Page 1

INSTALLATION & OPERATION MANUAL

CHEESEMELTER

MODELS

VCM24

VCM36

VCM48

VCM60

VCM72

CMJ24

CMJ36

CMJ48

CMJ60

CMJ72

VCM48

CMJ48

©ITW Food Equipment Group, LLC

3600 North Point Blvd.

Baltimore, MD 21222

RETAIN THIS MANUAL FOR FUTURE USE

FORM F-36954 (3-11)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO

INSTALL GAS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD

START-UP AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS

MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN

THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE

OBTAINED FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

adjustment, alteration, service or maintenance

can cause property damage, injury, or death.

Read the installation, operating and maintenance

instructions thoroughly before installing or

servicing this equipment.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

Improper installation,

-

2 -

Page 3

INSTALLATION, OPERATION AND CARE OF

CHEESEMELTERS

GENERAL

Cheesemelters are produced with quality workmanship and material. Proper installation,

usage and maintenance of your Cheesemelter will result in many years of satisfactory

performance.

Model # of Burners BTU/hr Input Rating

VCM24 / CMJ24 1 18,000

VCM36 / CMJ36 1 24,000

VCM48 / CMJ48 2 36,000 (2 @ 18,000)

VCM60 / CMJ60 2 42,000 (1 @ 18,000 + 1 @ 24,000)

VCM72 / CMJ72 2 48,000 (2 @ 24,000)

INSTALLATION

Before installing, verify that the type of gas (natural or propane) and the clearance

dimensions (see page 4) agree with the specifications on the rating plate which is located

under the crumb tray on the right side. If the supply and equipment requirements do not

agree, do not proceed with the installation. Contact your dealer immediately. It is

recommended that a trained gas service technician with the necessary tools, instruments

and skills perform the installation of the cheesemelter

UNPACKING

Immediately after unpacking, check for possible shipping damage. If the cheesemelter is

found to be damaged, save the packaging material and contact the carrier within 15 days

of delivery.

Before using, remove all packaging material and protective plastic from the surfaces of

the unit. Carefully unpack your cheesemelter and make sure that no parts are discarded

with the packaging material. A pressure regulator designed to operate with the

cheesemelter has been supplied and must be installed before the cheesemelter is placed

into service. (Refer to GAS PRESSURE REGULATOR INSTALLATION in this manual).

-

3 -

Page 4

LOCATION

The equipment area must be kept free and clear of combustible substances.

Minimum Clearances

Combustible Construction Non-Combustible Construction

Back 2" 0"

Sides 20" 0

Bottom 10" 4"

The installation location must allow adequate clearances for servicing and proper

operation. While another gas-fired cheesemelter can be placed adjacent to this

Cheesemelter, there must be no obstruction to the front of the Cheesemelter. A minimum

front clearance of 36" (91 cm) is required.

It is recommended that the cheesemelter not be installed directly over or directly adjacent

to charbroilers, griddles or fryer banks. Infrared burners can be susceptible to the effects

of grease laden smoke and installation in these locations may shorten burner life. The

cheesemelter must be installed so that it is level side to side and front to back.

Do not obstruct the flow of combustion and ventilation air. Adequate clearance for air

openings into the combustion chamber must be provided. Make sure there is an adequate

supply of air in the room to replace air taken out by the ventilating system.

Do not permit fans to blow directly at the Cheesemelter. Avoid wall-type fans which

create air cross currents within the room. Avoid open windows next to the Cheesemelter.

Maintain an 18" (46 cm) clearance from the top of the flue vent to the filters of the hood

venting system or any other obstruction.

INSTALLATION CODES AND STANDARDS

The Cheesemelter must be installed in accordance with:

In the United States of America:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1/NFPA #54 (latest edition). This shall include but

not be limited to: NFPA #54 Section 10.3.5.2 for Venting. Copies may be obtained

from The American Gas Association Accredited Standards Committee Z223, @ 400

N. Capital St. NW, Washington, DC 20001 or the Secretary Standards Council, NFPA,

1 Batterymarch Park Quincy, MA 02169-7471

NOTE: In the Commonwealth of Massachusetts

All gas appliances vented through a ventilation hood or exhaust system equipped with

a damper or with a power means of exhaust shall comply with 248 CMR.

3. NFPA Standard # 96 Vapor Removal from Cooking Equipment, latest edition, available

from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada:

1. Local codes.

2. CAN/CSA-B149.1 Natural Gas Installation (latest edition)

3. CAN/CSA-B149.2 Propane Installation Code (latest edition), available from the

Canadian Gas Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3

-

4 -

Page 5

The cheesemelter and its parts are hot. Use care when operating,

cleaning or servicing the cheesemelter.

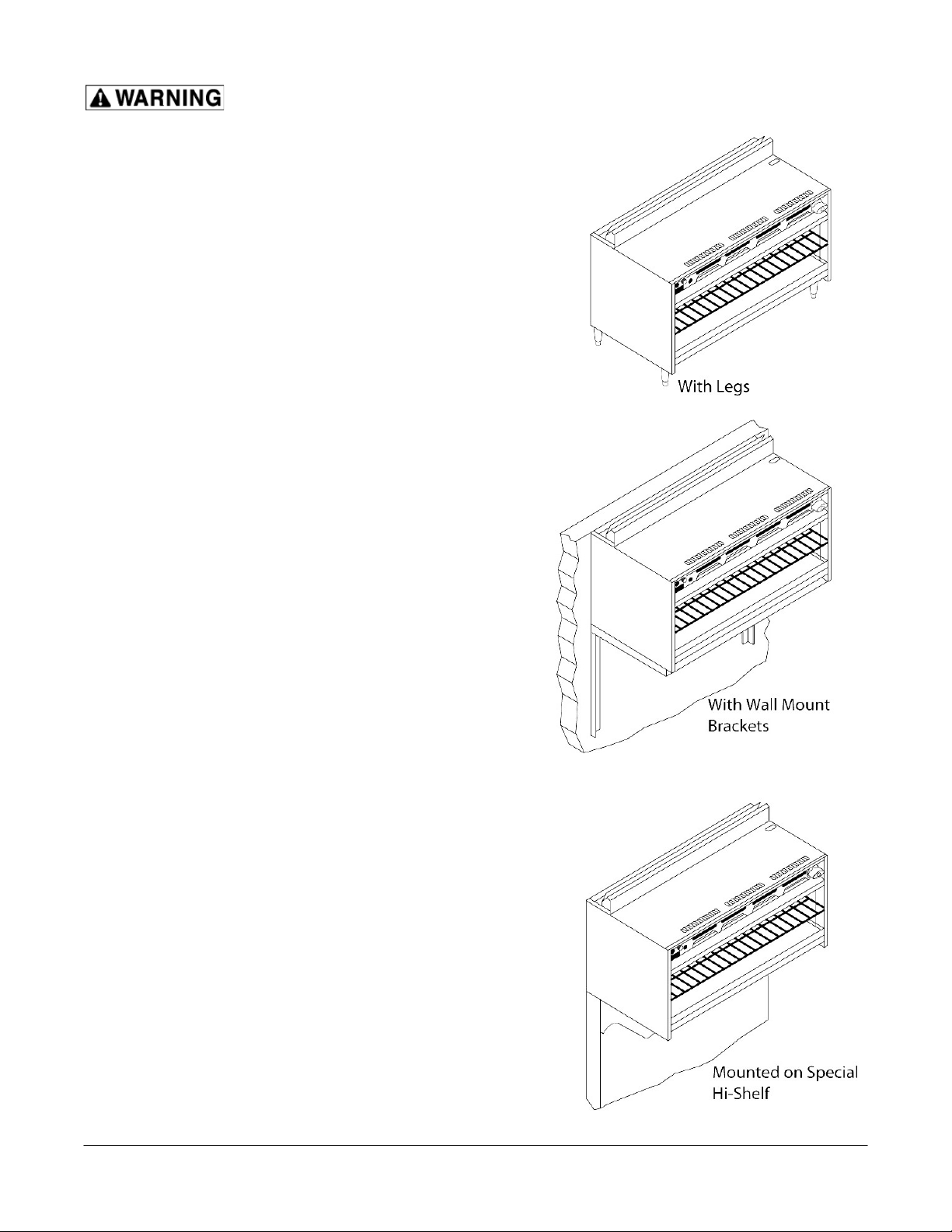

ASSEMBLY

Cheesemelters Mounted on a Counter

Cheesemelters mounted on a counter must be equipped

with 4" (10 cm) legs(sold separately). Screw the legs

into the threaded attachment points on the bottom of the

unit. The countertop must be of noncombustible

construction. Place Cheesemelter in position, then level

by adjusting the bullet feet.

Cheesemelters Mounted on a Wall

1. Make sure brackets are level and properly spaced

so that bracket holes will align with the threaded

attachment points on the bottom of the unit.

2. Mount the brackets only in the upside-down “L”

position as shown. 24 thru 48 models require two

brackets while 60 and 72 models require three

brackets for proper support.

3. Secure brackets to wall by means of lag screws or

bolts. Make sure the lag bolts or screws engage

wall studs.

4. Place unit into position on the brackets, making sure

that the unit’s bottom threaded attachment points

are aligned with the holes in the brackets.

5. Secure unit into position with four (24 to 48 models)

or six (60 and 72 models) 3/8” bolts. Thread the bolts

through the holes in the brackets and into the threaded

attachment points on the bottom of the unit.

Cheesemelter Mounted on Special Hi-Shelf

If the Cheesemelter is to be mounted over a Gas Range,

a reinforced hi-shelf designed for that range is required.

1. Place and align Cheesemelter on top of shelf brackets;

place the back of the unit flush with the rear of the shelf.

2. Align holes in the shelf with the threaded attachment

points on the bottom of the cheesemelter.

3. Secure cheesemelter into place with four 3/8” bolts .

Thread the bolts through the shelf and into the threaded

attachment points at each corner of the cheesemelter.

-

5 -

Page 6

GAS CONNECTIONS

Gas supply connections and any pipe joint compound must be resistant to the

action of propane gases.

Location of the gas inlet is at the top right rear corner of the top panel. Codes require that

a gas shutoff valve must be installed in the gas line ahead of the Cheesemelter.

Use a ¾” NPT gas supply line for the cheesemelter inlet. All flexible and semi-rigid gas

supply lines must comply with the applicable ANSI standard. To ensure maximum

operating efficiency this appliance must be connected with a gas supply line of solid pipe

or a commercial type Flexible Connector with the net inside diameter (I.D.) as large as or

larger than the gas pipe inlet on this appliance.

Prior to lighting, check all joints in the gas supply line for leaks.

Use soap and water solution. Do not use an open flame.

After checking for leaks all lines receiving gas should be fully purged to remove air.

Maximum line pressure for natural and propane gas is 14" W.C. Minimum line pressure is

7" W.C. for natural gas and 11" W.C. for propane gas.

TESTING THE GAS SUPPLY SYSTEM

When gas supply pressure exceeds ½ psig (3.45 kPa), the Cheesemelter and its

individual shutoff valve must be disconnected from the gas supply piping system.

When gas supply pressure is ½ psig (3.45 kPa) or less, the Cheesemelter should be

isolated from the gas supply system by closing its individual manual shutoff valve.

FLUE CONNECTIONS

Do not obstruct flow of flue gases from the flue located on the rear of the Cheesemelter.

It is recommended that the flue gases be ventilated to the outside of the building through

a ventilation system installed by qualified personnel.

Information on the construction and installation of ventilating hoods may be obtained from

the standard for "Vapor Removal from Cooking Equipment," NFPA No. 96 (latest edition),

available from The National Fire Protection Association, Batterymarch Park, Quincy, MA

02269.

-

6 -

Page 7

GAS PRESSURE REGULATOR INSTALLATION

Gas regulator pressure is preset at 5” Water Column (W.C.) for natural gas, and 10” W.C.

for propane gas. Minor adjustments may be required based on site specific gas pressure.

Install the regulator as close to the cheesemelter on the gas supply line as possible.

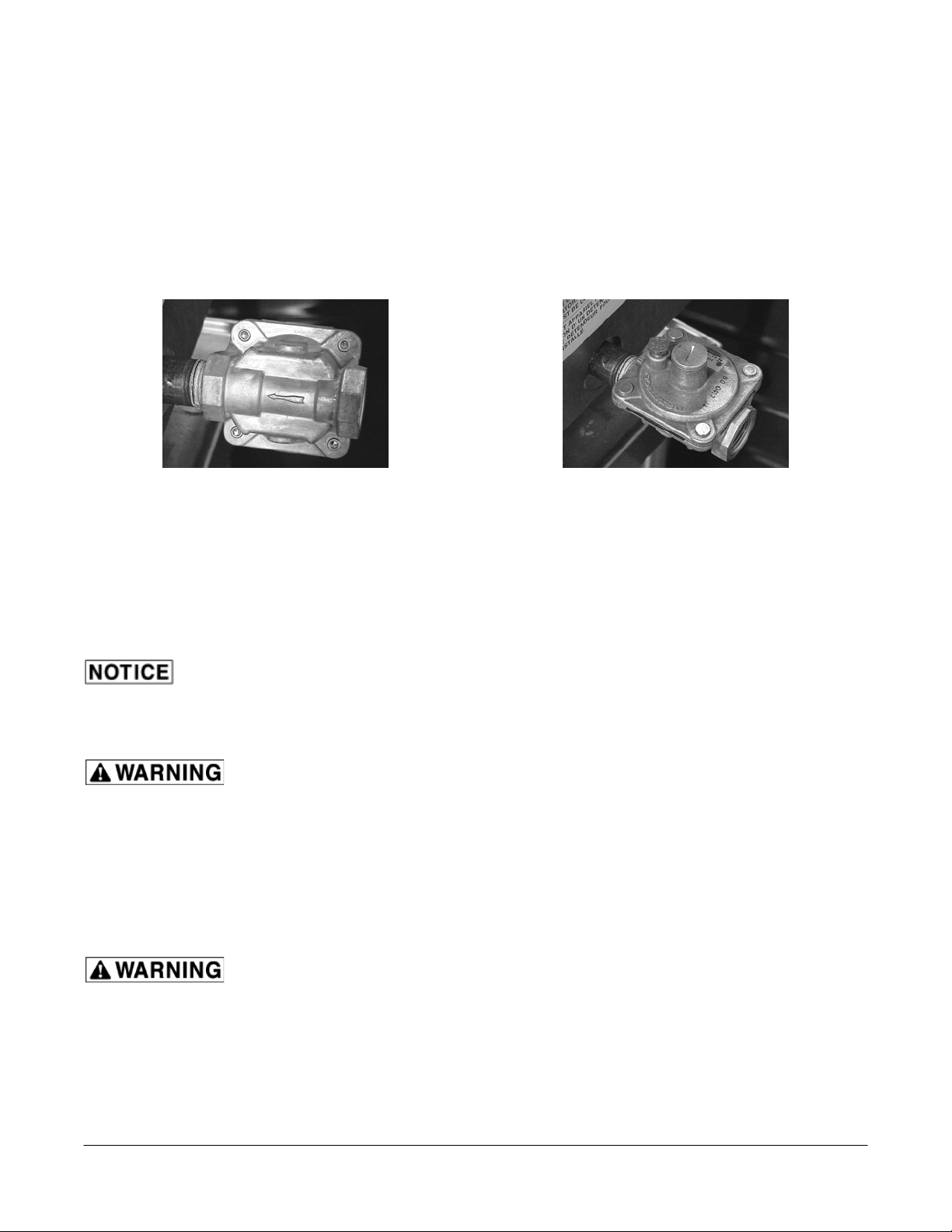

Make sure that the arrow on the underside of the regulator is oriented in the direction of

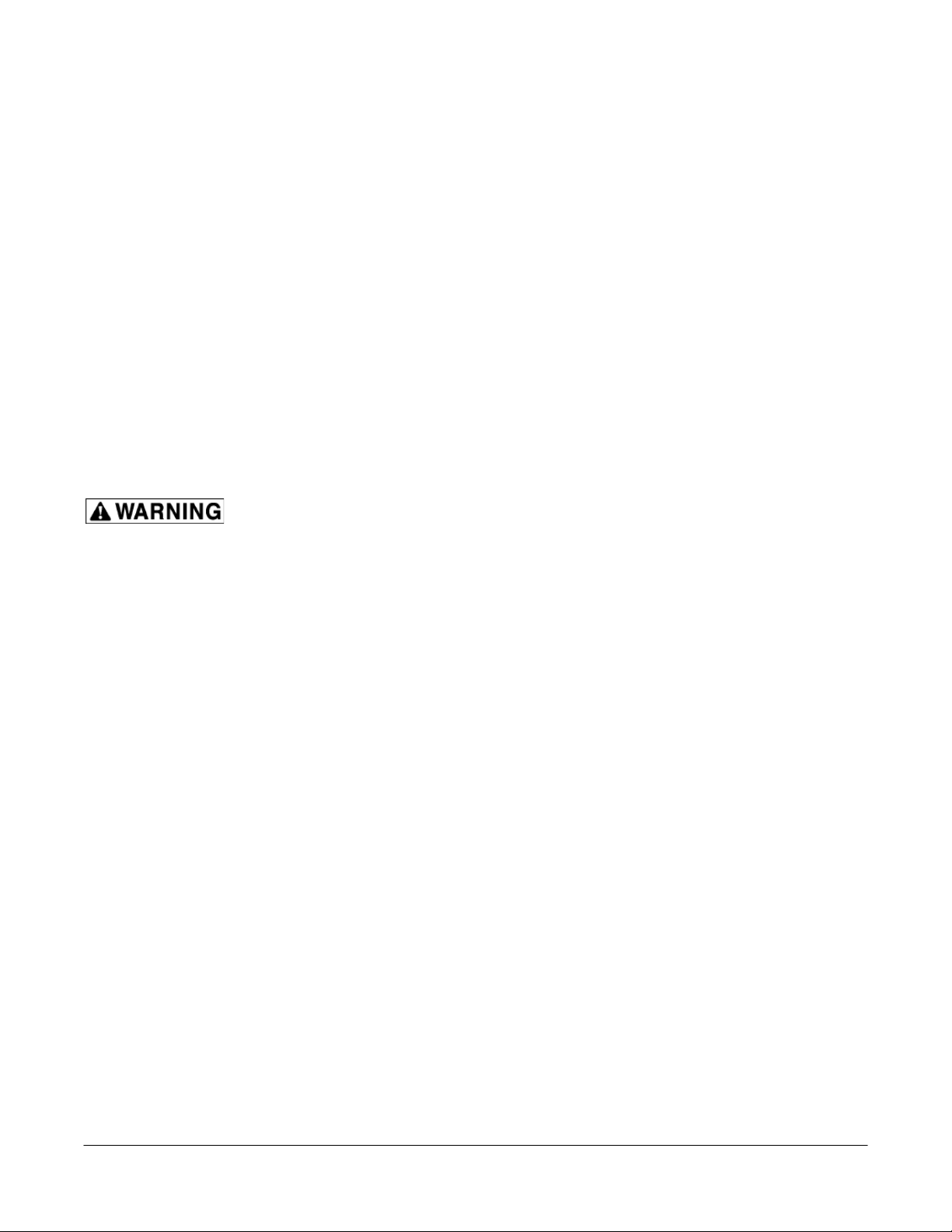

gas flow to the cheesemelter (Fig. 2) and the regulator is positioned with the vent plug

and adjustment screw upright (Fig. 3).

Fig. 2

The minimum supply pressure (upstream of the regulator) should be 7-9” W.C. for natural

gas and 11-12” W.C. for propane gas. At no time should the cheesemelter be connected

to supply pressure greater than ½ psig (3.45 kPa) or 14” W.C.

Gas supply connections and any pipe joint compound must be resistant to the

action of propane gases.

Prior to lighting, check all joints in the gas supply line for leaks.

Use soap and water solution. Do not use an open flame.

Fig. 3

OPERATION

The cheesemelter and its parts are hot. Use care when operating,

cleaning or servicing the cheesemelter

LOADING AND UNLOADING

Place the rack in the desired position. Pull the rack out for loading and avoid spillage.

Push the rack into place and cook for the appropriate time. Pull the rack out for

unloading.

-

7 -

Page 8

PREHEATING

Place the rack in its highest position. Turn the burner valve knob completely

counterclockwise and preheat for 15 minutes.

RECIPE AND RACK ADJUSTMENT

Positioning the Cheesemelter rack is an important factor in the desired product end

results. Position the rack farther away from the burners for thick casseroles and for

melting cheese or butter to avoid drying the product. Position the rack closer to the

burners for bacon, toast and quick heating, but watch carefully to avoid burning.

CLEANING

The cheesemelter and its parts are hot. Use care when operating,

cleaning or servicing the cheesemelter

Interior

When the Cheesemelter is cool, remove rack. Clean the rack and crumb tray daily by

soaking in warm detergent water. Scrub with a stiff-bristled brush. Do not use harsh

abrasives.

After scrubbing, wash with soapy water, rinse and dry. Soap and water will normally do

the job. Heavy spattering or spillovers may require cleaning with mild cleaner or soapy

wet pads.

Exterior

When the Cheesemelter is cool, knobs and stainless steel surfaces may be cleaned with

mild soap and water applied with a damp cloth. Wipe the surface with clean water and

dry with a soft clean cloth. Do not use abrasive cleaners or strong liquid cleaners on

stainless steel surfaces as they may damage the finish.

Spray-On Cleaners

Be careful when using spray-on cleaners. Some cleaners may contain caustics. Please

follow cleaner manufacturer's instructions.

-

8 -

Page 9

CONTROLS

The cheesemelter and its parts are hot. Use care when operating,

cleaning or servicing the cheesemelter

pilot adjustment valves

sliding shelf (rack) crumb trays

burner valves

Burner Valve

Each burner is independently controlled by an infinite control burner valve. Once the pilots are lit,

turning the burner valves to the ON position (completely counter clockwise) will light each burner. The

burner valves regulate the flow of gas to the burners. Gas flow is increased by turning the valve

counterclockwise. After preheating, the maximum output is not required. Turn the valve clockwise until

the desired performance is achieved.

Sliding Shelf (Rack)

There are three rack positions. Place the shelf on the rack needed for Cheesemelting. For deeper,

longer heat, use lower positions. For thinner foods, or faster cooking, use top shelves.

Crumb Tray

The crumb tray collects crumbs and waste. Do not allow the crumb tray to overflow. Empty the crumb

tray when three-quarters full to reduce the possibility of spillage.

Pilot Adjustment Valve

The pilot adjustment valve regulates the flow of gas to the pilot burner. Using a flathead screwdriver,

turn the slotted screw clockwise to decrease the flame, and counter clockwise to increase the flame.

-

9 -

Page 10

SHUTDOWN

1. Turn the burner valve knobs completely clockwise to cut off burners.

2. The pilots will remain lit as long as the gas supply is on.

EXTENDEDSHUTDOWN

1. Turn the burner valve knobs completely clockwise to cut off burners.

2. Turn the unit gas shutoff valve to the OFF position.

LIGHTING THE PILOT

1. Turn the main gas shutoff valve

and the individual burner valves

to the OFF position and wait 5

minutes.

2. Turn the main gas shutoff valve

ON. Light the pilot adjacent to

each burner with a lit taper.

Adjust the pilot valve screw until

the pilot flame has a slight

yellow tip.

3. After the pilot has been

established, turn the burner

valves to the ON position

(completely counter clockwise).

4. If the burners fail to light, turn

all burner valves and the main

gas shutoff valve to the OFF

position and contact an

authorized service agency.

Pilot

-

10 -

Page 11

MAINTENANCE

The cheesemelter and its parts are hot. Use care when operating,

cleaning or servicing the cheesemelter

LUBRICATION

All moving parts must be checked for wear and lubricated if necessary. Contact your local

Service Agency.

All valves and controls should be lubricated with a high-temperature grease by a trained

service technician.

FLUE

When the Cheesemelter is cool, check the flue and clear any obstructions. Never block

flue or place anything on top of the cheesemelter.

SERVICE AND PARTS INFORMATION

Contact your local Service Agency for any repairs or adjustments needed on this

equipment. For a complete listing of service and parts depots refer to

www.vulcanequipment.com

available from the appliance identification plate: Model Number and Serial Number. The

identification plate is located under the crumb tray on the right side.

. When calling for service, the following information should be

-

11 -

Page 12

PROBLEM POSSIBLE CAUSES

Uneven heating

Side burning

Too much top heat

TROUBLESHOOTING

1. Temperature too low

2. Improper operation of Cheesemelter

3. Fluctuating gas pressure

4. Improperly adjusted burner valve

5. Check for clogged vent on regulator

6. Low gas pressure (Call for service)

1. Temperature too high

2. Improper ventilation

3. Improperly adjusted burner valve

4. High gas pressure (Call for service)

Uneven heat, side to

side

Uneven heat, front to

back

Dried-out products

Pilot outage

Poor ignition

1. Cheesemelter not level, side to side

2. Cheesemelter burner improperly installed

1. Cheesemelter not level, front to back

1. Melting time too long, or product too close to burners

2. High gas pressure (Call for service)

1. Pilot flame too low

2. Restriction in pilot orifice

3. Low gas pressure (Call for service)

1. Insufficient gas input

2. Restriction in pilot orifice

3. Restriction in burner orifice

4. Pilot adjustment is incorrect

5. Restriction in pilot orifice

6. Too high or too low gas pressure (Call for service)

-

12 -

Page 13

FORMULAIRE F-36954 (3-11)

GARDER CE MANUEL POUR UNE UTILISATION FUTURE

Baltimore, MD 21222

3600 North Point Blvd.

©ITW Food Equipment Group, LLC

CMJ48

VCM48

CMJ72

CMJ60

CMJ48

CMJ36

CMJ24

VCM72

VCM60

VCM48

VCM36

VCM24

MODÈLES

SALAMANDRE

MANUEL D’INSTALLATION ET D’EMPLOI

Page 14

2 -

-

Une installation, un

APPAREIL.

TENTER DE FAIRE FONCTIONNER CET

EN CAS DE PANNE DE COURANT, NE PAS

servir de cet équipement.

d’emploi et d’entretien avant d’installer ou de se

minutieusement les instructions d’installation,

matériel, une blessure ou la mort. Lire

entretien inapproprié peut causer du dommage

ajustement, une modification, un service ou un

APPAREIL.

PROXIMITÉ DE CET APPAREIL OU TOUT AUTRE

AUTRES VAPEURS OU LIQUIDES INFLAMMABLES À

NE PAS ENTREPOSER OU UTILISER DE L’ESSENCE OU

POUR VOTRE SÉCURITÉ

DU SERVICE.

FOURNISSEUR DE GAZ LOCAL AFIN D’OBTENIR

AVEC VOTRE COMPAGNIE DE GAZ OU VOTRE

PRINCIPAL DES APPAREILS ET COMMUNIQUEZ

DÉTECTÉE, FERMEZ LE ROBINET D’ARRÊT

AU CAS OÙ UNE ODEUR DE GAZ SERAIT

IMPORTANT

LOCAL.

POUVEZ DEMANDER CES RENSEIGNEMENTS AU FOURNISSEUR DE GAZ

ÊTRE SUIVIES AU CAS OÙ UNE ODEUR DE GAZ SERAIT DÉTECTÉE. VOUS

PLACEZ DANS UN ENDROIT IMPORTANT LES INSTRUCTIONS QUI DOIVENT

RÉGLAGES INITIAUX DE L’ÉQUIPEMENT DONT IL S’AGIT DANS CE MANUEL.

ÉQUIPEMENT AU GAZ, QUI DOIT EFFECTUER LA MISE EN MARCHE ET LES

CE MANUEL A ÉTÉ CONÇU POUR LE PERSONNEL APTE À INSTALLER UN

IMPORTANT POUR VOTRE SÉCURITÉ

Page 15

3 -

-

PRESSION DU GAZ de ce manuel)

ne soit mise en service. (consultez la section INSTALLATION DU RÉGULATEUR DE

fonctionner avec la salamandre a été fourni et doit être installé avant que la salamandre

qu’aucune pièce n’a été jetée avec l’emballage. Un régulateur de pression conçu pour

l’appareil avant l’utilisation. Déballez soigneusement votre salamandre et assurez-vous

Retirez tout le matériel d’emballage et la protection en plastique des surfaces de

communiquez avec le livreur dans les 15 jours suivant la livraison.

vous découvrez que la salamandre est endommagée, conservez l’emballage et

Immédiatement après avoir déballé, vérifiez s’il y a des dommages dus à la livraison. Si

DÉBALLAGE

salamandre.

outils, les instruments et les compétences nécessaires, effectue l’installation de la

immédiatement. Il est recommandé qu’un technicien qualifié du service de gaz ayant les

correspondent pas aux exigences de celui-ci. Communiquer avec le fournisseur

l’installation du produit si les exigences en matière d’alimentation ou d’équipement ne

qui est située sous le ramasse-miettes du côté droit. Il ne faut pas procéder à

le dégagement (voir page 4) correspondent aux spécifications de la plaque signalétique,

Avant d’effectuer l’installation, vérifier que le type de gaz (naturel ou propane) ainsi que

INSTALLATION

VCM72/CMJ72 2 48 000 (2 à 24 000)

VCM60/CMJ60 2 42 000 (1 à 18 000 + 1 à 24 000)

VCM48/CMJ48 2 36 000 (2 à 18 000)

VCM36/CMJ36 1 24 000

VCM24/CMJ24 1 18 000

Débit calorifique BTU/h

brûleurs

Nombre de

Modèle

nombreuses années de performance satisfaisante.

L’installation, l’utilisation et l’entretien adéquats de votre salamandre vous apporteront de

Les salamandres sont fabriquées avec une exécution et des matériaux de qualité.

GÉNÉRAL

DES SALAMANDRES

INSTALLATION, FONCTIONNEMENT ET ENTRETIEN

Page 16

4 -

-

l’Association Canadienne du Gaz, 178 boul. Rexdale, Etobicoke, Ontario, Canada M9W 1R3

3. Code d’installation du propane CAN/CSA-B149.2 (dernière édition), disponible auprès de

2. Code d’installation du gaz naturel CAN/CSA-B149.1 (dernière édition)

1. Codes locaux.

Au Canada :

MA 02269.

disponible auprès de la National Fire Protection Association, Batterymarch Park, Quincy,

3. La norme NFPA nº 96 Vapor Removal from Cooking Equipment, dernière édition,

d’échappement qui doivent être conformes à 248 CMR.

système d’échappement muni d’une clef de réglage ou avec une moyenne potentielle

Tous les appareils d’utilisation du gaz aérés grâce à une hotte de ventilation ou un

REMARQUE : dans l’État du Massachusetts

Standards Council, NFPA, 1 Batterymarch Park Quincy, MA 02169-7471

Committee Z223, à 400 N. Capital St. NW, Washington, DC 20001 ou le Secretary

pouvez obtenir des copies auprès de l’American Gas Association Accredited Standards

comprendre sans être limité à : NFPA No54 Section 10.3.5.2 pour la ventilation. Vous

2. National Fuel Gas Code, ANSI-Z223.1/NFPA Nº 54 (dernière édition). Cela doit

1. Codes locaux et d’État.

Aux États-Unis d’Amérique :

La salamandre doit être installée conformément à :

CODES ET NORMES D’INSTALLATION

de ventilation de la hotte ou de toute autre obstruction.

46 cm (18 po) dans le haut du conduit de ventilation de la fumée jusqu’aux filtres du système

d’avoir des fenêtres ouvertes près de la salamandre. Veuillez conserver un dégagement de

ventilateurs de type mural qui créent des courants d’air en biais à travers la pièce. Évitez

Empêchez les ventilateurs de faire circuler directement de l’air sur la salamandre. Évitez les

par le système de ventilation.

vous qu’il y ait suffisamment d’alimentation en air dans la pièce afin de remplacer l’air sorti

d’espace pour les ouvertures d’air de la chambre de combustion doit être fourni. AssurezN’obstruez pas la circulation de la combustion ainsi que l’air de ventilation. Suffisamment

installée au niveau d’un côté à l’autre et de l’avant vers l’arrière.

d’avoir ce type de fumée peut raccourcir la durée de vie du brûleur. La salamandre doit être

des fumées provenant de la graisse brûlée et une installation dans un endroit susceptible

de plaques chauffantes ou de friteuses. Les brûleurs par infrarouge peuvent réagir aux effets

Il est recommandé que la salamandre ne soit pas installée directement sur ou à côté de grils,

salamandre. Un dégagement avant minimal de 91 cm (36 po) est requis.

puisse être placée au côté de celle-ci, il ne doit pas y avoir d’obstruction à l’avant de la

l’entretien et le fonctionnement adéquats. Malgré le fait qu’une autre salamandre au gaz

L’emplacement de l’installation doit offrir un dégagement approprié afin de permettre

Bas 25 cm 10 cm

Côtés 50 cm 0 cm

Arrière 5 cm 0 cm

Construction combustible Construction non combustible

Dégagements minimaux

Le lieu de l’installation de l’appareil doit être libre de toute présence de combustibles.

EMPLACEMENT

Page 17

5 -

A

p

-

filetés aux quatre coins de la salamandre.

Vissez les boulons dans la tablette et dans les points d’ancrage

particulière

tablette surélevée

Installé sur une

3. Fixez la salamandre en place avec quatre boulons de 3/8 po.

au bas de la salamandre.

2. Alignez les trous de la tablette avec les points d’ancrage filetés

tablette.

tablette; placez l’arrière de l’appareil à égalité avec l’arrière de la

1. Placez et alignez la salamandre sur le dessus des supports de la

cuisinière.

gaz, une tablette surélevée et renforcée est requise pour ce type de

Si la salamandre doit être installée au-dessus d’une cuisinière à

particulière

Salamandre installée sur une tablette surélevée

d’ancrage filetés au bas de l’appareil.

boulons dans les trous des supports et dans les points

l’installation sur le mur

Avec des supports pour

ou six (modèles 60 et 72) boulons de 3/8 po. Vissez les

5. Fixez l’appareil en place avec quatre (modèles 24 à 48)

les trous des supports.

que les points d’ancrage filetés inférieurs sont alignés avec

4. Positionnez l’appareil sur les supports, en vous assurant

montants de cloison.

Assurez-vous que les tirefonds pénètrent dans les

3. Fixez les supports en mur en utilisant des tirefonds.

nécessitent trois supports pour offrir un soutien approprié.

nécessitent deux supports tandis que les modèles 60 à 72

renversée comme illustré. Les modèles 24 à 48

2. Installez les supports seulement selon la position en « L »

de l’appareil.

attes

vec des

supports s’alignent avec les points d’ancrage filetés au bas

sont espacés adéquatement afin que les trous des

1. Assurez-vous que les supports sont au niveau et qu’ils

Salamandres installées sur un mur

en ajustant la base des pattes.

Placez la salamandre en position. Mettez-la ensuite au niveau

comptoir doit être fabriqué d’un matériau non combustible.

pattes dans les fentes filetées situées au bas de l’appareil. Le

de pattes de 10 cm (4 po) (vendues séparément). Vissez les

Les salamandres installées sur un comptoir doivent être pourvues

Salamandres installées sur un comptoir

ASSEMBLAGE

attention lorsque vous employez, nettoyez ou entretenez la salamandre.

La salamandre et ses pièces sont chaudes. Faites

Page 18

6 -

-

Quincy, MA 02269.

édition, disponible auprès de la National Fire Protection Association, Batterymarch Park,

décrits dans la norme « Vapor Removal from Cooking Equipment », NFPA nº 96, dernière

Les renseignements sur la construction et l’installation des hottes d’aspiration sont

compétent.

l’extérieur de l’édifice à l’aide d’un système de ventilation installé par du personnel

l’arrière de la salamandre. Il est recommandé que les gaz de combustion soient aspirés à

Ne pas obstruer la circulation des gaz de combustion provenant des conduits, situés à

CONNEXIONS DES CONDUITS

robinet d’arrêt manuel individuel.

la salamandre devrait être isolée du système d’alimentation en gaz en fermant son

Lorsque la pression de l’alimentation en gaz est inférieure ou égale à 0,5 psi (3,45 kPa),

d’alimentation en gaz.

son robinet d’arrêt individuel doivent être débranchés du système de tuyauterie

Lorsque la pression de l’alimentation en gaz excède 0,5 psi (3,45 kPa), la salamandre et

ÉVALUATION DU SYSTÈME D’ALIMENTATION EN GAZ

18 cm CE pour le gaz naturel et de 28 cm CE pour le gaz propane.

propane est de 36 cm CE. La pression d’alimentation minimum recommandée est de

La pression d’alimentation maximale de la canalisation pour le gaz naturel et le gaz

entièrement vidées pour enlever l’air.

Après avoir vérifié s’il y a des fuites, toutes les conduites recevant du gaz devraient être

N’utilisez pas une flamme nue.

d’alimentation en gaz pour les fuites. Utilisez une solution d’eau et savon.

Avant l’allumage, vérifiez tous les joints dans la conduite

intérieur (Di) net aussi large ou plus large que l’entrée du tuyau de gaz sur cet appareil.

en tuyau solide ou avec un raccord flexible de type commercial ayant un diamètre

fonctionnement, cet appareil doit être connecté avec une conduite d’alimentation en gaz

conformes à la norme ANSI applicable. Pour assurer l’efficacité maximum du

Toutes les conduites d’alimentation en gaz flexibles et semi-rigides doivent être

Utilisez une conduite d’alimentation en gaz NPT de ¾ po pour l’entrée de la salamandre.

conduite de gaz en amont de la salamandre.

panneau supérieur. Les codes exigent qu’un robinet d’arrêt du gaz soit installé dans la

L’emplacement de l’entrée de gaz est situé dans le coin supérieur droit arrière du

propane.

Toutes les connexions et toute pâte à joints doivent résister à l’action du gaz

CONNEXIONS DU GAZ

Page 19

7 -

-

Retirez la grille pour effectuer le déchargement.

éviter les déversements. Poussez la grille en place et faites cuire le temps nécessaire.

Placez la grille selon la position voulue. Retirez la grille pour effectuer le chargement et

CHARGEMENT ET DECHARGEMENT

attention lorsque vous employez, nettoyez ou entretenez la salamandre

La salamandre et ses pièces sont chaudes. Faites

EMPLOI

N’utilisez pas une flamme nue.

d’alimentation en gaz pour les fuites. Utilisez une solution d’eau et savon.

Avant l’allumage, vérifiez tous les joints dans la conduite

propane.

Toutes les connexions et toute pâte à joints doivent résister à l’action du gaz

0,5 psi (3,45 kPa) ou 36 cm CE.

ne devrait à aucun moment être connectée à une pression d’alimentation supérieure à

23 cm CE pour le gaz naturel et de 28 à 30 cm CE pour le gaz propane. La salamandre

La pression d’alimentation minimale (en amont du régulateur) devrait être de 18 à

Fig. 3

Fig. 2

placé avec le bouchon d’aération ainsi que la vis d’ajustement vers le haut (Fig. 3).

dans la direction de la circulation du gaz à la salamandre (Fig. 2) et que le régulateur est

d’alimentation en gaz. Assurez-vous que la flèche au-dessous du régulateur est orientée

Installez le régulateur aussi près que possible de la salamandre sur la conduite

peuvent être nécessaires selon la pression des gaz spécifique au site.

naturel et 25,4 cm colonne d’eau (CE) pour le gaz propane. Certains réglages mineurs

Le régulateur de pression du gaz est préréglé à 12,7 cm colonne d’eau (CE) pour le gaz

INSTALLATION DU RÉGULATEUR DE PRESSION DU GAZ

Page 20

8 -

-

instructions du fabricant du produit nettoyant.

produits nettoyants peuvent contenir des substances corrosives. Veuillez suivre les

Soyez prudent lorsque vous utilisez des produits nettoyants en vaporisateur. Certains

Produits nettoyants en vaporisateur

en acier inoxydable puisqu’ils pourraient en endommager la surface.

propre. N’utilisez pas de nettoyants abrasifs ou de nettoyants puissants sur des surfaces

humide. Rincez la surface avec de l’eau propre et essuyez-la avec un chiffon doux

peuvent être nettoyés avec un savon doux et de l’eau appliqués à l’aide d’un chiffon

Une fois que la salamandre est refroidie, les boutons et les surfaces en acier inoxydable

Extérieur

nécessiter d’être nettoyés avec un nettoyant doux ou une éponge savonneuse et humide.

suffiront habituellement. Les plus gros déversements ou éclaboussures peuvent

Après avoir frotté, lavez à l’eau savonneuse, rincez puis séchez. L’eau et le savon

abrasifs.

détergent. Frottez-les avec une brosse à poils rigides. N’utilisez pas de produits

miettes quotidiennement en les faisant tremper dans de l’eau tiède contenant du

Retirez la grille lorsque la salamandre est refroidie. Nettoyez la grille et le ramasse-

Intérieur

attention lorsque vous employez, nettoyez ou entretenez la salamandre

La salamandre et ses pièces sont chaudes. Faites

NETTOYAGE

soyez attentif pour éviter de faire brûler les aliments.

grille plus près des brûleurs pour le bacon, les rôtis et le réchauffement rapide, mais

pour faire fondre du fromage ou du beurre afin d’éviter d’assécher le produit. Placez la

résultat voulu. Placez la grille plus loin des brûleurs pour les cocottes à fond épais ou

Le positionnement de la grille de la salamandre est un facteur important pour atteindre le

RECETTE ET AJUSTEMENT DE LA GRILLE

complètement dans le sens antihoraire et préchauffez pendant 15 minutes.

Placez la grille à sa position la plus élevée. Tournez le bouton de la soupape du brûleur

PRECHAUFFAGE

Page 21

9 -

-

flamme.

d’allumage dans le sens horaire pour diminuer la flamme et dans le sens antihoraire pour augmenter la

veilleuse d’allumage. À l’aide d’un tournevis à tête plate, tournez la vis de réglage de la veilleuse

La soupape d’ajustement de la veilleuse d’allumage gère le débit de gaz se rendant au brûleur de la

Soupape d’ajustement de la veilleuse d’allumage

débordement.

Videz le ramasse-miettes lorsque celui-ci est plein aux trois quarts afin de réduire les risques de

Le ramasse-miettes recueille les miettes et les déchets. Ne laissez pas le ramasse-miettes déborder.

Ramasse-miettes

cuisson plus rapide.

profonde et plus longue. Utilisez les positions supérieures pour les aliments plus minces ou pour une

vous désirez faire à l’intérieur de la salamandre. Utilisez les positions inférieures pour une chaleur plus

La grille peut être placée selon trois positions différentes. Placez-la en fonction du type de cuisson que

Grille coulissante

soupape dans le sens horaire jusqu’à ce que le niveau recherché soit atteint.

sens antihoraire. Le débit maximal n’est plus requis une fois le préchauffage terminé. Tournez la

débit de gaz qui se rend aux brûleurs. Le débit de gaz est augmenté en tournant la soupape dans le

(complètement dans le sens antihoraire) allumera chaque brûleur. Les soupapes des brûleurs gèrent le

fois que les veilleuses sont allumées, tourner la soupape du brûleur à la position OUVERT

Chaque brûleur est contrôlé indépendamment par une soupape de réglage de la chaleur infinie. Une

miettes

grille coulissante

ramasse-

soupapes du brûleur

Soupape du brûleur

d’allumage

soupapes d’ajustement de la veilleuse

attention lorsque vous employez, nettoyez ou entretenez la salamandre

La salamandre et ses pièces sont chaudes. Faites

COMMANDES

Page 22

d’allumage

Veilleuse

10 -

-

service autorisée.

communiquez avec une agence de

ainsi que le robinet d’arrêt principal et

fermez toutes les soupapes des brûleurs

4. Si les brûleurs ne s’allument pas,

(complètement dans le sens antihoraire).

brûleurs afin de les ouvrir

allumée,tournez les soupapes des

3. Une fois la veilleuse d’allumage

pointe légèrement jaune.

de la veilleuse d’allumage ait une

d’allumage jusqu’à ce que la flamme

vis de la soupape de la veilleuse

d’allumage pour bougie. Ajustez la

chaque brûleur avec une tige

la veilleuse d’allumage adjacente à

à la position ouverte (ON). Allumez

2. Tournez le robinet d’arrêt principal

(OFF) et attendez 5 minutes.

brûleurs à la position FERMÉE

et les soupapes individuelles des

1. Tournez le robinet d’arrêt principal

ALLUMAGE DE LA VEILLEUSE D’ALLUMAGE

2. Fermez le robinet d’arrêt principal du gaz de l’appareil.

pour fermer les brûleurs.

1. Tournez les boutons des soupapes des brûleurs complètement dans le sens horaire

ARRET PROLONGE

gaz est ouverte.

2. Les veilleuses d’allumage resteront allumées aussi longtemps que l’alimentation en

pour fermer les brûleurs.

1. Tournez les boutons des soupapes des brûleurs complètement dans le sens horaire

ARRET

Page 23

11 -

-

sous le ramasse-miettes sur le côté droit.

l’appareil : le numéro du modèle et le numéro de série. La fiche signalétique est située

renseignements suivants devraient être disponibles sur la fiche signalétique de

. Lorsque vous appelez pour du service, les

consultez www.vulcanequipment.com

nécessaire sur cet équipement. Pour une liste des bureaux des services et des pièces,

Communiquez avec votre service à la clientèle local pour toute réparation ou tout réglage

RENSEIGNEMENTS SUR L’ENTRETIEN ET LES PIÈCES

bloquez jamais le conduit et ne placez jamais d’objets sur le dessus de la salamandre.

Lorsque la salamandre est refroidie, vérifiez le conduit et retirez toute obstruction. Ne

CONDUIT

supportant les températures élevées par un technicien de service formé à cet effet.

Toutes les soupapes et les commandes doivent être lubrifiées à l’aide d’une graisse

au besoin. Communiquez avec votre agence de services locale.

L’usure de toutes les pièces mobiles doit être vérifiée et celles-ci doivent être lubrifiées

LUBRIFICATION

attention lorsque vous employez, nettoyez ou entretenez la salamandre

La salamandre et ses pièces sont chaudes. Faites

ENTRETIEN

Page 24

12 -

-

6. Pression trop élevée ou trop basse du gaz (appelez le service)

5. Obstruction à l’intérieur de l’orifice de la veilleuse d’allumage

4. Le réglage de la veilleuse d’allumage est inadéquat

3. Obstruction à l’intérieur de l’orifice du brûleur

2. Obstruction à l’intérieur de l’orifice de la veilleuse d’allumage

1. Alimentation en gaz insuffisante

Allumage difficile

3. Faible pression du gaz (appelez le service)

2. Obstruction à l’intérieur de l’orifice de la veilleuse d’allumage

1. Flamme de la veilleuse d’allumage trop faible

d’allumage

Panne de la veilleuse

2. Pression élevée du gaz (appelez le service)

1. Temps de cuisson trop long, ou produit trop près des brûleurs

1. La salamandre n’est pas au niveau de l’avant vers l’arrière

2. Le brûleur de la salamandre est mal installé

1. La salamandre n’est pas au niveau d’un côté à l’autre

Produits desséchés

l’avant vers l’arrière

Chaleur inégale de

côté à l’autre

Chaleur inégale d’un

4. Pression élevée du gaz (appelez le service)

3. Soupape du brûleur mal réglée

2. Ventilation inadéquate

1. Température trop élevée

6. Faible pression du gaz (appelez le service)

5. Vérifiez si la prise d’air du régulateur est bouchée

4. Soupape du brûleur mal réglée

3. Variation de la pression du gaz

2. Emploi inadéquat de la salamandre

1. Température trop basse

PROBLÈME CAUSES POSSIBLES

dessus

Trop de chaleur sur le

Brûle sur le côté

Chaleur inégale

DÉPANNAGE

Loading...

Loading...