Page 1

INSTALLATION & OPERATION MANUAL

RRG Heavy Duty Gas Griddles

MODEL

24RRG ML-135339-00024

36RRG ML-135340-00036

48RRG ML-135341-00048

60RRG ML-135342-00060

www.vulcanhart.com

MLS

36RRG

ITW Food Equipment Group, LLC

3600 North Point Blvd.

Baltimore, MD 21222

RETAIN THIS MANUAL FOR FUTURE USE

FORM F-36981 (07-08)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO

INSTALL GAS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD

START-UP AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS

MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN

THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE

OBTAINED FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury, or death. Read the

installation, operating and maintenance instructions thoroughly before

installing or servicing this equipment.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

-

2 -

Page 3

INSTALLATION, OPERATION AND CARE OF

HEAVY DUTY GAS GRIDDLES

GENERAL

Heavy Duty Gas Griddles are produced with quality workmanship and materials. Proper

installation, usage and maintenance of your griddle will result in many years of

satisfactory performance.

Thoroughly read this entire manual and carefully follow all of the instructions provided

Model Number of Burners BTU/hr Input Rating

24RRG 2 55,000

36RRG 3 82,500

48RRG 4 110,000

60RRG 5 137,500

INSTALLATION

Before installing, verify that the type of gas supply (natural gas or propane) agree with

the specifications on the rating plate located inside the griddle front panel. If the supp ly

and equipment requirements do not agree, do not proceed with the installation. Contact

your dealer immediately.

UNPACKING

This griddle was inspected before leaving the factory. The transportation company

assumes full responsibility for safe delivery upon acceptance of shipment. Check for

possible shipping damage immediately after unpacking. If the griddle is found to be

damaged, save the packaging material an d contact the carrier within 15 days of delivery.

Carefully unpack your griddle and make sure that no parts are discarded with packaging

material. A pressure regulator designed to operate with the griddle has been supplied and

must be installed before the griddle is placed into service (Refer to GAS PRESSURE

REGULATOR INSTALLATION in this ma nual).

LOCATION

The installation location must be kept free and clear of combustibles. When installing,

never enclose the bottom of the griddle with a raised curb or other constructions that

would obstruct flow of air into or out of the griddle. Adequate clearance for air openings

into the combustion chamber must be provided. Make sure there is an adequate supply of

air in the room to replace air tak en out by the ventilation system.

Do not permit air to blow directly at the griddle. Avoid open windows next to the griddle

wherever possible. Avoid wall-type fans which create air cross-currents within the room.

-

3 -

Page 4

This griddle is Design Certified for installa tion on a non-combustible counter with 4” legs,

or combustible floor with 25” high stand.

INSTALLATION CLEARANCES

COMBUSTIBLE CONSTRUCTION NON-COMBUSTIBLE CONSTRUCTION

Back: 6” 0”

Right 6” 0”

Left Side 6” 0”

INSTALLATION CODES AND STANDARDS

The griddle must be installed in accordance with:

In the United States of America:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1/NFPA #54 (latest edition). This shall incl ude but

not be limited to: NFPA #54 Section 10.3.5.2 for Venting. Copies may be obtained

from The American Gas Association Accredited Standards Committee Z223, @ 400

N. Capital St. NW, Washington, DC 20001 or the Secretary Standards Council, NFPA,

1 Batterymarch Park Quincy, MA 02169-7471

NOTE: In the Commonwealth of Massachusetts

All gas appliances vented through a ventilation hood or exhaust system equipped with

a damper or with a power means of exhaust shall comply with 248 CMR.

3. NFPA Standard # 96 Vapor Removal from Cooking Equipment, latest edition, availabl e

from the National Fire Protection Associa tion, Batterymarch Park, Quincy, MA 02269.

In Canada:

1. Local codes.

2. CAN/CSA-B149.1 Natural Gas Installation (latest edition)

3. CAN/CSA-B149.2 Propane Installation Code (latest edition), available from the

Canadian Gas Association, 178 Rexdale Blvd. , Etobicoke, Ontario, Canada M9W 1R3

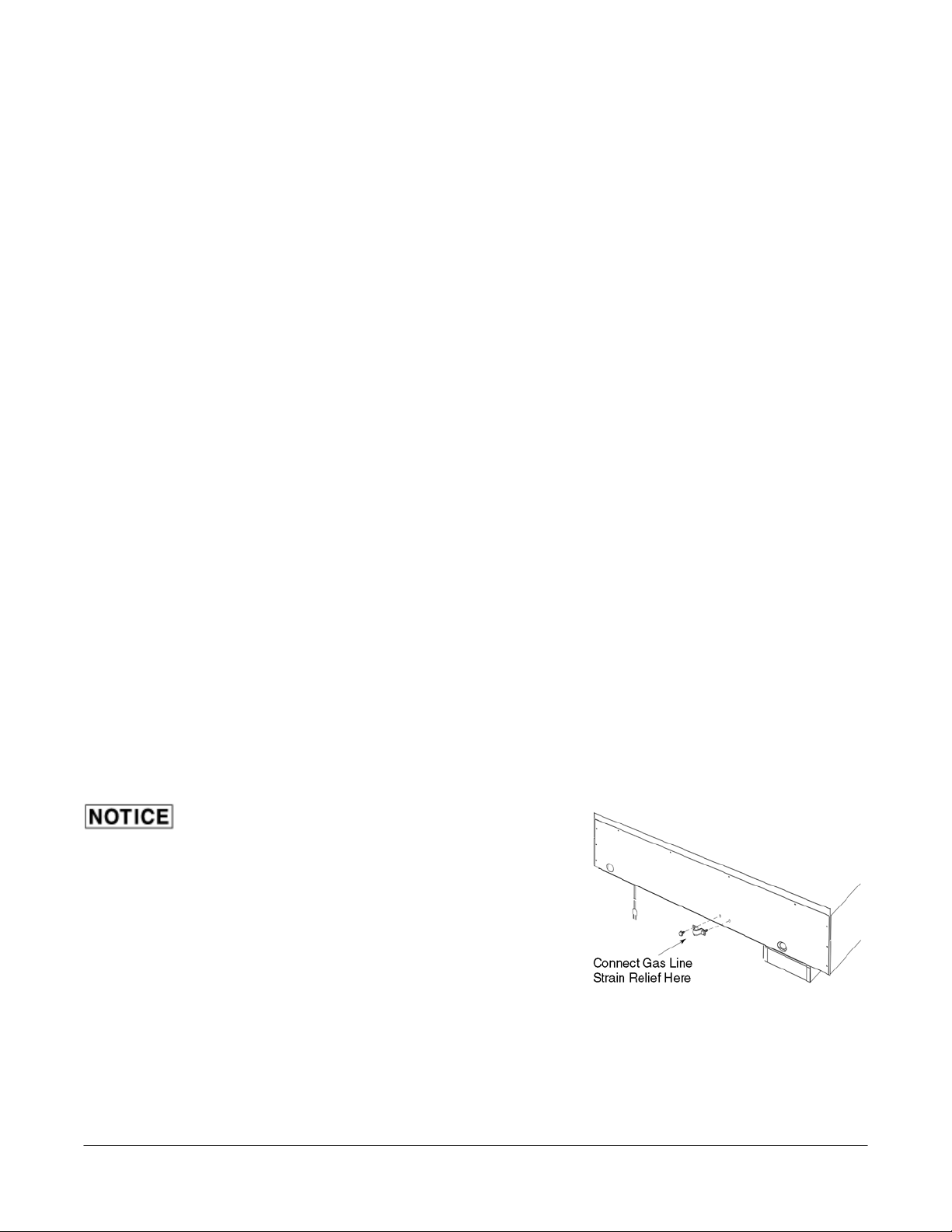

GRIDDLES MOUNTED ON STANDS WITH CASTERS

Griddles mounted on stands with casters

must use a flexible connector (not supplied) that

complies with the Standard for Connectors for Movable

Gas Appliances ANSI Z21.69•CSA6.16, and a quickdisconnect device that complies with Gas Fuel, ANSI

Z21.3•CSA6.9. In addition, adequate means must be

provided to limit movement of the appliance without

depending on the connector and the quick-disconnect

device (or its associated piping) to limit appliance

movement. Attach the restraining device at the rear of

the griddle as shown in Fig. 3.

Fig. 3.

If disconnection of the restraint is necessary, turn off the gas supply before

disconnecting. Reconnect the restraint prior to turning the gas supply on and returning

the griddle to its installatio n position.

-

4 -

Page 5

Casters are only supplied on a griddle stand. If the griddle is moved for any reason the

griddle should be re-leveled (see LEVELING in this manual).

FLUE CONNECTIONS

Do not obstruct the flow of flue gases from the flue, located at the rear of the griddle. It is

recommended that flue gases be ventilated to the outside of the building through a

ventilation system installed by qualified personnel.

From the termination of the flue to the filters of the hood venting system, a minimum

clearance of 18” must be maintained.

Information on the construction and installation of ventilating hoods may be obtained from

the standard for “Vapor Removal from Cooking Equipment”, NFPA No. 96 (latest editio n),

available from the National Fire Protection Association, Batterymarch Park, Quincy, MA

02269.

STANDS

The griddle has an optional 25” high by 30” deep by 24”, 36”, 48” or 60” wide stainless

steel stand with casters. The two front casters lock. The stand includes a top shelf with

marine edges style lip and a lower shelf.

GAS CONNECTIONS

Gas supply connections and any pipe joint compound must be resistant to the

action of propane gases.

Use a ¾” NPT gas supply line for the griddle inlet, located at the rear of the griddle . All of

flexible and semi-rigid gas supply lines must comply with the applicable ANSI standard.

To ensure maximum operating efficiency this appliance must be connected with a gas

supply line of solid pipe or a commercial type Flexible Connector with the net inside

diameter (I.D.) as large as or larger than the gas pipe inlet on this appliance. Codes

require that a gas shutoff valve must be installe d in the gas line upstream of the griddle.

Prior to lighting, check all joints in the gas supply line for leaks.

Use soap and water solution. Do not use an op en flame.

After checking for leaks all lines recei ving gas should be fully purged to re move air.

TESTING THE GAS SUPPLY SYSTEM

When the gas supply pressure exceeds ½ psig (3.45 kPa), the griddle and its individual

shutoff valve must be disconnected from the gas supply piping system.

When the gas supply pressure is ½ psig (3.45 kPa) or less, the griddle should be isolated

from the gas supply system by closing its individual manual shutoff valve.

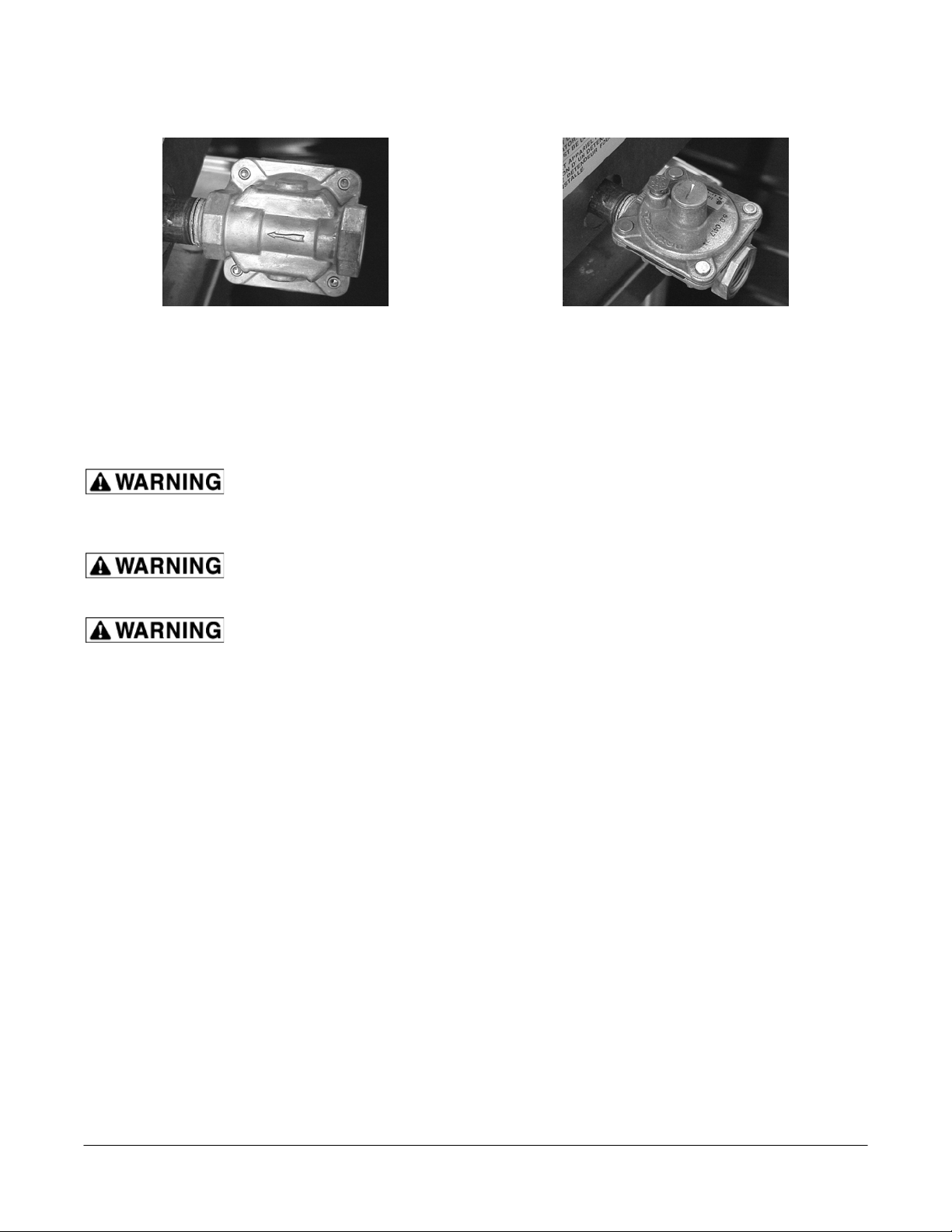

GAS PRESSURE REGULATOR INSTALLATION

Gas regulator pressure is preset at 5” Water Column (W.C.) for natural gas, and 10” W.C.

for propane gas. No further adjustment should be required.

Install the regulator as close to the griddle on the gas supply line as possible. Make sure

that the arrow on the underside of the regulato r is oriented in the direction of gas flow to

-

5 -

Page 6

the griddle (Fig. 1) and the regulator is positioned with the vent plug and adjustment

screw upright (Fig. 2).

Fig. 1

The supply pressure (upstream of the regulator) should be 7-9” W.C. for natural gas and

11-12” W.C. for propane gas. At no time should the griddle be connected to supply

pressure greater than ½ ps ig (3.45 kPa) or 14” W.C.

ELECTRICAL CONNECTIONS

Electrical and grounding connections must comply with the

applicable portions of the National Electrical Code and/or other local electrical

codes.

Disconnect the electrical power to the griddle and follow lockout /

tagout procedures.

Appliances equipped with a flexible electric supply cord are provided

with a three-prong grounding plug. It is imperative that this plug be connected into

a properly grounded three-prong receptacle. If the receptacle is not the proper

grounding type, contact an electrician. Do not remove the grounding prong from

this plug.

Fig. 2

Power supply for electric ignition is 120 volts, 1 amp, 50/6 0 Hertz, 1 phase.

Do not connect the griddle to electrical supply until after gas connections are made.

-

6 -

Page 7

OPERATION

The griddle and its parts are hot. Use care when operating, cleaning

or servicing the griddle.

Disconnect power supply before cleaning and servicing the

appliance.

BEFORE FIRST USE

It is recommended that you clean your VULCAN RRG griddle th oroughly with a mild soap

and water. Rinse the griddle surface tho roughly with water and wipe dry with a soft clean

cloth.

SEASONING THE GRIDDLE

Before turning the unit ON, apply a high tempe rature oil– about one ounce per square

foot of surface. DO NOT use plain vegetable oil as it is not stabilized for high heat an d

may cause food stick and result in improperly cooked food. Turn the griddle ON and with

a regular wipe cloth; work the oil into the whole griddle surface for two mi nutes.

After cleaning your griddle with chemicals, you should repea t the seasoning procedure for

proper cooking.

DO NOT use hardened steel spatulas. Use mild steel spatulas with rounded corners.

CONTROLS

There is at least one pilot for every two burners. The 36” and 60” models have an odd

number of main burners, therefore one of the sets of pilots and one of the electronic

safety-ignition modules in these models will control only one main burner. The pilot

burners are aligned with pilot sight holes. The pilot burners are inset 12” from the front

panel.

This model features an electronic safety-ignition system that is controlled by the power

switch. Turning the power switch ON is all that is required to put the unit into service. The

power switch turns the pilot valve, the temperature controllers, the indicator lamps and

the electronic safety-ignitio n modules. When the unit turned ON, electronic safety-ignition

modules start generating sparks until the detection of a proven flame at the pilot burner.

Upon the flame rectification, electronic safety-ignition module energizes the solenoid gas

valve(s) for that specific zone(s).

The pilots are monitored by flame detection through igniters. If the pilot goes out, the

igniter will immediately reignite the pilot. If the pilot does not achieve reignition in a short

period of time, the electronic safety-ignition module will shut-off the gas supply to the

main burners and keeps generating sparks at the pilot burner.

Each 12” section of the griddle is independently controlled by a solid state temperature

controller and an embedded thermocouple. The temperature controllers have an operating

range of 150 to 450 degrees.

-

7 -

Page 8

USING THE GRIDDLE

To preheat, set the temperature controllers for the desired temperatures and turn on the

power switch 10-12 minutes before cooking.

A uniform and systematic approach to loading the griddle will produce the most consistent

product results.

The griddle plate is a composite material which is engineered to provide a high heat

transfer rate to the food. The top surface is stainless steel and can be scored or dented

by careless use of a spatula or scraper. Be careful not to dent, scratch, or gouge the

plate surface. Do not try to knock off loose food that may be on the spatula by tapping the

corner or the edge of the spatula on the griddle surface.

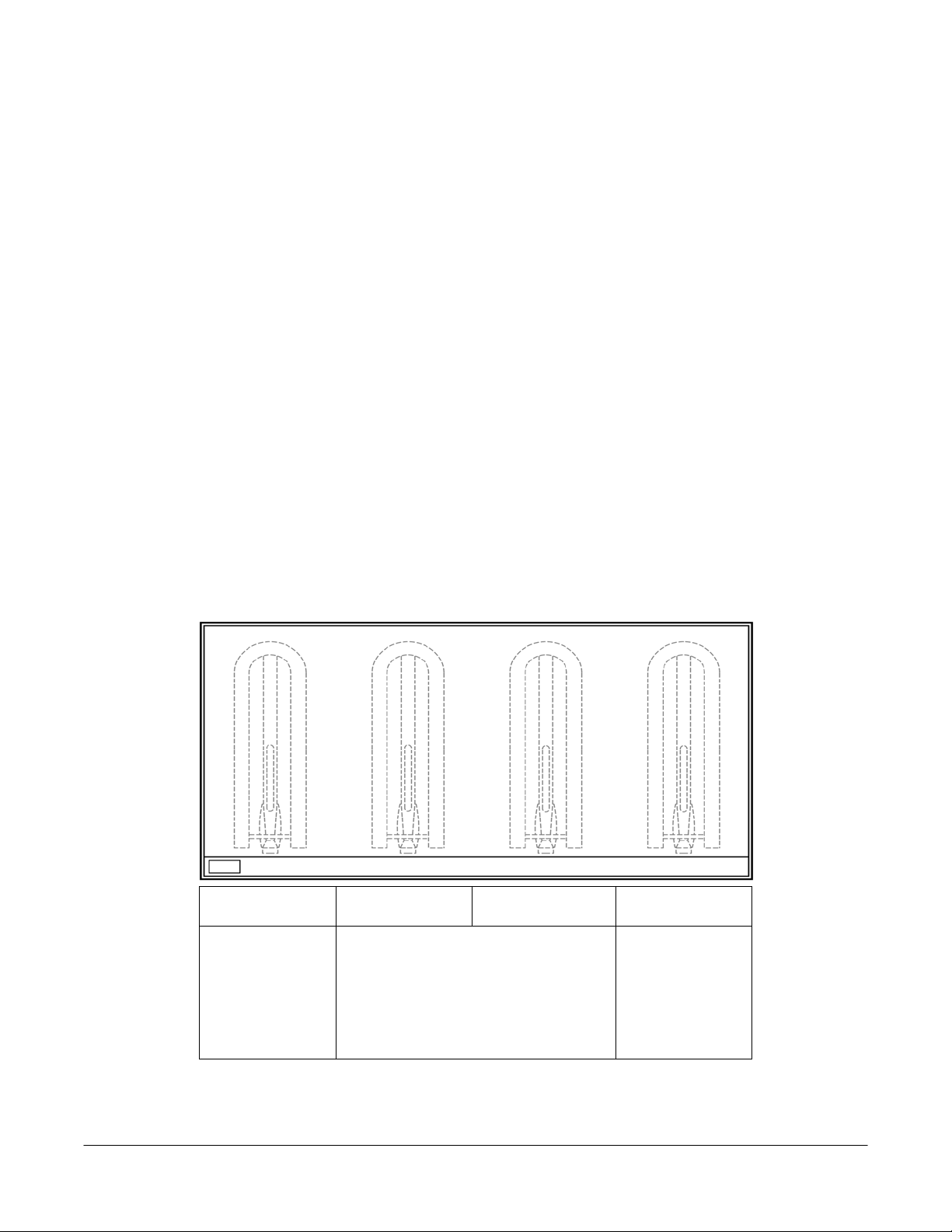

ZONE COOKING

This griddle features a tubular U-shaped burner in 12” sections, each controlled by

independent temperature controllers. Each 12” section is a separate cooking zone, and

allows cooking a wide variety of prod ucts over a single griddle plate. The chart below is a

suggested usage of zone co oking.

When zone cooking, it is suggested that you start with your lowest temperature se tting at

either side of the griddle, increasing the zone temperature as you move up the zone line.

These zone cooking guidelines will vary depending on product temperatures, size and

shape. This guide should be adjusted to suit your product and operational cooking

preference.

ZONE 1

(300°F)

PRODUCT

Sausage

Eggs (Hard Fried)

Eggs (Scrambled)

Burger (Well Done)

Steak (Well Done)

Chicken Breast

Frozen Foods

Pork Chops

ZONE 2

(350°F)

ZONE 3

(350°F)

PRODUCT PRODUCT

Pancakes

French Toast

Bacon

Eggs (Sunny Side Up)

Boiled Ham

Steak (Medium Well)

Fresh Burger (Medium Well)

Small Frozen Burger (Medium Well)

Omelet

Hash Browns

Canadian Bacon

-

8 -

ZONE 4

(400°F)

Steak (Rare)

Stir Fry Vegetables

Salmon

Fish Cakes

Lobster

Scampi

Page 9

CLEANING THE GRIDDLE

Empty the grease drawer as neede d throughout the day and regularly clean at l east once

daily.

Clean the griddle regularly. A clean griddle always looks better, lasts longer and performs

better. To produce evenly cooked, perfectly browned griddle products keep the griddle

plate clean and free of carbonized grease. Carbonized grease on the surface hinders the

transfer of heat from the griddle surface to the food, resulting in spotty browning and loss

of cooking efficiency. Carbonized grease tends to cling to griddle foods, giving them a

highly unsatisfactory and unappet izing appearance.

To keep the griddle clean and operating at peak efficienc y, follow these procedures:

AFTER EACH USE

Clean the griddle with Nemco Easy Grill Scraper™ or similar type of scraper during the

work shift.

ONCE PER DAY

Thoroughly clean the griddle back splash, sides and front. Turn the griddle off and allow it

to cool down between 275°F-300°F, apply some water and clean it with a heavy scraper.

Remove, empty and wash the grease drawer in the same manner as an ordinary cooking

utensil.

ONCE PER WEEK

Clean the griddle surface thoroughly with water, Scotch-Brite

System or Ecolab Grease Express High-Temp Grill Cleaner.

After removal of detergent the surface of the plate the griddle should be seasoned

according to the instructi ons in this manual.

Clean stainless steel surfaces with a damp cloth and polish with a soft dry cloth. To

remove discoloration, use a griddle cleaner.

If the griddle usage is very high, consider conducting this weekly cleaning procedure

more than once per week.

DO NOT use a brick or griddle stone for cleaning.

DO NOT use water-jet to clean the griddle.

DO NOT use chlorine sanitizer in contact with griddle. Contact can cause discoloration,

corrosion and permanent damage.

DO NOT use cleaning agents including Sodium Hydroxide, which is common in house hold

oven cleaners.

TM

Quick Clean Griddle

-

9 -

Page 10

ADJUSTMENTS

CALIBRATION

1. Each temperature controller controls a 12” z one

of the griddle. Using a Surface Probe

temperature measurement device, observe the

temperatures at the center points of the

cooking zones. These points are located by

starting 6” from the side splash (left or right)

and every 12” across the width of the griddle,

with all points located 12” back from the front

edge of the griddle plat e.

NOTE: Use of infrared thermometers is not

recommended. These devices are highly

sensitive to surface color (clean or dirty), angl e

of reading and distance fro m the unit.

2. Set thermostats to 350°F and allow to stabilize,

allowing the indicator light to cycle ON and

OFF at least two times.

3. Watch for indicator light to cycle OFF, then

measure the temperature for that zone. The

temperature should be 350°F ±5°F. If not,

continue to Step 4.

4.

a. Decide on the temperature

adjustment needed for the

temperature controller. DO NOT

allow the knob to turn. Carefully

remove the knob from the

temperature controller shaft.

b. Loosen screws on the back of

knob and turn the transparent ring

around the black knob to the

desired position. Knob will have to

be placed back on the shaft to

verify adjustment.

IMPORTANT: NEVER ADJUST THE

SCREW ON THE BACK SIDE OF THE

TEMPERATURE CONTROLLER. This

will ruin the factory calibration; the

temperature controller will no longer

operate properly and will need to be

replaced.

5. Once calibration is achieved, tighten the

knob screws.

Step 4a. Set knob &

check Temperature.

Remove knob

Step 4b. – Adjust

the position of outer

knob ring relative to

black knob body &

verify temperature

setting

Step 4c. –Replace

knob and verify the

reading. Carefully

remove the knob &

tighten screws

-

10 -

Page 11

LEVELING

The griddle must be level (side-to-side and front-to-back) during operation to ensure

proper performance. Improper leveling can result in uneven temperature distribution, cold

spots, and possibly damage elec trical components.

1. Place a level on the griddle.

2. Adjust legs by turning the bullet feet at the bottom of each leg. Using pliers or a

crescent wrench, turn the feet counter-clockwise to increase height, and clockwise to

decrease height until leveli ng is achieved. Do not exte nd the legs more than 1-¾ ”.

PILOT ADJUSTMENT

Using a flathead screwdriver, turn the slotted hex-head pilot adjustment screw clockwise

to decrease the flame, and counterclockwise to increase the flame. Pilot adjustments

should only be performed by Service Personnel.

SHUTDOWN OF GRIDDLE WITH ELECTRIC IGNITION SYSTEM

1. Push the power switches to OFF. This will shuts down the griddle completely.

EXTENDED SHUTDOWN

1. Shut off the main gas supply valve.

2. Unplug the griddle elect rical supply cord.

3. Apply a heavy coat of vegetable oil over the griddle plate to inhibit rust.

MAINTENANCE

The griddle and its parts are hot. Use care when operating, cleaning

or servicing the griddle.

LUBRICATION

There are no parts on this unit that require lubrication.

VENT

Daily, when the griddle i s cool, check the flue and clear a ny obstructions.

SERVICE AND PARTS INFORMATION

Contact the Service Agency in your area to obtain service and parts information. For a

complete listing of Service and Parts depots refer to or www.vulcanhart.com

When calling for service the following information should be available from the appliance

serial plate: Model Number, Serial Number and Gas Typ e.

-

11 -

.

Page 12

ACCESSORIES

STANDS

The griddle has an optional 24” high by 30” deep by 24”, 36”, 48” or 60” wide stainless

steel stand with casters or flanged legs. The front casters lock, and flanged legs may be

bolted to the floor. The stand includes a top shelf with ma rine edges style lip and a lower

shelf. When mounted on a stand with standard legs and properly leveled, t he griddle plate

cooking surface should approximately 36” from the flo or.

CUTTING BOARDS & TOWEL BARS

Refer to the installation instructions provided with the cutting board or towel bar kit.

-

12 -

Page 13

PROBLEM POSSIBLE CAUSES

Heat does not come on

when the temperature

controller is turned on

Pilot burner will not light

Pilot burner will not stay

lit

Fat appears to smoke

excessively

Food sticks to griddle or

burned around edges or

contains dark specs

Food under-cooked inside

Food tastes greasy or has

objectionable off-flavor

Noticeable build-up of

gum on griddle

TROUBLESHOOTING

1. Problem with temperature controlle rs. (Call for service)

2. Problem with safety-ignition module. (Call for service)

3. Problem with burner solenoid va lves. (Call for service)

4. Problem with thermocouple. (Call for service)

5. Pilot burner not lit. (Call for service)

1. Obstructed pilot orifice. (Call for service)

2. Problem with safety-ignition module. (Call for service)

3. Problem with pilot safety valve. (Call for service)

4. ON/OFF switch not in the ON position

1. Low gas pressure - problem with regulator or system gas

pressure. (Verify or Call for Service)

2. Obstructed or wrong size pilot orifice. (Call for service)

3. Gas supply not purged of air. (Call for service)

4. Air blowing pilot out. (Call for service)

5. Problem with pilot safety valve. (Call for service)

1. Temperature set too high.

2. Moisture in food may be turning into steam

1. Temperature set too high.

2. Griddle surface requires cleaning and/or seasoning.

3. Surface under food not covered with enough cooking oil.

1. Temperature set too low.

2. Food not cooked for long enough time .

1. Food itself may have off-flavor.

2. Food stored improperly before cooki ng.

3. Too much griddle fat used.

4. Temperature set too low.

1. Temperature set too high.

2. Griddle surface needs cleaning a nd/or seasoning.

3. Too much griddle fat used.

-

13 -

Page 14

MODE D'INSTALLATION ET MODE D’EMPLOI

Plaques à frire au gaz à service intense RRG

MODEL

24RRG ML-135339-00024

36RRG ML-135340-00036

48RRG ML-135341-00048

60RRG ML-135342-00060

www.vulcanhart.com

MLS

36RRG

-

14 -

Page 15

MESURES DE SÉCURITÉ IMPORTANTES

CE MANUEL A ÉTÉ PRÉPARÉ À L’INTENTION D’UN PERSONNEL QUALIFIÉ ET

AUTORISÉ À INSTALLER DES APPAREILS FONCTIONNANT AU GAZ ET À

EFFECTUER LE DÉMARRAGE INITIAL CHEZ LE CLIENT DE MÊME QUE LE

RÉGLAGE DES APPAREILS CONCERNÉS DANS CE MANUEL.

AFFICHER À UN ENDROIT VISIBLE LES PREMIERS SOINS À ADMINISTRER À TOUTE

PERSONNE AYANT RESPIRÉ LES GAZ QUE CET APPAREIL DÉGAGE. ON PEUT SE

PROCURER CES INFORMATIONS CHEZ LE FOURNISSEUR DE GAZ LE PLUS PRÈS.

IMPORTANT

EN CAS D’ODEURS DE GAZ, ÉTEINDRE L’APPAREIL PAR

LE ROBINET D’ARRÊT PRINCIPAL ET COMMUNIQUER AVEC

LA COMPAGNIE DE GAZ LA PLUS PRÈS OU AVEC LE

FOURNISSEUR DE GAZ ATTITRÉ POUR L’ENTRETIEN.

MESURE DE SÉCURITÉ

NE PAS RANGER NI UTILISER DE L’ESSENCE NI TOUT

AUTRE LIQUIDE OU VAPEUR INFLAMMABLE À PROXIMITÉ

DE CET APPAREIL OU DE TOUT AUTRE APPAREIL.

L’installation, le réglage, la modification et l’entretien

incorrects de cet appareil peuvent causer des dommages

matériels, des blessures et même la mort. Lire les

instructions d’installation, de fonctionnement et d’entretien

avant de procéder à toute installation ou tout entretien.

EN CAS DE PANNE DE COURANT, NE PAS FAIRE

FONCTIONNER CET APPAREIL.

-

15 -

Page 16

INSTALLATION, FONCTIONNEMENT ET ENTRETIEN

PLAQUES À FRIRE AU GAZ À SERVICE INTENSE

GÉNÉRALITÉS

Les plaques à frire au gaz à servi ce intense sont fabriquées a vec le plus grand soin et à

partir des meilleurs matériaux. Leur installation, utilisation et entretien appropriés

permettent d’en obtenir un rendement optimal pe ndant de nombreuses années. Il est

recommandé de lire le manuel au complet et de suivre atte ntivement toutes les

instructions.

Modèle Nombre de brûleurs Débit BTU/h

24RRG 2 55 000

36RRG 3 82 500

48RRG 4 110 000

60RRG 5 137 500

INSTALLATION

Avant d’installer cet appareil, s’assu rer que l’alimentation électriqu e et le type de gaz

(naturel ou propane) de l’immeuble co rrespondent aux spécifications de la plaq ue

signalétique placée à l’inté rieur du panneau avant. S’i ls ne correspondent pas, ne pas

installer l’appareil et communiquer sans tarder avec votre détaillant.

DÉBALLAGE

Avant de quitter l’usine, cet app areil a été inspecté soigneusemen t. Le transporteur est

entièrement responsable de la marchandise jusqu’à la livraison. Immédiatement après

avoir déballé l’appareil, vérifie r s’il n’a pas été endommagé lors du transport. En cas de

dommages, conserver le matériel d’emballage et aviser le transporteur dans les 15 jours

suivant la date de réception.

Déballer l’appareil avec soin. S’assurer qu’aucune pièce n’est jetée avec le matériel

d’emballage. Un régulateur de pression conçu pour fonctionner avec cette plaque à frire est

fourni et doit être installé avant que la plaque à frire ne soit en état de fonctionner. (Se référer à

la section PRESSION DU GAZ ET INSTALLATION D’UN RÉGULATEUR de ce manuel.)

EMPLACEMENT

Aucune substance combustible ne doit se trouver à proximité de cet appareil. Lors de l’installation, ne

jamais enfermer la partie inférieure de l’appareil dans un muret élevé ou autre construction qui

pourraient obstruer le débit d’air à l’intérieur et à l’extérieur de la plaque à frire. Prévoir un dégagement

suffisant pour l’ouverture d’approvisionnement d’air dans la chambre de combustion. S’assurer qu’il y a

un débit d’air suffisant dans la chambre pour remplacer l’air évacué par le système de ventilation.

Veiller à ce que les ventilateurs ne soufflent pas directe ment sur la plaque à frire et, dans l a

mesure du possible, ne pas ouvrir les fenêtres à proximité de l’appareil ni utiliser des

ventilateurs muraux qui produisent des courants d’air.

-

16 -

Page 17

Cette plaque à frire a été conçue en fonction d’u ne installation sur un comp toir incombustible

muni de pattes de 102 mm (4 po) ou sur un plancher combustible muni d’un support de 635 mm

(25 po) de hauteur.

DÉGAGEMENT REQUIS POUR L’INSTALLATION

CONSTRUCTION COMBUSTIBLE CONSTRUCTION INCOMBUSTIBLE

Arrière : 152 mm (6 po) Aucun

Côté droit : 152 mm (6 po) Aucun

Côté gauche : 152 mm (6 po) Aucun

CODES D’INSTALLATION ET NORMES

Installer la plaque à frire selon le s codes suivants :

Aux États-Unis :

1. Codes locaux.

2. Norme ANSI/Z223.1 /NFPA N° 54 (dernière édition) du National Fuel Gas Code. Ceci

devra inclure mais ne pas se limiter à la norme NFPA N° 54 pour la ventilation,

section 10.3.5.2, dont on peut se procurer un exemplaire auprès de l’American Gas

Association Accredited Standards Committee Z223, 400 N. Capital St. NW,

Washington, DC 20001, ou the Sec retary Standards Council, NFPA, 1 Batterymarch

Park, Quincy, MA 02169-7471.

NOTA : Dans l’État du Massach usetts

Tous les appareils au gaz ventilés par une hotte de ventilation ou un système d’évacuation

muni d’un registre ou de moyens d’évacuati on à puissance doivent être conf ormes à la

règlementation 248 CMR.

3. Norme NFPA N° 96 pour l’évacuation de la fumée des appareils de cuisson (dernière

édition) dont on peut se procurer un exemplaire auprès de la National Fire Protection

Association, Batterymarch Park, Quincy, MA 02269.

Au Canada :

1. Codes locaux.

2. Norme CAN/CSA B149.1 du Code d’installation des appareils fonctionn ant au gaz

naturel (dernière édition).

3 . Norme CAN/CSA-B149.2 du Code d’installation des appareils fonctionnant au gaz propane

(dernière édition) dont on peut se procurer un exemplai re auprès de l’Association

canadienne du gaz, 178 Rexdale Blvd, Etobicoke, Ontario, Canad a M9W 1R3.

PLAQUE À FRIRE MONTÉ SUR UN SUPPORT MUNI DE ROULETTES

AVIS Si la plaque à frire doit être installée sur des roulettes, se

munir d’un connecteur flexible (non fourni) conforme aux normes

ANSI-Z21.69 ou CSA 6.16 sur les connecteurs des appareils au

gaz mobiles, et d’un raccord à débranchement rapide conforme

aux normes ANSI-Z21.3 ou CSA 6.9 sur les dispositifs à

débranchement rapide d’appareils au gaz. En plus, prendre les

moyens nécessaires pour limiter le mouvement de l’appareil

sans devoir compter sur le connecteur ou le raccord à

débranchement rapide (ni même sur la tuyauterie) pour le

garder immobile. Fixer le dispositif de retenue à l’arrière de la

plaque à frire, tel qu’illustré à la Fig. 3).

Fig. 3

Si le débranchement du dispositif de retenue est nécessaire, éteindre l’alimentation en gaz

avant le débranchement. Rattacher le disp ositif de retenue avant de rétablir l’alimen tation en

gaz et de remettre l’appareil à la position d’installation.

-

17 -

Page 18

Les roulettes sont fournies seulement sur le support de la p laque à frire. Si l’appareil est

installé sur des roulettes et doit être déplacé pour une raison ou u ne autre, il est conseillé de

le niveler à nouveau (se référer à la section NIVELAGE de ce manuel).

SYSTÈME D’ÉVACUATION

NE PAS obstruer le débit des gaz brûlés du conduit d’évacuation à l’arrière de l’appareil.

On recommande l’évacuation des gaz brûlés à l’extérieur de l’immeu ble au moyen d’une

hotte de ventilation installée par un perso nnel qualifié.

Maintenir un dégagement minimal de 457 mm (18 po) entre le conduit d’évacuation de

l’appareil et les filtres de l a hotte.

Pour toute information sur la construction et l’installation des hottes de ventilation, voir la

norme NFPA N° 96 (dernière édition) sur l’évacuatio n de la fumée des appareils d e cuisson

dont on peut se procurer un exemplaire auprès de la National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269.

SUPPORTS

La plaque à frire est munie d’un support avec roulettes en inox de 635 mm (25 po) de hauteur par

762 (30 po) de profondeur par 610, 914, 1 219 ou 1 524 mm (24, 36, 48 ou 60 po) de largeur

en option. Les deux roulettes avant sont verrouillables . Le support inclut une tablette

supérieure à rebord marin de type lèvre et une tablette inférieure.

BRANCHEMENT DU GAZ

AVIS Tous les raccords d’alimentation de la conduite de gaz et la pâte à joints de tuyaux

doivent résister à l’action du gaz propane.

Pour l’entrée de la plaque à frire, utiliser une conduite d’alimentation en gaz de 19 mm (3/4 po)

NPT qui se trouve à l’arrière de l’appareil. Tous les raccordements de type flexible et semi-rigide

doivent être conformes aux normes ANSI en vigueur. Pour s’assurer d’une efficacité d’exploitation

maximale, raccorder cet appareil avec une conduite d’alimentation en gaz fabriqué à l’aide d’un

tuyau solide ou d’un raccord souple de type commercial dont le diamètre intérieur net est aussi

grand ou plus grand que l’entrée de canalisation de gaz de cet appareil. Conformément aux

exigences des codes, installer un robinet d’arrêt dans la conduite de gaz, en amont de l’appareil.

!

AVERTISSEMENT Avant de procéder à l’allumage, faire circuler de l’eau

savonneuse dans tous les joints de la conduite de gaz pour s’assurer qu’ils ne

présentent aucune fuite. Ne pa s se servir d’une flamme nue.

Après avoir enrayé toute possibilité de fuite, purger la conduite de gaz pour é vacuer tout l’air

qu’elle contient.

ESSAIS DE LA CANALISATION DE GAZ

Si la pression de la canalisation de gaz est supérieure à 3,45 kPa (1/ 2 psig) lors d’essais

de pression, débrancher la plaque à frire et son robinet d’arrêt de la conduite de gaz.

Lorsque la pression est égale ou inférieure à 3,45 kPa (1/2 psig), isoler l’appareil de la

canalisation de gaz en fermant le robinet manuel.

PRESSION DU GAZ ET INSTALLATION D’UN RÉGULATEUR

La pression du régulateur de gaz est réglée en usine à une pression de 1,24 kPa (5 p o de

colonne d’eau) pour le gaz naturel et de 2,49 kPa (10 po de colonn e d’eau) pour le gaz

propane. Aucun autre réglage n’est requis.

Installer le régulateur aussi près que possible de la plaque à frire , sur la conduite de gaz.

S’assurer que la flèche sur l a face intérieure du régula teur pointe vers le débit de gaz

allant à la plaque à frire (Fig. 1) et que le régulateur est positionné de façon à ce que le

bouchon d’aération et la vis de réglage soient dirigés vers l e haut droit (Fig. 2).

-

18 -

Page 19

Fig. 1

Fig. 2

La pression d’alimentation (en amont du régulateur) devrait être de 1,74 à 2,24 kPa (7 à 9 po

de colonne d’eau) pour le gaz naturel et de 2,74 à 2 ,99 kPa (11 à 12 po de colon ne d’eau) pour le

gaz propane. Ne jamais raccorder la plaque à frire à une pression d’alimentation de plus de 3,45 kPa

(1/2 psig) ou 3,45 kPa (14 po de colonne d’e au).

RACCORDEMENT ÉLECTRIQUE

!

AVERTISSEMENT Le raccordement électrique et la mise à la terre doivent être conformes

aux normes concernées du code canadien de l’électricité ou de tout autre code d’électricité en

vigueur.

!

AVERTISSEMENT : Couper l'alimentation électrique de l’appareil et suivre les procédures de

verrouillage et d’étiquetage.

!

AVERTISSEMENT : Le cordon d’alimentation est pourvu d’une fiche de mise à la terre à

trois broches. La prise dans laquelle elle est branchée doit être correctement mise à la terre. Si

elle ne l'est pas, communiquer avec un électricien. Ne pas enlever la broche de mise à la terre

de la fiche.

L’alimentation électrique pour l’allumage électrique es t de 120 V, 50-60 Hz , mon ophasée, 1 A.

Ne pas raccorder la plaque à frire à l’ali mentation élec trique a vant que le raccorde ment du ga z ne

soit fait.

-

19 -

Page 20

FONCTIONNEMENT

! !

AVERTISSEMENT : La plaque à frire et ses composants sont chauds. Exercer une extrême

prudence lors de l’exploitation, du nettoyage et de l’entretien de cet appareil.

! !

AVERTISSEMENT : Débrancher l’alimentation électrique avant le nettoyage et l’entretien

de cet appareil.

AVANT UNE PREMIÈRE UTILISATION

Il est conseillé de nettoyer à fond la plaque à frire VULCAN RRG dans une eau tiède savonneuse.

Rincer la surface avec soin avec de l’eau et essuyer à l’aide d’un chiffon doux.

APPRÊTAGE DE LA PLAQUE À FRIRE

Avant de faire fonctionner l’appareil, appliquer une huile chauffée à haute température - environ 28 g

par mètre carré (une once par pied carré). NE PAS utiliser d’huile végétale pure car elle n’est pas

stabilisée pour une chaleur élevée et pourrait faire coller les aliments et donner une cuisson non

satisfaisante. Mettre la plaque à frire à ON (marche) et, à l’aide d’un chiffon, étendre l’huile sur toute la

surface pendant deux minutes.

Après avoir nettoyé votre plaque à frire avec des produits chimiques, l’apprêter à nouveau pour une

meilleure cuisson.

NE PAS utiliser de spatules en acier trempé. Utiliser une spatule en acier doux avec des coins

arrondis.

COMMANDES

Il y a a u m oins une v eilleuse pour cha q u e d eux brûle u rs. Les brûleurs principaux sont en chiffres impairs

pour les modèles de 914 et 1 524 mm (36 et 60 po), cependant un des ensembles de veilleuses et un

de modules d’allumage de sécurité électroniques de ces modèles commandera seulement un brûleur

principal. Les brûleurs de la veilleuse sont alignés avec les trous d’observation de la veilleuse. Les

brûleurs de la veilleuse sont insérés à 305 mm (12 po) du panneau avant.

Ce modèle est muni d’un système d’allumage de sécurité électronique commandé par un interrupteur

d’alimentation. Tout ce qu’il suffit de faire, c’est de mettre l’interrupteur d’alimentation à la position ON

(marche) pour faire fonctionner l’appareil. L’interrupteur d’alimentation allume la soupape de la

veilleuse, les thermostats, les voyants lumineux et les modules d’allumage de sécurité électroniques.

Lorsque l’appareil est à la position ON (marche), les modules d’allumage de sécurité électroniques

commencent à générer des étincelles jusqu’à l’apparition d’une flamme apparente au brûleur de la

veilleuse. Lors d’une rectification de la flamme, le module d’allumage de sécurité électronique met en

fonction les électrovannes au gaz pour ces zones précises.

Les veilleuses sont contrôlées par la détection de flamme à travers les allumeurs. Si la veilleuse

s’éteint, l’allumeur va immédiatement rallumer la veilleuse. Si la veilleuse ne réussit pas à réallumer

les brûleurs dans un court délai, le module d’allumage de sécurité électronique fermera l’alimentation

en gaz de la veilleuse aux brûleurs principaux et continuera à générer des étincelles au brûleur de la

veilleuse.

Chaque section de 305 mm (12 po) de la plaque à frire est contrôlée de façon indépendante par un

thermostat à semi-conducteur et un thermocouple enchâssé. Les thermostats possèdent une plage

de fonctionnement de 66 à 232 degrés °C (150 à 450 °F)

-

20 -

Page 21

UTILISATION DE LA PLAQUE À FRIRE

Pour le préchauffage de la plaque, r égler les the rmostat s à la tempér ature désirée et allumer l’interru pteur

d’alimentation de 10 à 12 minutes avant la cuisson.

Pour obtenir des résultats des plus constants, il est important de placer les aliments dans la plaque de

façon uniforme et systématique.

La plaque à frire est un matériaux composite et a été conçue pour fournir un degré de transfert de

chaleur élevé. La plaque à frire est en acier inoxydable, mais la surface est relativement fragile et peut

rayer ou bosseler suite à l’utilisation d’une spatule ou d’un racloir d’une manière négligente. Prendre

soin de ne pas la bosseler, l’égratigner ni la rayer. Ne pas y cogner les coins ou les rebords d’une

spatule pour tenter de déloger les particules d’aliments qui pourraient s’y trouver.

ZONE DE CUISSON

La plaque à frire est équipée d’un brûleur tubulaire profilé en “U” dans des sections de 305 mm (12 po)

et dont chacune possède des thermostats indépendants. Chaque section de 305 mm (12 po) est une

zone de cuisson indépendante. Ceci permet la cuisson d’une grande variété de produits sur une simple

plaque à frire. Le tableau ci-dessous donne une idée de l’usage de la zone de cuisson.

Dans la zone de cuisson, il est conseillé de commencer par le réglage de la plus basse température de

chaque côté de la plaque à frire et d’augmenter la zone de température à mesure qu’on approche de la

ligne de cuisson. Ce guide de zone de cuisson peut varier selon les températures, la taille et la forme

du produit. Vous pouvez régler ce tableau selon vos produits et votre préférence de cuisson.

ZONE 1

149 °C (300 °F)

PRODUIT

Saucisses

Oeufs frits (durs)

Oeufs brouillés

Boulettes de viande

pour hamburger

(bien cuites)

Bifteck (bien cuit)

Poitrine de poulet

Aliments congelés

Côtelettes de porc

ZONE 2

177 °C (350 °F)

ZONE 3

177 °C (350 °F)

PRODUIT PRODUIT

Crêpes

Pain doré

Bacon

Oeufs (au miroir)

Jambon blanc

Bifteck (à point)

Boulettes de viande fraîches

pour hamburger (à point)

Petites boulettes de viande

congelées pour hamburger (à point)

Omelette

Pommes de terre

rissolées

Bacon de dos

-

21 -

ZONE 4

204 °C (400 °F)

Bifteck (saignant)

Légumes sautés à

feu vif

Saumon

Fricadelles de

poisson

Homard

Langoustines

Page 22

NETTOYAGE DE LA PLAQUE À FRIRE

Vider le tiroir de propreté au besoin durant le jour et régulièrement au moins une fois par jour.

Nettoyer la plaque à frire régulièrement. Une plaque propre a meilleure apparence, dure plus

longtemps et donne de meilleurs résultats. Pour obtenir des résultats de cuisson uniformes et des

produits parfaitement dorés, garder la plaque propre et exempte de graisse carbonisée. La graisse

carbonisée nuit au transfert de la chaleur de la plaque à la surface des aliments, occasionnant leur

brunissement partiel et réduisant la qualité de cuisson. Pire encore, elle a tendance à coller aux

aliments et leur donne une apparence peu appétissante qui laisse vraiment à désirer.

Pour garder la plaque à frire propre et opérationnelle en période de forte affluence, suivre les directives

suivantes :

APRÈS CHAQUE USAGE

Nettoyer la plaque au moyen d’un racloir Nemco Easy Grill Scraper

MD

ou de type similaire durant les

quarts de travail.

UNE FOIS PAR JOUR

Nettoyer à fond le dosseret, les côtés et le devant. Mettre la plaque à frire à OFF (arrêt) et la laisser

refroidir entre 93 et 149 °C (275 et 300 °F). Verser un peu d’eau et la nettoyer avec un racloir épais.

Enlever le tiroir de propreté, le vider et le nettoyer de la même manière que tout autre ustensile de

cuisson.

UNE FOIS PAR SEMAINE

Nettoyer à fond la surface de la plaque à frire avec un peu d’eau, un tampon Scotch Brite

nettoyage rapide de la plaque à frire ou un nettoyant rapide pour graisse chauffée à haute température

Ecolab

MD

.

MD

pour

Après avoir enlevé toute trace de détergent, apprêter la surface de la plaque à frire conformément aux

instructions de ce manuel.

Nettoyer les surfaces en acier inoxydable à l’aide d’un chiffon humide et les polir ensuite avec un

chiffon doux et sec. Enlever les taches de décoloration au moyen d’un nettoyant à plaque à frire.

Si l’usage de la plaque à frire est très élevé, procéder au nettoyage plus d’une fois par semaine.

NE PAS utiliser une brique ou une pierre à plaque à frire pour le nettoyage.

NE PAS utiliser de jet d’eau pour nettoyer la plaque à frire.

NE PAS utiliser d’agent désinfectant à base de chlore sur la plaque à frire. Ceci peut causer une

décoloration, une corrosion et un dommage permanent.

NE PAS utiliser d’agents de nettoyage incluant de l’hydrate de sodium, que l’on retrouve souvent dans

les nettoyants à usage domestique.

-

22 -

Page 23

RÉGLAGES

ÉTALONNAGE

6 . Chaque thermostat commande une zone de 305 mm

(12 po) de la plaque à frire. Utiliser un dispositif de

mesurage de la température adéquat pour observer

les températures à des points centraux des zones de

cuisson. En partant de 152 mm (6 po) d’un côté ou

de l’autre de la plaque et à chaque 305 mm (12 po) à

travers la largeur de la plaque, on peut retrouver ces

points qui sont tous placés à 305 mm (12 po) derrière

le rebord avant de la plaque à frire.

NOTA: L’usage de thermomètres à infrarouge n’est

pas recommandé. Ceux-ci sont très sensibles à la

couleur de la surface (propre ou sale), à l’angle de

lecture et à la distance de l’apparei l.

7. Régler les thermostats à 177 °C (350 °F) et les laisser

se stabiliser. Laisser fonctionner le voyant lumineux

en le mettant à ON et OFF (marche et arrêt) au moins

deux fois.

8. Surveiller le voyant lumineux jusqu’à ce qu’il indique OFF

(arrêt), puis mesurer la température pour cette zone. La

température devrait être à 177 °C (350 °F) ± 3 °C (5 °F).

Si ce n’est pas le cas, suivre l’étape 4 suivante.

9.

a. Décider du réglage de la température

nécessaire pour le thermostat. NE PAS

laisser le bouton tourner. Enlever le

bouton de l’arbre du thermostat avec

soin.

b. Dévisser les vis derrière le bouton et

tourner l’anneau transparent autour du

bouton noir à la position désirée.

Replacer le bouton sur l’arbre pour

vérifier le réglage.

IMPORTANT : NE JAMAIS RÉGLER LA VIS

DU CÔTÉ ARRIÈRE DU THERMOSTAT.

Ceci pourrait détruire l’étalonnage fait à

l’usine; le thermostat ne fonctionnera plus

correctement et devra être remplacé.

1 0. Une fois que l’étalonnage est terminé, serrer

les vis du bouton.

Étape 4a. - Régler

le bouton et vérifier

la température.

Enlever le bouton.

Étape 4b. – Régler

la position de

l’anneau extérieur

du bouton avec le

bouton noir et régler

la température.

Étape 4c. –

Replacer le bouton

et vérifier la lecture.

Enlever le bouton

avec soin et serrer

les vis.

-

23 -

Page 24

NIVELAGE

Niveler la plaque à frire (d’un côté à l’autre et d’avant en arrière) pour obtenir un meilleur

rendement de l’appareil, faute de quoi la distribution de température ne sera pas égale,

certains endroits seront plus fro ids et les composants électriques pourraient possiblement

être endommagés.

3. Placer un niveau sur la plaque à frire.

4. Régler les pattes en tournant le pied télescopique au bas de ch aque patte. En se

servant de pinces multiprises, tourner le pied à l’in verse des aiguilles d’une montre

pour augmenter la hauteur ou l’inverse pour la diminuer jusqu’à ce qu’elle soit de

niveau. À la position la plus basse, ne pas étirer les pattes de plus de 44 mm (1 3/4 po).

RÉGLAGE DE LA VEILLEUSE

Pour faire baisser la flamme, utiliser un tournevis à tête plate et tourner la vis de réglage de la

veilleuse dans le sens des aiguilles d’une montre et l’inverse pour l’augmenter. Les réglages de

la veilleuse devraient seulement être effectués par un technicien d’entretien qualifié.

ARRÊT DE LA PLAQUE À FRIRE AVEC UN SYSTÈME D’ALLUMAGE ÉLECTRIQUE

1. Mettre l’interrupteur d’aliment ation à OFF (arrêt). Ceci éteindra la plaque à frire

complètement.

ARRÊT PROLONGÉ

1. Fermer le robinet de gaz d’alimentation principal.

2. Débrancher le cordon d’alimentation de la plaque à frire.

5. Enduire la plaque à frire d’un e couche épaisse d’huile végétal e pour prévenir la

corrosion.

ENTRETIEN

! !

AVERTISSEMENT : La plaque à frire et ses composants sont chauds. Exercer une extrême

prudence lors de l’exploitation, du nettoyage et de l’entretien de cet appareil.

LUBRIFICATION

Aucune pièce de cet appareil ne nécessite de lubrification.

CONDUIT D’ÉVACUATION

À tous les jours, lorsque la plaque à frire est froide, vérifier le conduit d’évacuation pour s’assurer qu’il

n’est pas obstrué.

SERVICE DE L’ENTRETIEN ET PIÈCES DE RECHANGE

Pour l’entretien de l’appareil ou pour obtenir des renseignements sur les pièces de rechange,

communiquer avec le service de l’entretien le plus près. Pour une liste complète de nos succursales de

service de l’entretien, visiter notre site Web à l’adresse : www.vulcanhart.com

Lors d’une demande de service, fournir les renseignements suivants que vous trouverez sur la plaque

signalétique de l’appareil : le numéro de modèle, le numéro de série et le type de gaz.

-

24 -

Page 25

ACCESSOIRES

SUPPORTS

La plaque à frire possède un support en inox en option de 610 mm (24 po) de hauteur par

762 mm (30 po) de profondeur par 610, 91 4, 1 219 ou 1 524 mm (24, 36, 48, ou 60 po) de

largeur muni de roulettes ou de pattes à ailettes . Les roulettes de verrouillage avant et

les pattes à ailettes peuvent être vissées au sol. Le support incl ut une tablette supérieure

munie de rebords marins style lè vre et une tablette inférieure. L orsque la surface de

cuisson est installée sur un supp ort muni de pattes standard et q u’elle est bien de niveau,

elle devrait être approximativement à 914 mm (36 po) du plancher.

PLANCHES À DÉCOUPER ET PORTE-SERVIETTES

Se référer aux directives d’installation f ournies avec la planche à découper o u la trousse

de porte-serviettes.

-

25 -

Page 26

DÉPANNAGE

PROBLÈME CAUSES POSSIBLES

Aucune chaleur lorsqu’on

ouvre le thermostat

Le brûleur de la veilleuse

ne s’allume pas

Le brûleur de la veilleuse

ne reste pas allumé

6. Problème de thermostat. (Communiquer a vec le service

de l’entretien).

7. Problème avec le module d’allumage de sécurité.

(Communiquer avec le service de l’entretien).

8. Problème avec les électrovannes du brûleur.

(Communiquer avec le service de l’entretien).

9. Problème avec le thermocouple. (Communiquer avec le

service de l’entretien).

10. Le brûleur de la veilleuse ne s’allume pas. (Communiquer

avec le service de l’entretien).

5. Orifice de la veilleuse obstrué (Co mmuniquer avec le

service de l’entretien).

6. Problème avec le module d’allumage de sécurité.

(Communiquer avec le service de l’entretien).

7. Problème avec la soupape de sûreté de la veilleuse.

(Communiquer avec le service de l’entretien).

8. L’interrupteur ON/OFF (marche/arrêt) n’est pas à la

position ON (marche).

6. Pression du gaz basse – problème avec le régulateur ou

la pression du gaz. (Vérifier ou communiquer avec le

service de l’entretien).

7. Orifice de la veilleuse obstrué ou de mauvaise taille.

(Communiquer avec le service de l’entretien).

8. La conduite de gaz n’a pas été purgée pour évacuer l’air.

(Communiquer avec le service de l’entretien).

9. La veilleuse s’éteint au contact de l’air. (Communiquer

avec le service de l’entretien).

10. Problème avec la soupape de sûreté de la veilleuse.

(Communiquer avec le service de l’entretien).

Production excessive de

fumée

Les aliments collent à la

surface de la plaque ou brûlent

sur les bords ou comportent

des taches sombres

L’intérieur des aliments n’est

pas suffisamment cuit.

Les aliments sont

graisseux ou manquent

de saveur

Accumulation visible d’une

substance gommeuse à la

surface de la plaque.

3. Réglage de la température trop élevé.

4. Teneur en eau des aliments élevée, produisant ainsi de

la vapeur.

4. Réglage de la température trop élevé.

5. Nettoyage ou apprêtage de la surface de la plaque requis.

6. Quantité insuffisante d’huile de cuisson sur la plaque.

3. Réglage de la température trop bas.

4. Cuisson insuffisante des aliments.

5. Altération de la saveur des aliments.

6. Entreposage inadéquat des aliments avant la cuisson.

7. Utilisation d’une trop grande quantité d’huile de cuisson.

8. Réglage de la température trop bas.

4. Réglage de la température trop élevé.

5. Nettoyage ou apprêtage de la surface le la plaque requis.

6. Utilisation d’une trop grande quantité d’huile de cuisson.

-

26 -

Loading...

Loading...