Vulcan-Hart FK, FK36-A User Manual

ONE POWERFUL PACKAGE

OPERATIONS MANUAL

COMMANDER SERIES

GAS RANGE

MODEL

FK Series Convection Oven

FV Series Standard Oven

FB Series Cabinet Base

FM Series Modular Unit

FK36_A Convection Oven

- NOTICE -

This manual is prepared for use by trained service technicians

and should not be used by those not properly qualied.

If you have attended a service school for this product, you may

still be qualied to perform the procedures described in this

manual.

This manual is not intended to be all encompassing. If you have

not attended a service school for this product, you should read,

in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained service technician.

DESCRIPTION

Reproduction or other use of this manual, without the express

written consent of Vulcan-Hart/Wolf, is prohibited.

For additional information on Vulcan-Hart/Wolf or to locate an authorized parts and service

provider in your area, visit our website at www.vulcanhart.com or www.wolfrange.com.

VULCAN-HART/WOLF

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

WWW.VULCANHART.COM / WWW.WOLFRANGE.COM

3600 NORTH POINT BLVD.

BALTIMORE, MD 21222

F-35683 (02-2007)

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPM ENT , WHO SH OULD PERFOR M THE IN ITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

IMP ROP ER IN STA LLA TION, A DJU STMENT,

ALTERATION OR MODIFICATION, SERVICE OR

MA INT ENA NCE CA N CA USE PROPE RTY

DAMAGE , INJ URY O R DEA TH. REA D THE

INSTALLATION, OPERATING AND MAINTENANCE

IN STR UCT ION S TH ORO UGH LY BEFO RE

INSTALLING OR SERVICING THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

— 2 —

— 3 —

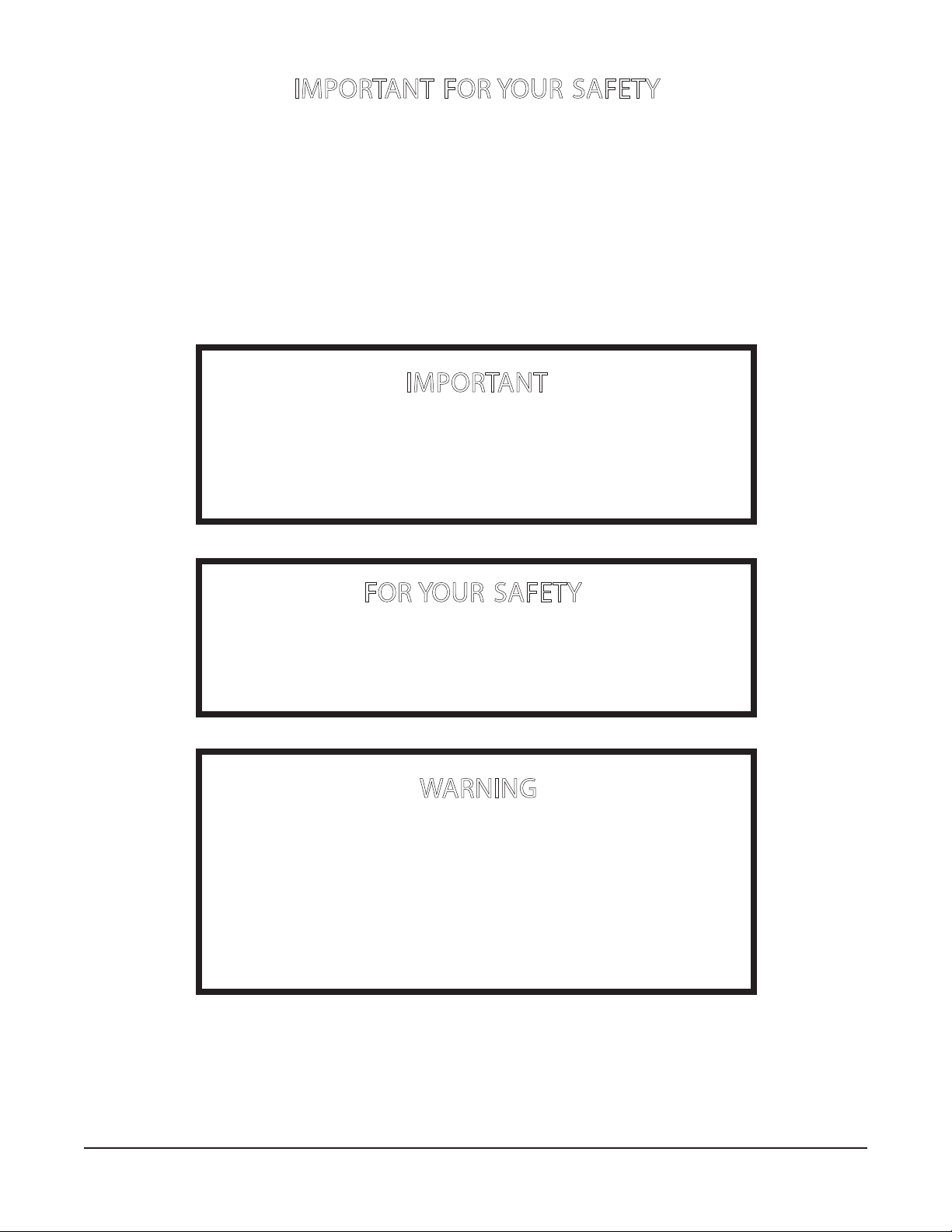

Installation, Operation and Care Of

HEAVY DUTY SECTIONAL GAS RANGES

PLEASE KEEP THIS MANUAL FOR FUTURE REFERENCE

GENERAL

Heavy duty sectional ranges are produced with quality workmanship and material. Proper installation,

usage and maintenance of your range will result in many years of satisfactory performance.

The manufacturer suggests that you thoroughly read this entire manual and carefully follow all of the

instructions provided.

INSTALLATION

UNPACKING

This range was inspected before leaving the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of the shipment. Immediately after unpacking, check

for possible shipping damage. If the range is found to be damaged, save the packaging material and

contact the carrier within 15 days of delivery.

Carefully unpack range(s) and place in the approximate installation position, whether as a battery or

single stand-alone range.

Remove parts (packed in a cardboard box) from oven cavity, or cabinet body, or on top of modular

range(s).

Remove wire or nut from rear of each burner before installing the range.

Before installing, check the electrical service (Convection Oven Models only) and type of gas supply

(natural or propane) to make sure they agree with the specications on the rating plate located on the

inside of the burner box lower panel. The rating plate will show the voltage, phase, cycle, full load

ampere, BTU, as well as the type of gas. If the supply and equipment requirements do not agree, do

not proceed with the installation. Contact your dealer or manufacturer.

LOCATION

CAUTION: The equipment area must be kept free and clear of combustible substances.

The minimum installation clearances from combustible and noncombustible construction for ranges

using inputs of 30,000 BTU/Hr. per open top burner are:

Combustible Noncombustible

Sides 20" (508 mm) 0"

Rear 2" (51 mm) 0"

— 4 —

The minimum installation clearances from combustible and noncombustible construction for ranges

using inputs of 20,000 Btu/Hr per open top burner are:

Combustible Noncombustible

Sides 6" (152 mm) 0"

Rear 2" (51 mm) 0"

The ranges are suitable for installation on combustible oors when 6" (152 mm) adjustable legs are

used. When legs are removed, use only on noncombustible oors, curb, or platform, with front

appliance projecting 3" (76 mm) beyond curb or platform.

Ranges with convection ovens should be installed on 6" (152 mm) legs or casters, allowing 6" (152 mm)

clearance from the rear of the range. If ranges with convection ovens are installed directly on curbs,

without legs, or in back-to-back installations, provisions must be made for adequate air circulation, and

these provisions must be approved by the manufacturer's Service Department. Contact the Service

Department at the address or phone number shown on the front cover of this manual.

All modular ranges are to be installed only on non-combustible oors.

The installation location must allow adequate clearances for servicing and proper operation. A

minimum front clearance of 35" (889 mm) is required.

The range(s) must be installed so that the ow of combustion and ventilation air will not be obstructed.

Adequate clearance for air openings into the combustion chamber(s) must be provided. Make sure

there is an adequate supply of air in the room to allow for combustion of the gas at the burners.

INSTALLATION CODES AND STANDARDS

Your range(s) must be installed in accordance with:

In the United States:

1. State and local codes.

2. National Fuel Gas Code, ANSI/Z223.1/NFPA #54 (latest edition). Copies may be obtained

from The American Gas Association, Accredited Standards Committee Z223 @ 400 N.

Capital St. NW, Washington, DC 2001 or the Secretary Standards Council, NFPA,

1 Batterymarch Park, Quincy, MA 02169-7471.

NOTE: In the Commonwealth of Massachusetts, All gas appliances vented through a

ventilation hood or exhaust system equipped with a damper or with a power means of

exhaust shall comply with 248 CMR.

3. Vapor Removal From Cooking Equipment, NFPA #96 (latest edition). Copies may be

obtained from The National Fire Protection Association, Batterymarch Park, Quincy MA

02169-7471.

4. National Electrical Code, ANSI/NFPA-70 (latest edition). Copies may be obtained from

The National Fire Protection Association, Batterymarch Park, Quincy, MA 02169-7471.

In Canada:

1. Local codes.

2. CSA B149.1 Natural Gas and Propane Installation Code.

3. CSA C22.1 Canadian Electrical Code (latest edition).

The above are available from The Canadian Standard Association, 5060 Spectrum Way, Suite 100,

Mississauga, Ontario, Canada L4W 5N6.

— 5 —

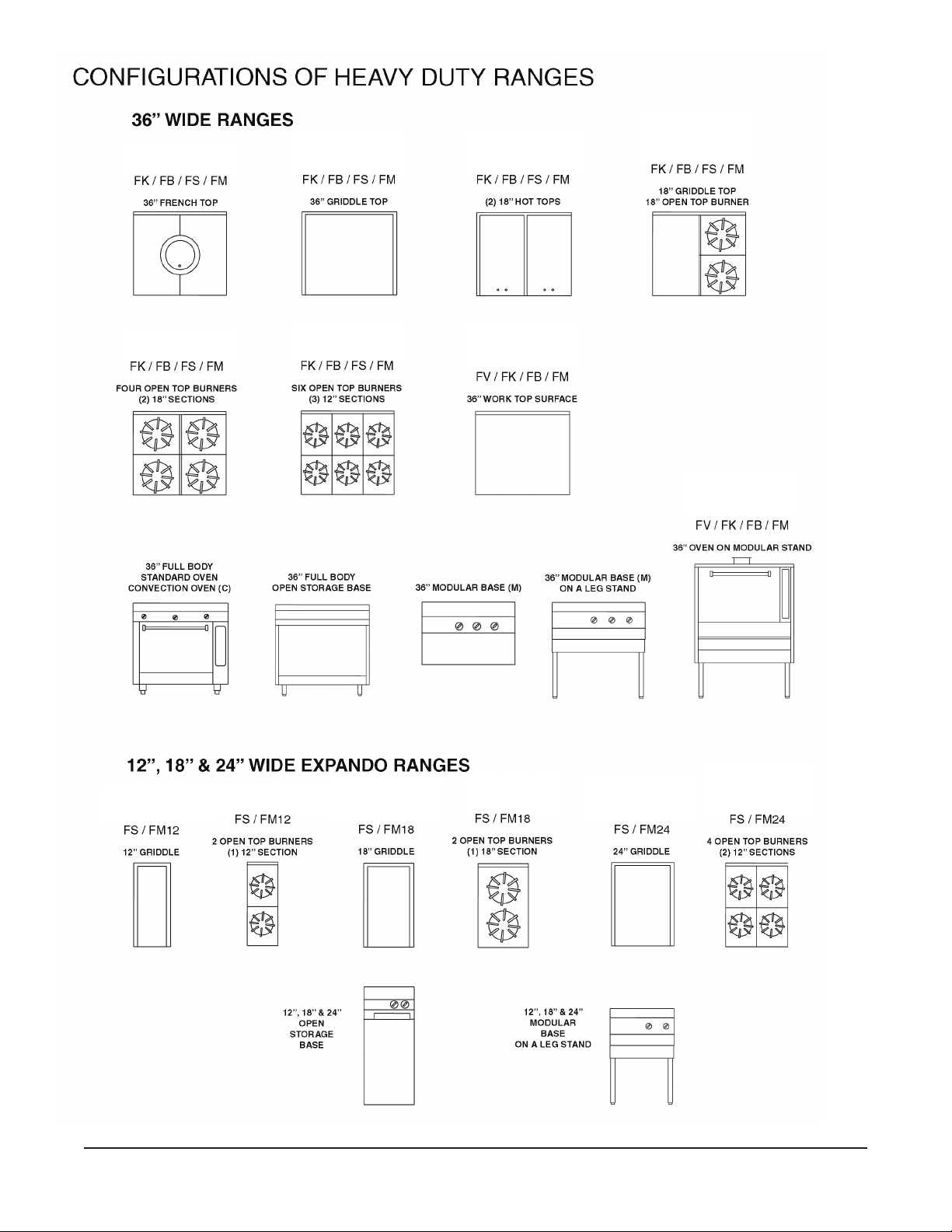

RANGES MOUNTED ON CASTERS

Ranges mounted on casters must use a exible connector

(not supplied by manufacturer) that complies with the

Standard for Connectors for Movable Gas Appliances,

ANSI Z21.69 • CSA 6.16 and a quick-disconnect device

that complies with the Standard for Quick-Disconnect

Devices for Use With Gas Fuel, ANSI-Z21.41 • CSA 6.9. In

add i tion, adequate means mus t be provided to limi t

movement of the appliance without depending on the

connector and the quick-disconnect device or its associated

piping to limit appliance movement. Attach the restraining

CONNEC T GAS LI NE

STRAIN

RELIEF H ERE

device at the rear of the range as shown in Fig. 1.

PL-5121 9

If disconnection of the restraint is necessary, turn o the gas

supply before disconnection. Reconnect this restraint prior to

Fig. 1

turning the gas supply on and returning the range to its

installation position.

Separate instructions for installing casters to the range are included with the casters.

Note: If the range is installed on casters and is moved for any reason, it is recommended that the range

be releveled front to back and side to side.

LEVELING

Curb Installation

Ranges must overhang curb 3" (76 mm) in front. To level each range, remove oven bottom. Adjust

four corner leveling bolts as required to level the appliance on all sides.

Convection Oven

Remove lower front kick plate. Remove two screws holding electric gas valve and move valve o to

the side. Pull oven burner out of compartment through opening. Adjust four corner bolts to level range.

Replace burner valve and kick plate.

Floor Installation on Legs

The 6" (152 mm) adjustable legs must be tightened securely. Level each range by turning the foot

portion of the adjustable legs.

Lining up Range Battery

In batteries of ranges, it is recommended that the center range be installed and leveled rst. Level each

range, one at a time, to line up high shelf and roll front with adjacent range. Bolt the high shelves and

roll fronts together.

— 6 —

CONNECTION OF MANIFOLDS IN BATTERY

Two or more ranges can be coupled together at the manifold by removing the front control panel to

make necessary connections. Be sure to cap open ends. To connect:

1. Adjust manifold by loosening U-bolts. In a large battery of eight or more ranges, gas should

be fed from both ends of the battery. "T" gas connections can be installed whenever necessary

for increased gas supply. For further details, consult your gas company. The top roll front may

also be removed for your convenience.

2. Bolt risers together at top rear.

3. If risers have high shelves, bolt the high shelf brackets together. Replace the high shelves.

4. Use clamp to pull ranges together at the rear. (There is a slotted hole in the top frame side at

5

the rear that can be used to bolt ranges together if necessary. Run a

/16" (8 mm) diameter drill

through the slotted hole, drilling from inside out on each range.) Use 1/4" (6 mm)-2 x 2" (51 mm)

bolt that is provided.

5. Replace all top sections. Make manifold union connections at the front. Do not allow manifold

pipe to turn.

1

6. Bolt the roll front ends together at the front. (Make sure roll fronts match.) Use

/4" (6 mm)-20

x 1" (25 mm) bolts provided.

7. Tighten the front roll front bolts after the roll front ends have been properly bolted together.

8. Before replacing manifold panels, check all gas connections for leaks. (See GAS

CONNECTIONS in this manual.)

If appliance has rear gas connection, carefully check for open gas lines.

The gas pressure regulator must have proper outlet pressure capacity for this battery application.

INSTALLING OVERLAPPING GRIDDLE TOP

1. Bolt ranges together and level per instructions in this manual.

2. Remove chrome bull noses from ranges receiving overlapping griddle tops. Bull noses are held

by bolts on the bottom side.

3. MANUAL CONTROLS ONLY — Set griddle tops in place and level with bolts located under the

griddle top in both rear corners. Should you desire griddle plate to slope forward, adjust

accordingly. Make sure hole in front gutter ts into drain in range. Reinstall bull noses.

4. THERMOSTAT CONTROL ONLY — Set griddle top in place and support front with 4" to 6" (102

to 152 mm) blocks. Insert thermostat probe into smaller of two angles on bottom of griddle top

(bend probe slightly while inserting to hold in place). Slide insulation sleeving around probe

lead up to angle on griddle top. Coil excess lead near thermostat, leaving as little as possible

in burner area. Make sure that thermostat probe lead is not over burner or pilot ame. Remove

supporting blocks and lower griddle top in place.

Level griddle top with bolts located under both rear corners. Should you desire griddle plate

to slope forward, adjust accordingly. Make sure hole in front gutter ts into drain in range.

Reinstall bull noses.

Leveling bolts are provided under each griddle plate at the rear, should you desire griddle plate to slope

forward. Top frame sealing channels are supplied to seal o any space between two or more ranges.

— 7 —

GAS CONNECTIONS

CAUTION: All gas supply connections and any pipe joint compound used must be resistant

to the action of propane gases.

This appliance must be connected with a gas supply line as large or larger ID (net inside diameter) than

the gas pipe inlet provided on the rear of the appliance. Connect gas supply to the range(s). Make sure

the pipes are clean and free of obstructions, dirt, and piping compound.

Codes require that a gas shuto valve be installed in the gas line ahead of the range(s).

Ranges manufactured for use with propane gas are equipped with xed orices.

A gas pressure regulator must be furnished by the installer or plumber at the time of installation. The

regulator must be listed by a nationally recognized testing agency. These appliances are rated at the

following pressure: Natural Gas - 5" W.C. (Water Column) (1.25 kPa); Propane Gas - 10" W.C.

(2.49 kPa).

WARNING: PRIOR TO LIGHTING, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR LEAKS

USE SOAP AND WATER SOLUTION. DO NOT USE AN OPEN FLAME.

A. CHECK ALL JOINTS PRIOR TO THE GAS VALVE (SOLENOID) BEFORE LIGHTING UNIT.

B. CHECK ALL JOINTS BEYOND GAS VALVE (SOLENOID) AFTER UNIT IS LIT.

After piping has been checked for leaks, all piping receiving gas should be fully purged to remove air.

TESTING THE GAS SUPPLY SYSTEM

1

When test pressures exceed

/2 psig (3.45 kPa), the range and its individual shuto valve must be

disconnected from the gas supply piping system.

1

When test pressures are

/2 psig (3.45 kPa) or less, the range must be isolated from the gas supply

system by closing its individual manual shuto valve.

FLUE CONNECTIONS

DO NOT obstruct the ow of ue gases from the ue duct located on the rear of the range. It is

recommended that the ue gases be ventilated to the outside of the building through a ventilation

system installed by qualied personnel.

A minimum of 18" (457 mm) must be maintained between the ventilation system and the cooking

surface.

Information on the construction and installation of ventilating hoods may be obtained from the standard

for "

Vapor Removal from Cooking Equipment

," NFPA No. 96 (latest edition), available from the

National Fire Protection Association, Batterymarch Park, Quincy, MA 02169-7471.

— 8 —

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW

LOCKOUT / TAGOUT PROCEDURES.

WARNING: APPLIANCES EQUIPPED WITH A FLEXIBLE ELECTRIC SUPPLY CORD ARE

PROVIDED WITH A THREE-PRONG GROUNDING PLUG. IT IS IMPERATIVE THAT THIS

PLUG BE CONNECTED INTO A PROPERLY GROUNDED THREE-PRONG RECEPTACLE. IF

THE RECEPTACLE IS NOT THE PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN.

DO NOT REMOVE THE GROUNDING PRONG FROM THIS PLUG.

Do not connect the range to electrical supply until after gas connections have been made.

LIGHTING AND SHUTTING DOWN PILOTS

Open Top, Griddle Top, and Hot Top

1. Turn the main burner valve to the ON position.

2. Turn all burner valves to the OFF position. Wait 5 minutes.

3. If pilot fails to light, repeat steps 1-2 above.

4. For a complete shutdown, turn all burner valves to the OFF position.

Turn gas shut-o valve OFF.

— 9 —

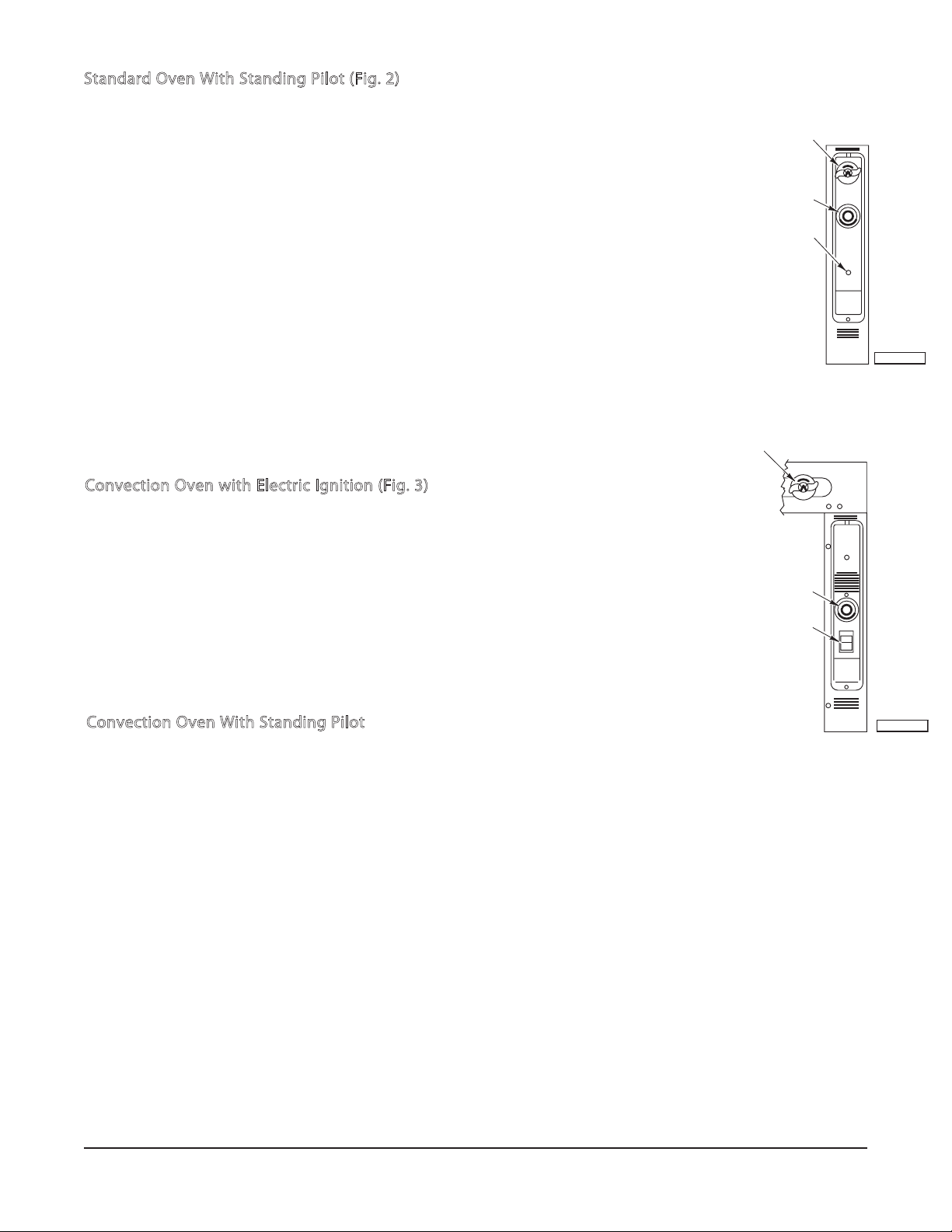

Standard Oven With Standing Pilot (Fig. 2)

1. Turn Thermostat and Shut-Off Valve to the OFF position.

2. Wait 5 minutes.

3. Remove lower panel.

4. Depress Red Button on Safety Valve and light Pilot through observation

hole.

5. Hold down Red Button for at least 30 seconds.

6. When Red Button is released, Pilot should remain lit. Pilot flame may be

adjusted with screw on Pilot Adjustment Valve on Pilot supply tubing located

behind Control Panel. There should be only a slight amount of yellow in the

properly adjusted pilot flame.

7. Replace lower panel.

8. Turn Shut-Off Valve to the ON position and turn the Thermostat to the desired

temperature.

9. If pilot flame becomes extinguished, repeat above procedure.

10. For a complete shutdown, turn the Thermostat, Shut-Off Valve, and gas

shut-off valve to the OFF position.

Convection Oven with Electric Ignition (Fig. 3)

1. Turn Thermostat and Shut-Off Valve to the OFF position.

2. Wait 5 minutes.

3. Turn Shut-Off Valve to ON position.

4. Turn Fan Switch to ON position.

5. Turn Thermostat to desired setting.

6. Oven burner lights automatically.

7. For a complete shutdown, turn Thermostat, Fan Switch, Shut-Off Valve,

and gas shut-off valve to the OFF position.

THERMOSTAT

RED BUTTON

SHUT-OFF

VALVE

THERMOSTAT

FAN SWITCH

SHUT-OFF

VALVE

(SAFETY)

PL-53 512

Fig. 2

FAN

Convection Oven With Standing Pilot

1. Turn Thermostat, Shut-O Valve, and Fan Switch to the OFF position.

2. Wait 5 minutes.

3. Remove lower panel.

4. Depress Red Button on Safety Valve and light Pilot through observation

hole.

5. Hold down Red Button for at least 30 seconds.

6. When Red Button is released, Pilot should remain lit. Pilot flame may be

adjusted with screw on Pilot Adjustment Valve on Pilot supply tubing located

behind Control Panel. There should be only a slight amount of yellow in the

properly adjusted pilot flame.

7. Replace lower panel.

8. Turn the Shut-Off Valve and Fan Switch to the ON position and turn the Thermostat

to the desired temperature.

9. If pilot flame becomes extinguished, repeat above procedure.

10. For a complete shutdown, turn the Thermostat, Shut-Off Valve, and gas shut-off

valve to the OFF position.

— 10 —

PL-53 515

Fig. 3

OPERATION

WARNING: THE APPLIANCE AND ITS PARTS ARE HOT. USE CARE WHEN OPERATING,

CLEANING OR SERVICING THE APPLIANCE.

BEFORE FIRST USE

Griddle Tops: Before using your griddle, the protective coating that was applied at the factory must

be completely removed with a commercial degreaser. After a thorough cleaning, apply a

high temperature, salt-free frying oil and you are ready to use the griddle.

The griddle requires no “breaking-in” or “seasoning”.

OPERATING SUGGESTIONS

Standard Oven: If you have a standard oven, use your normal recipe times and temperatures.

Convection Oven: The convection oven does everything a regular oven can do, but with less energy

consumption. The oven pre-heats faster, and baking time, temperature settings, and

shrinkage are reduced.

In general, reduce temperature 25°F (10°C) from conventional recipes.

• Bakery Products: Reduce temperature 25°F (10°C). Reduce time by 25%.

• Casserole Cookery: Reduce temperature about 25°F, and time by 25%.

• Meat Roasting: Reduce temperature to 275-300°F (135-149°C). Use meat thermometer.

Cooking time may be reduced up to 25%.

Use fan for preheating and baking.

Place open-face pies with thin lling mixture in preheated oven 2 to 3 minutes before turning on fan

switch.

Check product at half the time of the regular recipe.

Level pans bake more evenly; warped pans will give uneven baking results.

— 11 —

Loading...

Loading...