Page 1

MODEL VSX3E SHOWN

SERVICE MANUAL

VSX SERIES CONVECTION STEAMERS

(ELECTRIC AND GAS)

VSX3E ML-52396 VSX10EC ML-114824

VSX3E ML-52397 VSX10EO ML-114823

VSX4E ML-52398 VSX5G ML-114946

VSX5E ML-52399 VSX5GC ML-114947

VSX7EC ML-114822 VSX7GC ML-114949

VSX7EO ML-114821 VSX10GC ML-114949

- NOTICE This Manual is prepared for the use of trained Vulcan Service

Technicians and should not be used by those not properly

qu alif ied. If yo u have attend ed a Vulcan Service School for this

product, you may be qualified to perform all the procedures

described in this man ual.

Thi s manu al i s no t i nten ded to be al l en co mpassi ng . I f you have

not atte nded a Vulca n Servic e School f or this produc t, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have th e n ecessary too ls, in strument s and skills should be

performed b y a trained Vu lcan Service Technician.

Reproduction or other use of this Manual, without the express

written consent of Vulcan, is prohibited.

A product of VULCAN-HART LO UISVILLE, KY 40201-0696

Form 24618 ( Rev.A, March 2000)

Page 2

VSX SERIES STEAMERS

TABLE OF CONTENTS

GENERAL............................................................................. 3

Introduction ........................................................................ 3

Specifications ...................................................................... 4

Electric Steamers................................................................ 4

Gas Steamers .................................................................. 4

Tools ............................................................................. 5

Control Location..................................................................... 5

Water Conditi oning .................................................................. 5

REMOVAL AND REPLACEMENT OF PARTS ................................................. 6

Covers and Panels ................................................................... 6

Thermostats........................................................................ 7

Timer............................................................................. 9

Heating Elements (Electric) ............................................................ 9

Gas Solenoid Valve .................................................................. 9

Gas Pressure Regulator .............................................................. 11

Flam e S ense Pr obe ( Gas) ............................................................ 11

Water Level Control Board............................................................ 11

Hot Surface Ignitor (Gas)............................................................. 12

Gas Burner ....................................................................... 12

Gas Ignition Module ................................................................. 13

Steam G ener ator Tank .............................................................. 13

Water Level Probes ................................................................. 14

Fill and Cold W ater Solenoid Valv es .................................................... 15

Drain Valve ....................................................................... 16

Door............................................................................. 18

SERVICE PROCEDURES AND ADJUSTMENTS .............................................. 20

Steam G ener ator Cleaning ........................................................... 20

Delime Board Operation and Adjustm ent ................................................. 20

Control Thermostat Adjustment ........................................................ 20

Drain Tank M anually ................................................................ 21

Door Sealing Adjustment ............................................................. 22

Door Latch Adjustment............................................................... 22

Manifold Pressure Adjustment ......................................................... 23

Flam e S ense Pr obe ( Gas) ............................................................ 24

Hot Surface Ignitor (Gas)............................................................. 25

Heating Element (Electric)............................................................ 25

ELECTRICAL OPERATION .............................................................. 26

Component Func tion ................................................................ 26

Component Locat ion ................................................................ 28

Electric Models ................................................................. 28

Gas Models ................................................................... 29

Water Level Control Operation ........................................................ 30

Sequence of O per ation .............................................................. 30

Electric Models ................................................................. 30

Gas Models ................................................................... 32

Schematic Electric Steamers.......................................................... 34

Wiring Diagram Electric Steamers...................................................... 35

Schematic Gas Steamers ............................................................ 36

Wiring Diagram Gas Steamers ........................................................ 37

TROUBLESHOOTING .................................................................. 38

All Models ........................................................................ 38

Gas Models Only ................................................................... 40

© VULCAN 2000

Page 2 of 40

Page 3

VSX SERIES STEAMERS -GENERAL

GENERAL

INTRODUCTION

General

This manual is applic able for all models listed on the cover page. Several models are pic tured below for

reference.

Serial Numb er Break

Listed below, are t he beginning serial numbers for each model when the soli d state water level control (three

probe design) was added.

MODEL SERIAL

VSX-3 AP100704-9Q-4565

VSX-4 AP1007141-9Q-4615

VSX-5 AP1007555-11Q-5522

Steam Cooking

Pressure-less steamers offer an ef ficient way to produce m any foods in smal l portions or l ar ger batches.

Pressure-less, convection steam cooking will steam cook fresh foods or will steam defrost and cook frozen foods

providing the maximum color, flavor and nutriti onal value with the least expenditure of energy and labor . The

pressure-less steaming compartment allows the operator to open and close the door, anytime during a cooking

cycle. The steam suppl y will shut off when the door is opened, then re-start when the door is closed.

VSX7EC

VSX7EO

Page 3 of 40

VSX5GC

VSX5G

Page 4

VSX SERIES STEAMERS -GENERAL

SPECIFICATIONS

Model Designations

VSX3 - 3 pan unit.

VSX4 - 4 pan unit.

VSX5 - 5 pan unit.

VSX7 - Combi nation VSX3 and VSX4 unit.

VSX10 - Combi nation of two VSX5 units.

(based on 2.5 inch pan depth)

Electric Steamers

AMPERAGE

3 PHASE 1 PHASE

MODEL

TOTAL

KW

208V 240V 480V 208V 240V

7.5 std. 20.9 18.1 9.0 36.1 31.3

VSX3E

10.0 opt. 27.8 24.1 12.1 48.1 41.7

VSX4E 10.0 27.8 24.1 12.1 48.1 41.7

VSX5E 15.0 41.6 36.2 18.1 72.2 62.5

VSX7E 17.5 48.7 42.2 21.1

VSX10E 30 83.2 72.4 36.2

Gas Steamers

INPUT

BTU/HR

MODEL NAT. PROP. NAT. PROP. RECOMMEND MIN RECOMMEND MIN

VSX5G 45,000 45,000 3.5 5.0 7.0 5.0 11.0 7.0

VSX5GC 45,000 45,000 3.5 5.0 7.0 5.0 11.0 7.0 180 1.5

VSX7GC 90,000 90,000 3.5 5.0 7.0 5.0 11.0 7.0 360 3.0

VSX10GC 90,000 90,000 3.5 5.0 7.0 5.0 11.0 7.0 360 3.0

MANIFOLD

PRESSURE

(INCHES W.C.)

NATURAL PROPANE

LINE PRESSURE

(INCHES W.C.)

MAX

14.0

LOAD

(WATTS)

180 1.5

Water Supply

Supply pressure should be ........................ 20-80 psig

In line strainer f or suppl y line (Suppl ied)

Total dissolved solids (TDS)* .................... l ess than 60 ppm

Total alkalinity ........................................... less than 20 ppm

Silica ......................................................... less than 13 ppm

Chloride .................................................... less than 30 ppm

PH factor ................................................... 7 to 8

(*17.1 ppm = 1 grain of har dness)

AMPS

(MAX)

120V

60HZ

Page 4 of 40

Page 5

VSX SERIES STEAMERS -GENERAL

TOOLS

Standard

Standard set of hand tools.

VOM with an AC c ur r ent tester (any quality

VOM with a sensitivity of at least 20,000 ohm s

per volt can be used).

Gas leak checking equipment.

Special

CLR Treatm ent Kit (p/ n 817634) - Used to

remove Calci um/Lime/Rust from a steam

generator tank.

CONTROL LOCAT ION

WATER CONDITIONING

Furnishing the steam generator with soft water to

reduce scale formation is impor tant. Scal e formation

will reduce steam out put, cause prematur e

component failure, and shorten equipment life. Most

water supplies contai n scale producing m inerals

such as Calcium and M agnesi um. As steam is

generated, the mineral s remain and dissolve into

the water. As the concentration of these miner als

increases past a certai n point, they pr ec ipitate from

the water and coat the inside of t he tank, heating

element s, thermostat bulbs and water lev el probes.

Because of the high temperature of these surfaces,

the precipitated m inerals bake onto them and

become very difficult to remove.

This phenomenon c auses sev er al problem s:

1. Reduce the heat t r ansfer efficiency of t he

heaters.

2. Cause premature failure of the heaters.

3. Water level probes will give false readings.

4. Thermostat bulbs will sense temperature

incorrectly.

These problem s are common to any manufacturer's

steamer regardless of design, but t hey c an all be

prevented by furnishing the steam gener ator tank

with soft water. Vulcan recommends the water

contain l ess than 60ppm of “t otal dissolved solids”

(TDS) and have a PH factor between 7 to 8. These

water properties can be achieved by usi ng a

properly maintai ned water softener.

Other chemical pr oper ties in water supplies can also

affect good steam generation and vary fr om within

each state and locality.

The water level probes in the steam generator tank

use ions in the water to det ec t the water level.

not use

since it is "non conductive" and the water level can

not be detected.

NOTE:

remove mi nerals from the water.

fully demi neralized or de- ionized water

The use of strainers, or fibers will not

Do

(Gas Model Shown)

Therefor e, it i s recommended that a local water

treatm ent speciali st be c onsul ted before the

installation of any steam generating equipment.

Steamers that operate over a long peri od of time

without the benefit of a water softener, which have

developed a heavy scale build up, should be

cleaned bef or e using a water softener.

Page 5 of 40

Page 6

VSX SERIES STEAMER - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

COVERS AND PANELS

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

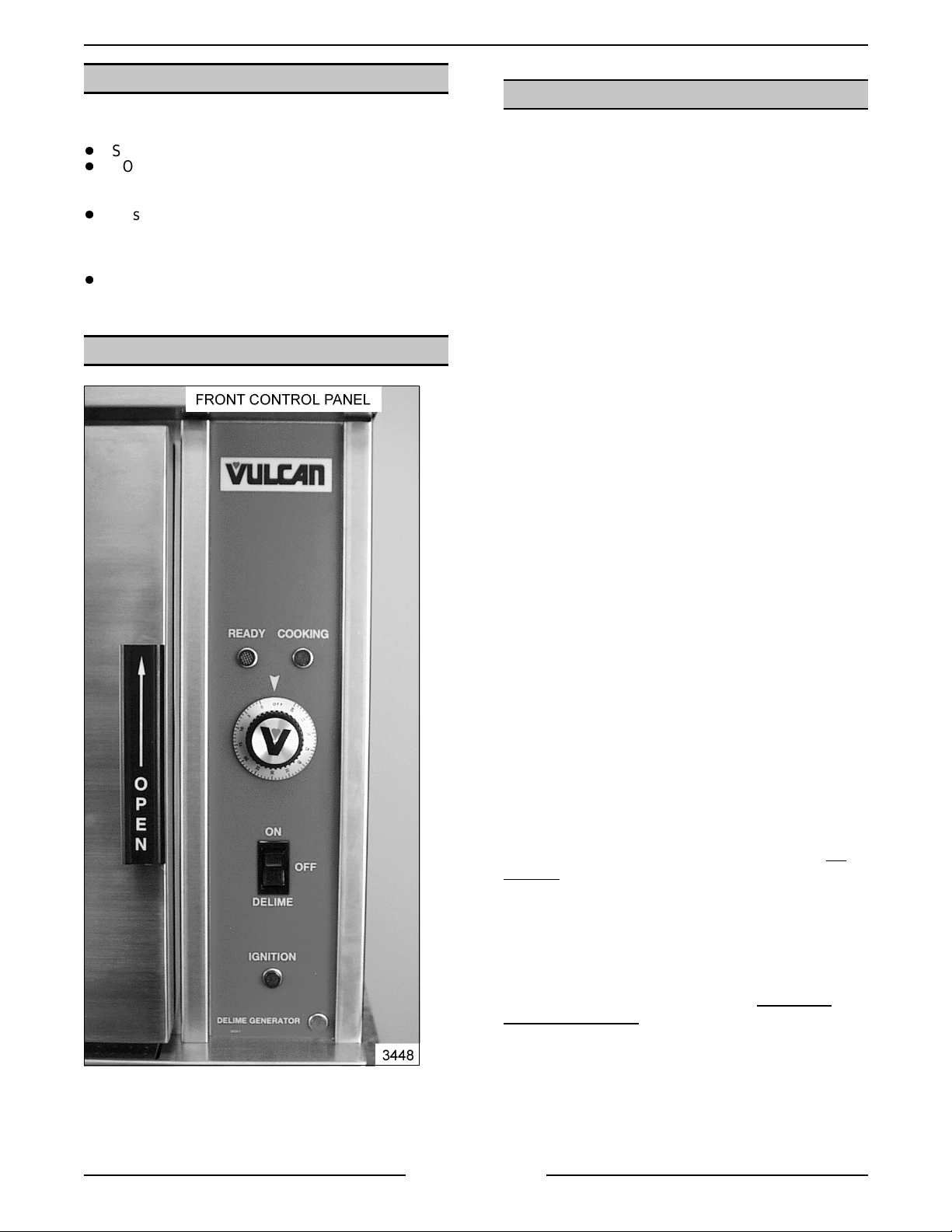

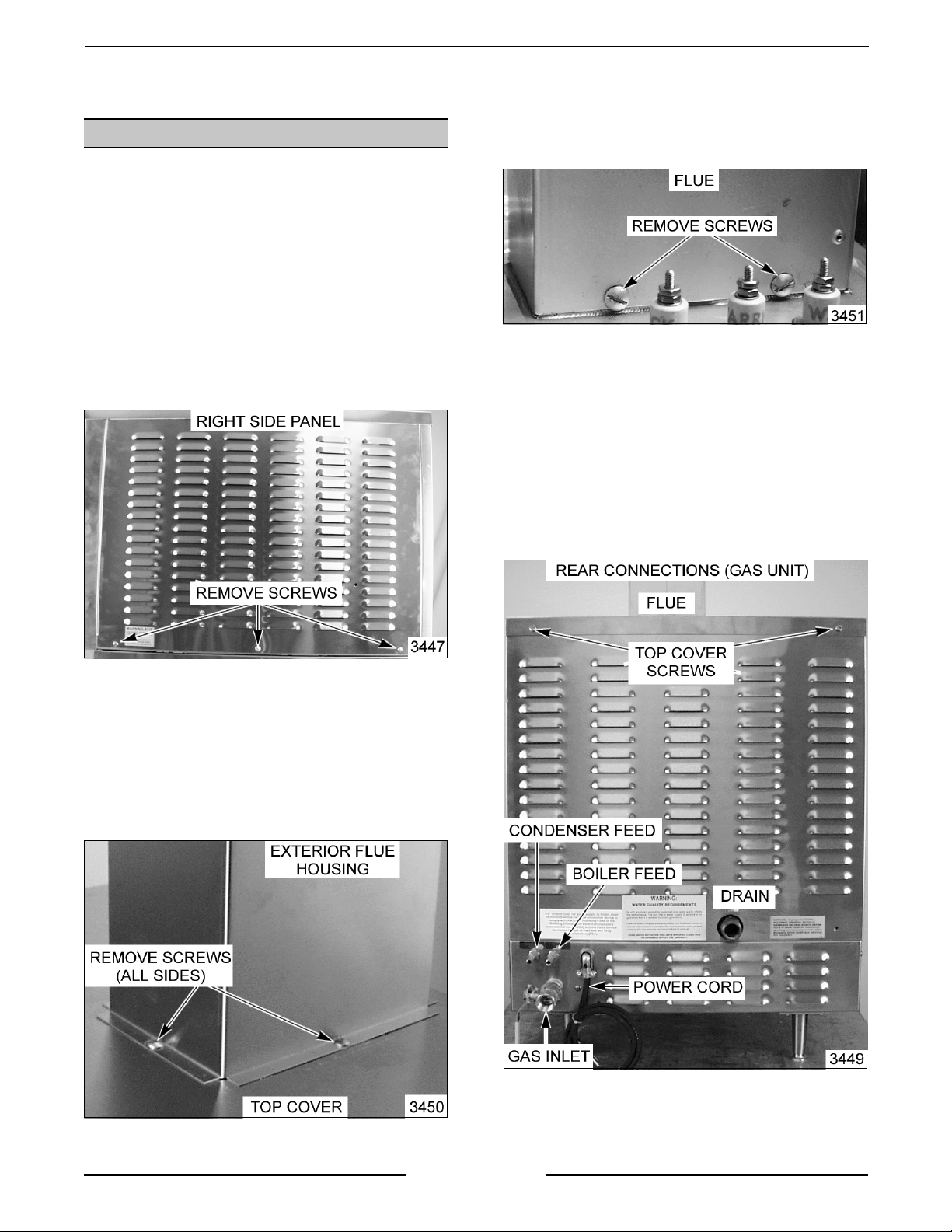

Right Side Panel

1. Remove screws from the bottom of the panel.

2. Sli de panel down to clear the top cover .

3. Rev er se proc edur e to install .

DISCONNECT THE ELECTRICAL

B. Remove the screws that secure the flue to

the tank and lift it off.

2. Push up on the rear of the cover and slide the

top cover forward to c lear the f r ont edge.

3. Lift the cover off the cabi net.

4. Rev er se proc edur e to install .

Left Side and Rear Panel

1. Remove the top cover screws an disconnect t he

utilities.

(Gas Model Shown)

Top Cover

1. Remove screws from the top rear of c over. If

steamer i s a gas model, follow steps 1A and 1B.

A. Remove the screws at the base of the

exterior flue housing and lift of f.

Page 6 of 40

Page 7

VSX SERIES STEAMER - REMOVAL AND REPLACEMENT OF PARTS

2. Remove the screws at the bott om of panel.

3. Remove the lower acc ess panels on the right

and left side of the unit to gain ac cess to the

lower compartment.

4. Remove the screws Inside the l ower

compartment that run along the top rear of the

base frame that secure the lip of the r ear panel.

replaced.

5. Remove screws that secure the thermostat.

NOTE:

base frame and the top li p of the small rear access

panel.

5. Pull the combination left side and rear panel off.

6. Rev er se proc edur e to install .

Rear panel lip is “sandwiched” between the

THERMOSTATS

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Turn “off” t he water suppl y and allow hot parts to

cool down if necessary.

2. Remove the ri ght side panel as outlined under

"COVERS AND PANELS".

3. Manuall y drain the steam gener ator tank if

necessary, as outlined in "DRAIN TANK

MANUALLY”.

DISCONNECT THE ELECTRICAL

6. If r eplacing the control thermostat, fully loosen

the compression nut, slidi ng it away from tank,

then remove the bul b.

NOTE:

thermostat calibration and/or damage to therm ostat

may occur.

When installing, do not over tighten as

4. Disconnect t he lead wires from thermostat being

Page 7 of 40

Page 8

VSX SERIES STEAMER - REMOVAL AND REPLACEMENT OF PARTS

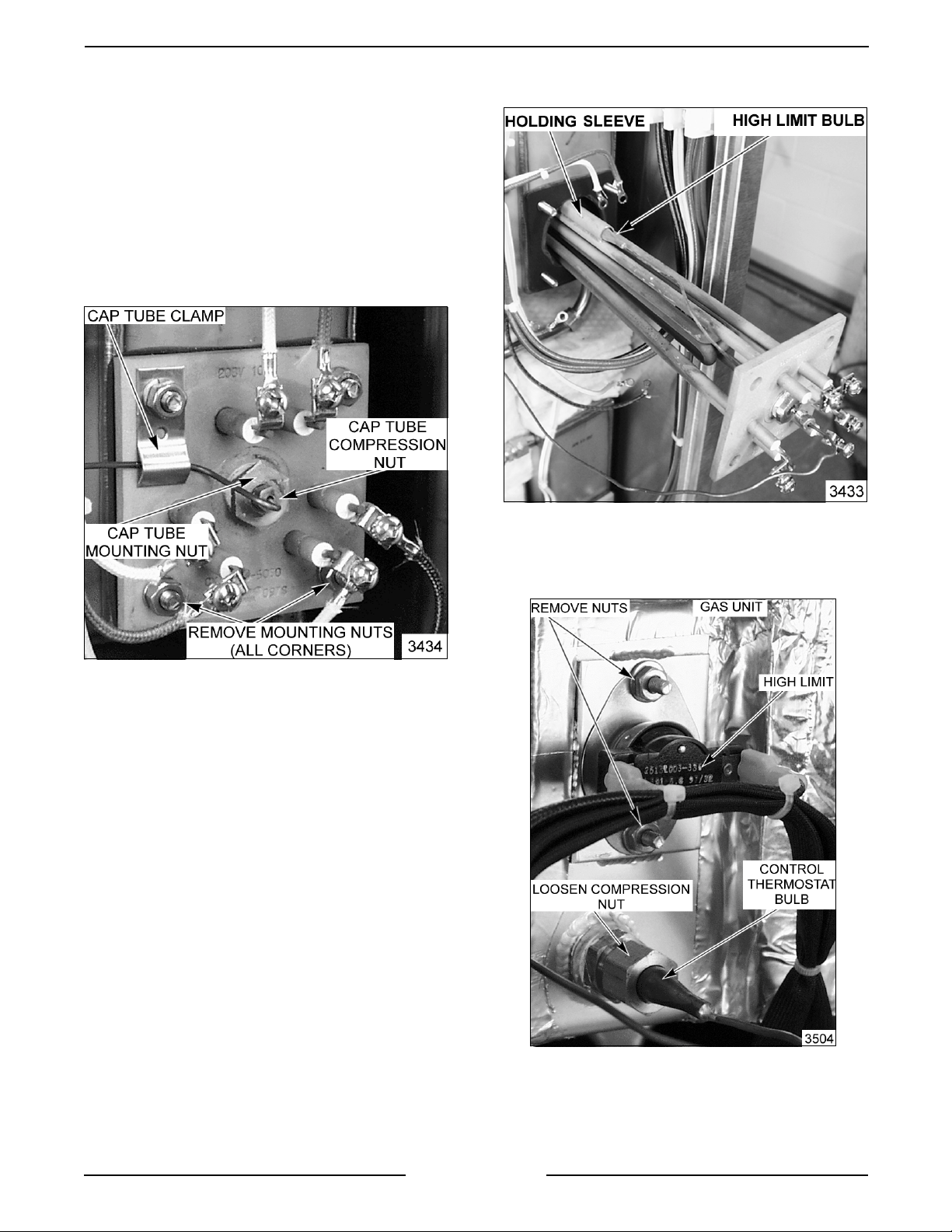

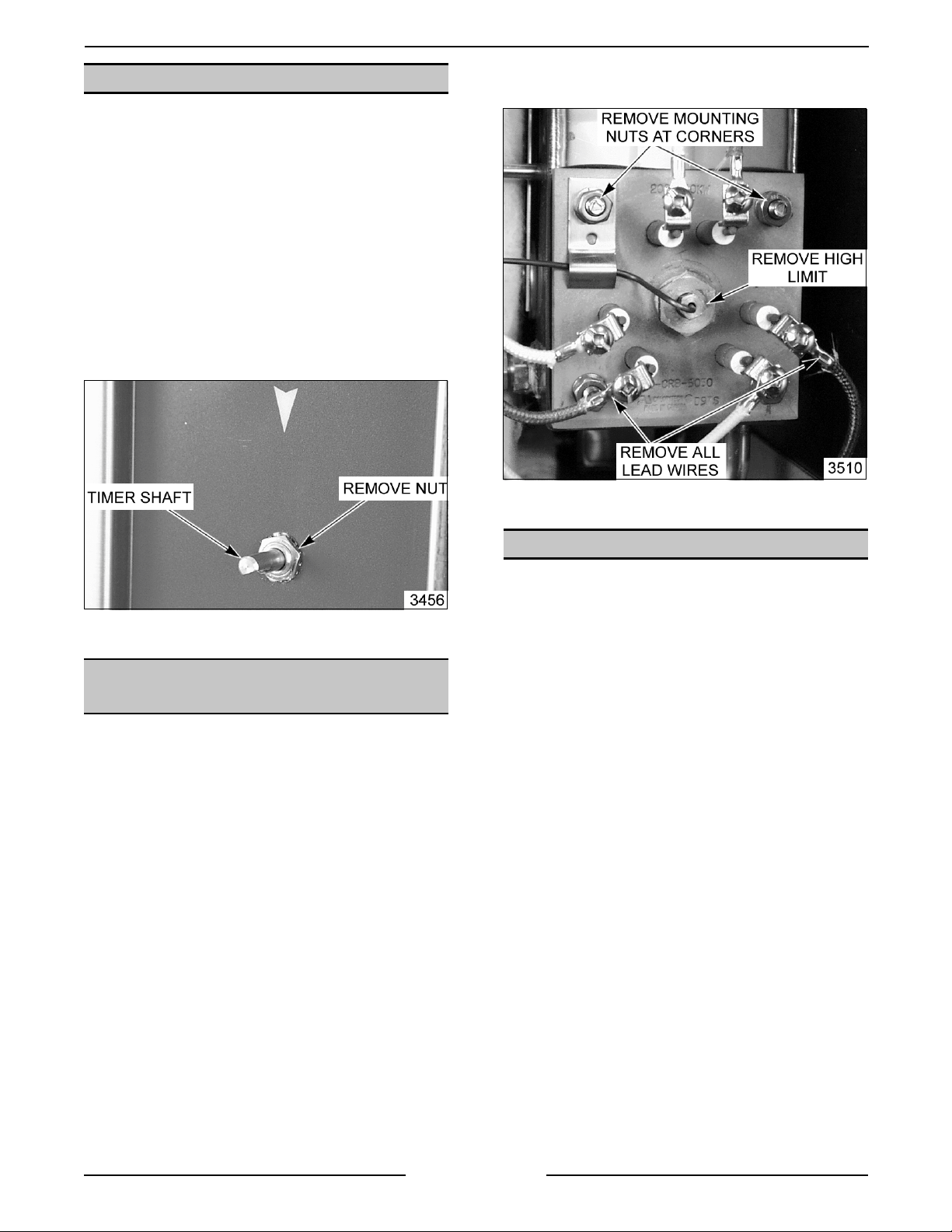

7. If r eplacing the high limit ther mostat:

A.

Electric Mo dels

1) Remove nut on capillary tube hold down

clamp.

2) Fully loosen the small capillary tube

compression nut and sl ide it away f r om

heater.

3) Remove large capillary nut from heater

base plate and slide it away from

heater.

5) Pull the bulb from its holding sleeve and

remove from the heater.

B.

Gas Model s

1) Remove t he nuts securing the

thermostat to the tank surface plate and

lift it off.

4) Remove t he r emaining nuts that secure

heater to the t ank and pull heater out

just enough to ex pose t he holding

sleeve on the element and the bulb.

NOTE:

wires together so the heating element c an be pulled

out without disconnecting the lead wires.

Cut the wire ties holding the heat er lead

8. Rev er se the procedure to install the new

thermostat and check for pr oper oper ation as

outlined under "CONTROL THE RM OSTAT

ADJUSTMENT".

Page 8 of 40

Page 9

VSX SERIES STEAMER - REMOVAL AND REPLACEMENT OF PARTS

TIMER

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the ri ght side panel as outlined under

"COVERS AND PANELS".

2. Pull timer knob from shaft.

3. Disconnect lead wires to timer.

4. Remove nut from timer shaft and remove timer

from the unit.

DISCONNECT THE ELECTRICAL

5. Remove the nuts that secur e the heater to the

tank and remove the heat er from the unit.

6. Rev er se proc edur e to install .

5. Rev er se the procedure to install.

HEATING ELEMENTS

(ELECTRIC)

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Turn “off” t he water suppl y and allow hot parts to

cool down if necessary.

2. Remove the ri ght side panel as outlined under

"COVERS AND PANELS".

3. Manuall y drain steam generator tank if

necessary, as outlined under " DRA IN TANK

MANUALLY".

4. Disconnect t he heater lead wires and rem ove

the high limit thermostat bulb fr om heater as

outlined under “THERMOSTATS”.

DISCONNECT THE ELECTRICAL

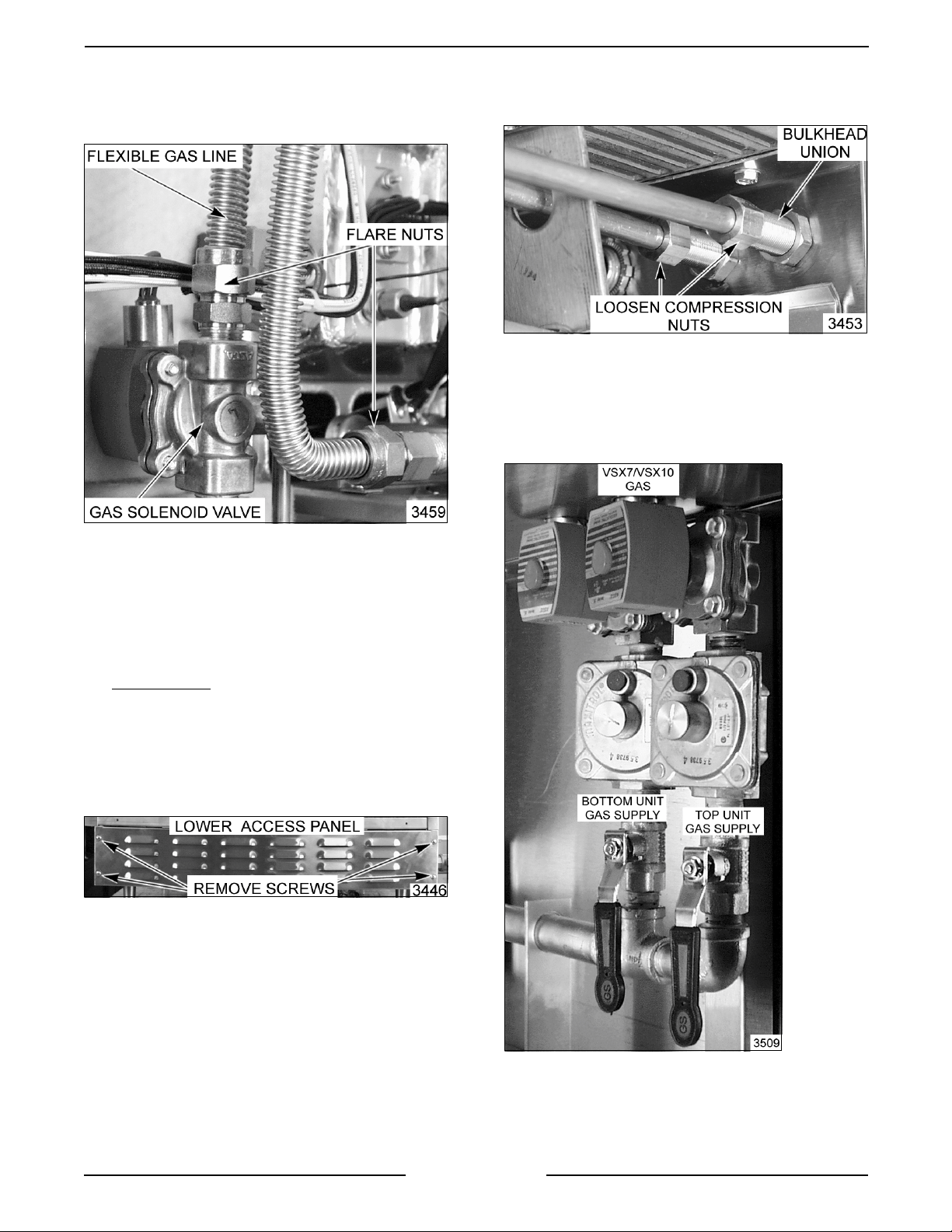

GAS SOLENOID VALVE

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

BEFORE SERVICING THE UNIT.

WARNING:

DURING SERVI CING MUST BE CHECK E D FOR

LEAKS. CHECK USING A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

A. BEFORE LIG HTING UNIT, CHECK ALL

B. CHECK ALL JOINTS BEYOND GAS

1. Remove the ri ght side panel as outlined under

"COVERS AND PANELS".

2. Cut the wire t ies around “wire bundle” and trac e

the solenoid wires to

remove.

DISCONNECT THE ELECTRICAL

SHUT OFF THE GAS SUPPLY

ALL GAS JOINTS DISTURBED

JOINTS PRIOR TO THE GAS VALVE

(SOLENOID).

VALVE (SOLENOID) AFTER THE UNIT

HAS LIT.

there terminati ons and

Page 9 of 40

Page 10

VSX SERIES STEAMER - REMOVAL AND REPLACEMENT OF PARTS

3. Loosen the compression nuts on the flexible gas

line then r emove line from the gas solenoid

valve and manif old.

B. Loosen the compression nuts on the

“condenser feed” and “tank feed” water lines

and place the l ines to the side.

NOTE:

compression nut on the “cold water condenser”

solenoid and rotate it out of the way.

6. Open the l ower cabinet base door to gain

If necessary, loosen the remai ning

access the gas solenoid valves.

(VSX5G SHOWN)

4. If r emov ing gas val ve from a single unit,

proceed to step 5. If rem oving gas solenoid

valve from a double unit, proc eed to step 6.

5. Turn “off” t he water suppl y to the “tank fill ” and

“cold water condenser” solenoi ds and

disconnect the fittings (bulkhead uni on) on the

opposite end

connections.

A. To access the compression fitt ings for the

incoming water connecti on, remove the

small access panel to the lower

compartment.

of the incoming water

7. Remove the gas solenoid valve f r om the pipe

8. Rev er se proc edur e to install and c hec k unit for

Page 10 of 40

nipple bel ow i t.

proper operati on.

Page 11

VSX SERIES STEAMER - REMOVAL AND REPLACEMENT OF PARTS

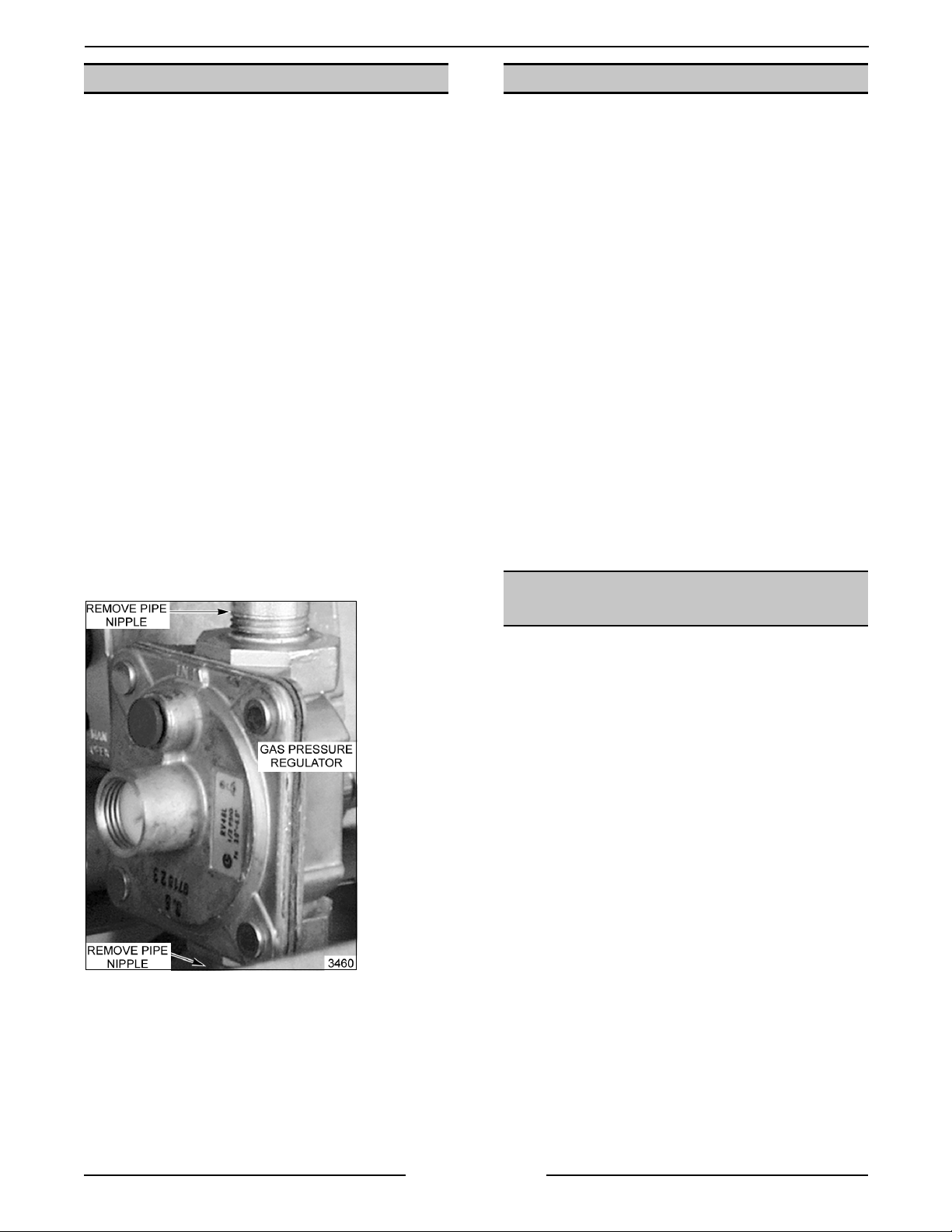

GAS PRESSURE REGULATOR

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

BEFORE SERVICING THE UNIT.

WARNING:

DURING SERVI CING MUST BE CHECK E D FOR

LEAKS. CHECK USING A SOAP AND WATER

SOLUTION (BUBBLES). DO NOT USE AN OPEN

FLAME.

A. BEFORE LIG HTING UNIT, CHECK ALL

B. CHECK ALL JOINTS BEYOND GAS

1. Remove the ri ght side panel as outlined under

"COVERS AND PANELS".

2. Remove the gas solenoid valve as outline under

“GAS SOLENOID VALVE”.

3. Remove the gas pressure regulator from the

pipe nippl e below it.

DISCONNECT THE ELECTRICAL

SHUT OFF THE GAS SUPPLY

ALL GAS JOINTS DISTURBED

JOINTS PRIOR TO THE GAS VALVE

(SOLENOID).

VALVE (SOLENOID) AFTER THE UNIT

HAS LIT.

FLAME SENSE PROBE (GAS)

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

BEFORE SERVICING THE UNIT.

1. Cut the wire t ies around “wire bundle” and trac e

the Flame Sense Probe (FSP) wir e to an in-line

splice (but t connector) and cut the wire close to

the connector.

2. Remove the screw holdi ng the flame sense

probe onto the m ounting bracket and lif t out.

3. Rev er se the procedure to install a new probe

then check FSP for proper oper ation as outli ned

under “FLAME SENSE PROBE”.

NOTE:

have t o be c ut close to the connec tor and the wire

insulation stripped back approximately 0.250 i nc h to

install a new connector.

DISCONNECT THE ELECTRICAL

SHUT OFF THE GAS SUPPLY

The opposite end of the in-line splice will

WATER LEVEL CONTROL

BOARD

4. Rev er se the procedure to install.

5. Adjust the gas regulator pressure as outlined

under “MANIFOLD PRESSURE

ADJUSTMENT”.

6. Check unit for proper operation.

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the ri ght side panel as outlined under

"COVERS AND PANELS".

2. Disconnect t he lead wires from the water level

control board (WLC) .

3. Remove mount ing screws.

4. Move board to the left and rotate outwards when

removing, t o clear wire bundle.

5. Rev er se the procedure to install, then chec k unit

for proper operation.

DISCONNECT THE ELECTRICAL

Page 11 of 40

Page 12

VSX SERIES STEAMER - REMOVAL AND REPLACEMENT OF PARTS

HOT SURFACE IGNITOR (GAS)

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

BEFORE SERVICING THE UNIT.

1. Remove the ri ght side panel as outlined under

"COVERS AND PANELS".

2. Cut the wire t ies around “wire bundle” and trac e

the wire for the Hot Surface Ignit or ( HS I) to an

in-line splice (but t connector) and cut the wire

off close to the connector.

3. Remove the screw that holds the flame sense

probe and ground terminal wire ont o the

mounti ng bracket and lift out .

4. Rev er se the pr ocedure to instal l then check HSI

for proper operation as outlined under “HOT

SURFACE IGNITOR”.

DISCONNECT THE ELECTRICAL

SHUT OFF THE GAS SUPPLY

GAS BURNER

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the ri ght side panel as outlined under

"COVERS AND PANELS".

2. Remove the screws securing the burner

mounti ng bracket to the bur ner box frame.

3. Sli de the burner for ward enough to c lear the gas

nozzles and lift it out.

DISCONNECT THE ELECTRICAL

NOTE:

have t o be c ut, close to t he c onnec tor and the wire

insulation stripped back approximately 0.250 i nc h to

install a new connector.

The opposite end of the in-line splice will

4. Remove the screws securing the burners to the

mounti ng bracket and lift t he bur ner s off.

5. Rev er se proc edur e to install then check for

proper operati on.

NOTE:

sure burner flame is not impinging on the opening of

the burner box.

When c hec king for pr oper oper ation, m ak e

Page 12 of 40

Page 13

VSX SERIES STEAMER - REMOVAL AND REPLACEMENT OF PARTS

GAS IGNITION MODULE

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the ri ght side panel as outlined under

"COVERS AND PANELS".

2. Disconnect t he c ontrol wires by pulling of f wire

harness connector locat ed on the right side of

module.

3. Remove screws that secure the m odule to the

control boar d and lif t off.

DISCONNECT THE ELECTRICAL

3. Manuall y drain steam generator tank if

necessary, as outlined under " DRA IN TANK

MANUALLY".

4. Disconnect t he lead wire fr om each water level

probe and then remove probes from tank. Mark

probes accordingl y for replac ement.

4. Rev er se the pr ocedure to instal l the new gas

ignition module then check f or pr oper oper ation.

STEAM GENERAT OR TANK

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Turn “off” t he water suppl y and allow hot parts to

cool down if necessary. On gas models, shut the

gas supply “off” to the unit.

2. Remove the ri ght side panel and top cover as

outlined under "COVERS AND PANE LS " .

DISCONNECT THE ELECTRICAL

Page 13 of 40

(

Electric Model Shown)

Page 14

VSX SERIES STEAMER - REMOVAL AND REPLACEMENT OF PARTS

5. Disconnect t he st eam lines on the top right and

left side of the tank, the water fill tube, the drain

line, then the delime li ne at the bottom left

corner.

7. Gas Model Only

A. Remove the burner assembly and place to

the side.

B. Remove the bolts that secure the manifold

to the burner box frame and place to t he

side.

C. Remove the surface high limit and the

control t hermostat bul b from the tank.

(Gas Model Shown)

6. Elect r ic Models Only - For gas models proceed

to step 7.

A. Remove the heater lead wir es, c ontrol and

high li mit thermostat bulbs, then remove the

heater fr om the tank.

B. To remove tank, loosen

side mounting stud of the tank and remove

the two nuts from the mounting studs on the

right side of the tank.

(Electric Model Shown)

the nut on the l eft

D. Remove the combination Left side and Rear

panel as outlined under “COVERS AND

PANELS”.

8. Remove the nuts and washers from studs on

each side of t he tank that secure i t to the steam

cavity and lift t he steam generator t ank out.

9. Rev er se proc edur e to install and c hec k unit for

proper operati on.

WATER LEVEL PROBES

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the top cover as outl ined under

"COVERS AND PANELS".

2. Disconnect t he lead wire to water level pr obes.

DISCONNECT THE ELECTRICAL

C. Push the r ight side of the tank toward the

rear of t he unit enough to clear the studs

from the mounting bracket t hen, pull tank

toward the right to remove.

D. Reverse the procedure to install and c heck

unit for proper operation.

Page 14 of 40

Page 15

VSX SERIES STEAMER - REMOVAL AND REPLACEMENT OF PARTS

3. Unscrew probes from steam generator tank .

(Gas Model Shown)

NOTE:

Remove all acc umulated deposi ts from the insulator

using a soft cloth.

NOTE:

insulators.

NOTE:

assembling.

Probe should be cleaned thoroughly.

Do not use anything abrasi ve on the

If t he pr obes are dirty, delime t he unit after

3. Cut the wire t ies around “wire bundle” and trac e

the power wires for the sol enoid valve being

servi ced back to there t er minations and remove.

4. Disconnect t he fittings on each side of the valve

and remove the valve from the unit.

5. Rev er se proc edur e to install .

(Electric Model)

4. Rev er se proc edur e to install .

NOTE:

outlined under "STEAM GENE RA TOR TANK

CLEANING".

Perform a steam generator tank cleaning as

FILL AND COLD WATER

SOLENOID VALVES

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Removal

1. Turn “off” t he water suppl y to the steamer.

2. Remove the ri ght side panel as outlined under

"COVERS AND PANELS".

DISCONNECT THE ELECTRICAL

(Gas Model)

Disassembly

NOTE:

removed from the unit for cl eaning to prevent

damage to the lines and fittings when the stem is

removed from the body.

1. Remove the coi l assembly from the valve stem .

2. Disconnect t he fittings on each side of the valve

NOTE:

that f its these solenoids is available, the body of the

valve might be hel d wi th vise grips and then,

remove the stem wi th your spanner wrench. If this

can be done without damaging the line or fittings,

proceed to step 5.

3. Clam p the body of the valve in a vise.

4. Mark a scri be line

It is recommended that the v alve be

and remove it from t he unit. Read note before

removing.

If a standard or adjustable spanner wrench

on the stem nut to the v alve

body for proper retightening.

Page 15 of 40

Page 16

VSX SERIES STEAMER - REMOVAL AND REPLACEMENT OF PARTS

5. Use a hammer and punc h to turn the stem

counterclockwise to remove the stem from the

body.

6. All par ts are now accessible for inspection and

cleaning.

A. Check rubber seal on bottom of plunger.

B. Check plunger spring.

DRAIN VALVE

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Removal

1. Turn “off” t he water suppl y to the steamer.

2. Remove the ri ght side panel and top cover as

outlined under "COVERS AND PANE LS " .

3. Manuall y drain the steam gener ator tank if

necessary, as outlined under " DRA IN TANK

MANUALLY".

4. Disconnect t he lead wires from the water level

control and the ground wire from the control

panel if necessary, to access the drai n valve

connections.

5. Disconnect t he fittings on each side of the valve

and remove the valve from the unit.

DISCONNECT THE ELECTRICAL

C. Check "O"ring in valve body.

D. Check por ts in valve body .

6. Rev er se proc edur e to install .

Disassembly

1. Turn “off” t he water suppl y to the steamer.

2. Remove the ri ght side panel as outlined under

"COVERS AND PANELS".

3. Manuall y drain the steam gener ator tank if

necessary, as outlined under " DRA IN TANK

MANUALLY".

7. Rev er se proc edur e to install .

4. Remove the cover f r om the drain valve m otor.

Page 16 of 40

Page 17

VSX SERIES STEAMER - REMOVAL AND REPLACEMENT OF PARTS

5. Loosen the screws from the motor assembly

and lift up on the m otor to rem ove it from the

valve body.

6. Remove the screws from the cover plate and

remove the cover plate and ball assembly from

the v alve body .

NOTE:

stem perpendi c ular to the i nlet and outlet of the

drain valve. The valve will be in the open position

whenever power is removed from t he motor.

7. Rev er se proc edur e to install .

When r e-install ing, place flat sides of ball

Page 17 of 40

Page 18

VSX SERIES STEAMER - REMOVAL AND REPLACEMENT OF PARTS

DOOR

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Removal

1. Remove top cover as outlined under "COVERS

AND PANELS".

2. Open the door.

3. Pull hinge rod up.

4. Rev er se the procedure to install, m ak ing sure

the door bushings are in place.

DISCONNECT THE ELECTRICAL

Gasket

1. Open the door.

2. Remove screws from the gasket plate.

3. Pull the gasket plate out from the door housing

and remove the gasket.

4. Positi on the new gasket on the gasket plate and

rever se t he pr oc edur e to install . Adjust the door

as outlined under "DOOR SEALING

ADJUSTMENT".

NOTE:

this will compress the gasket excessively and

interfere with proper door seal ing.

Do not ov er tighten gasket plate screws as

Page 18 of 40

Page 19

VSX SERIES STEAMER - REMOVAL AND REPLACEMENT OF PARTS

Handle

1. Open the door.

2. Remove screws from the top and bottom of the

door.

3. Pull the “inner” door panel out from the door

housing with the gasket plate and gasket stil l

attached.

Latch Assembly

1. Open the door.

2. Remove screws from the top and bottom of the

door.

3. Pull the “inner” door panel out from the door

housing with the gasket plate and gasket stil l

attached.

4. Remove the screws from the side edge of the

door that secure the latch mec hanism and

remove the lat ch from the door.

4. Remove the nuts and spacers f r om the handle

screws and remove the handle fr om the door.

NOTE:

diamet er fits into the slot in the door and the l atch

lever must rest on t op of the handle latch screw.

When installing the spacers, the smaller

NOTE:

top of t he handle latch screw.

5. Rev er se proc edur e to install .

When installing, the latch lever must rest on

5. Rev er se proc edur e to install .

Page 19 of 40

Page 20

VSX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

WARNING:

MEASUREMENTS WHILE POWER IS APPLIED TO THE MACHINE. EXERCISE EXTREME CAUTION AT ALL

TIMES. IF TEST POI NT S ARE NOT EASI LY ACCESSIBLE, DISCONNECT POWER, ATTACH TEST

EQUIPMENT AND REAPPLY POWER TO TEST .

STEAM GENERAT OR CLEANING

Follow the pr oc edur e as outlined in t he " C LR

TREATMENT KIT" to remove the

Calcium/Lime/Rust buil d- up inside the tank, water

level probes, elec tric elements and drain system .

The CLR Kit c ontains, C.L.R. c leaner, f unnel,

measuring cup, and G" tubing.

In addition but not f ur nished in kit , rubber gloves

should be used.

CERTAIN PROCEDURES IN THIS SECTION REQUIRE ELECTRICAL TEST OR

NOTE:

hrs.

Factory default time set on t he boar d is 100

DELIME BOARD OPERATION

AND ADJUSTMENT

CONTROL THERMOSTAT

The delime timer board track s the c umulative

cooking hours and lights the deli me light on the

control panel when the delime tim er boar d r eac hes

a preset number of cooking hours. A n LE D on the

delime timer board lights indicating cook time hours

are accumulating.

After the delime timer board has accumul ated the

preset number of cooking hours, the delime light will

light. It will stay lit until the power switch is moved to

the delime positi on or off. If t he power switch is

turned “off” and then t urned “on” without going t o the

delime position, the delime light will relight.

1. To adjust t he length of c ooking hours before the

delime light will come on:

2. Access the delime ti mer board.

The procedure outlined below is to adjust the

thermostat temperat ur e setting to a “ready” state

which is slight ly below a continuous boi l, (212°F) to

achieve the best “cooking” and steamer

performance.

When a c ook ing time is set on the ti mer, the delay

tim e for the steam generator to deliver a high quality

and volume of steam into t he cooking com par tment

will be minimal.

Correctl y identifying the amount of steam coming

out of t he por ts is subjective. To help determine this,

does the steam coming out of the ports exhibit the

following:

ADJUSTMENT

Position the switches in the “on” or “off” position to

obtain the desired hours. The number of switches

that are positioned “on” or “off” set the tot al hours. It

does not matter which individual switch is “on” or

“off”.

HRS 30 50 100 150 200

SWITCH

POSITION

ON 0123ALL

OFF ALL 3 2 1 0

Page 20 of 40

1. Appear to be coming out under pr essure.

2. Create a distinctive “whistling” sound during

steaming.

3. Produce a good “cloud” of steam in the cooking

compartment.

If t he steaming meets the above criteria, the

thermostat is set correctly.

1. Remove the ri ght side panel as outlined under

"COVERS AND PANELS.”

Page 21

VSX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

2. Turn the t her mostat adjustment stem full y

clockwise for a starting position.

3. Open the water valve and turn the power switch

"on.”

4. Open the steam compartment door whil e the

steam generator tank is heating up, and wait for

“drif t steam” to begin coming out of the steam

ports. Approximat e time 10 minutes.

NOTE:

until thermostat temperature is satisfied and the

“ready” li ght comes on.

5. Once “drift” steam is seen coming out of the

The door switch has no effect during preheat

steam ports, sl owly turn the thermostat

adjustment CCW until the thermostat “opens”

and the ready light comes on.

MODEL APPROXIMATE

TIME FOR STEAM

TO ENTER

COMPARTMENT

ELECTRIC 5 sec.

GAS 13 sec.

NOTE:

ready light stays “on” (heat not on) then the

thermostat is still satisfied. To shorten the wait time

until the heat comes on agai n, turn the power switch

“off” for several seconds to drai n some hot water out

of the t ank , then turn the switc h bac k “on”. At this

point, t he tank should begin filling with cold water,

bringing t he temperatur e down and causing t he

thermostat to call for heat. Repeat if nec essary.

If after inc reasing the thermostat setting, the

C. I f steam comes out of t he por ts like the

steamer was in a “cooki ng mode” and the

ready light never c omes on, the set point

temperat ure is too high. P r oc eed to step D.

D. Adjust the setting 1/8 of a turn CCW to

decrease temperature set point and repeat

step 6 until st eam exi ts the ports in the time

listed.

E. If steam comes out of the ports in the time

listed above, then t hermostat i s set

correctly.

F. After adjusting the thermostat to it s hi ghest

setting and steam does not come out of the

ports as described, then replace the

thermostat.

DRAIN TANK MA NUALLY

NOTE:

ports along with “drift” steam, then the tank water

has reached too high of a temperature and is

boili ng. The thermostat setting must be adjusted

down as indicated above.

6. With the door still open, set a time on the cook

If water begins to drip “heavily” out of steam

tim er and depress the door switch button.

Immediately after depr essing t he door switc h

button, begi n c ounting the seconds until steam

is “seen” coming out of the ports.

A. If i t takes longer than t ime listed in the char t

below, the thermostat setti ng is too low and

must be increased. Proceed to step B.

B. Adjust the setting 1/8 of a t ur n CW to

increase the set poi nt temperat ur e and

repeat step 6 until steam exits the ports i n

the time listed.

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Turn “off” t he water suppl y to the steamer.

2. Remove the ri ght side panel as outlined under

3. Remove the cover f r om the drain valve m otor

4. Loosen the screws from the motor assembly

5. Turn the stem of the dr ain valve so t hat it is

Page 21 of 40

DISCONNECT THE ELECTRICAL

"COVERS AND PANELS".

as outlined under “DRAIN VALVE”.

and lift up on the m otor to rem ove it from the

valve body.

perpendicular to the inlet and outlet lines. Thi s

should drain the tank unless the drain l ine is

clogged.

Page 22

VSX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

DOOR SEALING ADJUSTMENT

1. Check the door gasket quality. If damaged or

worn, replace as outl ined under “DOOR”.

2. Loosen screws until the screw heads no longer

touch the gasket plate.

3. Tight en scr ews until screw head touches gasket

plate and at t hat point begin counting turns.

4. Tight en all screws approximately two turns.

5. Close the door and check unit for proper

operation.

6. If nec essary, tighten all screws an additional ½

turn and repeat step 5.

7. Repeat step 6 unti l the door cl oses properl y and

no steam “leaks” are seen around the gasket

seal.

DOOR LATCH ADJUSTMENT

Should the cooker door jam and c an not be opened,

DO NOT FORCE OR PRY

occur.

the door as damage wil l

To ad just

1. Reinstall the strik er with the slot pointing

2. Close the door to c enter the strik er in the oval

3. Open the door and chec k the strikers’ sl ot for

:

upwards and “hand tighten” nut onl y .

mounti ng hole.

horizontal alignment. The slot on the striker

must be kept hor izontal in order for the door

latch to c atch it proper ly and latch.

First, try lifting up on the bottom of the door at the

handle end, to disengage the latch.

If t hat does not work, remove the right side panel.

The striker that catches on the “door latch” is

located behi nd the front face of the cooking cavit y .

Remove the nut from the striker and thi s will release

it from the panel.

Once the nut and washer have been removed, door

will open freely.

Remove any burrs on the stri k er that may cause the

latch to stick.

Reinstall the striker and adjust, so door will not jam.

4. Once the proper slot alignment has been set,

hold the striker close to i ts base using a rag and

vise grips, then tighten the strik er nut. Be

careful not to damage the striker “slot” when

tightening or door may not latch properly.

NOTE:

to turn and change al ignment.

Do not over tighten as the striker will begin

Page 22 of 40

Page 23

VSX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

MANIFOLD PRESSURE

ADJUSTMENT

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

BEFORE SERVICING THE UNIT.

1. Remove right side panel as outli ned under

"COVERS AND PANELS".

2. Remove the 1/4" NP T pipe plug from the

manifold and att ac h a manomet er .

3. Remove the adjustment screw cap to access the

pressure adjustment screw.

A. To increase pressure, turn the screw

B. To decrease pressure, turn the screw

DISCONNECT THE ELECTRICAL

SHUT OFF THE GAS SUPPLY

clockwise

counterclockwise

minimum st ated, then the manifold pressure can not

be set correctly.

6. Once the cor rect pressure has been set, turn the

power switch “off”, replace t he adjustment

screw cap and manifold pipe plug.

7. Check unit for proper operation.

4. Plug i n the unit, t urn “on” the gas and set the

power switch to “on”. If adjusting pressure on a

double unit, both must be “on” before a pressure

adjustment is made.

NOTE:

Accurate gas pressure adjustments can only

be made with the gas “ON” and the burner lit.

5. After the burner lights, set the pressure as

outline below:

PRESSURE READINGS

(INCHES W.C.)

GAS TYPE MANIFOLD

NATURAL 3.5 7.0 5.0

PROPANE 5.0 11.0 7.0

RECOMMENDED MIN MAX

* If t he incomi ng line pressure is

LINE

less than

the

14

Page 23 of 40

Page 24

VSX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

FLAME SENSE PROBE (GAS)

WARNING:

POW E R TO BE APPLIED TO THE UNI T DURING

THE TEST. USE EXTREME CAUTION AT ALL

TIMES.

1. Assure that the unit has a proper ground, correc t

polarit y and that the value of incom ing voltage

is correct.

A. Check the flame sense voltage (burner on)

THE FOLLOWI NG ST EPS REQUIRE

between the fl ame sense lead wire

termination i n the ignition module edge

connector and ground wit h a V OM set on

DC volts. The voltage measurement wil l

fluc tuate but should be no l ess than 20

VDC.

2. Perf or m a v isual check to determine if the flame

sense probe is in the upper portion of flame. If

the probe is bent or not in the upper port ion of

the flame then check for alignment and adjust

as necessary.

A. The center line of the pr obe shoul d be

approximately 1 15/16 inches from the f ac e

of the burner and 5/16 inches up fr om the

center line of the bur ner .

B. If voltage is less than indicat ed, replace

flame sense probe and check unit for proper

operation.

3. If no adjustments can be made to the probe to

correct its alignment then replac e and c hec k

unit for proper operation.

Page 24 of 40

Page 25

VSX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

HOT SURFACE IGNITOR (GAS)

1. Check to see if hot surface ignitor is operating

during

A. Visual verificati on - HS I should be heating

B. Voltage verification - check f or 24V A C to

ignition trial

up “glowing brightly” to ignite gas.

HSI termination on the edge connector to

ground.

by:

HEATING ELEMENT (ELECTRIC)

WARNING:

POW E R TO BE APPLIED TO THE UNI T DURING

THE TEST. USE EXTREME CAUTION AT ALL

TIMES.

1. Check voltage at the heating element terminals.

A. If voltage is correct then proc eed to step 2.

B. If voltage is not correct, c hec k the following:

2. Check current draw (amps) through the heat ing

element lead wires using an amp clamp meter.

A. If curr ent draw is correct then heating

B. If curr ent draw is not correct then proceed to

THE FOLLOWI NG ST EPS REQUIRE

1) Voltage supply to the unit.

a. Fuses or breaker blown.

b. Power to contactor coils.

c. Contactors not pulling in.

(Mechanical)

element is ok.

step 3.

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

2. Unplug the edge connec tor from the ignition

module and chec k resistance between HSI lead

wire and ground.

CONDITION

COLD 1 - 4

DISCONNECT THE ELECTRICAL

HSI

HOT 8 - 10

RESISTANCE

(approx. Ohms)

3. Remove the lead wires from the heating

element and c heck the element resistance using

a VOM.

A. If resistanc e r eadings are not correct ,

replace heating element.

4. Check unit for proper operation.

AMPERAGE

VOLTAGE

208 7.5 36.1 20.9 17.4

240 7.5 31.3 18.1 23.1

480 7.5 9.0 30.6

208 10 48.1 27.8 12.96

240 10 41.7 24.1 17.28

480 10 12.1 23.01

208 15 72.2 41.6 8.64

240 15 62.5 36.2 11.52

480 15 18.1 15.36

TOTAL

KW

PER LINE

1 PH 3 PH

RESISTANCE

PER LINE

(OHMS)

NOTE:

+5/-10 %.

Page 25 of 40

Values in the table are nominal. Tolerance is

Page 26

VSX SERIES STEAMER - ELECTRICAL OPERATION

ELECTRICAL OPERATION

COMPONENT FUNCTION

1A Delime Timer Board

Buzzer

1CON & 2CON

Heater Contactor

1-3HTR Heaters

1K Relay

2K Relay

3K Relay

1T

2T

Ignition Module

................. Signals end of cook cycle, must be t urned “off” manually .

.......... Heat water in Steam Generator tank . (electr ic model s onl y )

............... Suppli es power to control cir c uit when steam is bei ng gener ated and the tank

............... Prevents operation of the cook timer until initial fill and heat is complete.

............... Operates drain motor and resets delime timer board when the power switch is

.................... Provides 12VAC power to the delime board.

.................... Provides 24VAC power to ignition control module and HSI. (gas models only)

......... Controls and monit ors gas heating. Applies power to HSI for burner igniti on,

. . . Tracks the cumulative cooking hours by using a cur r ent sensor to monitor

current flow through the cold water condenser solenoid lead, then signal’s

operator to perform delime pr oc edur e after the steamer has operated in cook

mode f or a preset number of hours.

......... Controls power to tank heaters. (electric models only)

water level drops below the low level pr obe.

moved to the delime position.

monit ors flame presence through FSP, c ontrols 5 second purge time and 8.5

second ignition trial tim e and powers gas solenoid valve. (gas models only)

1LT Read y Light

2LT Delime Light

3LT Cook Light

4LT Ignition Light

High Level Probe

Low Level Probe

Low Level Cut Off Probe

FSP (Flame Sense Probe)

HSI (Hot Surface Igni t er)

1M Drain Mot or

......... Indicates steam generator tank is up to tem per ature and cooking can begin.

........ Indicates preset number of cook time hours have accumulated and the tank

.......... Indicates cook timer has been set and a cook cycle is in process.

........ Indicates gas burner is on. (gas models only)

......... Monitors tank water level and signals the WLC when tank is full.

......... Keeps the WLC relay coil HL energiz ed when the water level drops below the

.......... Controls the tank drain. (normally open valve, water flows when de-energized)

should be delimed.

high level probe.

. . . Monitors tank water level and r emov es el ec trical power to the LLCO relay when

the water level drops below the low level cut off probe.

. . Supplies a current signal back to the igniti on module indicating t he pr esence of a

flame. (gas models only)

. . When Ignition module applies power, the el ement heats up to very high

temperat ures causing gas igniti on. (gas models only)

Page 26 of 40

Page 27

VSX SERIES STEAMER - ELECTRICAL OPERATION

1S Power Switch

2S Door Switch

1SOL Fill Solenoid

2SOL Cold Water Solenoid

GAS Valve Solenoid

1TAS High Limit

Thermostat

2TAS Control Th ermostat

1TR Timer

........ Controls electrical power to the control circuit and delime c ircuit.

.......... Removes electrical power to the timer when the door is opened and the control

....... Controls tank water supply. (normall y c losed val ve, water flows when energized)

...... Allows gas flow to burner when solenoid i s energized. A normally closed val ve.

............. Will not allow heater contactor (on elect r ic model s) or igniti on module (on gas

.............. On electric models it contr ols the cold water solenoi d and power t o the heater

thermostat is open.

. Controls cold water supply going into drain to mi x and condense exhaust steam .

(normally closed valve, water flows when energized)

(gas models only )

models) t o ener gize if the tank temperature goes beyond 125°C (257(F).

. . On electric models it cycles power to heater contactors. O n gas m odels it cycles

power to the igni tion control module. On either model, this will maintain the

steam generator tank set point temperature, when no time is on cook t imer.

contactors. On gas models it c ontrols the cold water solenoid and power to the

ignition control module. T his occurs on either model after the tank reaches its set

point temperature and time is di aled into the timer. Also, energiz es the buz zer

when time expires.

WLC (Water Level

Control Board)

........... Monitors water level probes to control the tank water level and heater c ontactors.

Individual LE D’s on board light up when water level reaches LLCO and t hen HL

probes. W hen water level drops below one of these probes, LED goes out.

Page 27 of 40

Page 28

Electric Models

VSX3E, 4E & 5E

VSX SERIES STEAMER - ELECTRICAL OPERATION

COMPONENT LOCATION

VSX7E & 10E

Page 28 of 40

Page 29

Gas Models

VSX5G

VSX SERIES STEAMER - ELECTRICAL OPERATION

VSX 7G & 10G

Page 29 of 40

Page 30

VSX SERIES STEAMER - ELECTRICAL OPERATION

WATER LEVEL CONTROL OPERATION

The water level cont r ol (WLC) has line voltage acr oss terminals 11 and 12 which powers the pri mary side of the

transformer. The secondary si de of the transformer provides power to t he c ontrol by a series path t hr ough

chassis ground; through the water in the steam generat or tank; through the water level probes; to the i nternal

relay coils on the control. The other side of the secondary windi ng is attached to t he c ontrol that directs the power

to the other side of the internal rel ay c oils. As water enters the t ank , the water becomes part of the ci r c uit. As the

water level reaches the probes, t he c ircuit with that particular probe is completed to the water level contr ol, thus

energizing the internal relay coi l. LED’s on the board f or LLCO and HL relays will illuminate as the water level

reaches each of these probes. When the water level drops below the LL probe, the HL relay LED will go out until

the water level reaches the HL pr obe again. This LED will go on and off during a cook cycle as the tank water

level raises and lowers. The LLCO LE D will only go out if the water level drops below the low level probe.

ELECTRIC MODEL S

INITIAL FILL & PREHEAT

1. Conditions.

A. Unit connected to correct voltage.

B. Supply water valve "on".

C. Power switch "off".

D. High limit thermostat closed.

E. Control Thermostat closed.

F. Drain open and steam generator tank

(referred to as tank) empty.

G. Door closed.

SEQUENCE OF OPERATION

H. Timer "off".

I. Tank and WLC pr oper ly grounded. (share

comm on ground)

2. Power switch turned "on".

A. L1 vol tage to one side of 1M ; Pin 11, WLC;

1SOL, 1K; 2K; 1CON; 2CON; 2LT; 2SOL;

BUZZER; TM.

B. L3 vol tage to one side of 1M , drain motor;

pins 4,8 & 12 of water level control.

1) 1M drain motor ener gized; drain valve

closed.

2) 1SO L ener gized thru HL-2; Water flows

to tank.

3. Water reaches LLCO probe.

Page 30 of 40

Page 31

VSX SERIES STEAMER - ELECTRICAL OPERATION

A. LLCO energizes.

1) Contac ts LLCO-1 open; LLCO-2 close.

2) LLCO LE D lights.

4. Water reaches LL (Low Lev el) probe.

5. Water reaches HL (High Level) pr obe.

A. Internal relay HL energizes.

B. HL LED lights.

C. I nternal relay c oil HL lock s thr ough HL- 1.

6. 1SOL de-energized; water f low off.

A. After the initial fill, the water level is

maint ained by 1SOL bei ng ener gized when

the water level drops below the LL probe

and being de-energi z ed when the water

level reaches the HL probe. This will not

affect operati on of either the preheat or

cook cycle due to 1K being energized and

locked during the initial fill.

B. 1K energized and loc k s 1K coil when 1K

NO/C close.

C. 2K ener gized thru 2TAS , 1K-NO/C, WLC-

LLCO-2.

D. 1CO N and 2CON energized thru 2K -2

NO/C, 2TAS, 1K-NO/C, WLC-LLCO-2.

7. Heaters are energi z ed.

8. Tank temperature reaches set poi nt.

A. 2TAS opens.

9. 2K de-energiz ed.

A. 1CON & 2CON de-energi z ed.

B. Heaters de-energized.

C. 1LT r eady light energized thru 1CON &

2CON coils to indicate tank is at hold

temperat ure. 1LT uses bleed through

voltage.

10. Tank temperature drops below set point.

A. Tank temper ature is mai ntained by the

heaters cycling with control thermostat

2TAS unti l time is dialed on the tim er , water

level drops below the low level c ut-off probe

or the power switch is turned “off”.

B. 1LT ready li ght goes out.

11. Water level drops below LL probe.

A. Internal relay HL de-energized, contacts HL-

1 open; HL-2 close; HL- 3 open.

1) Power is removed from the heating and

cooking circuits.

COOK CYCLE

1. Cook cycle can not start until the initial fill and

preheat is completed and the door is closed.

A. 2K-1 (NC/C) contac ts are open during

preheat and will prevent operation of the

tim er, buzzer, 2SOL and 2LT.

2. Ready li ght lit.

A. Product is insert ed into steamer .

B. Door is closed.

C. T ime is di aled on the timer.

3. Contacts 1/3 of timer close.

A. 1CON and 2CON are energiz ed by the

closing of 1TR 1/3 contacts and thru 2K-2

NC/C contacts.

NOTE:

Heaters are not contr olled by 2TAS and

are on continuously duri ng the cook cycle.

B. Ready light goes out.

C. Cook light l ights.

D. 2SOL energized and water flows to drain to

condense steam.

E. Timer motor energi z ed.

F. Del ime timer board begi ns to monitor

cooking hours.

4. Time expir es on t imer.

A. Timer c ontacts 1/3 open, 2LT de-energized.

B. Timer c ontacts 4/1 close and energize

buzzer until manual ly turned "off".

C. T imer motor de-energized.

D. 2SOL de-energized and water i s shut off

from drain.

E. 1CON and 2CON de-energiz ed and ar e

controlled by 2TAS.

5. Steamer reverts to preheat cycle until ti me is

dialed i nto timer and the door is shut, water

level drops below low level cut - off pr obe or the

power switch is turned "off".

WATER REFILL (AFTER INITIAL FILL)

NOTE:

This water refill cycle will not affect

operation of either the preheat or cook cycle due to

1K being energized and locked duri ng the initial f ill.

1. Water level drops below l ow level pr obe ( LL) .

A. WLC internal coil HL de-energiz ed.

1) WLC contacts HL-3 open.

2) WLC contacts HL-2 close.

2. 1SOL energi z ed, water fl ows.

3. Water reaches LL (Low Lev el) probe.

A. Power to pin 2 of water level control.

4. Water reaches high level probe.

A. Internal coil HL of water level control is

energized.

1) WLC HL-2 opens.

2) WLC HL-3 cl oses.

3) WLC HL-1 cl ose.

5. 1SOL de-energized.

6. The water refill cycle will occur whenever the

water level is below the low level probe.

Page 31 of 40

Page 32

VSX SERIES STEAMER - ELECTRICAL OPERATION

DELIME CYCLE

1. Steamer is in a cook cycle where the delime

board monitors the cook ti me.

2. Delime light comes on.

A. Cook cycle ends and product removed.

3. Power switch turned to delime posi tion.

4. 3K energized.

A. Contacts 3K-1 NO close.

B. 1M energized and drai n c loses.

C. Delime board transform er energized.

D. Cont ac ts 3K-1 NC open.

E. Contacts 3K-2 NO close.

1) Delime time is reset to “0".

5. Turn steam er off and perform delime procedure.

GAS MODELS

INITIAL FILL & PREHEAT

1. Conditions.

A. Unit connected to correct voltage.

B. Supply water valve "on".

C. G as supply valve “on”.

D. Power switch "off".

E. High limit t her mostat closed.

F. Contr ol Thermostat closed.

G. Drain open and tank empty.

H. Door c losed.

I. Timer "off".

J. Tank and WLC properl y gr ounded ( share

comm on ground).

2. Power switch turned "on".

A. L1 (120VAC) to one side of 1M; Pin 11,

WLC; 1SOL, 1K; 2K; 2LT; 2SOL; BUZZER;

TM; 1T whic h in turn supplies 24VAC to one

side of Ignition Module, TH, 4LT and Gas

Valve.

B. NEUTRAL (120VAC) t o one si de of 1M,

drain motor; pins 4,8 & 12 of water level

control.

1) 1M drain motor ener gized; drain valve

closed.

2) 1SO L ener gized thru HL-2; Water flows

to tank.

3. Water reaches LLCO probe.

A. LLCO energizes.

1) Contac ts LLCO-1 open; LLCO-2 close.

2) LLCO LE D lights.

4. Water reaches LL (Low Lev el) probe.

5. Water reaches HL (High Level) pr obe.

A. Internal relay HL energize.

B. HL LED lights.

C. I nternal relay c oil HL lock s thr ough HL- 1.

6. 1SOL de-energized; water f low off.

A. After the initial fill, the water level is

maint ained by 1SOL bei ng ener gized when

the water level drops below the LL probe

and being de-energi z ed when the water

level reaches the HL probe. This will not

affect operati on of either the preheat or

cook cycle due to 1K being energized and

locked during the initial fill.

B. 1K energized and loc k s 1K coil when 1K

NO/C close.

C. 2K ener gized thru 2TAS , 1K-NO/C, WLC-

LLCO-2.

D. I gnition Module energized thru 2K -2 NO/C,

2TAS, 1K-NO/C, WLC-LLCO-2.

7. After the igni tion module is energized, igniti on

trial cycle begins.

A. Module purges for 5 seconds to allow time

for any residual gas to dissipate. A fter purge

tim e elapses, HSI begins a 3 second heat

up tim e.

B. When HSI heat up time elapses, the gas

solenoid valve opens to supply gas to the

hot ignitor.

C. Burner will light, flame sense probe detects

flame, HSI de-ener gizes after an 8.5 second

ignition trial time, gas valve stays open and

heating begins.

8. Tank temperature reaches set poi nt.

A. 2TAS opens.

9. 2K de-energiz ed.

A. Igniti on M odule de-energized.

1) Burner s off.

B. 1LT ready li ght energized, indicating tank is

at hold temperature. 1LT uses bleed through

voltage.

10. Tank temperature drops below set point.

A. Tank temper ature is mai ntained by the

burners cycling with control thermostat

2TAS unti l time is dialed on the tim er , water

level drops below the low level c ut-off probe

or the power switch is turned “off”.

B. 1LT ready li ght goes out.

11. Water level drops below LL probe.

A. Internal relay HL de-energized, contacts HL-

1 open; HL-2 close; HL- 3 open.

1) Power is removed from the heating and

cooking circuits.

Page 32 of 40

Page 33

VSX SERIES STEAMER - ELECTRICAL OPERATION

COOK CYCLE

1. Cook cycle can not start until the initial fill and

preheat is completed and the door is closed.

A. 2K-1 (NC/C) contac ts are open during

preheat and will prevent operation of the

tim er, buzzer, 2SOL and 2LT.

2. Ready li ght lit.

A. Product is insert ed into steamer .

B. Door is closed.

C. T ime is di aled on the timer.

3. Contacts 1/3 of timer close.

A. Igniti on module is energized by the closing

of 1TR 1/ 3 c ontacts and thru 2K-2 NC/C

contacts. The ignition trial cycle begi ns,

burners come on.

NOTE:

Ignition module power i s not c ontrolled

by 2TAS during a cook cycle therefore the

burners will stay on continuously duri ng

cooking.

B. Ready light goes out.

C. Cook light l ights.

D. 2SOL energized and water flows to drain to

condense steam.

E. Timer motor energi z ed.

F. Del ime timer board start s monitoring

cooking hours.

4. Time expir es on t imer.

A. Timer c ontacts 1/3 open, 2LT de-energized.

B. Timer c ontacts 4/1 close and energize

buzzer until manual ly turned "off".

C. T imer motor de-energized.

D. 2SOL de-energized and water i s shut off

from drain.

E. Igniti on M odule de-energized and is

controlled by 2TAS.

F. Del ime timer board stops monitoring

cooking hours.

5. Steamer reverts to preheat cycle until ti me is

dialed i nto timer and the door is shut, water

level drops below low level cut - off pr obe or the

power switch is turned "off".

WATER REFILL (AFTER INITIAL FILL)

A. Power to pin 2 of water level control.

4. Water reaches high level probe.

A. Internal coil HL of water level control is

energized.

1) WLC HL-2 opens.

2) WLC HL-3 cl oses.

3) WLC HL-1 cl ose.

5. 1SOL de-energized.

6. The water refill cycle will occur whenever the

water level is below the low level probe.

DELIME CYCLE

1. Steamer is in a cook cycle where the delime

board monitors the cook ti me.

2. Delime light comes on.

A. Cook cycle ends and product removed.

3. Power switch turned to delime posi tion.

4. 3K energized.

A. Contacts 3K-1 NO close.

B. 1M energized and drai n c loses.

C. Delime board transform er energized.

D. Cont ac ts 3K-1 NC open.

E. Contacts 3K-2 NO close.

1) Delime time is reset to “0".

5. Turn steam er off and perform delime procedure.

NOTE:

This water refill cycle will not affect

operation of either the preheat or cook cycle due to

1K being energized and locked duri ng the initial f ill.

1. Water level drops below l ow level pr obe ( LL) .

A. WLC internal coil HL de-energiz ed.

1) WLC contacts HL-3 open.

2) WLC contacts HL-2 close.

2. 1SOL energi z ed, water fl ows.

3. Water reaches LL (Low Lev el) probe.

Page 33 of 40

Page 34

VSX SERIES STEAMER - ELECTRICAL OPERATION

SCHEMATIC ELECTRIC STEAMERS

Page 34 of 40

Page 35

VSX SERIES STEAMER - ELECTRICAL OPERATION

WIRING DIAGRAM ELECTRIC STEAMERS

Page 35 of 40

Page 36

VSX SERIES STEAMER - ELECTRICAL OPERATION

SCHEMATIC GAS STEAMERS

Page 36 of 40

Page 37

VSX SERIES STEAMER - ELECTRICAL OPERATION

WIRING DIAGRAM GAS STEAMERS

Page 37 of 40

Page 38

VSX SERIES STEAMER - TROUBLESHOOTING

TROUBLESHOOTING

ALL MODELS

WARNING:

MEASUREMENTS WHILE POWER IS APPLIED TO THE MACHINE. EXERCISE EXTREME CAUTION AT ALL

TIMES. IF TEST POI NT S ARE NOT EASI LY ACCESSIBLE, DISCONNECT POWER, ATTACH TEST

EQUIPMENT AND REAPPLY POWER TO TEST .

CERTAIN PROCEDURES IN THIS SECTION REQUIRE ELECTRICAL TESTS OR

SYMPTOM POSSIBLE CAUSES

Compartment leaks water around door. 1. Unit not level.

2. Drain l ine obstructed or not to an open gap drain.

Cold water condenser not operat ing

properly.

Steam leaks around door. 1. Worn gasket - See “DOOR” in “SERVICE PROCEDURES

Steam generated inside compartment

when timer is off .

Steam leaking insi de shel l. 1. Tank gasket not sealing.

Heat coming on without water in tank. 1. Dirty high level probe (shorted t o gr ound) .

1. 2SOL inoper ative or plugged.

2. Lack of water supply.

AND ADJUSTMENTS”.

2. Damaged gasket.

3. Drain l ine obstructed or not to an open drain.

1. 2TAS cont r ol therm ostat malfunction or not adjusted.

2. Loose steam line.

2. Retenti on of water in probe guar d.

3. 1K stuck closed.

4. WLC-5/8 stuck cl osed.

Unit will not heat (Ready li ght off). 1. Check incoming voltage.

2. Tank not filled.

3. Power switch malfunction.

4. Water Level Control malfunction.

5. 1K inoperat ive.

6. High limit thermostat open (1TAS).

7. Heating element i noperative (elect r ic only).

8. 1CON or 2CON malf unc tion.

9. Control thermostat open ( 2TAS).

10. Relay 2K malfunction.

11. Water too “pure” for pr obes to pr oper ly conduct el ec trici ty.

Unit leak s water. 1. Loose water, steam or dr ain line connec tions.

Tank water level too high. 1. Fill solenoid 1SOL does not shut of f.

2. High level pr obe malfunction (open circuit).

3. Water level cont r ol inoperative ( WLC).

Page 38 of 40

Page 39

VSX SERIES STEAMER - TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSES

Tank does not fill. 1. Water supply not on.

2. Fill solenoid 1SOL not openi ng or plugged.

3. Water level cont r ol malfuncti on ( WLC).

4. Water level probes shorted t o gr ound.

Tim er motor does not run. 1. Door open or door switch 2S inoperative.

2. 2K-1 NC/C cont ac ts not closing.

3. Timer inoperative.

Water running out of drain during fill or

when the power switch 1S is off.

Delime light does not r eset after power

switch has been moved to de-lime

position.

Delime tim er board LED is not lit when

tim e is dialed i nto cook timer.

Delime light does not light after pre-set

tim e. (Delime timer board LED lights.)

Door not closi ng pr oper ly. 1. D oor latch assembly.

Door won’t open. 1. Latch won’t release see “DOOR LA TCH ADJUSTMENT ” in

Buzzer not operating. 1. Timer mal function.

1. 1SOL stuck open.

2. 2SOL stuck open.

1. Relay 3K-2 open.

2. Delime timer board malfunct ion.

1. NC contacts of 3K-1 open.

2. Transfor mer inoperative.

3. Current sensor malfunct ion.

4. Delime timer board malfunct ion.

1. Delime light open.

2. Delime timer board malfunct ion.

2. Stri k er adjustment .

“SERVICE PROCEDURES AND ADJUSTMENTS”.

2. Buzzer malfunc tion.

Page 39 of 40

Page 40

VSX SERIES STEAMER - TROUBLESHOOTING

GAS MODELS ONLY

SYMPTOM POSSIBLE CAUSES

Burner won’t light. 1. Gas not “on”.

2. Low incoming gas pressure.

3. HSI not operating see “HOT SURFACE IGNITOR” in

“SERVICE PROCEDURES AND ADJUSTMENTS”.

4. Unit not pr operly grounded and/or polarity of incoming power

is incorrect.

5. Ignit ion module not receiving power. Check 2T for 24VAC

output to module.

6. Ignit ion module malfunctioning.

Burner won’t stay li t. 1. Gas pressure low see “GAS PRESSURE ADJUSTMENT” in

“SERVICE PROCEDURES AND ADJUSTMENTS”.

2. Check position of flame sense probe see “FLAME SENSE

PROBE” in SERVICE PROCEDURES AND

ADJUSTMENTS”.

3. Flame sense probe malfunction.

4. Ignit ion module malfunction.

5. Check gas orifice for obstructi on.

HSI heats up but gas will not light. 1. Gas supply is off.

2. Gas v alve ( solenoid) malfunct ion.

3. Ignit ion module not receiving power. Check 2T for 24VAC

output to module.

4. Ignit ion module malfunction.

Form 24618 (R ev. A, March 2000) Printed in U.S.A.

Loading...

Loading...