Page 1

MODELS

EV12 EV48S

EV24S EV48SS

EV36S EV60SS

INSTALLATION

& OPERATION MANUAL

ELECTRIC RESTAURANT RANGES

For additional information on Vulcan-Hart or to locate an authorized parts and

service provider in your area, visit our website at www.vulcanequipment.com

VULCAN-HART 3600 NORTH POINT BLVD.

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC BALTIMORE, MD 21222

www.vulcanequipment.com F-38251 (09-13) REV F

Page 2

TABLE OF CONTENTS

ELECTRIC RESTAURANT RANGE MODELS…………………….........................................,,,,,,, 3

GENERAL..................................................................................................................................... 5

FIELD INSTALLABLE ACCESSORIES ……………………………………………………………... 5

INSTALLATION ........................................................................................................................... 6

Unpacking ...................................................................................................................... 6

Location.......................................................................................................................... 7

Installation Codes and Standards ................................................................................. 7

Assembly....................................................................................................................... 7

Electrical Connections................................................................................................... 9

Leveling ......................................................................................................................... 9

Accessory Bullnose Installation……………………………………………………………. 9

OPERATION………………………………………………………………………………………….. 11

Controls ........................................................................................................................ 11

Before First Use ............................................................................................................. 12

French Plates................................................................................................................. 12

Griddle ........................................................................................................................... 13

Oven .............................................................................................................................. 14

Power Outage ................................................................................................................ 14

Cleaning.......................................................................................................................... 14

MAINTENANCE .......................................................................................................................... 16

Service and Parts Information ........................................................................................ 16

ELECTRICAL CONNECTION INFROMATION……………………………………………………… 17

WIRING DIAGRAMS………………………………………………………………………………….. 18 – 22

NOTES………………………………………………………………………………………………….. 23

2 F-38251 (09-13) REV F

Page 3

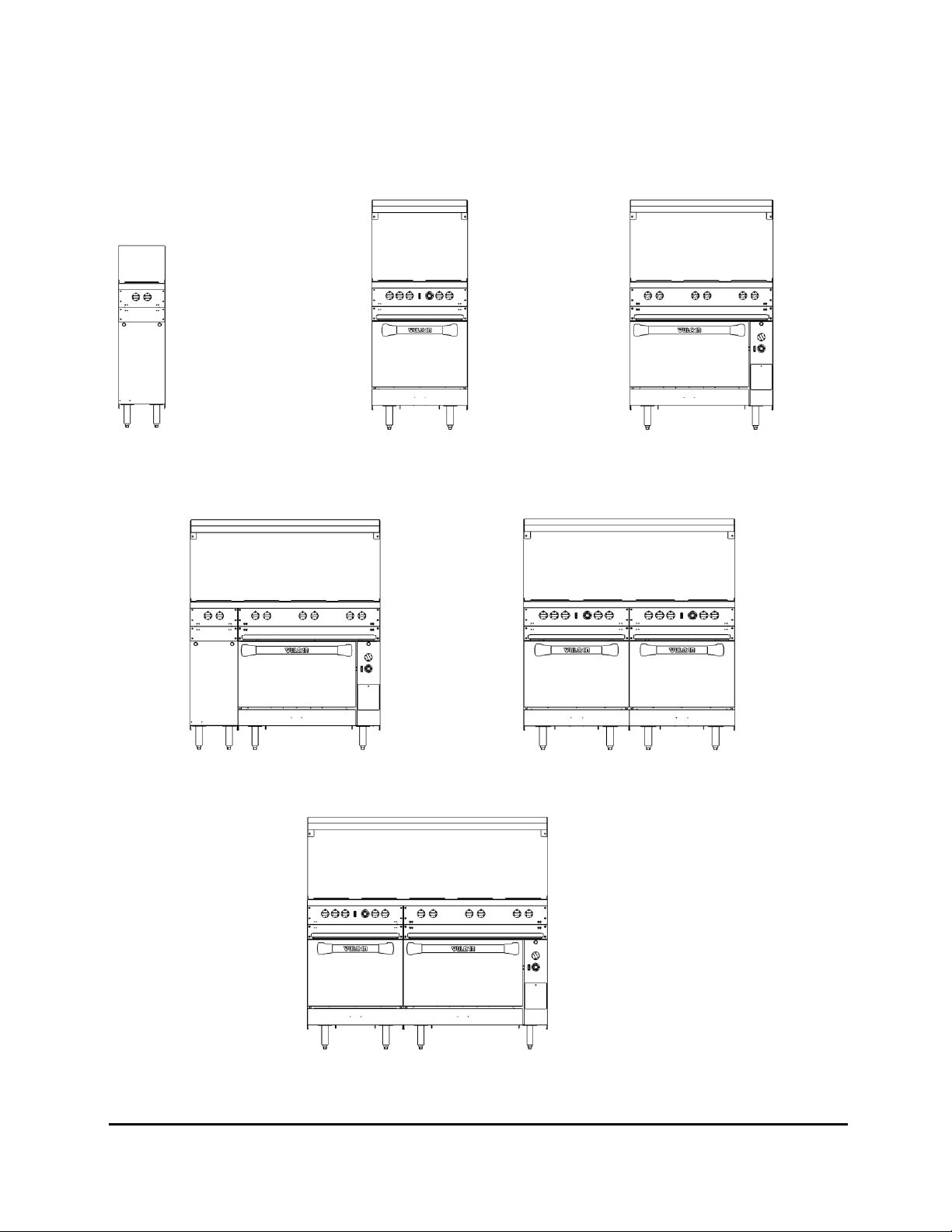

ELECTRIC RESTAURANT RANGE MODELS

EV12 EV24S EV36S

EV48S EV48SS

EV60SS

3 F-38251 (09-13) REV F

Page 4

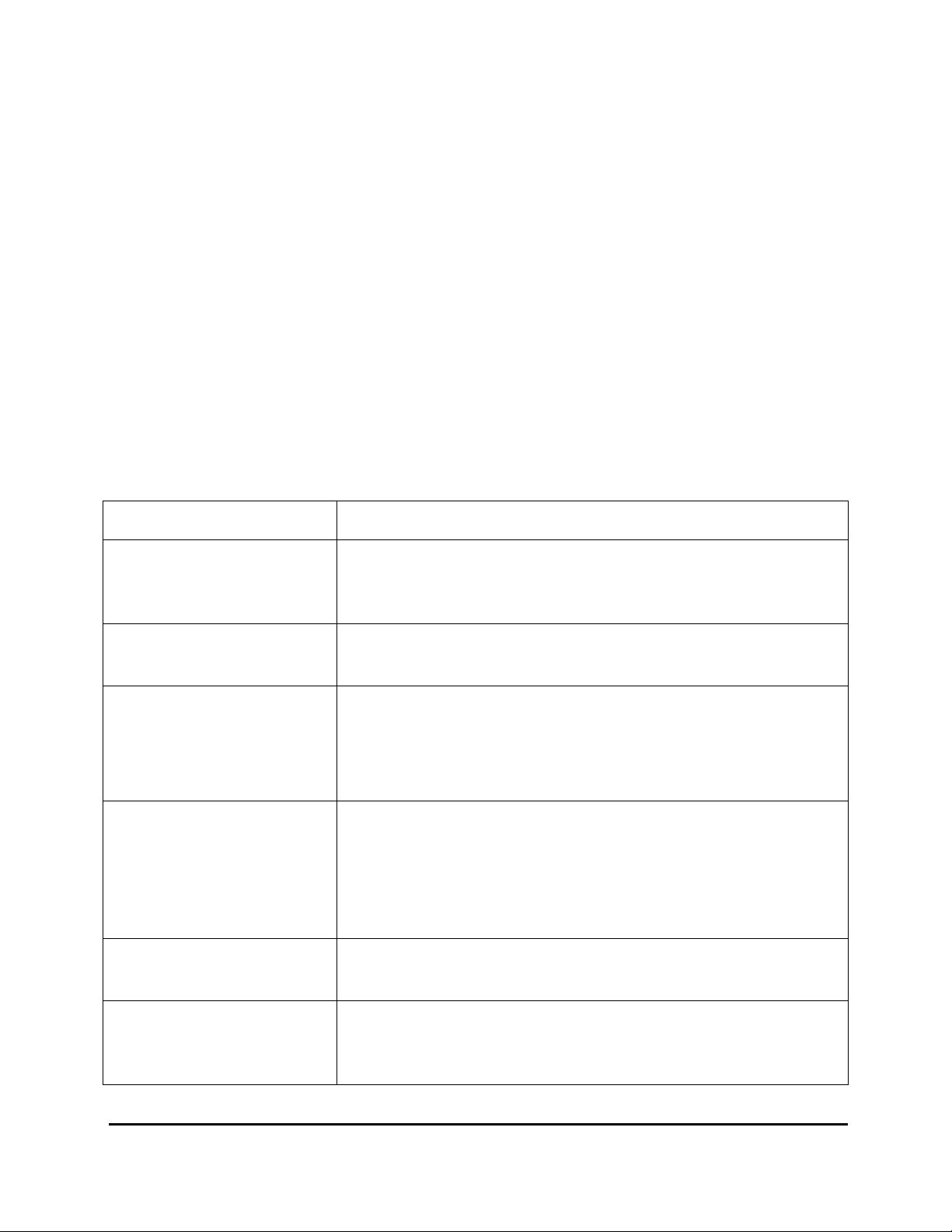

ACCESSORY CODE

DESCRIPTION

RSHELF-ELEC

(24,36,48,60,72)

Reinforced High Shelf - 23" (584 mm) high stainless steel

backsplash with broiler mounting brackets for

Salamander/Cheesemelter.

STUB10-XL

(12,24,36,48,60,72)

10" Stainless steel stub riser. Available for 12", 24", 36", 48", 60",

and 72" ranges.

CONRACK-XL(20,26)

OVNRACK-XL(20,26)

RKGUIDE-XL

1 extra oven rack with convection ovens.

1 extra oven rack with standard ovens.

1 pair of rack guides (set of 2).

CASTERS-RR4

CASTERS-RR8

CASTERS-ADJRR4

Set of four (4) standard casters.

Set of eight (8) standard casters.

Set of four (4) adjustable casters. Two (2) sets required for 48",

60", and 72" ranges.

RCTWLBR-(24,36,48,60,72)

Towel Bar Assembly - Replaces standard bullnose. Available for

24", 36", 48", 60", and 72" ranges.

RCCUTBD-(24,36,48,60,72)

Cutting Board Assembly - Replaces standard bullnose. Available

for 24", 36", 48", 60", and 72" ranges. (Includes Sani-TUFF®

all-rubber cutting board)

INSTALLATION, OPERATION AND CARE OF

ELECTRIC RESTAURANT RANGES

KEEP THESE INSTRUCTIONS FOR FUTURE USE

GENERAL

Thoroughly read this entire manual and carefully follow all of the instructions provided.

Your Vulcan-Hart range is produced with quality workmanship and material. Proper installation, usage and

maintenance of your range will result in many years of satisfactory performance.

OPTIONAL FIELD INSTALLABLE ACCESSORIES

4 F-38251 (09-13) REV F

Page 5

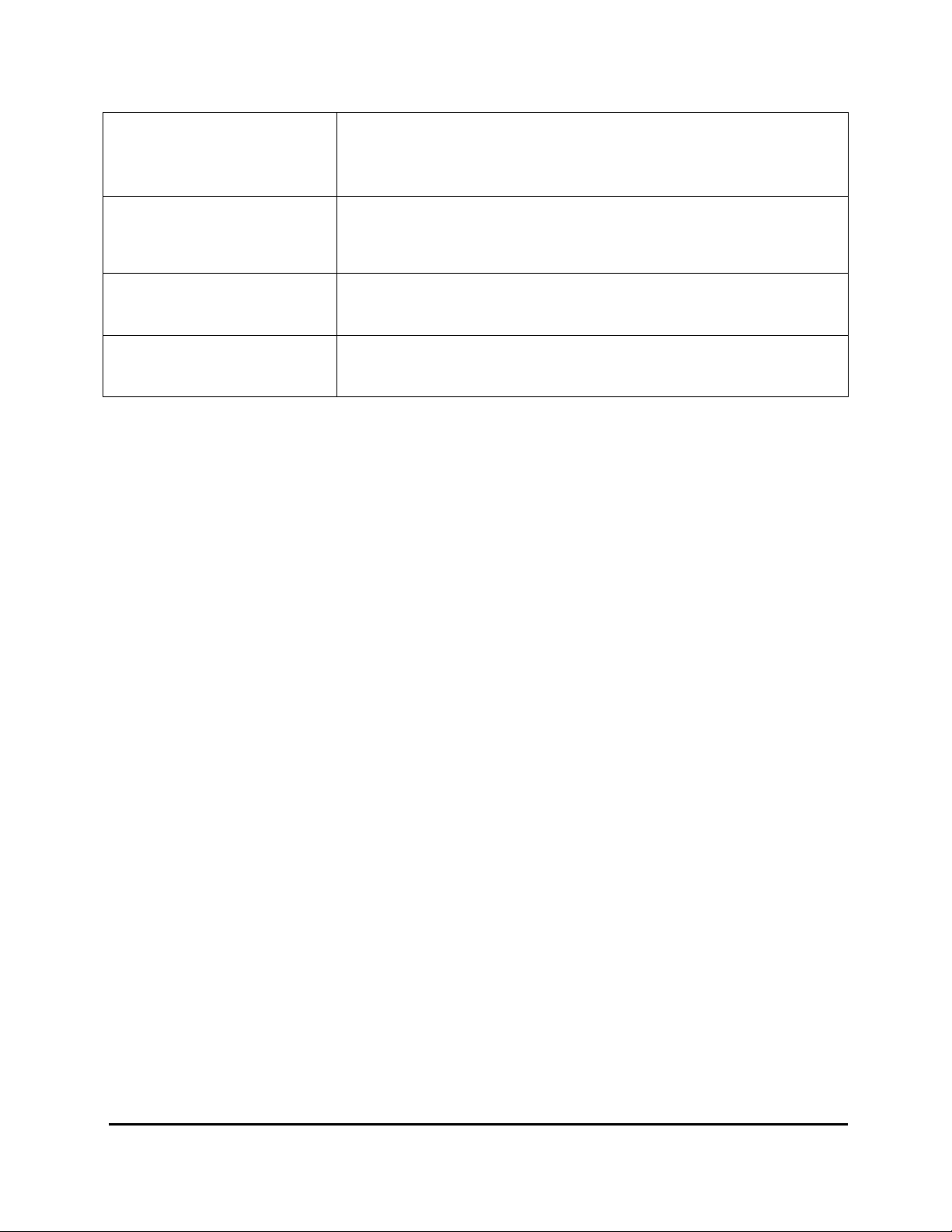

RCCONRL-(24,36,48,60,72)

Condiment Rail Assembly - Replaces standard bullnose.

Available for 24", 36", 48", 60", and 72" ranges. (Does not

include condiment pans)

SHIELD-FRYRH

SHIELD-FRYLH

Fryer Splash Shield - Right hand or left hand side. Protects

range top against grease splatter from adjacent fryer.

VFLANGED-FEET/4

Set of four (4) flanged feet. Two (2) sets required for 48", 60",

and 72" ranges.

CURBMNT-XL4

Curb mounting kit. Two (2) sets required for 48", 60", and 72"

ranges.

INSTALLATION

UNPACKING

This range was inspected before leaving the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of the shipment. Immediately after unpacking, check for

possible shipping damage. If the range is found to be damaged, save the packaging material and contact

the carrier immediately.

Remove all shipping bands, blocking, and packaging. Remove the high shelf, and backsplash assembly.

Before installing, verify that the electrical service agrees with the specifications on the rating plate located

behind the kick panel on the left side. If the supply and equipment requirements do not agree, contact your

dealer or Vulcan-Hart immediately.

If it is required to remove the door and install it for access through a kitchen door, follow the instructions

below.

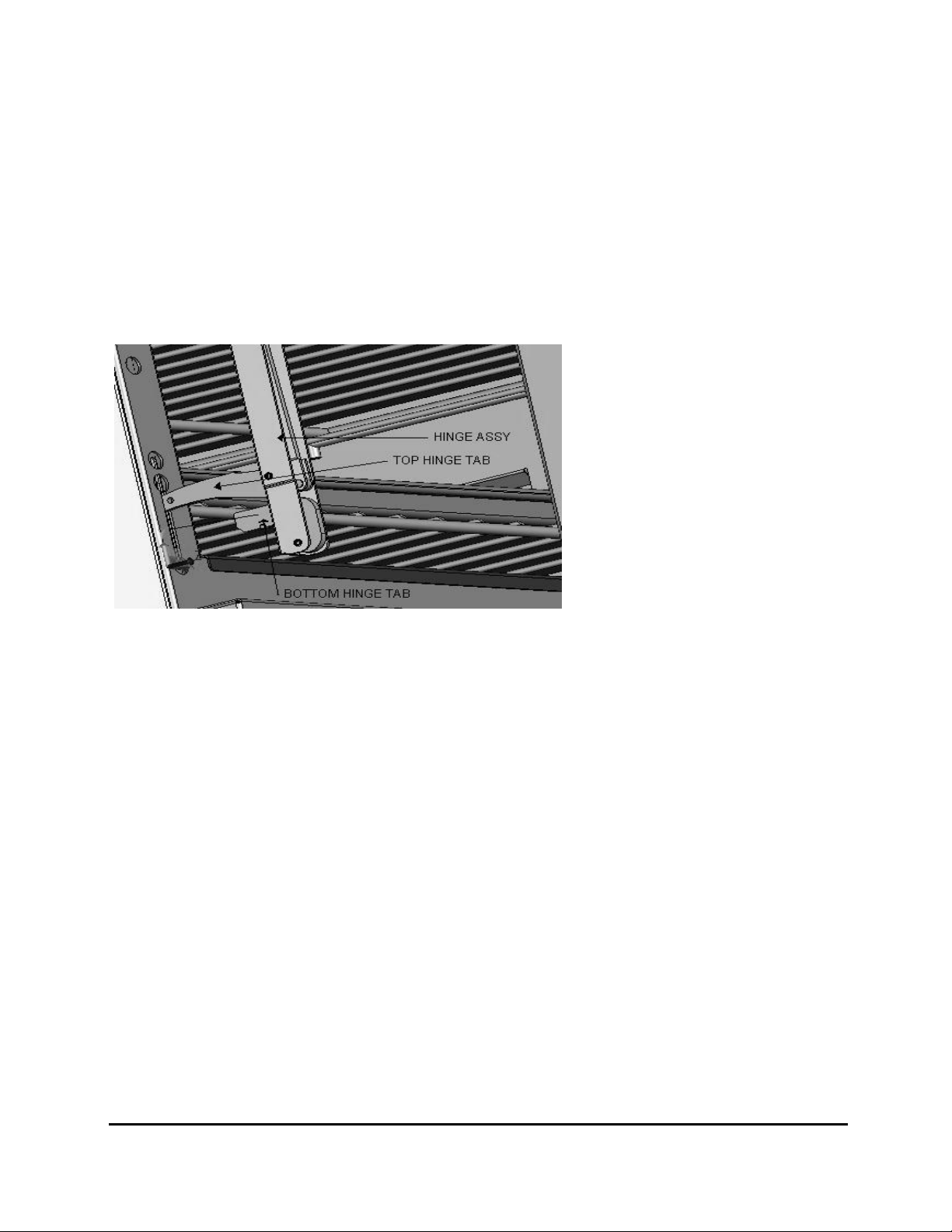

Door removal

1. Open door.

2. Grasp door firmly at both sides.

3. Lift door upward and pull it out so bottom hinge tab disengages.

* This may be easier to accomplish one side at a time.

4. Close door almost shut and lower slightly to disengage top hinge tab.

5. Pull door outward.

5 F-38251 (09-13) REV F

Page 6

Door installation

1. Grasp door firmly at both sides.

2. Starting with either LH or RH side top hinge tab, angle door and slide top hinge tab into opening

between hinge stop roller and hinge stop pin.

3. Lift door up (compress door hinge as if opening the door) and position bottom tab downward about 30

degrees down from horizontal.

4. Push door inward, inserting downward angled bottom hinge tab into opening just above hinge stop pin.

* Bottom hinge tab must enter chassis at downward angle to engage.

5. Bottom hinge tab should engage on hinge stop pin.

6. Open door and pull door outward until bottom hinge tab locks on hinge stop pin.

7. Repeat above steps for opposite side.

8. Open and close door to make sure door hinges are locked in place and door operates smoothly.

LOCATION

The installation location must allow adequate clearance for servicing and proper operation. A minimum front

clearance of 40" (1016 mm) is required. 0" sides and rear clearance from combustible and non-combustible

construction is required except when hot top sections are incorporated. Ranges incorporating hot top

sections require a 0" sides and rear clearance from non-combustible construction and 6" from combustible

construction.

INSTALLATION CODES AND STANDARDS

Your Vulcan range must be installed in accordance with state and local codes, or in the absence of local

codes, with National Electrical Code ANSI/NFPA-70 (latest edition) available from The National Fire

Protection Association, Batterymarch Park, Quincy, MA 02269. In Canada refer to Canadian electrical code

C22.1 Part 1 (latest edition).

ASSEMBLY

Leg/Caster Assembly

The range is shipped fully assembled, except for the legs. The range is provided with 6"(152 mm)

adjustable stainless steel legs (hardware included), packaged in a box located inside of the oven. A set of

6"(152 mm) casters or 6” adjustable casters are available as an optional field installable accessories.

6 F-38251 (09-13) REV F

Page 7

RANGE SERIES

LEGS TO INSTALL

CASTERS TO INSTALL

EV12 4 4

EV24 4 4

EV36 4 4

EV48 8 8

EV60 8 8

EV72 8 8

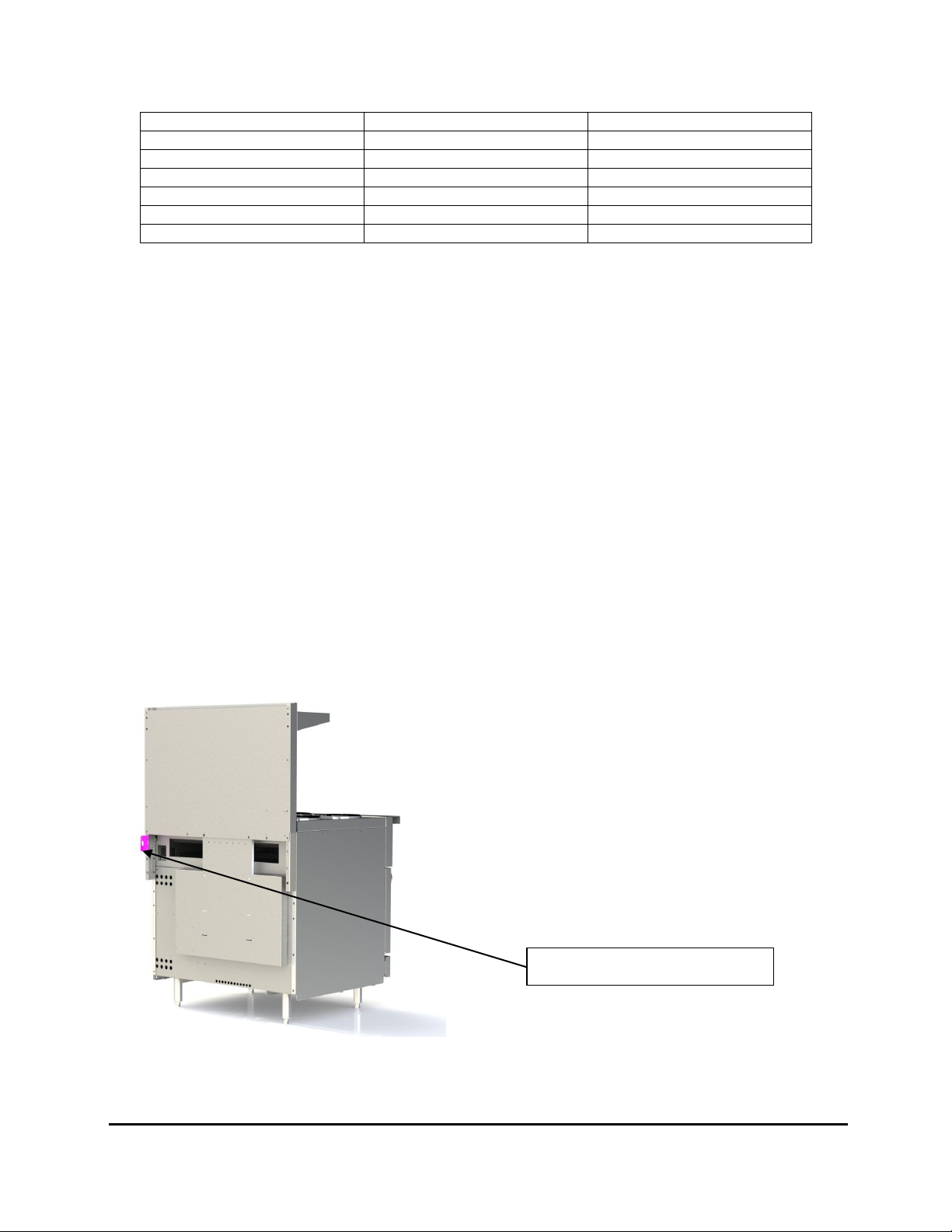

Restraining Connection Bracket

Installation of Legs/Casters:

1. Carefully tip or lift range to access bottom for leg installation.

2. Align holes in leg/caster mounting plate with pre-drilled holes in bottom of range located in each of

the four corners.

3. Attach mounting plate to bottom of range using four ¼ - 20 x ⅝“ self tapping screws (provided). If

casters are being installed, the locking casters should be mounted on the front.

4. After all legs/casters have been installed, carefully return the range to its upright position.

(For additional leg information, see Leveling section of this manual).

A permanently connected appliance mounted on casters and intended to be secured to the building

structure should adhere to the following:

a. Adequate means must be provided to limit the movement of the appliance without depending on or

transmitting stress to the electrical conduit;

b. The location(s) where restraining means are to be attached to the appliance needs to be on the

outside rear parts of the oven chassis frame of the Range (where the bottom rear heat shield is

bolted to the Range). Use brackets provided as connection points as shown below.

c. The appliance shall be installed using a flexible conduit.

If the range is installed on casters and is moved for any reason, it is recommended that the range be

re-leveled front to back and side to side for even baking.

7 F-38251 (09-13) REV F

Page 8

ELECTRICAL CONNECTIONS

ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH TO INDICATE THAT YOU ARE WORKING ON THE CIRCUIT.

Position the range in its final location. Bring conduit containing the proper supply wire to the range through

the knockout located on the bottom of the range. Select the size and type of field wire in accordance with the

National Electrical Code suitable for carrying the equipment's rated amps and voltage. Use field wires

suitable for 75°C on units carrying more than 80 amps.

If you have purchased an EV48, EV60 OR EV72 model, it will have two (2) electrical

connections. The left and the right portions of the range are supplied with individual branch

circuits, the connection points are found under each oven or in the right hand side control panel.

THE 48, 60 AND 72 INCH UNITS HAVE MORE THAN ONE SOURCE OF ELECTRICAL

SUPPLY. EACH SOURCE MUST BE CONNECTED IN ACCORDANCE WITH THE NATIONAL

ELECTRIC CODE (LATEST EDITION) OR OTHER LOCAL CODES.

Connect supply leads to field terminal block and green grounding lead to the labeled ground lug. The supply

wire should be anchored through the access hole with a bulkhead fitting.

Ranges ship wired for 3-phase service but may be changed to 1-phase, in the field. Refer to the wiring

diagram and schematic decal attached to the range for necessary alterations.

LEVELING

Place a carpenter's level on top of the range and level the range front-to-back and side-to-side by turning

the adjustable feet.

ACCESSORY BULLNOSE INSTALLATION

1.) Remove screws holding the switch cover in place and allow it to pivot down out of the way.

2.) Remove screws, from the front, holding the Bullnose in place.

3.) Slide standard Bullnose up to remove it from the range.

4.) Slide accessory back into the gap the standard Bullnose was removed from and align with

the side of range for fit.

5.) Start screw at one end of the Range, do not tighten completely.

6.) Going across the width of the Range install the next screw, as shown in Figure 2, set the

alignment and tighten screw completely.

7.) Install the remaining screws and tighten all screws completely.

8 F-38251 (09-13) REV F

Page 9

Condiment Rail

(Accessory)

Cutting Board

(Accessory)

Towel Bar

(Accessory)

Standard

Bullnose

Install Screws, #10-24 x

½ Phillips Head, in slots

on Bullnose as noted.

Note: Align the end of

the Bullnose with the

Range for fit.

Figure 1

Figure 2

9 F-38251 (09-13) REV F

Page 10

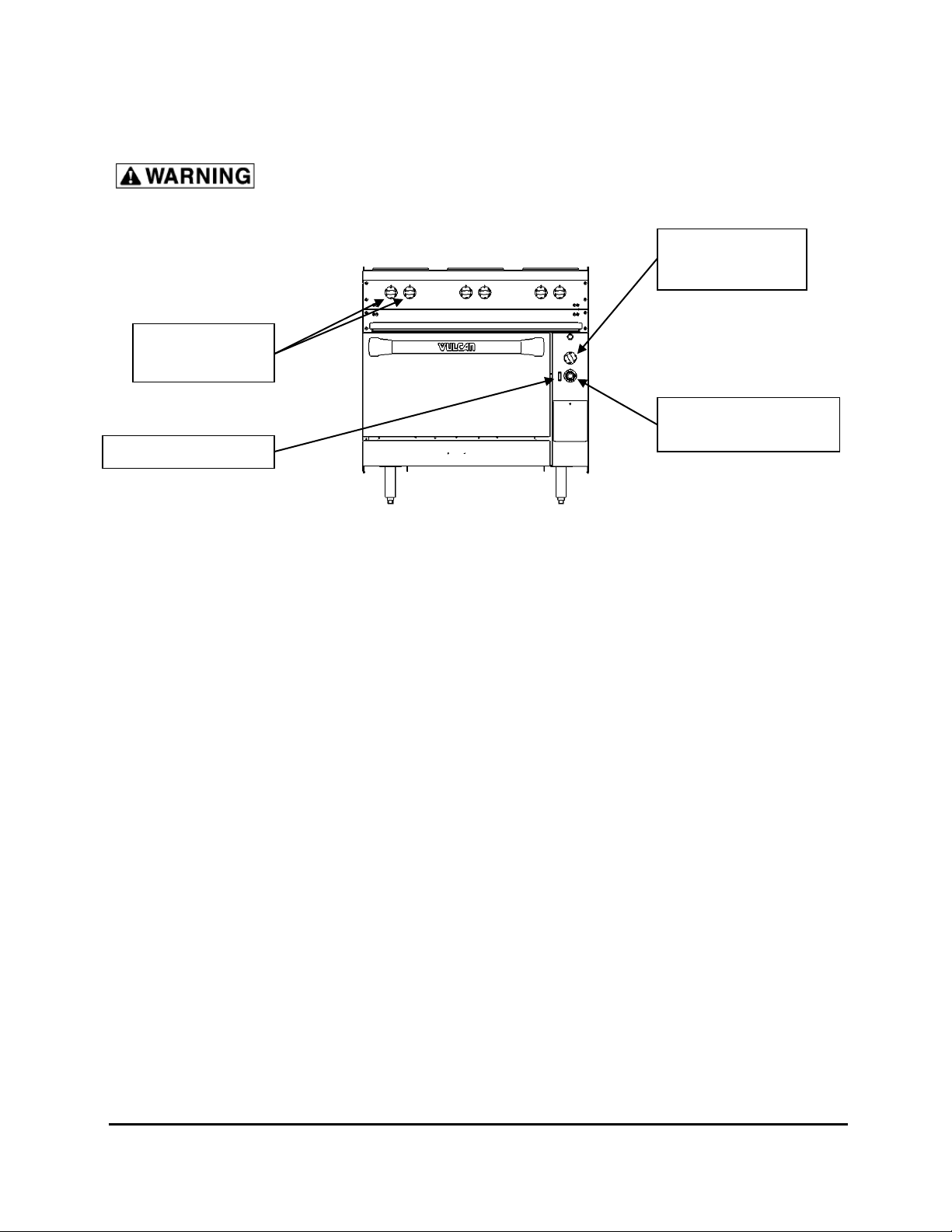

OPERATION

Element Control

Knobs

Oven Infinite

Switch Knob

Oven Indicator Light

Oven Thermostat

Knob

THE RANGE AND ITS PARTS ARE HOT. BE VERY CAREFUL WHEN

OPERATING, CLEANING OR SERVICING THE RANGE.

CONTROLS (Fig. 6)

Model EV36 Shown

Fig. 6

Element Controls — Infinite load switches that control and maintain heat to the surface plates. The

controls are arranged in pairs; the left knob controls the front plate and the right

knob controls the rear plate. NOTE: On 480 volt units, French plates are

controlled with a 3-heat switch (HIGH = 2000 watts, MED = 1000 watts, LOW =

500 watts).

Hot Top Switch — (Not shown.) A thermostat (1-10) controls and maintains heat to the top section.

Select desired heat level, (1 is minimum, 10 is maximum).

Griddle Thermostat — (Not shown.) Regulates the amount of heat needed to maintain the set

temperature. Each 12" (305 mm) section of the griddle has its own thermostat

with a temperature range of 200°F (93°C) to 550°F (288°C).

Griddle Indicator Light — (Not shown.) Will be lit until the selected temperature is reached or when it is

being maintained.

Oven Thermostat — Regulates the amount of heat needed to control and maintain oven temperature

around the desired set temperature. The temperature range is from 200°F

(93°C) to 550°F (288°C). Turn dial counterclockwise to increase temperature

and clockwise to decrease temperature.

Infinite Switch for Oven — Provides control for top browning element. Adjust as needed for the amount

Top Heating Element of top heat required in order to brown product as desired. NOTE: Infinite switch

not available on 480 volt units. This position on the panel will be filled with a

panel plug.

Oven Indicator Light — Will be lit until the selected temperature is reached or when it is being

maintained.

10 F-38251 (09-13) REV F

Page 11

BEFORE FIRST USE

Cleaning

Clean the range and all accessories with water and a mild detergent. Rinse thoroughly and wipe dry with a

soft clean cloth.

Griddle Seasoning

A new griddle surface must be seasoned. The metal surface of the griddle is porous. Food tends to get

trapped in these pores and stick; therefore, it is important to "season" or "fill up" these pores with cooking oil

before cooking. Seasoning gives the surface a slick, hard finish from which the food will release easily.

To season, heat griddle top section at a low setting. Pour one ounce of cooking oil per square foot of surface

over the griddle top section. With an insulated cloth, spread the oil over the entire griddle surface to create

a thin film. Wipe off any excess oil with an insulated cloth.

Repeat this procedure 2 to 3 times until the griddle has a slick surface.

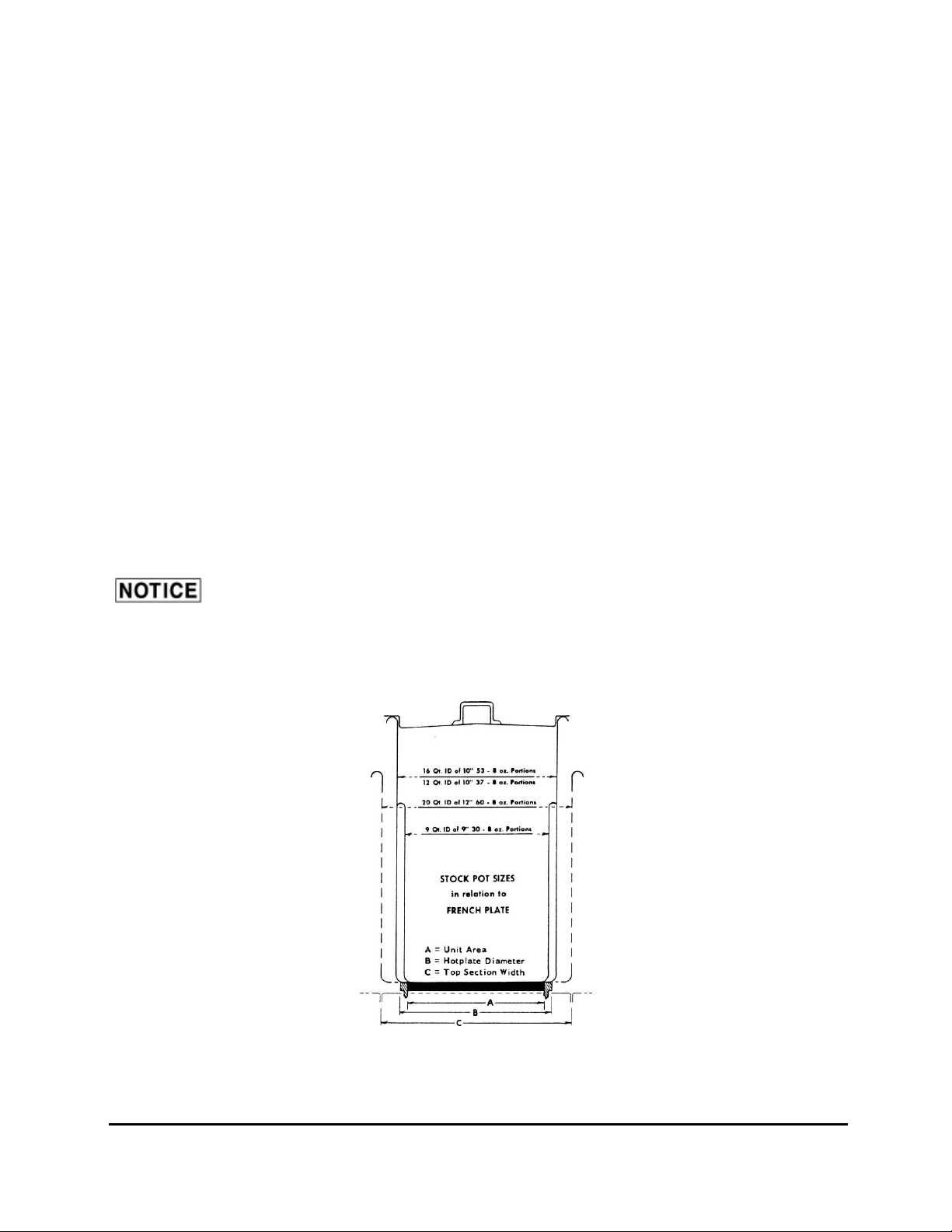

FRENCH PLATES

French plates are most efficient when used with utensils having a maximum inside diameter of 10" (254)

or a minimum inside diameter of 9" (229). Stock pots of 9, 12 and 16 qt. capacities are recommended for

bulk cooking. (Fig. 7)

It is important that the utensil used has a flat bottom that sits uniformly on the surface of the

plate. Utensils with curved bottoms (either through design or warped from use) will have poor contact and

therefore poor heat transfer. This will result in poor cooking performance.

Fig. 7

11 F-38251 (09-13) REV F

Page 12

The French (solid surface) Plates are rated for 2000 Watts and are controlled by an infinite heat switch. A

French (solid surface) Plate will reach cooking temperature from room temperature in 5 to 7 minutes at a HI

switch setting.

Each control knob is marked HI, MED, LO, MED-LO, and VERY-LO. The HI setting is full heat. Use the HI

setting to start cooking quickly and to bring water to a boil.

Some DO'S and DO NOT'S of Surface Cooking

DO use utensils to fit the tops (9" to 10" [229 to 254 mm] inside diameter).

DO use flat-bottomed, straight-sided pots and pans.

DO use covers for stock pot work. Water will boil much sooner and much less heat is required for cooking in

a covered container. Less water may be used, thereby retaining vitamins and minerals in the food.

DO turn off plates a few minutes before cooking is completed to use the heat stored in the plate.

DO NOT allow surface plates to idle unloaded at HI switch settings. The surface plates will reach

very high temperatures, and this can cause the casting to warp or dome. Plates idled at a setting of

MED-LO and turned to HI when loaded, will perform bulk cooking jobs just as rapidly, without

damage to the plates. Damage caused by plates left running unloaded on HI will void the warranty.

HOT TOPS

Hot Tops can make up for the irregularity of stock pots that have an inside diameter of over 10”. Pots can

overlap from one Hot Top section to another without any loss of heating area.

It is important that the utensil used has a flat bottom that sits uniformly on the surface of the

hot top plate. Utensils with curved bottoms (either through design or warped from use) will have poor

contact and therefore poor heat transfer. This will result in poor cooking performance.

The Hot Top section is rated for 2500 Watts and are controlled by snap action thermostatic controller, with

knob indicator marks from 0 to 10 (with 10 being the highest temperature setting). A Hot Top section will

reach cooking temperature from room temperature in 15 to 20 minutes at a 10 thermostat setting.

Some DO’S of Hot Top Cooking

DO use flat-bottomed, straight-sided pots and pans.

DO use covers for stock pot work. Water will boil much sooner and much less heat is required for cooking in

a covered container. Less water may be used, thereby retaining vitamins and minerals in the food.

GRIDDLE

See BEFORE FIRST USE in this manual for griddle seasoning procedure.

12 F-38251 (09-13) REV F

Page 13

This griddle plate is steel, but the surface is relatively soft and can be scored or

dented by the careless use of a spatula or scraper. Be careful not to dent, scratch, or gouge the

plate surface. Do not try to knock off loose food that may be on the spatula by tapping the corner

edge of the spatula on the griddle surface.

Griddles are supplied with one 3400 watt heating element per 12” of griddle surface. Each heating element

is individually controlled by a thermostat with a range of 200°F to 550°F (93°C to 288°C).

OVEN

Never cover the oven deck or rack with aluminum foil. The oven will not operate

properly and the range may be damaged.

Model EV24S, EV36S and EV48S ranges have a single oven; Model EV48SS, EV60SS AND EV72SS

ranges have two separate ovens. Each oven is equipped with top and bottom heating elements. The top

element has an infinite heat switch for browning. THIS IS NOT A BROILER ELEMENT. (infinite switch is

not available on the 480 volt range for the top element)

The oven has an input of 5000 W., 3750 W. for the bottom element and 1250 W. for the top element.

Preheating

Thoroughly preheat the oven by setting the switch and the thermostat to the desired temperature. When the

red light goes out, the oven is ready for use. For full loads and delicate baked products, it may be desirable

to allow the oven to cycle (red light on and off) a second time before loading.

Baking

Most products can be baked with the top element infinite switch set between VERY LO and LO.

Hard-to-brown products, such as corn bread or biscuits, may require a top switch setting of MED to HI. Start

off by using a LO setting on top element and then increase only as needed.

Roasting

Place meat on a rack in an open pan with sides sufficiently high to retain the drippings. Roasting may be

done on the oven rack or the deck. For best results, roast at the low temperatures of 200°F (93°C) to 325°F

(163°C) recommended by the Department of Agriculture and the American Meat Institute. Most meats may

be roasted with the infinite heat switch set at HI. If heavy browning on poultry is not desired, the switch

should be set between MED-LO and VERY-LO.

The top oven element is not suitable for broiling, and will not operate independent of the oven thermostat

(bottom element).

POWER OUTAGE

If a power outage occurs, the range will automatically shut down. When power is restored, the range will

automatically resume normal functions. If the range is left unattended during the power outage, turn all

control knobs/switches OFF. When power is restored, turn desired control knobs/switches back ON. The

unit will be preheated in 5 minutes and normal cooking operations can be resumed.

13 F-38251 (09-13) REV F

Page 14

CLEANING

DISCONNECT ELECTRICAL POWER SUPPLY BEFORE CLEANING.

DO NOT use Dawn ® dish detergent to clean the exterior or interior components of the range.

DO NOT use scouring powder. It is extremely difficult to remove completely. It can build up accumulations

that will damage the range.

DO NOT use cleaning products containing TSC.

Clean all parts of the range and the oven with a soft cloth and warm water and detergent. Rinse thoroughly

and wipe dry with a soft clean cloth.

Griddle

Scrape the griddle with an approved scraper after each use. The griddle grease can should be emptied on

a routine basis. A weep hole is provided to indicate that the grease can is near full capacity. Failure to empty

the grease can will cause it to overflow and may result in damage to the range. Weekly, or more often if

necessary, thoroughly clean the griddle surface. You may use a griddle screen or stone with a little grease,

rubbing with the grain of the metal while it is still warm, or use water and detergent with a steel brush. The

detergent must be thoroughly removed. After each thorough cleaning, the griddle must be re-seasoned

(see BEFORE FIRST USE in this manual).

Avoid build-up of caked grease under the drip edge and around the outside edges of the griddle.

If the griddle is to be shut down for an extended period, put a heavy coat of grease over the griddle plate.

Oven

Clean oven and oven door daily, especially if fruit pies or tomato sauces were baked, meats roasted, and if

there have been spillovers. Failure to clean spills may result in corrosion of metal components.

If the oven liners and decks are heavily soiled, ammonia or oven cleaner may be used to remove spillage of

burned on sugar and grease, but must be thoroughly rinsed with water to prevent corrosion.

After processing some foods at low temperatures, odors may linger in the oven. These odors may be

cleared by setting the thermostat at 500°F (260°C) and allowing the oven to operate unloaded for 30 to 45

minutes.

14 F-38251 (09-13) REV F

Page 15

MAINTENANCE

THE RANGE AND ITS PARTS ARE HOT. BE VERY CAREFUL WHEN

OPERATING, CLEANING OR SERVICING THE RANGE.

Disconnect power supply and follow lockout / tagout

procedures before cleaning and servicing the appliance.

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this range, contact the Vulcan-Hart Service Department

in your area or Service Department at the address or phone number shown on the front cover of this

manual.

15 F-38251 (09-13) REV F

Page 16

ELECTRICAL CONNECTION INFORMATION

Model

Configuration

X-Y Y-Z Z-X

Single

Phase

X Y Z

Single

Phase

X Y Z

Single

Phase

X Y Z

Single

Phase

EV12-2FP 2.0 2.0 0.0 4.0 8.0 17.0 8.0 19.0 7.0 14.0 7.0 17.0 3.6 7.2 3.6 8.3

EV12-1HT 5.0 24.0 21.0 10.4

EV24S-4FP 5.0 4.0 4.0 13.0 37.5 37.5 33.3 62.5 32.5 32.5 28.9 54.2 16.3 16.3 14.4 27.1

EV24S-2HT 5.0 5.0 5.0 15.0 41.6 41. 6 41.6 72.1 36.1 36.1 36.1 62.5 18.1 18.1 18.1 31.2

EV36S-6FP 4.0 8.0 5.0 17.0 37.5 50.0 54.1 81.7 32.5 43.3 46.9 70.8 16.3 21.7 23.5 35.4

EV36S-3HT 5.0 10.0 5.0 20.0 41.6 62.5 62.5 96.2 36.1 54.1 54.1 83.3 18.1 27. 1 27.1 41.7

EV36S-2HT2FP 4.0 10.0 5.0 19.0 37.5 58.3 62.5 91.4 32.5 50.5 54.1 79.2 16.3 25.3 27.1 39.6

EV36S-1HT4FP 4.0 9.0 5.0 18.0 37.5 54.1 58.3 86.5 32.5 46.9 50.5 75.0 16.3 23.5 25.3 37. 5

EV36S-2FP24G 3.4 7.4 5.0 15.8 35.0 45. 0 51.6 76.0 30.3 39.0 44.7 65.8 15.2 19.5 22.4 32.9

EV36S-1HT24G 3.4 8.4 5.0 16.8 35.0 49.1 55.8 80. 8 30.3 42.6 48.4 70.0 15.2 21.3 24.2 35.0

EV36S-4FP12G 3.4 8.0 5.0 16.4 35.0 47. 5 54.1 78.8 30.3 41.1 46.9 68.3 15.2 20.6 23.3 34.2

EV36S-2HT12G 3.4 10.0 5.0 18.4 35.0 55.8 62.5 88.5 30.3 48.4 54.1 76.7 15.2 24.2 27.1 38.4

EV36S-36G 3.4 6.8 3.4 15.2 35. 0 42.5 49.1 73.1 30.3 36.8 42.6 63.3 15.2 18.4 21.3 31.7

Key - FP = French Plates (2 per 12inch section) HT = Hot Top (1 per 12 inch section) G = Griddle (can actually have a 12, 24 or 36 inch Griddle)

All Griddle s less than 36 inches are always positioned on the right hand side of the range.

Kilowatts

208 Volt Amps

240 Volt Amps

480 Volt Amps

24 Inch Range w/Standard Oven

36 Inch Range w/Standard Oven

12 Inch Range

All ranges over 36 inches in width have two electrical connections. Ensure both

power supplies have been disconnected before beginning service on the appliance.

DOUBLE RANGES

Ranges ordered over 36 inches wide are constructed as follows:

EV48S - Consists of an EV36S and an EV12

EV48SS - Consists of two EV24S

EV60SS - Consists of an EV24S and an EV36S

EV72SS - Consists of two EV36S

16 F-38251 (09-13) REV F

Page 17

0 7S0 1234567089:273;0<=>010

0 0

Page 18

0 740 1234567089:273;0<=>010

0 0

Page 19

0 7:0 1234567089:273;0<=>010

0 0

Page 20

0 590 1234567089:273;0<=>010

Page 21

0 570 1234567089:273;0<=>010

0 0

Page 22

NOTES

22 F-38251 (09-13) REV F

Page 23

0 550 1234567089:273;0<=>010

NOTES

Page 24

0 570 1234567089:273;0<=>010

0 0

Page 25

0 590 1234567089:273;0<=>010

Page 26

0 7:0 1234567089:273;0<=>010

0 0

Page 27

0 740 1234567089:273;0<=>010

0 0

Page 28

0 7S0 1234567089:273;0<=>010

0 0

Page 29

0 7@0 1234567089:273;0<=>010

SPÉCIFICATIONS ÉLECTRIQUES

0

Clé – FP = Feux de type français (2 par section de 12 po) HT = Surface coup de feu (1 par section de 12 po) G = Gril lisse (on peut commander

des grils de 12, 24 ou 36 po)

Tous les grils lisses de moins de 36 pouces sont toujours montés du côté droit de la cuisinière.

Toutes les cuisinières d’une largeur de plus de 36 pouces comportent deux

connexions électriques. Assurez-vous que les deux sources d’alimentation ont été débranchées avant de

commencer tout entretien de l’appareil.

CUISINIÈRES DOUBLES

Les cuisinières d’une largeur de plus de 36 pouces sont construites de la façon suivante :

• EV48S – Jumelage d’un EV36S avec un EV12

• EV48SS – Jumelage de deux EV24S

• EV60SS – Jumelage d’un RV24S et d’un EV36S

• EV72SS – Jumelage de deux EV36S

0 0

Page 30

0 760 1234567089:273;0<=>010

ENTRETIEN

LA CUISINIÈRE ET SES COMPOSANTS SONT CHAUDS.

EXERCEZ UNE EXTRÊME PRUDENCE LORS DE SON UTILISATION, NETTOYAGE

ET ENTRETIEN.

Avant de nettoyer et d’entretenir cet appareil, coupez

l’alimentation électrique et observez les procédures de verrouillage et

d’étiquetage appliance.

RENSEIGNEMENTS SUR L’ENTRETIEN ET LES PIÈCES DE RECHANGE

Pour obtenir des renseignements sur l’entretien de l’appareil ou sur les pièces de rechange, communiquez avec

le service de l’entretien Vulcan-Hart près de chez-vous ou à l’adresse ou numéro de téléphone inscrits sur la page

couverture de ce manuel.

Page 31

0 7?0 1234567089:273;0<=>010

NETTOYAGE

DÉBRANCHEZ L’APPAREIL AVANT DE LE NETTOYER

N’UTILISEZ PAS le détergent à vaisselle Dawn® pour nettoyer les composants

extérieurs et intérieurs de la cuisinière®.

N’UTILISEZ PAS de poudre à récurer. Elle s’enlève très difficilement et peut s’accumuler, ce qui risque

d’endommager l’appareil.

N’UTILISEZ PAS des produits contenant des TSC.

Nettoyez la cuisinière et le four avec de l’eau chaude savonneuse et un chiffon doux. Rincez à fond et essuyez à

l’aide d’un chiffon doux et propre.

Gril lisse

Nettoyez le gril lisse avec une spatule approuvée après chaque usage. Le tiroir capteur de graisse devrait être

vidé sur une base routinière. Un trou de purge indique que le tiroir de graisse est près de sa pleine capacité. Si le

tiroir de graisse n’est pas vidé, il débordera et cela pourrait endommager la cuisinière. Hebdomadairement, ou

plus souvent au besoin, nettoyez à fond la surface du gril lisse au moyen d’une pierre pour plaque lisse et d’un

peu de graisse. Frottez dans le sens du grain pendant qu’elle est encore chaude. On peut aussi la nettoyer à l’eau

et au détergent à l’aide d’une brosse d’acier. Toute trace de détergent doit être soigneusement retirée. Après

chaque grand nettoyage, le gril lisse doit être conditionné de nouveau (voir la section AVANT LA PREMIÈRE

UTILISATION de ce mode d’emploi).

Évitez l’accumulation de graisse collée sous le rebord du trou d’égouttement et autour des bords extérieurs du

gril lisse.

Si le gril lisse ne sera pas utilisé avant une longue période, étendez une épaisse couche de graisse sur toute sa

surface.

Le four

Nettoyez le four et la porte quotidiennement, spécialement après la cuisson de tartes aux fruits, de sauces aux

tomates et de viandes ou après des débordements. Si on ne le fait pas, il peut en résulter de la corrosion dans les

composants de métal.

Si les parois et les soles du four sont très sales, enlevez les débordements de sucre ou de graisse brûlés au moyen

d’ammoniaque ou d’un nettoyant pour four, mais ceux-ci doivent être rincés à l’eau en profondeur pour éviter la

corrosion.

L’odeur de certains aliments cuits à basse température peut persister dans le four. Pour éliminer ces odeurs,

faites chauffer le four à vide à 260 °C (500 °F) pendant 30 à 45 minutes.

Page 32

0 730 1234567089:273;0<=>010

Cette plaque lisse est en acier, mais sa surface est relativement tendre et peut rayer ou

bosseler suite à l’utilisation d’une spatule ou d’un grattoir d’une manière négligente. Prenez soin de ne

pas la bosseler, l’égratigner ou la rayer. Ne pas y cogner les coins ou les rebords d’une spatule pour tenter

de déloger les particules d’aliments qui pourraient s’y trouver.

Les grils lisses sont équipés d’un élément chauffant de 3 400 watts par zone de gril de 305 mm (12 po). Chaque

élément est commandé par un thermostat séparé gradué de 93 à 288 °C (200 à 550 °F)

FOUR

Ne jamais recouvrir la sole ou la grille de papier d’aluminium. Le four ne fonctionnera

pas correctement et la cuisinière pourrait être endommagée.

Les cuisinières EV24S et EV36S sont pourvues d’un seul four tandis que les modèles EV48S, EV60SS et EV72SS sont

pourvus de deux fours séparés. Chaque four est muni d’éléments chauffants supérieurs et inférieurs. L’élément

supérieur est commandé par un commutateur à réglage continu pour le brunissage. CECI N’EST PAS UN ÉLÉMENT

À GRILLER. (L’interrupteur à réglage continu n’est pas livrable pour un élément supérieur de 480 volts).

La puissance totale du four est de 5 000 W, soit 1 250 W pour l’élément chauffant supérieur et 3 750 W pour

l’élément chauffant inférieur.

Préchauffage

Préchauffez le four avant de l’utiliser. Pour ce faire, réglez le commutateur et le thermostat à la température

désirée. Lorsque le voyant rouge s’éteint, le four est prêt pour la cuisson. Pour les charges pleines et les produits

de boulangerie et pâtisseries délicats, il est préférable de laisser le voyant rouge s’allumer et s’éteindre une

seconde fois avant de procéder au chargement du four.

Cuisson pâtisserie/boulangerie

On peut cuire la plupart des produits en réglant le commutateur de l’élément chauffant supérieur entre

VERY LO (TRÈS BAS) et LO (BAS). Il se peut que les aliments qui brunissent difficilement, comme le pain de maïs

ou les biscuits, requièrent un réglage MED (MOYEN) ou HI (ÉLEVÉ). Commencez par utiliser le réglage LO (BAS)

sur l’élément chauffant supérieur puis augmentez seulement si nécessaire

Rôtissage

Mettez la viande dans un plat à rôtir dont les bords sont suffisamment hauts pour empêcher le jus de cuisson de

déborder. Déposez le plat sur la grille ou sur la sole. Pour de meilleurs résultats, le ministère de l’agriculture des

États-Unis et l’Institut américain de la viande recommandent de faire rôtir la viande à basse température, soit

entre 93 et 163 °C (200 et 325 °F). Réglez le commutateur à réglage continu à HI (ÉLEVÉ) pour la plupart des

viandes. Dans le cas de la volaille, réglez-le entre MED-LO (MOYENNEMENT BAS) et VERY-LO (TRÈS BAS) pour

empêcher de trop brunir.

L’élément chauffant supérieur du four n’est pas approprié pour le grillage et ne fonctionne pas séparément du

thermostat du four (élément inférieur).

PANNE DE COURANT

En cas de panne de courant, la cuisinière s’éteint automatiquement. Dès que le courant est rétabli, elle poursuit son

cycle de cuisson normal. Si elle était sans surveillance pendant une panne de courant, mettez tous les

interrupteurs et boutons de commande à OFF (Arrêt). Dès que le courant est rétabli, remettez ceux-ci à

ON (Marche). L’appareil préchauffe pendant cinq minutes avant de poursuivre la cuisson normalement.

!

Page 33

0 750 1234567089:273;0<=>010

Les feux à la française (à surface pleine) fonctionnent à une puissance nominale de 2 000 W et sont commandés

par un commutateur à réglage continu. Ils requièrent de 5 à 7 minutes pour atteindre la température de cuisson

au réglage ÉLEVÉ à partir de la température ambiante.

Chaque bouton de commande porte les inscriptions HI, MED, LO, MED-LO et VERY-LO (ÉLEVÉ, MOYEN, BAS,

MOYENNEMENT BAS et TRÈS BAS respectivement). La marque ÉLEVÉ correspond au réglage le plus puissant.

Utilisez ce réglage pour amorcer la cuisson rapidement ou amener l’eau à ébullition.

Certaines choses À FAIRE et NE PAS FAIRE à l’égard de la cuisson sur la surface

À FAIRE : utilisez des marmites et casseroles de même dimension que les plaques (diamètre intérieur de 229 à

254 mm (9 à 10 po).

À FAIRE : utilisez des marmites et casseroles à fond plat et côtés droits.

À FAIRE : couvrez les marmites. L’eau vient ainsi à ébullition beaucoup plus rapidement. De plus, la cuisson dans

un récipient couvert requiert une quantité moindre d’eau et d’énergie, de sorte que les aliments conservent

leurs vitamines et minéraux

À FAIRE : éteignez les feux quelques minutes avant la fin de la cuisson de façon à utiliser la chaleur

emmagasinée dans la plaque.

NE PAS FAIRE : laisser les plaques chauffer à vide à intensité élevée, car elles atteindront des

températures très élevées qui risquent de provoquer le gauchissement ou le bombement de la fonte. Les

plaques chauffées à vide à l’intensité MED-LO (MOYEN-ÉLEVÉ) puis HI (ÉLEVÉ) lorsque des marmites ou

casseroles s’y trouvent assurent une cuisson tout aussi rapide sans toutefois endommager les plaques.

Les dommages causés aux plaques laissées à chauffer sans charge au réglage HI (ÉLEVÉ) annuleront la

garantie.

PLAQUE COUP DE FEU

Les plaques coup de feu peuvent compenser pour les marmites dont le diamètre interne dépasse 254 mm

(10 po). Les marmites peuvent dépasser d’une section coup de feu à une autre sans aucune perte de zone

de chauffage.

Il est important d’utiliser des marmites ou des casseroles à fond plat qui couvrent

uniformément toute la surface de la plaque coup de feu. Les marmites ou casseroles à fond courbé (que ce

soit par design ou qu’elles soient gauchies par l’utilisation) auront un mauvais contact et, par le fait même,

le transfert de chaleur ne se fera pas bien. Ceci aura pour résultat une piètre performance de cuisson.

Les sections coup de feu ont une intensité de 2 500 watts et sont commandées par un contrôle à action

rapide dont le bouton est marqué de 0 à 10 (10 étant le réglage de température le plus élevé). À partir de la

température ambiante, une section coup de feu atteindra la température de cuisson en 15 à 20 minutes à

un réglage de thermostat de 10.

Choses À FAIRE et NE PAS FAIRE à l’égard de la cuisson sur une plaque coup de feu

À FAIRE : utilisez des marmites et casseroles à fond plat et côtés droits.

À FAIRE : couvrez les marmites. L’eau vient ainsi à ébullition beaucoup plus rapidement. De plus, la cuisson dans

un récipient couvert requiert une quantité moindre d’eau et d’énergie, de sorte que les aliments conservent

leurs vitamines et minéraux.

GRIL LISSE

Se reporter à sa section AVANT LA PREMIÈRE UTILISATION pour le conditionnement du gril lisse.

Page 34

0 770 1234567089:273;0<=>010

AVANT LA PREMIÈRE UTILISATION

Nettoyage

Nettoyez la cuisinière et tous les accessoires avec de l’eau et du détergent doux. Bien rincer et essuyer à l’aide

d’un chiffon propre et doux.

Conditionnement du gril lisse

Il est nécessaire de conditionner un gril lisse neuf. Sa surface de métal est poreuse. Les aliments ont tendance à

s’incruster dans les pores et à y adhérer; Il est donc important de « conditionner » ou de « remplir » ces pores

d’huile de cuisson avant de commencer. Le conditionnement donne à la surface un fini lisse et dur, ce qui facilite

l’enlèvement des aliments.

Pour la conditionner, chauffez la surface du gril à basse température et versez-y une once d’huile de cuisson par

pied carré. À l’aide d’un chiffon isolé, étendez l’huile sur toute la surface du gril lisse de manière à obtenir un

mince film puis essuyez tout surplus d’huile avec le chiffon.

Répétez la manœuvre à deux ou trois reprises jusqu’à ce que la surface soit bien lisse.

FEUX À LA FRANÇAISE

Pour maximiser l’efficacité des plaques à la française, utilisez des marmites ou casseroles dont le diamètre

intérieur n’excède pas 254 mm (10 po) ou mesure au moins 229 (9 po). On recommande l’utilisation de marmites

de 8,4, 11,3 et 15,4 litres (9, 12 et 16 pintes) pour la cuisson en vrac (Fig. 7).

Il est recommandé d’utiliser des marmites ou des casseroles à fond plat qui couvrent toute la

surface de la plaque. Les marmites ou casseroles à fond courbé (que ce soit par design ou qu’elles soient

gauchies par l’utilisation) auront un mauvais contact et, par le fait même, le transfert de chaleur ne se fera pas

bien. Ceci aura pour résultat une piètre performance de cuisson.

Fig. 7

Page 35

0 790 1234567089:273;0<=>010

FONCTIONNEMENT

LA CUISINIÈRE ET SES COMPOSANTS SONT CHAUDS. EXERCEZ UNE EXTRÊME

PRUDENCE LORS DE SON UTILISATION, NETTOYAGE ET ENTRETIEN.

COMMANDES (Fig. 6)

Modèle EV36 illustré

Fig. 6

Commande des éléments Commutateurs à réglage continu servant à régler et à maintenir la température des

chauffants — feux de surface. Ces commutateurs fonctionnent par paires; le bouton de gauche

commande la température du feu avant et celui de droite, la température du feu arrière.

NOTA : Pour les appareils de 480 V, les feux à la française sont commandés par un

commutateur à 3 positions (FEU ÉLEVÉ = 2 000 W, FEU MOYEN = 1 000 W, FEU

BAS = 500 W).

Interrupteur de la surface (Non illustré). Un thermostat (1-10) servant à régler et à maintenir la température

coup de feu — de la section coup de feu. Choisir le niveau de chaleur désiré, 1 étant le minimum et

10 le maximum.

Thermostat de gril lisse — (Non illustré). Dispositif servant à régler la quantité de chaleur requise pour le

maintien de la température désirée. Chaque section de 12 po (305 mm) du gril lisse

est dotée de son propre thermostat dont la fourchette de température va de 93 à

288 °C (200 à 550 °F).

Voyant du gril lisse — (Non illustré) Ce voyant demeure allumé tant que la température désirée n’est pas

atteinte ou maintenue.

Bouton du thermostat Bouton servant à régler la quantité de chaleur requise pour le réglage et le maintien

du four — de la température du four. Celui-ci est gradué de 93 à 288°C (200 à 550 °F). Pour

augmenter la température, tournez le bouton dans le sens contraire de l’horloge et

dans le sens inverse pour la réduire.

Commutateur à réglage Dispositif servant à commander la cuisson par l’élément chauffant du haut pour

continu de l’élément brunir. Réglez au besoin selon la température désirée pour brunir le produit.

supérieur du four NOTA : Le commutateur à réglage continu n’est pas disponible pour les appareils de

480 V. L’endroit où il est placé sur le panneau sera bouché par une fiche.

Voyant de four — Lorsqu’il est allumé, ce voyant indique que la température désirée est atteinte ou

maintenue.

V/$./(B0E)0

&/--'(E)0E)B0

G%G-)(.B0&M'$FF'(.B0 0

Z/--$.'.)$D0O0DG H%' H)0

&/(.+($0E$0F/$D0

>/['(.0E)0B+H('%+B'.+/(0

E$0F/$D0

V/$./(0E$0.M)D-/B.'.0

E$0F/$D0

Page 36

0 :0 1234567089:273;0<=>010

!

0

0

0

0

!

U'P%)..)0O0&/(E+-)(.B0

8L&&)BB/+D);0

U'P%)..)0O0EG&/$,)D0

8L&&)BB/+D);0

V'DD)0O0B )D#+)..)B0

8L&&)BB/+D);0

U'P%)..)0'#'(.0

'DD/(E+)0B.'(E'DE0

V$%%(/B)0

W(B.'%%)X0%)B0#+B0&D$&+F/D-)B07925?0Q0Y0,/0

E'(B0%)B0F)(.)B0E)0%'0.'P%)..)0'DD/(E+)0

.)%0*$)0(/.G"0

Remarque!:0'%+H()X0P+)(0%)0

P/$.0E$0D)P/DE0'DD/(E+0'$0

P/$.0E)0%'0&$+B+(+CD)"0

1+H$D)070

1+H$D)050

0

Page 37

0 40 1234567089:273;0<=>010

RACCORDEMENTS ÉLECTRIQUES

LE RACCORDEMENT ÉLECTRIQUE ET LA MISE À LA TERRE DOIVENT ÊTRE

CONFORMES AUX NORMES CONCERNÉES DU CODE CANADIEN DE L’ÉLECTRICITÉ OU DE TOUT AUTRE

CODE D’ÉLECTRICITÉ EN VIGUEUR.

COUPEZ L’ALIMENTATION ÉLECTRIQUE DE L’APPAREIL ET APPOSEZ UNE

ÉTIQUETTE AU DISJONCTEUR POUR AVERTIR QU’UN TECHNICIEN TRAVAILLE SUR LE CIRCUIT.

Placez la cuisinière à l’emplacement prévu. Passez le conduit renfermant le fil d’alimentation approprié à la

cuisinière dans la débouchure située dans le bas de l’appareil. Il vous faut choisir le calibre et le type de fil

conformément au Code canadien de l’électricité et en fonction de la tension et l’intensité nominale de l’appareil.

Pour les appareils de plus de 80 A, utilisez des fils pouvant supporter des températures allant jusqu’à 75 °C (167 °F).

Si vous avez acheté un modèle EV48, EV60 ou EV72, il y aura deux (2) raccordements

électriques. Les parties à gauche et à droite de la cuisinière sont munies de circuits de dérivation individuels

et on trouve les points de raccordement sous chaque four ou dans le panneau de commande du côté

droit.

LES APPAREIL DE 48, 60 ET 72 PO COMPORTENT PLUS D’UNE SOURCE D’ALIMENTATION

ÉLECTRIQUE. CHAQUE SOURCE DOIT ÊTRE RACCORDÉE CONFORMÉMENT AU CODE NATIONAL

ÉLECTRIQUE (ÉDITION LA PLUS RÉCENTE) OU AUX CODES LOCAUX.

Raccordez les fils d’alimentation au bloc de jonction sur les lieux ainsi que le fil vert au raccord de mise à la terre

étiqueté comme tel. Le conduit d’alimentation devrait être ancré dans le trou d’accès avec un raccord de traversée.

À l’expédition, les cuisinières sont câblées pour un courant triphasé, mais ce câblage peut être changé sur place

pour un courant monophasé. Voir le schéma de câblage et le décalque schématique attaché à la cuisinière si des

changements sont nécessaires.

NIVELAGE

Déposez un niveau de menuisier sur le dessus de la cuisinière et procédez à son nivelage d’avant vers l’arrière

puis d’un côté à l’autre en tournant le pied de réglage.

INSTALLATION DE L’ACCESSOIRE REBORD AVANT ARRONDI

1) Retirez les vis qui retiennent le couvercle du commutateur en place et laissez-le pivoter vers le bas

pour l’écarter.

2) Retirez les vis du devant qui le retiennent en place.

3) Faites glisser le devant arrondi standard pour le retirer de la cuisinière.

4) Faites glisser l’accessoire dans le chemin duquel le devant arrondi standard a été retiré et alignez

le bien avec le côté de la cuisinière.

5) Commencez à serrer une vis à un bout de la cuisinière en ne la serrant pas complètement.

6) Allez à l’autre côté de la cuisinière pour installer une autre vis tel qu’illustré à la figure 2, procédez

à l’alignement et serrez la vis solidement.

7) Installez les vis qui vous restent et serrez toutes les vis solidement.

Page 38

0 S0 1234567089:273;0<=>010

MODÉLES DES CUISINIÉRES

INSTALLATION DES PIEDS

INSTALLATION DES ROULETTES

EV12 4 4

EV24 4 4

EV36 4 4

EV48 8 8

EV60 8 8

EV72 8 8

Installation des pieds ou des roulettes :

1. Penchez ou soulevez doucement la cuisinière pour avoir accès au sous plancher pour l’installation des

pieds.

2. Alignez les trous de la plaque de montage des pieds ou des roulettes avec les trous déjà perforés aux

quatre coins dans le bas de la cuisinière.

3. Attachez la plaque de montage au bas de la cuisinière en utilisant quatre vis auto taraudeuses de

1/4 – 20 x 5/8 po (livrées). Si des roulettes sont installées, les roulettes de freinage devraient être

installées à l’avant.

4. Après avoir installé tous les pieds et les roulettes, remettez doucement la cuisinière debout

(Pour des renseignements supplémentaires au sujet des pieds, voir la section Nivelage de ce manuel).

Un appareil monté sur roulettes qui est raccordé en permanence et qui doit être fixé à la structure de l’édifice

doit être conforme aux critères suivants :

a. Prenez les moyens nécessaires pour limiter le mouvement de l’appareil sans avoir à dépendre de la

conduite électrique ou d’avoir à tirer dessus.

b. Les endroits où les dispositifs de retenue sont attachés à l’appareil doivent être situés à l’extérieur des

pièces arrière du châssis du four de la cuisinière (là où le bas arrière de l’écran thermique est boulonné à

la cuisinière.) Utilisez les supports inclus comme points de raccordement tel qu'illustré ci-dessous.

c. Utilisez un conduit flexible pour l’installation de cet appareil.

Si la cuisinière est installée sur des roulettes et doit être déplacée pour une raison quelconque, il est conseillé de

la niveler de nouveau d’avant vers l’arrière et d’un côté à l’autre.

T$,,/D.0E$0E+B,/B+.+F0E)0D ).)($)0

Page 39

0 @0 1234567089:273;0<=>010

Installation de la porte

1. Agrippez la porte fermement des deux côtés.

2. En commençant par la languette supérieure de la charnière de gauche ou de droite, penchez la porte et

glissez la languette supérieure de la charnière dans l’ouverture entre le rouleau d’arrêt et la goupille d’arrêt

de la charnière.

3. Soulevez la porte vers le haut (compressez la charnière comme si vous ouvriez la porte) et positionnez la

languette inférieure vers le bas à un angle d’environ 30 degrés du plan horizontal.

4. Poussez la porte vers l’intérieur, en insérant la languette inférieure de la charnière à un angle descendant

dans l’ouverture juste au-dessus la goupille d’arrêt de la charnière.

*La languette de la charnière inférieure doit entrer dans le châssis à un angle descendant pour pouvoir

s’engager.

5. La languette inférieure de la charnière devrait s’engager sur la goupille d’arrêt de la charnière.

6. Ouvrez et tirez la porte vers l’extérieur jusqu’à ce que la languette inférieure de la charnière se verrouille sur

la goupille d’arrêt de la charnière.

7. Reprendre les étapes ci-dessus pour le côté opposé.

8. Ouvrez et fermez la porte pour vous assurer que les charnières sont bien verrouillées en place et que la

porte fonctionne en douceur.

EMPLACEMENT

A)B0&$+B+(+CD)B0E/+#)(.0B)0.D/$#)D0E'(B0$(0)(ED/+.0B$FF+B'--)(.0EGH'HG0,/$D0)(0,)D-)..D)0%I)(.D).+)(0).0%)0

F/(&.+/(()-)(.0',,D/,D+G"0J(0E GH 'H )-)(.0-+(+-'%0E)07097@0--08?90, / ;0)B .0D)*$+B0E)#'(.0%K',,'D)+%"0L$&$(0

EGH'H)-)(.0(K)B.0D)*$+B0E)0&M'*$)0&N.G0).0O0%K'DD+CD)0E)0./$.)0&/(B.D$&.+/(0&/-P$B.+P%)0).0+(&/-P$B.+P%)0)Q&),.G0

B+0E)B0B)&.+/(B0E)0,%'*$)B0&/$,0E)0F)$0B/(.0+(&/D,/DG)B"0A)B0&$+B+(+CD)B0E/(.0%)B0B)&.+/(B0E)0,%'*$)B0&/$,0E)0F)$0

B/(.0+(&/D,/DG)B0()0D)*$+CD)(.0'$&$(0EGH'H)-)(.0E)0&M'*$)0&N.G0).0O0%K'DD+CD)0E)0./$.)0&/(B.D$&.+/(0+(&/-P$B.+P%)R0

-'+B0D)*$+CD)(.0$(0EGH'H)-)(.0E)07650--08@0,/;0E)0./$.)0&/(B.D$&.+/(0&/-P$B.+P%)"0

CODES D’INSTALLATION ET NORMES

L’installation des cuisinières Vulcan doit se faire selon les codes locaux ou, en l’absence de tels codes, selon la

norme ANSI/NFPA-70 (édition la plus récente) du Code national de l’électricité dont on peut se procurer copie

auprès de la National Fire Protection Association, Batterymarch Park, Quincy, MA 02269. Pour le Canada, se

référer au Code canadien de l’électricité C22.1, Partie 1 (édition la plus récente).

ASSEMBLAGE

Assemblage des pieds et des roulettes

La cuisinière est expédiée complètement assemblée excepté les pieds. Elle est pourvue de pieds réglables en

inox de 152 mm (6 po) (quincaillerie incluse), emballés dans une boîte placée à l’intérieur du four. Un ensemble

de roulettes de 152 mm (6 po) est un accessoire offert en option qui peut s’installer sur place.

Page 40

0 60 1234567089:273;0<=>010

INSTALLATION

DÉBALLAGE

Cette cuisinière a été inspectée avant de quitter l’usine. En acceptant de livrer cette marchandise, le transporteur

en assume l’entière responsabilité jusqu’à sa livraison. Immédiatement après avoir déballé l’appareil, vérifiez s’il

n’a pas été endommagé lors du transport. En cas de dommages, conservez le matériel d’emballage et avisez le

transporteur immédiatement.

Enlevez toutes les attaches et blocs de bois servant à l’expédition ainsi que tous les accessoires. Déballez

l’étagère surélevée et les dosserets.

Avant l’installation, assurez-vous que l’alimentation électrique de l’immeuble correspond aux spécifications de la

plaque signalétique se trouvant derrière le panneau inférieur du côté gauche. S’ils ne correspondent pas,

communiquez immédiatement avec votre détaillant ou avec Vulcan-Hart.

S’il est nécessaire de retirer la porte et de la réinstaller pour accéder à la cuisine, veuillez suivre les instructions

ci-dessous.

Pour retirer la porte

1. Ouvrez la porte.

2. Agrippez la porte fermement des deux côtés.

3. Soulevez la porte vers le haut et faites-la coulisser de façon à dégager la languette inférieure de la charnière.

*Il est plus facile de faire un côté à la fois.

4. Fermez la porte presqu’au complet et abaissez-la légèrement pour dégager la languette supérieure de la

charnière.

5. Tirez la porte vers l’extérieur

Page 41

0 ?0 1234567089:273;0<=>010

INSTALLATION, FONCTIONNEMENT ET ENTRETIEN DES

CUISINIÈRES ÉLECTRIQUES DE RESTAURANTS

DOCUMENT À CONSERVER EN CAS DE BESOIN

GÉNÉRALITÉS

Lisez ce manuel au complet et observez soigneusement toutes les instructions mentionnées.

Les appareils Vulcan-Hart sont fabriqués par une main d’œuvre de qualité et avec de bons matériaux. Leur

installation, utilisation et entretien appropriés permettront d’en obtenir un rendement satisfaisant pendant de

nombreuses années.

ACCESSOIRES À INSTALLER SUR LES LIEUX

OFFERTS EN OPTION

CODE D’ACCESSOIRE

DESCRIPTION

RSHELF-ELEC (24,36,48,60,72)

Étagère renforcée – Dosseret en inox d’une hauteur de 23 po (584 mm)

équipé de supports de montage pour salamandres/grilloirs.

STUB10-XL (12,24,36,48,60,72)

Dosseret court de 10 po en inox. Livrable avec les cuisinières de 12, 24, 36,

48, 60 et 72.

CONRACK-XL(20,26)

OVNRACK-XL(20,26) RKGUIDE-XL

1 grille supplémentaire avec les fours à convection.

1 grille supplémentaire avec les fours standards.

1 paire de glissières pour les grilles (jeu de 2).

CASTERS-RR4

CASTERS-RR8

CASTERS-ADJRR4

Jeu de quatre (4) roulettes de série.

Jeu de huit (8) roulettes de série.

Jeu de quatre (4) roulettes réglables – 2 jeux requis pour les cuisinières de

48, 60 et 72 po.

RCTWLBR-(24,36,48,60,72)

Ensemble porte-serviettes – Remplace le rebord arrondi de série. Livrable

avec les cuisinières de 24, 36, 48, 60 et 72.

RCCUTBD-(24,36,48,60,72)

Ensemble planche à découper – Remplace le rebord arrondi de série.

Livrable avec les cuisinières de 24, 36, 48, 60 et 72 po (comprend une

planche à découper tout caoutchouc de marque Sani-TUFF®).

RCCONRL-(24,36,48,60,72)

Ensemble rail à condiments – Remplace le rebord arrondi de série. Livrable

avec les cuisinières de 24, 36, 48, 60 et 72 po (ne comprend pas les bacs à

condiments).

SHIELD-FRYRH

SHIELD-FRYLH

Bouclier pour friteuses – Côté gauche ou droit. Pour protéger le dessus de la

cuisinière contre les projections d’huile venant d’une friteuse adjacente.

VFLANGED-FEET/4

Jeu de quatre (4) pieds à collerette – Deux (2) jeux requis pour les cuisinières

de 48, 60 et 72 po.

CURBMNT-XL4

Montage sur muret porteur – Deux (2) jeux requis pour les cuisinières de 48,

60 et 72 po.

Page 42

0 30 1234567089:273;0<=>010

MODÈLES DES CUISINIÈRES ÉLECTRIQUES DE RESTAURANTS

EV12 EV24S EV36S

EV48S EV48SS

EV60SS

Page 43

0 50 1234567089:273;0<=>010

TABLE DES MATIÈRES

CUISINIÈRES ÉLECTRIQUES DE RESTAURANTS .………………………………………………………………… 3

GÉNÉRALITÉS ……………………………………………………………………………………………………. 5

ACCESSOIRES À INSTALLER SUR LES LIEUX ..……………………………………………………………………. 5

INSTALLATION …………………………………………………………………………………………………… 6

Déballage …….………………………………………………………………………………………… 6

Emplacement .………….………………………………………………………………………………. 7

Codes d’installation et normes ………………………………………………………………………… 7

Assemblage……………………………………………………………………………………………… 7

Raccordements électriques …………………………………………………………………………… 9

Nivelage ………………………………………………………………………………………………… 9

Installation du rebord avant à chanfrein arrondi ……………………………………………………… 9

FONCTIONNEMENT ……………………………………………………………………………………………… 11

Commandes ….………………………………………………………………………………………… 11

Avant la première utilisation …..……………………………………………………………………… 12

Feux de type français ……………………………………………………………………….………… 12

Grils lisses ……………………………………………………………………………………………. 13

Four …………………………………………………………………………………………………… 14

Panne de courant ……………………………………………………………………………………… 14

Nettoyage ……………………………………………………………………………………………… 14

ENTRETIEN ………………………..……………………………………………………………………………… 16

Service de l’entretien et pièces de rechange ………………………………………………………… 16

SPÉCIFICATIONS ÉLECTRIQUES ………………………………………………………...……………………….. 17

SCHÉMAS DE CÂBLAGE ……………………………………………………………………………………. 18 – 22

NOTES ………………………………………………………………………………………………………..…. 23

Page 44

!!!"#$%&'()*$+,-)(."&/-0 0 1234567089:273;0<=>010

MANUEL D’INSTALLATION

& MODE D’EMPLOI

CUISINIÈRES ÉLECTRIQUES DE RESTAURANTS

Pour de plus amples détails concernant la Compagnie Vulcan-Hart ou pour trouver un fournisseur de pièces de

rechange et d’entretien autorisé près de chez-vous, visitez notre site Web au : www.vulcanequipment.com

VULCAN-HART 3600 BOULEVARD NORTH POINT

UNE DIVISION DU GROUPE ITW ÉQUIPEMENT ALIMENTAIRE, SRL BALTIMORE, MD 21222

00 00000 0

MODÈLES(

EV12( ((EV48S(

EV24S( ((EV48SS(

EV36S( ((EV60SS(

Loading...

Loading...