Page 1

©ITW Food Equipment Group, LLC

3600 North Point Blvd.

Baltimore, MD 21222

RETAIN THIS MANUAL FOR FUTURE USE

FORM F-36951 (9-15)

MODELS

VSP100

WSPR1

VSP200F

WSPR2F

For additional information on Vulcan or to locate an authorized parts and

service provider in your area, visit our website at www.vulcanequipment.com

INSTALLATION & OPERATION MANUAL FOR

STOCKPOT RANGE

Page 2

IMPORTANT FOR YOUR SAFETY

Improper installation,

adjustment, alteration, service or maintenance

can cause property damage, injury, or death.

Read the installation, operating and maintenance

instructions thoroughly before installing or

servicing this equipment.

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO

INSTALL GAS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD

START-UP AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS

MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN

THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE

OBTAINED FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNITS AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

IN THE EVENT OF A POWER FAILURE, DO NOT

ATTEMPT TO OPERATE THIS DEVICE.

- 2 -

Page 3

INSTALLATION, OPERATION AND CARE OF

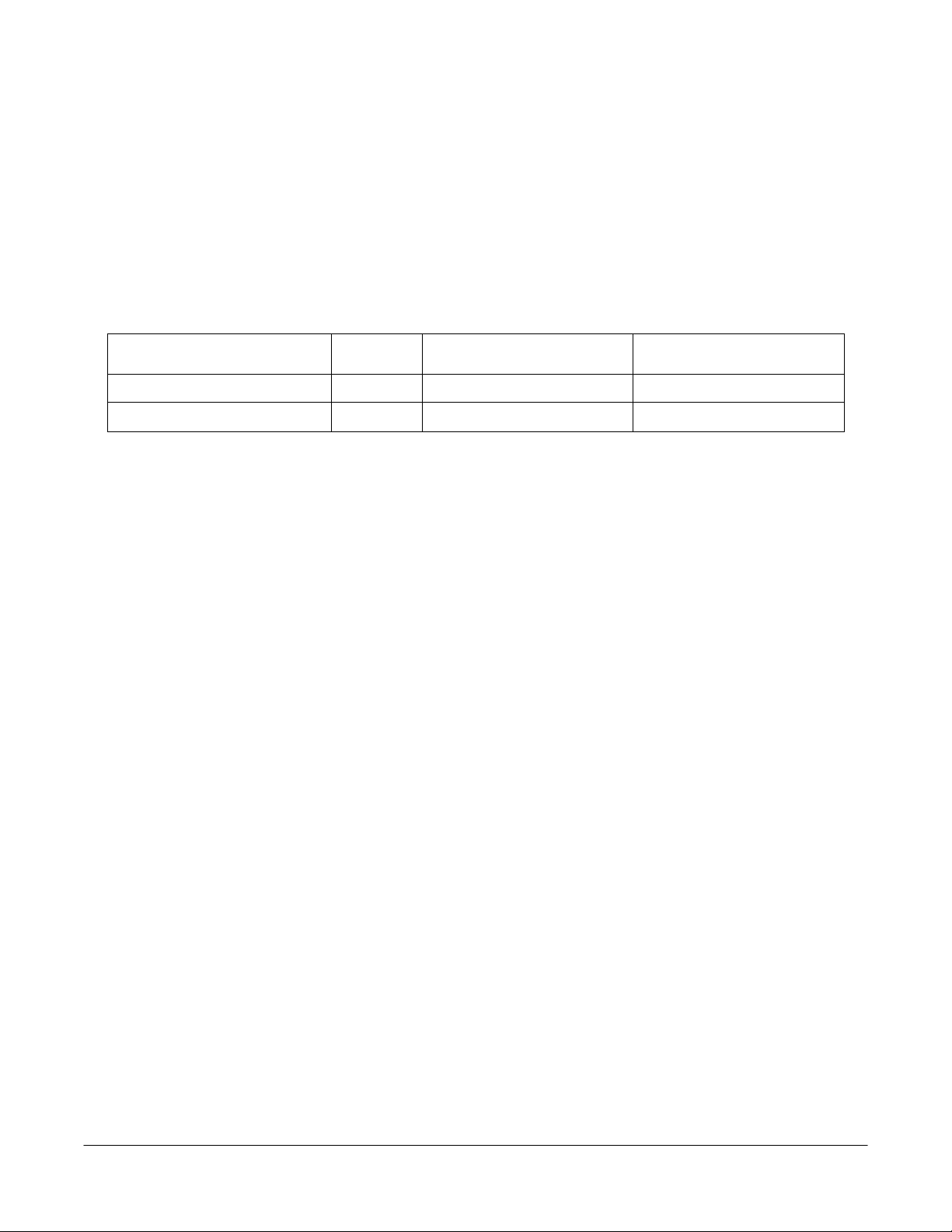

Model

# of

Burners

Natural Gas BTU/hr

Input Rating

Propane Gas BTU/hr

Input Rating

VSP100,WSPR1

2

110,000

90,000

VSP200F,WSPR2F

4

220,000

180,000

STOCKPOT RANGE

GENERAL

Stockpot ranges are designed for commercial use only and feature fast, efficient gas

heat. Each burner is controlled by an adjustable gas valve. Heavy-duty, cast iron top

grate(s) are easily removed for cleaning when cool. A grease drawer is provided to collect

fat run-off; it opens to the front for inspection or drain-off.

INSTALLATION

UNPACKING

This stockpot was inspected before leaving the factory. The carrier assumes full responsibility for the

safe delivery upon acceptance of the shipment. Check for possible shipping damage immediately after

receipt.

If the stockpot is found to be damaged, complete the following steps:

1. Carrier must be notified within 5 business days of receipt.

2. Carrier’s local terminal must be notified immediately upon discovery (note time, date, and

who was spoken to), and follow up and confirm with written or electronic communication.

3. All original packing materials must be kept for inspection purposes.

4. The stockpot cannot have been moved, installed, or modified.

5. Notify Vulcan Customer Service immediately at 800-814-2028.

Remove all packing material and protective plastic from the surfaces of the unit.

Before installing, verify that the type of gas (natural or propane) and the clearance

dimensions agree with the specifications on the rating plate which is located at the back

of the stockpot.

- 3 -

Page 4

The burner shipping bracket(s) lab e led “ Pl e as e remove t h is pa r t before use”

Minimum Clearance

Combustible Construction

Non-Combustible Construction

Rear

24”

4”

Sides

18”

0”

SHIPPING

BRACKET

IN PLACE

SHIPPING

BRACKET

REMOVED

must be removed before the stockpot range is used.

LOCATION

The installation location must be kept free and clear of combustibles. Do not obstruct the

flow of combustion and ventilation air. DO NOT install the stockpot adjacent to open

burners or fryers.

Sufficient air should be allowed to enter the room to compensate for the amount of air

removed by any ventilating system and for combustion of the gas burners. Do not

obstruct the air flow into and around the appliance. Do not obstruct the flow of flue gases

through and above the stockpot top grate. Position the stockpot in its final location.

Check that there are sufficient clearances to service the stockpot and to make the

required gas supply connection(s). Provide 24" clearance at the front for cleaning,

maintenance, service and proper operation.

INSTALLATION CODES AND STANDARDS

The Stockpot Range must be installed in accordance with:

In the United States of America:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1/NFPA #54 (latest edition). This shall include but

not be limited to: NFPA #54 Section 10.3.5.2 for Venting. Copies may be obtained

from The American Gas Association Accredited Standards Committee Z223, @ 400

N. Capital St. NW, Washington, DC 20001 or the Secretary Standards Council, NFPA,

1 Batterymarch Park Quincy, MA 02169-7471

- 4 -

Page 5

NOTE: In the Commonwealth of Massachusetts

THREADED LEG

WELDMENT

LEG

Fig. 1

Fig. 2

All gas appliances vented through a ventilation hood or exhaust system equipped with

a damper or with a power means of exhaust shall comply with 248 CMR.

3. NFPA Standard # 96 Vapor Removal from Cooking Equipment, latest edition, available

from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada:

1. Local codes.

2. CAN/CSA-B149.1 Natural Gas Installation (latest edition)

3. CAN/CSA-B149.2 Propane Installation Code (latest edition), available from the

Canadian Gas Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W

1R3

LEG INSTALLATION

The stockpot range is shipped without the legs attached. The

stockpot range must not be operated without the legs attached to the unit.

1. Remove cast iron grate and burners from chassis.

2. Turn chassis upside down and locate threaded leg weldments (Fig. 1).

3. Screw legs into threaded leg weldments until tight (Fig. 2). Use a pipe or strap wrench

with a towel (so as not to scratch leg) if needed to firmly tighten legs.

4. Continue process until all legs are installed. Single stockpots will have four legs

and double stockpots will have six legs.

5. Return stockpot to upright position; reinstall burners and grates.

- 5 -

Page 6

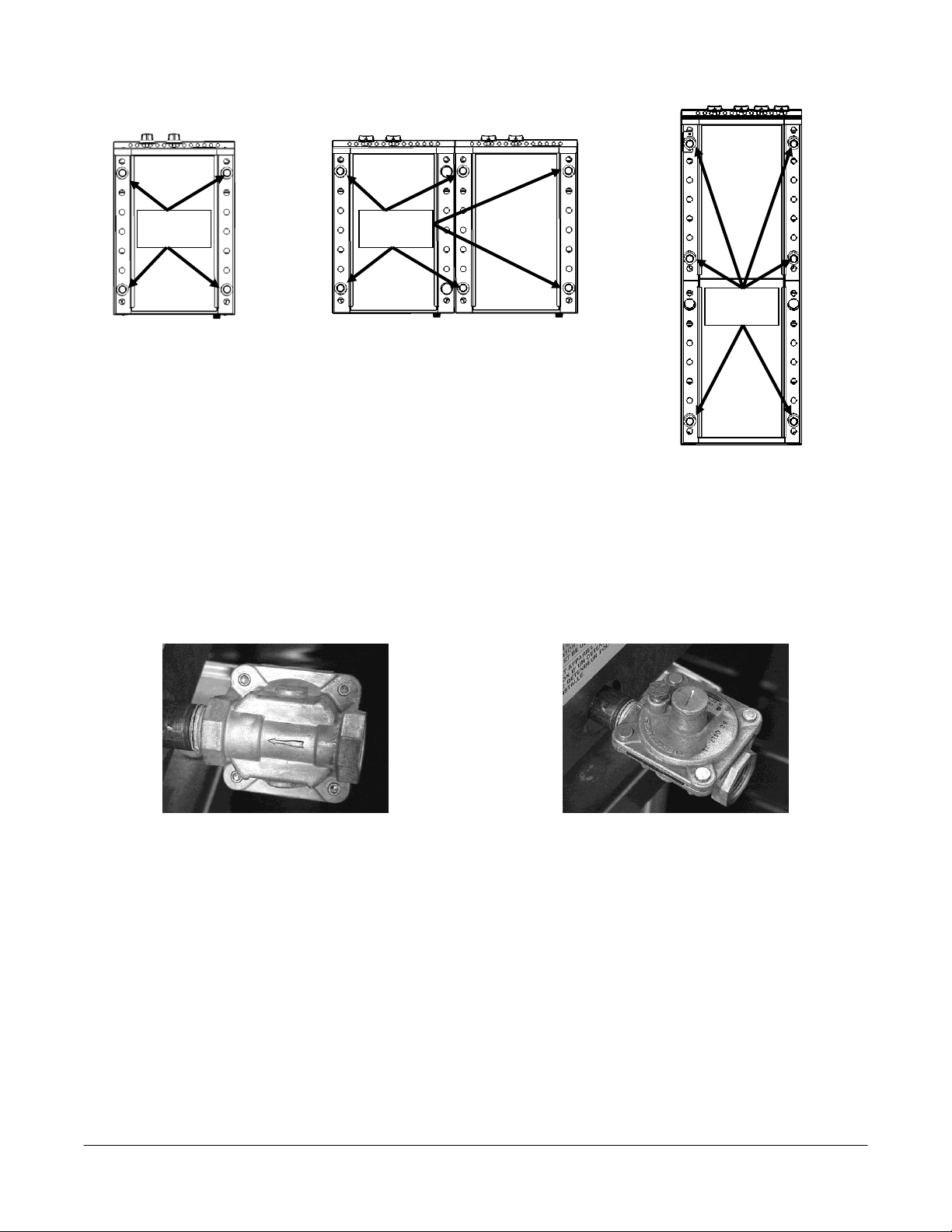

LEG ORIENTATION

Fig. 3

Fig. 4

LEGS

LEGS

LEGS

GAS PRESSURE REGULATOR INSTALLATION

Gas regulator pr es s u r e is preset at 5” W ater Colu m n (W.C.) f or na t ur a l gas, and 10” W.C.

for propane gas. Minor adjustments may be required based on site specific gas pressure.

Install the regulator as close to the stockpot on the gas supply line as possible. Make

sure that the arrow on the underside of the regulator is oriented in the direction of gas

flow to the stockpot (Fig. 3) and the regulator is positioned with the vent plug and

adjustment screw upright (Fig. 4).

The minimum supply pressure (upstream of the regulator) should be 7-9” W .C. fo r natural

gas and 11-12” W.C. for propane gas. At no tim e should the hotplate be connected to

suppl y p r e ssur e greater than ½ psig (3.45 kPa) or 14” W.C.

LEVELING

The Stockpot Range is equipped with legs. Turn the feet at the bottom of the legs in or

out to level the Stockpot Range in the final installed location.

VENTILATION HOOD

The stockpot should be installed under a suitable ventilation hood. For safe operation and

proper ventilation, keep the space between the stockpot and vent hood free from any

obstructions.

- 6 -

Page 7

GAS CONNECTION

The data plate on the rear of the stockpot indicates the type of gas your unit is equipped

to burn. DO NOT connect to any other gas type.

Gas supply connections and any pipe joint compound must be resistant to the

action of propane gases.

Purge the supply line to clean out any dust, dirt, or any foreign matter before connecting

the line to the unit.

Codes require that a gas shut-off valve be installed in the gas line ahead of the stockpot.

The gas supply line must be at least the equivalent of ¾” iron pipe.

A pressure regulator is supplied and must be installed outside of the broiler when making

the gas supply connection. Standard orifices are set for 5"WC (Water Column) for

Natural Gas — 10"WC (Water Column) for Propane. Use the 1/

manifold for checking pressure. Make sure the gas piping is clean and free of

obstructions, dirt, and piping compound.

An adequate gas supply is necessary. Undersized or low pressure lines will restrict the

volume of gas required for satisfactory performance. A minimum supply pressure of 7"

W.C. for natural gas and 11" W.C. for propane gas is recommended. With all units

operating simultaneously, the manifold pressure on all units should not show any

appreciable drop.

” pipe tap o n the burner

8

When testing the gas supply piping system, if test pressures exceed ½ psig (3.45 kPa),

the stockpot and its individual shutoff valve must be disconnected from the gas supply

piping system. When test pressures are ½ psig (3.45 kPa) or less, the stockpot must be

isolated from the gas supply piping system by closing its individual manual shut -off valve

during any pressure testing of the system.

Prior to lighting, check all joints in the gas supply line for leaks.

Use soap and water solution. Do not use an open flame.

OPERATION

The stockpot range and its parts are hot. Use care when operating,

cleaning or servicing the stockpot range.

CONTROLS

The burner is in two sections, controlled by two heavy duty infinite control valves. The

center “Star” section (Fig. 6) is on separate burner with an input of 55,000 BTU/hr. It is

controlled by the right burner valve knob. The outer circle of the burner (Fig. 6) is the

other separate 55,000 BTU/hr input burner, controlled by the left burner valve knob.

These two separate burners provide heat flexibility. With one burner off and the second

burner set low, up to both burners full on, you can move from low simmer on up to

110,000 BTU/hr input.

- 7 -

Page 8

Fig. 5

Fig. 6

LIGHTING INSTRUCTIONS

INNER

BURNER

OUTER

BURNER

PILOT VALVE

SCREW

PILOT

1. Turn all burner valves to OFF position and wait 5 minutes.

2. Turn gas shutoff valve ON.

3. Light standing pilot with a lit taper (see Fig 6). Adjust pilot to ¼” high f la m e, if

necessary, by turning pilot valve adjusting screw (see Fig. 5) counterclockwise to

increase or clockwise to decrease flame.

4. Turn burner valve to ON position.

5. If pilot does not light, turn main gas supply OFF and repeat steps 1 through 4.

TO COMPLETELY SHUTDOWN THE BURNERS AND PILOT LIGHTS

For complete shutdown: Turn the main gas supply valve OFF.

CLEANING

Top grate(s) may be immersed in strong commercial cleaning compound overnight. In the

morning, rinse with hot water to remove any residues of cleaning compound. Thoroughly

dry and apply a light coating of cooking oil to prevent rusting.

Stainless steel surfaces may be cleaned using damp cloth with mild detergent and water

solution. Places where fat, grease, or food can accumulate must be cleaned regularly.

The grease drawer should be emptied regularly when cool.

- 8 -

Page 9

MAINTENANCE

PROBLEM

POSSIBLE CAUSES

Pilot Outage

1. Pilot flame too low

2. Restriction in pilot orifice

3. Restriction in pilot valve

Improper burner

combustion

1. Improper ventilation

Poor Ignition

1. Insufficient gas input

2. Poor air-gas adjustment

3. Restriction in pilot orifice

4. Restriction in main burner ignition port

5. Restriction in control valve

6. Restriction in gas orifice

The stockpot range and its parts are hot. Use care when operating,

cleaning or servicing the stockpot range.

LUBRICATION

All valves must be checked and lubricated periodically. At the first sign of sticking, valves

should be lubricated by a trained technician using high temperature grease. Check with

your service agency for details.

SERVICE AND PARTS INFORMATION

Contact the Service Contractor in your area to obtain service and parts information. For a

complete listing of Service and Parts depots refer to www.vulcanquipment.com.

When calling for service the following information should be available from the appliance

serial plate: Model Number, Serial Number and Gas Type. The appliance serial plate is

located on the back panel.

TROUBLESHOOTING

- 9 -

Page 10

NOTES

- 10 -

Page 11

- 10 -

REMARQUES

Page 12

- 9 -

PROBLÈME

CAUSES POSSIBLES

Extinction de la

veilleuse

1. Flamme de la veilleuse trop faible

2. Orifice de la veilleuse obstrué

3. Robinet de veilleuse obstrué

Mauvaise combustion du

brûleur

Mauvaise ventilation

Mauvais allumage

1. Entrée de gaz insuffisante

2. Rapport air-gaz mal réglé

3. Orifice de la veilleuse obstrué

4. Orifice d’allumage de brûleur principal obstrué

5. Robinet de commande obstrué

6. Orifice de gaz obstrué

DÉPANNAGE

du modèle et le numéro de série.

suivants devraient être disponibles sur la plaque d'identification de l'appareil : le numéro

www.vulcanequipment.com. Lorsque vous appelez pour du service, les renseignements

appareil. Pour une liste des bureaux des services et des pièces, consultez

Communiquer avec le service de l’entretien le plus près pour tout ent retien sur cet

SERVICE DE L’ENTRETIEN

résistant aux températures élevées dès le premier signe de coincement.

Toutes les soupapes devraient être lubrifiées par un technicien qualifié avec une huile

LUBRIFICATION

NETTOYAGE OU DE L’ENTRETIEN DE CET APPAREIL.

CH AUDS. EXERCER UNE EXTRÊME PRUDENCE LORS DE L’EXPLOITATION, DU

LA CUISINIÈRE À MARMITES ET SES COMPOSANTS SONT

ENTRETIEN

Page 13

- 8 -

BRÛLEUR

INTÉRIEUR

BRÛLEUR

EXTÉRIEUR

VIS DE ROBINET DE VEILLEUSE

Veilleuses d’allumage

Fig. 5

Fig. 6

Les ramasse-miettes doivent être vidés régulièrement lorsqu'ils sont froids.

s’accumuler.

de l’eau.Nettoyer régulièrement les endroits où les graisses et aliments peuvent

Nettoyer les surfaces en acier inoxydable avec un chiffon humide, un détergent doux et

mettez de l’huile de cuisson afin de prévenir la rouille.

rincer avec de l’eau chaude pour enlever tout résidu du nettoyant. Rincez à fond et

Immerger les grilles dans un composé de nettoyant commercial pour la nuit. Le matin, les

NETTOYAGE

Pour un arrêt complet, mettre le robinet d’alimentation en gaz principal à OFF (arrêt).

ARRÊT COMPLET DES BRÛLEURS ET DES VOYANTS DE VEILLEUSE

et reprendre les étapes de 1 à 4.

5. Si la veilleuse refuse de s’allumer, mettre l’alimentation en gaz principal à OFF (arrêt)

4. Mettre le robinet de brûleur à ON (marche).

réduire.

montre pour augmenter la f lamme ou dans le sens des aiguilles d’une montre pour la

de réglage du robinet de veilleuse (Fig. 5) dans le sens inverse des aiguilles d’une

veilleuse à une hauteur de flamme de 6 mm (1/4 po), si nécessaire, en tournant la vis

3. Allumer la veilleuse permanente en utilisant une bougie conique(Fig.6). Régler la

2. Mettre le robinet d’arrêt de gaz à ON (marche).

1. Mettre tous les robinets de brûleurs à OFF (arrêt) et attendre 5 minutes.

ALLUMAGE DE LA VEILLEUSE

pouvez passer de mijotage à petit feu puis à feu plus élevé avec un débit de 110 000 BTU/h.

mettant l’autre à un bas régl ag e, puis en mettant les deux br û leurs à pleine puissanc e, vous

Ces deux brûleurs séparés produisent une flexibilité de chaleur. En éteignant un brûleur et en

bouton de robinet du brûleur gauche.

brûleur (Fig. 6) est l’autre brûleur séparé qui f ournit u n débit de 55 000 BTU/h, comm andé par le

de 55 000 BTU/h. Il est contrôlé par le bouton de robinet du brûleur droit. Le cercle extérieur du

réglage infini. La section centrale « Star » (Fig. 6) est sur un brûleur séparé qui fournit un débit

Le brûleur est en deux sections, commandé par deux robinets de commande à service intense, à

COMMANDES

Page 14

- 7 -

NETTOYAGE OU DE L’ENTRETIEN DE CET APPAREIL.

CH AUDS. EXERCER UNE EXTRÊME PRUDENCE LORS DE L’EXPLOITATION, DU

LA CUISINIÈRE À MARMITES ET SES COMPOSANTS SONT

FONCTIONNEMENT

QU’ILS NE PRÉSENTENT AUCUNE FUITE. NE PAS SE SERVIR D’UNE FLAMME NUE.

JOINTS DE LA CONDUITE DE GAZ À L’AIDE D’EAU SAVONNEUSE POUR S’ASSURER

AVANT DE PROCÉDER À L’ ALLUMAGE, VÉRIFIER TOUS LES

de la conduite de gaz en fermant son robinet d’arrêt individuel.

Lorsque la pression d’essai est égale ou inférieure à 3,45 kPa (1/2 psig), isoler l’appareil

pression, débrancher l’appareil et son robinet d’arrêt individuel de la conduite de gaz.

Si la pression de la conduite de gaz est supérieure à 3,45 kPa (1/2 psig) lors d’essais de

tubulure d’alimentation de tous les appareils ne devrait pas indiquer de baisse sensible.

propane. Même en faisant fonctionner tous les appareils simultanément, la pression de la

1,74 kPa (7 po) de colonne d’eau pour le gaz naturel et de 2,74 kPa (11 po) pour le gaz

performance satisfaisante. La pression d’alimentation maximale recommandée est de

ou une pression trop basse peut restreindre le volume de gaz requis pour une

Une alimentation en gaz adéquate est nécessaire. Une conduite de pression trop petite

et exempte de toute obstruction, de poussière et de composant dans la tuyauterie.

sur la tubulure d’alimentation du brûleur. S’assurer que la canalisation de gaz est propre

(10 po) pour le gaz propane. Pour vérifier la pression, utiliser un tuyau de 3 mm (1/8 po)

pression de sortie de 1,24 kPa (5 po) de colonne d’eau pour le gaz naturel et de 2,49 kPa

raccordement de l’alimentation en gaz. Les orifices standard sont réglés en usine à une

Un régulateur de pression est fourni et doit être installé à l’extérieur de l’appareil lors du

mm (3/4 po) de diamètre.

gaz en avant de l’appareil. La conduite de g az devrait être l’équivalent d’un tuyau de 19

Conformément aux exigences des codes, installer un robinet d’arrêt dans la conduite de

avant de la raccorder à l’appareil.

Purger la conduite d’alimentation pour enlever toute poussière, saleté ou corps étranger

doivent résister à l’action du gaz propane.

Tous les raccords d’alimentation de la conduite de gaz et la pâte à joints de tuyaux

gaz de l’appareil. NE PAS raccorder à aucun autre type de gaz.

La plaque signalétique placée dans le bas du côté droit de l’appareil indique le type de

BRANCHEMENT DU GAZ

exempt de toute obstruction.

bonne ventilation, garder l’espace entre la cuisinière à marmites et la hotte de ventilation

Placer l’appareil sous une hotte de ventilation appropriée. Pour plus de sécurité et une

HOTTE DE VENTILATION

Page 15

- 6 -

Fig. 3

Fig. 4

PIEDS

PIEDS

PIEDS

vers l’extérieur pour le placer à son emplacement final.

L’appareil est muni de pieds. Pour le niveler, tourner la base des pieds vers l’intérieur ou

NIVELAGE

d’alimentation plus élevée que 3,45 kPa (1/2 psig) ou (14 po) de colonne d’eau.

pour le gaz propane. En aucun temps, l’appareil ne devrait être branché à une pression

kPa (7 à 9 po) de colonne d’eau pour le gaz naturel et de 2,74 à 2,99 kPa (11 à 12 po)

La pression d’alimentation minimale (en amont du régulateur) devrait être de 1,74 à 2,24

verticale (Fig. 4).

positionné de façon à ce que le bouchon de ventilation et la vis de réglage soient à la

l’écoulement du gaz vers la cuisinière à marmites (Fig. 3) et que le régulateur est

en gaz. S’assurer que la flèche sous le régulateur est orientée dans la direction de

Installer le régulateur aussi près que possible de l’appareil sur la conduite d’alimentation

peuvent être requis selon la pression de gaz spécifique au site.

colonne d’eau pour le gaz naturel et de 2,49 kPa (10 po) pour le gaz propane. Des réglages mineurs

Le régulateur de pression de gaz est réglé en usine à une pression de sortie de 1,24 kPa (5 po) de

INSTALL ATION D’UN RÉGUL ATEUR DE PRESSION DE G AZ

ORIENTATION DES PIEDS

Page 16

- 5 -

PIED

ENSEMBLE

SOUDÉ OÙ

VISSER LES

PIEDS

Fig. 1

Fig. 2

les grilles à leur place.

5. Remettre la cuisinière à marmites dans le bon sens, puis repositionner les brûleurs et

sont munies de quatre pieds, contre six pieds pour les doubles cuisinières à marmites.

4. Répéter ces étapes pour installer les autres pieds. Les cuisinières à marmites simples

les pieds) pour serrer les pieds correctement.

nécessaire, utiliser une clé à tuyau ou à sangle avec une serviette (pour éviter d’érafler

3. Visser les pieds à l’intérieur de ces ensembles; serrer fermement (Fig. 2). Si

2. Retourner le châssis et situer les ensembles soudés où visser les pieds. (Fig. 1).

1. Retirer la grille en fonte et les brûleurs du châssis.

marmites tant ses pieds ne sont pas montés.

montés lors de son expédition. Ne jamais faire fonctionner cette cuisinière à

Les pieds de cette cuisinière à marmites ne sont pas

INSTALLATION DES PIEDS

1R3.

l’Association canadienne du gaz, 178 Rexdale Blvd, Etobicoke, Ontario, Canada M9W

propane (dernière édition) dont on peut se procurer un exemplaire auprès de

3. Norme CAN/CSA-B149.2 du Code d’installation des appareils fonctionnant au gaz

naturel (dernière édition).

2. Norme CAN/CSA B149.1 du Code d’installation des appareils fonctionnant au gaz

1. Codes locaux.

Au Canada:

Association, Batterymarch Park, Quincy, MA 02269.

édition) dont on peut se procurer un exemplaire auprès de la National Fire Protection

3. Norme NFPA N° 96 pour l’évacuation de la fumée des appareils de cuisson (dernière

conformes à la règlementation 248 CMR.

d’évacuation muni d’un registre ou de moyens d’évacuation à puissance doivent être

Tous les appareils au gaz ventilés par une hotte de ventilation ou un système

NOTA : Dans l’État du Massachusetts

Page 17

- 4 -

Dégagement minimal

Construction combustible

Construction incombustible

Arrière

610 mm (24 po)

102 mm (4 po)

Côtés

457 mm (18 po)

Aucun

AVANT LE RETRAIT DU

SUPPORT D’EXPÉDITION

APRÈS LE RETRAIT DU

SUPPORT D’EXPÉDITION

Park, Quincy, MA 02169-7471.

Washington, DC 20001, ou the Secretary Standards Council, NFPA, 1 Batterymarch

Association Accredited Standards Committee Z223, 400 N. Capital St. NW,

ventilation, dont on peut se procurer un exemplaire auprès de l’American Gas

devra inclure, mais ne pas se limiter à la norme NFPA N° 54, Section 10.3.5.2 pour la

2. Norme ANSI/Z223.1/NFPA N° 54 (dernière édition) du National Fuel Gaz Code. Ceci

1. Codes locaux.

Aux États-Unis :

L’installation de cet appareil doit être conforme aux codes suivants :

CODES D’INSTALL ATION ET NORMES

pour un bon

dégagement de 610 mm (24 po) à l’avant de l’appareil pour le nettoyage, l’entretien et

l’appareil et les raccordements nécessaires d’alimentation du gaz. Prévoir un

l’emplacement prévu. S’assurer d’un dégagement suffisant pour effectuer l’entretien de

obstruer le débit des gaz brûlés du conduit d’évacuation. Placer l’appareil à

la combustion des gaz et à la ventilation à l’intérieur et autour de l’appareil. Ne pas

la cuisinière à marmites de manière à ne pas obstruer la circulation de l’air nécessaire à

évacué par le système de ventilation et pour la combustion des brûleurs à gaz. Installer

Maintenir une aération suffisante dans la pièce pour assurer le remplacement de l’air

installer l’appareil près des brûleurs découverts ou friteuses.

obstruer la circulation de l’air nécessaire à la combustion et à la ventilation. NE PAS

Aucune substance combustible ne doit se trouver à proximité de l’appareil. Ne pas

EMPLACEMENT

Le ou les supports d’expédition du brûleur portant la mention « Please remove this

cuisinière à marmites.

part before use » (À retirer avant utilisation) doivent être ôtés avant toute utilisation de la

Page 18

- 3 -

Modèle

Nombre

de

brûleurs

Gaz Naturel Débit

BTU/h

Gaz Propane Débit

BTU/h

VSP100,WSPR1

2

110,000

90,000

VSP200F,WSPR2F

4

220,000

180,000

l’arrière de l’appareil.

dessous) correspondent aux spécifications de la plaque signalétique que l’on trouve à

de gaz (naturel ou propane) de l’immeuble et les dimensions de dégagement (voir ci -

l’appareil. Avant d’installer cet appareil, s’assurer que l’ali mentation électrique et le type

Retirer l’ensemble du matériel d’emballage et des plastiques protecteurs des surfaces de

5. Avisez le Service à la clientèle de Vulcan immédiatement en faisant le (800) 814-2028.

4. Les cuisinières à marmites ne doit pas avoir été déplacé, installé ou modifié.

3. Pour fins d ’inspection, tou t le matériel d’em ballage origina l doit être conser vé.

suivi en confirmant les faits par écrit ou par communication électronique.

découverte des dommages ( indiquez l’heur e, la date et à qui vous avez p arlé) et assurez le

2. Les gens du terminus local du transporteur doivent être avisés immédiatement lors de la

1. Le transporteur doit être averti dans les 5 jours ouvrables suivant la réception.

suivantes :

S’il s’avère que Les cuisinières à marmites a été endommagé, veuillez suivre les procédures

livr aison, vérifie z s ’il a effectivem ent subi des dom mages pendant le t ransport.

transporteur prend l’entière respons abilité de le livrer e n toute sécurité. Immédiatemen t après la

Les cuisinières à marmites a é té inspecté avant de quitter l’usine. En acc eptant sa livraiso n, le

DÉBALLAGE

INSTALLATION

l’écoulement de la graisse; il s’ouvre à l’avant pour l’inspection ou la vidange.

de nettoyage lorsqu’ils sont froids. Un tiroir de propreté est fourni pour récupérer

réglable. Des éléments radiants en fonte à service intense s’enlèvent facilement aux fins

une chaleur rapide et efficace. Chaque brûleur est commandé par un robinet à gaz

Les cuisinières à marmites sont conçues pour usage commercial seulement et fournissent

GÉNÉRALITÉS

CUISINIÈRE À MARMITES

INSTALLATION, FONCTIONNEMENT ET ENTRETIEN

Page 19

- 2 -

Une installation, un

ajustement, une modification, un service ou un

entretien inapproprié peut causer du dommage

matériel, une blessure ou la mort. Lire

minutieusement les instructions d’installation,

d’emploi et d’entretien avant d’installer ou de se

servir cet équipement.

FONCTIONNER CET APPAREIL.

EN CAS DE PANNE DE COURANT, NE PAS FAIRE

DE CET APPAREIL OU DE TOUT AUTRE APPAREIL.

AUTRE LIQUIDE OU VAPEUR INFLAMMABLE À PROXIMITÉ

NE PAS RANGER NI UTILISER DE L’ESSENCE NI TOUT

MESURE DE SÉCURITÉ

ATTITRÉ POUR L’ENTRETIEN.

PLUS PRÈS OU AVEC LE FOURNISSEUR DE GAZ

COMMUNIQUER AVEC LA COMPAGNIE DE GAZ LA

PAR LE ROBINET D’ARRÊT PRINCIPAL ET

EN CAS D’ODEURS DE GAZ, ÉTEINDRE L’APPAREIL

IMPORTANT

PROCURER CES INFORMATIONS CHEZ LE FOURNISSEUR DE GAZ LE PLUS PRÈS.

PERSONNE AYANT RESPIRÉ LES GAZ QUE CET APPAREIL DÉGAGE. ON PEUT SE

AFFICHER À UN ENDROIT VISIBLE LES PREMIERS SOINS À ADMINISTRER À TOUTE

MESURES DE SÉCURITÉ IMPORTANTES

DES APPAREILS CONCERNÉS DANS CE MANUEL.

EFFECTUER LE DÉMARRAGE INITIAL CHEZ LE CLIENT DE MÊME QUE LE RÉGLAGE

AUTORISÉ À INSTALLER DES APPAREILS FONCTIONNANT AU GAZ ET À

CE MANUEL A ÉTÉ PRÉPARÉ À L’INTENTION D’UN PERSONNEL QUALIFIÉ ET

Page 20

©Groupe ITW Équipement alimentaire, LLC

3600 North Point Blvd.

Baltimore, MD 21222

DOCUMENT À CONSERVER EN CAS DE BESOIN

FORM F-36951 (9-15)

MODELS

VSP100

WSPR1

VSP200F

WSPR2F

Pour obtenir des renseignements supplémentaires au sujet de Vulcan-Hart

ou pour trouver un fournisseur de pièces et service autorisé dans votre

région, veuillez visiter notre site web à www.vulcanequipment.com

CUISINIÈRE À MARMITES

MODE D’INSTALLATION ET MODE D’EMPLOI

Loading...

Loading...