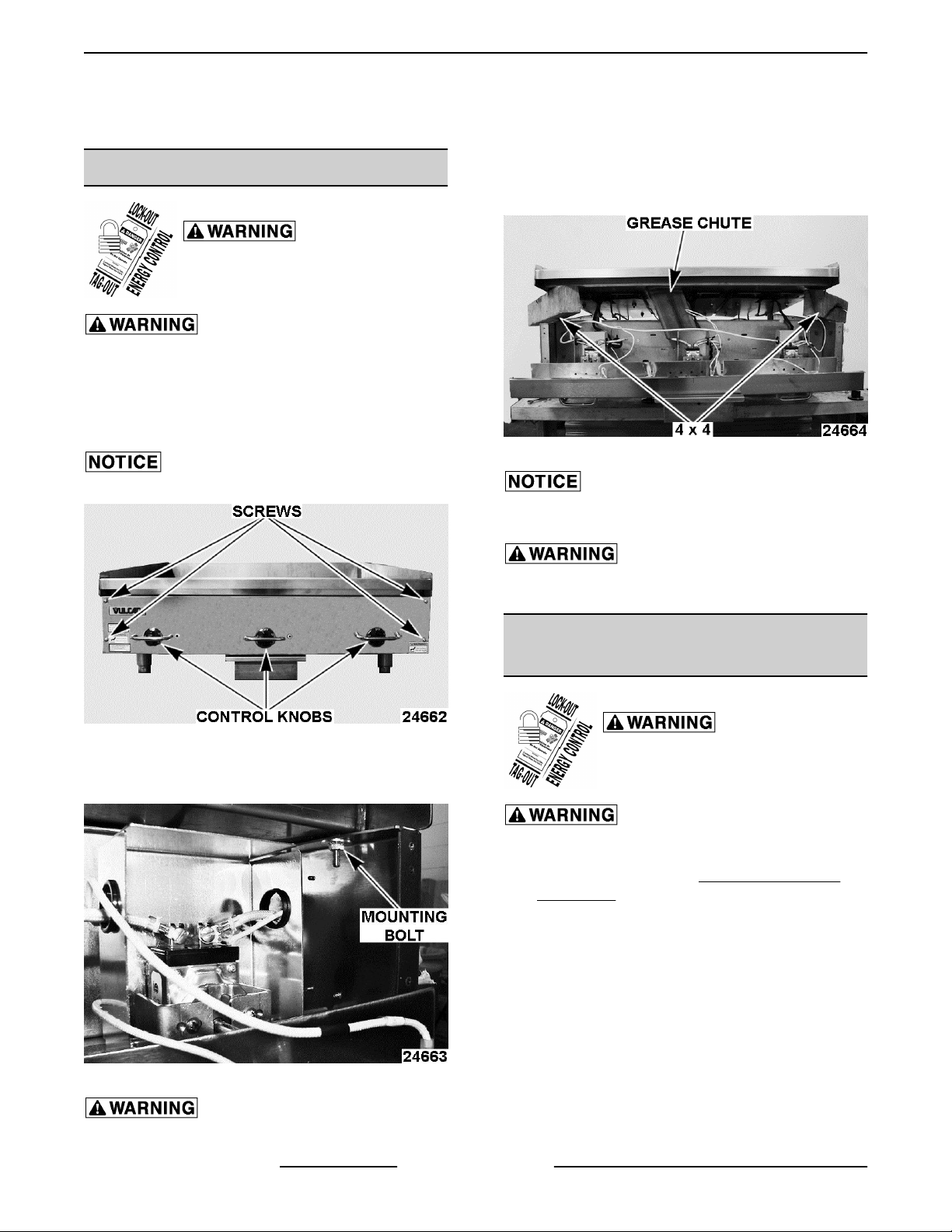

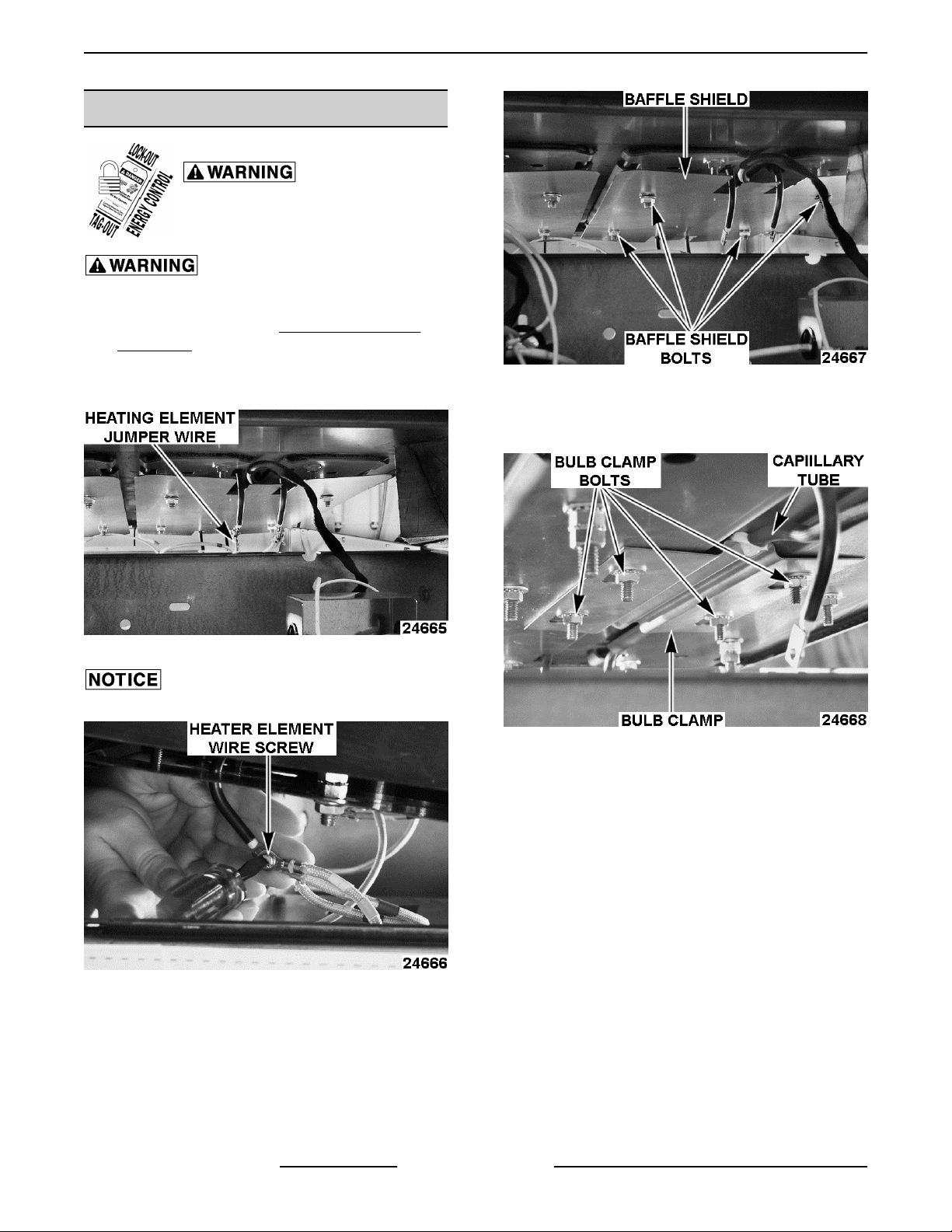

Heating Element Removal

1. Place griddle plate into GRIDDLE SERVICE

POSITION.

2. Remove front heater element jumper wire

connection.

Lift griddle plate straight up to

prevent the griddle plate from sliding to the left or right.

F45490 Rev. A (0315) Page 4 of 27

Page 5

HEG / WEG / RRE Series Griddle - REMOVAL AND REPLACEMENT OF PARTS

Fig. 4

When removing heater element jumper

wire screw, support heater element.

Fig. 7

5. Remove heater element jumper wire on the back

heater element connections.

When removing heater element jumper

wire screw, support heater element. Refer to figure

24666.

Fig. 5

3. Remove element baffle shield.

Fig. 6

4. Remove bulb clamp.

6. Remove heating element pressure plate.

NOTE: Heater element is held into place by the

pressure plate.

Fig. 8

7. Reverse procedures to install.

NOTE: Nuts should be torqued to 30-35 Inch Pounds.

8. See THERMOSTAT REPLACEMENT for proper

installation of the thermostat.

NOTE: Coat threaded studs with high temperature

anti-seize compound prior to putting bolts back on.

NOTE: Tighten nuts to 30-35 inch-pounds.

NOTE: Loosen front and rear bolts and remove

thermostat probe from bulb clamp. Secure thermostat

probe to prevent damage.

Page 5 of 27 F45490 Rev. A (0315)

Over tightening the nuts can cause

damage and prevent the element from moving with

expansion and contraction that can lead to premature

failures.

9. Check for proper operation.

Page 6

HEG / WEG / RRE Series Griddle - REMOVAL AND REPLACEMENT OF PARTS

THERMOSTAT REPLACEMENT

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Griddle plate might be hot.

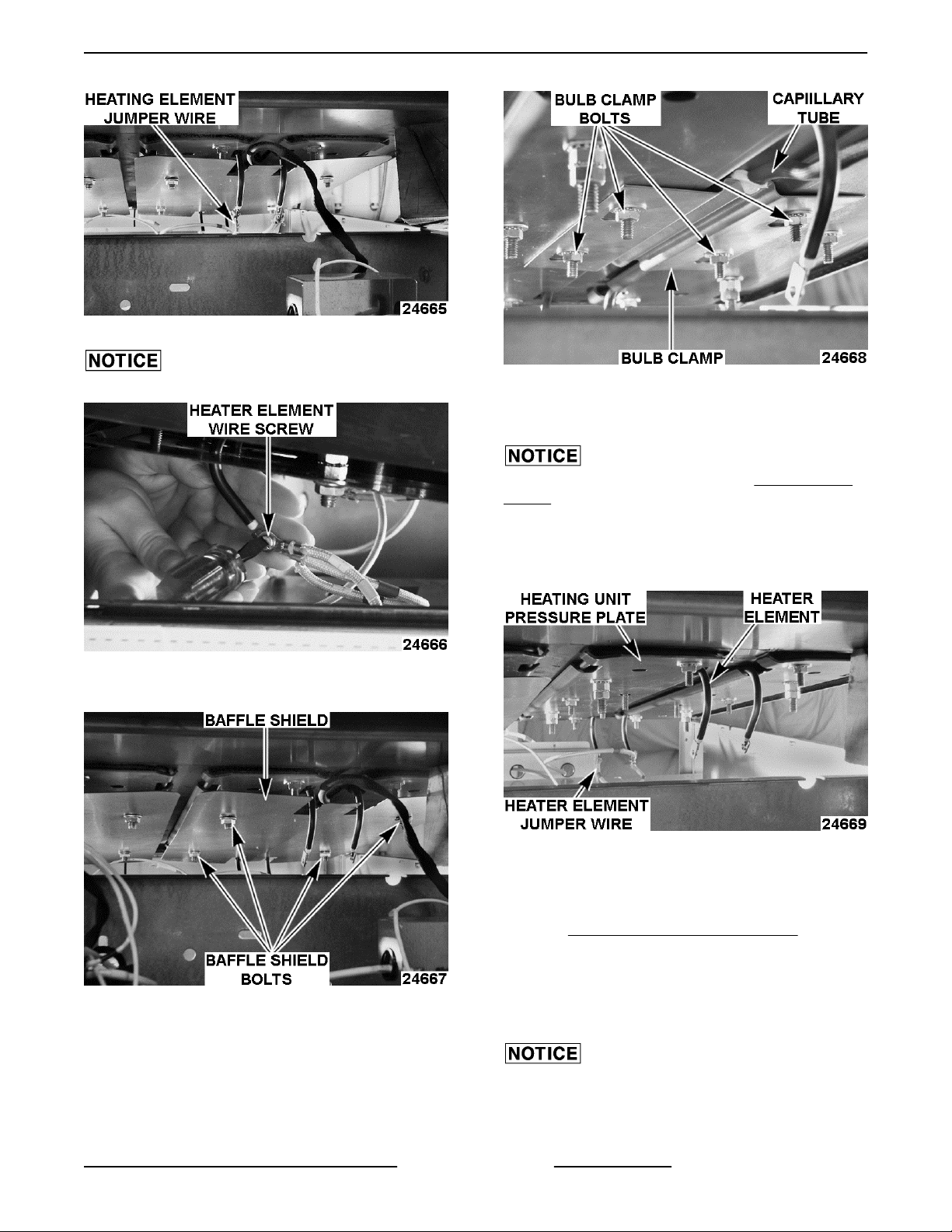

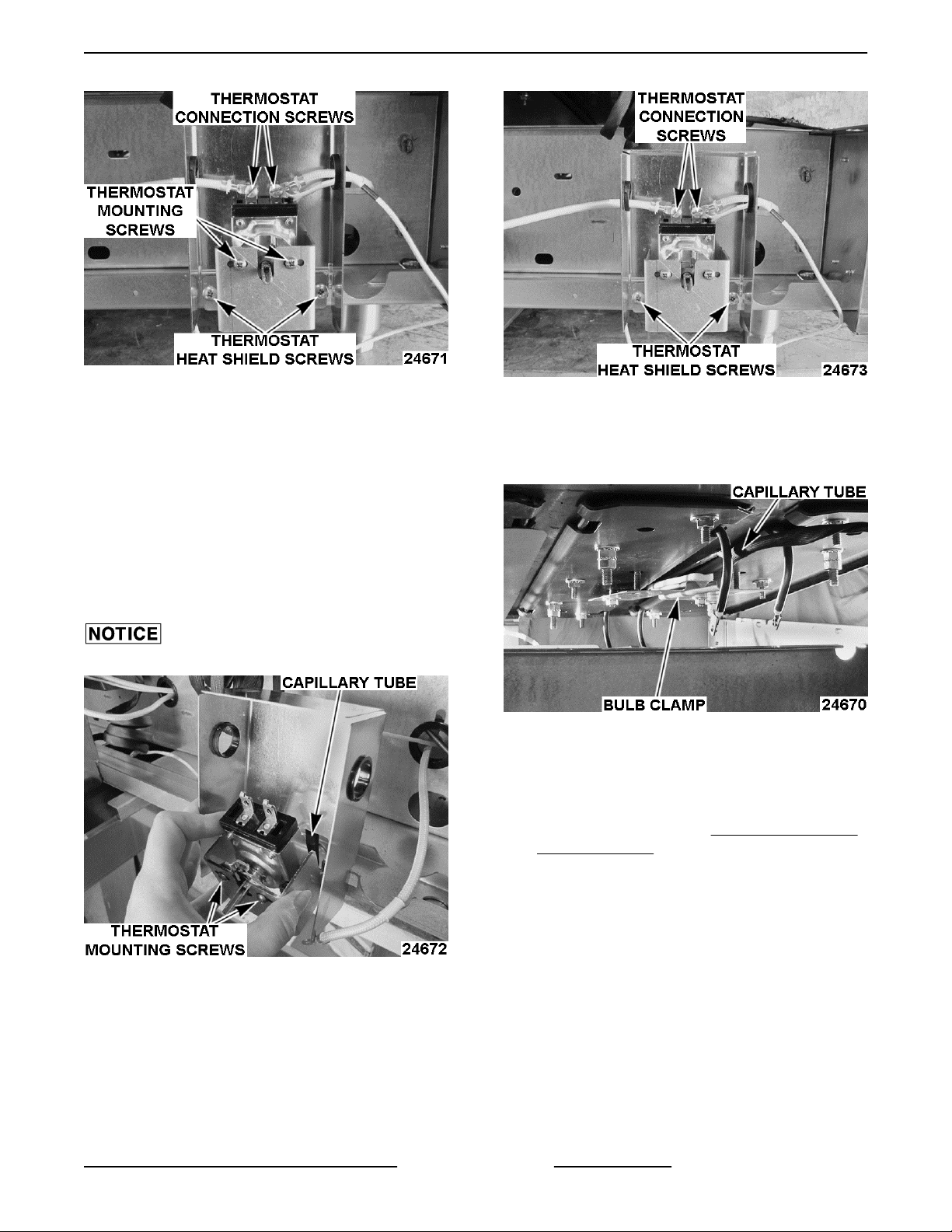

Capillary Tube Removal

1. Place griddle plate into

POSITION.

2. Remove front heater element jumper wire

connection.

When removing heater element jumper

wire screw, support heater element.

GRIDDLE SERVICE

Fig. 9

Fig. 11

4. Loosen back bolts to bulb clamp.

5. Remove front bolts to bulb clamp.

Fig. 12

6. Pull thermostat probe to remove.

NOTE: Retain capillary sleeve for new thermostat.

Thermostat Control Removal

1. Remove thermostat connection screws.

NOTE: Note heater element wire locations on the

thermostat connection tabs.

2. Remove thermostat mounting screws.

Fig. 10

3. Remove heater element baffle shield.

F45490 Rev. A (0315) Page 6 of 27

Page 7

HEG / WEG / RRE Series Griddle - REMOVAL AND REPLACEMENT OF PARTS

Fig. 13

3. Remove thermostat heat shield screws.

4. Remove thermostat assembly from unit.

Thermostat Control Installation

1. Install capillary sleeve on replacement

thermostat.

2. Install thermostat to thermostat bracket using

mounting screws.

3. Thread capillary tube through opening located on

the thermostat heat shield.

Secure thermostat capillary tube to

prevent damage, while installing thermostat.

Fig. 15

Capillary Tube Installation

1. Slide capillary tube between bulb clamp and

bottom of griddle plate.

Fig. 16

NOTE: Verify capillary tube is flush against the bottom

of the griddle plate.

2. Tighten bolts. Torque to 30-35 inch pounds.

3. Install baffle shield using HEATING ELEMENT

REPLACEMENT instructions.

Fig. 14

4. Install thermostat bracket with the thermostat

heat shield to the unit.

5. Connect heater wires to the thermostat per the

wire connections noted earlier.

4. Check for proper operation.

Page 7 of 27 F45490 Rev. A (0315)

Page 8

HEG / WEG / RRE Series Griddle - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

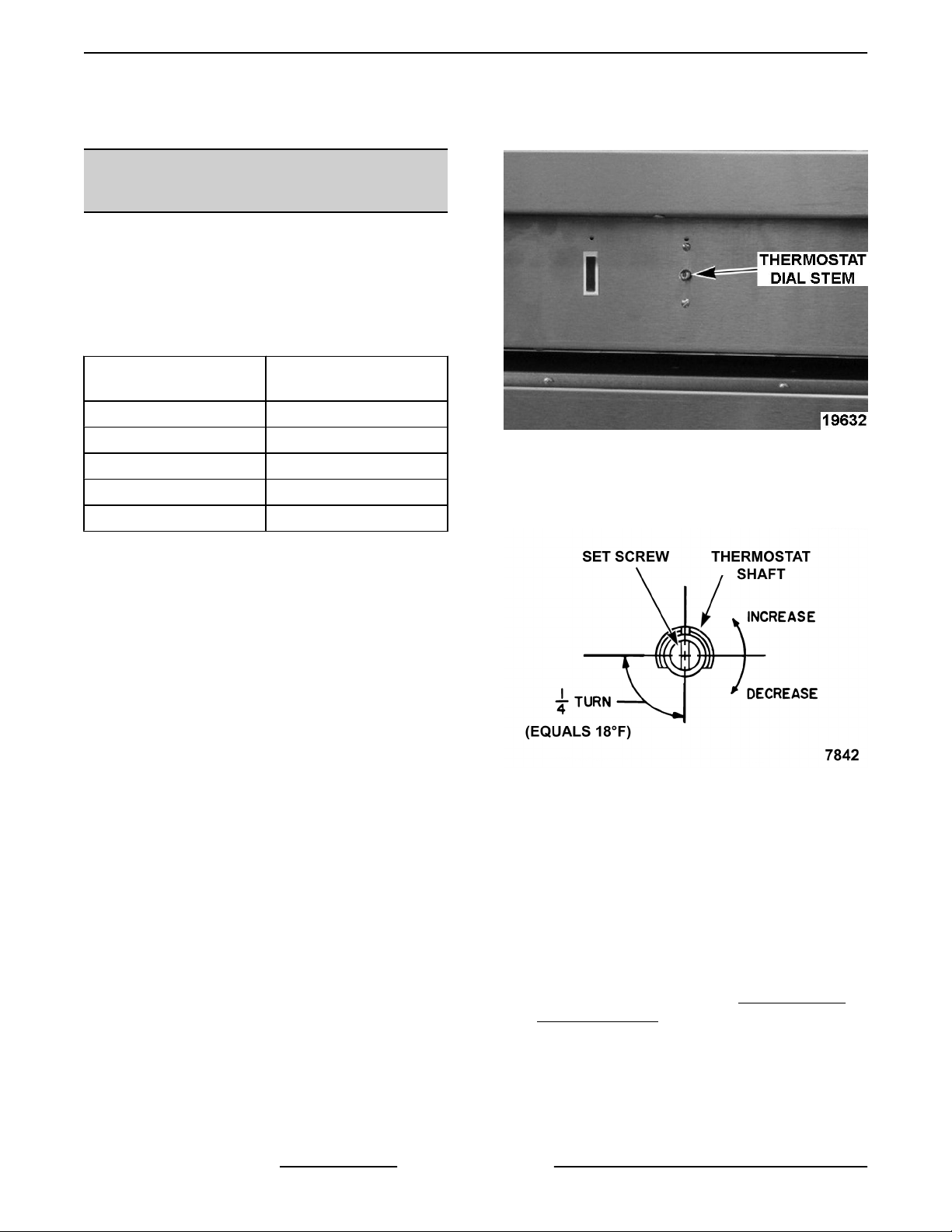

THERMOSTAT CALIBRATION

PROCEDURES

1. Clean temperature test section that is not

working. Center temperature tester surface

mount probe in center of thermostat probe. See

table for proper testing locations according to

griddle size.

NOTE: All readings taken 12" from front of griddle.

Griddle Size

24" 6", 18"

36" 6", 18", 30"

48" 6", 18", 30", 42"

60" 6", 18", 30", 42", 54"

72" 6", 18", 30", 42", 54", 66"

2. Set the thermostat to a temperature above

300°F.

3. Allow the thermostat to cycle three times.

4. Note the tester reading when the indicator light

turns ON and OFF.

NOTE: If the difference between the ON and OFF

temperatures is greater than 25°F, replace the

thermostat.

5. Add these two temperatures together, then

divide the sum by 2 to obtain an average

temperature.

A. If the average temperature is within 15°F of

the set temperature, the thermostat is

calibrated.

B. If the average temperature is not within 15°F

of the set temperature:

1) Remove thermostat knob.

2) Insert a flathead screwdriver into

thermostat dial stem until it reaches the

calibration screw.

Distance(s) From Left

Edge of Griddle

Fig. 17

3) Turn adjustment screw CCW to

increase and CW to decrease

temperature.

Fig. 18

NOTE: A 1/4 turn equals 18°F change.

6. Replace knob and repeat steps 3 and 5 until

average temperature is within 15°F of set

temperature.

7. Reseal adjustment screw to prevent movement.

NOTE: Finger nail polish can be used to reseal screw

to prevent movement.

8. If thermostat cannot be calibrated, replace

thermostat as outlined under THERMOSTAT

REPLACEMENT.

F45490 Rev. A (0315) Page 8 of 27

Page 9

HEG / WEG / RRE Series Griddle - SERVICE PROCEDURES AND ADJUSTMENTS

TESTING VOLTAGE TO HEATER(S)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Test supply voltage to verify it is correct.

2. Turn power off to griddle.

3. Place griddle into GRIDDLE SERVICE

POSITION.

4. Connect voltmeter to leads of heating element in

question.

5. Set meter on the appropriate range, determined

by line voltage rating stamped on griddle data

plate.

VOLTS COLOR CODE POWER AMP RESISTANCE

208 YELLOW 2.7kW 13 16

240 RED 2.7kW 11.3 21.3

480 GREEN 2.7kW 5.6 85.7

1. Values in table are nominal. Tolerance is +5/-10%.

NOTES:

2. Resistance values (ohms) are @ 77°F room temperature.

6. Turn on electrical power.

7. Turn thermostat to 350°F.

A. Pilot light will energize.

8. Reading should agree with the voltage rating

stamped on the griddle data plate.

A. If voltage reading is incorrect, and the line

voltage is correct, the thermostat is not

functioning properly.

B. If current draw is correct, then heating

element is functioning properly. See table

below for proper values.

Page 9 of 27 F45490 Rev. A (0315)

Page 10

HEG / WEG / RRE Series Griddle - ELECTRICAL OPERATION

ELECTRICAL OPERATION

PROCEDURE OF OPERATION

1. Refer to the schematic in the appropriate

electrical diagram at the end of this section to

trace circuits explained in this section.

2. The electrical connection(s) to the griddle are

made in the junction box.

A. Detailed information about the electrical

connections to the griddle is contained in the

"Installation and Owners Manual".

3. From the junction box, one electrical connection

is made to the thermostat. The other electrical

connection is made to the common side of the

two heating elements which the thermostat

controls.

4. With the dial set to "OFF", the thermostat

contacts are open.

5. Turn dial to 350°F.

A. The thermostat contacts close, electrical

power is applied to the heating elements,

the griddle begins to heat.

B. The indicator light energizes.

6. When the griddle surface reaches 350°F, the

thermostat contacts open and electrical power is

removed from the heating elements.

A. The indicator light de-energizes.

7. The thermostat will cycle the heating elements

and indicator light to maintain the griddle

temperature.

F45490 Rev. A (0315) Page 10 of 27

Page 11

HEG / WEG / RRE Series Griddle - ELECTRICAL OPERATION

24" WIRING DIAGRAM

24" WIRING DIAGRAM

Notes:

1. For supply connections, use copper wire sized in accordance with the national electrical code and suitable for

at least 90°C (194°F).

2. Lead marker numbers are the same as lead item numbers unless otherwise specified.

3. Wiring to be:

A. 10G,m 532515 - leads 1, 5, 6, 10, 11, J and GRD.

B. 18GA., 532518 - leads 2 and 3.

Page 11 of 27 F45490 Rev. A (0315)

Page 12

HEG / WEG / RRE Series Griddle - ELECTRICAL OPERATION

24" SCHEMATIC

1 & 3 PHASE

208, 240, & 480 VAC, 1 & 3 PHASE

X-Y Y-Z X-Z TOTAL

kW PER LINE 5.4 5.4 0.0 10.8

NOMINAL AMPS PER LINE

3-PHASE 1-PHASE

X Y Z -

208 22.5 45.0 22.5 51.9

240 19.5 39.0 19.5 45.0

480 9.7 19.5 9.7 22.5

FOR 3-PHASE:

1. Connect wire #5 to L1.

2. Connect wire #6 & #11 to L2.

3. Connect wire #10 to L3.

FOR 1-PHASE:

1. Connect wire #5 & #10 to L1.

2. Connect wire #6 & #11 to L2.

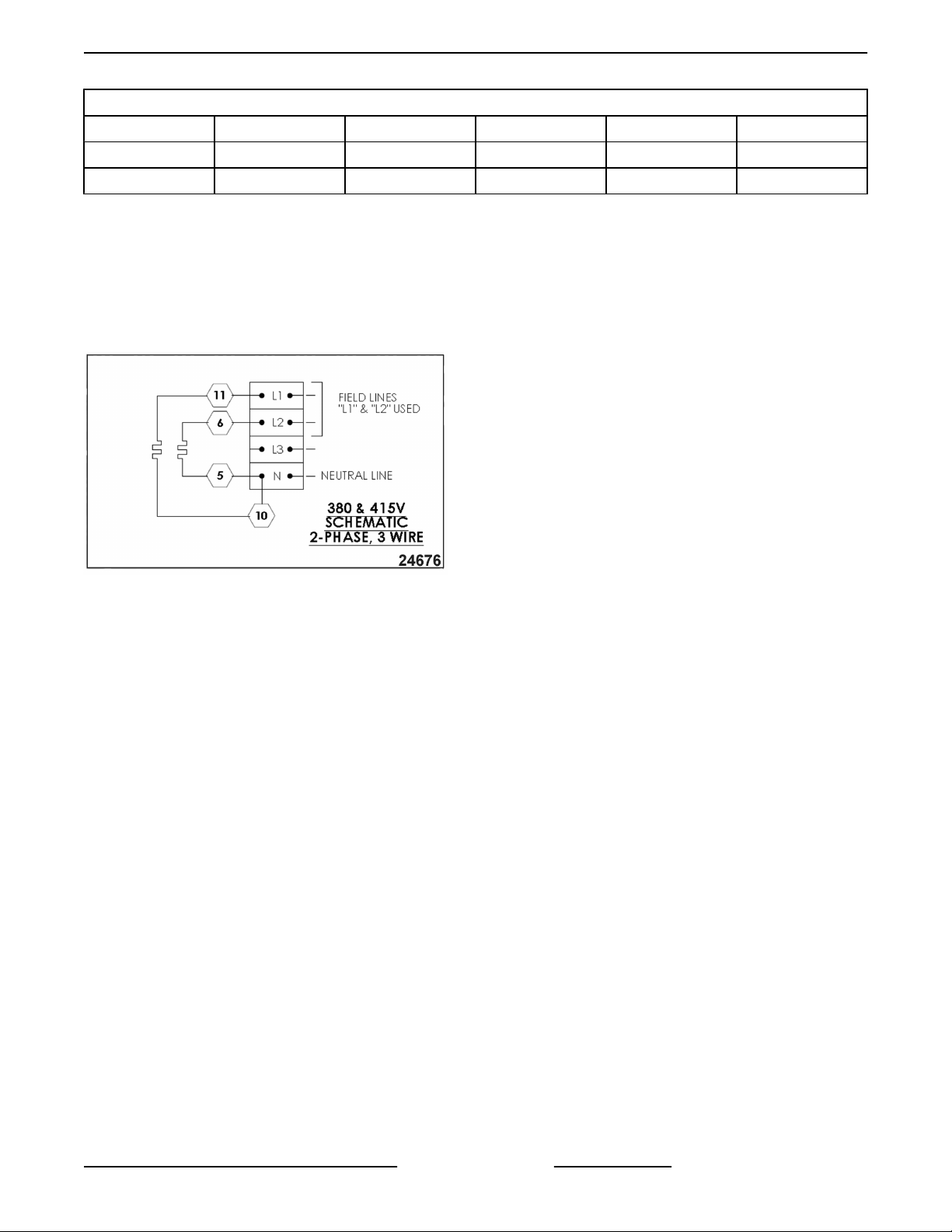

2 PHASE, 3 WIRE

1 & 3 PHASE

220/380 & 240/415 VAC. 2-PHASE, 3 WIRE

L1-N L2-N L3-N

kW PER LINE 5.4 5.4 0.0

F45490 Rev. A (0315) Page 12 of 27

Page 13

HEG / WEG / RRE Series Griddle - ELECTRICAL OPERATION

NOMINAL AMPS PER LINE

L1 L2 L3 N TOTAL kW

220/380 5.2 5.2 0.0 3.4 9.1

240/415 5.6 5.6 0.0 3.8 10.8

FOR 2-PHASE, 3 WIRE:

1. Connect wire #5 & #10 to neutral ("N").

2. Connect wire #11 to L1.

3. Connect wire #6 to L2.

2 PHASE, 3 WIRE

Page 13 of 27 F45490 Rev. A (0315)

Page 14

HEG / WEG / RRE Series Griddle - ELECTRICAL OPERATION

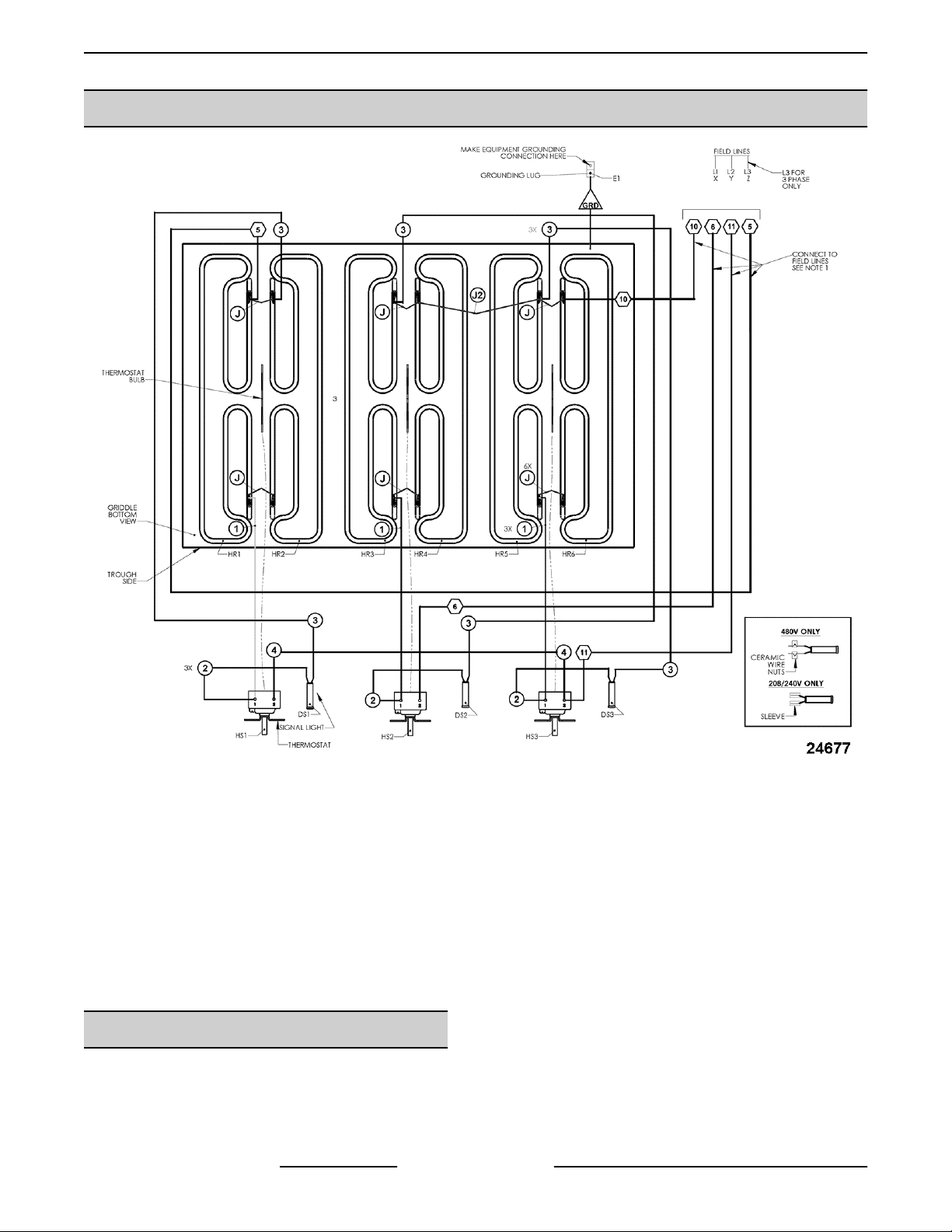

36" WIRING DIAGRAM

36" WIRING DIAGRAM

Notes:

1. For supply connections, use copper wire sized in accordance with the national electrical code and suitable for

at least 90°C (194°F).

2. Lead marker numbers are the same as lead item numbers unless otherwise specified.

3. Wiring to be:

A. 10G,m 532515 - leads 1, 4 - 6, 10, 11, J, J2 and GRD.

B. 18GA., 532518 - leads 2 and 3.

36" SCHEMATIC

1 & 3 PHASE

F45490 Rev. A (0315) Page 14 of 27

Page 15

HEG / WEG / RRE Series Griddle - ELECTRICAL OPERATION

208, 240, & 480 VAC, 1 & 3 PHASE

X-Y Y-Z X-Z TOTAL

kW PER LINE 5.4 5.4 5.4 16.2

NOMINAL AMPS PER LINE

3-PHASE 1-PHASE

X Y Z -

208 45.0 45.0 45.0 77.9

240 39.0 39.0 39.0 67.5

480 19.5 19.5 19.5 33.8

FOR 3-PHASE:

1. Connect wire #10 to L1.

2. Connect wire #11 to L2.

3. Connect wire #5 & #6 to L3.

FOR 1-PHASE:

1. Connect wire #5 & #10 to L1.

2. Connect wire #6 & #11 to L2.

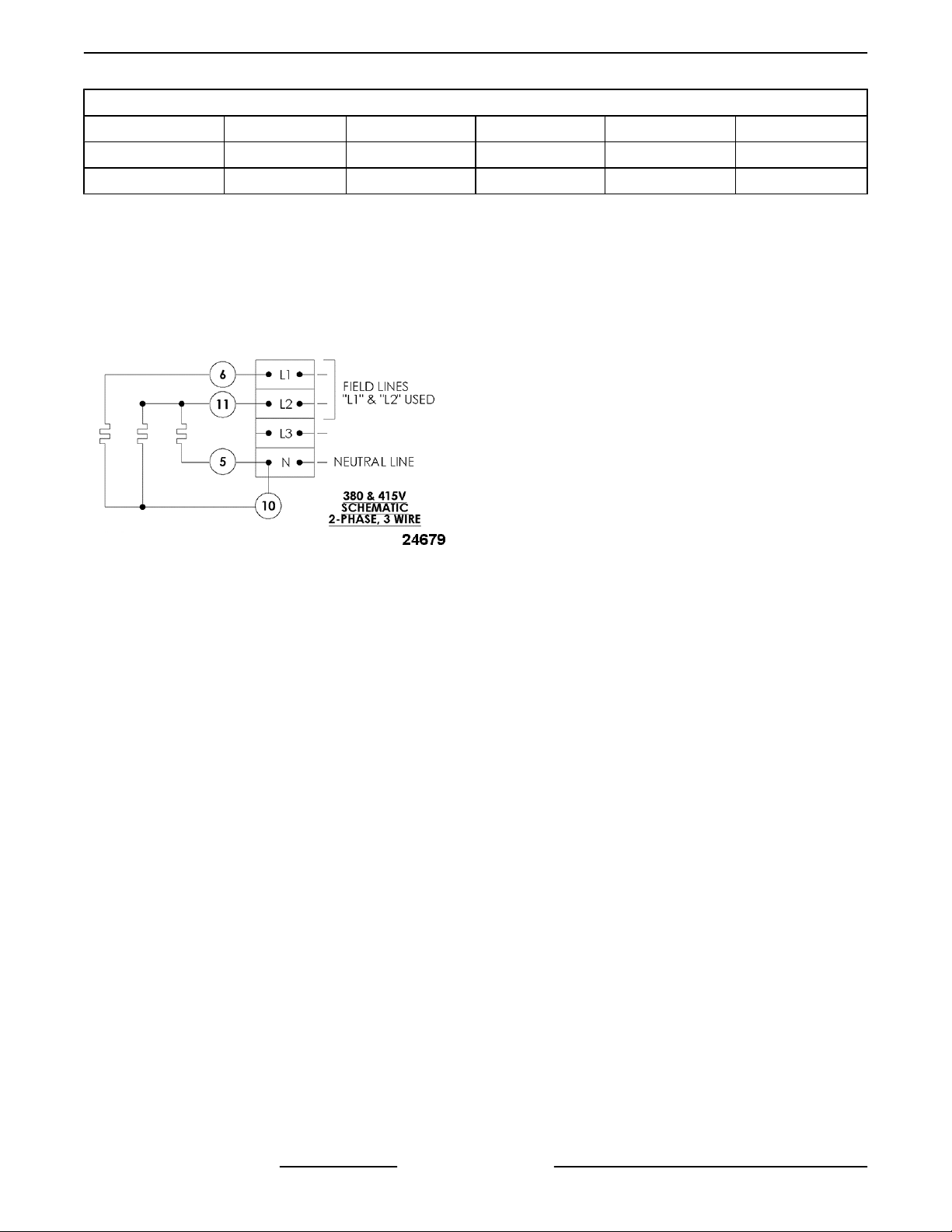

2 PHASE, 3 WIRE

1 & 3 PHASE

220/380 & 240/415 VAC. 2-PHASE, 3 WIRE

L1-N L2-N L3-N

kW PER LINE 5.4 10.8 0.0

Page 15 of 27 F45490 Rev. A (0315)

Page 16

HEG / WEG / RRE Series Griddle - ELECTRICAL OPERATION

NOMINAL AMPS PER LINE

L1 L2 L3 N TOTAL kW

220/380 6.9 6.9 0.0 4.6 13.6

240/415 7.5 7.5 0.0 5.0 16.2

FOR 2-PHASE, 3 WIRE:

1. Connect wire #5 & #10 to neutral ("N").

2. Connect wire #6 to L1.

3. Connect wire #11 to L2.

2 PHASE, 3 WIRE

F45490 Rev. A (0315) Page 16 of 27

Page 17

HEG / WEG / RRE Series Griddle - ELECTRICAL OPERATION

48" WIRING DIAGRAM

48" WIRING DIAGRAM

Notes:

1. For supply connections, use copper wire sized in accordance with the national electrical code and suitable for

at least 90°C (194°F).

2. Lead marker numbers are the same as lead item numbers unless otherwise specified.

3. Wiring to be:

A. 10G,m 532515 - leads 1, 4, 8 - 13, J, J2 and GRD.

B. 18GA., 532518 - leads 2 and 3.

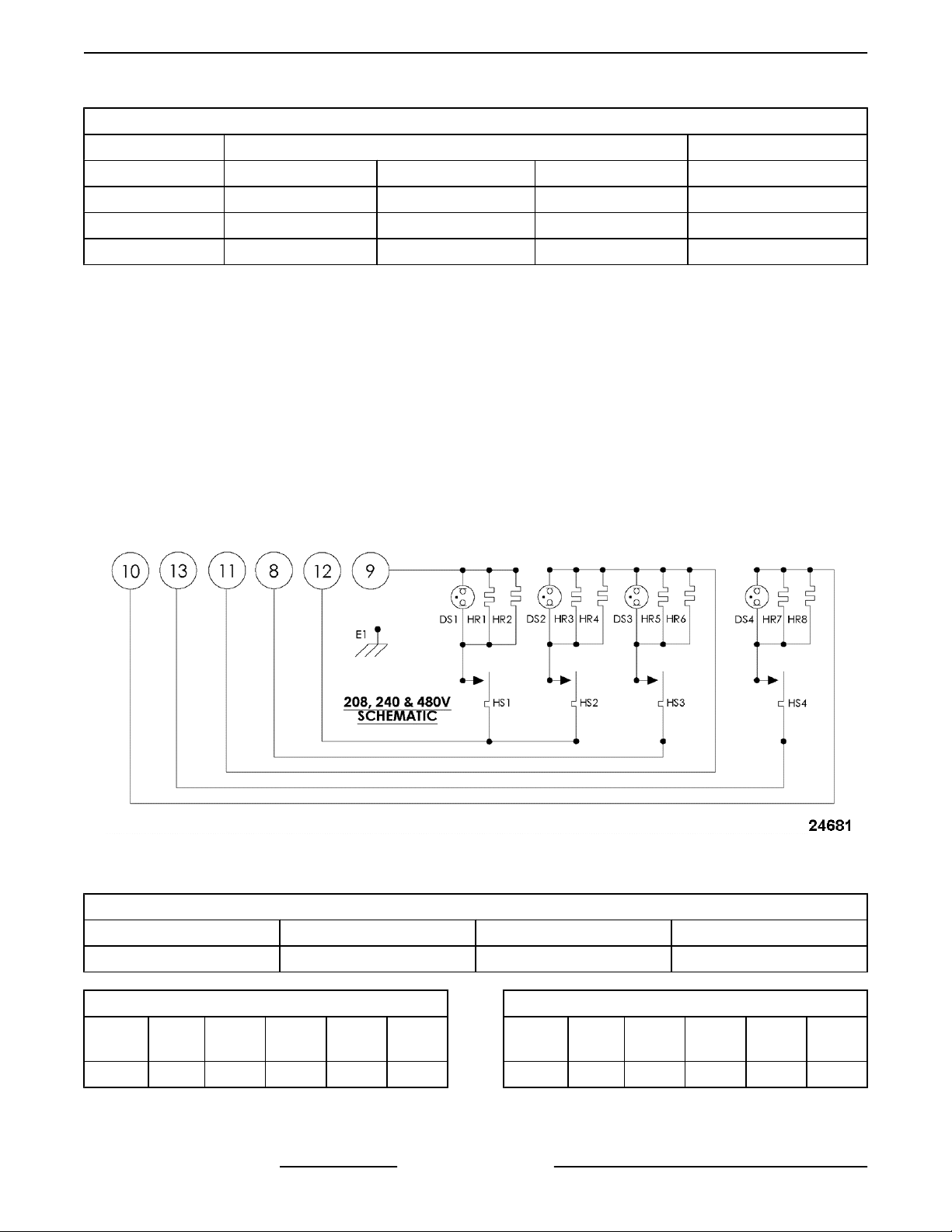

48" SCHEMATIC

1 & 3 PHASE

208, 240, & 480 VAC, 1 & 3 PHASE

X-Y Y-Z X-Z TOTAL

kW PER LINE 10.8 5.4 5.4 21.6

Page 17 of 27 F45490 Rev. A (0315)

Page 18

HEG / WEG / RRE Series Griddle - ELECTRICAL OPERATION

X Y Z -

208 67.4 67.4 45.0 103.8

240 58.5 58.5 39.0 90.0

480 29.2 29.2 19.5 45.0

FOR 3-PHASE:

1. Connect wire #10 & #11 to L1.

2. Connect wire #8, #9 & #13 to L2.

3. Connect wire #12 to L3.

FOR 1-PHASE:

1. Connect wire #8, #12 & #13 to L1.

NOMINAL AMPS PER LINE

3-PHASE 1-PHASE

2. Connect wire #9, #10 & #11 to L2.

3 PHASE, 4 WIRE

220/380 & 240/415 VAC. 3-PHASE, 4 WIRE

L1-N L2-N L3-N

kW PER LINE 10.8 5.4 5.4

NOMINAL AMPS PER LINE

L1 L2 L3 N

220/380 13.8 12.0 12.0 3.7 18.2

TOTAL

kW

1 & 3 PHASE

240/415 15.0 13.1 13.1 4.0 21.6

NOMINAL AMPS PER LINE

L1 L2 L3 N

TOTAL

kW

F45490 Rev. A (0315) Page 18 of 27

Page 19

HEG / WEG / RRE Series Griddle - ELECTRICAL OPERATION

FOR 3-PHASE, 4 WIRE:

1. Connect wire #9, #10 & #11 to neutral ("N").

2. Connect wire #12 to L1.

3. Connect wire #8 to L2.

4. Connect wire #13 to L3.

3-PHASE, 4 WIRE

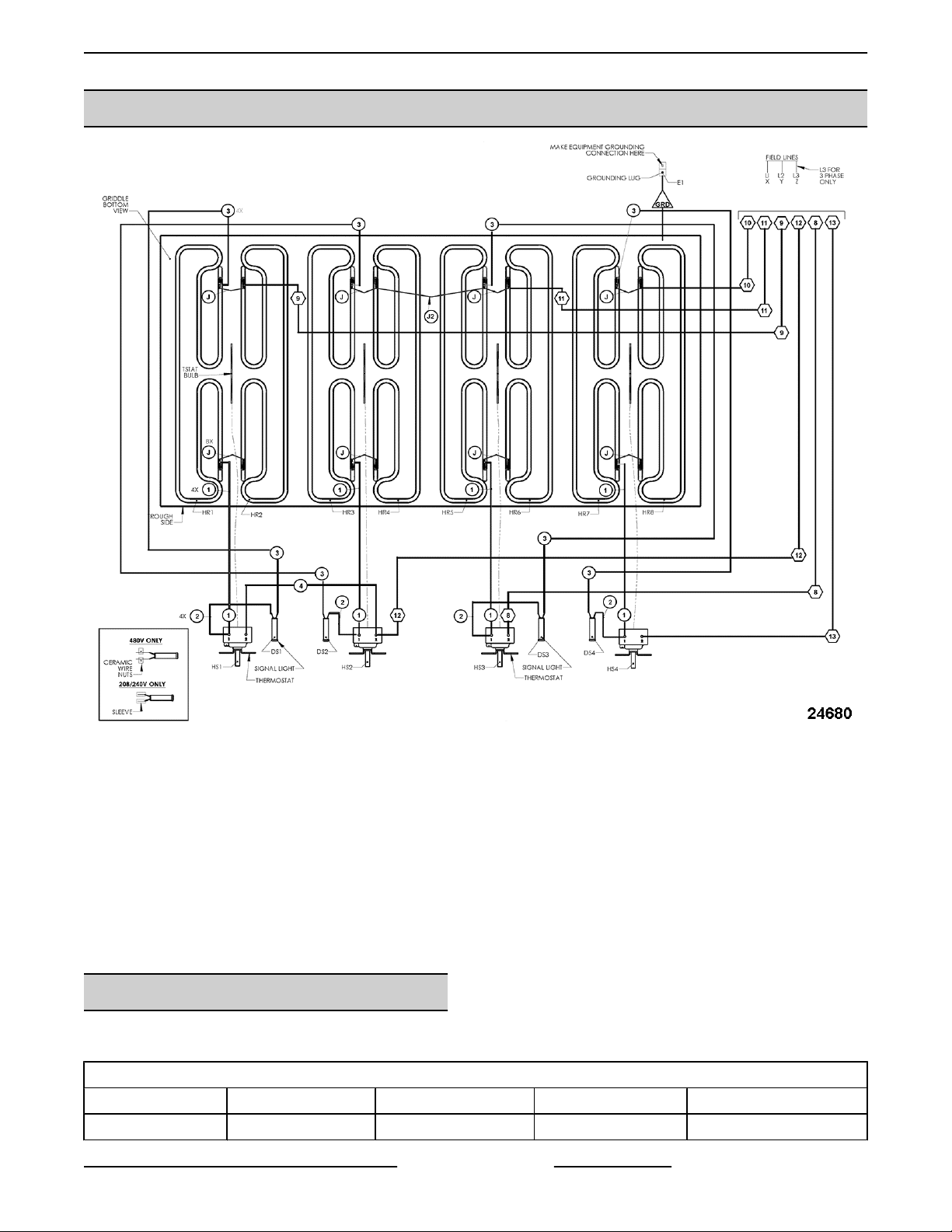

60" WIRING DIAGRAM

60" WIRING DIAGRAM

Page 19 of 27 F45490 Rev. A (0315)

Page 20

HEG / WEG / RRE Series Griddle - ELECTRICAL OPERATION

Notes:

1. For supply connections, use copper wire sized in accordance with the national electrical code and suitable for

at least 90°C (194°F).

2. SERVICING ONLY

Each half of this griddle is wired separately and terminates in its own junction box. Each junction box requires

a separate fused branch circuit power supply as the griddle is not fused. Both power sources have to be

disconnected before servicing the device.

3. Lead marker numbers are the same as lead item numbers unless otherwise specified.

4. Wiring to be:

A. 10G,m 532515 - leads 1, 4, 8, 10, 12, 15 - 18, J, J2 and GRD.

B. 18GA., 532518 - leads 2 and 3.

60" SCHEMATIC

1 & 3 PHASE

208, 240, & 480 VAC, 1 & 3 PHASE

X-Y Y-Z X-Z TOTAL

kW PER LINE

LEFT 5.4 0 5.4 10.8

RIGHT 5.4 5.4 5.4 16.2

LEFT 45.0 22.5 22.5 51.9

208

RIGHT 45.0 45.0 45.0 77.9

LEFT 39.0 19.5 19.5 45.0

240

RIGHT 39.0 39.0 39.0 67.5

LEFT 19.5 9.7 9.7 22.5

480

RIGHT 19.5 19.5 19.5 33.8

FOR 3-PHASE:

1. Connect wire #18 to L1.

2. Connect wire #16 to L2.

3. Connect wire #15 to L3.

FOR 1-PHASE:

NOMINAL AMPS PER LINE

3-PHASE 1-PHASE

X Y Z -

LEFT JUNCTION BOX PHASE WIRING:

1. Connect wire #15 & #16 to L1.

2. Connect wire #18 to L2.

F45490 Rev. A (0315) Page 20 of 27

Page 21

HEG / WEG / RRE Series Griddle - ELECTRICAL OPERATION

FOR 3-PHASE:

1. Connect wire #8 & #10 to L1.

2. Connect wire #17 to L2.

3. Connect wire #12 to L3.

FOR 1-PHASE:

1. Connect wire #10 & #12 to L1.

2. Connect wire #8 & #17 to L2.

RIGHT JUNCTION BOX PHASE WIRING:

2 PHASE, 3 WIRE

kW PER LINE

220/380

240/415

1 & 3 PHASE

220/380 & 240/415 VAC. 2-PHASE, 3 WIRE

L1-N L2-N L3-N

LEFT 5.4 5.4 0.0

RIGHT 5.4 10.8 0.0

NOMINAL AMPS PER LINE

L1 L2 L3 N TOTAL kW

LEFT 5.2 5.2 0.0 3.4 9.1

RIGHT 6.9 6.9 0.0 4.6 13.6

LEFT 5.6 5.6 0.0 3.8 10.8

RIGHT 7.5 7.5 0.0 5.0 16.2

Page 21 of 27 F45490 Rev. A (0315)

Page 22

HEG / WEG / RRE Series Griddle - ELECTRICAL OPERATION

LEFT JUNCTION BOX PHASE WIRING

1. Connect wire #18 to neutral (N).

2. Connect wire #16 to L1.

3. Connect wire #15 to L2.

RIGHT JUNCTION BOX PHASE WIRING

1. Connect wire #8 & #10 to neutral (N).

2. Connect wire #12 to L1.

3. Connect wire #17 to L2.

2-PHASE, 3 WIRE

72" WIRING DIAGRAM

72" WIRING DIAGRAM

F45490 Rev. A (0315) Page 22 of 27

Page 23

HEG / WEG / RRE Series Griddle - ELECTRICAL OPERATION

Notes:

1. For supply connections, use copper wire sized in accordance with the national electrical code and suitable for

at least 90°C (194°F).

2. SERVICING ONLY

Each half of this griddle is wired separately and terminates in its own junction box. Each junction box requires

a separate fused branch circuit power supply as the griddle is not fused. Both power sources have to be

disconnected before servicing the device.

3. Lead marker numbers are the same as lead item numbers unless otherwise specified.

4. Wiring to be:

A. 10G,m 532515 - leads 1, 4, 8, 10, 11, 15 - 19, J, J2 and GRD.

B. 18GA., 532518 - leads 2 and 3.

72" SCHEMATIC

1 & 3 PHASE

208, 240, & 480 VAC, 1 & 3 PHASE

X-Y Y-Z X-Z TOTAL

kW PER LINE

LEFT 5.4 5.4 5.4 16.2

RIGHT 5.4 5.4 5.4 16.2

LEFT 45.0 45.0 45.0 77.9

208

RIGHT 45.0 45.0 45.0 77.9

LEFT 39.0 39.0 39.0 67.5

240

RIGHT 39.0 39.0 39.0 67.5

LEFT 19.5 19.5 19.5 33.8

480

RIGHT 19.5 19.5 19.5 33.8

FOR 3-PHASE:

1. Connect wire #16 & #11 to L1.

2. Connect wire #15 to L2.

3. Connect wire #18 to L3.

FOR 1-PHASE:

NOMINAL AMPS PER LINE

3-PHASE 1-PHASE

X Y Z -

LEFT JUNCTION BOX PHASE WIRING:

1. Connect wire #11 & #18 to L1.

2. Connect wire #16 & #15 to L2.

Page 23 of 27 F45490 Rev. A (0315)

Page 24

HEG / WEG / RRE Series Griddle - ELECTRICAL OPERATION

FOR 3-PHASE:

1. Connect wire #8 & #10 to L1.

2. Connect wire #17 to L2.

3. Connect wire #19 to L3.

FOR 1-PHASE:

1. Connect wire #10 & #19 to L1.

2. Connect wire #8 & #17 to L2.

RIGHT JUNCTION BOX PHASE WIRING:

1 & 3 PHASE

2 PHASE, 3 WIRE

220/380 & 240/415 VAC. 2-PHASE, 3 WIRE

L1-N L2-N L3-N

kW PER LINE

LEFT 6.9 6.9 0.0 4.6 13.6

220/380

RIGHT 6.9 6.9 0.0 4.6 13.6

LEFT 7.5 7.5 0.0 5.0 16.2

240/415

RIGHT 7.5 7.5 0.0 5.0 16.2

F45490 Rev. A (0315) Page 24 of 27

LEFT 5.4 10.8 0.0

RIGHT 5.4 10.8 0.0

NOMINAL AMPS PER LINE

L1 L2 L3 N TOTAL kW

Page 25

HEG / WEG / RRE Series Griddle - ELECTRICAL OPERATION

LEFT JUNCTION BOX PHASE WIRING

1. Connect wire #11 & #18 to neutral (N).

2. Connect wire #16 to L1.

3. Connect wire #15 to L2.

RIGHT JUNCTION BOX PHASE WIRING

1. Connect wire #19 & #10 to neutral (N).

2. Connect wire #8 to L1.

3. Connect wire #17 to L2.

2-PHASE, 3 WIRE

Page 25 of 27 F45490 Rev. A (0315)

Page 26

HEG / WEG / RRE Series Griddle - TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

Troubleshooting Guide

PROBLEM POSSIBLE CAUSES

1. Main power supply disconnected.

Heat does not come on when the temperature controller

is turned on.

Fat appears to smoke excessively.

Food sticks to griddle or burned around edges or contains

dark specs.

Food under-cooked inside.

Food tastes greasy or has objectionable off-flavor.

Noticeable build-up of gum on griddle.

2. Problem with thermostats. Refer to THERMOSTAT

REPLACEMENT.

3. Problem with heating elements. Refer to HEATING

ELEMENT REPLACEMENT.

1. Temperature set too high.

2. Moisture in food may be turning into steam.

1. Temperature set too high.

2. Griddle surface requires cleaning and/or seasoning.

3. Surface under food not covered with enough

cooking oil.

1. Temperature set too low.

2. Food not cooked for long enough time.

1. Food itself may have off-flavor.

2. Food stored improperly before cooking.

3. Too much griddle fat used.

4. Temperature set too low.

1. Temperature set too high.

2. Griddle surface needs cleaning and/or seasoning.

3. Too much griddle fat used.

1. No power to the machine. Circuit breaker tripped.

Griddle does not heat. (Indicator light does not glow).

Griddle does not heat. (Indicator light glows).

Hot and cold spots controlled by the same thermostat.

F45490 Rev. A (0315) Page 26 of 27

2. Thermostat inoperative. Refer to THERMOSTAT

Heating element(s) inoperative. Refer to HEATING

ELEMENT REPLACEMENT.

1. Uneven loading patterns.

2. Heating element(s) not clamped tight to griddle

3. Different voltage heating elements.

4. Heating elements inoperative. Refer to HEATING

5. Air drafts on griddle plate.

REPLACEMENT.

plate. Refer to HEATING ELEMENT

REPLACEMENT.

ELEMENT REPLACEMENT.

Page 27

HEG / WEG / RRE Series Griddle - TROUBLESHOOTING

Troubleshooting Guide

PROBLEM POSSIBLE CAUSES

Too hot in area controlled by the same thermostat.

Too cold in area controlled by the same thermostat.

1. Incorrect voltage supply.

2. Thermostat bulb not clamped tight to griddle plate.

Refer to CAPILLARY BULB INSTALLATION.

3. Thermostat not calibrated correctly. Refer to

THERMOSTAT CALIBRATION PROCEDURES.

1. Incorrect voltage supply.

2. Thermostat not calibrated correctly. Refer to

THERMOSTAT CALIBRATION PROCEDURES.

Page 27 of 27 F45490 Rev. A (0315)

Loading...

Loading...