Page 1

©ITW Food Equipment Group, LLC

3600 North Point Blvd.

Baltimore, MD 21222

RETAIN THIS MANUAL FOR FUTURE USE

FORM F38330 (9-15)

MODELS

VTEC14

VTEC25

VTEC36

VTEC48

VTEC60

VTEC48

For additional information on Vulcan or to locate an authorized parts and

service provider in your area, visit our website at www.vulcanequipment.com

INSTALLATION & OPERATION MANUAL

GAS INFRARED CHARBROILER

Page 2

IMPORTANT FOR YOUR SAFETY

Improper installation,

adjustment, alteration, service or maintenance

can cause property damage, injury, or death.

Read the installation, operating and maintenance

instructions thoroughly before installing or

servicing this equipment.

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO

INSTALL GAS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD

START-UP AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS

MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN

THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE

OBTAINED FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

- 2 -

Page 3

INSTALLATION, OPERATION AND CARE OF

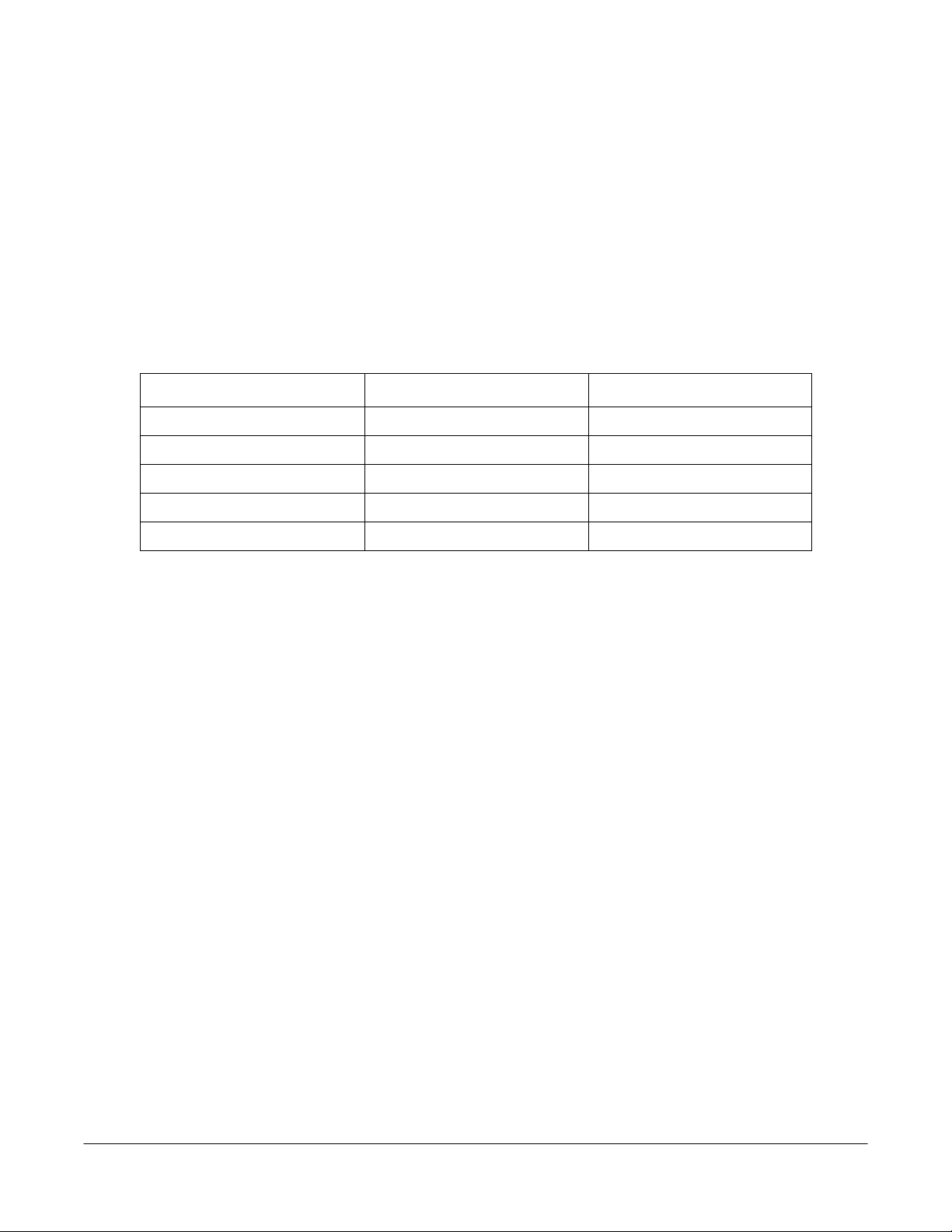

Model

Number of Burners

BTU/hr Input Rating

VTEC14

1

22,000

VTEC25

2

44,000

VTEC36

3

66,000

VTEC48

4

88,000

VTEC60

5

110,000

GAS COUNTERTOP CHARBROILERS

GENERAL

Gas Infrared Charbroilers are designed for commercial use only and feature fast, efficient

gas heat. Each burner is controlled by an adjustable gas valve. Emitter panels are

located directly above each burner to maintain uniform temperature and provide infrared

cooking. Emitter panels and stainless steel cooking grids are easily removed for cleaning

when cool. A crumb tray is provided to collect fat run-off and debris; it opens to the front

for inspection or drain-off.

INSTALLATION

UNPACKING

This charbroiler was inspected before leaving the factory. The carrier assumes full responsibility for the

safe delivery upon acceptance of the shipment. Check for possible shipping damage immediately after

receipt.

If the charbroiler is found to be damaged, complete the following steps:

1. Carrier must be notified within 5 business days of receipt.

2. Carrier’s local terminal must be notified immediately upon discovery (note time, date, and

who was spoken to), and follow up and confirm with written or electronic communication.

3. All original packing materials must be kept for inspection purposes.

4. The charbroiler cannot have been moved, installed, or modified.

5. Notify Vulcan Customer Service immediately at 800-814-2028.

.

Carefully unpack your charbroiler and make sure that no parts are discarded with

packaging material. A pressure regulator designed to operate with the broiler has been

supplied and must be installed before the charbroiler is placed into service (Refer to GAS

PRESSURE REGULATOR INSTALLATION in this manual).

Before installing, verify that the type of gas (natural or propane) and the clearance

dimensions agree with the specifications on the rating plate which is located on the upper

front corner on the right side.

- 3 -

Page 4

LOCATION

The installation location must be kept free and clear of combustibles. Do not obstruct the

flow of combustion and ventilation air. DO NOT install the charbroiler adjacent to fryers

unless following the provisions detailed by local codes and/or the applicable sections of

ANSI-Z223.1/NFPA #54 (latest edition) and NFPA #96 (latest edition) in the United States

of America or CAN/CSA 149.1 (latest edition) and CAN/CSA149.2 (latest edition) in

Canada.

Sufficient air should be allowed to enter the room to compensate for the amount of air

removed by any ventilating system and for combustion of the gas burners. Do not

obstruct the air flow into and around the appliance. Do not obstruct the flow of flue gases

through and above the broiler's cooking grids. Position the broiler in its final location.

Check that there are sufficient clearances to service the broiler and to make the required

gas supply connection(s). Provide 36" clearance at the front for cleaning, maintenance,

service and proper operation.

This broiler is for use in non-combustible locations only. Installation in combustible

locations is prohibited unless following the provisions detailed by local codes and/or the

applicable sections of ANSI-Z223.1/NFPA #54 (latest edition) and NFPA #96 (latest

edition) in the United States of America or CAN/CSA 149.1 (latest edition) and

CAN/CSA149.2 (latest edition) in Canada and approved by the authority having

jurisdiction.

Minimum clearances to non-combustible walls are 0" to the rear and 0" to the sides.

INSTALLATION CODES AND STANDARDS

The Charbroiler must be installed in accordance with:

In the United States of America:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1/NFPA #54 (latest edition). This shall include but

not be limited to: NFPA #54 Section 10.3.5.2 for Venting. Copies may be obtained

from The American Gas Association Accredited Standards Committee Z223, @ 400

N. Capital St. NW, Washington, DC 20001 or the Secretary Standards Council, NFPA,

1 Batterymarch Park Quincy, MA 02169-7471

NOTE: In the Commonwealth of Massachusetts

All gas appliances vented through a ventilation hood or exhaust system equipped with

a damper or with a power means of exhaust shall comply with 248 CMR.

3. NFPA Standard # 96 Vapor Removal from Cooking Equipment, latest edition, available

from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada:

1. Local codes.

2. CAN/CSA-B149.1 Natural Gas Installation (latest edition)

3. CAN/CSA-B149.2 Propane Installation Code (latest edition), available from the

Canadian Gas Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3

- 4 -

Page 5

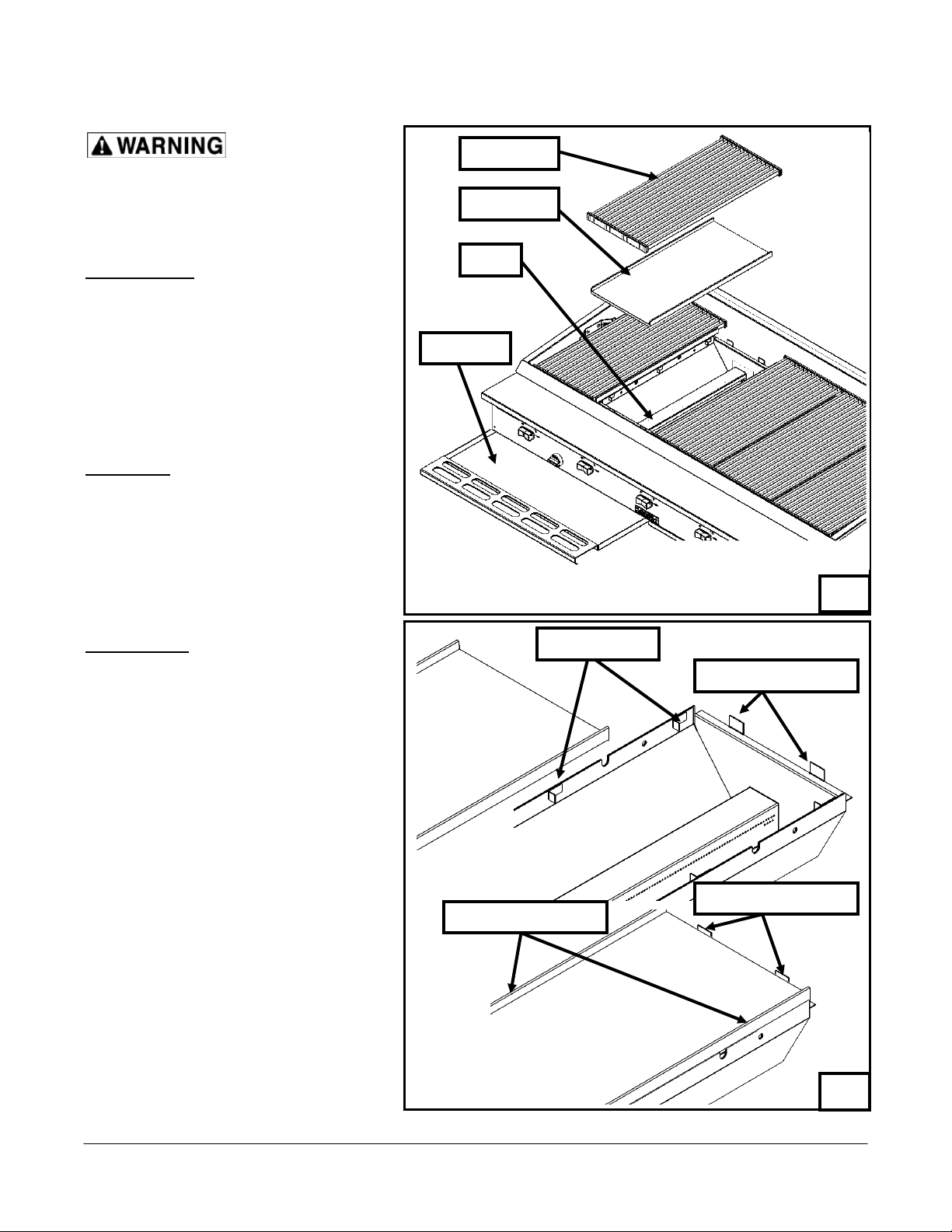

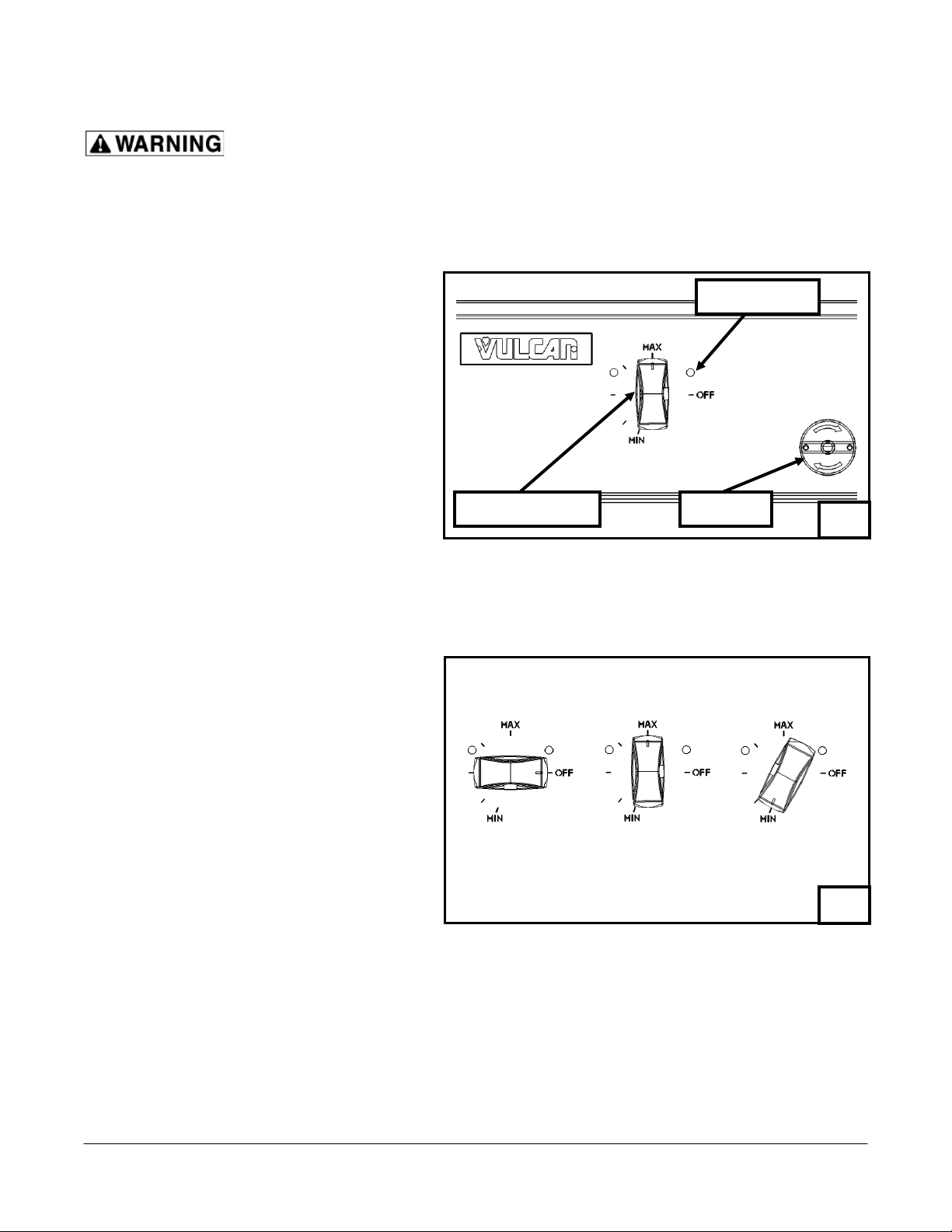

KEY COMPONENTS

The charbroiler

and its parts are hot. Use care

when operating, cleaning or

servicing the charbroiler.

Cooking Grids – The cooking grids

should always be in place and properly

seated on the emitter panels during

operation. Wash grids thoroughly with

soap and water solution and rinse

before first use.

Crumb tray – The crumb tray is the

removable pan that catches any debris

that falls from the broiling area. The

crumb trays should be pushed all the

way in while the unit is operation.

Emitter Panel – The charbroiler must

never be operated without the emitter

panels in place. The emitter panels

protect the burner from food drippings

and debris. Operating the burner without

the emitter panels in place will cause

poor performance and clogging of the

burner ports. The emitter panels

disperse energy and facilitate infrared

cooking.

The emitter panels should rest on top of

the side burner tabs and inside of the

front and rear burner tabs over each

burner. The emitter panels should be

placed in position with the flanged

edges pointing upwards. See Fig. 2.

Cooking Grid

Fig. 1

Emitter Panel

Crumb Tray

Burner

Fig. 2

Emitter Panel In Place

Emitter Panel Flanges

Emitter Panel

Side Burner Tabs

Front/Rear Burner Tabs

Front/Rear Burner Tabs

- 5 -

Page 6

LEVELING

It is important that the charbroiler is level front to back and left to right. Areas of uneven

heat distribution will occur on an unleveled unit. The charbroiler is equipped with

adjustable legs. Turn the feet at the bottom of the legs to adjust to level. The unit should

be rechecked for level anytime it has been moved.

VENTILATION HOOD

The broiler should be installed under a suitable ventilation hood. For safe operation and

proper ventilation, keep the space between the charbroiler and vent hood free from any

obstructions.

GAS CONNECTION

The data plate on the lower right side of the charbroiler indicates the type of gas your unit

is equipped to burn. DO NOT connect to any other gas type.

All gas supply connections and any pipe joint compound must be resistant to

the action of propane gases.

Purge the supply line to clean out any dust, dirt, or any foreign matter before connecting

the line to the unit.

Codes require that a gas shut-off valve be installed in the gas line ahead of the

charbroiler. The gas supply line must be at least the equivalent of ¾” iron pipe.

A pressure regulator is supplied and must be installed outside of the broiler when making

the gas supply connection. Standard orifices are set for 4"WC (Water Column) for

Natural Gas — 10"WC (Water Column) for Propane. Use the 1/

” pipe tap on the bur n er

8

manifold for checking pressure. Make sure the gas piping is clean and free of

obstructions, dirt, and piping compound.

An adequate gas supply is necessary. Undersized or low pressure lines will restrict the

volume of gas required for satisfactory performance. A minimum supply pressure of 7"

W.C. for natural gas and 11" W.C. for propane gas is recommended. With all units

operating simultaneously, the manifold pressure on all units should not show any

appreciable drop.

When testing the gas supply piping system, if test pressures exceed ½ psig (3.45 kPa),

the charbroiler and its individual shutoff valve must be disconnected from the gas supply

piping system. When test pressures are ½ psig (3.45 kPa) or less, the charbroiler must

be isolated from the gas supply piping system by closing its individual manual shut-off

valve during any pressure testing of the system.

- 6 -

Page 7

Prior to lighting, check all joints in the gas supply line for leaks.

Fig. 3

Fig. 4

Use soap and water solution. Do not use an open flame.

GAS PRESSURE REGULATOR INSTALLATION

Gas regulator pressure is preset at 4” Water C olumn (W .C.) f or natural gas, and 10” W.C.

for propane gas. Minor adjustments may be required based on site specific gas pressure.

Install the regulator as close to the broiler on the gas supply line as possible. Make sure

that the arrow on the underside of the regulator is oriented in the direction of gas flow to

the broiler (Fig. 3) and the regulator is positioned with the vent plug and adjustment

screw upright (Fig. 4).

The minimum supply pressure (upstream of the regulator) should be 7-9” W.C. for n atural

gas and 11-12” W .C. for propane gas. At n o tim e should the charbroiler be connected to

supply pressure greater than ½ psig (3.45 kPa) or 14” W.C.

CASTER EQUIPPED CHARBROILERS

Charbroilers mounted on stands with casters must use a flexible connector (not supplied)

that complies with the Standard for Connectors for Movable Gas Appliances, ANSI Z21.69

• CS A 6 . 1 6 an d a q u ick -disconnect device that complies with the Standard for Quick-

Disconnect Devices for use With Gas Fuel, ANSI-Z21.41 • CSA 6. 9 . In add it io n , adequate

means must be provided to limit movement of the broiler without depending on the

connector and the quick-disconnect device or its associated piping to limit broiler

movement. Attach the restraining device at the rear of the charbroiler. If disconnection of

the restraint is necessary, turn off the gas supply before disconnection. Reconnect the

restraint prior to turning the gas supply on and return the charbroiler to its installation

position.

- 7 -

Page 8

The charbroiler and its parts are hot. Use care when operating,

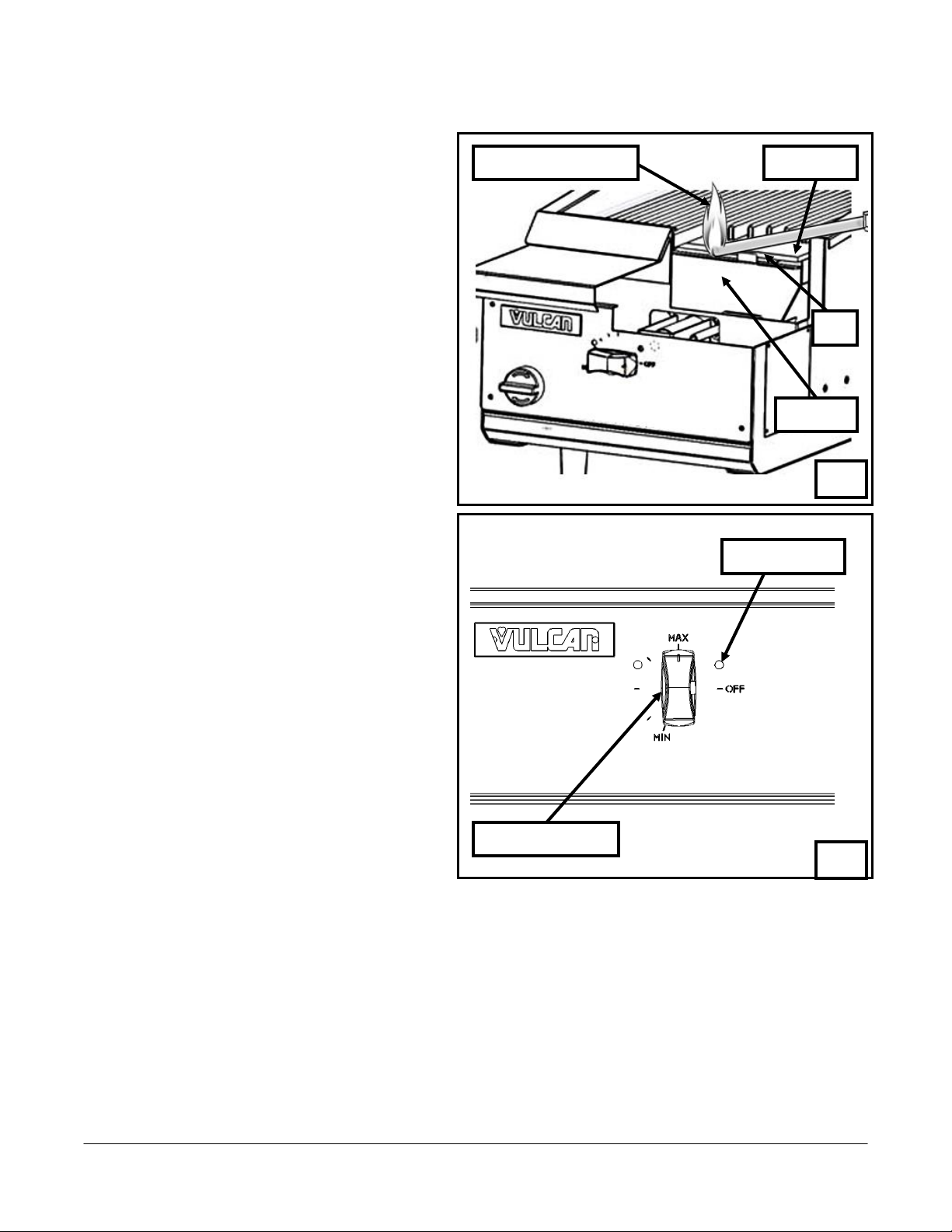

The VTEC charbroiler does not have a pilot

and each burner lights directly from a spark

igniter or from an outside ignition source (such

as a lit taper, long handle lighter, etc).

LIGHTING BURNER WITH SPARK IGNITER

1. Turn the main gas shut-off valve and the

individual burner control knobs to the OFF

position (clockwise until stops). Wait 5

minutes.

2. Push and turn the burner control knob to the

MAX setting (counterclockwise to vertical/90°

position) on the burner you intend to light.

(Fig. 5)

3. Immediately, while viewing through the

burner sight hole, turn the igniter knob

clockwise until you hear a click (approx. ¼

turn) and see the spark. The burner should

ignite immediately and flames should be

visible through the burner sight hole.

4. If the burner fails to light immediately,

repeat step 3, two more times. If the burner

has still not ignited at this point, turn the

main gas shut-off valve and all burner

valves to the OFF position (clockwise until

stops) and proceed with manual burner

lighting instructions on following page.

5. Repeat steps 2-4 until all burners are lit.

Turn on one burner control knob at a time

and ensure burner is lit before proceeding

to light the next burner.

Fig. 6

Fig. 5

Burner Sight Hole

Burner Control Knob

Igniter Knob

OFF MAXIMUM MINIMUM

cleaning or servicing the charbroiler.

BURNER LIGHTING

The burners should be left on the maximum (MAX) setting for most efficiency when

cooking. The burners may be turned to the minimum (MIN) setting during slow periods to

save energy. See Fig. 6.

OPERATION

- 8 -

Page 9

LIGHTING BURNER MANUALLY

1. Turn the main gas shut-off valve and the

individual burner control knobs to the OFF

position (clockwise until stops). Wait 5

minutes.

2. Apply a flame from an outside ignition source

(such as a lit taper, long handle lighter, etc)

directly to the gap between the bottom of the

emitter panel and the top of the intended

burner box at the front of the unit. See Fig. 7.

3. Push and turn the burner control knob to the

MAX setting (counterclockwise to vertical/90°

position) on the burner you intend to light.

(Fig. 8)

4. View through the burner sight hole (Fig.8) to

ensure the burner has lit.

5. If the burner fails to light within 4 seconds of

applying flame to the directed area, turn the

main gas shut-off valve and all burner

valves to the OFF position (clockwise until

stops). Contact an authorized service

contractor.

6. Repeat steps 2-4 until all burners are lit.

Turn on one burner control knob at a time

and ensure burner is lit before proceeding

to light the next burner.

Burner Sight Hole

Burner Control Knob

Fig. 8

Cutaway View

Fig. 7

Outside Ignition Source

Emitter Panel

Gap

Burner Box

TO COMPLETELY SHUTDOWN THE BURNERS

For complete shutdown: Turn the main gas supply valve OFF. Make sure all individual

burner valves are OFF (turned completely clockwise until stops).

PREHEATING THE CHARBROILER

Allow the charbroiler to preheat for 20 minutes on the maximum (MAX) setting. Rub

grates with cooking oil before using to help reduce sticking.

- 9 -

Page 10

CLEANING

The charbroiler and its

parts are hot. Use care when operating,

cleaning or servicing the charbroiler.

Scrape cooking grids during broiling with a

stainless steel scraper or stainless steel wire

brush to keep the grates clean. Do not allow

debris to accumulate on the grates. (Fig. 9)

Top grates may be immersed in cleaning

compound overnight. In the morning, rinse

with hot water to remove any residues of

cleaning compound.

Stainless steel surfaces may be cleaned using

damp cloth with mild detergent and water

solution. Clean heavy, baked on grease and

splatter that do not respond to normal cleaning

by using cleaning solution with a ScotchBrite

TM

pad. Rub with the grain of the surface

– do not rub in a circular motion.

DAILY

After cooking, allow unit to run on MAX setting

for 10 minutes before shutting OFF.

This will make cleaning debris from the emitter

panels easier when they cool down.

When cool, remove cooking grids and emitter

panels, clean places where fat, grease, or food

can accumulate. Brush or use scraper to

remove any accumulated debris from emitter

panel surfaces. Be careful to keep inside

burner boxes clear of debris. Remove crumb

tray when cool and empty. (Fig. 10)

Fig. 10

Cooking Grid

Emitter Panel

Crumb Tray

Heat Shield

Inside

Burner Box

Fig. 9

Never leave emitter panels wet after cleaning. Leaving panels wet after

cooking or cleaning may accelerate corrosion process and result in premature failure.

WEEKLY

When cool, remove cooking grids, emitter panels and heat shield. Clean and vacuum any accumulated

debris from inside burner boxes. Clean inside chassis area anywhere fat, grease, or food can

accumulate. Clean heat shield while removed (Fig. 10). Repeat weekly process more often as needed.

- 10 -

Page 11

Ne ve r cover sur face of unit with pans or other objects in atte m pt to “b urn off”

or clean debris from unit. This will cause a buildup of heat that can potentially damage

and warp components of the charbroiler. Do not cover surfaces with aluminum foil as this

may block or disrupt the designed air flow pattern and affect performance.

MAINTENANCE

The charbroiler and its parts are hot. Use care when operating,

cleaning or servicing the charbroiler.

VENT SYSTEM

At least twice a year the exhaust hood (venting system) should be examined and cleaned.

LUBRICATION

All valves, at the first sign of sticking, should be lubricated by a trained technician using

high temperature grease.

SERVICE

Contact your local Service Contractor for any repairs or adjustments needed on this

equipment. For a complete listing of service and parts depots refer to

www.vulcanequipment.com. When calling for service, the following information should be

available from the appliance identification plate: Model Number and Serial Number.

- 11 -

Page 12

TROUBLE SHOOTING

Uneven heating

A. Burner valves improperly adjusted

B. Fluctuating gas pressure

C. Appliance is not level

D. Emitter panels are not properly seated or damaged

E. Emitter panels are excessively dirty

Too much top heat

A. Faulty hood ventilation

C. Overrated gas pressure

D. Unit is excessively dirty

E. Emitter panels are not properly seated or damaged

Uneven heat side to side

A. Burner valves improperly adjusted

B. Appliance is not level side to side

C. Crumb tray is not pushed all the way in

D. Emitter panels are not properly seated or damaged

E. Emitter panels are excessively dirty

Uneven heat front to back

A. Appliance is not level front to back

B. Faulty hood ventilation

C. Crumb tray is not pushed all the way in

D. Emitter panels are not properly seated or damaged

E. Emitter panels are excessively dirty

F. Designed air flow pattern obstructed

Burner not lighting

A. Check that igniter electrode is sparking when igniter

knob is turned clockwise

B. Check for damaged, loose or dirty igniter wires, igniter

and electrode

C. Burner valve not on MAX setting

D. Gas pressure too low

E. Inside burner box or burner venturi excessively dirty

Burner flames too low

A. Burner valves improperly adjusted

B. Gas pressure too low

C. Inside burner box or burner venturi excessively dirty

D. Clogged burner orifice

Burner flames to high

A. Emitter panels are not properly seated or damaged

B. Gas pressure too high

Fluctuating gas pressure

A. Checked for clogged vent on regulator

- 12 -

Page 13

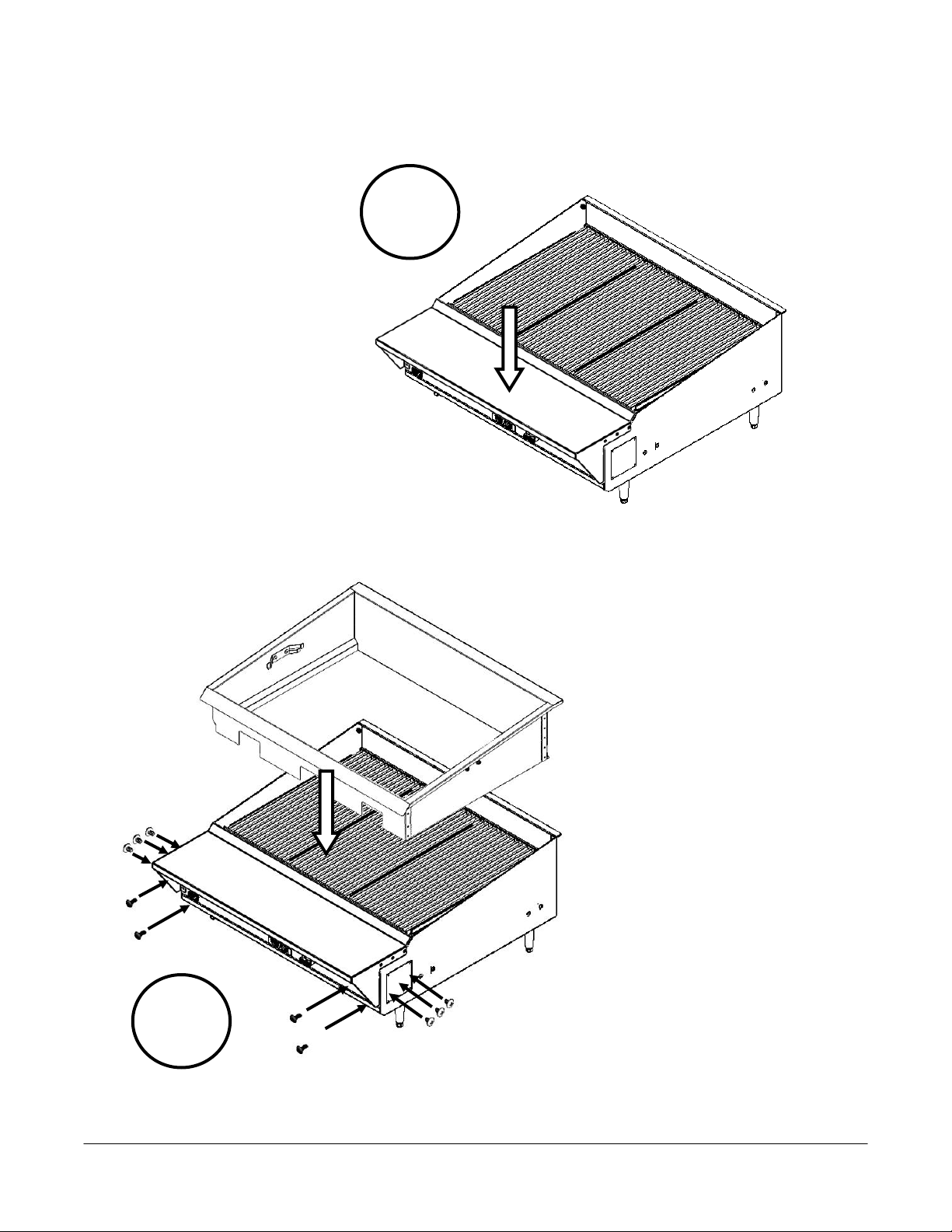

ACCESSORY INSTALLATION

1

2

The charbroiler and its parts are hot. Use care when operating,

cleaning or servicing the charbroiler.

- 13 -

Page 14

4

3

- 14 -

Page 15

- 14 -

3

4

Page 16

- 13 -

1

2

employez, nettoyez ou entretenez ce gril.

Le gril et ses pièces sont chauds. Faites attention lorsque vous

INSTALLATION DE COMPLICE

Page 17

- 12 -

Chaleur inégale

A. Boutons des brûleurs mal réglés

B. Variation de la pression du gaz

C. L'appareil n'est pas nivelé

D. Panneaux émetteurs mal placés ou endommagés

E. Les panneaux émetteurs sont excessivement sales

Trop de chaleur sur le dessus

A. Ventilation défectueuse de la hotte

B. La pression du gaz est surestimée

C. L'appareil est excessivement sale

D. Panneaux émetteurs mal placés ou endommagés

Chaleur inégale d’un côté à

l’autre

A. Boutons des brûleurs mal réglés

B. L'appareil n'est pas horizontal d'un côté à l'autre

C. Le ramasse-miettes n'est pas correctement rentré

D. Panneaux émetteurs mal placés ou endommagés

E. Les panneaux émetteurs sont excessivement sales

Chaleur inégale de l’avant

vers l’arrière

A. L'appareil n'est pas horizontal d'avant en arrière

B. Ventilation défectueuse de la hotte

C. Le ramasse-miettes n'est pas correctement rentré

D. Panneaux émetteurs mal placés ou endommagés

E. Les panneaux émetteurs sont excessivement sales

F. Schéma de circulation d'air obstrué

Le brûleur ne s'allume pas

A. Vérifiez que l'électrode de l'inflammateur jette des

étincelles quand le bouton de l'inflammateur est tourné

dans le sens des aiguilles d'une montre

B. Vérifiez que l'électrode de l'inflammateur jette des

étincelles quand le bouton de l'inflammateur est tourné

dans le sens des aiguilles d'une montre. Vérifiez si les

fils d'inflammateur sont sales, relâchés ou endommagés,

contrôlez l'inflammateur et l'électrode

C. Le bouton de brûleur n'est pas réglé sur MAX

D. Pression du gaz trop basse

E. L'intérieur du boîtier de brûleur ou le brûleur est

excessivement sale

Flammes des brûleurs trop

basses

A. Boutons des brûleurs mal réglés

B. Pression du gaz trop basse

C. L'intérieur du boîtier de brûleur ou le brûleur est

excessivement sale

D. Obstruction de l’orifice du brûleur

Flammes des brûleurs trop

hautes

A. Panneaux émetteurs mal placés ou endommagés

B. Pression du gaz trop haute

Variation de la pression du

gaz

A. Contrôlé pour obstruction de la ventilation du régulateur

LOCALISATION D'UNE PANNE

Page 18

- 11 -

AVIS

l’appareil : le numéro du modèle et le numéro de série.

renseignements suivants devraient être disponibles sur la fiche signalétique de

consultez www.vulcanequipment.com.. Lorsque vous appelez pour du service, les

nécessaire sur cet équipement. Pour une liste des bureaux des services et des pièces,

Communiquez avec votre service à la clientèle local pour toute réparation ou tout réglage

SERVICE

résistant aux températures élevées dès le premier signe de coincement.

Toutes les soupapes devraient être lubrifiées par un technicien qualifié avec une huile

LUBRIFICATION

moins deux fois par année.

La hotte à évacuation (système de ventilation) devrait être examinée et nettoyée au

SYSTÈME DE VENTILATION

employez, nettoyez ou entretenez ce gril.

Le gril et ses pièces sont chauds. Faites attention lorsque vous

ENTRETIEN

la performance.

pourrait provoquer le blocage ou la perturbation du plan de circulation de l'air et affecter

composants du gril. Ne recouvrez pas les surfaces avec du papier aluminium car cela

augmentation de la chaleur qui peut potentiellement endommager ou déformer les

pour essayer de « brûler » ou de nettoyer les débris de l’élément. Cela provoquera une

Ne jamais couvrir la surface de l’élément avec une casserole ou autres objets

(Fig.10). Répétez ce processus hebdomadaire aussi souvent que nécessaire.

de gras, graisse ou d'aliment à l'intérieur du châssis. Enlevez la protection anti-chaleur pour la nettoyer

Nettoyez et aspirez tout débris accumulé dans les boîtiers des brûleurs. Nettoyez toute accumulation

Une fois refroidis, retirez les grilles de cuisson, les panneaux émetteurs et la protection anti-chaleur.

PAR SEMAINE

Page 19

- 10 -

Le gril et ses pièces

sont chauds. Faites attention lorsque vous

employez, nettoyez ou entretenez ce gril.

Grattez les grilles de cuisson avec un grattoir

en acier inoxydable ou une brosse métallique

en acier inoxydable pour garder les grilles

propres. Empêchez les débris de s'accumuler

sur les grilles. (Fig. 9) Les grilles supérieures

peuvent être immergées dans du détersif

durant la nuit. Au matin, rincez-les avec de

l'eau chaude pour enlever tout résidu du

détersif.

Les surfaces en acier inoxydable peuvent être

nettoyées à l’aide d’un linge humide et d’une

solution d’eau et d’un savon doux. Netoyer la

graisse solidifiée et les éclaboussures qui sont

difficile à nettoyer utilisant une solution de

nettoyage et un tampon Scotch-Brite

MD

Frottez

dans le sens des veines de la surface - ne

frottez pas dans un mouvement circulaire.

QUOTIDIENNEMENT

Après la cuisson, laissez l'appareil tourner sur

MAX pendant 10 minutes avant de

l'ARRÊTER.

Ce qui facilitera le nettoyage des débris

des panneaux émetteurs après

refroidissement.

Une fois refroidis, retirez les grilles de cuisson,

et les panneaux émetteurs, nettoyez les

endroits où le gras, la graisse ou les aliments

ont pu s'accumuler. Brossez ou utilisez un

grattoir pour enlever toute accumulation de

débris sur les parois du panneau émetteur.

Veillez à ce que l'intérieur des boîtiers des

brûleurs soit débarrassé des débris. Retirez le

ramasse-miettes une fois refroidi et vidé. (Fig.

10)

Fig. 10

Grille de cuisson

Panneau émetteur

Ramasse-miettes

Protection anti-

chaleur

Intérieur du boîtier

de brûleur

Fig. 9

AVIS

processus de corrosion et les endommager prématurément.

de laisser les panneaux humides après la cuisson ou le nettoyage peut accélérer le

Ne laissez jamais les panneaux émetteurs humides après le nettoyage. Le fait

NETTOYAGE

avec de l'huile de cuisine avant l'utilisation pour réduire la viscosité.

Préchauffez le gril pendant 20 minutes sur réglage maximum (MAX) Frottez les grilles

PRÉCHAUFFAGE DU GRIL

Page 20

- 9 -

ALLUMAGE MANUEL DES BRÛLEURS

1. Tournez le robinet d'arrêt principal du gaz et

les boutons individuels de commande des

brûleurs en position OFF « FERMÉ » (dans

le sens des aiguilles d'une montre jusqu'à

l'arrêt). Attendez 5 minutes.

2. Appliquez une flamme à l'aide d'une source

d'allumage extérieure (comme par exemple

une fine bougie allumée, un allume-gaz à

long manche, etc.) directement dans

l'intervalle entre la base du panneau

émetteur et le dessus du boîtier du brûleur

choisi à l'avant de l'appareil. Voir Fig. 7.

3. Poussez et réglez le bouton de commande

du brûleur que vous voulez allumer en le

tournant sur MAX (dans le sens des aiguilles

d'une montre à la verticale/90°). (Fig.8)

4. Regardez par le trou de regard du brûleur

(Fig.8) pour vous assurer que le brûleur a

été allumé.

5. Si le brûleur ne s'allume pas dans les 4

secondes après l'application de la flamme à

l'endroit où elle a été dirigée, tournez le

robinet d'arrêt principal du gaz et tous les

boutons des brûleurs en position OFF

« FERMÉ » (dans le sens des aiguilles d'une

montre jusqu'à l'arrêt). Contactez le service

à la clientèle autorisé.

6. Répétez les étapes 2-4 jusqu'à ce que les

brûleurs soient allumés. Pour ouvrir tournez

un bouton de brûleur à la fois et vérifiez que

le brûleur est allumé avant de continuer à

allumer le brûleur suivant.

Trou de regard de brûleur

Bouton de commande des brûleurs

Fig. 8

Fig. 7

VUE DE COUPE

Source extérieure d'allumage

Panneau émetteur

Intervalle

Boîtier de brûleur

« FERMÉ » (tournés dans le sens des aiguilles d'une montre jusqu'à l'arrêt complet).

« FERMÉ ». Assurez-vous que les boutons individuels des brûleurs sont sur OFF

Pour fermer complètement : Tournez le robinet d'alimentation principal du gaz sur OFF

FERMETURE COMPLÈTE DES BRULEURS

Page 21

- 8 -

Le gril VTEC n'est pas muni de veilleuse et

chaque brûleur s'allume directement à

l'aide d'un inflammateur à étincelles ou

d'une source d'allumage extérieure

(comme par exemple une bougie fine

allumée, un allume-gaz à long manche,

etc).

ALLUMAGE DES BRULEURS AVEC UN

INFLAMMATEUR À ÉTINCELLES

1. Tournez le robinet d'arrêt principal du gaz et

les boutons individuels de commande des

brûleurs en position OFF « FERMÉ » (dans

le sens des aiguilles d'une montre jusqu'à

l'arrêt). Attendez 5 minutes.

2. Poussez et réglez le bouton de commande

du brûleur que vous voulez allumer en le

tournant sur MAX (dans le sens des aiguilles

d'une montre à la verticale/90°). (Fig. 5)

3. Immédiatement après, tout en regardant par

le trou de regard du brûleur, tournez le

bouton de l'inflammateur dans le sens des

aiguilles d'une montre jusqu'à ce qu'un

déclic se fasse entendre (approx.1/4 de tour)

et qu'il en sorte des étincelles. Le brûleur

devrait s'allumer immédiatement et les

flammes devraient se voir à travers le trou

de regard du brûleur.

4. Si le brûleur ne s'allume pas immédiatement,

répétez l'étape 3, deux fois de plus. Si le

bruleur n'a pas encore allumé à ce point,

tournez le robinet d'arrêt principal de gaz et

toutes les vannes du brûleur à la position

OFF « FERMÉ » (dans le sens horaire

jusqu'à l'arrêt) et procéder à l'allumage selon

le manuel d'instructions à la page suivante.

5. Répétez les étapes 2-4 jusqu'à ce que les

brûleurs soient allumés. Pour ouvrir tournez

un bouton de brûleur à la fois et vérifiez que

le brûleur est allumé avant de continuer à

allumer le brûleur suivant.

Fig.

6

Fig.

5

Trou de regard de brûleur

Bouton de commande des

brûleurs

Bouton

d'inflammateur

FERMÉ MAXIMUM MINIMUM

économie d'énergie. Voir Fig. 6.

la cuisson. Les brûleurs peuvent se régler sur MIN (minimum) à cuisson lente pour une

Les brûleurs doivent se régler sur MAX (maximum) pour un maximum d'efficacité pendant

ALLUMAGE DU BRÛLEUR

employez, nettoyez ou entretenez ce gril.

Le gril et ses pièces sont chauds. Faites attention lorsque vous

EMPLOI

Page 22

- 7 -

Fig. 3

Fig. 4

installé.

dispositif avant d’ouvrir l’alimentation en gaz et replacez le gril à l'endroit où il doit être

nécessaire, fermez l’alimentation en gaz avant le débranchement. Rebranchez le

Attachez le dispositif de retenue à l’arrière du gril. Si le débranchement du dispositif est

connecteur et du dispositif de prise à démontage rapide ou de leurs conduites associées.

appropriées doivent apportées pour limiter le mouvement du gril sans dépendre du

Disconnect Devices for use With Gas Fuel, ANSI-Z21.41 • CSA 6.9. De plus, des mesures

6.16 et un dispositif de prise à démontage rapide qui est conforme à la norme Quick-

est conforme à la norme Connectors for Movable Gas Appliances, ANSI Z21.69 • CSA

Les grils sur supports avec roulettes doivent employer un raccord flexible (non fourni) qui

GRILS MUNIS DE ROULETTES

(½ psi) ou 36 cm CE.

à aucun moment être connecté à une pression d’alimentation supérieure à 3,45 kPa

23 cm CE pour le gaz naturel et de 28 à 30 cm CE pour le gaz propane. Le gril ne devrait

La pression d’alimentation minimale (en amont du régulateur) devrait être de 18 à

bonde de l'orifice et la vis de réglage sont placés droit (fig.4).

circulation du gaz vers le gril (fig.3) et que le régulateur est positionné de sorte que la

Vérifiez que la flèche sur le dessous du régulateur est orienté dans la direction de la

Installez le régulateur le plus près possible du gril sur la conduite d'alimentation en gaz.

peuvent être nécessaires selon la pression des gaz spécifique au site.

naturel et 25,4 cm colonne d’eau (CE) pour le gaz propane. Certains réglages mineurs

Le régulateur de pression du gaz est préréglé à 12,7 cm colonne d’eau (CE) pour le gaz

INSTALLATION DU RÉGULATEUR DE PRESSION DU GAZ

N’utilisez pas une flamme nue.

d’alimentation en gaz pour les fuites. Utilisez un e solution d’eau et savon.

Avant l’allumage, vérifiez tous les joints dans la conduite

gaz en fermant son robinet d’arrêt individuel durant tout essai de la pression du système.

sont de ½ psi (3,45 kPa) ou moins, le gril doit être isolé de tuyauterie de l’alimentation en

Page 23

- 6 -

AVIS

déconnectés de la tuyauterie de l’alimentation en gaz. Lorsque les pressions d’essai

excèdent ½ psi (3,45 kPa), le gril et son robinet d’arrêt individuel doivent être

Lorsque vous évaluez la tuyauterie de l’alimentation en gaz, si les pressions d’essai

baisse notable.

même temps, la pression d’admission sur tous les éléments ne devrait pas démontrer une

gaz naturel et de 28 cm CE pour le gaz propane. Avec tous les éléments fonctionnant en

satisfaisante. On recommande une pression d'alimentation minimum de 18 cm CE pour le

ou à basse pression limiteront le volume de gaz nécessaire pour une performance

Une alimentation adéquate en gaz est requise. Des conduites de dimension insuffisante

de saleté et de toute pâte à tuyauterie.

pression. Assurez-vous que les conduites de gaz soient propres et libres d'obstructions,

propane. Utilisez le taraud de 0,3 cm (1/8 po.) sur la rampe de brûleurs pour vérifier la

10 cm CE (colonne d’eau) pour le gaz naturel — 25 cm CE (colonne d’eau) pour le

effectuez la connexion d’alimentation en gaz. Les orifices en mince paroi sont établis à

Un régulateur de pression est fourni et doit être installé à l’extérieur du gril lorsque vous

de 2 cm.

gril. La conduite d’alimentation en gaz doit être au moins l’équivalent d’un t uyau en fer

Les codes exigent que la soupape d’arrêt du gaz soit installée dans la conduite de gaz du

corps étranger avant de la connecter à l’appareil.

Vider la conduite d’alimentation pour la nettoyer de to ute poussière, saleté ou tout autre

tuyauterie doivent être résistants à l'action des gaz propane.

NOTEZ que tout le système de branchement de l'alimentation gaz et les joints de la

votre appareil. NE le raccordez à AUCUN autre type de gaz.

La plaque de données sur le côté inférieur droit du gril indique le type de gaz adapté à

CONNEXION DU GAZ

évacuation libre de toute obstruction.

sécuritaire et une ventilation adéquate, laissez un espace entre le gril et la hotte à

Le gril devrait être installé sous une hotte de ventilation appropriée. Pour un emploi

HOTTE DE VENTILATION

nouveau chaque fois qu'il est déplacé.

au bout des pattes pour régler le niveau. Vous devriez vérifier le niveau de cet appareil à

appareil qui n'est pas mis à niveau. Le gril est muni de pattes réglables. Tournez le pied

la droite. Il se produira des zones où la distribution de la chaleur sera inégale dans un

Il est important que le gril soit mis à niveau de l'avant vers l'arrière et de la gauche vers

MISE À NIVEAU

Page 24

- 5 -

Le gril et ses

pièces sont chauds. Faites

attention lorsque vous

employez, nettoyez ou

entretenez ce gril.

Les grilles de cuisson - Les grilles de

cuisson doivent toujours être en place et

correctement fixés sur les panneaux

émetteurs durant le fonctionnement.

Lavez entièrement les grilles avec une

solution d'eau et de savon et rincez

avant la première utilisation.

Ramasse-miettes - Le ramasse-miettes

est le plateau qui recueille tous les

débris qui tombent du gril. Les ramasse-

miettes doivent être complètement

rentrés pendant le fonctionnement de

l'appareil.

Panneau émetteur - Le gril ne doit

jamais fonctionner tant que les

panneaux émetteurs ne sont pas en

place. Les panneaux émetteurs

protègent le brûleur des jus de cuisson

et des débris. Le fait de faire fonctionner

le brûleur sans que les panneaux

émetteurs ne soient en place entraîne

une mauvaise performance et

l'obstruction des brûleurs. Les panneaux

émetteurs répandent l'énergie facilitant

ainsi la cuisson à infrarouge.

Les panneaux émetteurs doivent

s'appuyer sur les fixations des brûleurs

latéraux et dans les fixations des

brûleurs avant et arrière au-dessus de

chaque brûleur. Les panneaux

émetteurs doivent être positionnés avec

les rebords saillants pointés vers le

haut. Voir Fig. 2.

Grille de cuisson

Fig. 1

Panneau émetteur

Ramasse-miettes

brûleur

Fig. 2

Fixations des brûleurs

avant/arrière

Fixations du brûleur latéral

Fixations des brûleurs

avant/arrière

Panneau émetteur en place

Panneau émetteur

Les rebords du panneau

émetteur

COMPOSANTS PRINCIPAUX

Page 25

- 4 -

M9W 1R3

de l’Association Canadienne du Gaz, 178 boul. Rexdale, Etobicoke, Ontario, Canada

3. Code d'installation du propane CAN/CSA-B149.2 (dernière édition), disponible auprès

2. Code d'installation du gaz naturel CAN/CSA-B149.1 (dernière édition)

1. Codes locaux.

Au Canada :

Park, Quincy, MA 02269.

disponible auprès de l'organisme National Fire Protection Association, Batterymarch

3. Norme NFPA N° 96 Vapor Removal from Cooking Equipment, dernière édition,

d’échappement qui doivent être conformes à 248 CMR.

système d’échappement muni d’une clef de réglage ou avec une moyenne potentielle

Tous les appareils d’utilisation du gaz aérés grâce à une hotte de ventilation ou un

REMARQUE : Dans l’État du Massachusetts

Secretary Standards Council, NFPA, 1 Batterymarch Park Quincy, MA 02169-7471

Standards Committee Z223, à 400 N. Capital St. NW, Washington, DC 20001 ou le

pouvez obtenir des copies auprès de l’American Gas Association Accredited

comprendre sans être limité à : NFPA No 54 Section 10.3.5.2 pour la ventilation. Vous

2. National Fuel Gas Code, ANSI-Z223.1/NFPA Nº 54 (dernière édition). Cela doit

1. Codes locaux et d’état.

Aux États-Unis d’Amérique :

Le gril doit être installé conformément à :

CODES ET NORMES D’INSTALLATION

0 cm de chaque côté.

Les espaces minimums pour les parois non combustibles sont de 0 cm à l’arrière et de

l'autorité compétente.

et CAN/CSA149.2 (éditions les plus récentes) au Canada, le tout sujet à l’approbation de

96 (éditions les plus récentes) aux États-Unis d'Amérique ou les normes CAN/CSA 149.1

locaux et/ou les sections applicables des normes ANSI-Z223.1/NFPA N° 54 et NFPA N°

locaux combustibles est interdite, sauf suivant les dispositions prévues par les codes

Ce gril est uniquement conçu pour les lieux sans combustibles. Son installation dans des

espace libre de 61 cm à l’avant pour le nettoyage, l’entretien et l’emploi adéquat.

le gril et effectuer la (les) connexion(s) nécessaire(s) d’alimentation en gaz. Prévoyez un

emplacement définitif. Assurez-vous qu’il y a suffisamment d’espace libre pour entretenir

circulation des gaz dans les conduits des grils de cuisson du gril. Placez le gril dans son

obstruer la circulation de l’air à l’intérieur et autour de l’appareil. N'obstruez pas la

par tout système de ventilation et pour la combustion des brûleurs de gaz. Ne pas

Suffisamment d’air devrait entrer dans la pièce afin de compenser la quantité d'air enlevé

et CAN/CSA149.2 (éditions les plus récentes) au Canada.

96 (éditions les plus récentes) aux États-Unis d'Amérique ou les normes CAN/CSA 149.1

locaux et/ou les sections applicables des normes ANSI-Z223.1/NFPA N° 54 et NFPA N°

adjacent à une ou des friteuses à moins d’observer les dispositions prévues par les codes

pas la circulation de la combustion ainsi que l’air de ventilation. NE PAS installer le gril

Le lieu de l’installation doit être maintenu sans présence de combustibles. N’obstruez

EMPLACEMENT

Page 26

- 3 -

Modèle

Nombre de brûleurs

Débit calorifique BTU/h

VTEC14

1

22,000

VTEC25

2

44,000

VTEC36

3

66,000

VTEC48

4

88,000

VTEC60

5

110,000

supérieur avant droit.

dégagement sont conformes aux normes spécifiées sur la plaque située sur le côté

Avant l'installation, vérifiez que le type de gaz (naturel ou propane) et les espaces de

DU RÉGULATEUR DE PRESSION DU GAZ dans ce manuel).

fourni et doit être installé avant que le gril soit mis en service (Consultez INTALLATION

l’emballage. Un régulateur de pression conçu pour fonctionner avec le brûleur a été

Déballez soigneusement votre gril et assurez-vous qu’aucune pièce n’a été jetée avec

5. Avisez le Service à la clientèle de Vulcan immédiatement en faisant le (800) 814-2028

4. Le gril ne doit pas avoir été déplacé, installé ou modifié.

3. Pour f ins d’inspection, tout le matérie l d’emballage or iginal doit être conservé.

suivi en confirmant les faits par écrit ou par communication électronique.

découverte des domm ages (indiquez l’he ure, la date et à qui vous avez p arlé) et assure z le

2. Les gens du terminus local du transporteur doivent être avisés immédiatement lors de la

1. Le transporteur doit être averti dans les 5 jours ouvrables suivant la réception.

S’il s’avère que le gril a été end ommagé, veuille z suivre les proc édures suivantes :

s’il a effectivem ent subi des domm ages pendant le transpo rt.

l’entière responsab ilité de le livrer en to ute sécurité. Imm édiatement après la livr aison, vérifie z

Ce gril a été inspecté avant de quitter l’usine. En acceptan t s a livraison, le tr ansporteur pren d

DÉBALLAGE

INSTALLATION

graisse et les débris; il s'ouvre à l'avant pour la vérification ou le nettoyage.

le nettoyage, après refroidissement. Un ramasse-miettes est fourni pour recueillir la

panneaux émetteurs et les grils de cuisson en acier inoxydable s'enlèvent facilement pour

pour garder une température uniforme et produire une cuisson à infrarouge. Les

réglable. Les panneaux émetteurs sont situés directement au-dessus de chaque brûleur

une chaleur instantanée et efficace. Chaque brûleur est contrôlé par une soupape à gaz

Les grils infrarouges à gaz sont uniquement destinés à l'usage commercial et produisent

GÉNÉRAL

DES GRILS DU COMPTOIR À GAZ

INSTALLATION, FONCTIONNEMENT ET ENTRETIEN

Page 27

- 2 -

Une installation, un

ajustement, une modification, un service ou un

entretien inapproprié peut causer du dommage

matériel, une blessure ou la mort. Lire

minutieusement les instructions d’installation,

d’emploi et d’entretien avant d’installer ou de se

servir de cet équipement.

MISE EN GARDE

APPAREIL.

TENTER DE FAIRE FONCTIONNER CET

EN CAS DE PANNE DE COURANT, NE PAS

APPAREIL.

PROXIMITÉ DE CET APPAREIL OU TOUT AUTRE

AUTRES VAPEURS OU LIQUIDES INFLAMMABLES À

NE PAS ENTREPOSER OU UTILISER DE L’ESSENCE OU

POUR VOTRE SÉCURITÉ

DU SERVICE.

FOURNISSEUR DE GAZ LOCAL AFIN D’OBTENIR

AVEC VOTRE COMPAGNIE DE GAZ OU VOTRE

PRINCIPAL DES APPAREILS ET COMMUNIQUEZ

DÉTECTÉE, FERMEZ LE ROBINET D’ARRÊT

AU CAS OÙ UNE ODEUR DE GAZ SERAIT

IMPORTANT

LOCAL.

POUVEZ DEMANDER CES RENSEIGNEMENTS AU FOURNISSEUR DE GAZ

ÊTRE SUIVIES AU CAS OÙ UNE ODEUR DE GAZ SERAIT DÉTECTÉE. VOUS

PLACEZ DANS UN ENDROIT IMPORTANT LES INSTRUCTIONS QUI DOIVENT

IMPORTANT POUR VOTRE SÉCURITÉ

RÉGLAGES INITIAUX DE L’ÉQUIPEMENT DONT IL S’AGIT DANS CE MANUEL.

ÉQUIPEMENT AU GAZ, QUI DOIT EFFECTUER LA MISE EN MARCHE ET LES

CE MANUEL A ÉTÉ CONÇU POUR LE PERSONNEL APTE À INSTALLER UN

Page 28

©ITW Food Equipment Group, LLC

3600 North Point Blvd.

Baltimore, MD 21222

GARDER CE MANUEL POUR UNE

UTILISATION FUTURE

FORM F38330 9-15)

MODÈLES

VTEC14

VTEC25

VTEC36

VTEC48

VTEC60

VTEC48

Pour obtenir des renseignements supplémentaires au sujet de Vulcan-Hart

ou pour trouver un fournisseur de pièces et service autorisé dans votre

région, veuillez visiter notre site web à www.vulcanequipment.com

GRIL INFRAROUGE À GAZ

MANUEL D'INSTALLATION ET D'EMPLOI

Loading...

Loading...