Page 1

The Choice of Experience

INSTRUCTION MANUAL

A Product of Berkel

VSPH VEGETABLE SLICER

ML-136212

Troy, OH

Form 35007 Rev. A (December 2009)

Page 2

TABLE OF CONTENTS

GENERAL ............................................................................................................................................. 3

INSTALLATION ..................................................................................................................................... 3

Unpacking ........................................................................................................................................ 3

Back Case ....................................................................................................................................... 3

Feed Hopper .................................................................................................................................... 3

Adjustable Slicer Plate Unit ............................................................................................................. 4

Shredder Plate and Plate Holder ..................................................................................................... 4

Grater Plate and Plate Holder ......................................................................................................... 5

OPERATION .......................................................................................................................................... 5

Using the Vegetable Slicer .............................................................................................................. 5

CLEANING ............................................................................................................................................ 6

Immediately After Use ..................................................................................................................... 6

MAINTENANCE .................................................................................................................................... 7

Service ............................................................................................................................................. 7

TROUBLESHOOTING .......................................................................................................................... 7

– 2 –

Page 3

Installation, Operation and Care of

Vegetable Slicer Attachment

SAVE THESE INSTRUCTIONS

GENERAL

The Vegetable Slicer uses are many and varied: cutting cabbage for salads and cole slaw, slicing potatoes

ranging in thickness from that of a potato chip to

vegetables and fruits, and shredding or grating cheese, raw carrots, beets, etc.

The food is sliced by stainless steel scimitar knives for fast, clean, uniform cutting. The front of the Vegetable

Slicer is hinged at one side, and can be swung aside or removed, permitting quick and easy changing of

plates and cleaning.

The Vegetable Slicer Attachment includes back case, feed hopper, plate holder and

Optional accessories are the adjustable slicer plate and other size shredder plates and a grater plate.

The Vegetable Slicer may also be used with Power Drive units.

5

⁄8", slicing nuts, bananas, cucumbers, celery and other

3

/16" shredder plate.

INSTALLATION

UNPACKING

Immediately after unpacking the vegetable slicer, check for possible shipping damage. If the vegetable slicer

is found to be damaged, save the packaging material and contact the carrier within 15 days of delivery.

BACK CASE

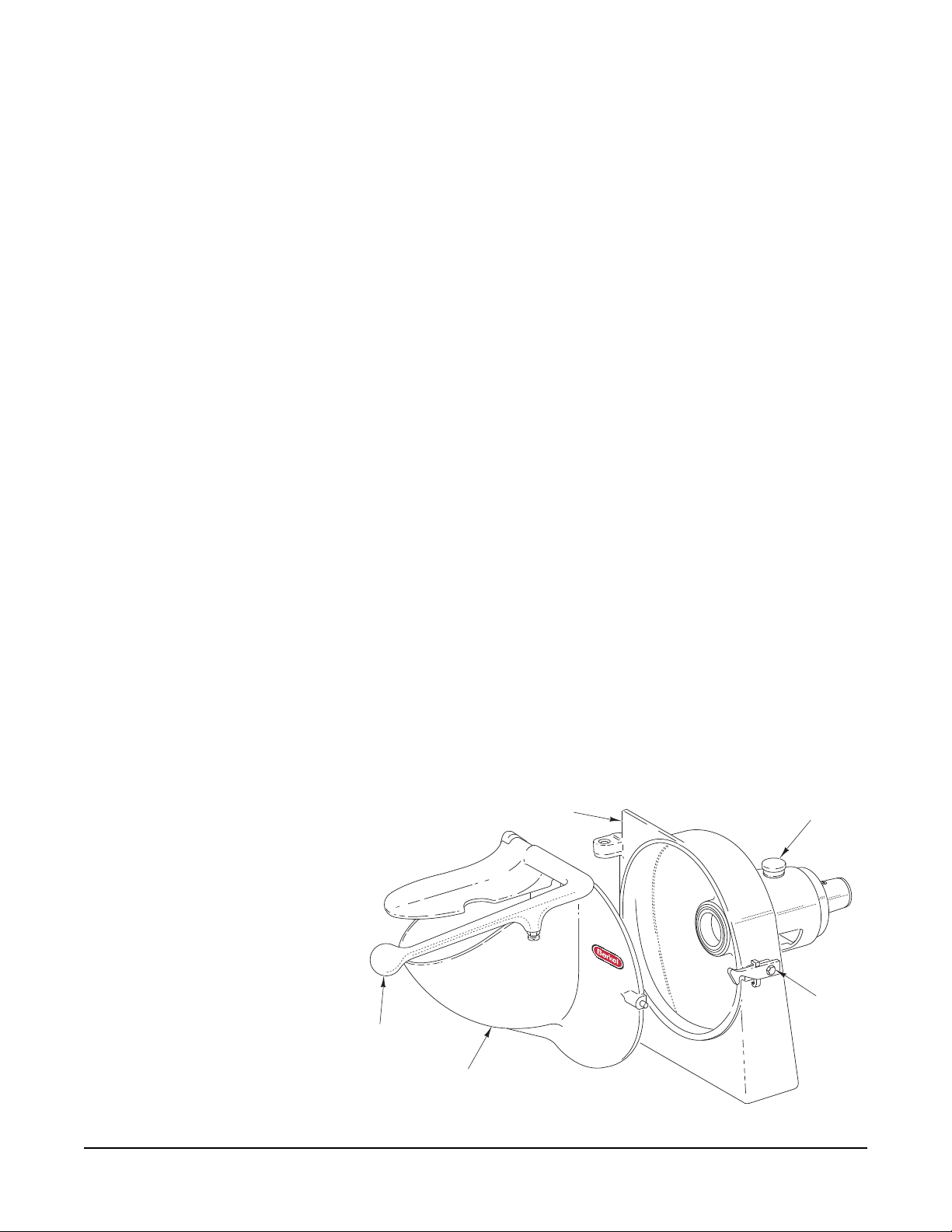

The back case (Fig. 1) mounts into the

attachment hub of a mixer, chopper,

food cutter, or power drive and is

retained by a thumb screw of that

machine. It is available with a #12

size hub.

FEED HOPPER

The standard front is the feed hopper

and pusher lever (Fig. 1) feed design. It

hinges onto the back case and is held

with a latch (Fig. 1). To remove front,

lift latch, swing front open, and raise

from hinge holes. The pusher lever is

held in the feed hopper by a large pin.

To remove pull the pin ring.

PUSHER

LEVER

BACK CASE

FEED HOPPER

– 3 –

PLUNGER

LATCH

Fig. 1

Page 4

ADJUSTABLE SLICER PLATE UNIT

Open front, lift plunger (Fig. 1) and slide the

adjustable slicer plate (Fig. 2) into operating

position. Slicing thickness may be adjusted

from approximately

1

/16" to 5/8" by turning

the adjusting nut (Fig. 2), without removing

unit from its assembled position. The easy

accessibility of this adjustment makes it

possible to vary the slice thickness to suit

the user's preference.

KNIFE AND

SHAFT ASSEMBLY

ADJUSTING NUT

SPRING

THRUST

COLLAR

SHREDDER PLATE AND PLATE

Fig. 2

HOLDER

Shredder plates are available with

3

/32", 3/16", 5/16" and 1/2" hole sizes. These plates have keyhole slots for

attaching to shoulder studs on the plate holder. The shredder

plate also has two locking tabs (Fig. 3), which prevent spin-off

during high-speed operation. The two tabs allow the shredder

plate to engage the plate holder shoulder pins in all positions;

one tab (and only one) will always engage a plate holder

spoke. A simple method of attaching is to loosely assemble

plate to plate holder, then place it plate side down on a work

surface (not a fi nished surface as teeth will mar the fi nish).

Press down and turn the plate holder until the plate locks

into place. To detach the plate from the plate holder, place

PLATE

HOLDER

SHREDDER

PLATE

the assembled plate and plate holder face down on a work

surface (as when attaching the plate), then, using a fi nger

of one hand, depress the tab (Fig. 3) while rotating the plate

holder with the other hand.

TABS

Fig. 3

The detachable plate design makes it possible to use one plate holder for several shredder plates;

however, a separate plate holder may be ordered and used for each size plate, if desired, for a complete

unit change. The coarse plate is normally used for making chopped slaw, cutting vegetables for soup

stock, salad blends or hash brown potatoes. The medium and fi ner plates are for fi ne shredding of carrots,

beets, turnips, etc., and for salads or quick cooking use.

GRATER PLATE AND PLATE HOLDER

The grater plate (Fig. 4) also has keyhole slots and

attaches to the same plate holder as the shredder

plates. Loosely assemble plate to plate holder, then

place the plate side down on a work surface (not

a fi nished surface as the teeth will mar the fi nish).

Press down and turn the plate holder until the plate

locks into place. Reverse assembly procedure to

detach plate from the plate holder.

The grater plate may be used for crumbling hard

cheese or grating hard vegetables.

PLATE HOLDER

GRATER PLATE

Fig. 4

– 4 –

Page 5

OPERATION

Rotating knives inside. Always use the pusher lever. Keep hands out.

Do not put meat, dough or frozen foods in the vegetable slicer. Remove all hard parts that can

damage the cutting plate blades, such as apple and pineapple stems, mango pits and fi brous cores.

USING THE VEGETABLE SLICER

1. Stop power unit (mixer, chopper, food cutter or power drive).

2. Attach back case (Fig. 1) of the slicer to attachment hub of companion machine and secure with the

thumb screw.

3. Drop hinge pins of feed hopper into holes in bosses of back case.

4. Select accessory (such as adjustable slicer plate) to be used. Lift plunger (Fig. 1) and insert rotating

unit into drive position. Release plunger.

5. Set slice thickness adjustment (if used) to proper thickness.

6. Close feed hopper and fasten latch.

7. Start companion machine. Set at a speed to produce the best product.

8. Raise pusher lever. Keep hands out of feed hopper.

9. Place commodity to be sliced in feed hopper and gently press down on the pusher lever. Too much

pressure crushes the food and causes irregularity in the slices.

– 5 –

Page 6

CLEANING

The cutting plates are sharp. Use care when handling to avoid injury.

Unplug the electrical cord.

Do not clean stainless steel with cleansers containing bleach like automatic dishwashing detergent.

Bleach can corrode stainless steel. Do not clean the aluminum parts with high-alkaline detergents like

automatic dishwashing detergent or with hot water: Black aluminum oxide can form.

IMMEDIATELY AFTER USE

1. Stop the power unit (mixer, chopper, food cutter or power drive).

2. Release the latch and open the feed hopper.

3. Lift the plunger (Fig. 1) and withdraw the rotating unit.

4. The shredder and grater plates are easily removed from the plate holder by rotating plate counter-

clockwise to release the keyslot from the shouldered studs.

5. All parts (case, hopper and rotating unit) may be immersed in warm soapy water for cleaning. Rinse

in hot clear water and dry immediately. It is important that juices be cleaned from slicer before they

can dry. When using the adjustable slicer unit, make sure it is cleaned frequently to assure easy

thickness adjustment. Use a drop of tasteless oil on the adjustment threads after cleaning. Occasionally

disassemble the slicer unit for a thorough cleaning. To do this it is necessary to unscrew the knurled

thrust collar (Fig. 2), which has left-hand threads. The spring (Fig. 2) is then free for removal. Withdraw

the knife and shaft assembly (Fig. 2). Unscrew the adjusting nut (Fig. 2) from the plate.

After cleaning to prevent damage thrust bearing (Fig. 2) must be tightened until seated against

shoulder on shaft (Fig. 2). Failure to properly reassemble can result in damage to knives, shaft and slicer

plate.

– 6 –

Page 7

MAINTENANCE

Unplug the electrical cord.

SERVICE

Contact your local Berkel authorized service offi ce for any repairs or adjustments needed on this

equipment.

TROUBLESHOOTING

Fault Possible Cause Remedy

Food is cut poorly or slowly. Wrong cutting plates used. Use correct cutting plate.

Cutting plates are dull or

knicked.

Pressing pusher too hard. Press down on the product lightly.

Sharpen or replace.

– 7 –

Page 8

FORM 35007 Rev. A (December 2009) PRINTED IN U.S.A.

– 8 –

Loading...

Loading...