Page 1

FORM 30011 (2/90)

INSTALLATION, OPERATING, SERVICE

AND PARTS MANUAL FOR

ELECTRIC COUNTER CONVECTION

STEAMER MODEL VSXII

Vulcan service agencies are located throughout the United States. For location

and phone number of one near you, call your local Vulcan dealer.

VULCAN-HART CORPORATION, P.O. BOX 696, LOUISVILLE, KY 40201-0696, TEL. (502) 778-2791

Page 2

IMPORTANT

OPERATING, INSTALLING AND SERVICE PERSONNEL

The operating information on this equipment has been prepared for use by qualified and/or

authorized operating personnel.

All installation and service on this equipment is to be performed by qualified, certified, licensed

and/ or authorized installation or service personnel, with the exception of any part marked with

a in front of the part number.

To obtain the name and location of an authorized Vulcan service agency, contact your Food

Service Equipment dealer.

DEFINITIONS

QUALIFIED AND/OR AUTHORIZED OPERATING PERSONNEL

Qualified or authorized operating personnel are those who have carefully read the information in

this manual and are familiar with the equipment's functions or have had previous experience with

the operation of the equipment covered in this manual.

1. For the installation of gas piping from the outlet side of the gas meter, or the service regulator

when the meter is not provided, and the connection and installation of the gas appliance,

qualified installation personnel must be experienced in such work, be familiar with all

precautions required, and have complied with all requirements of state or local authorities

having jurisdiction. In the absence of local codes, installation must comply with National Fuel

Gas Code ANSI Z223.1 -latest edition.

2. For the installation of electrical wiring from the electric meter, main control box or service outlet

to the electric appliance, qualified installation personnel must be experienc ed in such work, be

familiar with all precautions required, and have complied with all requirements of state or local

authorities having jurisdiction. In the absence of local codes, installation must comply with the

National Electrical Code ANSI NFPA No. 70 latest edition.

3. For the installation of steam piping from the source of supply to the service inlet of the

appliance, qualified installation personnel must be experienced in such work, be familiar with all

precautions required, and have complied with all requirements of state or local authorities

having jurisdiction.

QUALIFIED SERVICE PERSONNEL

Qualified service personnel are those who are familiar with this equipment who have been

endorsed by our company. All authorized service personnel are required to be equipped with a

complete set of service and parts manuals and stock a minimum amount of parts for this

equipment.

SHIPPING DAMAGE CLAIM PROCEDURE

For your protection, please note that equipment in this shipment was carefully inspected and

packed by skilled personnel before leaving the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of this shipment.

If shipment arrives damaged:

1. VISIBLE LOSS OR DAMAGE — Be certain this is noted on freight bill or ex press receipt

and signed by person making delivery.

2. FILE CLAIM FOR DAMAGES IMMEDIATELY — Regardless of extent of damage.

3. CONCEALED LOSS OR DAMAGE — If damage is unnoticed until merchandise is

unpacked, notify transportation company or carrier immediately, and file "concealed damage"

claim with them. This must be done within fifteen (15) days of the date the delivery is made to

you. Be sure to retain container for inspection.

We cannot assume responsibility for damage or loss incurred in transit. We will, however, be glad

to furnish you with necessary documents to support your claim.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE

Page 3

IMPORTANT NOTES FOR ALL VULCAN APPLIANCES

1. These units are produced with the best possible workmanship and material. Proper installation is vital if best

performance and appearance are to be achieved. Installer must follow the installation instructions carefully.

2. Information on the construction and installation of ventilating hoods may be obtained from the "Standard for the

installation of equipment for the removal of smoke and grease laden vapors from commercial cooking

equipment," NFPA No. 96 (latest edition) available from the National Fire Protection Association, Battery March

Park, Quincy MA 02269.

3. For an appliance equipped with a flexible electric supply cord, the cord is equipped with a three prong

(grounding) plug. This grounding plug is for your protection against shock hazard and should be plugged

directly into a properly grounded three prong receptacle. Do not cut or remove the grounding prong from this

plug. If the appliance is not equipped with a grounding plug, and electric supply is needed, ground the

appliance by using the ground lug provided (refer to the wiring diagram).

(FOR GAS APPLIANCES ONLY)

4. Do not obstruct the air flow into and around the appliance. This air flow is necessary for proper combustion of

gases and for ventilation of the appliance. Provisions for ventilation of incoming air supply for the equipment in

the room must be in accordance with National Fuel Gas Code ANSI Z223.1 (latest edition).

5. Do not obstruct the flow of flue gases from the flue duct (when so equipped) located on the rear (or sides) of

the appliance. It is recommended that the flue gases be ventilated to the outside of the building through a

ventilation system installed by qualified personnel.

6. For an appliance equipped with casters, (1) the installation shall be made with a connector that complies with

the Standard for Connectors for Movable Gas Appliances, ANSI Z21.69 (latest edition), and Addenda, Z21.69a

(latest edition), and a quick-disconnect device that complies with the Standard for Quick-Disconnect Devices

for Use With Gas Fuel, ANSI Z21.41 (latest edition), and Addenda, Z21.41 a (latest edition), and Z21.41 b

(latest edition), and (2) adequate means must be provided to limit the movement of the appliance without

depending on the connector and the quick-disconnect device or its associated piping to limit the appliance

movement.

If disconnection of the restraint is necessary, reconnect this restraint after the appliance has been returned to

its originally installed position.

7. The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in excess of 1/2 psig (3.45 k Pa).

8. The appliance must be isolated from the gas supply system by closing its individual manual shutoff valve

during any pressure testing of the gas supply system at test pressures equal to or less than 1/2 psig (3.45 k

Pa).

CAUTIONS

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS EQUIPMENT OR ANY OTHER

APPLIANCE.

1. KEEP THE APPLIANCE FREE AND CLEAR FROM ALL COMBUSTIBLE SUBSTANCES.

2. IN THE EVENT A GAS ODOR IS DETECTED, SHUT UNIT(S) DOWN AT THE MAIN

SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS SUPPLIER

FOR SERVICE.

3. POST IN A PROMINENT LOCATION, INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION MAY BE OBTAINED

FROM A LOCAL GAS SUPPLIER.

3

Page 4

ELECTRIC COUNTER CONVECTION STEAMER

MODEL: VSXII

INSTALLATION, OPERATING, SERVICE

AND PARTS MANUAL INDEX

Your Vulcan Counter Steamer is produced with quality

workmanship and material. Proper installation, usage

and maintenance will result in many years of

satisfactory performance.

The manufacturer suggests that you thoroughly read

this entire manual and carefully follow all of the instruc -

DESCRIPTION PAGE

DEFINITIONS OF PERSONNEL (Operating, Installation and Service) and

SHIPPING DAMAGE CLAIM PROCEDURE

IMPORTANT NOTES 3

INDEX 4

WATER CONDITIONING 5

DESCRIPTION 5

tions provided. Please retain this manual for future

reference.

A data plate with the unit model number and serial

number, electrical characteristics, etc., is on the lower

left front corner of the body side panel.

(Inside Front Cover)

ELECTRICAL CHARACTERISTICS 6

INSTALLATION 7

SERVICE CONNECTIONS 7

START -UP 8

OPERATING 8

CLEANING 9

COOKING CHART 10-12

SERVICE 13-14

PARTS LIST 15-20

WIRING DIAGRAM 21-23

RECOMMENDED SPARE PARTS LIST 24

4

Page 5

WATER CONDITIONING

It is important to furnish the steam generator with soft

water to minimize scale formation, which will reduce

steam output, cause premature component failure,

and shorten equipment life. Most water supplies

contain scale producing minerals. As steam is

produced by the steam generator, the minerals

remain and dissolve into the water. As the

concentration of these minerals increases past a

certain point, they precipitate from the water and coat

the surfaces inside the generator, the heating

elements, the steam generator interior surfaces, and

water level control probes. Because of the high

temperature of these surfaces, the precipitated

minerals bake onto them and become very difficult to

remove.

This phenomenon causes several problems.

1. The surfaces of the heating devices will become

coated with scale, reducing the heat transfer effi ciency. On electric heating elements, the scale will

produce hot spots on the elements and cause

premature failure of the elements.

2. Water level probes are used in all steam

generators, and these too will become coated with

scale. In this case, scale will bridge across the

probe insulator from the metal extension, which

senses the water level, to the boiler shell. Once

the scale is wet, it can prevent the water level

control from maintaining the proper water level in

the boiler shell. This situation may cause an electric

heating element to fail as a result of the element not

being adequately covered by water.

All of these problems are common to any

manufacturer's steamer regardless of design, but they

can all be prevented by furnishing the steam

generator with soft water. Vulcan-Hart recommends

the water contain no more than 2.0 grains of hardness

(TDS) and have a pH of 7.5. This degree of hardness

can be easily and inexpensively achieved by the use

of a properly maintained water softener. The use of a

water meter will determine the water consumption and

when the water softener needs regeneration or

recharging.

NOTE: The use of strainers, or filters will not remove

minerals from the water.

Steamers which have been operated for a period of

time without the benefit of a water softener, and which

have developed a heavy scale build up should be

cleaned prior to the use of a water softener. Our

recommended method used for removing scale is

"Descaling" on page 14.

DESCRIPTION

This Vulcan self generating electric counter

convection steamer is manufactured with a 7.5 KW

electric input. This steamer generates steam in a

stainless steel pressureless steam generator located

behind the steaming compartment. The sheathed

electric elements are mounted inside the steam

generator. When the "red" (ON-OFF) operating switch

is turned ON the generator automatically fills with

water to a preset level. The electric elements are

automatically turned ON allowing the water to be

heated to a high temperature ready condition (door

open or closed). The probes automatically measure

the water level allowing the water to fill the

generator to the proper level and automatically

maintain the water level necessary for proper

operation.

Place full sized 12" x 20" (or half sized) pans in the

compartment. Close the door. Press the minutes to

cook button(s). Press the start button to begin

cooking. When the end of cooking buzzer sounds,

open the door and remove the cooked food. The

buzzer shuts off. When through cooking for the day,

turn the power switch off and the "blown down" cycle

automatically begins using the remaining steam to

"blow out" the water and loose scale in the generator

to the drain.

5

Page 6

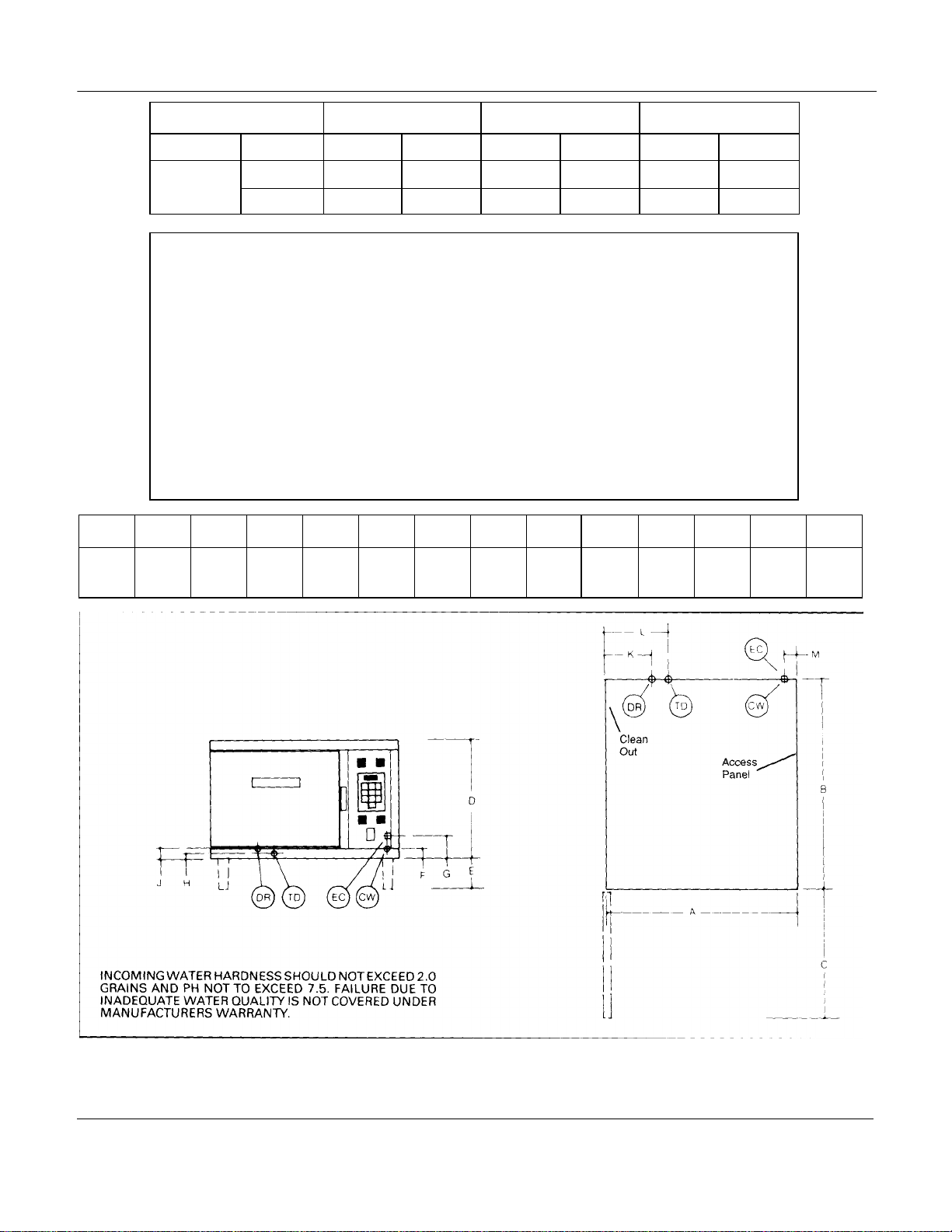

ELECTRICAL CHARACTERISTICS

4

9

2

208V 230V 240V

Model

VSXII

Model

PH KW AMP KW AMP KW AMP

1 7.5 36.1 7.5 32.6 7.5 31.3

VSXII

3 7.5 20.8 7.5 18.9 7.5 18.1

SERVICE CONNECTIONS

CW Cold Water: 3/8" (9.5mm) tubing to

condensor at min 25 to max 50

PSI.

DR Drain: 1" (25 mm) IPS piped to

open floor drain. No solid connection.

Must be open air gap with a maximum

24" length before the open air gap

opening (no bends or elbows in 24").

Total length maximum 6' with only one

elbow.

inches

mm

A B C D E F G H J K L M

24

610

27 1/2

699

18

457

15 1/8

384

102

TD Trough Drain: Interconnected

to main drain (DR).

EC Electric Connection: 1 1/ 2" (38mm)

conduit connection to

electrical box.

1 1/2

38

4 7/8

124

1 1/4

32

1 1/2

38

229

10

254

51

6

Page 7

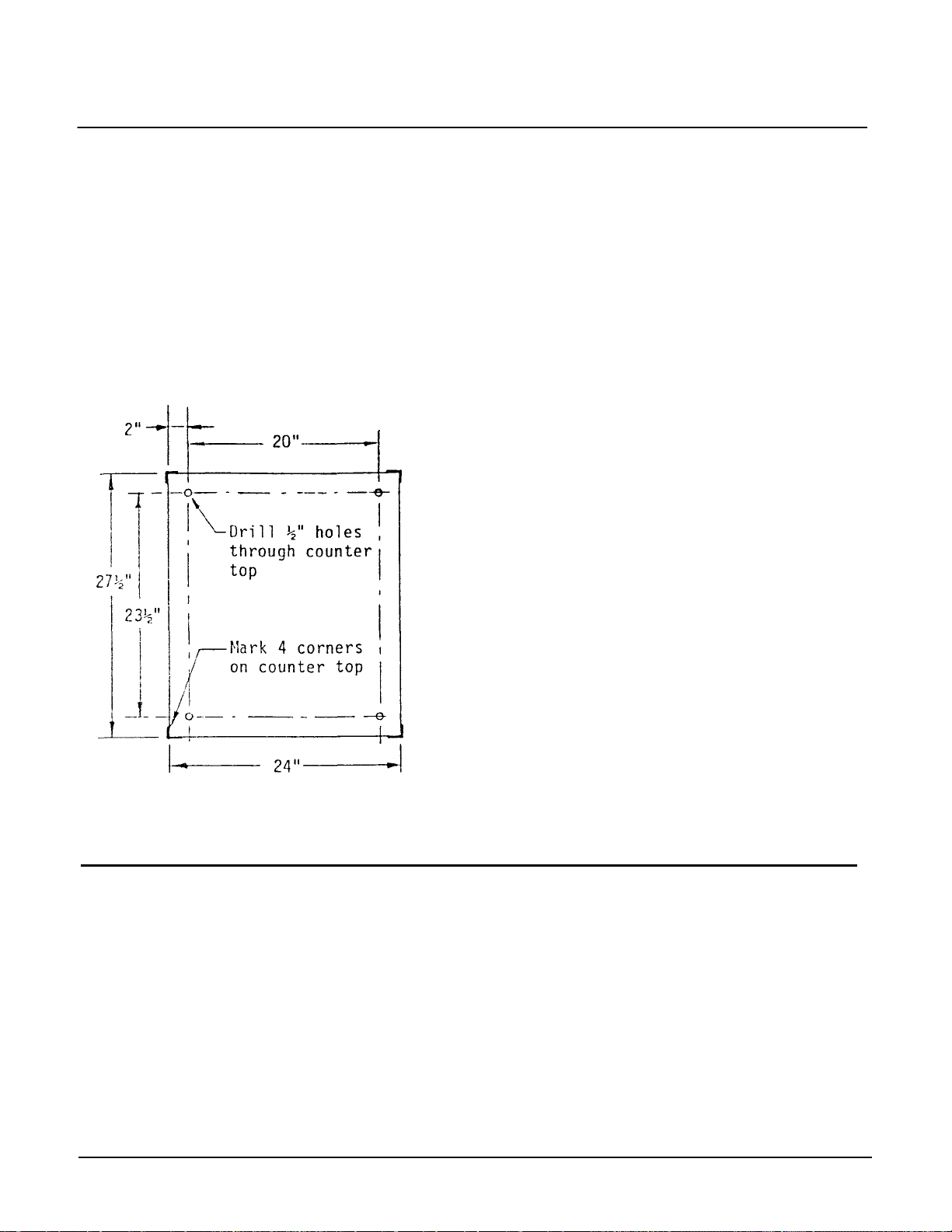

INSTALLATION

WARNING: Electrical and ground

connections must comply with the applicable

portions of the National Electrical Code

and/or other local electrical codes.

WARNING: Plumbing connections must

comply with applicable health, safety and

plumbing codes.

The Vulcan VSXII is a single compartment

pressureless steam cooker that has been factory

assembled and tested. The unit has been crated to

protect it during transportation.

A. Remove the counter steamer from the carton.

B. It is a free standing unit not to be enclosed. Place

the unit in the desired position on a level counter

top. Then mark the 4 corners. Check that there

are suffi cient clearances to service the controls,

for door swing, etc., so that there will be no

problem in making the required supply

connections. Minimum clearances are 2" on the

sides and 6" on the back for proper air circulation

through the louvers on the sides and the rear of

the unit, and 6" away from any open heat. A 36"

minimum clearance is required at the front for

adequate access to the cooking compart ment.

Next, set the unit aside to drill four 1/2" holes.

C. Drill 1/2" holes as indicated in the drawing.

D. Apply a bead of high grade sealant around the

bottom outside edge of this unit. Failure to comply

with this requirement will void the N.S.F. label.

E. Set the unit back on the counter and bolt it down

securely with 3/8-l 6 bolts.

When ordered as an option, the Vulcan counter

steamer will have 4 adjustable 4" legs packed in

the carton. Screw the legs securely into the

bottom corner of the unit. Set the unit on the

counter top. Use the levelers supplied with the 4"

legs to level the unit using a spirit level. Level left

to right and front to back. Steamers should be

elevated in the front just enough (approximately

1/16" to 1/8" ) to give proper drainage. (Check

level by pouring a little water in the compartment.

All of the water should drain).

SERVICE CONNECTIONS___________________________________

The Vulcan counter steamer is a self-contained unit

with field replaceable elements rated at 7.5 KW.

A. Water Connection: the unit has a 3/8" copper tube

input to which the water supply line has to be connected.

The 3/8" copper tube supplies water to both the

generator tank and to the cold water condenser

which condenses the steam entering the drain

line. A manual shut off valve (supplied by others)

must be provided convenient to the unit to use

when removing scale.

B. Electrical Connection: The voltage and phase sup

plied at the installation point must be the same as

indicated on data plate. The supply wiring and

circuit protection must be adequate for the

kilowatt load drawn by the unit. Use copper wire

suitable for at least 200°F. (90°C.). The unit must

be grounded.

C. Drain Connection: Use with an open gap drain.

Must be 1" IPS vertically down and preferably with

only one elbow and a maximum of 6 feet in

length, piped to an open floor drain. A solid

connection will result in back pressure to the

compartment and overflow the drain trough.

7

Page 8

START UP

WARNING: The cooking compartment

contains hot steam. To avoid burns, stay

clear of the door when opening it.

When the unit has been installed and all service

connections have been made, the steamer should be

checked out before operating.

A. Turn the power switch on the control panel to

"ON". The COOK TIME-MINUTES "Window" will

display "00".

B. Touch number 8 on digital control panel twice.

Note that two complete 8's (all segments of the 8)

in the display window light up. Next, touch all the

other numbers and check that they also light up

completely

C. Touch CANCEL and the display window will show

"00".

D. 15 minutes after turning on the power switch, the

READY (green) light will come on, indicating that

the steamer is ready for the cooking cycle. Open

the door and check that no steam has entered the

cooking compartment.

E. Close the door and touch number 2 and "02" will be

displayed. This indicates that the unit is set for two

minutes of cooking time.

F. Touch START. The READY light will go off and

the COOK (red) light will come on and steam will

be heard entering the cooking compartment.

Inspect that the cold water condenser is operating

and is evident by observing water entering the

open drain.

G. After one minute when the display window shows

"01", open the door and observe for two or three

minutes that the steam has stopped entering the

cooking compartment, while the COOK light and

cooking time at "01" are still showing.

H. Shut the door. Steam generation and the cook

time will start again. When the display window

shows "00", the buzzer will start, steam generation

will stop, the COOK light will go off and the

READY light will come on.

I. To stop the buzzer, open the door and the food

should be removed.

J. Turn the power switch to OFF. The drain solenoid

valve will open and the steam generator will "blow

down". Check the open drain and note that hot

water is being drained.

OPERATING

WARNING: The cooking compartment

contains hot steam. To avoid burns, stay

clear of the door when opening it.

A. Prepare for cooking by turning the power switch

"ON" The cook time minutes "Window" will display

"00" and the generator tank will automatically fill

with water and be brought up to the READY

temperature with the heater elements, in about 15

minutes.

B. When the READY light (green) comes on, preheat

the cooking compartment for one minute by

pressing number 1 on digital panel and then press

START. The READY light will go off and the

COOK light (red) will come on. Be certain that the

door is closed. Steps A and B are only required

when the cooking compart ment is cold or when

the unit is to be used the first time during the day.

When the buzzer sounds, open and then close the

door to silence it.

C. Your unit is now ready for cooking.

D. With compartment preheated and the READY light

on place pans of food into cooking compartment

and shut the door. Refer to the cooking guide

located after the cleaning section.

E. Press cooking minutes on the digital panel, then

touch START for the cooking cycle to begin. The

cooking cycle may be interrupted at any time by

opening the door and it can be started again by

closing the door.

F. When the buzzer sounds, it indicates the end of

the cooking cycle and no more steam will be

entering the cooking compartment. The buzzer is

silenced by opening the door and removing the

cooked food. The COOK light will go off and the

READY light will come on.

G. Touching CANCEL will automatically display "00"

on "Window". The correct minute time can now be

entered and the next item to be cooking can begin

its cycle.

H. To shut down your steamer, turn the power switch

to OFF and the generator tank will automatically

blow down, removing water and loose scale.

8

Page 9

PAN CAPACITY

Each steamer compartment will hold combinations of

the following pan sizes (either solid or perforated):

PAN SIZE MAXIMUM QUANTITY DEPTH OF PAN

12X20 1 6"

12x20 2 4"

12X20 3 2-1/2"

12x20 6 1"

CLEANING

Remove any pans and oven racks from the compart ment and wash them in the sink. Wash the

compartment interior with clean water. Never use

steel wool or abrasive scouring pads as they will

scratch and ruin the general surface appearance of

your appliance. Use a clean damp cloth to wipe down

the exterior.

CAUTION: NEVER SPRAY WATER ON TO

THE ELECTRIC CONTROLS.

9

Page 10

COOKING CHART

Long grain

regular/vermicelli

shells/elbows

wide

15

18

15

Ground chuck

25

Pounds

Beans

9

Can

THE FOLLOWING ITEMS MUST BE COOKED IN SOLID PANS:

FOOD

TIMER SETTING

IN MINUTES

Eggs - Scrambled 10- 12 8 Dozen

Rice (Add 4 cups water/Ib)

Pasta (Place a perforated pan inside a solid pan, cover pasta with cold water)

-Spaghetti -

-Macaroni -

-Noodles -1/2"

-Lasagna noodles

Frozen casseroles, lasagna 35 Full pan

Meat Loaf (3 - 5 Ibs each) 40 15 Pounds

Beef -

-Sliced as purchased

Shrimp, frozen

(10 shrimps per Ib)

25 2 Pounds

12151215-18

2035-40

5

FOOD WEIGHT

PER PAN

10

10 Pounds

4 Pounds

-Baked

-Refried

Canned vegetables 6 10 Pound Opened Can

Prunes, dried 12- 15

9

10 Pound Opened

10 Pound Opened Can

10

Page 11

COOKING CHART (Cont.)

PERFORATED PANS ARE RECOMMENDED FOR FOLLOWING ITEMS:

ITEM

Clams

-Frozen 10- 12 3 Dozen

-Fresh, cherrystone 5-6 3 Dozen

King Crab (frozen)

-Claws 4 2 1/2 Pounds

-Legs 4-6 4 1/2 Pounds

Lobster tail (frozen) 6 10 Pounds

Lobster live (10"-12") 5 4 Per Pan

Salmon fillets (frozen - 8 oz. ea.) 5 7 1/2 Pounds

Scallops (fresh) 4 3 Pounds

Scrod fillets (fresh) 3-5 4 Pounds

Eggs

-Hard Cooked 15 4 Dozen

-Soft Cooked 9-10 4 Dozen

-Soft yoke for Caesar Salad 6-8 4 Dozen

Chicken

-Breasts, legs, thighs 20 15 Pounds

Turkey (frozen)

-Breasts (2) 90 6-7 Pounds each

-Cut lengthwise 55 20-25 Pounds

Corned Beef 40-75 6-8 Pounds

Hot dogs or wieners 3 80-100 Count

Asparagus spears

-Frozen 10- 12 3 Dozen

-Fresh 5 5 Pounds

Beans

-Green - 2" cut (frozen/fresh) 6 5 Pounds

-Lima (frozen) 8 5 Pounds

-Baby lima (frozen) 5 5 Pounds

Broccoli

-Spears (frozen) 8 4 Pounds

-Spears (fresh) 6 5 Pounds

-Flowerettes (froz en) 6 5 Pounds

TIMER SETTING

IN MINUTES

WEIGHT

PER PAN

11

Page 12

COOKING CHART (Cont.)

TIMER SETTING

WEIGHT

PERFORATED PANS RECOMMENDED FOR FOLLOWING ITEMS: (Continued)

ITEM

Brussel sprouts (frozen) 6 5 Pounds

Cabbage (fresh) 1/6 cut 8 5 Pounds

Carrots

-Baby whole (frozen) 8 7 Pounds

-Crinkle cut (frozen) 7-8 4 Pounds

-Sliced (fresh) 11 9 Pounds

Cauliflower, flowerettes

-Frozen 6 4 Pounds

-Fresh 7-8 5 Pounds

Celery (1" diagonal cut) 7 5 Pounds

Corn

-Yellow whole kernel (frozen) 5 5 Pounds

-Cobbettes (frozen) 8 27 Ears

-Corn-On-Cob (fresh) 10-12 18 Ears

Peas,green 6 5 Pounds

Potatoes, whole russet 55 40 Pounds

Spinach

-Chopped (frozen) 17 6 Pounds

-Defrosted 5 6 Pounds

-Fresh cut 3 2 Pounds

Squash-Acorn Halves 25 10 halves

Zucchini, slices 8 10 Pounds

Frozen mixed vegetables 6-7 5 Pounds

Fruit-Blanch for peeling:

-Grapefruit 3

-Oranges

Pineapple - whole for cutting 4

INMINUTES

16- 18 80 Ears

16-18 54 Ears

PER PAN

12

Page 13

SERVICE

WARNING: Disconnect the electrical power to

the machine at the disconnect switch. Place a

tag on the disconnect switch indicating the

circuit is being worked on.

WARNING: Certain procedures in this section

require electrical tests or measuremen ts

while power is applied to the machine.

Exercise extreme caution at all times. If test

points are not easily accessible, disconnect

power, attach test equipment and reap-ply

power to test.

HIGH ALTITUDE LOCATIONS

The Vulcan counter steamer has been factory set

when ON to maintain water temperature during the

READY phase in the steam generator tank at

approximately 205 deg.F. (just below water boiling

point). However, for high altitude locations a qualified

service person must adjust this temperature using the

following procedure:

A. Remove the side panel and turn the control panel

power switch to ON.

B. Open the compartment door. After about 15

minutes steam will be seen entering the cooking

department.

C. On the large printed circuit board, use a

screwdriver to turn the "TEMP" dial slowly

counter-clockwise to lower the temperature until

steam just ceases to enter cooking compartment

and the READY light goes on.

D. Replace the side panel.

E. Follow Start Up Instructions - Page No. 7.

WATER FLOWING INTO THE DRAIN

DURING SHUT DOWN

When the unit is shut down and yet cold water is

running continuously into open drain, it indicates

that either or both solenoid valves did not close

when de-energized. Solenoid valve(s) must be

disassembled and examined for scalant or foreign

particles lodging in the diaphram or the core tube.

Clean valve(s) thoroughly and reas semble or

replace the valve(s).

WATER OVERFLOWS INTO THE COOKING

COMPARTMENT

When the unit is first turned on for the day -and the

READY light does not come on after about 15

minutes of operating time and water begins to

overflow into the cooking compartment and the

water fill solenoid valve is open

any or all of the above symptoms may indicate that the

failure of the operating probe to function is due to

either:

A. A "short" between the operating probe terminal

and the terminal on large printed circuit board

marked "OP" - or

B. Excessive scale has built up on the operating

probe. This acts as "insulation" and prevents the

probe from sensing the water level and, therefore,

it is unable to de-energize the water fill (solenoid)

valve to shut the water off.

As a temporary solution, with power off, probes

should be unscrewed, checked visually and

scalant cleaned or chipped off and then replace

the probe. This is an indication of severe harmful

water conditions and should be corrected

immediately to avoid damage to the components

and the ultimate malfunction of your unit.

COOKING CYCLE DOES NOT OPERATE

NOTE: Tests should be performed by a qualified

service technician.

Check that the READY (green) light is on. A glass

encased switch, magnetically activated, is located inside and directly behind the front enclosure (above the

striker) indirect alignment with a magnet in the door.

When the door is opened, this switch automatically

opens and will place the cooking time on hold and

shut down the heater elements. When cooking, the

steam generating and time fail to start when the door

is closed, then malfunction of the switch is likely.

Check by:

A. Close the door and have both the power switch

and the READY light ON.

B. Touch "1" on digital control panel and "01" will be

displayed on the "Window".

C. Touch START and the READY light will go off and

the COOK light (red) will come on.

D. "Jump" both terminals marked "DS" on the right

side of the large printed circuit board and if the

cooking cycle is activated, -

13

Page 14

SERVICE (Cont.)

Then (with top removed) either -

1. The magnetic switch is lodged in the panel

"pocket" out of alignment and must be

slightly rotated so that the "reeds" In the

glass case are directly one behind the other

when facing the front to back, for proper

magnetic action of door magnet, or;

2. The magnetic switch is defective and must

be replaced. Remove by placing a slotted

screwdriver under the spring retaining clip

and wedge out wards and remove the switch

from the pocket. Care must be taken not to

damage the glass casing when inserting the

new switch.

Check that the "reeds" are one behind the

other when facing front to back of appliance.

HEATER ELEMENTS DO NOT COME ON

When the unit is turned ON and the heater

elements do not activate and, therefore, the

READY light does not come on, then possibly the

contactors may be burned out. If considerable

amount of "chattering" of contactors has been

previously experienced, then the thermistor must

be coated with scalant and was unable to sense

water temperature accurately in the generator

tank and, therefore, was unable to control the

contactors with any degree of certainty.

Contactors will have to be replaced and the

thermistor screwed out, clean the scalants off and

screw it back in.

This condition is a reflection of inadequate water

quality and is not covered by the warranty. Have

the water quality analyzed and corrected right

away to avoid the complete malfunction of your

unit.

WATER HARDNESS

After two weeks of operation, make an initial

inspection of both probes in your unit. With power

OFF to the unit and the side panel removed,

unscrew and remove probes. Visually examine the

tips of the probes and if a grayish tawny film is

present, then lime build up has occurred and

unless precautions are undertaken, malfunction of

your unit is about to happen. Since break downs

due to inadequate quality of water supplied to this

appliance are not covered by the WARRANTY, it

is the responsibility of the user to either install a

proper water conditioner and/or implement a rigid

descaling program to remove scalant build up.

DESCALING

A. Check that the condition on Page 13 - WATER

OVERFLOWS INTO COOKING COMPARTMENT does not occur.

B. With the power switch OFF, unscrew and remove

the plug located on the left side of your unit. Insert

a hose through the opening and flush out loose

scale. Replace the plug securely to prevent water

leakage.

C. Shut OFF water supply to the unit.

D. Turn on the unit power switch.

E. On the left side of the unit, near the top and directly

above the first plug you removed, is a smaller plug.

Remove this plug. Insert an appropriate hose, and

pour in ONE gallon of a recommended descaling

solution (full strength).

F. Replace the plug and screw it in securely to

prevent water leakage.

G. The water supply must now be turned ON to the

unit to fill the tank to the operating probe level and

the heater elements will come on and bring the

water in the generator tank to the READY

temperature.

H. Let the unit stay in the READY phase for one and a

half hours. Then turn OFF the power switch letting

the descaling solution and the scalants drain completely from the tank.

I. Turn the power switch ON and when the READY

light comes on, turn the switch to OFF again in

order to drain and flush the tank.

14

Page 15

DOOR - EXPLODED VIEW

15

Page 16

DOOR PARTS

1 840477

Door Panel

1

ITEM NO. PART NUMBER DESCRIPTION QUANTITY

2 840478 Hinge Rod Guide 1

3 840479 Bronze Bushing 3

4 836976 Latch Block Assembly 1

*5 * Compression Spring 1

*6 840480 Locking Device 1

*7 840500 Spring Tension Pin 1

*8 840481 Latch Pin 1

9 840482 Magnet 1

*10 840483 Enclosure Plate 1

*11 840484 Retaining Ring 1

12 SC-115-42 Stainless Steel Screw 2

13 840485 Door Handle

14 SC-041-50 Spring Tension Pin 1

15 836975 Compression Spring 4

16 836974 Mounting Plate 1

17 836919 Gasket 1

18 836973 Gasket Plate 1

19 840486 "0" Ring 6

20 SC-120-81 Stainless Steel Screw 6

*21 840487 Spring Tension Pin 1

*22 840488 Spring Tension Pin 1

*23 840489 Lock Pin 1

*24 * Stainless Steel Screw 2

25 840490 Spacer 2

* Part of P/N 836976. Not sold separately.

NOTE: Parts are sequenced in order of assembly. For disassembly and reassembly, the door must be removed

from the unit and placed face down on a flat surface. When assembling parts 15 thru 20 inclusive, screw

in four threaded 1/4-20 rods initially into Door Panel and insert Parts 15,16,17, and 18. Remove the

threaded rods one at a time and replace with "0" Rings and Stainless Steel Screws.

16

Page 17

STEAMER BODY - EXPLODED VIEW

17

Page 18

STEAMER BODY PARTS

ITEM NO. PART NUMBER DESCRIPTION QUANTITY

1 840491 Hinge Rod 1

2 840492 Door Assembly 1

3 840493 Bronze Bushing 2

4 840494 Compartment Drain Screen 1

5 840495 Perforated Trough Channel 1

6 836920 Switch 1

7 836923 Digital Control Panel 1

8 840496 Striker 1

9 WS-030-38 Stainless Steel Washer 1

10 WL-006-36 Lock Washer 1

11 NS-015-16 Nut 1

12 840497 Steam Generator Tank 1

13 881981 Probes 2

14 836926 Heater Element Gasket 1

15 840498 Heater Element Assembly (Spec. Voltage) 1

16 836930 Water Fill Solenoid Valve 1

17 836930 Cooling Solenoid Valve 1

18 836931 Blowdown Drain Solenoid Valve 1

19 836925 Thermistor 1

20 840499 Pan Racks (not shown) 2

18

Page 19

STEAMER BODY ASSEMBLY

19

Page 20

STEAMER BODY ASSEMBLY PARTS

ITEM NO. PART NUMBER DESCRIPTION QUANTITY

1 836921 Printed Circuit Board 1

2 881974 Contactors 2

3 836930 Solenoid Valves 2

4 881981 Probes 2

5 836933 Transformer 1

6 836934 Transformer (Specify Voltage) 1

7 836833 Shutdown Thermostat 1

8 836931 Blowdown Solenoid Valve 1

9 836922 Printed Circuit Board 1

10 836924 Door Switch 1

11 NS-015-16 Nut 1

* Specify Voltage & KW

20

Page 21

WIRING DIAGRAM 208/240V

21

Page 22

WIRING DIAGRAM 380V

22

Page 23

WIRING DIAGRAM 480V

23

Page 24

RECOMMENDED SPARE PARTS

VSXIl

(**) SELECT AS REQUIRED

836919 DOOR GASKET

836920 POWER SWITCH

836921 CIRCUIT BOARD

836922 CIRCUIT BOARD

836923 CONTROL TOUCH PANEL

836924 DOOR SWITCH

836925 THERMISTOR

836926 ELEMENT GASKET

** 836927 ELEMENT ASSY. 208V

** 836928 ELEMENT ASSY. 240V

** 836929 ELEMENT ASSY. 287V

836930 SOLENOID VALVE (FILL & COOL)

836931 BLOWDOWN SOLENOID

881974 CONTACTOR

836933 TRANSFORMER

836934 TRANSFORMER

836833 SHUTDOWN THERMOSTAT

881981 PROBE

24

Loading...

Loading...