Page 1

SERVICE MANUAL

SALAMANDER ELECTRIC

BROILER

VULCAN - 36ESB

- NOTICE -

This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qualified.

This manual is not intended to be all encompassing. If you have

not attended a Vulcan Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Vulcan Service Technician.

The reproduction, transfer, sale or other use of this Manual,

without the express written consent of Vulcan, is prohibited.

This manual has been provided to you by ITW Food Equipment

Group LLC ("ITW FEG") without charge and remains the property

of ITW FEG, and by accepting this manual you agree that you will

return it to ITW FEG promptly upon its request for such return at

any time in the future.

A product of Vulcan-Hart 3600 North Point Blvd Baltimore, MD 21222

F45545 (0315)

Page 2

SALAMANDER ELECTRIC BROILER

TABLE OF CONTENTS

GENERAL .................................................................................................. 3

INTRODUCTION ....................................................................................... 3

INSTALLATION, OPERATION AND CLEANING ......................................................... 3

GRID POSITION AND HEAT CONTROL SETTING ...................................................... 3

MODELS ............................................................................................... 3

SPECIFICATIONS ...................................................................................... 3

TOOLS ................................................................................................. 4

REMOVAL AND REPLACEMENT OF PARTS ............................................................... 5

FRONT PANEL ......................................................................................... 5

LEFT SIDE PANEL ..................................................................................... 5

RIGHT SIDE PANEL .................................................................................... 6

INFINITE SWITCH / 3 HEAT SWITCH ................................................................... 6

RACK SPRINGS ....................................................................................... 7

HEATING ELEMENTS .................................................................................. 7

SERVICE PROCEDURES AND ADJUSTMENTS ............................................................ 9

INFINITE SWITCH TEST (208V/240V) .................................................................. 9

3 HEAT SWITCH TEST (480V) ......................................................................... 9

RACK SPRING TENSION ADJUSTMENT ............................................................... 9

HEATING ELEMENTS TEST .......................................................................... 10

ELECTRICAL OPERATION ................................................................................ 11

COMPONENT FUNCTION ............................................................................ 11

SEQUENCE OF OPERATION ......................................................................... 11

208/240V - WIRING DIAGRAM ........................................................................ 12

480V - WIRING DIAGRAM ............................................................................. 13

TROUBLESHOOTING ..................................................................................... 14

TROUBLESHOOTING ................................................................................. 14

© VULCAN 2015

F45545 (0315) Page 2 of 14

Page 3

SALAMANDER ELECTRIC BROILER - GENERAL

GENERAL

INTRODUCTION

This manual is for the Vulcan and Wolf Electric

Salamander Broilers. Procedures in this manual will

apply to all models unless specified. Pictures and

illustrations will be of model 36ESB unless otherwise

noted.

All of the information, illustrations and specifications

contained in this manual are based on the latest

product information available at the time of printing.

INSTALLATION, OPERATION AND

CLEANING

For detailed installation, operation and cleaning

instructions, refer to Installation & Operation Manual

sent with each unit. The manual is also available

online at www.vulcanequipment.com.

NOTE: Using accessory options, Salamander

broilers can be mounted to the wall, over a range or

placed onto an appropriate table top by using 4" legs.

GRID POSITION AND HEAT

CONTROL SETTING

For detailed information refer to OPERATING THE

BROILER and GRID ADJUSTMENT in the Installation

& Operation Manual.

MODELS

Vulcan

• 36ESB-208

• 36ESB-240

• 36ESB-480

SPECIFICATIONS

3 PHASE MACHINE INFORMATION

NOMINAL AMPS PER LINE WIRE

Model Total KW

36ESB-208 4.5 11.0 18.9 11.0 — — — — — — 19.2

36ESB-240 4.5 — — — 9.4 16.4 9.4 — — — 25.6

36ESB-480 4.5 — — — — — — 4.9 8.4 4.9 102.4

1. Values in the table are nominal. Tolerance is +5/-10%.

208V 240V 480V

X Y Z X Y Z X Y Z

OHMS per

Element

NOTES:

Model Total KW

36ESB-208 4.5 21.6 — 19.2

36ESB-240 4.5 — 18.8 25.6

NOTES:

2. Voltage values are @ 60Hz.

3. Resistance values (ohms) are @ 77° F.

4. 2.25KW per element assembly (left or right).

1 PHASE MACHINE INFORMATION

NOMINAL AMPS PER LINE WIRE

OHMS per Element

208V 240V

1. Values in the table are nominal. Tolerance is +5/-10%.

2. Voltage values are @ 60Hz.

3. Resistance values (ohms) are @ 77° F.

4. 2.25KW per element assembly (left or right).

Page 3 of 14 F45545 (0315)

Page 4

SALAMANDER ELECTRIC BROILER - GENERAL

TOOLS

Standard

• Standard set of hand tools

• VOM with ability to measure micro amp current.

VOM with minimum of NFPA-70E CAT III 600V,

UL/CSA/TUV listed. Sensitivity of at least 20,000

ohms per volt. Meter leads must also be rated at

CAT III 600V.

• Clamp on type amp meter for measuring heating

element current draw.

• Temperature tester (thermocouple type)

F45545 (0315) Page 4 of 14

Page 5

SALAMANDER ELECTRIC BROILER - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

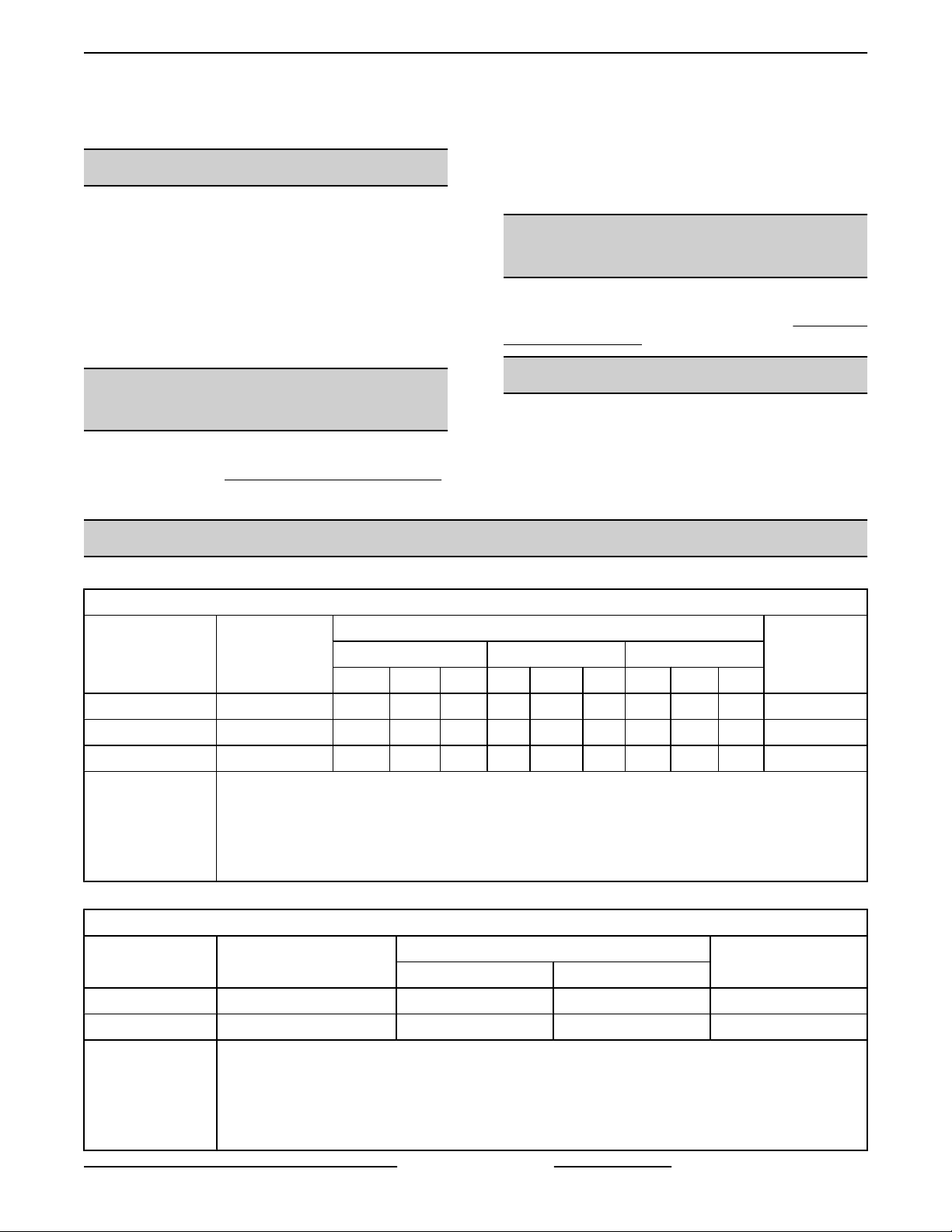

FRONT PANEL

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove screws that secure front panel to broiler.

2. Remove INFINITE SWITCH / 3 HEAT SWITCH

from front panel.

3. Reverse procedure to install.

Fig. 1

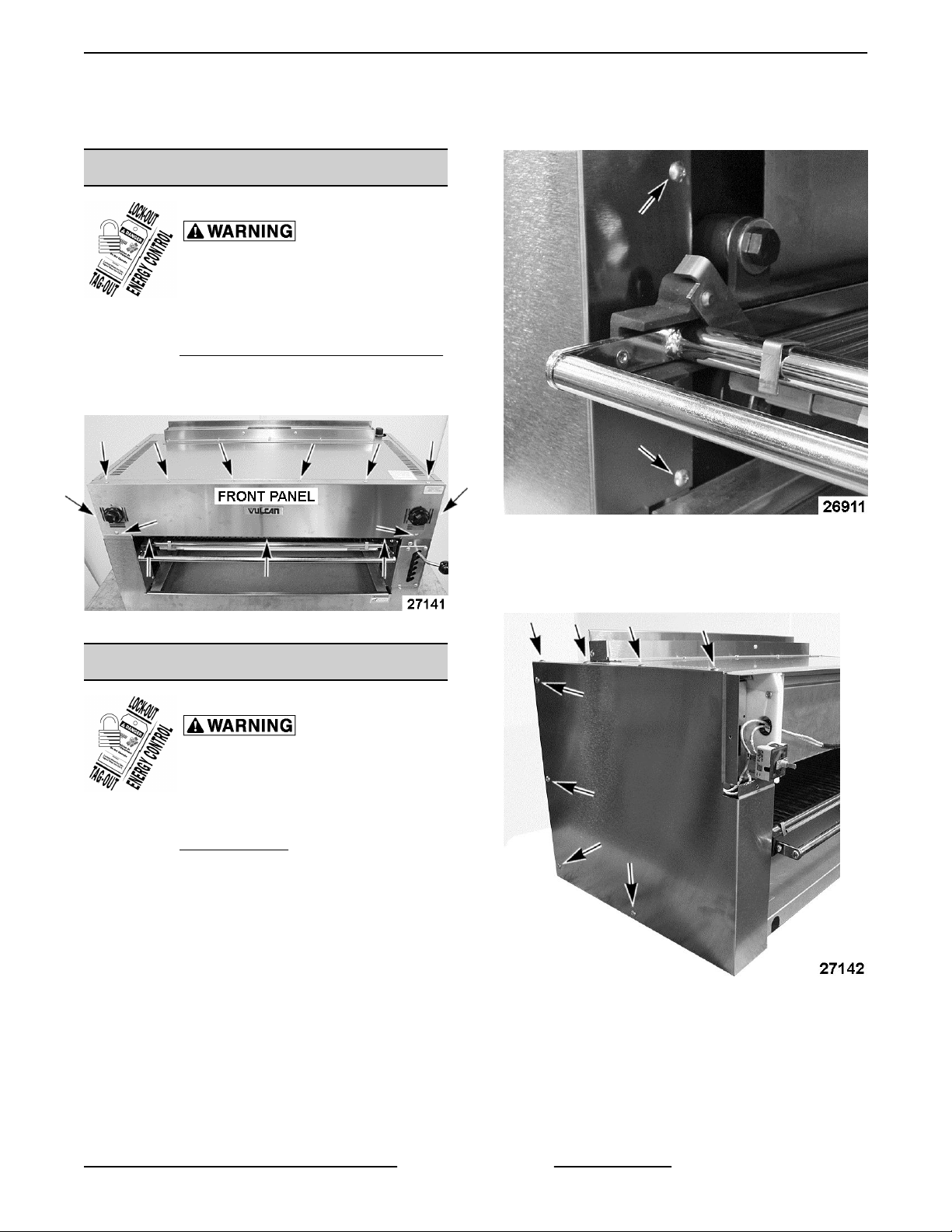

LEFT SIDE PANEL

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove crumb tray.

2. Remove

3. Position the rack assembly to access panel

screws in the broiler opening area.

FRONT PANEL.

Fig. 2

4. Remove screws securing left side panel. Slide

panel toward the front of broiler until panel clears

front mounting area then remove the panel.

Fig. 3

5. Reverse procedure to install.

Page 5 of 14 F45545 (0315)

Page 6

SALAMANDER ELECTRIC BROILER - REMOVAL AND REPLACEMENT OF PARTS

RIGHT SIDE PANEL

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove crumb tray.

2. Remove FRONT PANEL.

3. Remove screws securing plate stop to broiler.

Fig. 5

6. Remove screws securing right side panel to

broiler. Slide panel toward the front of broiler until

panel clears front mounting area then remove the

panel.

Fig. 4

4. Pull knob off the handle on rack positioning

bracket then remove plate stop.

5. Position the rack assembly to access panel

screws in the broiler opening area. Remove

screws from this area and the front of panel.

Fig. 6

7. Reverse procedure to install.

INFINITE SWITCH / 3 HEAT SWITCH

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove knob from switch.

F45545 (0315) Page 6 of 14

Page 7

SALAMANDER ELECTRIC BROILER - REMOVAL AND REPLACEMENT OF PARTS

2. Remove washer nut securing switch to front

panel.

Fig. 7

3. Remove FRONT PANEL from broiler.

4. Note wire locations then disconnect wires from

switch being replaced.

3. Loosen nuts to remove any remaining tension on

springs.

4. Access the bottom of broiler and remove springs

from the lower arm casting and eye bolt.

Fig. 8

5. Reverse procedure to install.

6. Check for proper operation.

RACK SPRINGS

NOTE: Springs should be replaced in pairs for proper

operation of the rack lift assembly.

Fig. 9

5. Reverse procedure to install.

6. Perform RACK SPRING TENSION

ADJUSTMENT.

HEATING ELEMENTS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove crumb tray from broiler.

2. Adjust rack assembly to the center position.

3. Pull rack assembly out and access the rack stops

on the left and right sides of the rack assembly.

Allow enough clearance at the rear of rack

assembly to rotate the rack stops to a horizontal

position. If the rack assembly is pulled all the way

out the rack assembly will engage the rack stops

and prevent removal.

1. Remove crumb tray to access tension

adjustment nuts from the front of broiler.

2. Raise the rack lift assembly to its highest position

on stop plate to relieve spring tension.

Page 7 of 14 F45545 (0315)

Page 8

SALAMANDER ELECTRIC BROILER - REMOVAL AND REPLACEMENT OF PARTS

Fig. 10

4. Grasp the rack assembly near the broiler, rotate

both the rack stops horizontally and pull the rack

assembly out enough for the rack assembly

frame to clear the rack stops.

Fig. 13

7. Note wire locations and disconnect wires from

heating element.

Fig. 11

5. Grasp the rack assembly and drip tray on each

side to support the tray and remove from broiler.

Fig. 12

6. From inside broiler cooking area, remove screws

securing heating element to broiler.

Fig. 14

8. Reverse procedure to install.

9. Check for proper operation.

F45545 (0315) Page 8 of 14

Page 9

SALAMANDER ELECTRIC BROILER - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

Certain procedures in this section require electrical test or measurements while

power is applied to the machine. Exercise extreme caution at all times and follow Arc Flash

procedures. If test points are not easily accessible, disconnect power and follow Lockout/Tagout

procedures, attach test equipment and reapply power to test.

INFINITE SWITCH TEST (208V/

240V)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

NOTE: Refer to AI3829 in WIRING DIAGRAMS for

switch terminal locations.

1. Remove

2. Connect a voltmeter to the output terminals H1

and H2.

3. Reconnect power to machine.

4. Turn knob to the desired setting.

5. Compare the percentage of ON time to OFF time.

NOTE: ±7.5% tolerance allowable.

Knob

Setting

Hi 100 ALL 0

Med. 48 15 15

Low 37 8 14

Med. Low 28 7 24

Very Low 7 3 33

6. If the percentage is not correct, replace the

switch as outlined under INFINITE SWITCH / 3

HEAT SWITCH.

FRONT PANEL.

% on Time

SecondsonSeconds

off

1. Remove FRONT PANEL.

2. Reconnect power to machine.

3. Check input voltage at L3 and L2 on the switch

terminals.

4. Check for the correct output voltage at the output

terminals for all knob settings of the switch.

L3 Input -

Knob Settings

High 1 & 3 2

Med 1 2

Low 1 3

5. If the voltages are not correct, replace the switch

as outlined under INFINITE SWITCH / 3 HEAT

SWITCH.

Output at

Terminal(s)

L2 Input -

Output at

Terminal(s)

RACK SPRING TENSION

ADJUSTMENT

1. Access the springs on the bottom of broiler.

2. Tighten nut to adjust rack spring tension. Adjust

both springs equally so there is approximately

3/4" of thread above the nut. If additional rack

spring tension is required, tighten each nut an

additional 2-3 turns.

3. Check for proper operation.

3 HEAT SWITCH TEST (480V)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

NOTE: Refer to AI3830 in WIRING DIAGRAMS for

switch terminal locations.

Page 9 of 14 F45545 (0315)

Page 10

SALAMANDER ELECTRIC BROILER - SERVICE PROCEDURES AND ADJUSTMENTS

1) If both measured values are

approximately the same as listed in the

machine information table, then

heating elements are functioning

properly.

2) If one or both of the measured values

do not agree with the values listed in

the machine information table, then

heating element is malfunctioning.

Turn broiler control switches OFF.

Disconnect the

Fig. 15

electrical power to the machine and

follow lockout / tagout procedures.

HEATING ELEMENTS TEST

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

NOTE: On 208V/240V broilers, the two heat controls

are Infinite load switches; On 480V broilers, the two

heat controls are 4 Position 3 Heat switches.

1. Access the

2. Reconnect power to machine.

3. Set broiler heat control switches to the highest

setting.

4. Measure the voltage at the heating element

terminals and verify it against the data plate

voltage.

A. If voltage is incorrect, see

TROUBLESHOOTING.

B. If voltage is correct, check current draw

(amps) through the heating element lead

wires at the X and Z phases on the outlet

side of the broiler terminal block. The X

phase value is the current draw for the left

element and the Z phase value is the current

draw for the right element.

HEATING ELEMENTS.

a. Install a replacement heating

element then proceed to step 2.

C. If unable to check current draw, a resistance

check (ohms) at heating element terminals

may indicate a malfunctioning element.

1) Remove lead wires from the heating

element and check resistance. See

machine information tables under

SPECIFICATIONS for proper

resistance values at room

temperature.

a. If resistance is incorrect, install a

replacement heating element.

b. If resistance is correct, heating

element has tested okay. If

heating element is still suspect,

see TROUBLESHOOTING.

5. Check broiler for proper operation.

See machine information tables under

SPECIFICATIONS for proper current draw

values and the appropriate 208/240V WIRING DIAGRAM or 480V - WIRING

DIAGRAM for heating element phase

connections.

NOTE: Checking current draw is the preferred

method over a resistance check when a clamp on type

amp meter is available.

F45545 (0315) Page 10 of 14

Page 11

SALAMANDER ELECTRIC BROILER - ELECTRICAL OPERATION

ELECTRICAL OPERATION

COMPONENT FUNCTION

Infinite Load Switch ... Two switches independently control the left and right heating elements on 208V and 240V

models. Depending on switch setting, provides a range of ON time from 7% to 100%.

3 Heat, 4 Position

Switch ...............

Heating Element

Assemblies ..........

Terminal Block ....... Provides connections for supply voltage to the broiler.

Two switches independently control the left and right heating elements on 480 volt

models. Provides approximately 100% of total available power of 4.5 KW with both

switches set to HI position, 50% at MED position, 25% at LO position, and 0% at the OFF

position.

Provides heat for broiling food product. There are 2 element assemblies per broiler.

SEQUENCE OF OPERATION

NOTE: On 208V/240V broilers, the two heat controls are Infinite load switches; On 480V broilers, the two heat

controls are 4 Position 3 Heat switches.

1. Conditions

A. Broiler connected to correct supply voltage.

B. Building circuit breakers ON (power to machine).

C. Broiler heat control switches are OFF.

D. Broiler at room temperature.

2. Broiler heat control switches are turned to desired heat setting.

A. Power to heating elements.

3. Broiler heat control switches reach desired heat setting.

A. Power removed from heating elements.

4. Broiler heat control switches drop below desired heat setting.

A. Broiler heat control switches will continue to cycle until turned to OFF or power is removed from broiler.

Page 11 of 14 F45545 (0315)

Page 12

SALAMANDER ELECTRIC BROILER - ELECTRICAL OPERATION

208/240V - WIRING DIAGRAM

Fig. 16

F45545 (0315) Page 12 of 14

Page 13

SALAMANDER ELECTRIC BROILER - ELECTRICAL OPERATION

480V - WIRING DIAGRAM

Fig. 17

Page 13 of 14 F45545 (0315)

Page 14

SALAMANDER ELECTRIC BROILER - TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSES

1. No power to broiler.

No heat.

Cooking problems (product not done/

overdone).

2. Infinite (208V/240V) or 3 heat switches (480V) are OFF or

malfunctioning.

3. Heating elements inoperative or malfunctioning.

1. Refer to Installation & Operation Manual for recommended grid

position and heat control switch settings .

F45545 (0315) Page 14 of 14

Loading...

Loading...