Page 1

SERVICE MANUAL

ENDURANCE SERIES

GAS RANGES

MODELS

G36 G36C

G60 G60C

G260 G260C

G481 G481C

- NOTICE -

This manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qualified. If you have attended a Vulcan Service School for this

product, you may be qualified to perform all the procedures

described in this manual.

This manual is not intended to be all encompassing. If you have

not attended a Vulcan Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Vulcan Service Technician.

Reproduction or other use of this Manual, without the express

written consent of Vulcan, is prohibited.

For additional information on Vulcan-Hart or to locate an authorized parts and

service provider in your area, visit our website at www.vulcanhart.com

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

WWW.VULCANHART.COM

3600 NORTH POINT BLVD.

BALTIMORE, MD 21222

F35648 (May 2005)

Page 2

ENDURANCE SERIES GAS RANGES

TABLE OF CONTENTS

GENERAL ............................................................................................................................................................... 3

Introduction ...................................................................................................................................................... 3

Installation........................................................................................................................................................ 3

Operation......................................................................................................................................................... 3

Cleaning .......................................................................................................................................................... 3

Lubrication ....................................................................................................................................................... 3

Specifications................................................................................................................................................... 3

Tools ................................................................................................................................................................ 3

REMOV AL AND REPLACEMENT OF P AR TS............................................................................................... .......... 4

Covers and Panels........................................................................................................................................... 4

Oven Manifold Cover (Models 60, 260, and 481)...................................................................................... 4

Oven Control Panel (Model 36) ............................................................................................................... 4

Broiler Manifold Cover .............................................................................................................................. 5

Kick Panel Assembly ................................................................................................................................ 5

St andard Oven Control V alve/Thermocouple ................................................................................................... 6

Model 36 Only .......................................................................................................................................... 6

Model 60, 260, and 481 ............................................................................................................................ 7

Oven Pilot Assembly ........................................................................................................................................ 8

Oven Burner Assembly .................................................................................................................................... 8

Convection Oven Control V alve/Thermocouple Pilot........................................................................................ 9

Oven Burner Nozzle and Orifice..................................................................................................................... 10

Pilot V alve and Quick Disconnect Valve ......................................................................................................... 10

Top Section Burner Valve............................................................................................................................... 11

Switch Replacement ...................................................................................................................................... 11

Motor Replacement.............................................................................................................. .......................... 11

Convection Oven Solenoid............................................................................................................................. 12

SERVICE PROCEDURES AND ADJUSTMENTS ................................................................................................. 13

Pilot Flame Height.......................................................................................................................................... 13

Top Burners ............................................................................................................................................ 13

Broiler/Griddle................................................................................................................

Air Shutter Adjustment ................................................................................................................................... 13

Oven Burner Adjustment................................................................................................................................ 13

Regulator Check ............................................................................................................................................ 14

Regulator Adjustment..................................................................................................................................... 14

Oven Burner Nozzle and Orifice Check.......................................................................................................... 15

Convection Oven Motor and Door Switch Check ........................................................................................... 15

Convection Oven Solenoid Check.................................................................................................................. 16

ELECTRICAL OPERA TION................................................................................................................................... 18

Component Function...................................................................................................................................... 18

Sequence of Operation .................................................................................................................................. 18

Schematic Diagram........................................................................................................................................ 19

Wiring Diagrams ............................................................................................................................................ 20

Double Oven 120 Volt Endurance Convection Range (Drawing 1 of 2) .................................................. 20

Double Oven 120 Volt Endurance Convection Range (Drawing 2 of 2) .................................................. 21

TROUBLESHOOTING .......................................................................................................................................... 22

CONDENSED SP ARE PARTS LIST...................................................................................................................... 23

©VULCAN 2005

......................... 13

F35425 (October 2005) Page 2 of 23

Page 3

ENDURANCE SERIES GAS RANGES - GENERAL

GENERAL

INTRODUCTION

Procedures in this manual will apply to all models

unless specified. Pictures and illustrations can be of

any model unless the picture or illustration needs to

be model specific.

INSTALLATION

Refer to the Installation and Operation Manual for

detailed installation instructions on ranges.

OPERATION

Refer to the Installation and Operation Manual for

specific operating instructions.

CLEANING

Refer to the Installation and Operation Manual for

specific cleaning instructions.

LUBRICATION

The blower motor has sealed bearings and requires

no additional lubrication.

TOOLS

Standard

• S tandard set of hand tools.

• VOM with A.C. current tester (Any quality VOM

with a sensitivity of at lease 20,000 ohms per

volt can be used).

• Gear puller to remove blower .

Special

• Temperature tester (thermocouple type).

• Manometer .

SPECIFICATIONS

Electrical (Convection ranges only)

• V oltage - 120/60/1 or 240/60/1 (optional)

• Amps - 15 Amps

• Frequency - 50/60 Hz

Gas Line Pressures

• Natural - Recommended (in. W .C.) 7.0, min 5.0

•

Propane - Recommended (in. W .C.) 11.0, min 11.0

Maximum 14.0 in. W .C. (Nat. or Prop.)

Orifice Size Requirements for Different Elevations for Restaurant Range

OPEN TOP GRIDDLE BRO/GRID OVEN OVEN

(STD) (CON)

INPUT A T SEA LEVEL

PER BURNER (BTU’S)

ORIFICE SIZE NA T/PROP NA T/PROP NA T/PROP NA T/PROP NA T/PROP

SEA LEVEL T O 36/51 (32000) 50/57 53/63 33/51 33/51

2499 FT

2499 FT TO 40/53 (32000) 51/57 54/65 37/52 37/52

4499 FT 37/52 (35000)

4500 FT TO 41/53 (32000) 51/58 54/65 38/52 38/52

6499 FT 38/52 (35000)

6500 FT TO 42/53 (32000) 52/59 55/66 40/53 40/53

8499 FT 40/53 (35000)

32000/35000 15,000 10,000 35,000 35,000

33/1.75MM

(35000)

8500 FT TO 42/54 (32000) 52/60 55/67 41/53 41/53

10,500 FT 41/53 (35000)

F35425 (October 2005)Page 3 of 23

Page 4

ENDURANCE SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

COVERS AND P ANELS

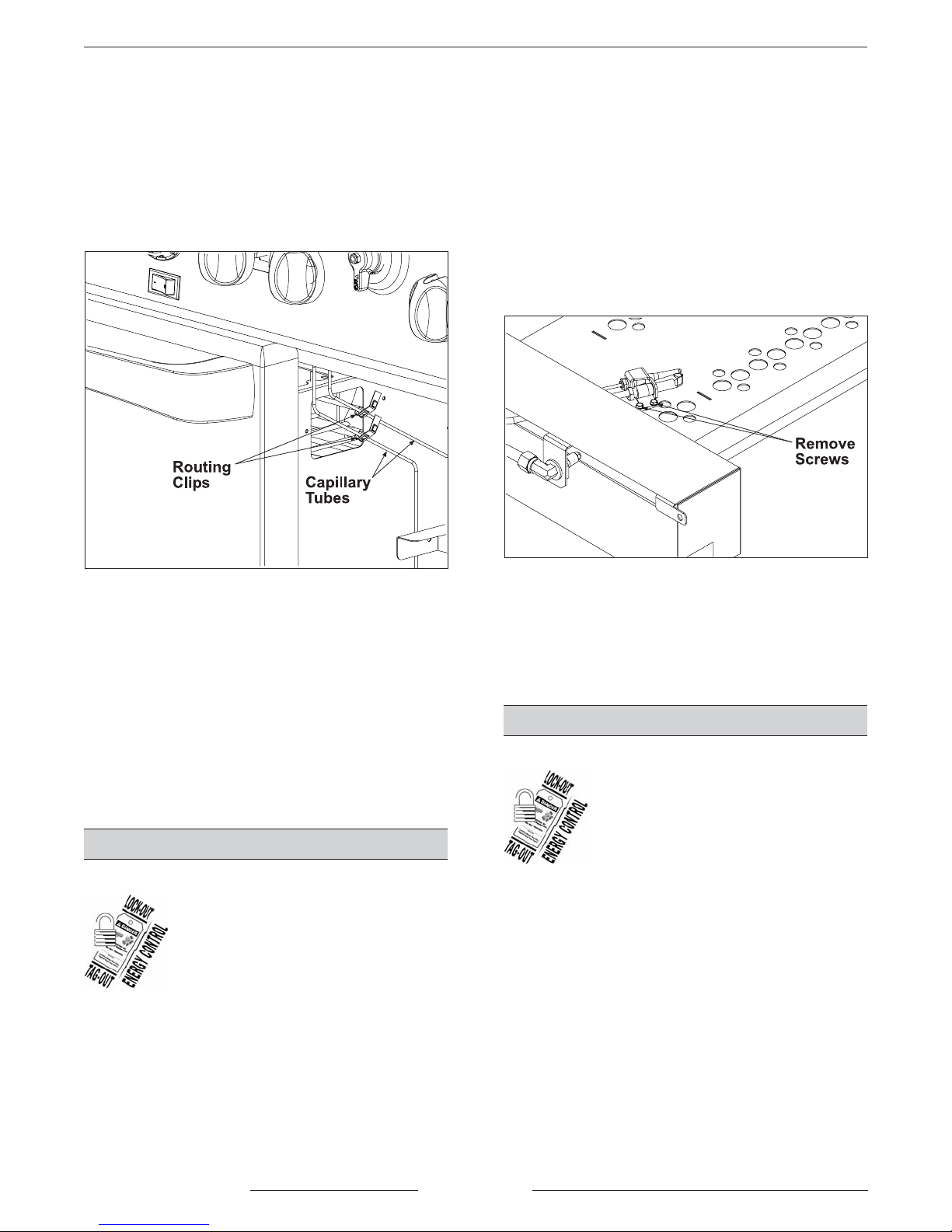

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

T AGOUT PROCEDURES.

Oven Manifold Cover (Models 60, 260, and 481)

1. Rotate the yellow gas shut-off valve to the OFF

position and allow range to cool.

3. Remove screws holding manifold cover in place

and remove manifold cover.

2.

Loosen the setscrew in the side of the burner

control knobs and oven control knob and remove

knobs.

4. Reverse the procedure to install the oven

manifold cover .

Oven Control Panel (Model 36)

1. Rotate the yellow gas shut-off valve to the OFF

position and allow range to cool.

F35425 (October 2005) Page 4 of 23

2. Remove the red oven control valve knob from

the control valve.

3. Open the kick plate at the bottom of the range.

Page 5

ENDURANCE SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

4. Remove the screw securing the oven control

panel and remove the panel.

3. Remove screws holding manifold cover in place

and remove broiler manifold cover .

4. Reverse the procedure to install the broiler

manifold cover .

5.

Reverse the procedure to install the oven control

panel.

Broiler Manifold Cover

1. Rotate the yellow gas shut-off valve to the OFF

position and allow range to cool.

2. Loosen the setscrew in the side of the burner

control knobs and remove knobs.

Kick Panel Assembly

1. Open kick panel.

2. Remove two screws securing left hinge and

remove hinge.

3. Slide kick plate to the left to disengage from left

hinge.

4. Reverse the procedure to install the kick plate

assembly.

F35425 (October 2005)Page 5 of 23

Page 6

ENDURANCE SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

STANDARD OVEN CONTROL

VALVE/THERMOCOUPLE

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

T AGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN

OPEN FLAME.

3. Remove the two screws attaching the bracket to

the thermocouple.

Model 36

The oven control valve is located to the front left of

the oven.

1. Remove the oven control panel as outlined

under P ANELS AND COVERS.

2. Remove the three bracket screws attaching the

thermocouple valve mounting bracket to the

range.

4. Open the oven door .

5. Remove capillary tube from all routing clips.

NOTE: When straightening the capillary tube be sure

not to place kinks in tubing.

F35425 (October 2005) Page 6 of 23

Page 7

ENDURANCE SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

6. Slide the capillary tube out of the bracket and

straighten the tube so that it can be passed

through the hole in the oven sidewall.

7. Carefully slide the capillary tube through the

hole in the oven sidewall.

8. Disconnect the gas input to the control valve.

Model 60, 260, and 481

The control valves are located behind the oven

manifold cover .

9. Disconnect the pilot tubing.

10. Disconnect the control valve burner tubing.

1 1. Remove the control valve assembly from the

oven.

12. Reverse the procedure to install a new control

valve assembly .

NOTE: During installation do not kink the new

capillary tube when feeding it through the hole in the

side of the oven cavity . Excess tubing can be loosely

wrapped.

1. Remove the oven manifold cover as outlined

under COVERS AND PANELS.

2. Remove top burner grates and deflector ,

if necessary , to access the control valve.

3. Disconnect the pilot tubing from the control

valve.

4. Remove two screws securing the control valve

to the manifold.

F35425 (October 2005)Page 7 of 23

Page 8

ENDURANCE SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

5. Remove the kick plate as outlined under

COVERS AND PANELS.

The oven pilot assembly is attached to the burner

assembly behind the kick plate.

NOTE: Do not kink the capillary tube when straightening the tubing for removal.

6. Slide the capillary tube and thermocouple out of

the bracket and straighten the tube so that it can

be passed through the holes in the oven liner .

7. Remove the capillary tube from all routing clips.

1. Remove the kick plate as outlined under

COVERS AND PANELS.

2. Remove the oven rack.

3. Remove the oven bottom.

4. Remove the oven left and right liner .

5. Remove the oven bottom heat shield.

6. Remove the screws securing oven pilot

assembly to the burner assembly .

8. Carefully slide the capillary tube and

thermocouple through the holes in the oven.

9. Remove the control valve, capillary tube, and

thermocouple from the unit.

10. Reverse the procedure to install a new control

valve assembly .

NOTE: During installation do not kink the new

capillary tube when feeding it through the holes in the

oven. Excess tubing can be loosely wrapped.

OVEN PILOT ASSEMBLY

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

T AGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

7. Pull the pilot assembly out through the front of

oven.

8. Reverse the procedure to install the oven pilot

assembly.

OVEN BURNER ASSEMBLY

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

T AGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN

OPEN FLAME.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN

OPEN FLAME.

F35425 (October 2005) Page 8 of 23

The oven burner assembly is located behind the

kick plate.

1. Remove the oven pilot assembly as outlined

under OVEN PILOT ASSEMBLY .

Page 9

ENDURANCE SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

2. Remove the two screws securing the oven

burner assembly .

3. Disconnect gas line to the burner.

4. Pull the oven burner assembly out of the oven.

5. Reverse the procedure to install a new oven

burner assembly .

CONVECTION OVEN CONTROL

VALVE/THERMOCOUPLE PILOT

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

T AGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN

OPEN FLAME.

5. Remove the kick plate as outlined under

COVERS AND PANELS.

NOTE: Do not kink the capillary tube when straightening the tubing for removal.

6. Slide the capillary tube and thermocouple out of

the bracket and straighten the tube so that it can

be passed through the holes in the oven liner .

7. Remove the capillary tube from all routing clips.

The control valve is located behind the oven manifold

cover.

1. Remove the oven manifold cover as outlined

under COVERS AND PANELS.

2. Remove top burner grates and deflector ,

if necessary , to access the control valve.

3. Disconnect the pilot tubing.

4. Remove the two screws securing the control

valve to the manifold.

8. Carefully slide the capillary tube and

thermocouple through the holes in the oven.

9. Remove the control valve, capillary tube and

thermocouple from the unit.

10. Reverse the procedure to install a new control

valve assembly .

NOTE: During installation do not kink the new

capillary tube when feeding it through the holes in the

oven. Excess tubing can be loosely wrapped.

F35425 (October 2005)Page 9 of 23

Page 10

ENDURANCE SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

OVEN BURNER NOZZLE

AND ORIFICE

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

T AGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN

OPEN FLAME.

The oven burner nozzle is mounted between the

oven gas supply tubing and the u-burner assembly .

1. Turn off the burners.

2. Disconnect the unit from gas flow and allow to

cool completely .

3. Remove the kick plate as outlined under

COVERS AND PANELS.

4. Remove the burner nozzle.

PILOT VALVE AND

QUICK DISCONNECT VALVE

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

T AGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN

OPEN FLAME.

The pilot valve for the griddle burners is mounted on

the gas supply manifold located behind the griddle

control panel.

1. Remove the oven manifold cover as outlined

under COVERS AND PANELS.

2. Remove top burner grates and deflector, if

necessary , to access the pilot valve.

3. Disconnect the pilot tubing from the holder .

5. Check for blockage or damage.

6. Reverse the procedure to install the burner

nozzle.

4. Disconnect the holder from the pilot valve.

5. Remove the pilot valve from the manifold.

6. Reverse the procedure to install a new pilot

valve.

F35425 (October 2005) Page 10 of 23

Page 11

ENDURANCE SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

TOP SECTION BURNER

CONTROL VALVE

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

T AGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

3. Disconnect wiring from the switch.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN

OPEN FLAME.

1. Remove the oven manifold cover as outlined

under COVERS AND PANELS.

2. Allow the range to cool completely .

3. Remove the burner grates and deflectors,

if necessary .

4.

Remove the griddle plate assembly , if necessary.

5. Remove the burner mounting screws.

6. Carefully move the burner assembly away from

the burner control valve.

7.

Remove the burner control valve from the manifold.

8. Clean the manifold of any thread sealant.

9. Inspect the control valve for wear and damage,

replace as necessary .

10. Reverse the procedure to install a new burner

control valve.

4. Remove the switch from mounting.

5. Reverse the procedure to install the

replacement switch.

MOTOR REPLACEMENT

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

T AGOUT PROCEDURES.

NOTE: A centrifugal switch is mounted inside the

motor assembly . If electrical volt age is available to

the motor , the motor and switch must be replaced.

1. Remove cover from the motor junction box.

NOTE: Apply a light coat of thread sealant to the

control valve threads before installing the burner

control valve in the manifold.

SWITCH REPLACEMENT

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

T AGOUT PROCEDURES.

1. Remove the oven manifold cover as outlined

under COVERS AND PANELS.

2. Allow the range to cool completely.

2. Disconnect motor wiring at the junction box.

3. If necessary , remove the motor guard.

F35425 (October 2005)Page 11 of 23

Page 12

ENDURANCE SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

4. Inside the oven remove the hex head bolts and

spacers attaching the motor grate to the motor

mounting plate and remove the motor grate.

CONVECTION OVEN SOLENOID

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

T AGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS BEFORE

SERVICING THE UNIT.

WARNING: ALL GAS JOINTS DISTURBED

DURING SERVICING MUST BE CHECKED FOR

LEAKS. CHECK WITH A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN

OPEN FLAME.

1. Disconnect gas supply to the range.

2. Disconnect the solenoid electrical connectors.

5. Remove the motor and rotor blower assembly

from inside the oven.

6. Remove the fan from the motor.

7. Remove motor from motor mounting plate.

8. Reverse the procedure to install a new motor.

3. Disconnect gas supply lines from both sides of

the solenoid.

4. Remove solenoid mounting screws and

solenoid.

5. Reverse the procedure to install the

replacement solenoid.

F35425 (October 2005) Page 12 of 23

Page 13

ENDURANCE SERIES GAS RANGES - REMOVAL AND REPLACEMENT OF PARTS

SERVICE PROCEDURES AND ADJUSTMENTS

WARNING: CERTAIN PROCEDURES IN THIS SECTION REQUIRE ELECTRICAL TEST OR MEASURE-

MENTS WHILE POWER IS APPLIED TO THE MACHINE. EXERCISE EXTREME CAUTION AT ALL

TIMES. IF TEST POINTS ARE NOT EASILY ACCESSIBLE, DISCONNECT POWER AND FOLLOW

LOCKOUT / TAGOUT PROCEDURES, ATTACH TEST EQUIPMENT AND REAPPLY POWER TO TEST.

PILOT FLAME HEIGHT

Top Burners

To adjust the pilot flame height of the top burners,

locate the pilot adjustment screws found on the front

manifold pipe. It is not necessary to remove the

manifold cover as adjustment access holes have

been provided in the panel.

1. Locate the pilot adjustment screw located

behind the adjustment access hole in the panel.

2. Rotate the screw clockwise to decrease and

counterclockwise to increase the flame height.

streaming flame on the burner is an indication of

insufficient air . To correct this condition, rotate the air

shutter open until the burner flame begins to lift from

the burner , then close the shutter slightly.

OVEN BURNER ADJUSTMENT

All Endurance Range series units equipped with a

pressure regulator and fixed orifices have been

adjusted at the factory and should require no further

adjustments. However , the ef ficiency of the range

depends on a delicate balance between the air

supply and the volume of gas. Whenever this

balance is disturbed, poor operating characteristics

and excessive gas consumption will occur. An air

shutter on the front of the oven burner controls the

gas mixer balance.

Broiler/Griddle

To adjust pilot flame height of broiler/griddle, locate

the pilot adjustment screws found on the broiler/

griddle manifold pipe. It is not necessary to remove

the manifold cover, as adjustment access holes have

been provided in the panel.

1. Locate the pilot adjustment screw located

behind the adjustment access hole in the panel.

2. Rotate the screw clockwise to decrease and

counterclockwise to increase the flame height.

AIR SHUTTER ADJUSTMENT

The efficiency of the oven depends on a delicate

balance between the air supply and the volume of

gas. Whenever this balance is disturbed, poor

operating characteristics and excessive gas consumption will occur. An air shutter on the front of the

oven burner controls the gas mixer balance. A yellow

F35425 (October 2005)Page 13 of 23

Page 14

ENDURANCE SERIES GAS RANGES - SERVICE PROCEDURES AND ADJUSTMENTS

A yellow streaming flame on the burner is an indication of insufficient air. To correct this condition, open

the air shutter until the burner flame begins to lift

from the burner, then close the shutter slightly and

lock into place.

REGULATOR CHECK

A gas regulator is mounted between the gas service

outlet and the appliance.

5. With regulator reading 7.0" W.C. (natural gas)

or 1 1.0" W.C. (propane gas), turn on two top

burners.

6. Check regulator pressure reading. The reading

should be steady ± 0.10". If fluctuation in excess

of ±0.10" occurs replace the regulator .

NOTE: If pressure readings climb to limits shown in

step 4 with the burners OFF, check the leak (vent)

limit device for obstruction. Check the regulator for

leaks at the leak limiter vent. If vent is leaking,

replace the regulator .

REGULATOR ADJUSTMENT

NOTE: Before adjusting regulator , check incoming gas

line pressure. Incoming pressure must be 7.0" W .C.

for natural gas and 1 1.0" W.C. for propane gas. If

incoming pressure is not correct have the gas source

checked and adjusted as necessary. Make sure the

regulator is mounted in the horizontal position with the

arrow pointing in the direction of gas flow .

1. Connect manometer to the pressure tap

provided on the range gas piping between the

regulator and range.

When servicing the equipment for possible gas

pressure problems, visually check that a regulator is

installed horizontal with the gas flow arrow pointing in

the direction of gas flow.

1. Turn on the range top burners.

2. Observe the burner flames.

A leak (vent) limiting device is inst alled in each

regulator to limit gas leakage if the regulator ruptures.

Do not obstruct the leak limiter (vent). Obstruction may

cause regulator malfunction or failure.

3. Connect the manometer to the pressure tap

provided between the regulator and range

supply piping.

4. Turn on two top burners and note manometer

reading. The reading should be 7.0" W .C. for

natural gas units and 11.0" W.C. for propan e

gas units. If readings are lower , check incoming

gas line pressure.

NOTE: The line pressure should never drop below

5.0" W .C. for natural gas or 11.0" W.C. for propane gas.

The incoming line pressure must be correct for

proper range operation. If line pressure is incorrect

have the gas supply source checked and adjusted.

If line pressure is correct adjust the regulator as

follows.

2. Check manometer reading. The reading should

be 7.0" W.C. for natural gas and 11.0" W.C. for

propane gas.

3. If incoming line pressure is correct, adjust the

regulator. Remove the regulator closing nut.

4. Insert a flat edge screwdriver through the

top of the regulator. Turn the adjusting screw

clockwise to increase pressure and

counterclockwise to decrease pressure.

5. While watching the manometer , turn the

adjusting screw for proper regulator outlet

pressure.

6. Install the regulator closing nut.

F35425 (October 2005) Page 14 of 23

Page 15

ENDURANCE SERIES GAS RANGES - SERVICE PROCEDURES AND ADJUSTMENTS

OVEN BURNER NOZZLE AND

ORIFICE CHECK

The oven burner nozzle is mounted between the

oven gas supply tubing and the u-burner assembly .

If burner operation seems poor and other systems

have been checked, remove the burner nozzle and

check for blockage or damage.

1. Turn off burners and oven.

2. Disconnect unit from gas flow and allow to cool

completely.

3. Remove the kick plate as outlined under

COVERS AND PANELS.

4. Remove the burner nozzle.

5. Check for blockage or damage.

1. Shut off the yellow gas supply knob.

2. Allow the range to cool completely .

3. Disconnect electrical power to the range.

4. Loosen the screws in the sides of the control

valve knobs and remove the knobs.

5. Remove the control panel mounting screws and

the control panel cover .

6. Activate the power switch (see illustration)

several times and check for wear, damage, and

loose wiring connections. Repair connections as

necessary.

7. Connect electrical power to the range.

8. Check power connections for power range (220

volts AC or 120 volt s AC).

9. With the power switch in the ON position, check

for voltage at both switch connections. If no

voltage is available, check power source and

breakers. If voltage is available at switch input

only , replace the switch.

NOTE: Nozzle blockage can be cleaned or nozzle

replaced. Use high-pressure water and tip cleaner to

clean the nozzle. Replace the nozzle if damaged or

blockage cannot be removed. Check nozzle for

correct orifice size and BTU rating. Use a flow meter

(available from Vulcan-Hart Service Parts Depots,

Part #495) to check BTU rate. See flow meter

instructions for proper installation and use.

CONVECTION OVEN MOTOR

AND DOOR SWITCH CHECK

A control switch mounted just below the convection

oven control valve controls the motor.

10. If voltage is available at power switch

connections, remove kick plate as outlined

under COVERS AND PANELS.

1 1. Locate the door switch.

12. Disconnect electrical power to the range.

13.

Inspect the door switch for wear , damage, and

loose or broken connections. Repair as necessary.

14. Place multimeter in the continuity range. Check

for continuity between the switch connections in

the open and closed position. If continuity is not

available replace the switch.

15. If continuity is available with switch closed,

connect electrical power to the range.

16. Place multimeter in appropriate AC range (220

volts AC or 120 volt s AC).

17. Place the power switch in the ON position.

18. Check for voltage at the door switch input

connection. If voltage is not available,

disconnect electrical power and check continuity

between the motor switch and door switch.

Repair wiring as necessary .

19. If input voltage is available, carefully close the

switch (close the door) and check for voltage at

the switch output connection. If voltage is not

available, replace the switch.

20. If output voltage is available, disconnect

electrical power to the range.

21. Remove the cover from the motor electrical

junction box located on the back of the range.

F35425 (October 2005)Page 15 of 23

Page 16

ENDURANCE SERIES GAS RANGES - SERVICE PROCEDURES AND ADJUSTMENTS

22. With the motor switch and door switch in the

closed position, check for voltage at the motor

input connection. If voltage is available, replace

the motor. If volt age is not available, disconnect

electrical power from the range and check

continuity between the door switch output

connection and motor input connection.

Repair as necessary .

CONVECTION OVEN

SOLENOID CHECK

The convection oven solenoid is mounted between the

gas supply and convection oven burner assembly .

1. Remove the kick plate as outlined under

COVERS AND PANELS.

2. Locate the convection oven solenoid.

3. Place the convection oven power switch in the

ON position. An audible click should occur when

the switch is activated. If the solenoid does not

cycle, check for proper voltage and ground at

the solenoid.

4. Place the multimeter in the appropriate AC

range (220 volts AC or 120 volts AC). Check

for voltage at the solenoid. If voltage is not

available, check continuity between the power

switch and solenoid.

5. If voltage is available, shut off electrical power

to the range. Place the multimeter in the

continuity range. Check for continuity between

the solenoid ground connection and a ground.

If continuity is not available, check and repair

ground connections.

6. If continuity is available, remove the solenoid

and check for solenoid orifice obstruction. See

the procedure REMOV AL OF CONVECTION

OVEN SOLENOID for solenoid removal

instructions.

7. Reinstall the solenoid.

F35425 (October 2005) Page 16 of 23

Page 17

- THIS PAGE INTENTIONALLY LEFT BLANK -

F35425 (October 2005)Page 17 of 23

Page 18

ENDURANCE SERIES GAS RANGES - SERVICE PROCEDURES AND ADJUSTMENTS

ELECTRICAL OPERATION

COMPONENT FUNCTION

Power Cord .............................. Connects range to power source.

Solenoid Valve......................... The solenoid is a normally closed valve. The solenoid opens when electrical

voltage flows to the solenoid coil. The coil is grounded on one side and

energized with voltage on the other side. When voltage flows a magnetic field

is created drawing on a spring-loaded plunger . When activated the plunger

opens allowing gas to flow to the burner assembly .

Door Switch ............................. Opens circuit to convection motor and solenoid when oven door is opened.

Single Phase

Convection Oven Motor.......... The convection oven motor circulates overheated air. The motor electrical

circuit is routed through door switches. The door closes the switch and allows

voltage to flow from the door switch to the motor . The motor should operate

with the door closed and shut off when the door is opened.

Junction Box............................ Connection point for electrical wires.

SEQUENCE OF OPERATION

Refer to schematic diagram.

Initial Conditions

1. Conditions.

A. Power switch off.

B. Oven door open.

2. Turn power switch on.

A. Power applied to one side of convection oven motor and one side of solenoid.

B. Power applied to common terminal on door switch.

3. Door switch closed.

A. Power applied to other side of convection oven motor and motor operates.

B. Power applied to other side of solenoid. Solenoid operates and opens gas flow to burner.

4. Door opened.

A. Power removed from solenoid cutting off gas flow.

B. Power is removed from convection oven motor causing motor to stop.

F35425 (October 2005) Page 18 of 23

Page 19

ENDURANCE SERIES GAS RANGES - ELECTRICAL OPERATION

SCHEMATIC DIAGRAM

Double Oven 120 V olt Endurance Convection Range

F35425 (October 2005)Page 19 of 23

Page 20

ENDURANCE SERIES GAS RANGES - ELECTRICAL OPERATION

WIRING DIAGRAMS

Double Oven 120 V olt Endurance Convection Range (Drawing 1 of 2)

F35425 (October 2005) Page 20 of 23

Page 21

ENDURANCE SERIES GAS RANGES - ELECTRICAL OPERATION

Double Oven 120 V olt Endurance Convection Range (Drawing 2 of 2)

F35425 (October 2005)Page 21 of 23

Page 22

ENDURANCE SERIES GAS RANGES - TROUBLESHOOTING

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSES

Convection oven motor does not operate. 1 . Oven door not closed.

2. Power switch not turned on.

3. Faulty convection motor.

Convection oven motor operates but no

gas flow to oven burner.

Convection oven motor noisy . 1. Motor mounting loose.

Pilots do not remain lit. Low gas pressure. Check incoming gas line and check

Burner flame too yellow. 1.

Faulty solenoid.

2. Fan loose on motor shaft.

regulator.

Check for correct orifice and for correct shutter adjustment.

2. Check for blockage at orifice.

F35425 (October 2005) Page 22 of 23

Page 23

ENDURANCE SERIES GAS RANGES - CONDENSED SP ARE PARTS LIST

CONDENSED SPARE PARTS LIST

ENDURANCE SERIES GAS RANGE

P ART NO. DESCRIPTION

411496-B1 Switch

411496-F1 Door Switch (Single Oven)

411496-F7 Door Switch (Double Oven)

497240-1 Griddle V alve

497246-1 Griddle Knob

404076 Burner V alve

428300-1 Burner V alve Knob

428904-1 Pilot Quick Disconnect Valve

404193-1 Broiler Pilot V alve

404193-2 Griddle Pilot V alve

497175-1 Solenoid V alve (36, 48 & RH of 60 & 260)

497175-2 Solenoid V alve (LH of 60 & 260)

412788-4 T/Couple (Single Oven)

428305-1 T/Couple (Double Oven)

419730-1 Motor

415780-2 Air Rotor

408279-26 Regulator 3/4 NPT (Single Oven) Nat. Gas

408279-27 Regulator 1 NPT (Single Oven) Nat. Gas

408279-21 Regulator 3/4 NPT (Single Oven) LP Gas

428807-1 Thermostat, Oven Control V alve (Single Oven)

428806-1 Thermostat, Oven Control V alve (Double Oven)

428617-1 Oven Thermostat Knob

F35425 (October 2005)Page 23 of 23

Loading...

Loading...